Patents

Literature

42results about How to "Strong binding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

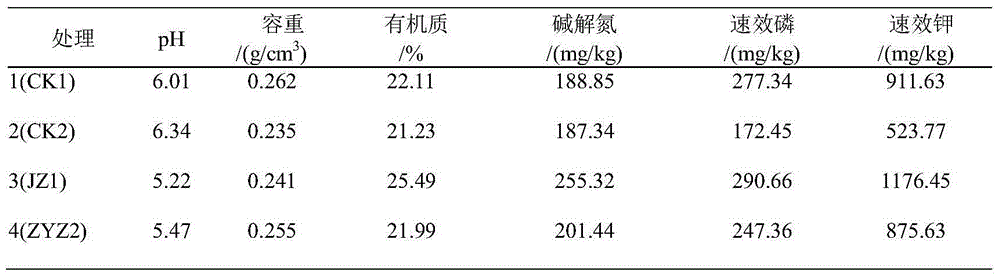

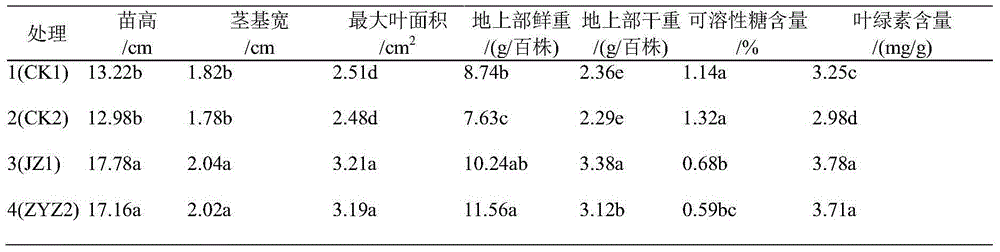

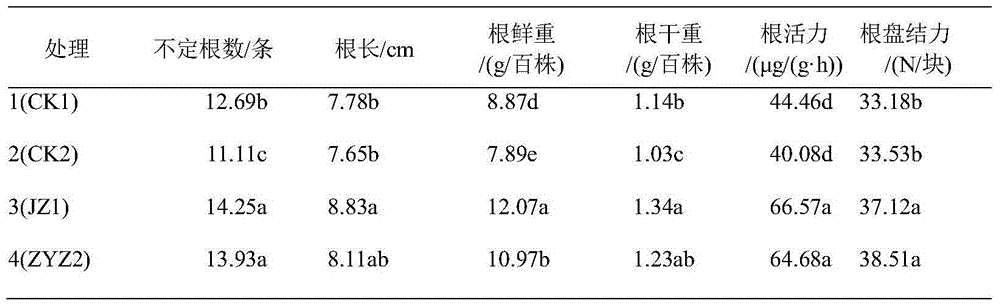

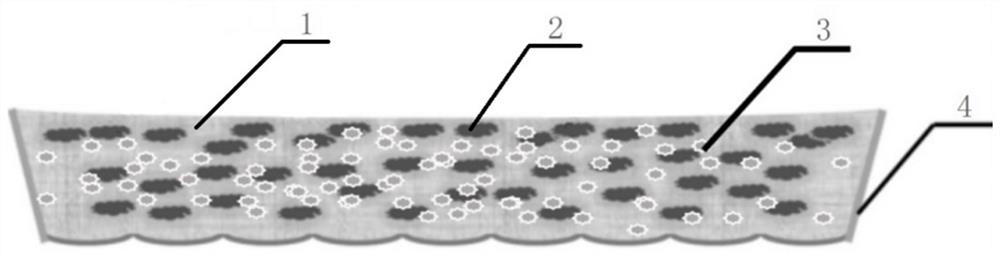

Organic ecological substrate for rice industrialized seedling production and preparation method of organic ecological substrate

InactiveCN104909909AGood qualityReduce pollutionBio-organic fraction processingOrganic fertiliser preparationMicrobial agentHusk

The invention belongs to the technical field of rice matrix seedling and discloses an organic ecological substrate for rice industrialized seedling production. The organic ecological substrate for rice industrialized seedling production comprises the following components in parts by mass: 20 to 40 parts of animal dung, 30 to 50 parts of organic waste, 15 to 30 parts of a conditioner, 20 to 40 parts of carbonized rice husk and 0.01 to 0.03 part of a microbial agent. The organic ecological substrate has high nutrient content and good seedling strengthening effect. The invention also provides a preparation method of the organic ecological substrate for rice industrialized seedling production.

Owner:ZUNYI NORMAL COLLEGE

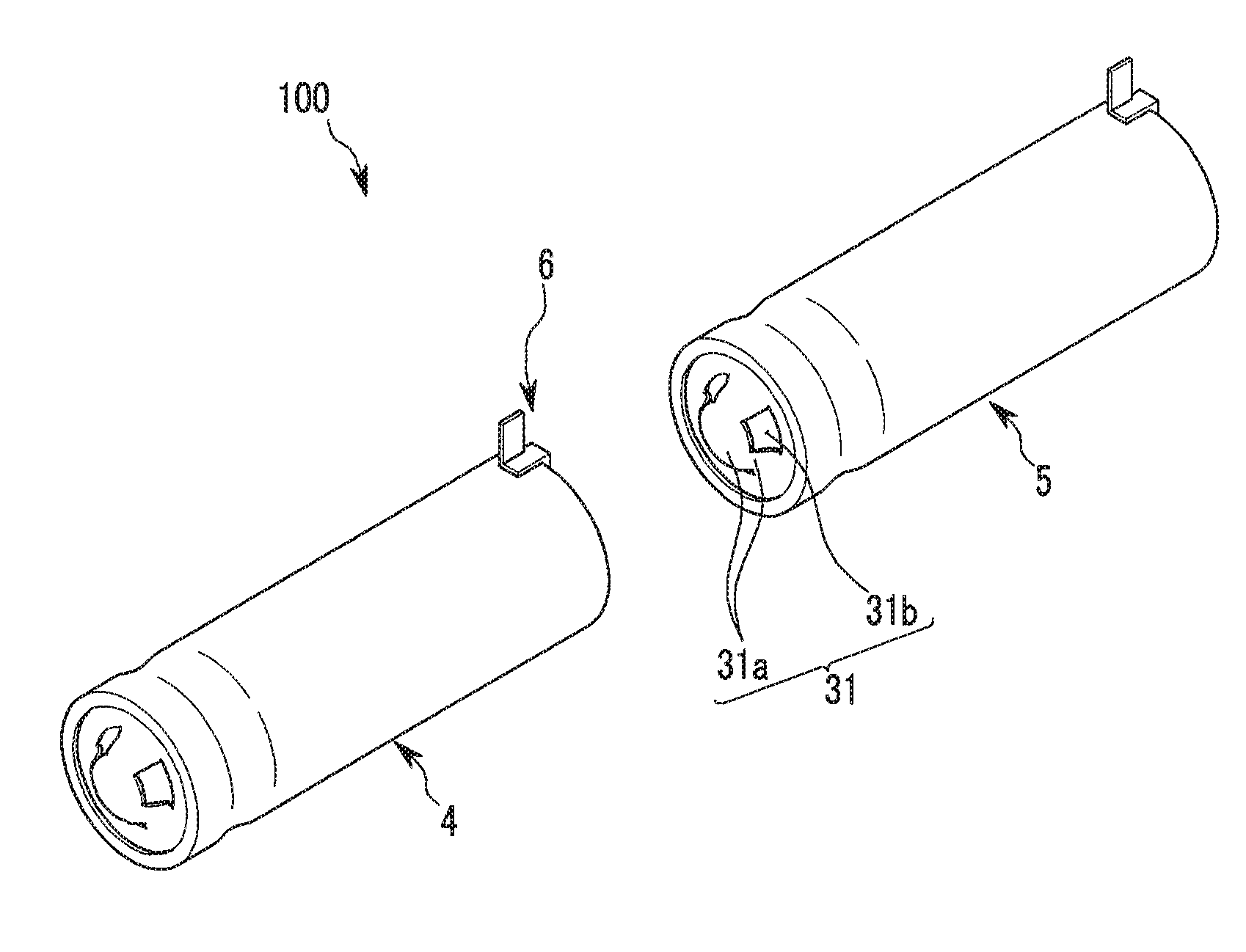

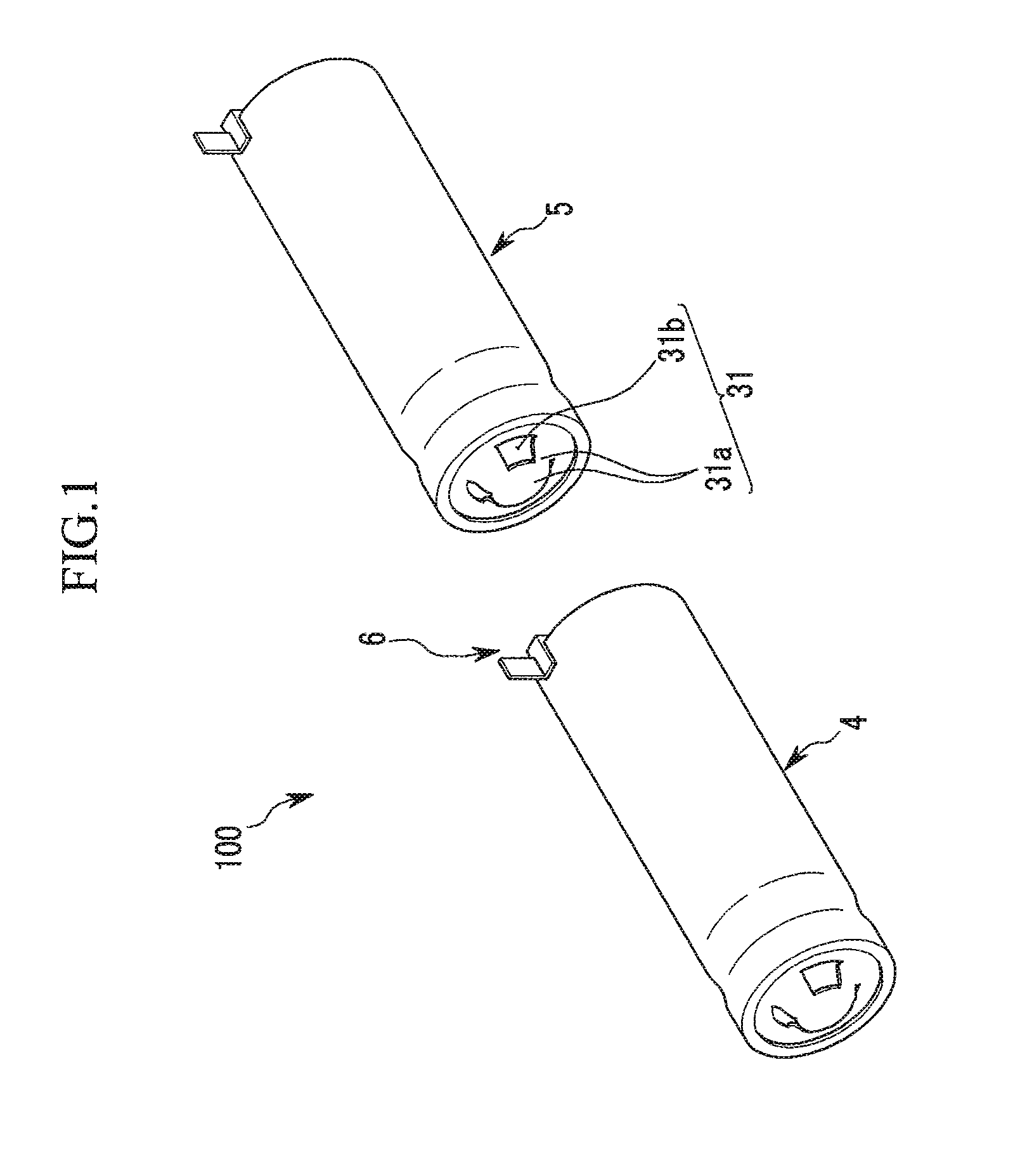

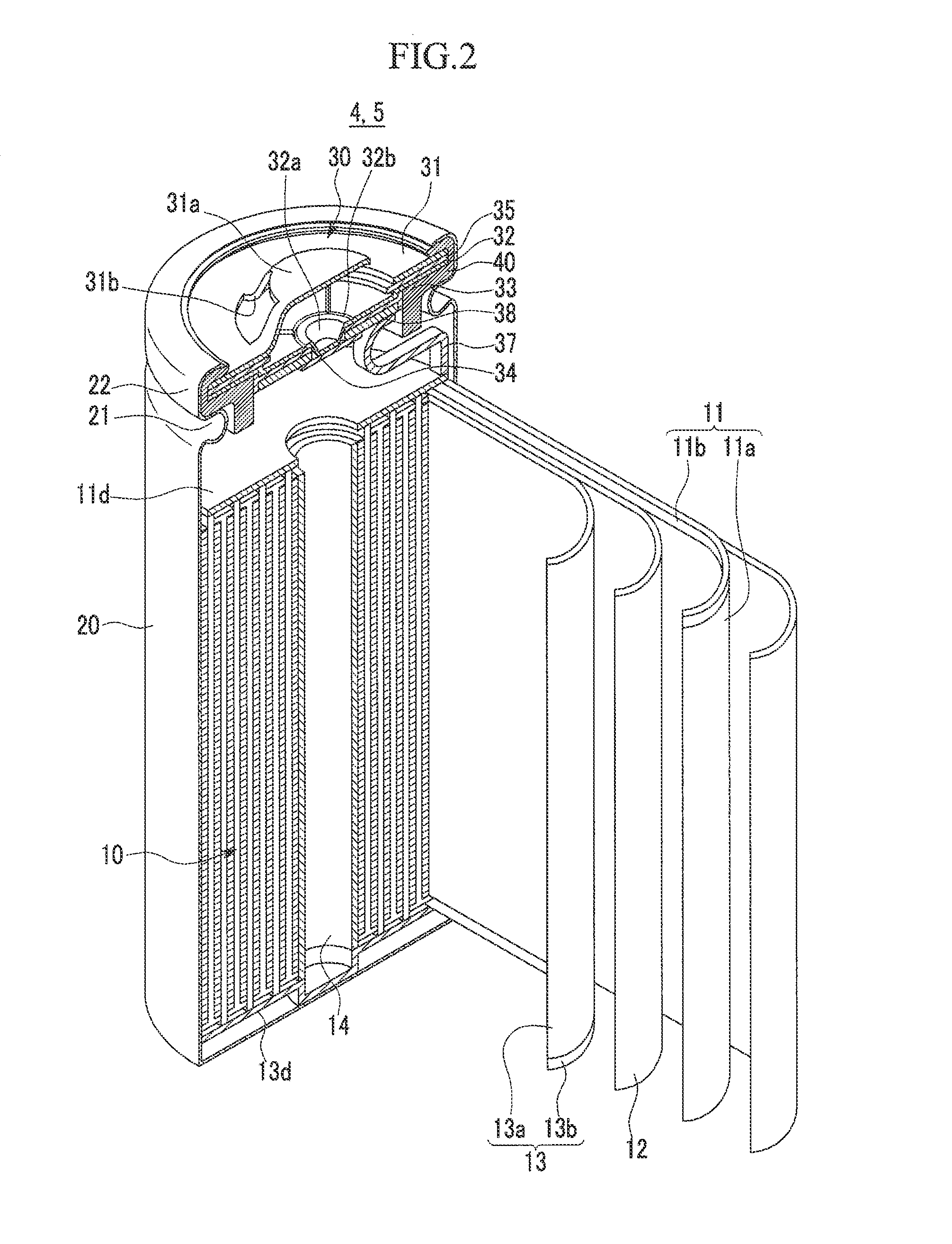

Rechargeable battery pack and connection tab used for the same

InactiveUS20110269011A1Reduce volumeStrong binding forcePrimary cell to battery groupingFinal product manufactureRechargeable battery packElectrical battery

There are provided a rechargeable battery pack, which, upon connecting a plurality of rechargeable battery cells, forms a strong binding force between the cells and reduces the volume of the cells, and a connection tab used for the same. A rechargeable battery pack comprises: a first unit cell and a second unit cell connected in series / parallel to form a core pack and formed as a rechargeable battery; and a connection tab connected to the case of the first unit cell to protrude to the opposite side of the case, coupled to a cap plate protruding from the second unit cell toward the first unit cell, and connected to a protection circuit.

Owner:SAMSUNG SDI CO LTD

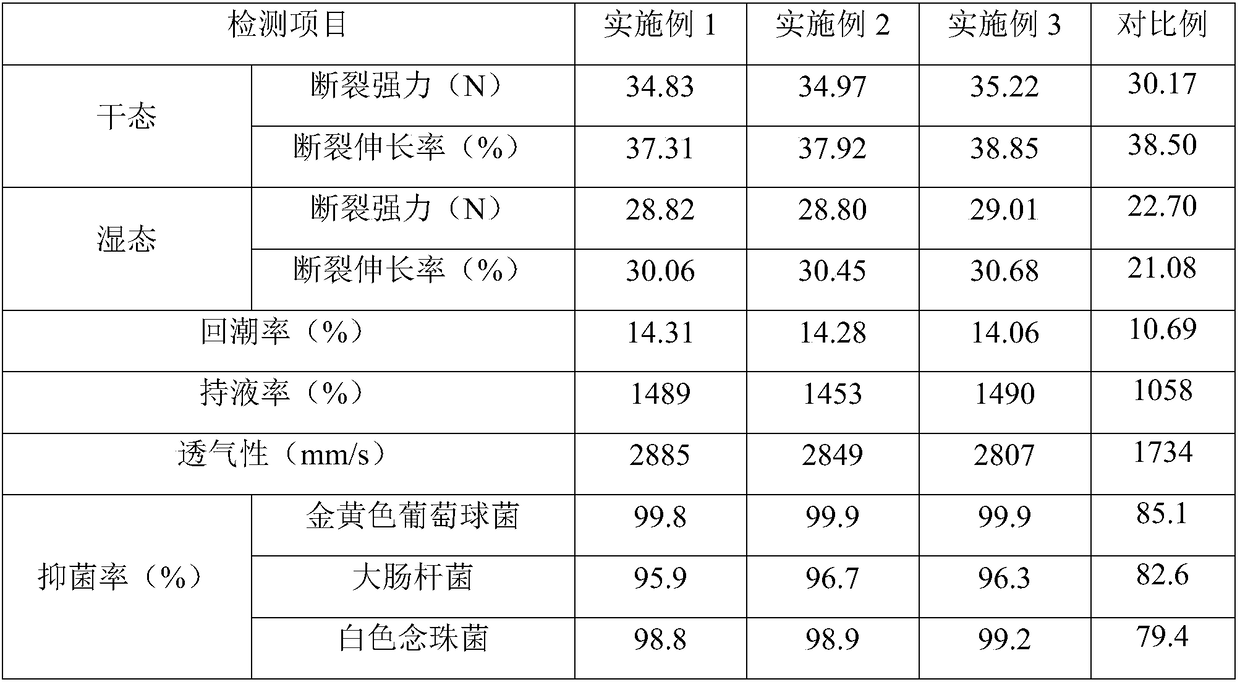

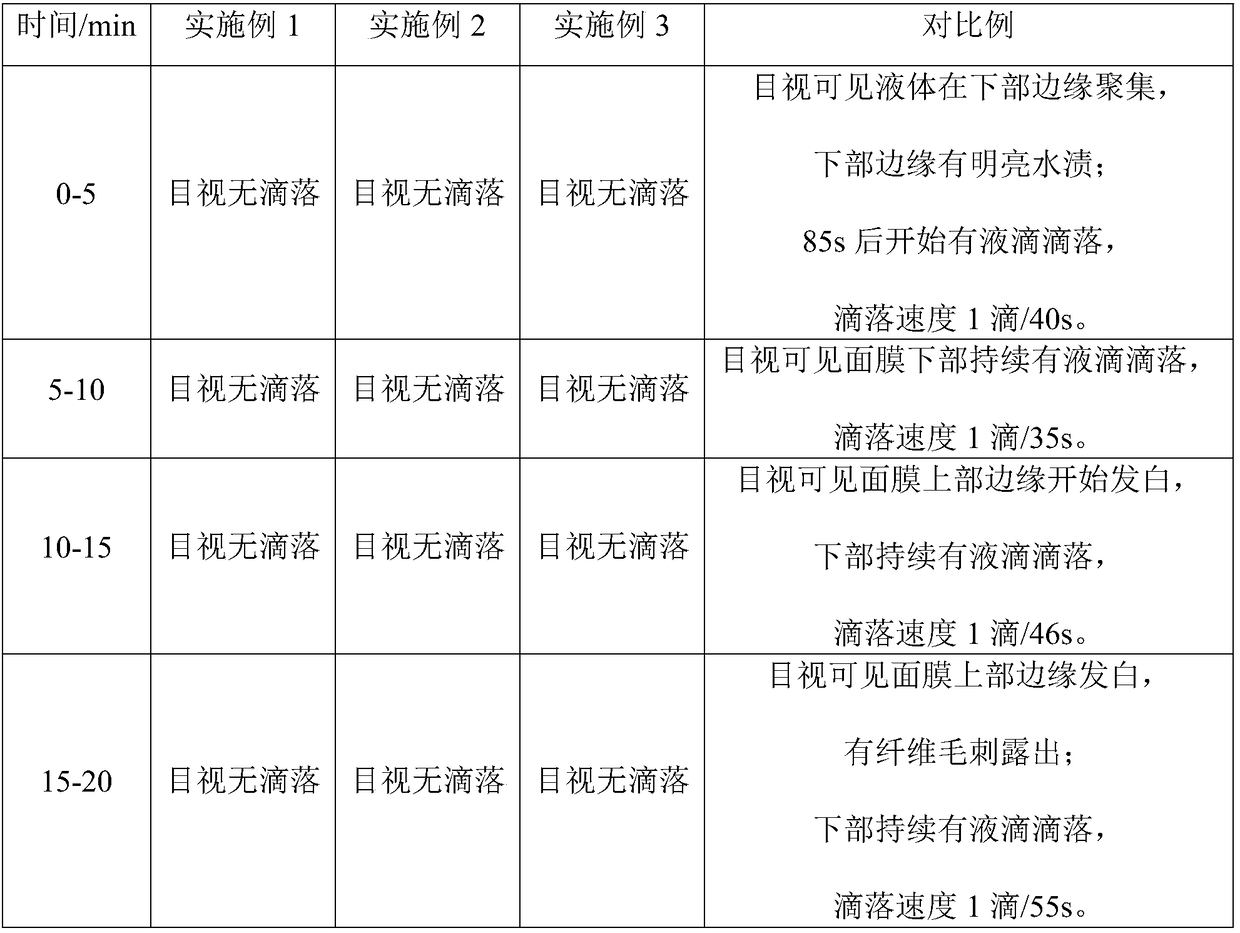

Bamboo charcoal viscose facial mask base cloth and high moisture retention and moisturizing facial mask

