Patents

Literature

70results about How to "Applicable to actual production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

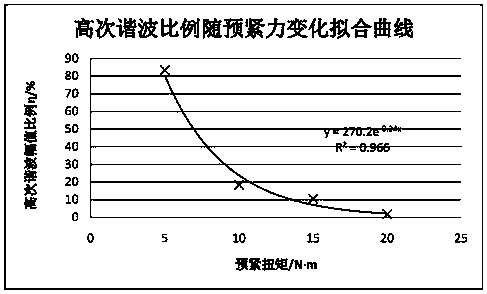

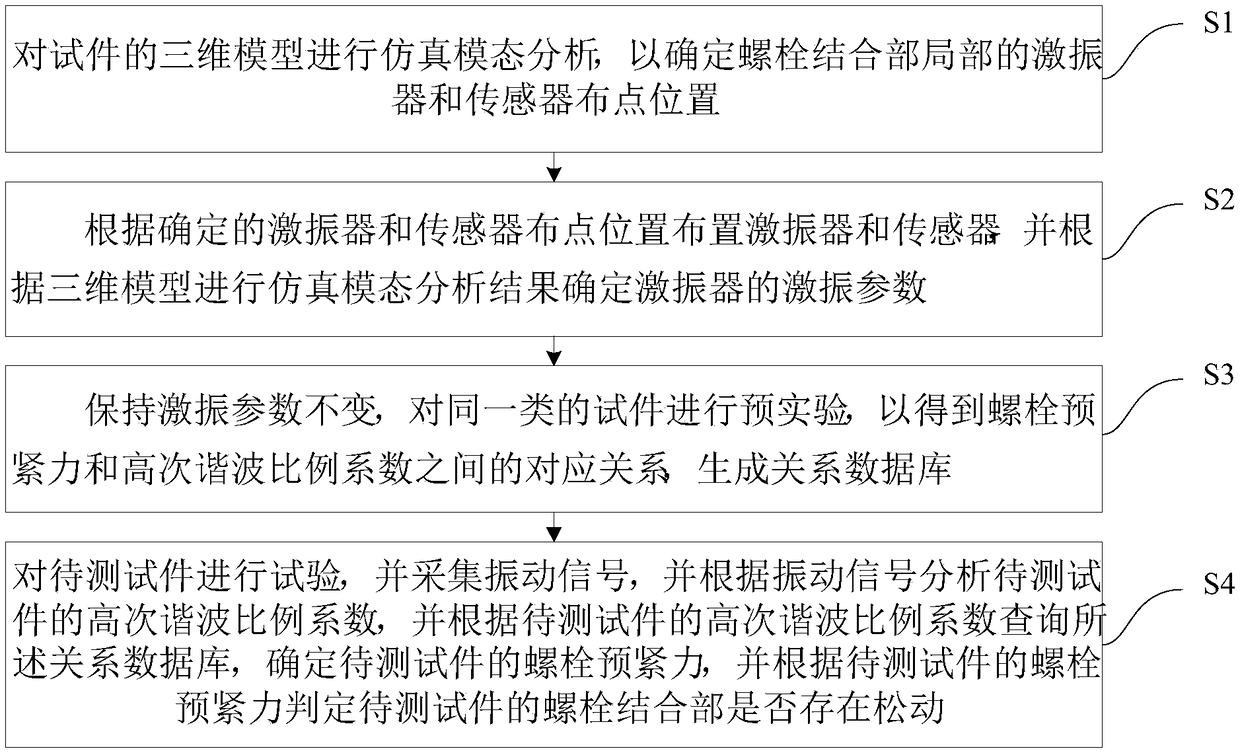

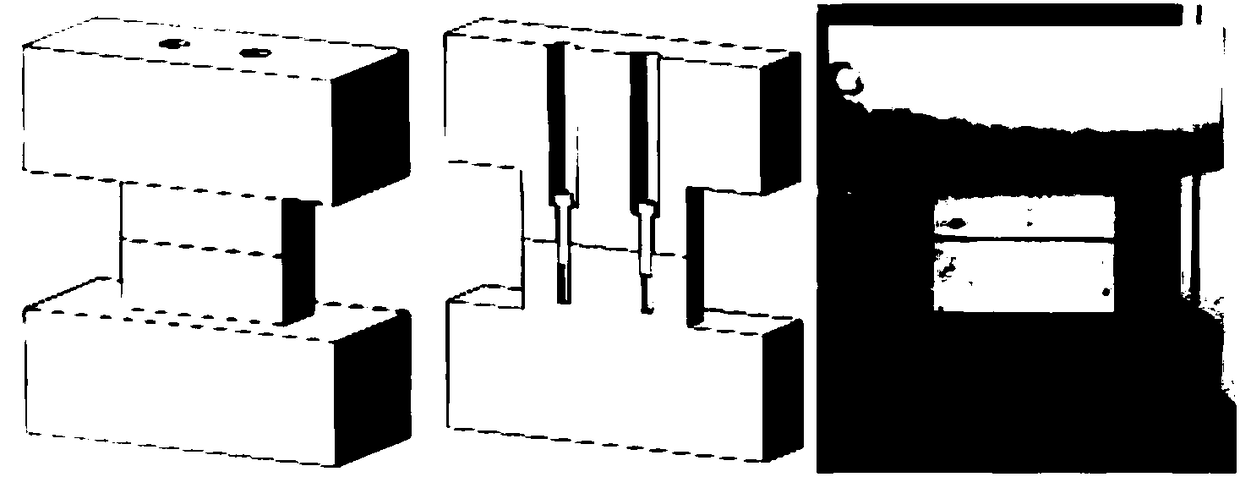

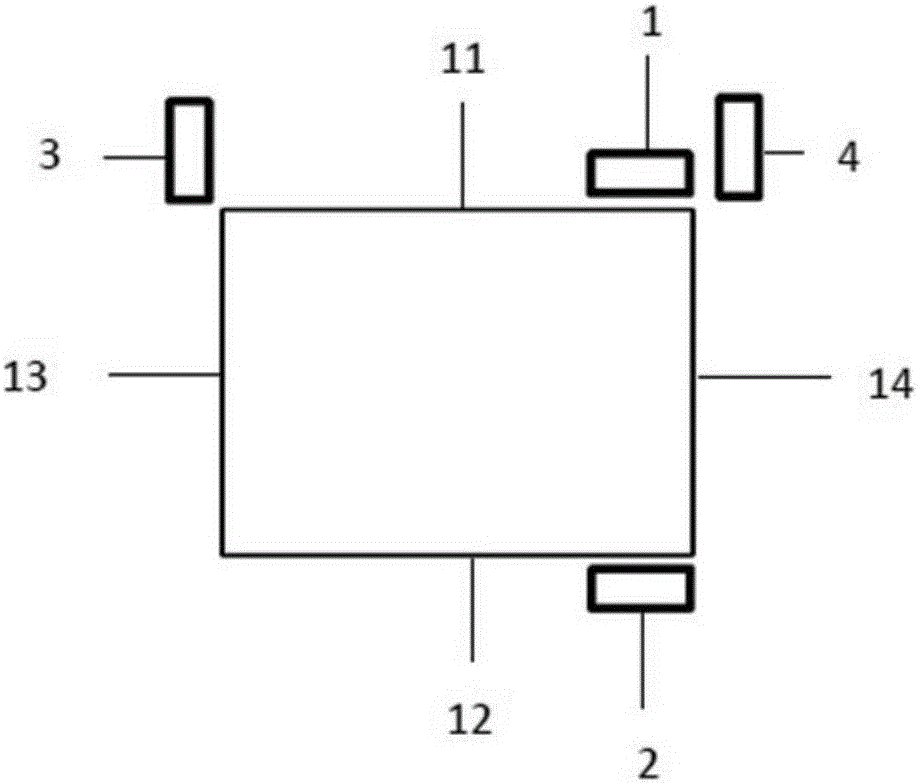

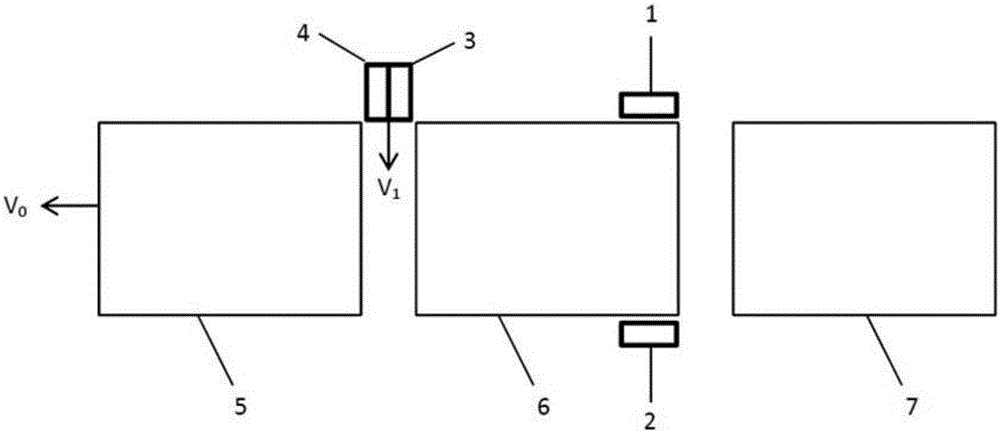

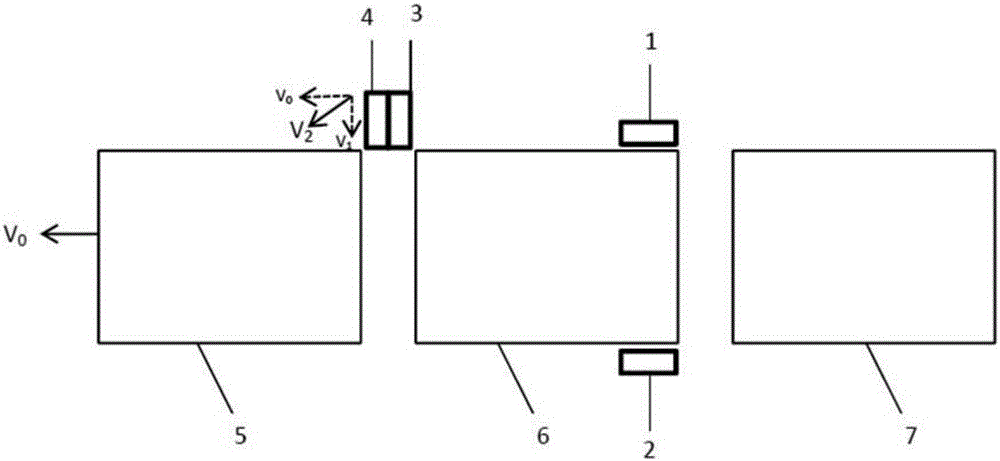

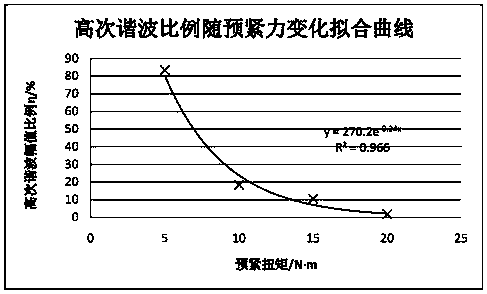

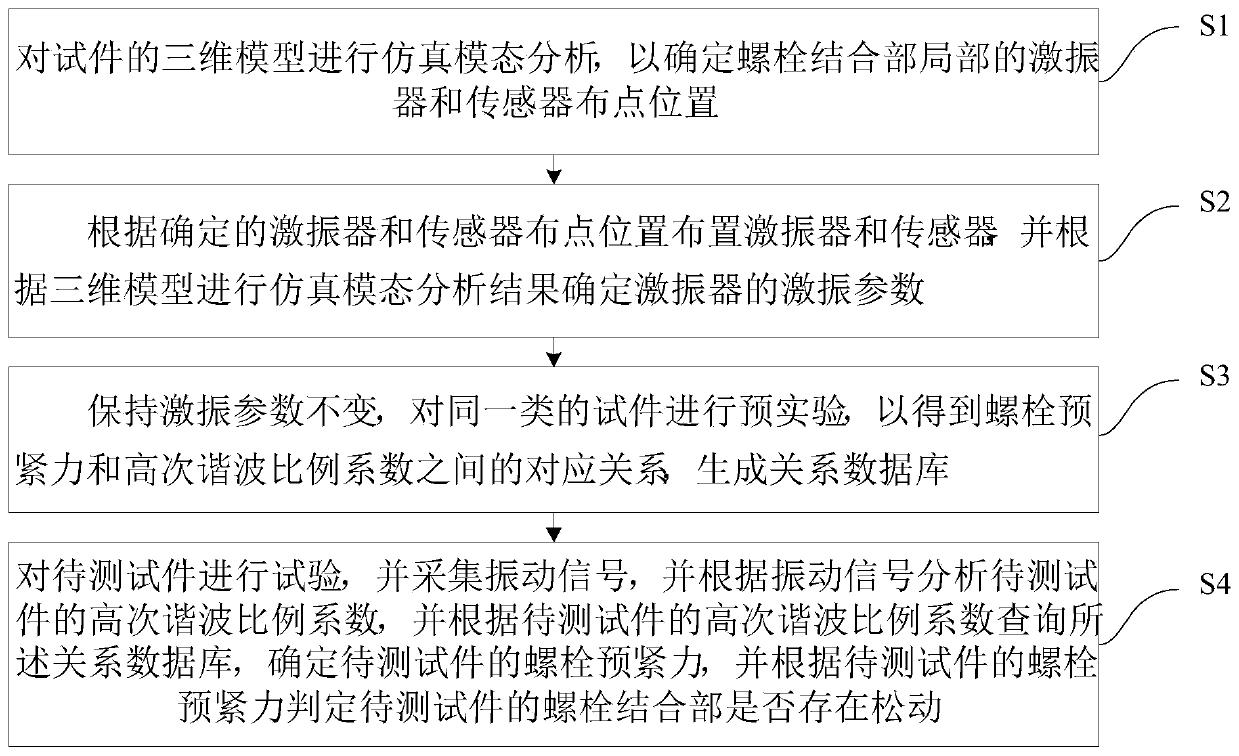

Bolt joint part looseness detecting method and system based on nonlinear shock excitation feature

The invention discloses a bolt joint part looseness detecting method and system based on a nonlinear shock excitation feature. The method comprises the following steps: carrying out simulated modal analysis on a three-dimensional model of a test piece, and determining the arrangement positions of a vibration exciter and a sensor of a local part of a bolt joint part; arranging the vibration exciterand the sensor according to the determined arrangement positions of the vibration exciter and the sensor, and determining a vibration excitement parameter of the vibrator exciter according to the simulated modal analysis result of the three-dimensional model; maintaining the vibration excitement parameter unchanged, carrying out preliminary experiment on the same kind of test pieces to obtain a corresponding relation between a bolt pretightening force and a high harmonic scaling factor, and generating a relation data base; and carrying out test on a test piece to be tested to obtain a high harmonic scaling factor, querying the relation data base, determining the bolt pretightening force of the test piece to be tested, and judging whether the bolt joint part of the test piece to be testedis loosen or not according to the bolt pretightening force of the test piece to be tested. The method has the advantages of wide applicability, flexibility and convenience in use, high sensitivity andthe like, implements nondestructive detection, and is suitable for actual production.

