Preparation method of AAO photonic crystal based high-temperature-resistant ternary nano composite heat-absorbing coating

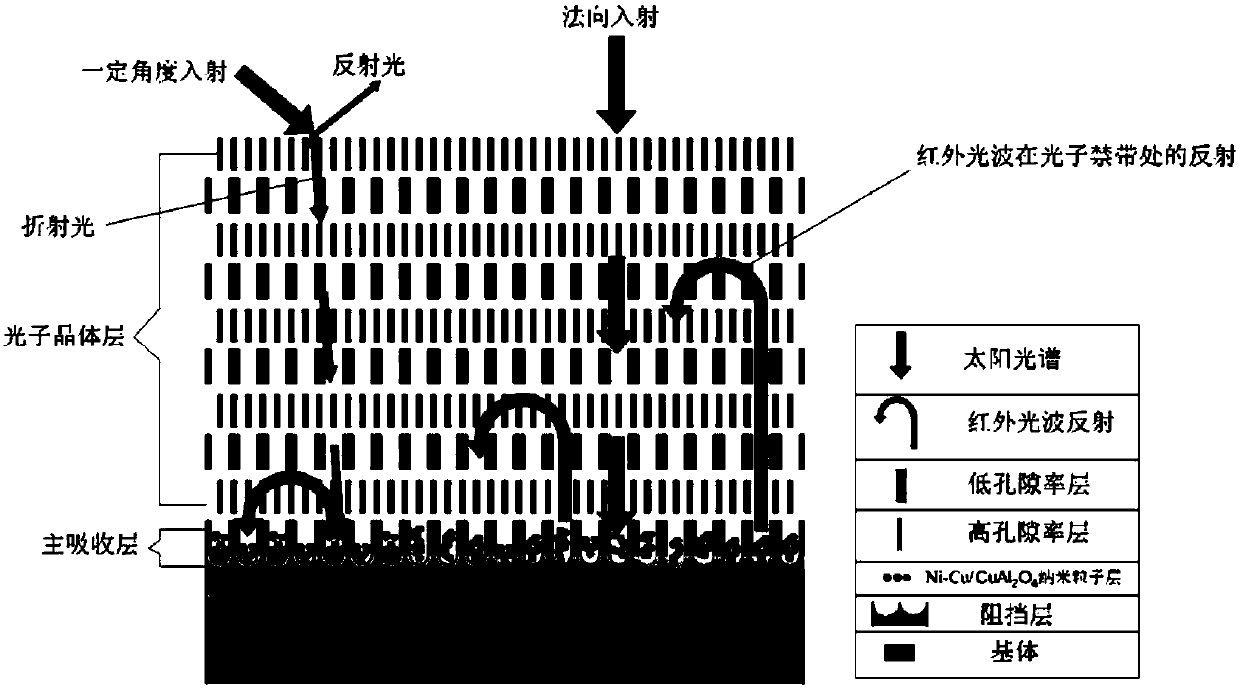

A photonic crystal and nano-composite technology, applied in anodic oxidation and other directions, can solve the problems of low solar spectral absorptivity, infrared emissivity, high-temperature thermal stability, etc., and achieve high-temperature resistance, wide material sources, and strong coating adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Pretreatment of the aluminum alloy sample: put the aluminum alloy sample in 45g / L NaOH, 1g / LC at a temperature of 70°C 12 h 25 SO 4 Alkaline etching in a mixed solution of Na for 3 minutes. Rinse the sample after alkali etching with water and put it in 10% H 2 SO 4 , 4% HNO 3 Pickling in the mixed solution for 4 minutes, the acid-treated test piece was rinsed with ultrapure water, and then the AAO photonic crystal was prepared.