ActiveCN108403446AMeet physiological requirementsEliminates allergy riskCosmetic preparationsToilet preparationsCardingSlurry

The invention relates to a bamboo charcoal viscose facial mask base cloth and a high moisture retention and moisturizing facial mask. The bamboo charcoal viscose facial mask base cloth is prepared with the following method: 1) adding nanometer bamboo charcoal powder and sodium alga acid into dispersion solution to be dispersed evenly in bamboo charcoal serous fluid; 2) adding the bamboo charcoal serous fluid into viscose spinning solution to be dispersed evenly, and filtering and deforming to obtain mixed spinning solution; 3) carrying out wet method spinning on the mixed spinning solution toobtain the bamboo charcoal viscose, and carrying out opening, mixing, carding and lapping to obtain a bamboo charcoal viscose felt; 4) dissolving chitosan in acetic acid aqueous solution, adding gelatin to be dissolved to obtain finishing liquor, and dipping the bamboo charcoal viscose felt into the finishing liquor to carry out impregnation modification to obtain a compound fiber felt; 5) carrying out spunlace reinforcement on the compound fiber felt. The bamboo charcoal viscose facial mask base cloth has high constraint ability on serum and good water retention and moisture liberation performance; after the facial mask serum is loaded through a liquid hanging step, the high moisture retention and moisturizing facial mask is obtained, situation that serum loss due to dripping and droppingcan be avoided, and waste is avoided.

Owner:魏科峰

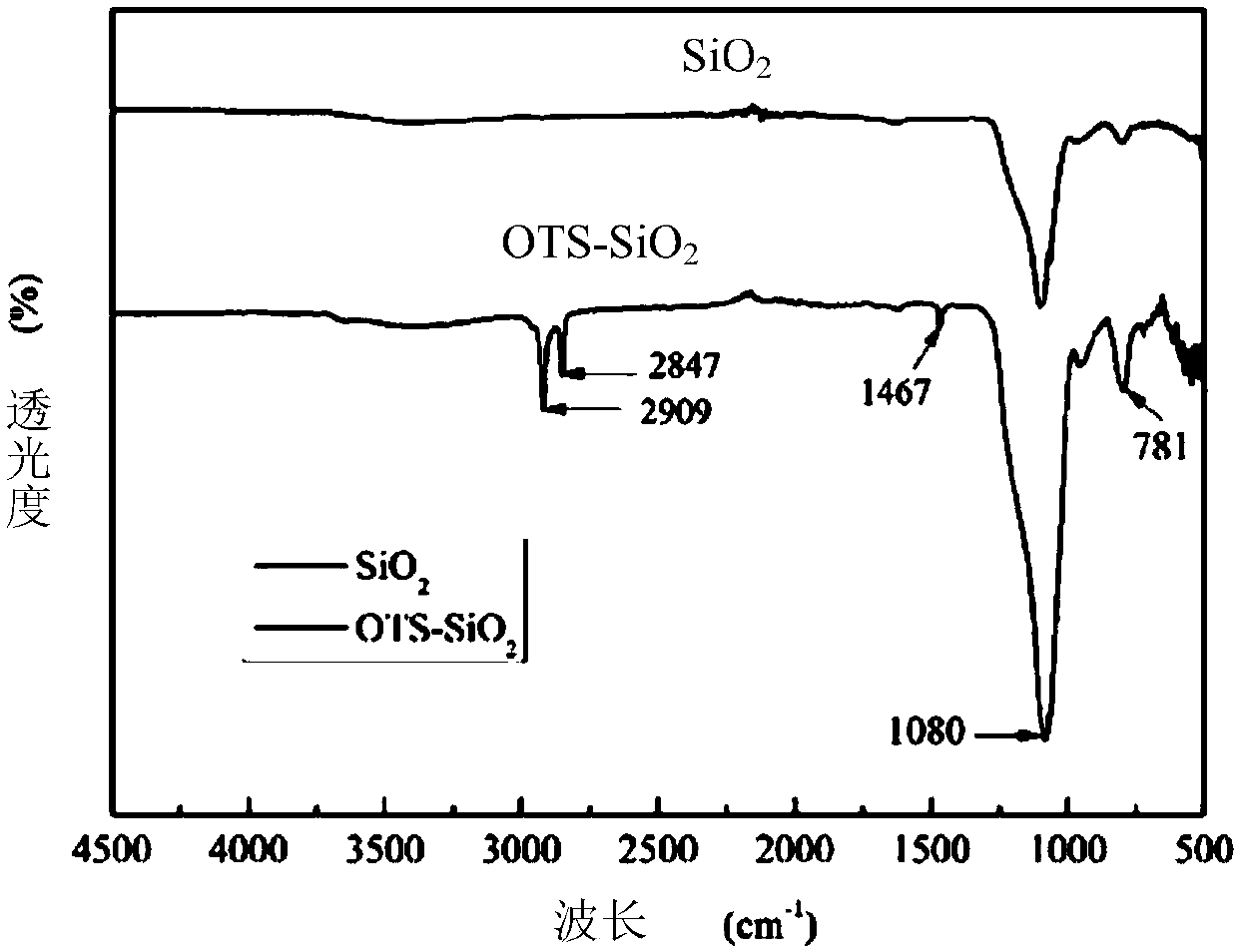

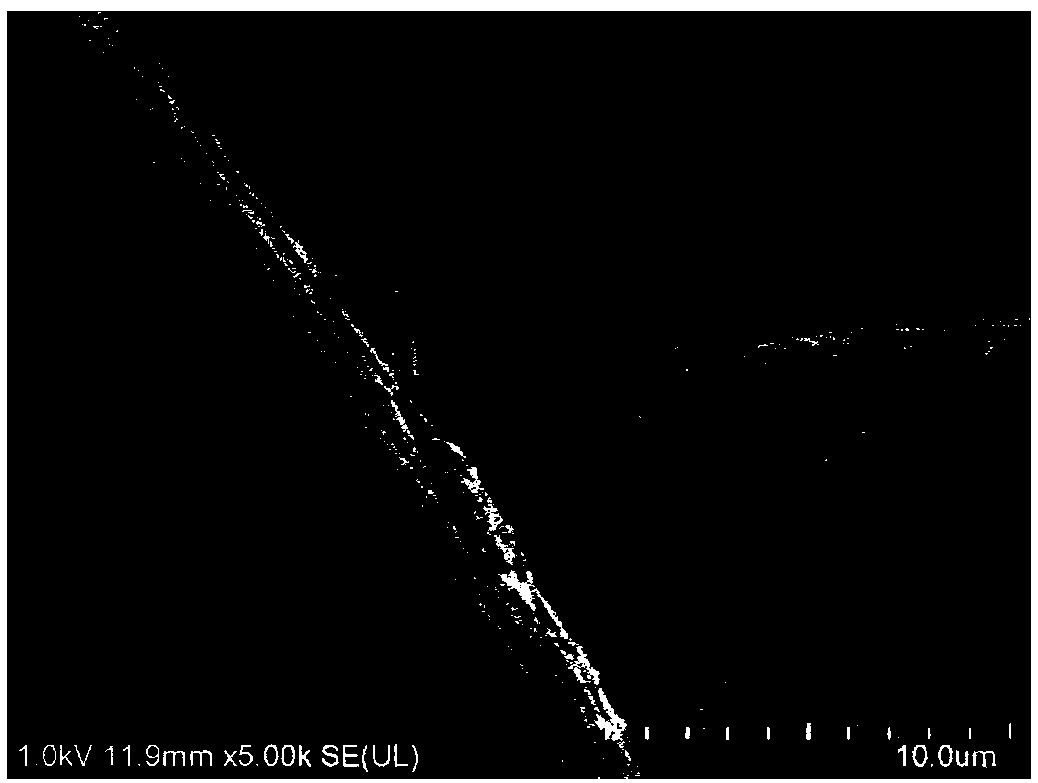

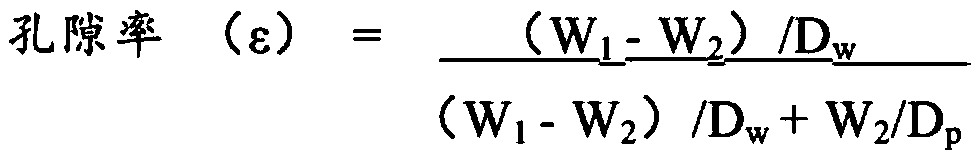

Super-hydrophobic water-proof moisture-permeable nanometer fiber material and preparation method thereof

InactiveCN109629113AHigh moisture permeabilitySuperhydrophobicElectro-spinningConjugated synthetic polymer artificial filamentsPorosityFiber

The invention belongs to the field of high polymer materials, and particularly relates to a super-hydrophobic water-proof moisture-permeable nanometer fiber material and a preparation method thereof.The super-hydrophobic water-proof moisture-permeable nanometer fiber material is prepared from super-hydrophobic electrospinning nanometer fibers of a three-dimensional through porous structure through mutually staggered arrangement, wherein the super-hydrophobic electrospinning nanometer fibers are a blend of polystyrene, polyurethane and a hydrophobe modified silicon dioxide. The preparation method comprises the steps that the polystyrene, the polyurethane and the hydrophobe modified silicon dioxide are uniformly dispersed into an organic solvent to form a spinning solution, and preparationis conducted through electrospinning. The fiber film is small in diameter, interfiber pores are small, the porosity is high, the moisture permeable flux is high, the water-proof performance is improved, the moisture permeable performance is improved, and the super-hydrophobic water-proof moisture-permeable nanometer fiber material has wide application prospects in the outdoor and protective fields.

Owner:SHANGHAI UNIV OF ENG SCI

Method for grafting Ilex sp. by taking Ilex dabieshanensis as stock

The invention provides a method for grafting Ilex sp. by taking Ilex dabieshanensis as a stock. The method comprises the following steps: performing ingraftment scion on the Ilex dabieshanensis serving as the stock and an Ilex sp. new variety serving as a scion by means of a cut grafting method; and performing layered alignment on the Ilex dabieshanensis and the Ilex sp. to graft successfully. Through adoption of the method, the adaptability of the Ilex sp. new variety is improved, the stock is readily-available, the cost is low, the propagation coefficient is increased, the yielding capacity is increased, and scale production of the Ilex sp. new variety becomes possible.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Low-temperature co-fired glass ceramic composites and preparation method thereof

ActiveCN102531396ASmall coefficient of thermal expansionLow thermal conductivityThermal dilatationCeramic composite

The invention discloses low-temperature co-fired glass ceramic composites and a preparation method thereof. The composites comprise the following components in percentage by weight: 5-10% of fluoride, 20-50% of aluminium nitride and 45-75% of cordierite-based glass material prepared by a sol-gel method, wherein cordierite is a promising packaging material with excellent characteristics of mechanics, electrics, thermal expansion performance and low-temperature sintering and the like, while powders prepared by the sol-gel method has small particle size and large surface energy, which can be conductive to reduce the sintering temperature and dense sintering; the ALN (aluminium nitride) can play a role of improving the thermal conductivity of the composites; fluoride ions in the fluoride has stronger electronegativity, which can effectively reduce dielectric constant, and the fluoride can play a role of fluxing, which can facilitate to reduce the co-fired temperature of the composites. The thermal conductivity of the low-temperature co-fired glass ceramic composites prepared by the method disclosed by the invention can reach 18W / mK.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

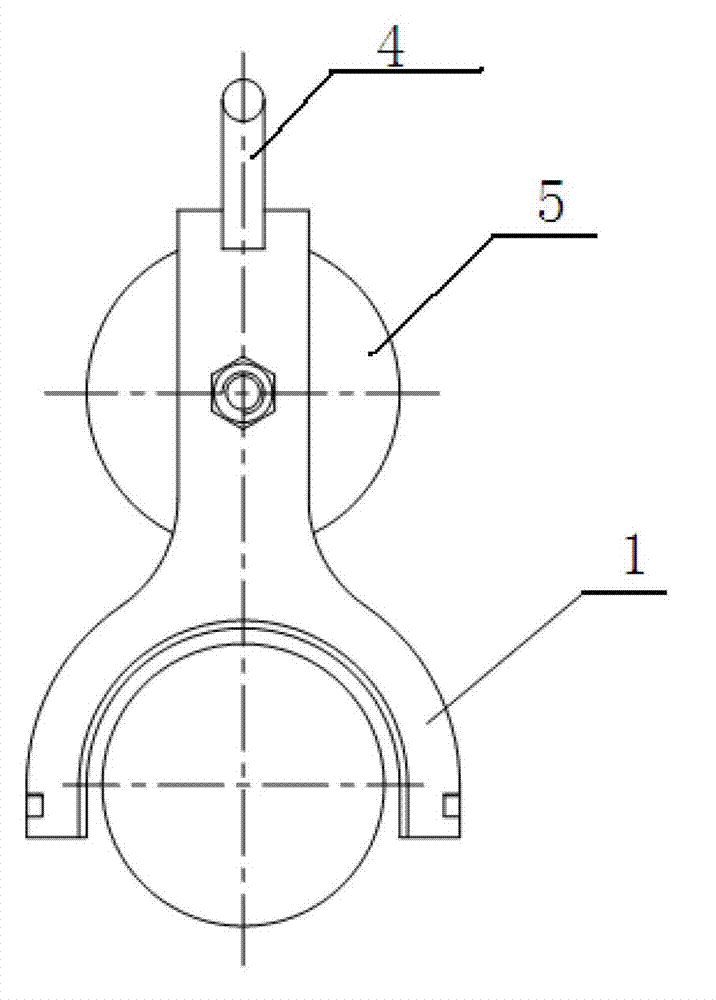

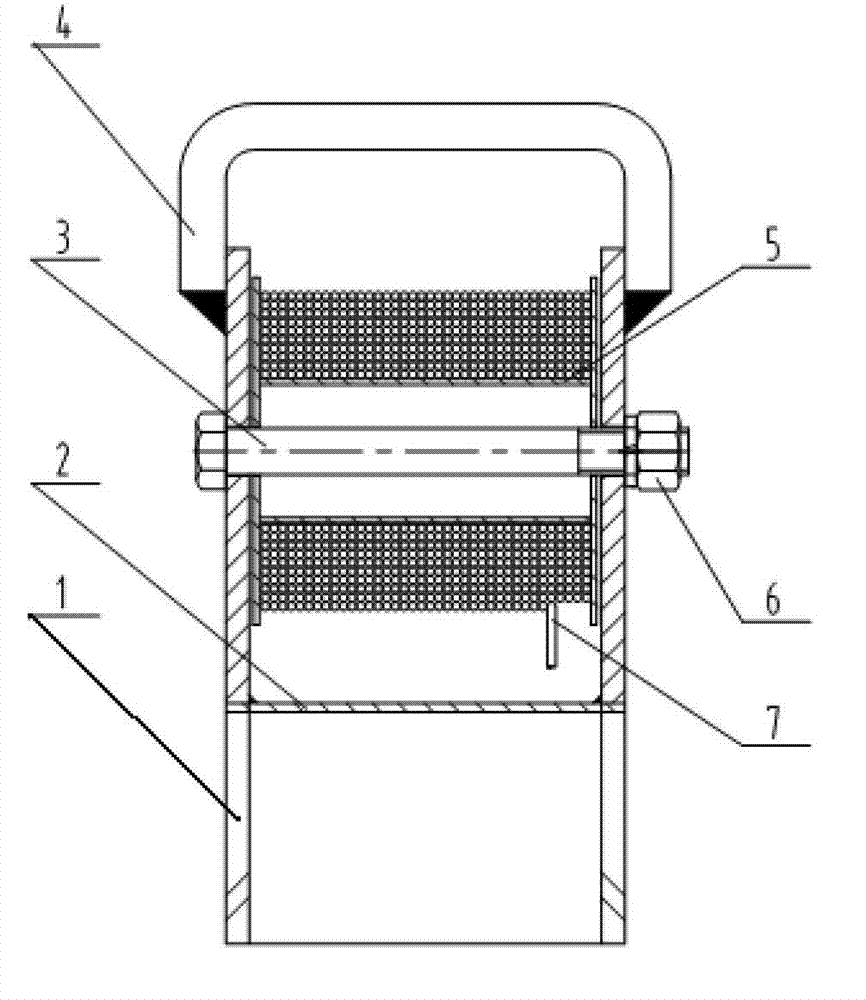

Steel wire rope binding machine

The invention provides a steel wire rope binding machine. The steel wire rope binding machine comprises an I-shaped wheel bracket and an I-shaped wheel, wherein the I-shaped wheel bracket comprises side guide plates, an arc plate, a pin shaft, a handle and a locking nut; the arc plate and the pin roll getting out of the side guide plates are connected between the two side guide plates; the I-shaped wheel rotating surrounding the pin roll is sleeved outside the pin roll; a winding rope is wound on the outer circumference of the I-shaped wheel; the pin shaft is arranged above the arc plate; the end part of the pin shaft is fixed by the locking nut; the arc plate is fixed on the lower ends of the side guide plates; and the handle is connected outside the upper ends of the two side guide plates. The steel wire rope binding machine is suitable for binding steel wire ropes, and also suitable for binding diameter products and objects, and has the characteristics of big binding force and high working efficiency.

