Glass-magnesium grain cored wire and production technology of steel for high heat input welding

A large heat input welding and production process technology, applied in the production process of steel for large heat input welding, glass-magnesium grain cored wire field, can solve the difficult Mg content, the adjustment of the timing of adding Mg, and the inability to fully realize Mg alone control , low temperature toughness, low alloy and high strength, etc., to achieve high effect and utilization rate, refine HAZ structure, and improve low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

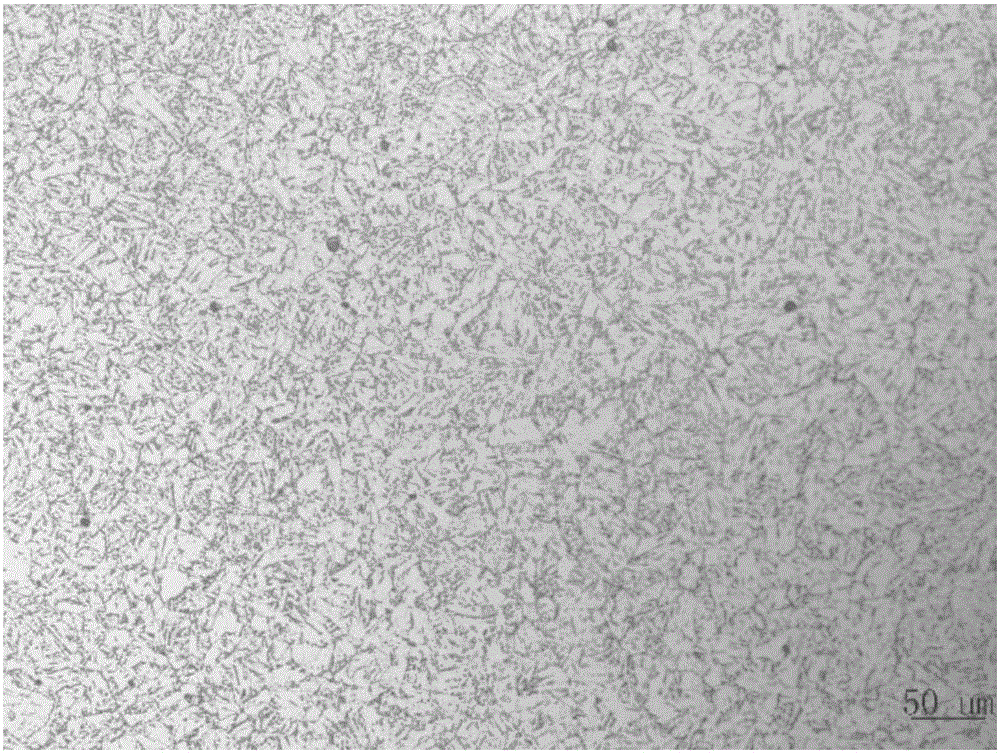

Embodiment 1

[0032] A glass-magnesium particle cored wire with a diameter of 13mm, the cored wire includes an outer layer and a core; the outer layer is low carbon steel 08Al with a thickness of 1.0mm; The core includes a slow-release agent and passivated magnesium particles, the slow-release agent is glass shavings, the slow-release agent accounts for 75% of the core content, and the passivated magnesium particles account for 25% of the core content. Passivated magnesium grains contain 92% magnesium, and the rest are passivating agents and unavoidable impurities.

[0033] The chemical composition and mass percentage range of slow-release agent glass shavings are as follows: SiO 2 : 72%, Al 2 o 3 : 2%, CaO: 8.5%, MgO: 3%, Na 2 O+K 2 O: 13.5%, and the balance is unavoidable impurities.

[0034] The particle size of passivated magnesium particles is 0.5-3 mm, and the proportion of particle size ≤ 80 mesh is 4%.

[0035] Bulk density of core-coated slow-release passivated magnesium part...