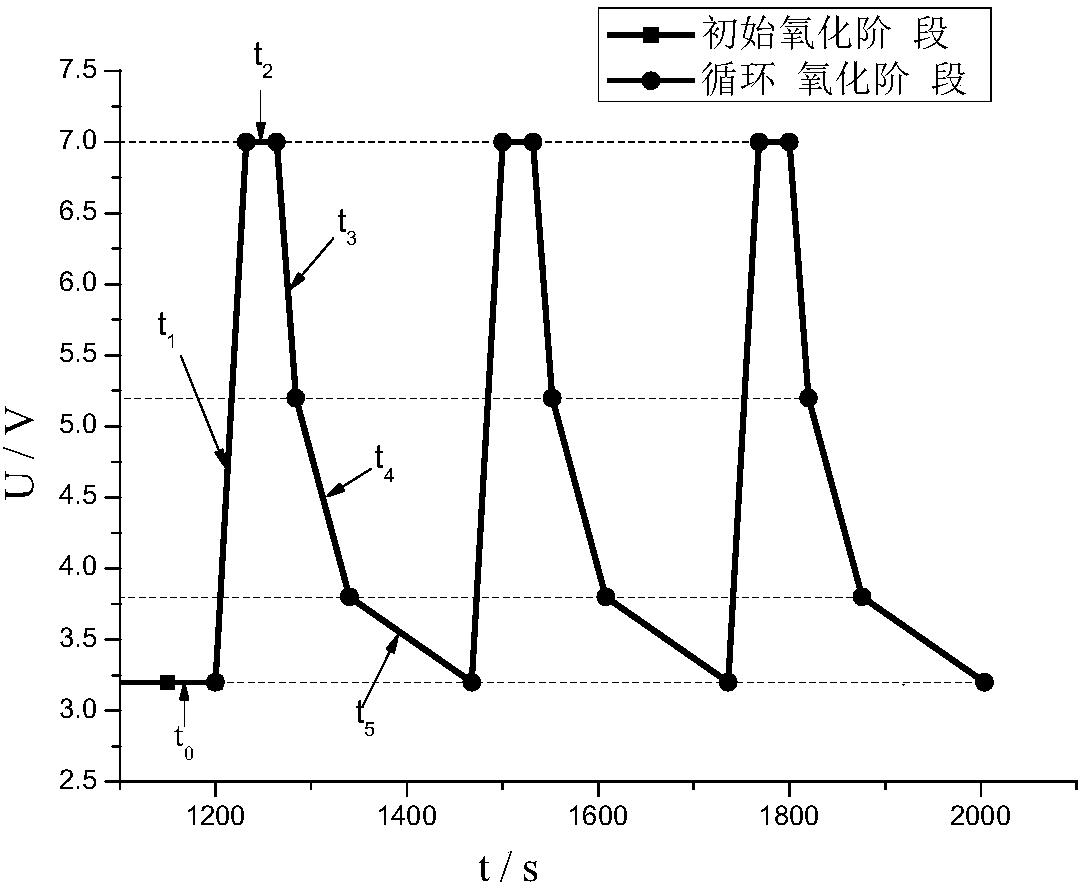

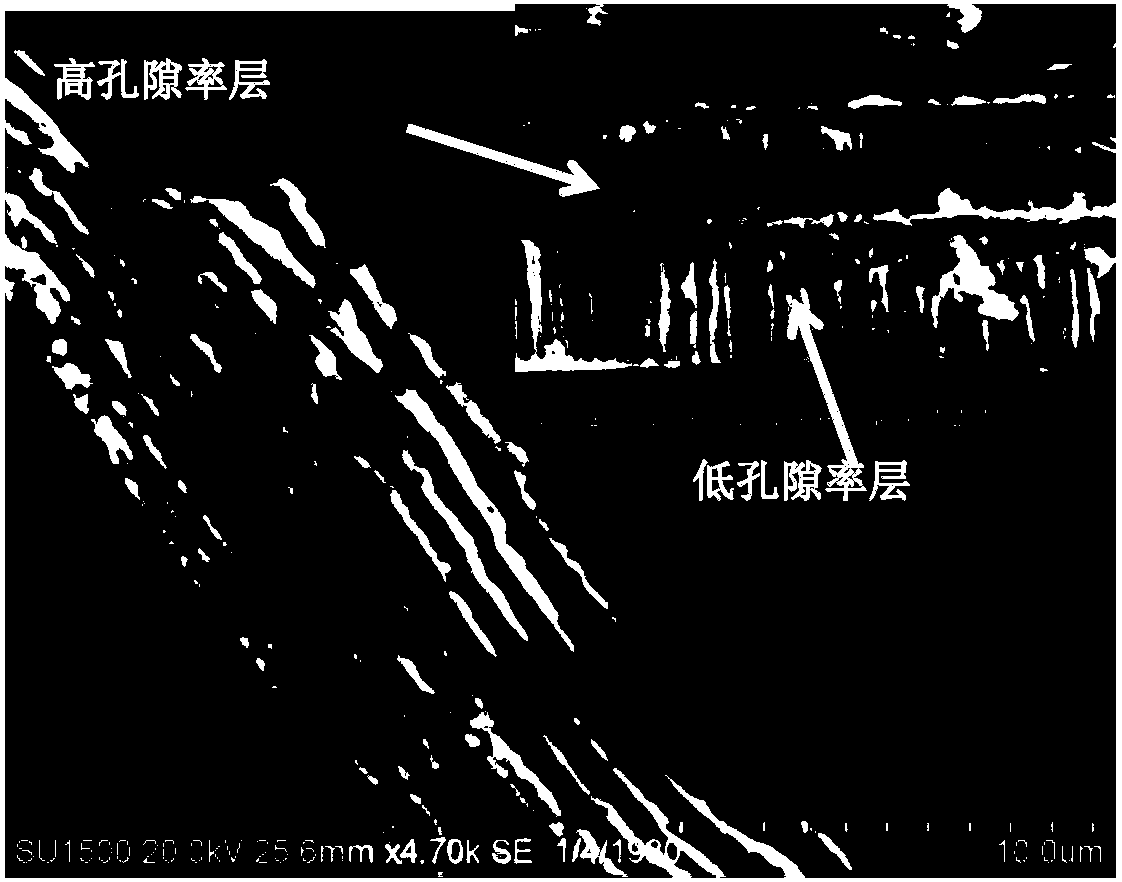

[0028] (2) Preparation of AAO photonic crystal: put the aluminum alloy sample into 2 SO 4 , Do periodic variable voltage oxidation in the electrolyte, and the cathode plate is made of high-purity lead plate. The voltage change in each cycle is mainly divided into 5 stages, and the corresponding time parameters are: t 1 =32s,t 2 =32s,t 3 = 20s, t 4 =56s,t 5 = 128s; t 0 =300s is the initial oxidation period, and the voltage at the initial stage plays a certain role in compensating for the drift of the photon forbidden band in the...

Embodiment 2

[0034] (1) Pretreatment of the aluminum alloy sample: put the aluminum alloy sample in 45g / L NaOH, 1g / LC at a temperature of 70°C 12 h 25 SO 4 Alkaline etching in a mixed solution of Na for 3 minutes. Rinse the sample after alkali etching with water and put it in 10% H 2 SO 4 , 4% HNO 3 Pickling in the mixed solution for 4 minutes, the acid-treated test piece was rinsed with ultrapure water, and then the AAO photonic crystal was prepared.

[0035] (2) Preparation of AAO photonic crystal: put the aluminum alloy sample into the 2 SO 4 , Do periodic variable voltage oxidation in the electrolyte, and the cathode plate is made of high-purity lead plate. The voltage change in each cycle is mainly