Owner:JULI SLING

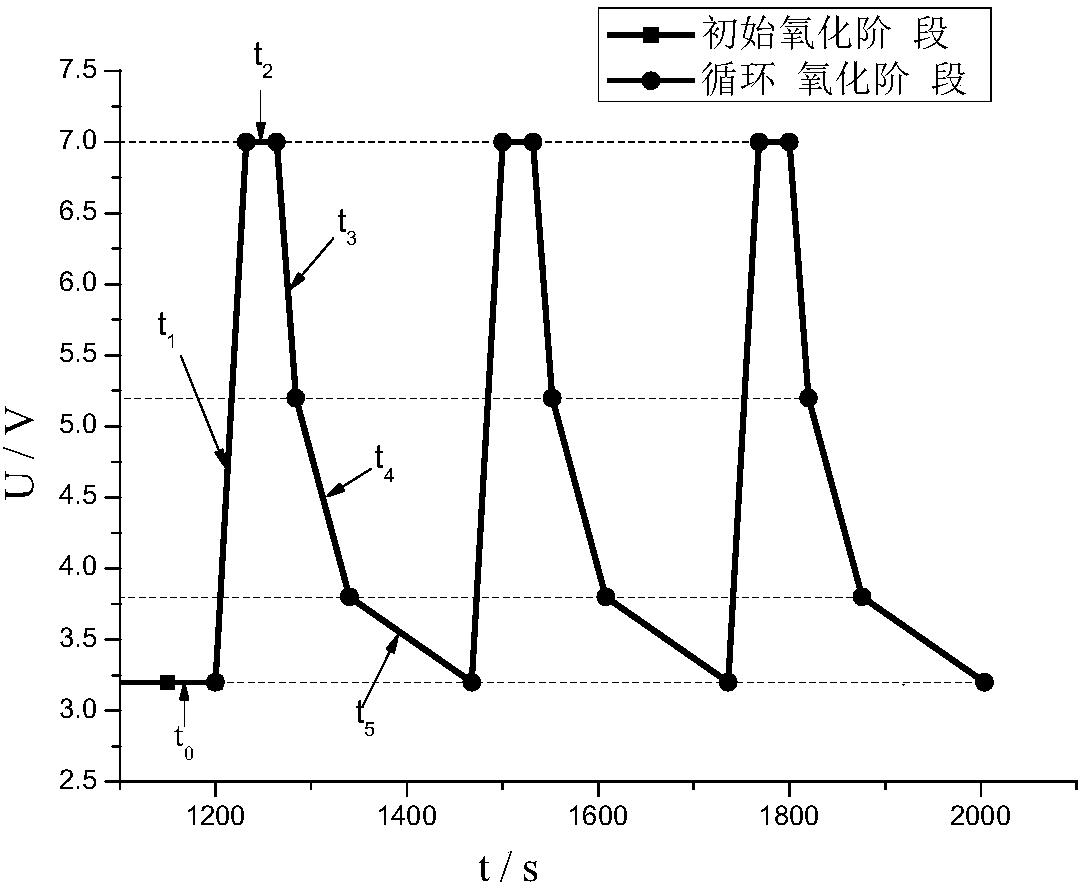

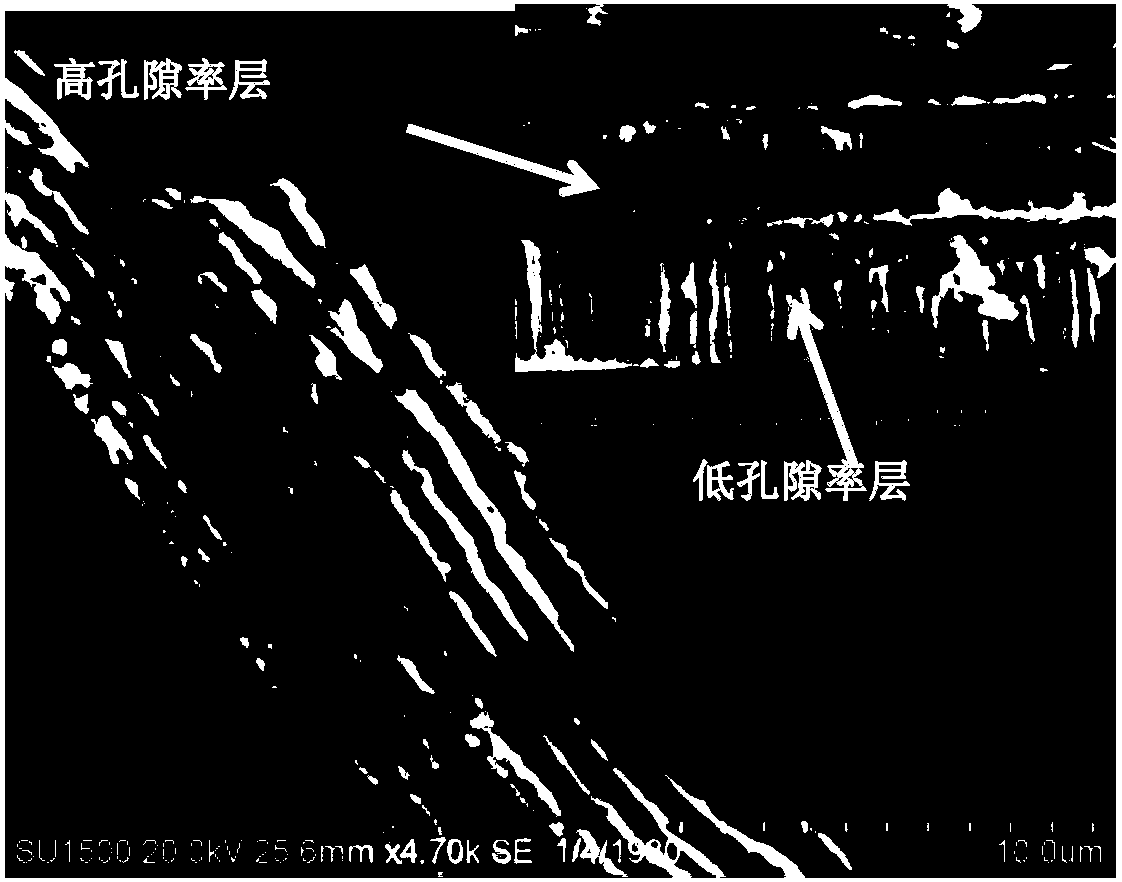

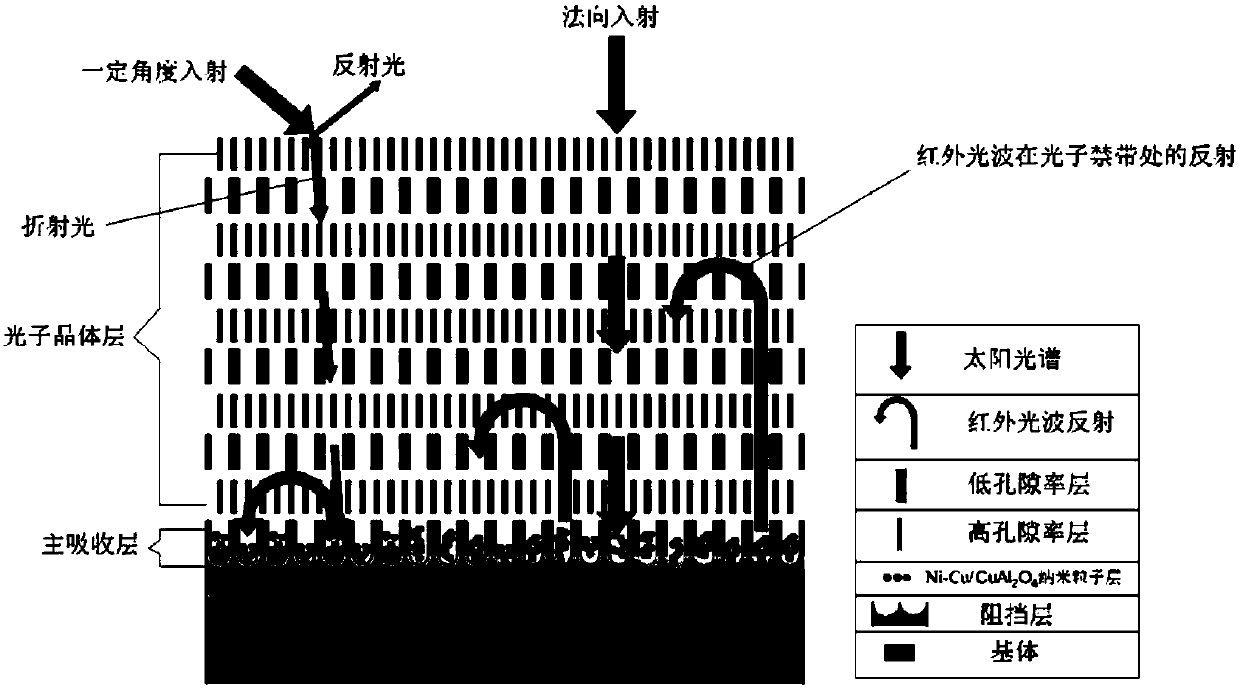

Preparation method of AAO photonic crystal based high-temperature-resistant ternary nano composite heat-absorbing coating

The invention discloses a preparation method of an AAO photonic crystal based high-temperature-resistant ternary nano composite heat-absorbing coating. The coating prepared by adopting the method is simple in process operation, is 0.84-0.94 in absorptivity and 0.12-0.21 in emissivity and has high solar absorptivity. After being thermally treated at 100-600 DEG C, a sample coating is comparativelytable in absorptivity and emissivity. The coating is high in solar spectrum absorptivity, low in emissivity, extensive in material source, firm in binding force and good in resistance to high temperature. The coating can be applied in the field of solar water heaters, solar cooker heat collection, high-temperature power generation and seawater desalination.

Owner:FOSHAN UNIVERSITY

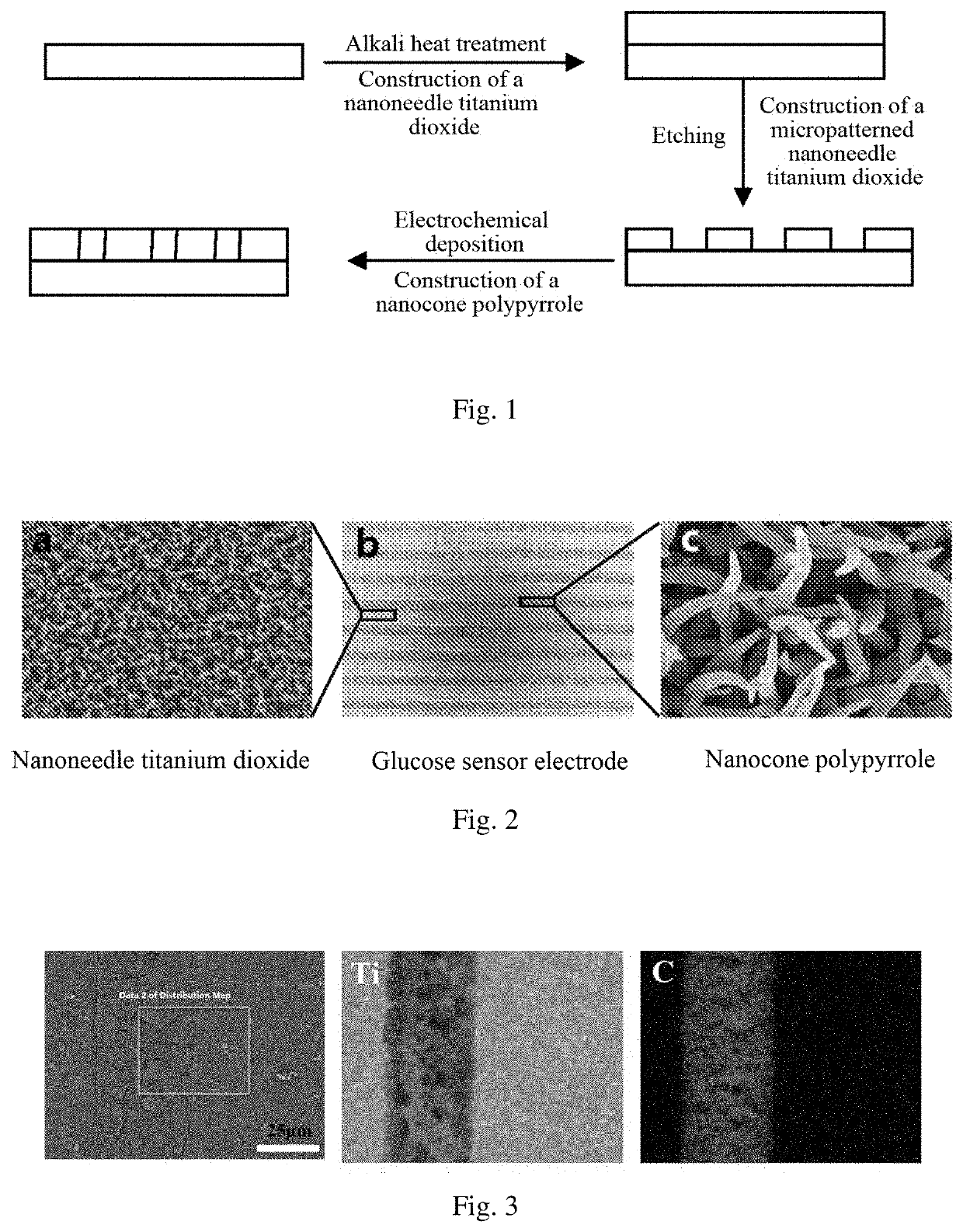

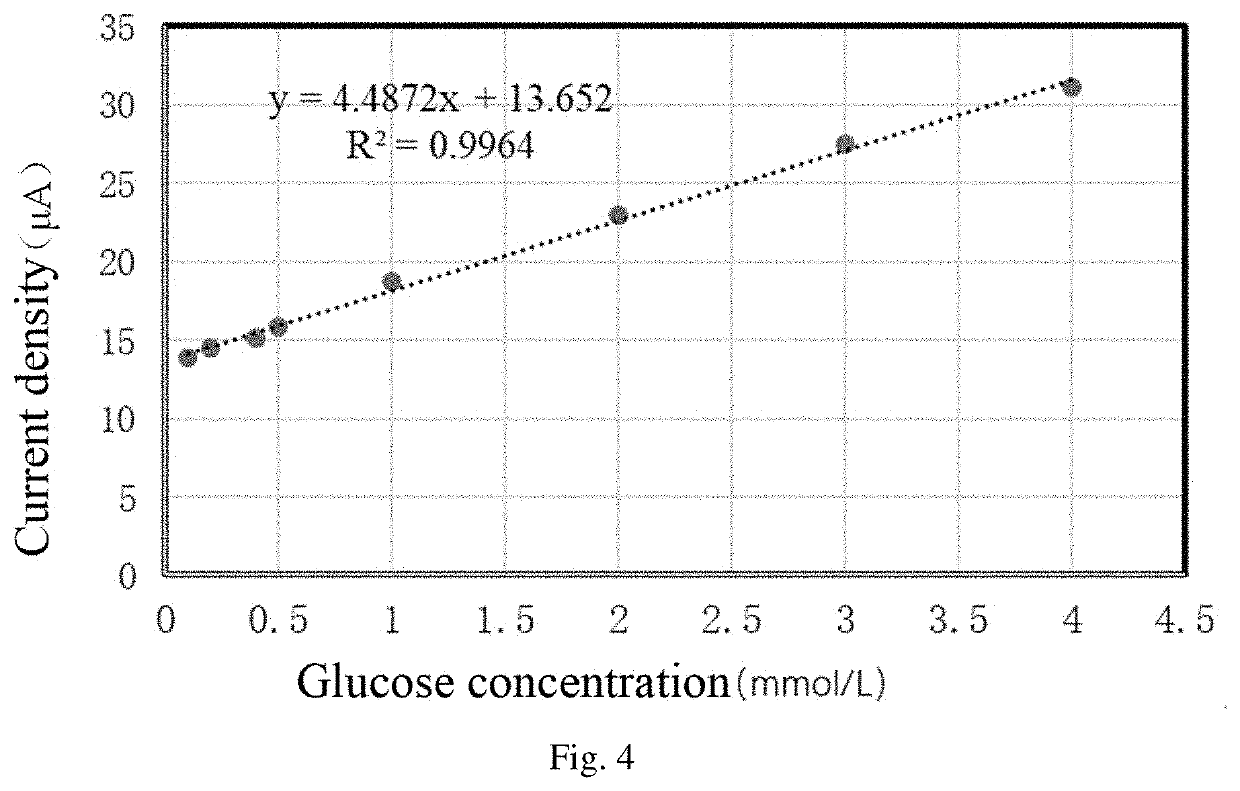

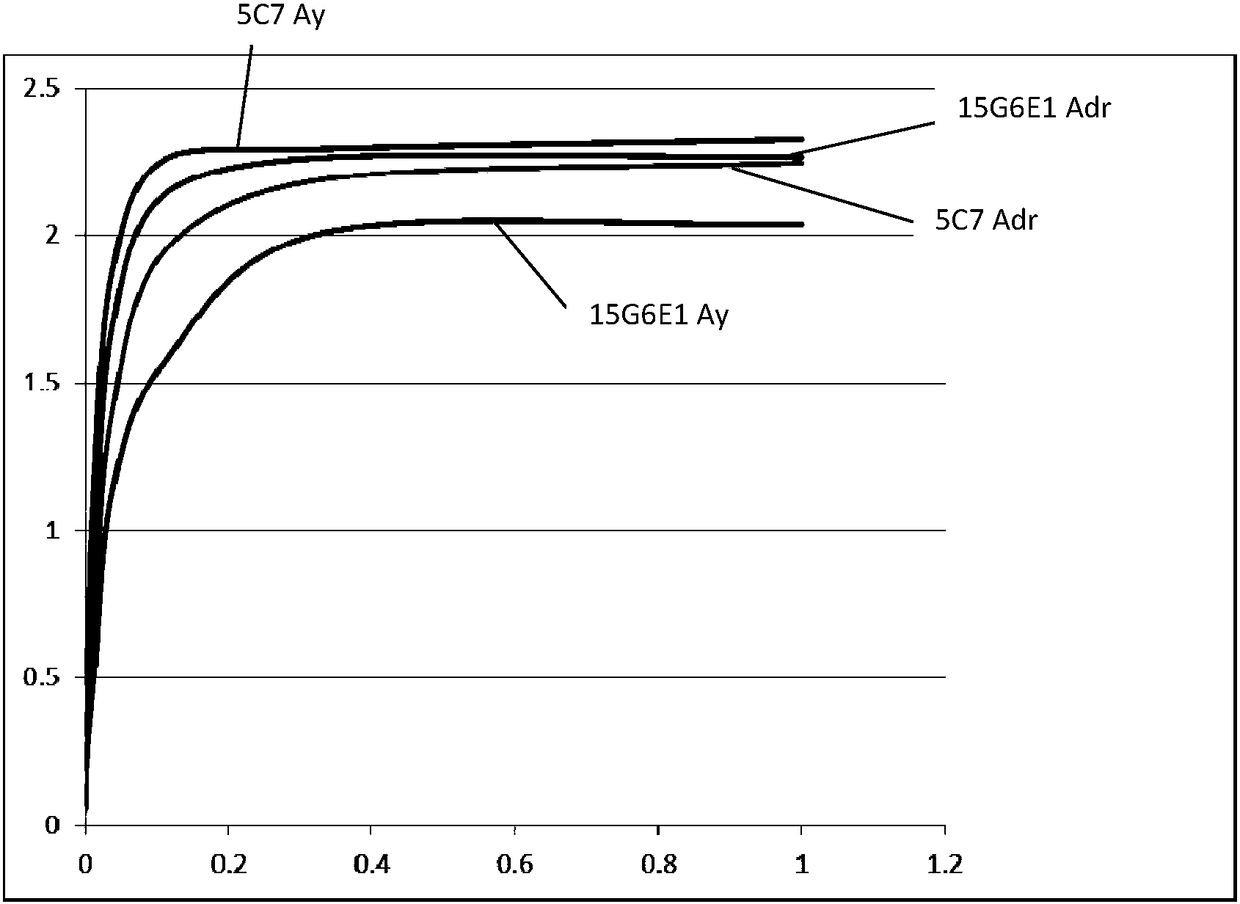

Glucose Sensor Electrode, Preparation Method Therefor and Use Thereof

PendingUS20210215632A1Improve bindingLow costMaterial analysis by electric/magnetic meansGlucose sensorsTitanium electrode

A glucose sensor electrode, a preparation method therefor and the use thereof are provided for the rapid and sensitive detection of glucose. The method involves: (1) performing an alkali heat treatment to form a nanoneedle-structured titanium dioxide on the surface of a titanium electrode; (2) forming micro-region grooves on a nanoneedle-structured titanium dioxide film layer to obtain a nanoneedle-structured titanium dioxide having a micropattern; (3) depositing a chlorine-doped polypyrrole in the grooves by using chronopotentiometry; (4) forming a nanocone-structured citric-acid-doped polypyrrole on the chlorine-doped polypyrrole by using chronopotentiometry; and (5) grafting an enzyme capable of detecting glucose to obtain the glucose sensor electrode. This simple and stable process is low in cost, efficiently grafts the enzyme capable of detecting glucose on the surface of the electrode, provides a stable electrode with higher reliability for detecting glucose.