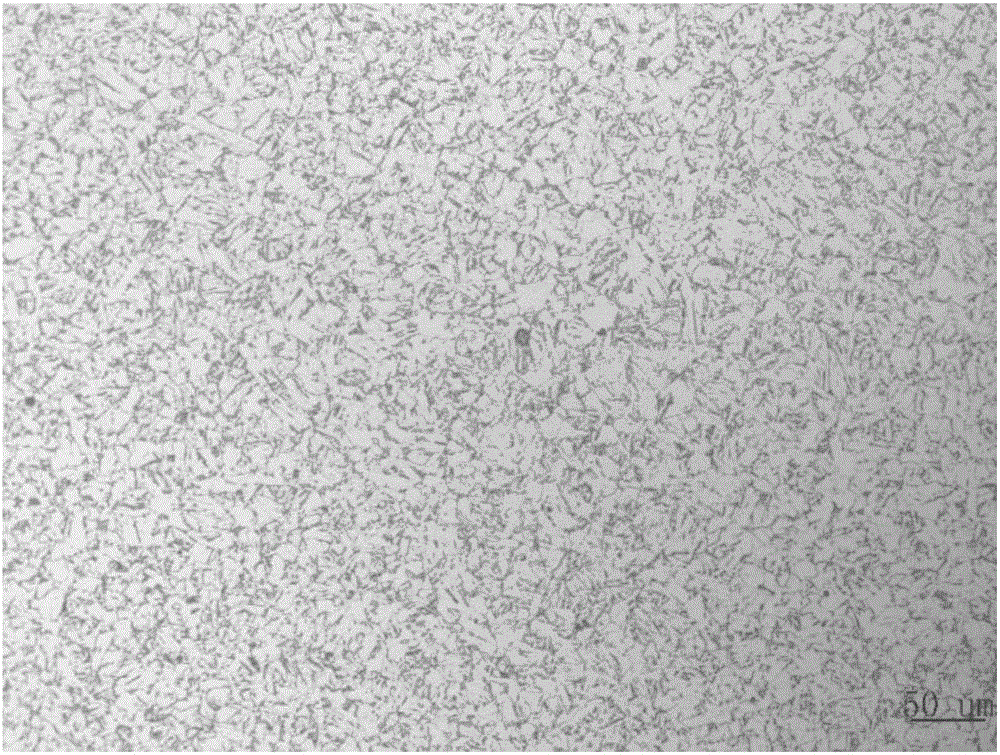

Embodiment 2

[0044] A glass-magnesium particle cored wire with a diameter of 12mm, the cored wire includes an outer layer and a core; the outer layer is low carbon steel 08Al with a thickness of 1.0mm; The core includes a slow-release agent and passivated magnesium particles, the slow-release agent is glass shavings, the slow-release agent accounts for 75% of the core content, and the passivated magnesium particles account for 25% of the core content. Passivated magnesium grains contain 93% magnesium, and the rest are passivating agents and unavoidable impurities.

[0045] The chemical composition and mass percentage range of slow-release agent glass shavings are as follows: SiO 2 : 71%, Al 2 o 3 : 2.5%, CaO: 10%, MgO: 2.5%, Na 2 O+K 2 O: 13%, and the balance is unavoidable impurities.

[0046] The particle size of passivated magnesium particles is 0.5-3 mm, and the proportion of particle size ≤ 80 mesh is 6%.

[0047] Bulk density of core-coated slow-release passivated magnesium par...

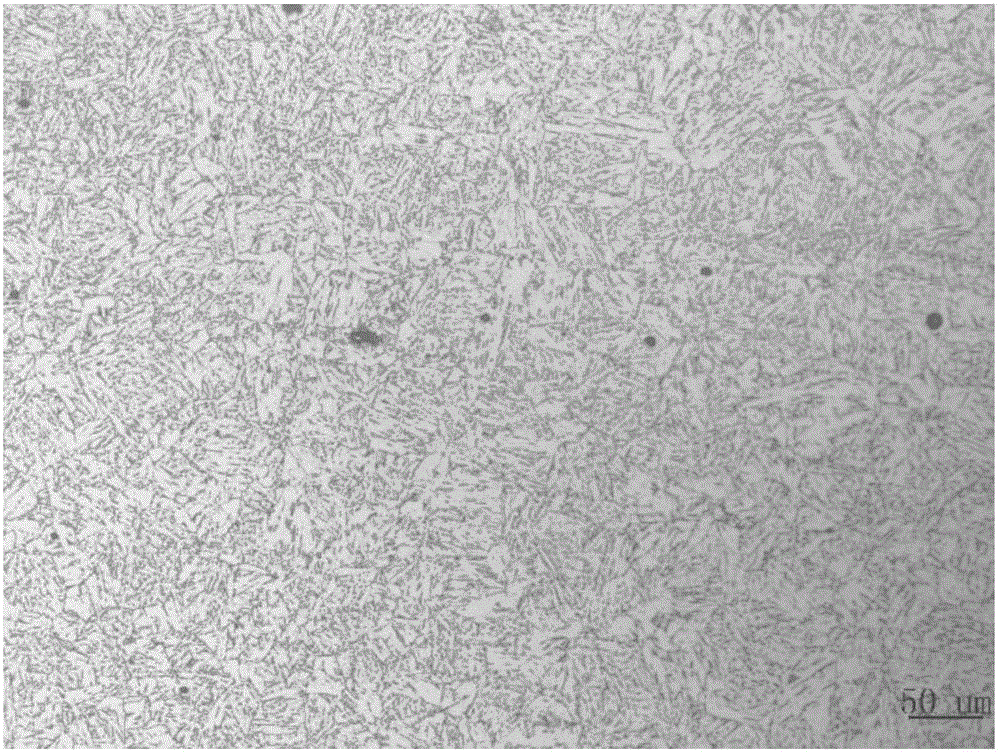

Embodiment 3

[0056] A glass-magnesium particle cored wire with a diameter of 11mm, the cored wire includes an outer layer and a core; the outer layer is low carbon steel 08Al, and the thickness is 1.0mm; The core includes a slow-release agent and passivated magnesium particles, the slow-release agent is glass shavings, the slow-release agent accounts for 75% of the core content, and the passivated magnesium particles account for 25% of the core content.

[0057] The chemical composition and mass percentage range of slow-release agent glass shavings are as follows: SiO 2 : 72%, Al 2 o 3 : 1.5%, CaO: 7%, MgO: 3.5%, Na 2 O+K 2 O: 15.5%, and the balance is unavoidable impurities.

[0058] The particle size of passivated magnesium particles is 0.5-3 mm, and the proportion of particle size ≤ 80 mesh is 4%.

[0059] Bulk density of core-coated slow-release passivated magnesium particles is 1.3g / cm 3 .

[0060] The production method of steel for high heat input welding using glass-magnesium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com