divided into 5 stages, and the corresponding time parameters are: t 1 = 36s, t 2 =32s,t 3 = 25s, t 4 =70s;t 0 =800s is the initial oxidation stage voltage, and the initial stage voltage plays a certain role in compensating for the drift of the photonic band gap in the subsequent...

Embodiment 3

[0040] (1) Pretreatment of the aluminum alloy sample: put the aluminum alloy sample in 45g / L NaOH, 1g / LC at a temperature of 70°C 12 h 25 SO 4 Alkaline etching in a mixed solution of Na for 3 minutes. Rinse the sample after alkali etching with water and put it in 10% H 2 SO 4 , 4% HNO 3 Pickling in the mixed solution for 4 minutes, the acid-treated test piece was rinsed with ultrapure water, and then the AAO photonic crystal was prepared.

[0041] (2) Preparation of AAO photonic crystal: put the aluminum alloy sample into 2 SO 4 , Do periodic variable voltage oxidation in the electrolyte, and the cathode plate is made of high-purity lead plate. The voltage change in each cycle is mainly divided into 5 stages, and the corresponding time parameters are: t 1 = 40s, t 2 = 36s, t 3 = 25s, t 4 =70s,t 5 = 128s; t 0 =2400s is the initial oxidation period, and the voltage in the initial period plays a certain role in compensating for the drift of the photonic band gap in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com