Owner:SOUTH CHINA UNIV OF TECH +1

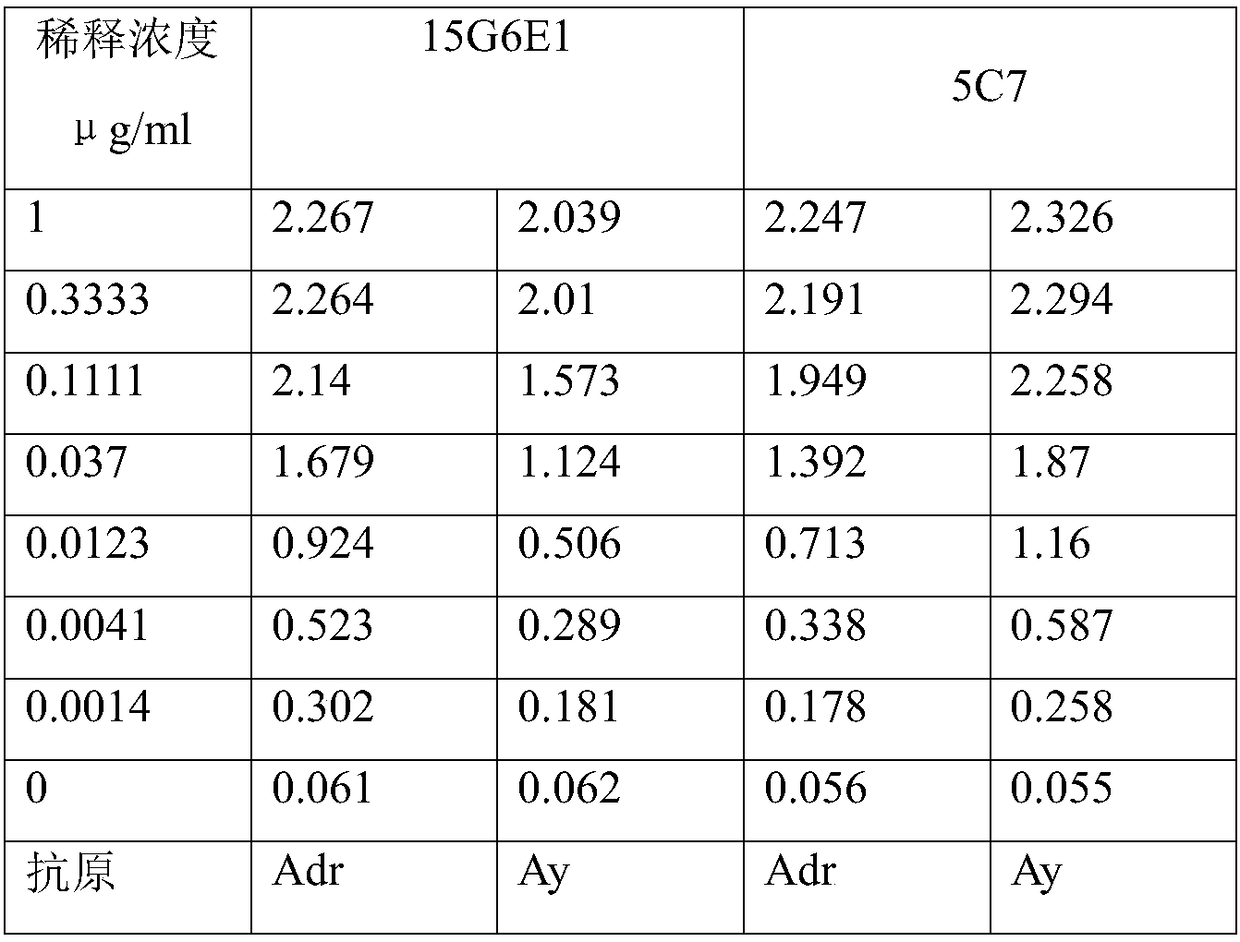

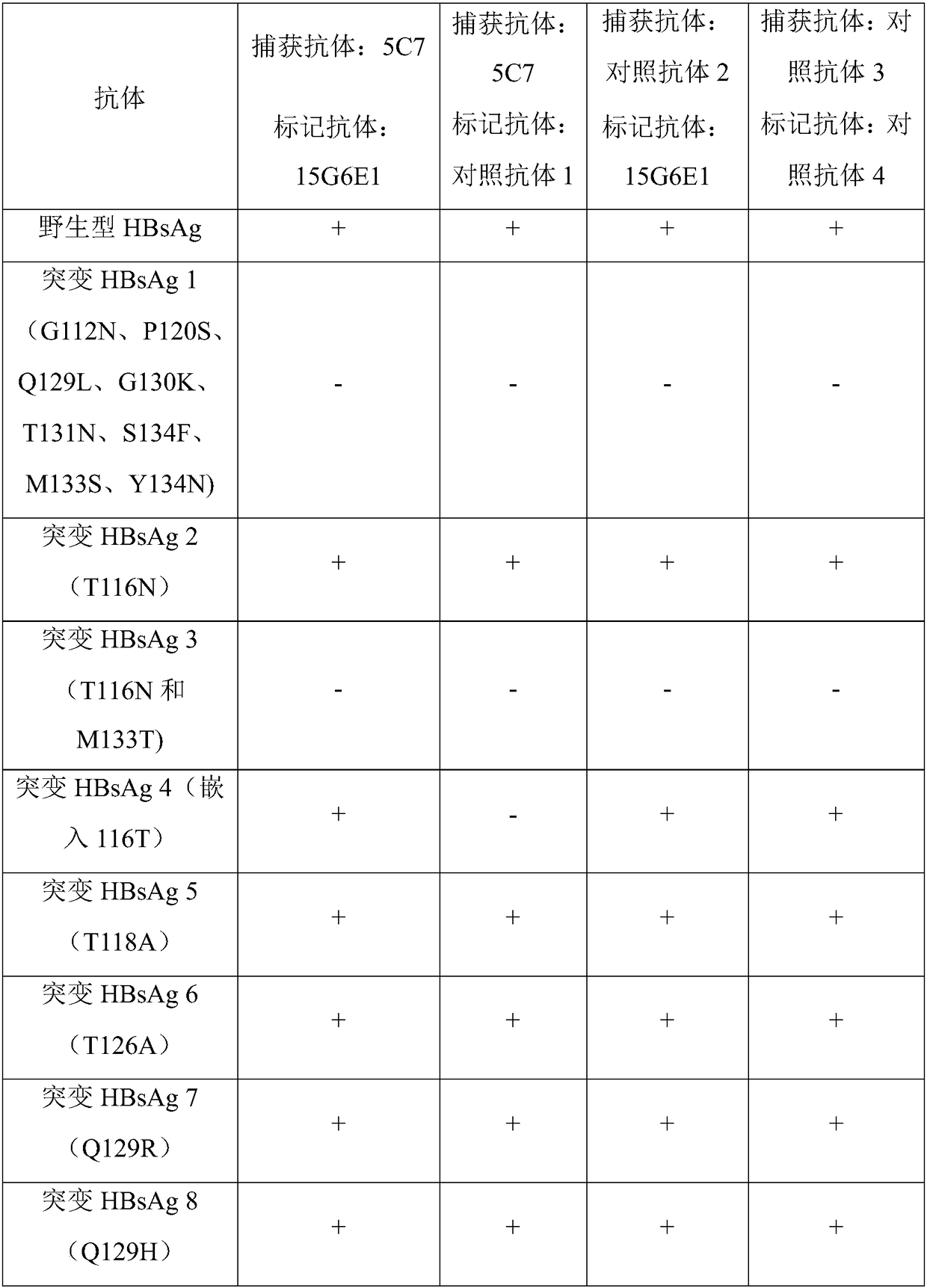

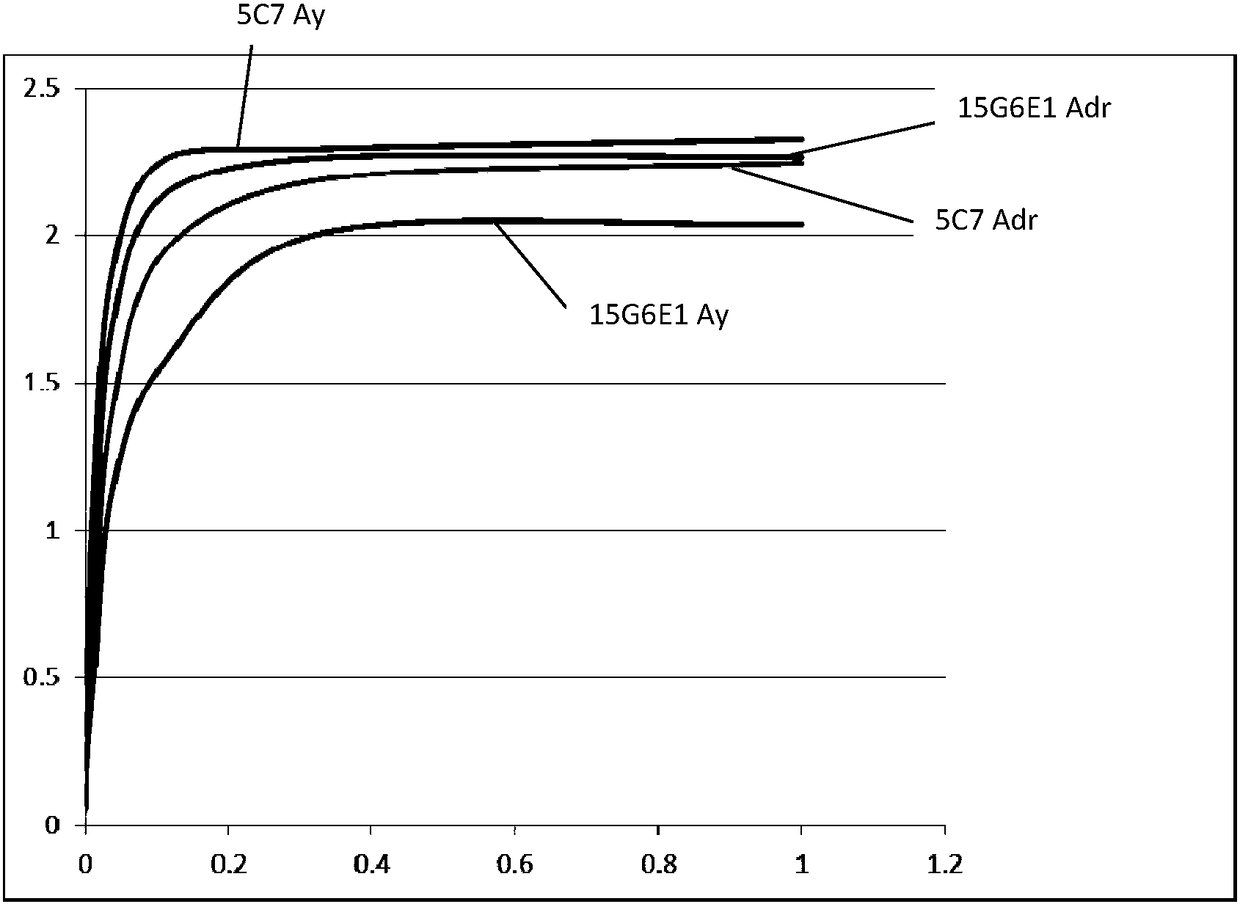

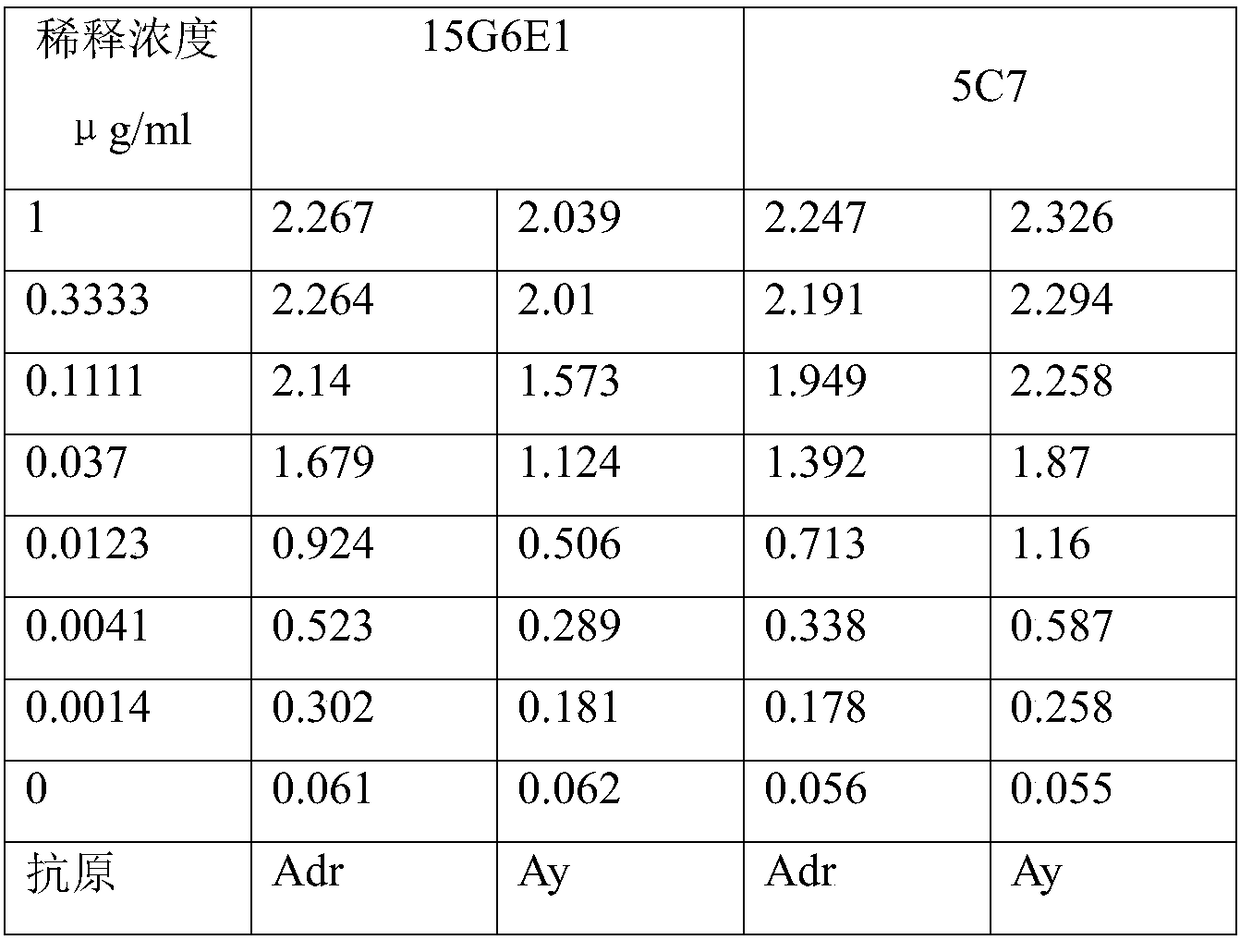

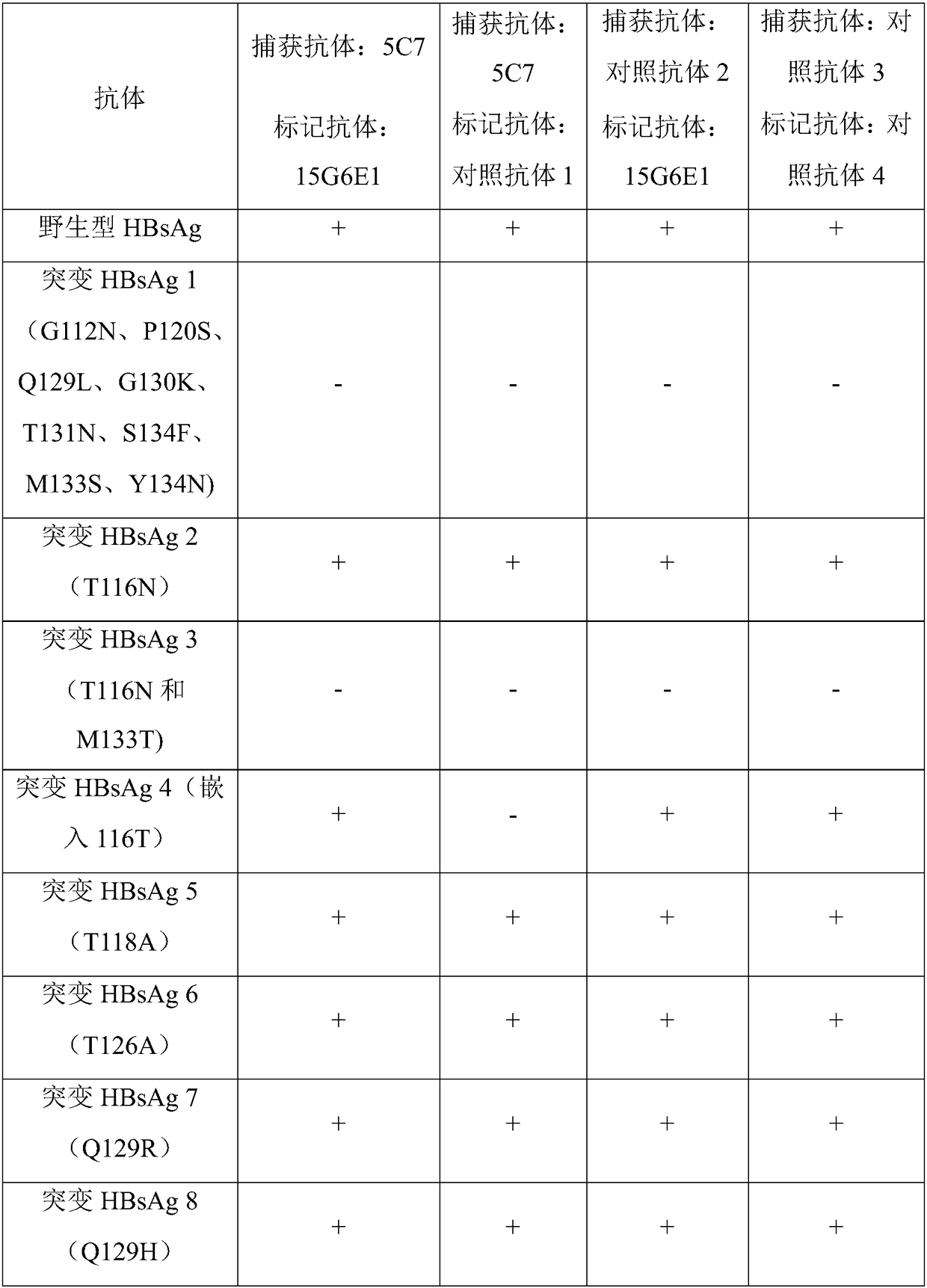

Preparation and screening of monoclonal antibody against hepatitis B surface antigen

InactiveCN108624564AImprove accuracyStrong binding forceBiological material analysisMicroorganism based processesHepatitis B Surface AntigensWild type

The present invention relates to a monoclonal antibody capable of binding to hepatitis B surface antigen, a hybridoma cell strain capable of producing the antibody and having the preservation number of CCTCC No:C2016198, a preparation method of the antibody, and applications of the antibody in hepatitis B surface antigen detection kits. According to the present invention, the antibody capable of binding to hepatitis B surface antigen is provided, can bind to wild type hepatitis B surface antigen or mutant hepatitis B surface antigen, has wide binding ability, can effectively reduce false negative test results, and further can improve the accuracy of hepatitis B virus detection.

Owner:ABON BIOPHARM HANGZHOU

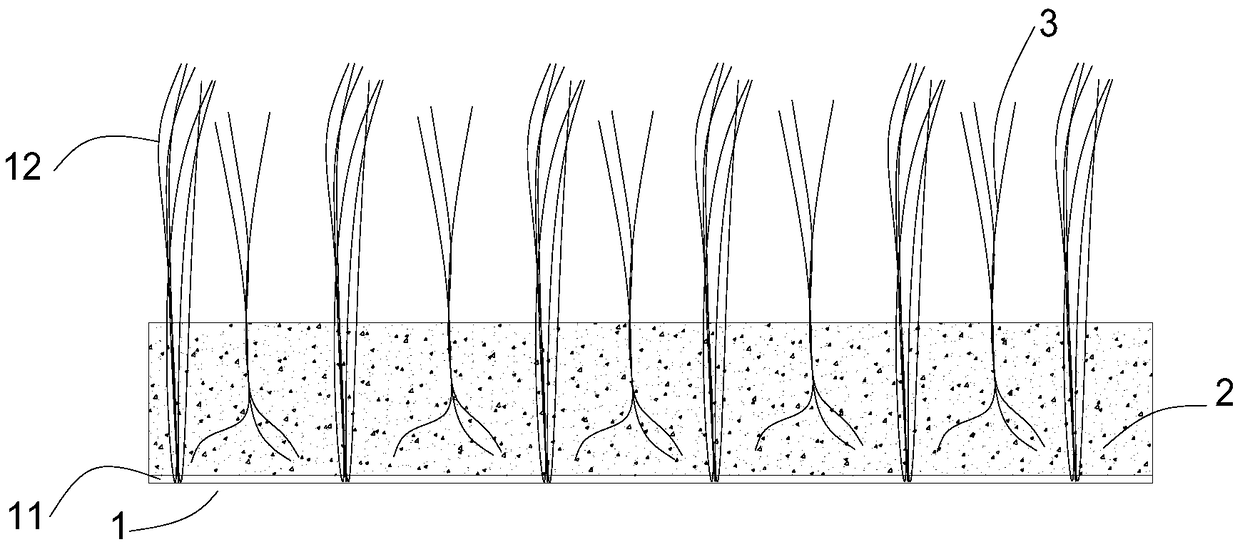

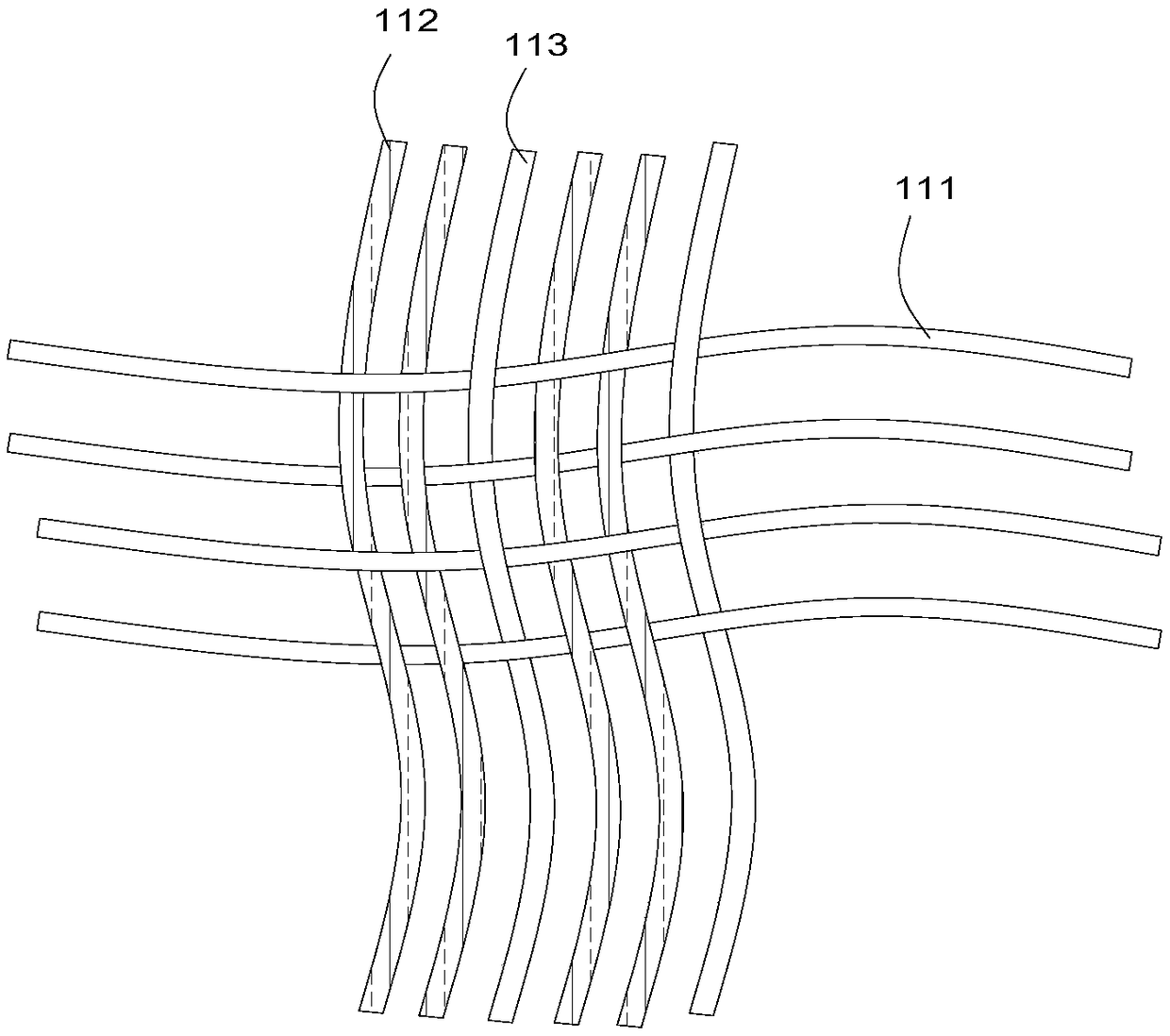

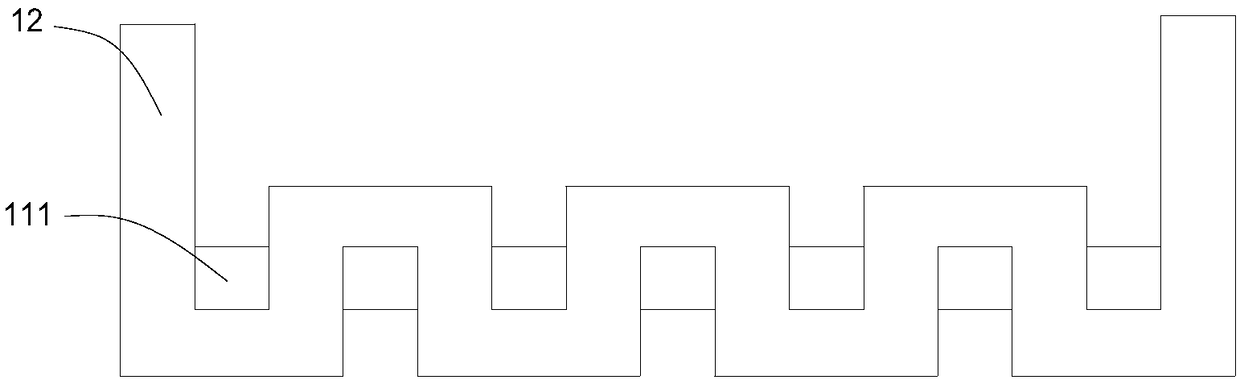

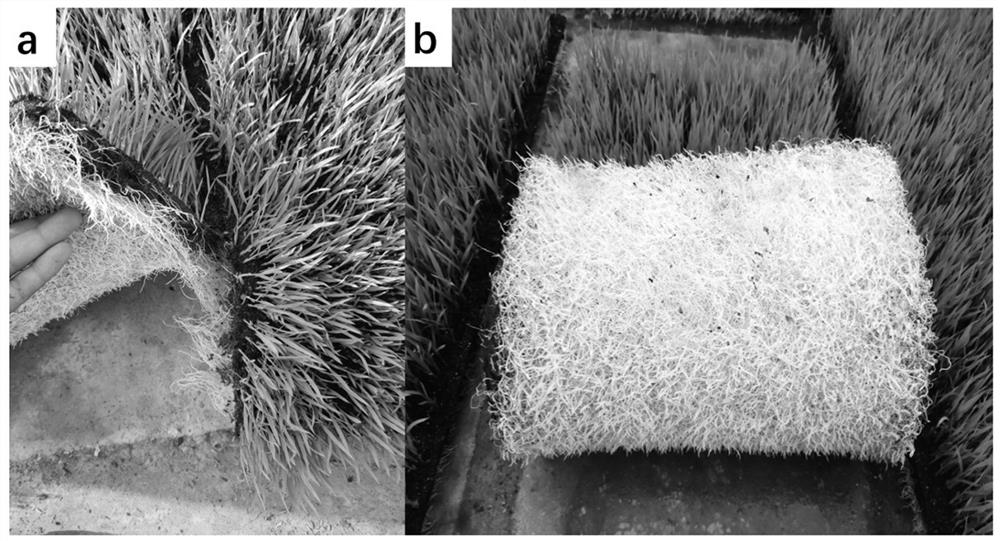

Natural grass and artificial grass-mixed lawn and preparation method thereof

The invention discloses a natural grass and artificial grass-mixed lawn and a preparation method thereof. The mixed lawn comprises woven artificial grass, a substrate layer and natural grass. The woven artificial grass includes a base fabric and artificial grass yarns; the base fabric comprises weft yarns and a plurality of warp yarn groups interwoven with the weft yarns; the warp yarn groups include first warp yarns and second warp yarns; and the substrate layer is laid on the base fabric; main roots of the natural grass are arranged in the substrate layer, and stems and upper parts of the natural grass penetrate the substrate layer. A manufacturing method comprises the steps of: a step of manufacturing the woven artificial grass; a step of filling the substrate layer; and sowing the natural grass. The mixed lawn does not need gluing and bonding, through weaving, the base fabric is formed and the base fabric and the artificial grass are connected, the mixed lawn is suitable for the growth of the natural grass, the mixed lawn has good stability, is trample-resistant, and has a wide application range, and the grass does not fall off easily.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

Preparation and screening of monoclonal antibody against hepatitis B surface antigen

InactiveCN108624565AImprove accuracyStrong binding forceImmunoglobulins against virusesTissue cultureHepatitis B Surface AntigensWild type

The present invention relates to a monoclonal antibody capable of binding to hepatitis B surface antigen, a hybridoma cell strain capable of producing the antibody and having the preservation number of CCTCC No:C2016210, a preparation method of the antibody, and applications of the antibody in hepatitis B surface antigen detection kits. According to the present invention, the antibody capable of binding to hepatitis B surface antigen is provided, can bind to wild type hepatitis B surface antigen or mutant hepatitis B surface antigen, has wide binding ability, can effectively reduce false negative test results, and further can improve the accuracy of hepatitis B virus detection.

Owner:ABON BIOPHARM HANGZHOU

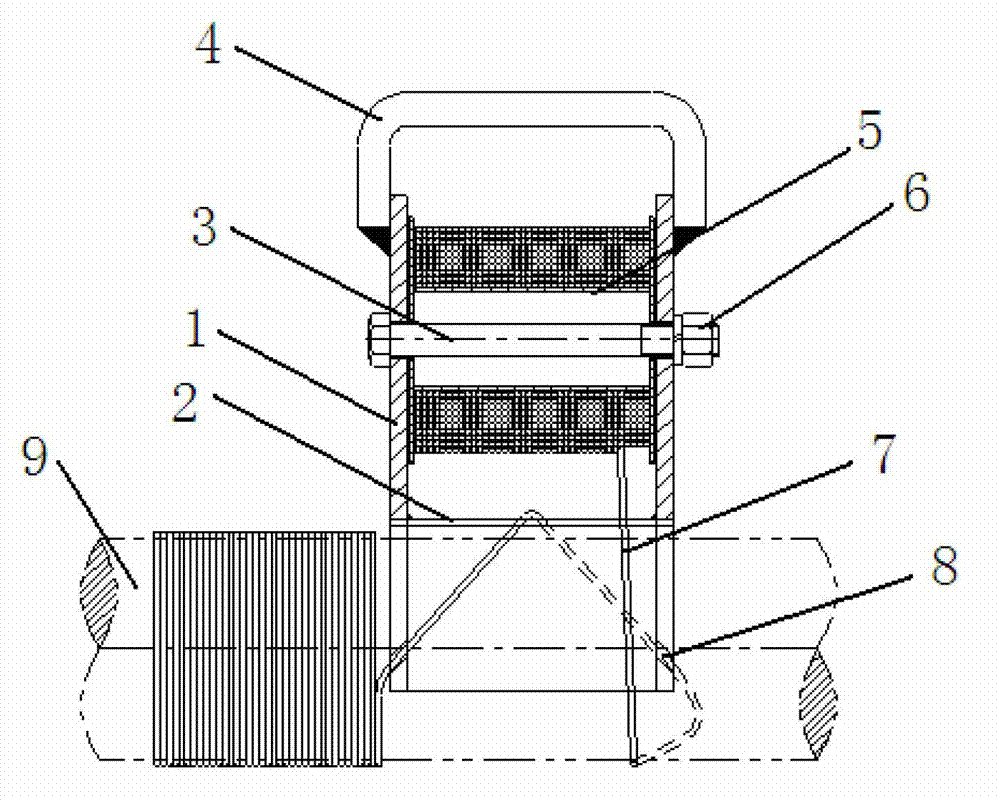

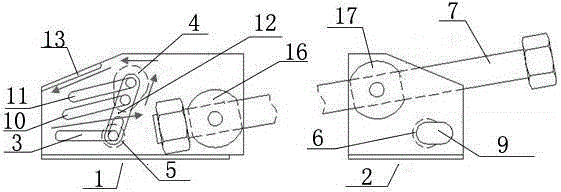

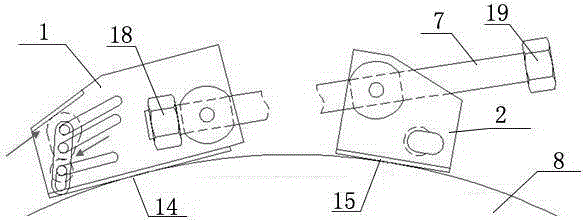

Binding method of large-sized transformer iron core and special tool for large-sized transformer iron core

InactiveCN105304309AStrong binding forceSurround binding effect is goodTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention relates to a binding method of a large-sized transformer iron core and a special tool for the large-sized transformer iron core, and belongs to the technical field of the production of a transformer. According to the technical scheme, the method comprises: connecting the head end of a binding tape to a dowel (9), matching the dowel with a lock-joint (6) in a main body II, straining the binding tape to enable the dowel to slide into the lock-joint to be locked; penetrating the tail end of the binding tape into a slide block I (4) and a slide block II (5) from the part between a slide rail I (3) and a slide rail II (10) on the main body I, bypassing the slide block I, then enabling the binding tape to stretch out of the main body I from the part between a slide rail III (11) and a bevel end surface (13), and extracting the excessive binding tape completely from the end of the main body I; and tightening a nut II (19) of a screw (7) by utilizing a wrench, shortening the distance between the main body I and the main body II to achieve binding and straining. The binding method has positive effects that the binding coercivity is high, multiple points are stressed simultaneously, stability and firmness are realized, the binding integrity is high, no additional clamping tool is needed, the operation is simple, and the binding work can be completed only by two persons at most.

Owner:TIANWEI BAOBIAN QINHUANGDAO TRANSFORMER

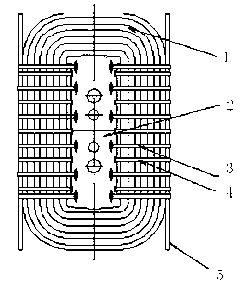

Method for binding transformer iron core

InactiveCN102592789AShorten the manufacturing cycleShort timeTransformers/inductances magnetic coresPolyesterTransformer

The invention discloses a method for binding a transformer iron core, which includes: firstly, cutting iron core chips which serve as raw materials, then sequentially stacking the iron core chips, clamping an iron core column and overturning and rising the iron core column; secondly, removing a center column clamping device and binding a Tenax polyester belt; thirdly, binding the other two columns of the transformer with Tenax polyester belts and then suiting the device body. According to the binding method for transformer iron core, without curing, the iron core binding has the advantages of having a short working time, high binding efficiency, big binding force of the polyester belt, high strength of extension, low cost and good economic benefits, besides, a large amount of working time is saved, the manufacturing cycle of the iron core is shortened, the operation is convenient and the production efficiency is improved.

Owner:ANHUI SHENHONG TRANSFORMER

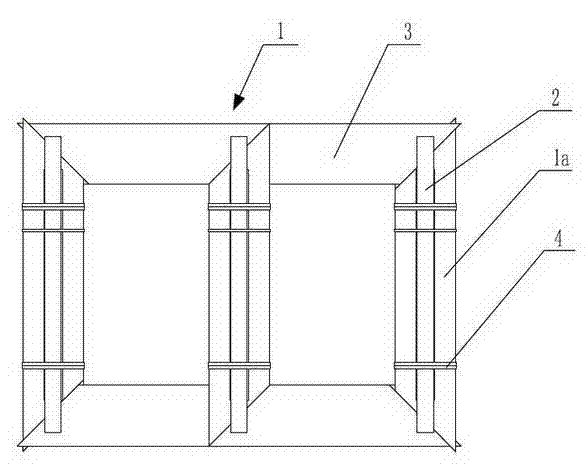

Electric reactor with integrally-bound iron core and binding method of iron core of electric reactor

InactiveCN103035375AShorten the manufacturing cycleNo curing requiredTransformers/inductances magnetic coresInductances/transformers/magnets manufactureExtensibilityPolyester

The invention relates to an electric reactor with an integrally-bound iron core and a binding method of an iron core of the electric reactor. The electric reactor comprises a three-column type iron core which is formed by stacking silicon steel sheets, adjusting pad strips are arranged along two side outer surfaces of an iron core column, and binding tapes which are used for integrally binding the iron core column and the adjusting pad strips are arranged outside the adjusting pad strips. The binding method of the iron core of the electric reactor comprises the following steps of firstly, forming the three-column type iron core by stacking the silicon steel sheets, and arranging the adjusting pad strips on the two outer side surfaces of the iron core; and then, integrally binding the iron core column and the adjusting pad strips at the outer sides of the adjusting pad strips. By adopting the structure and the binding method, disclosed by the invention, the binding tapes not only has the stretching resistance like a steel tape, but also has the shock-proof extensibility, solidification is not needed, a large amount of working hours can be saved, the manufacturing period of the iron core is shortened, the production efficiency is increased, the labor intensity of a worker is low, the running noise of a transformer is reduced, the temperature rising of the iron core is effectively reduced, and the binding arrangement of polyester tapes is regular and attractive.

Owner:QINGDAO HAIWO ELECTRICAL EQUIP

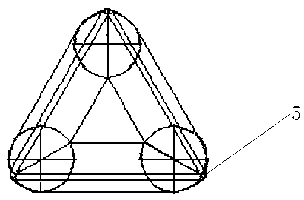

Method for binding iron cores of transformer with wound stereoscopic triangular iron core before annealing

InactiveCN103280310AAvoid deformationNo collapseTransformers/inductances detailsInductances/transformers/magnets manufactureTransformerMaterials science

The invention discloses a method for binding iron cores of a transformer with a wound stereoscopic triangular iron core before annealing. The wound stereoscopic triangular iron core is formed by combining three wound iron core sheets. The method includes: splicing the three wound iron core sheets into a stereoscopic triangular structure by arranging the same on a platform, and respectively arranging auxiliary round support steel at an outer triangular zone at the joint of the iron core sheets so as to prevent deformation during binding; binding three core limbs through a steel binding tape packing machine, and firstly binding internal steel binding tapes, aligning various contact surface edges and connecting seamlessly; then binding external steel binding tapes after the internal steel binding tapes in the three core limbs are all bound, and further firmly binding the iron core sheets into an integral stereoscopic triangular iron core. By the method, defects of collapse, deformation and waves and the like are avoided after annealing, and success rate of iron core production is greatly increased.

Owner:JIANG SU ZHONGRONG TECH

Method for binding transformer iron core

InactiveCN102592789BShorten the manufacturing cycleShort timeTransformers/inductances magnetic coresPolyesterTenax

The invention discloses a method for binding a transformer iron core, which includes: firstly, cutting iron core chips which serve as raw materials, then sequentially stacking the iron core chips, clamping an iron core column and overturning and rising the iron core column; secondly, removing a center column clamping device and binding a Tenax polyester belt; thirdly, binding the other two columns of the transformer with Tenax polyester belts and then suiting the device body. According to the binding method for transformer iron core, without curing, the iron core binding has the advantages of having a short working time, high binding efficiency, big binding force of the polyester belt, high strength of extension, low cost and good economic benefits, besides, a large amount of working time is saved, the manufacturing cycle of the iron core is shortened, the operation is convenient and the production efficiency is improved.

Owner:ANHUI SHENHONG TRANSFORMER

Method for filtering aquaculture sewage

InactiveCN109850995AAvoid deformationBroaden the photoresponse absorption rangeSemi-permeable membranesWater/sewage treatment by irradiationFilter effectPolymer

The invention provides a method for filtering aquaculture sewage, and belongs to the field of sewage filtration. The method comprises the steps: performing filtration by using a microporous membrane,introducing ultrasonic waves into the filtered water body simultaneously, performing irradiation with an artificial light source, and controlling the flow rate of water which flows through the microporous membrane at 10-1000 ml / min, wherein the microporous membrane comprises a polymer matrix, a metallic silver-containing coating attached to the surface of the substrate and a silver-covering titanium dioxide photocatalytic coating, and the titanium dioxide photocatalytic coating is prepared by using a powder heating cold spray technique. According to the method, a photocatalysis technology is combined with an ultrasonic technology, so that the filtering effect of the microporous membrane is reinforced, complete removal of organic matter, bacteria, viruses and other substances in the aquaculture sewage can be achieved, and the removal efficiency is high.

Owner:浦江县酉泽水产科技有限公司

Crucible for pulling monocrystalline silicon and preparation method therefor

InactiveCN105297132AHigh strengthSmall coefficient of thermal expansionBy pulling from meltElectric arcMonocrystalline silicon

The invention relates to a crucible for pulling monocrystalline silicon and a preparation method therefor. The crucible consists of a C / SiC crucible blank and various coatings, wherein the C / SiC crucible blank is prepared by manufacturing a green body by methods such as an SMC and then carrying out heat treatment; and the various coatings are prepared by an electric arc method. The crucible prepared by the method is comprehensively better than a quartz crucible prepared by the electric arc method.

Owner:罗万前

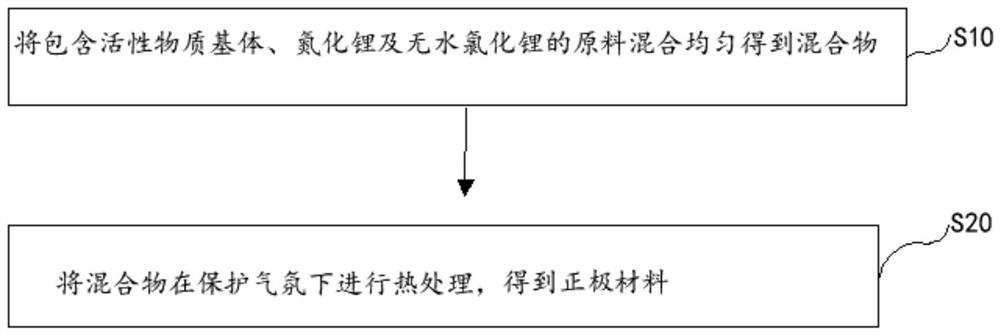

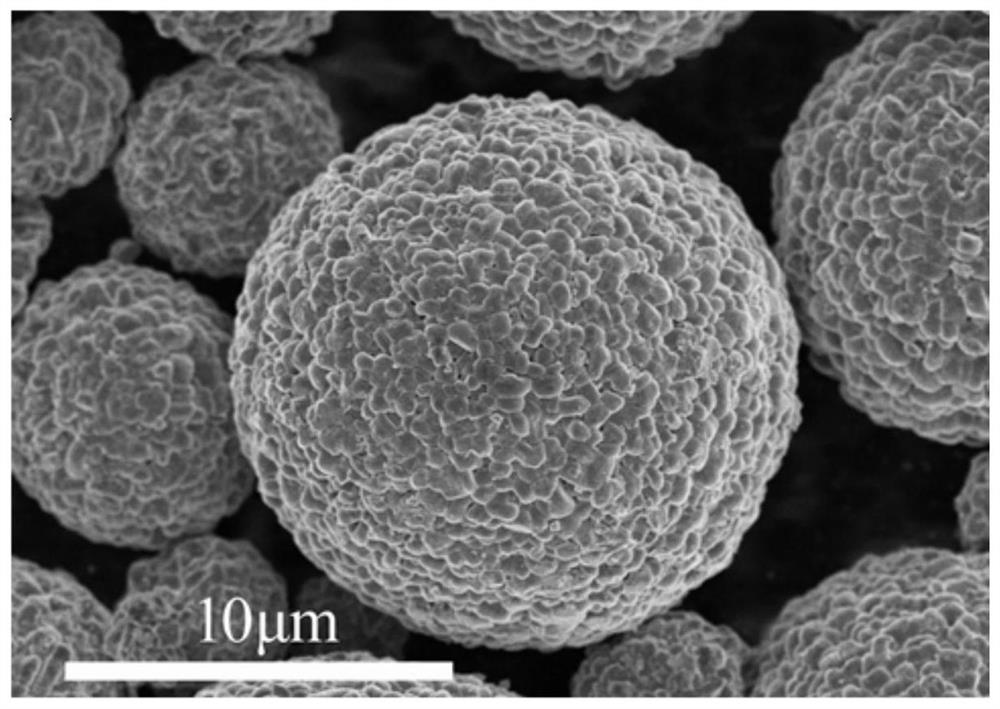

Positive electrode material, preparation method thereof and lithium ion battery

PendingCN114447334AImprove ionic conductivityImprove surface stabilityPositive electrodesSecondary cells servicing/maintenanceElectrolytic agentPhysical chemistry

The invention relates to the field of lithium ion batteries, and provides a positive electrode material, a preparation method thereof and a lithium ion battery, the positive electrode material comprises an active substance and a coating layer, the chemical general formula of the active substance is LiaNixCoyMnzO2, a is more than or equal to 1.0 and less than 1.1, x is more than or equal to 0.80 and less than 1, y is more than 0 and less than 0.20, z is more than 0 and less than 0.10, the coating layer is formed on at least part of the surface of the active substance, and the coating layer comprises at least two of Li3N, LiCl and Li9N2Cl3. The active substance of the positive electrode material provided by the invention has high capacity and excellent charge-discharge reversibility, and the cycle performance of the positive electrode material under a high-temperature condition is improved. And the coating layer is formed on the surface of the active substance, so that the reaction of the active substance and the electrolyte for generating gas can be reduced, and the thermal stability of the active substance in the circulation process can be improved.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

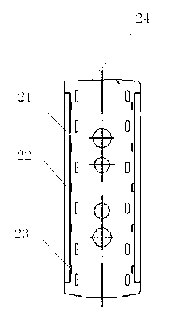

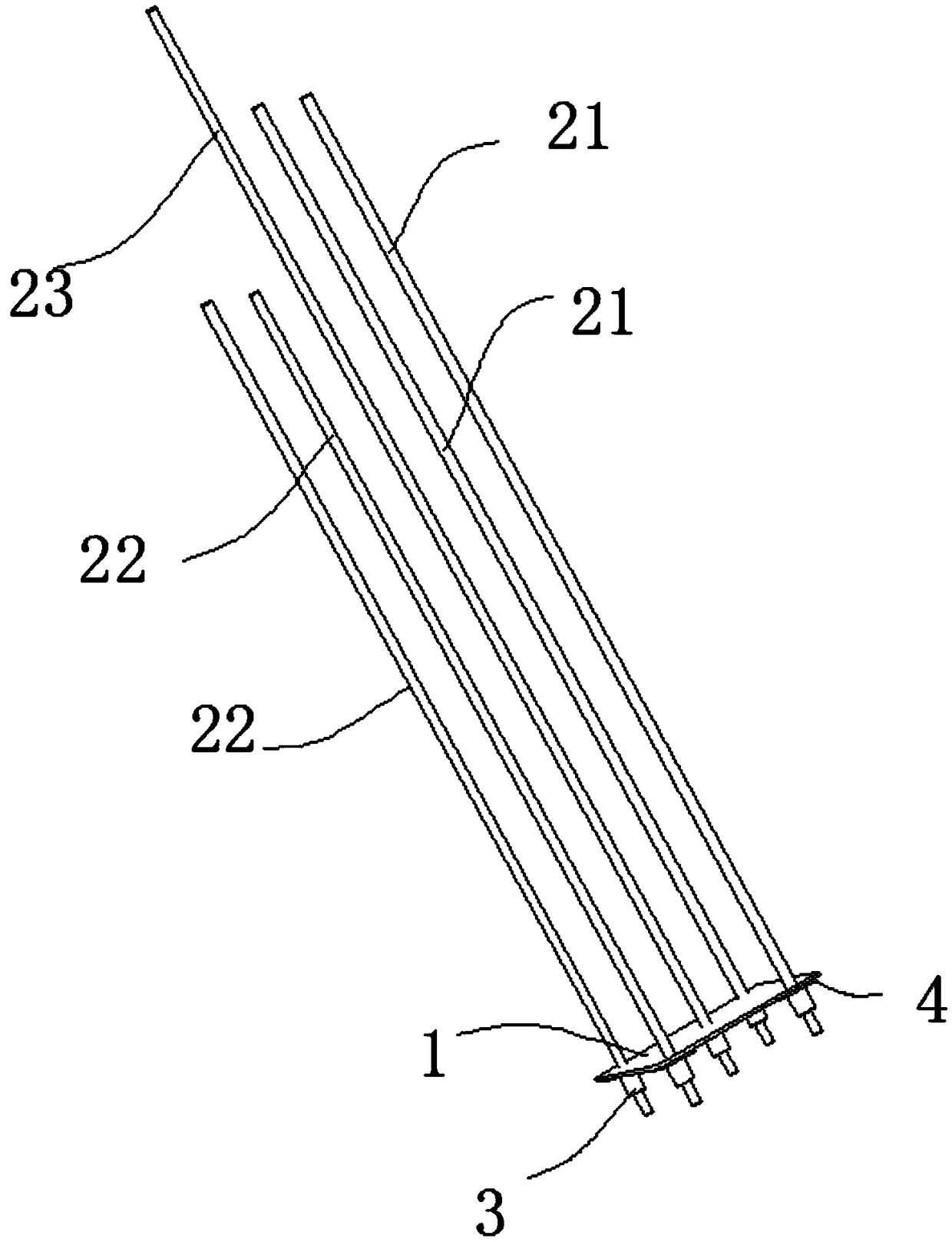

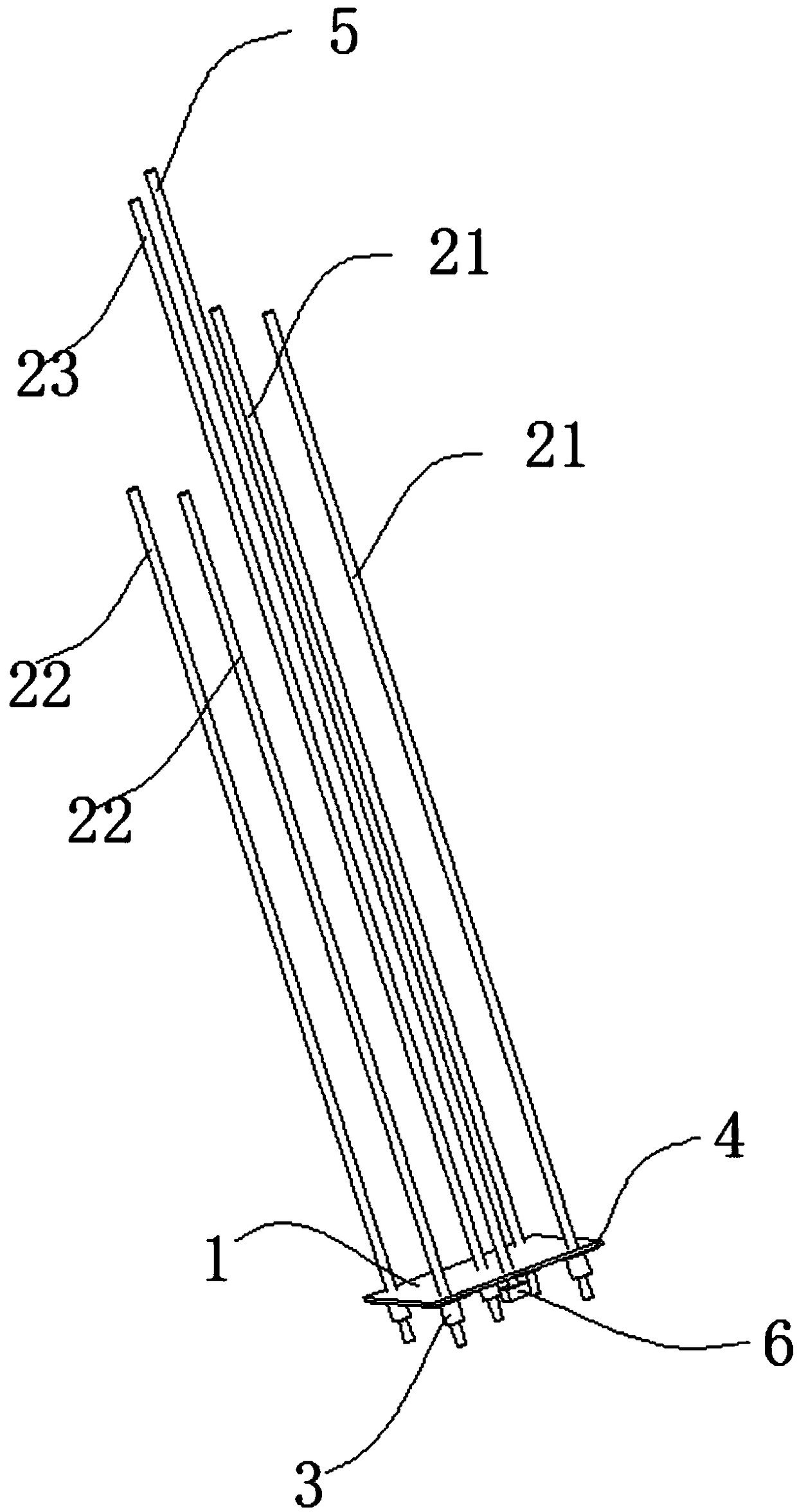

Anchor cable bundle supporting device and roadway supporting method

Owner:HUAINAN MINING IND GRP

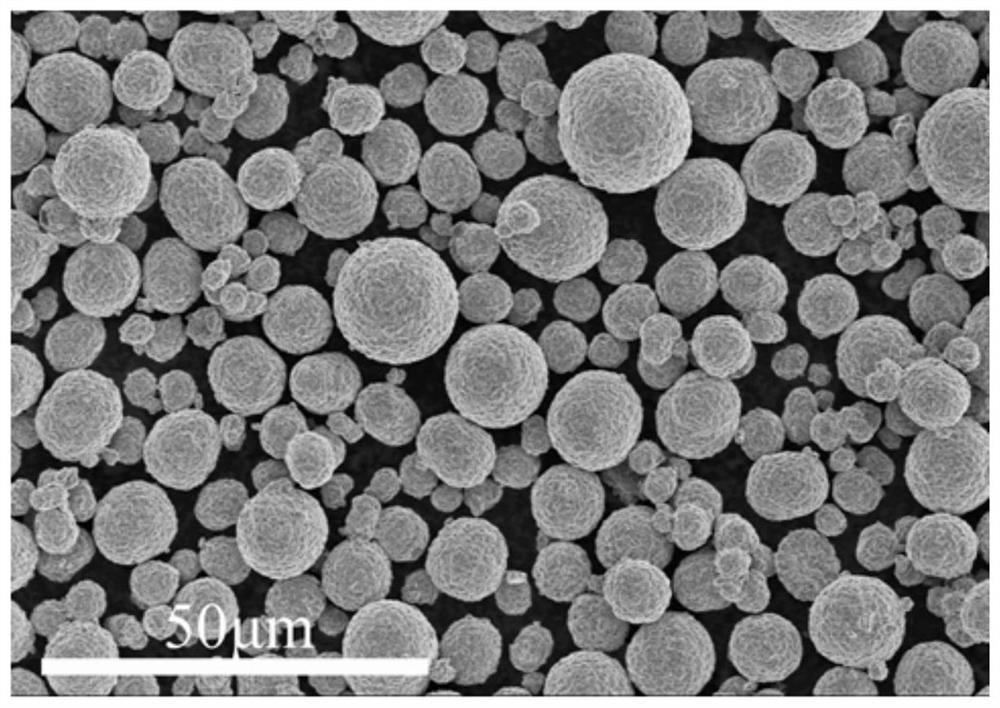

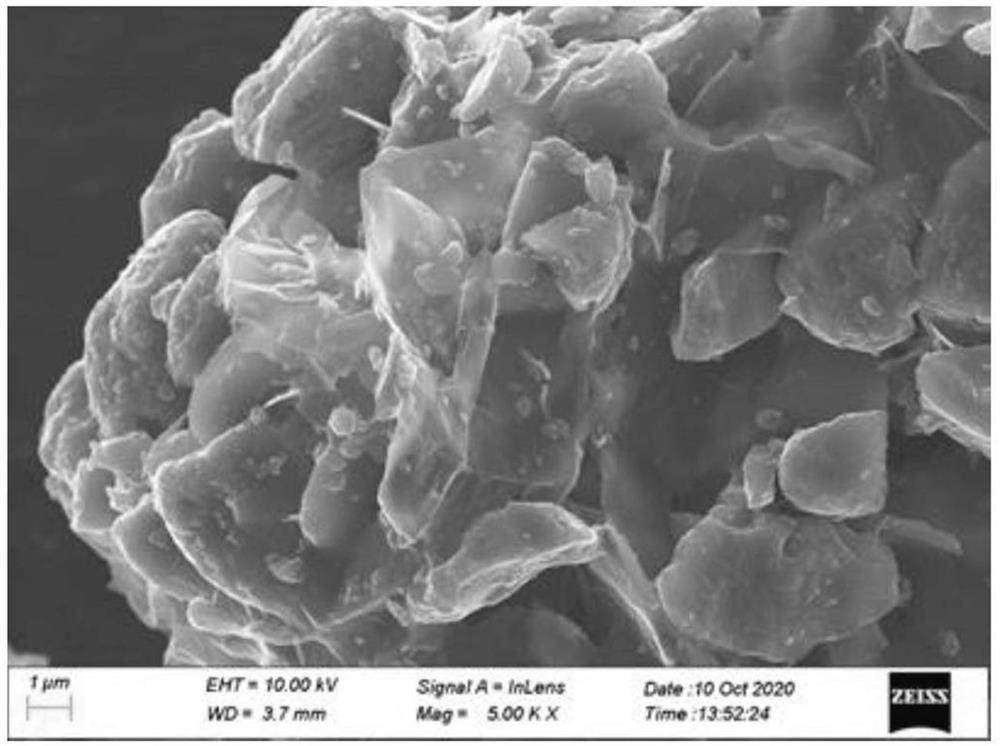

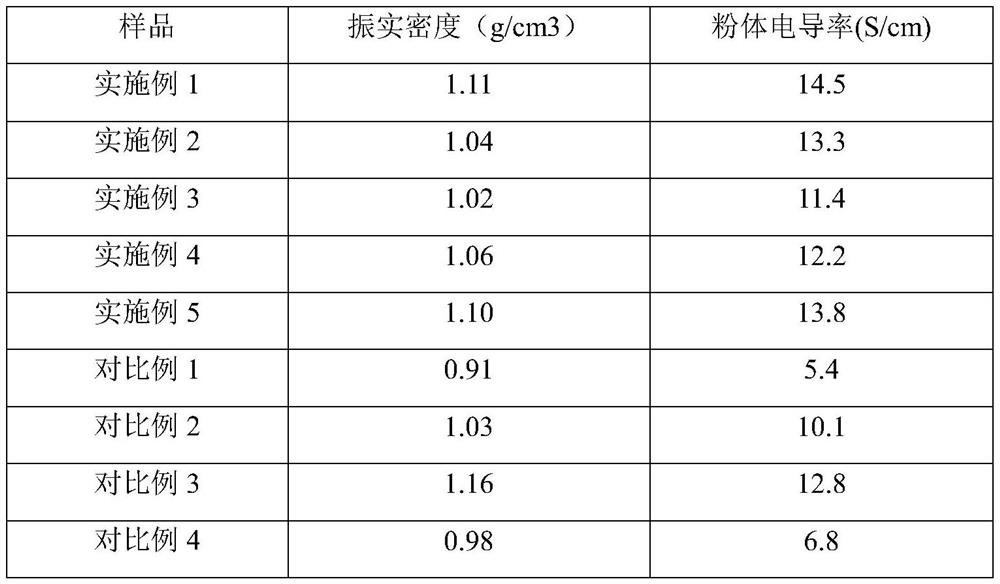

A kind of low-expansion silicon-carbon composite negative electrode material and preparation method thereof

ActiveCN113745489BIncrease loopImprove conductivityNegative electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention relates to the technical field of lithium ion battery materials, and proposes a low-expansion silicon-carbon composite negative electrode material, comprising a silicon monoxide material core and a coating layer coated on the surface of the silicon-carbon material core, the coating layer comprising: A first cladding layer arranged on the surface of the silicon carbon material core and a second cladding layer arranged on the surface of the first cladding layer, the first cladding layer is composed of materials with electronic conductivity and ionic conductivity ; The second coating layer is composed of a flexible conductive polymer material, which can effectively suppress the expansion of the material during the charging and discharging process of the material and improve the structural stability of the material; The two cladding layers are connected by chemical bonds, which improves the structural stability of the material and improves the cycle performance.

Owner:河北坤天新能源股份有限公司

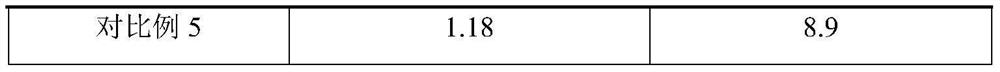

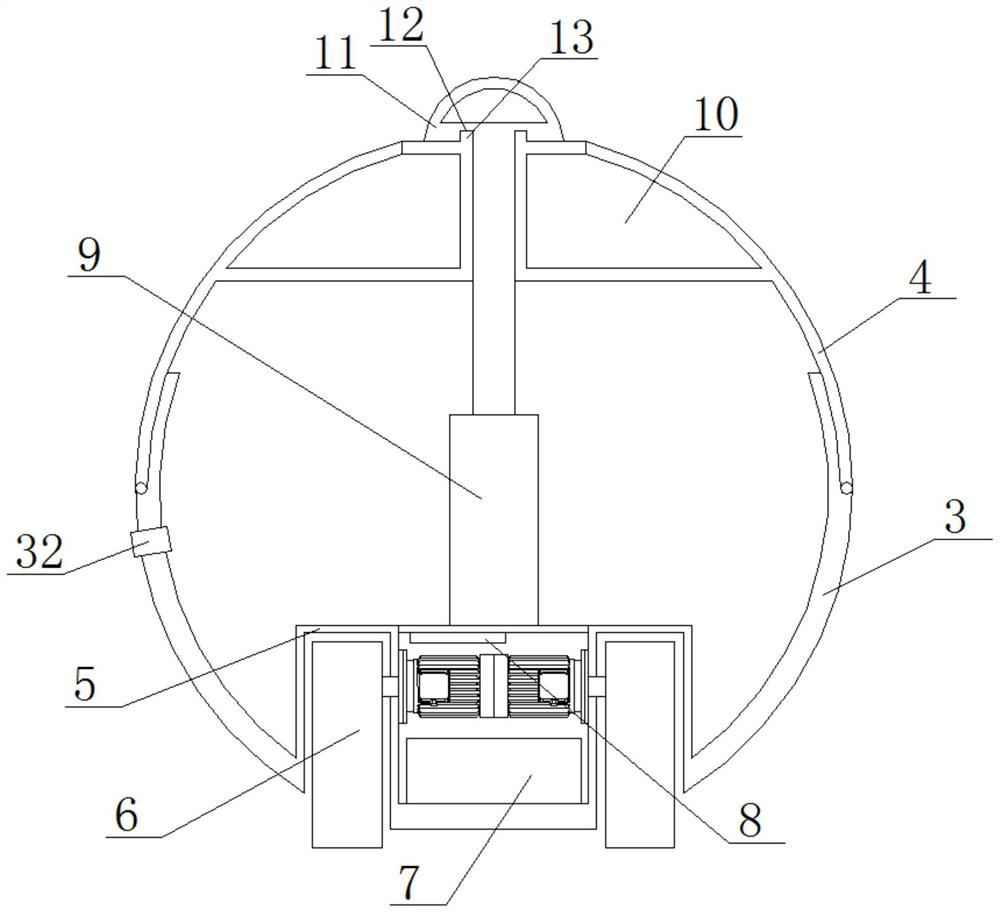

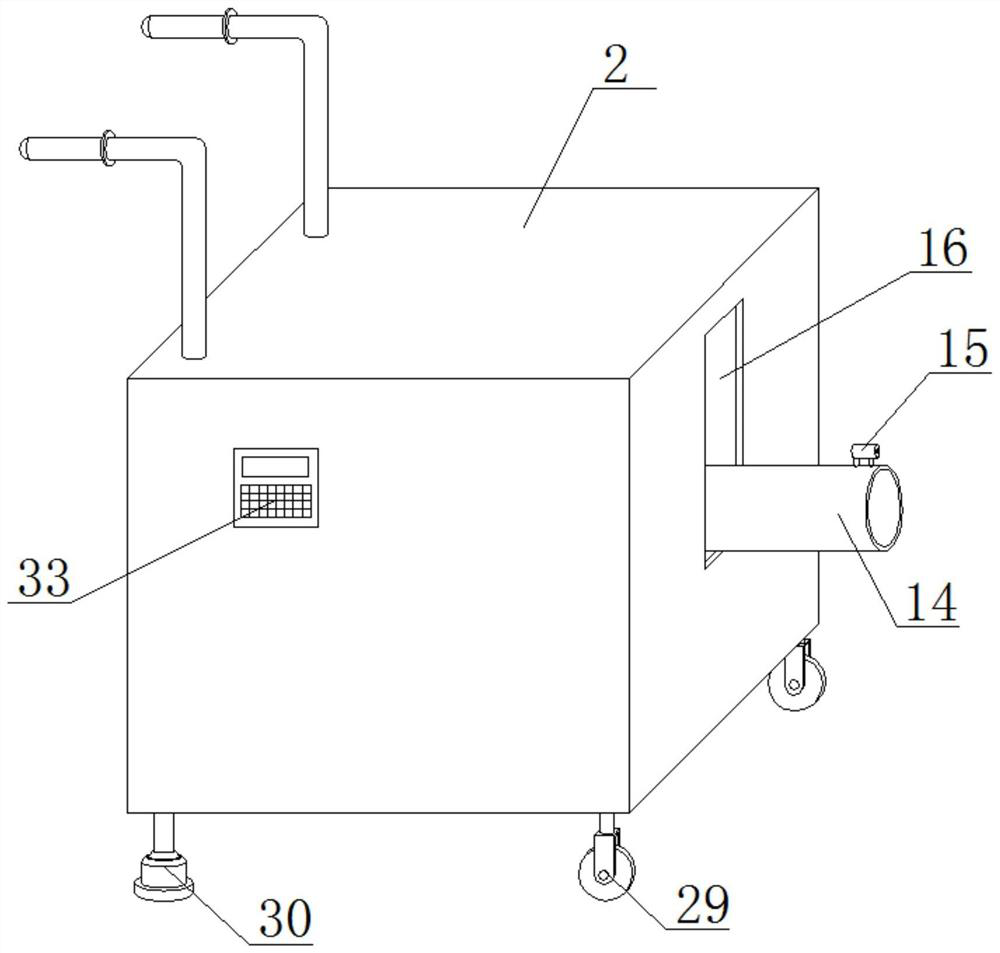

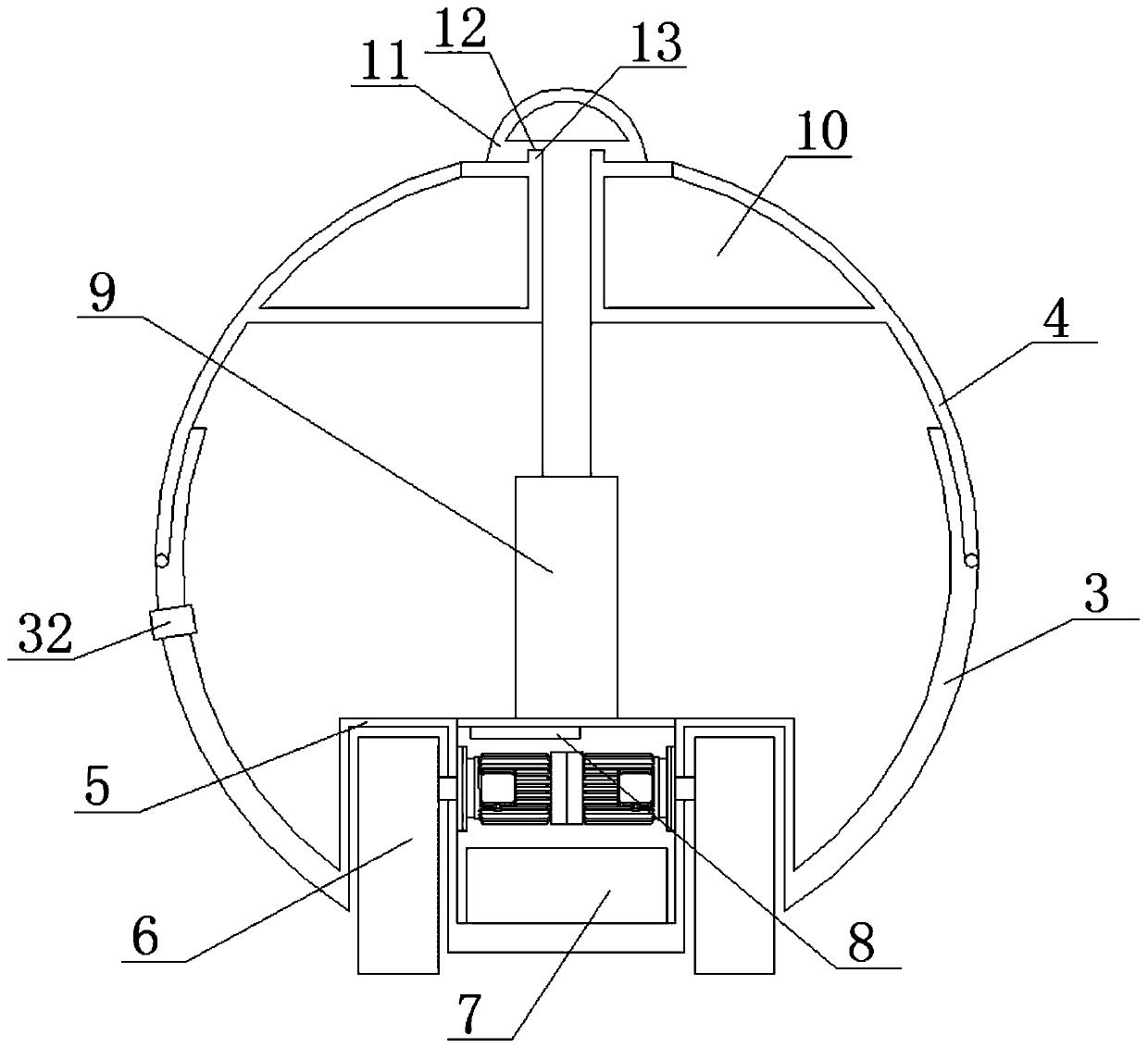

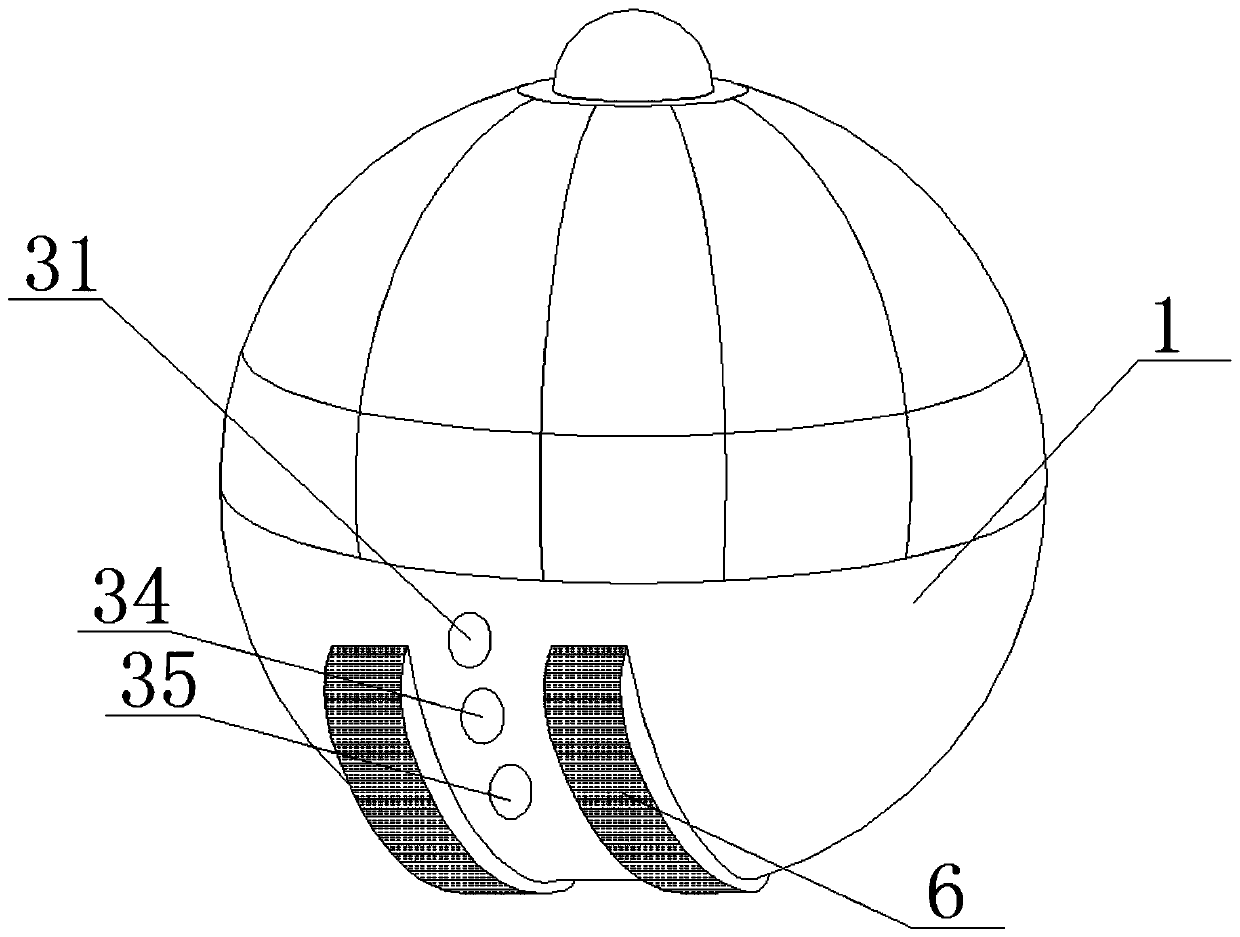

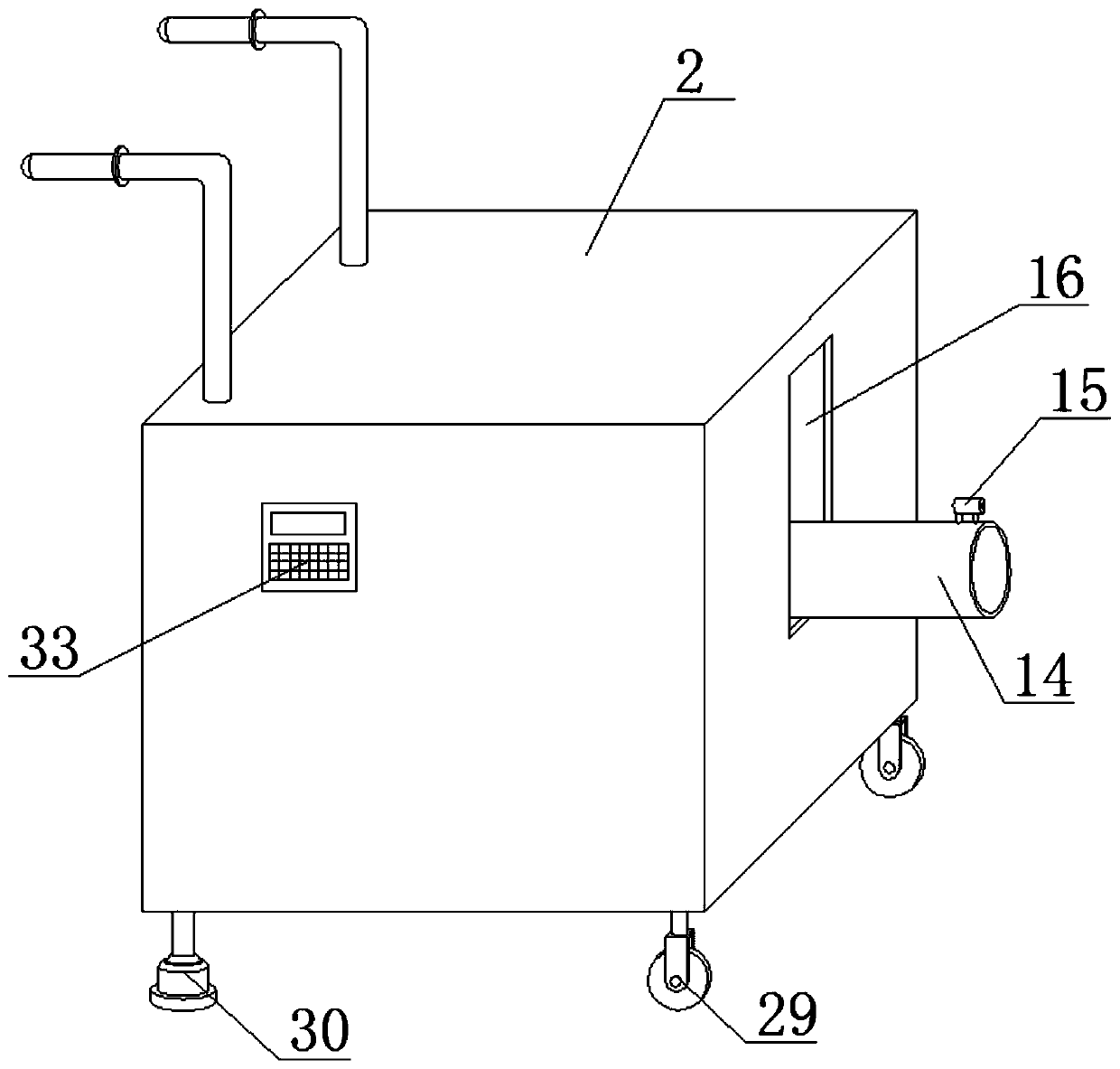

An automatic fire monitor

ActiveCN111197945BImprove fire extinguishing efficiencyImprove accuracyAmmunition projectilesFire rescueEngineeringStructural engineering

The present invention provides an automatic fire monitor, comprising a fire-extinguishing cannonball and a launching base. The fire-extinguishing cannonball includes a bottom shell and a plurality of petal-shaped blocking plates, and the bottoms of the plurality of petal-shaped blocking plates are sequentially mounted on a rotating shaft through a rotating shaft. On the outer side of the top of the bottom case, the bottom of the bottom case is fixedly inlaid with a bottom frame, and the bottom frame is installed with a crawler assembly, a battery 1 and a processor 1, and an electric motor is fixed on the inner side wall of the bottom of the bottom case. Push rod 1, a limit seat is fixedly installed on the output shaft of the electric push rod 1, a limit block is fixedly installed on the top of the petal-shaped blocking plate, and a position corresponding to the limit block is provided at the bottom of the limit seat A limit slot, the limit block is located in the limit slot, the automatic fire monitor has a reasonable design, can automatically track the fire source, has high fire extinguishing efficiency, and can be reused.

Owner:邦威(山西)消防科技发展有限公司

Bark grafting method of apocarya

Owner:南京绿宙薄壳山核桃科技有限公司 +1

Automatic fire monitor

ActiveCN111197945AImprove fire extinguishing efficiencyImprove accuracyAmmunition projectilesFire rescueStructural engineeringMechanical engineering

The invention provides an automatic fire monitor. The fire monitor comprises a fire extinguishing cannonball and an emission base. The fire extinguishing cannonball comprises a bottom shell and multiple petal-shaped blocking plates, the bottoms of the petal-shaped blocking plates are sequentially mounted on the outer side of the top of the bottom shell through a rotating shaft, a bottom frame is fixedly embedded on the bottom of the bottom shell, a crawler assembly, a first storage battery and a first processor are mounted in the bottom frame, a first electric push rod is fixedly mounted on the inner side wall of the bottom of the bottom shell, a limiting base is fixedly mounted on an output shaft of the first electric push rod, a limiting block is fixedly mounted on the top of each petal-shaped blocking plate, limiting grooves are formed in the positions, corresponding to the limiting blocks, of the bottom of the limiting base, and the limiting blocks are located in the limiting grooves. The automatic fire monitor is reasonable in design, can automatically trace a fire source, and is high in fire extinguishing efficiency and capable of being repeatedly used.

Owner:邦威(山西)消防科技发展有限公司

A method for grafting holly with Dabie Mountains as rootstock

The invention provides a method for grafting Ilex sp. by taking Ilex dabieshanensis as a stock. The method comprises the following steps: performing ingraftment scion on the Ilex dabieshanensis serving as the stock and an Ilex sp. new variety serving as a scion by means of a cut grafting method; and performing layered alignment on the Ilex dabieshanensis and the Ilex sp. to graft successfully. Through adoption of the method, the adaptability of the Ilex sp. new variety is improved, the stock is readily-available, the cost is low, the propagation coefficient is increased, the yielding capacity is increased, and scale production of the Ilex sp. new variety becomes possible.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

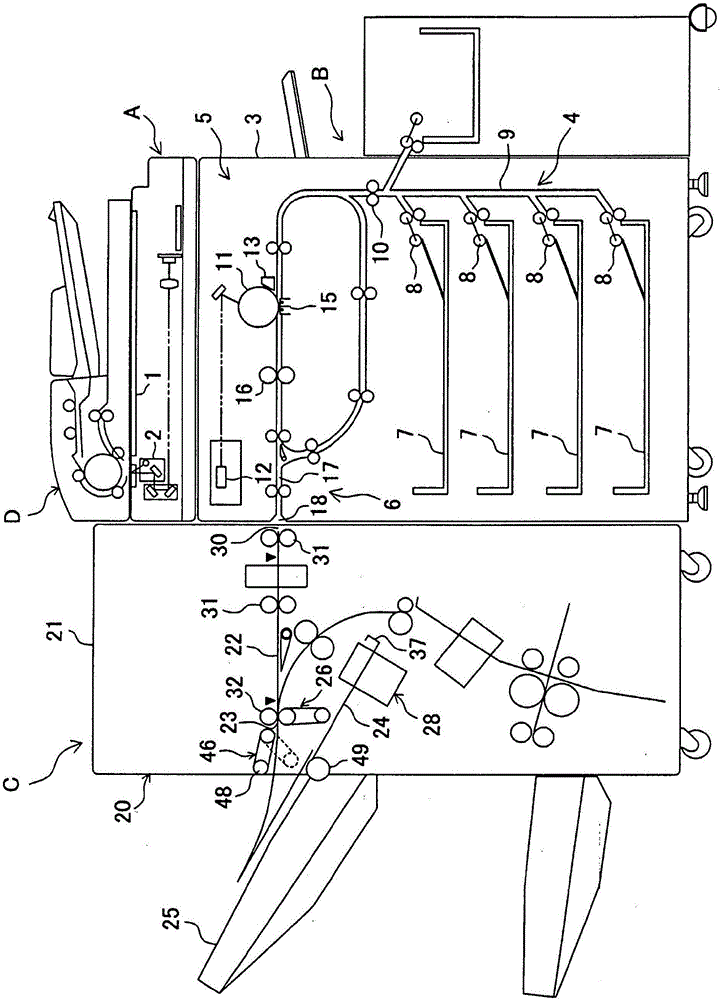

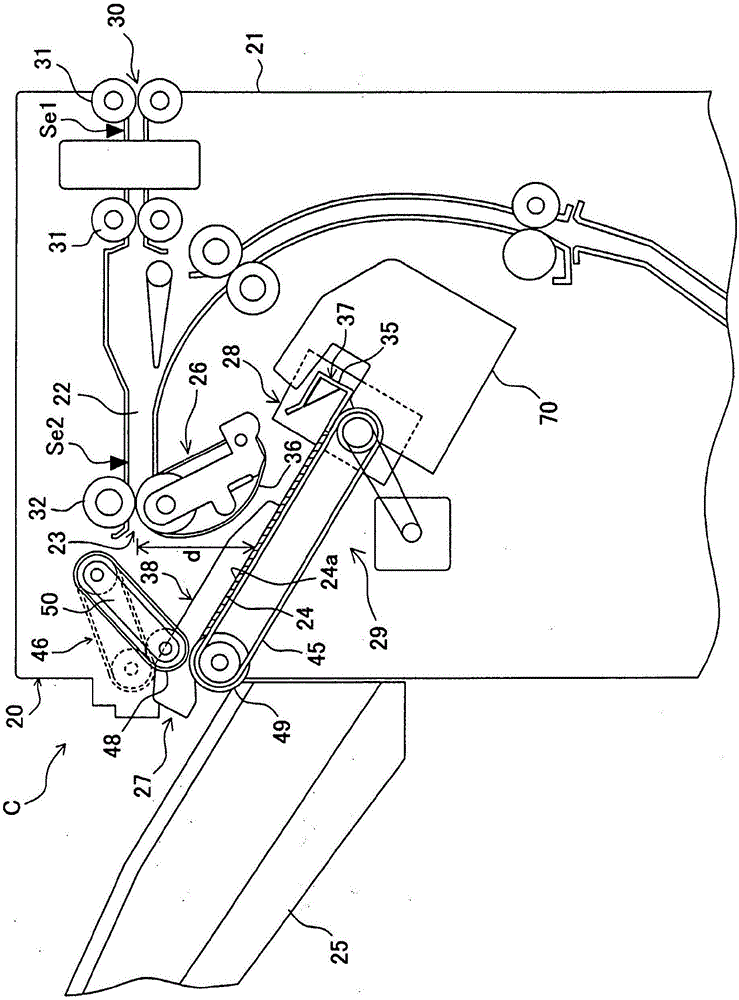

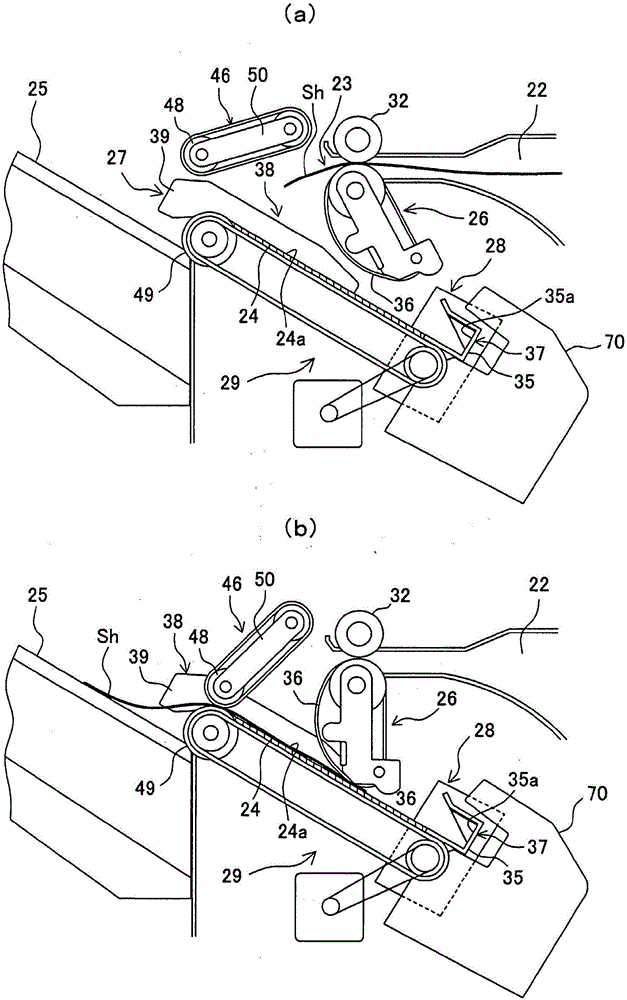

Sheet Bundle Binding Device And Image Forming System Having The Same

InactiveCN106560437AStrong binding forceEasy to removeElectrographic process apparatusPile receiversSheet material

The present invention is to provide a sheet bundle binding device capable of easily removing some sheets from a sheet bundle that has been subjected to staple-free binding. A corner Sc of a first sheet bundle Sb1 which is accumulated on a processing tray is subjected to proper binding by using a staple needle by a staple binding unit 70. Then, a corner of a second sheet bundle Sb2 obtained by accumulating additional sheets on the first sheet bundle is pressed and deformed between crimping toothed parts of a staple-free binding unit to temporarily bind the second sheet bundle. Thus, the additional sheets can easily be removed from the second sheet bundle.

Owner:COPYER

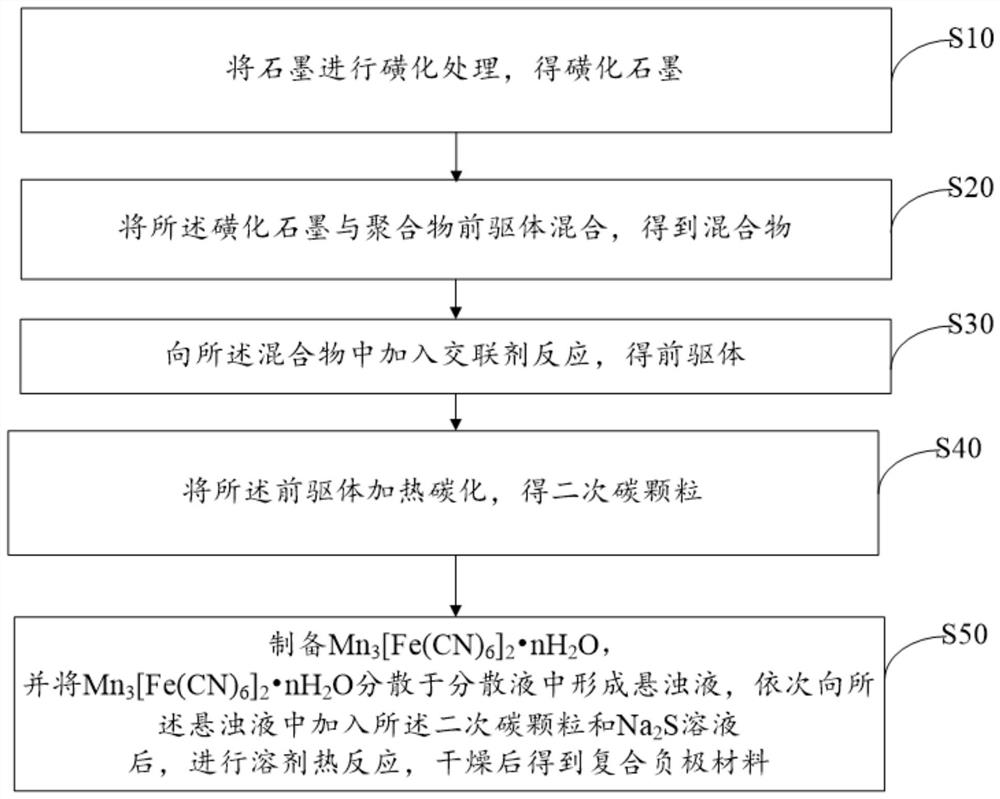

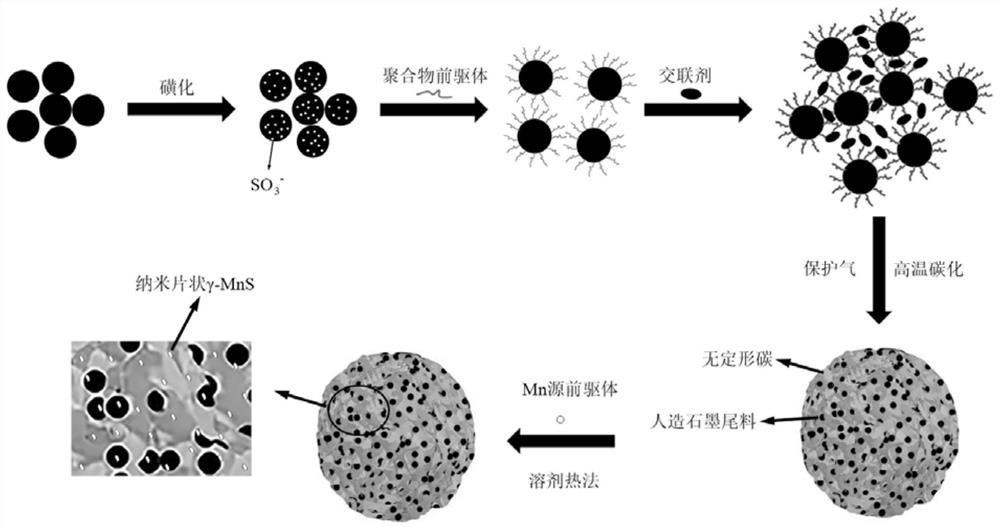

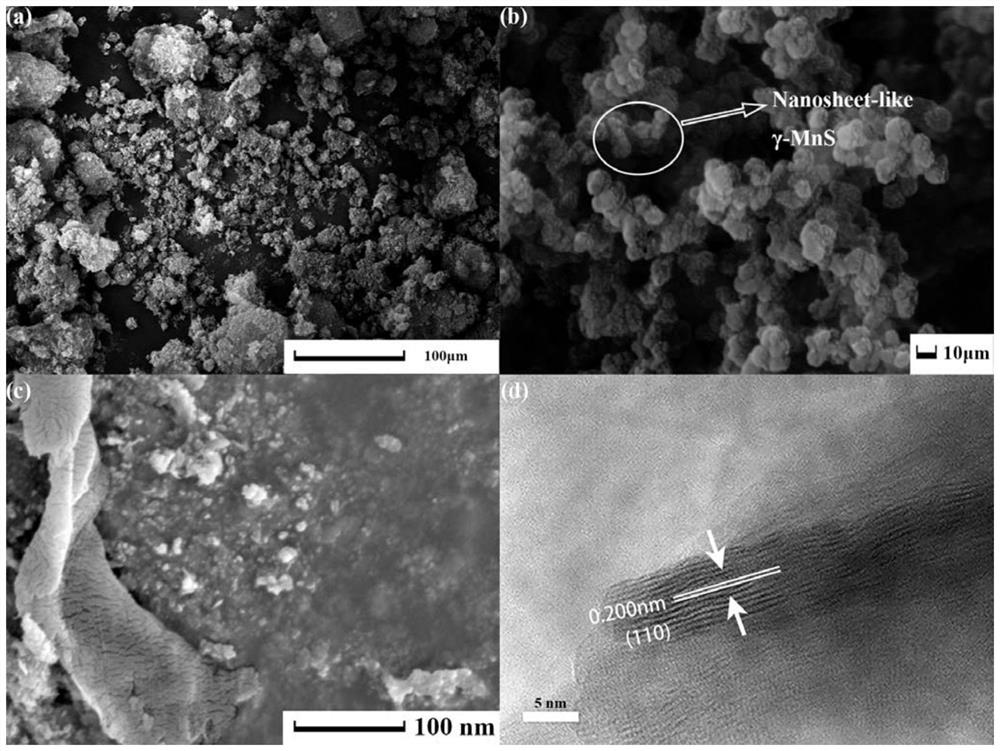

Composite negative electrode material, preparation method thereof, battery negative electrode and lithium ion battery

PendingCN114792803ALarge particle sizeGraphite with a particle size of less than 2 μm increases in particle size through compoundingMaterial nanotechnologyNegative electrodesElectrical batteryGraphite

The invention discloses a composite negative electrode material, a preparation method thereof, a battery negative electrode and a lithium ion battery, and relates to the technical field of battery materials. The composite negative electrode material comprises secondary carbon particles and gamma-MnS loaded on the secondary carbon particles, the secondary carbon particles comprise amorphous carbon and graphite, the particle size of the graphite is less than 2 microns, and the particle size of the secondary carbon particles is 10-50 microns. According to the composite negative electrode material provided by the invention, the particle size of the composite negative electrode material is increased, so that the particle size of the composite negative electrode material is uniform, the doping structure is stable, graphite is not easy to peel off in charge and discharge cycles when the composite negative electrode material is prepared into a battery negative electrode, and in addition, gamma-MnS is loaded on the surfaces of secondary carbon particles, so that the specific capacity of the composite negative electrode material is greatly improved; the contact area between the gamma-MnS and the electrolyte and the conductive substrate is increased, so that the Li < + > ion transmission coefficient is increased, the lithium removal and lithium insertion capabilities of the composite negative electrode material are stronger, the material is not easy to pulverize, and the cycle performance is better.

Owner:贝特瑞(江苏)新能源材料有限公司

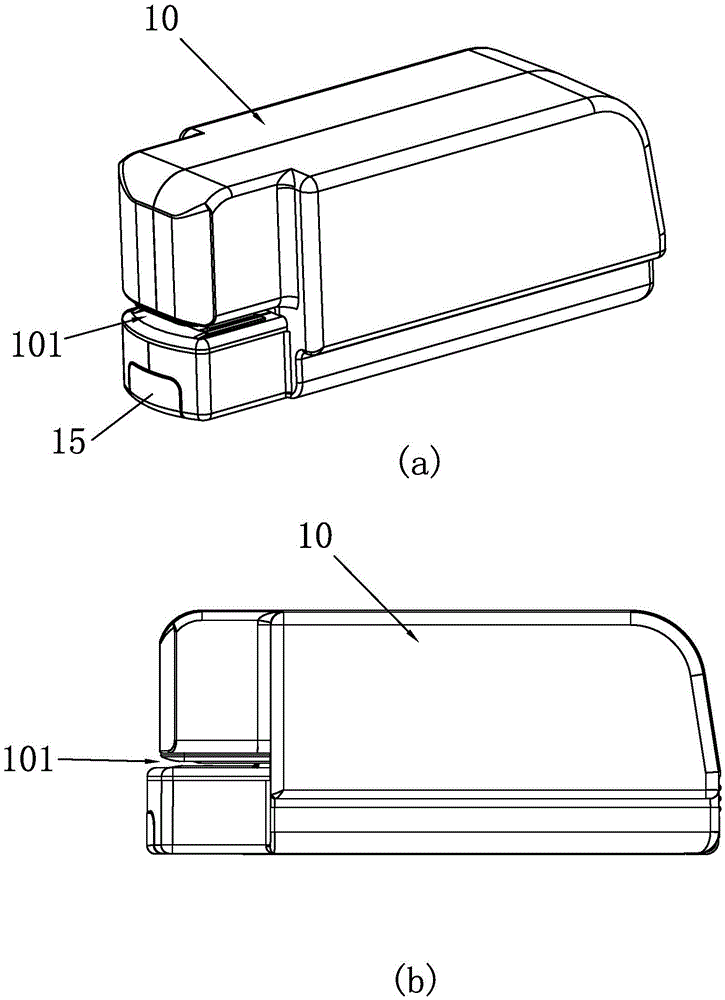

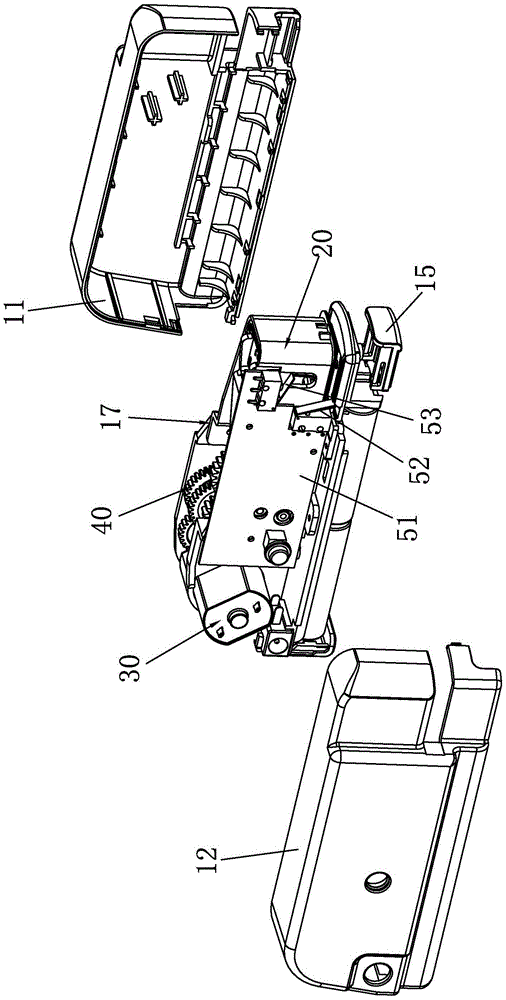

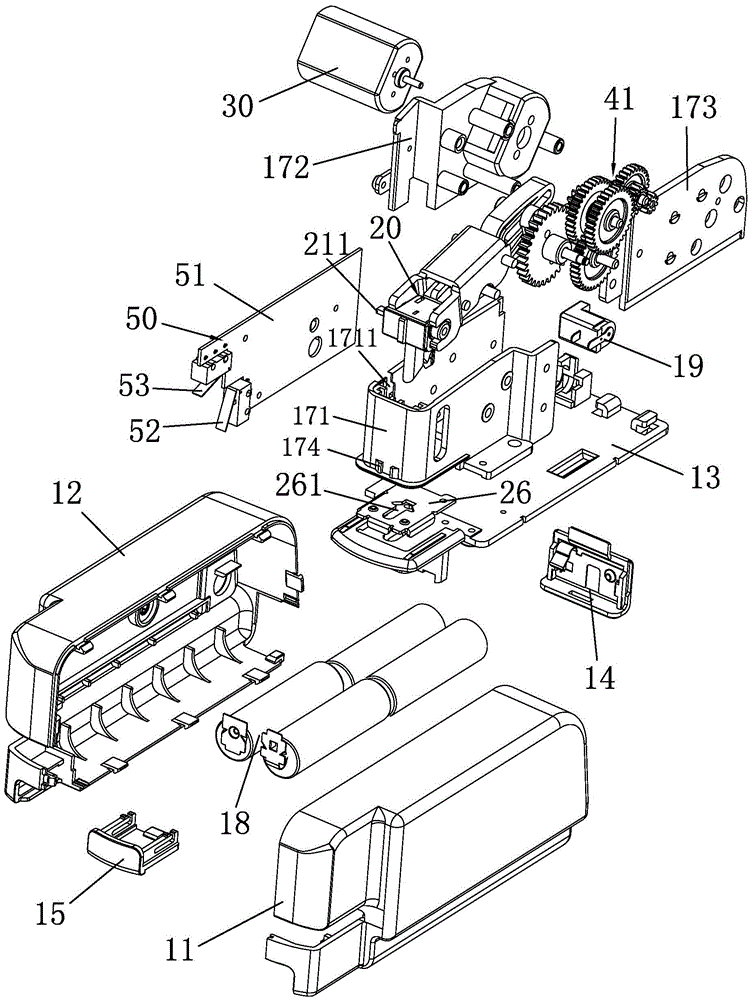

Fully automatic electric needle-free environmental paper stapler

ActiveCN104085221BRealize fully automatic binding operationEasy to useSheet bindingEnvironmental resistanceAutomatic control

The invention discloses a full-automatic electric needle-free environmental-friendly paper stapler, which comprises a shell and a needleless paper stapling assembly installed in the shell. A binding port is opened on the shell, and the needleless paper stapling assembly is set corresponding to the position of the binding port; The needleless paper stapling assembly is provided with a power supply, a motor, a mechanical transmission assembly driven between the motor and the needleless paper stapling assembly, an automatic control assembly for controlling the opening and closing of the motor, and a bracket for arranging the motor and the mechanical transmission assembly; The paper to be bound is inserted into the binding port to touch the start switch, and the power is turned on to start the motor to run. The motor drives the needleless paper binding assembly through the mechanical transmission component to bind the multi-part paper together; thus, the fully automatic paper binding is realized. , replacing the laborious operation mode of manual pressing in the traditional technology; especially, the mechanical transmission assembly of the present invention utilizes the cooperation of two rotating rods and the cam to achieve a large conversion of the output energy of the motor, and its overall volume is small and the stroke Large, and its action is smooth and reliable.

Owner:DONGGUAN YATSUKA YIZHIMEI METAL & PLASTIC

Preparation method and application of a kind of total nutrient degradable straw seedling raising matrix block

ActiveCN110692489BSolve pollutionQuality improvementAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiotechnologyFiber

The invention provides a preparation method and application of a full-nutrition degradable straw seedling raising matrix block. The preparation steps of the matrix block are as follows: 1) the straw is compounded with an active microbial agent and then fermented to obtain plastic silky straw fibers; The nutrient-releasing conditioner is loaded on the carbonized rice husk, air-dried and pulverized to obtain a nutrient-controllable slow-release conditioner carrier; 3) Mix hydrolyzed protein, water, paraformaldehyde, urea, polyvinyl alcohol, and nano-scale functional materials to prepare functional High molecular degradable polymer; 4) Mix plastic silky straw fiber, nutrient-controllable slow-release conditioner carrier, vermiculite, and water, then pulverize, homogenize, and absorb under negative pressure to obtain a straw seedling-raising matrix block, and spray it around The degradable functional macromolecule polymer obtains the matrix block of total nutrition and degradable straw seedling raising; the matrix block can be applied to the dry seedling raising of rice, as well as the seedling raising of landscape grass seeds, cotton, melons and fruits, vegetables, and rapeseed.

Owner:JIANGSU ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com