Owner:TSINGHUA UNIV

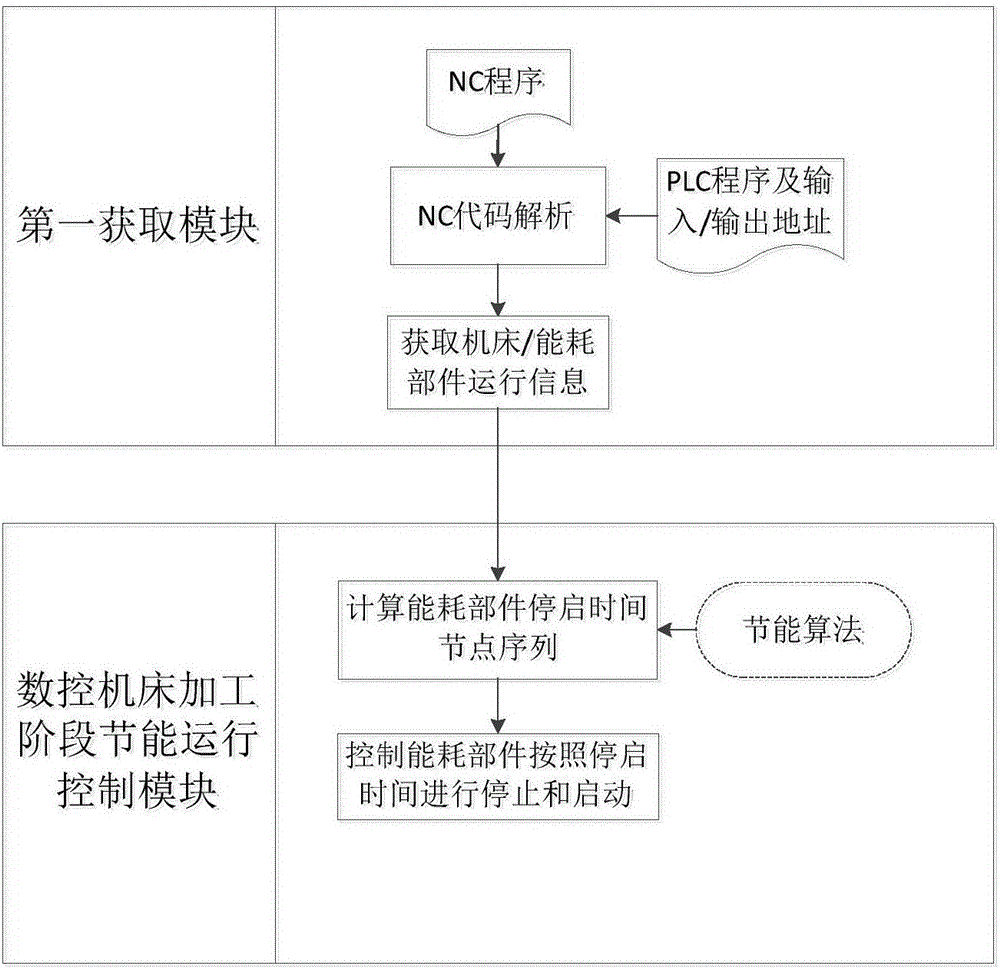

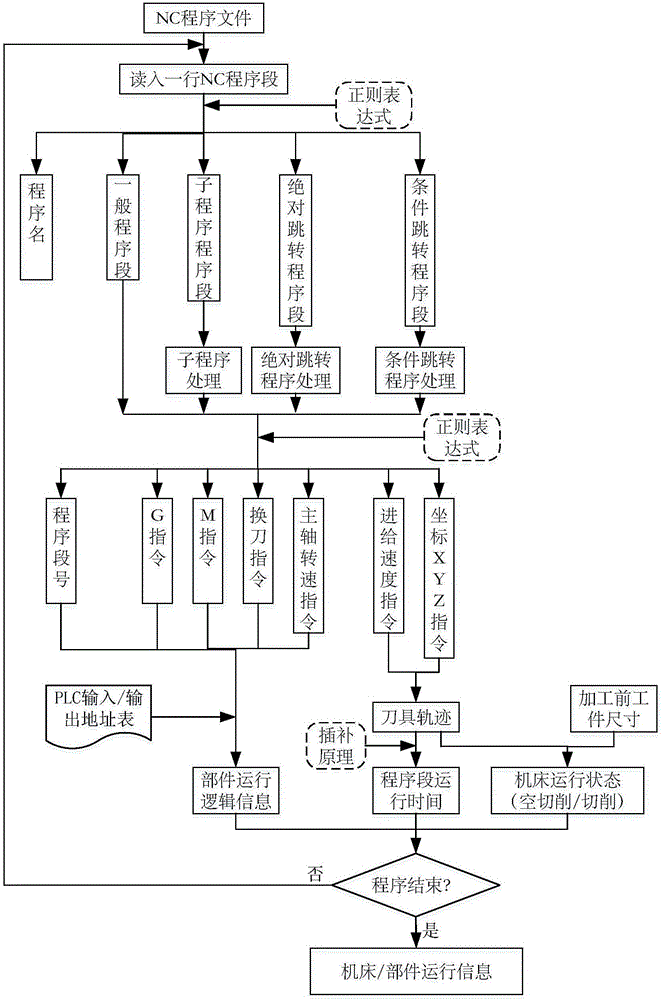

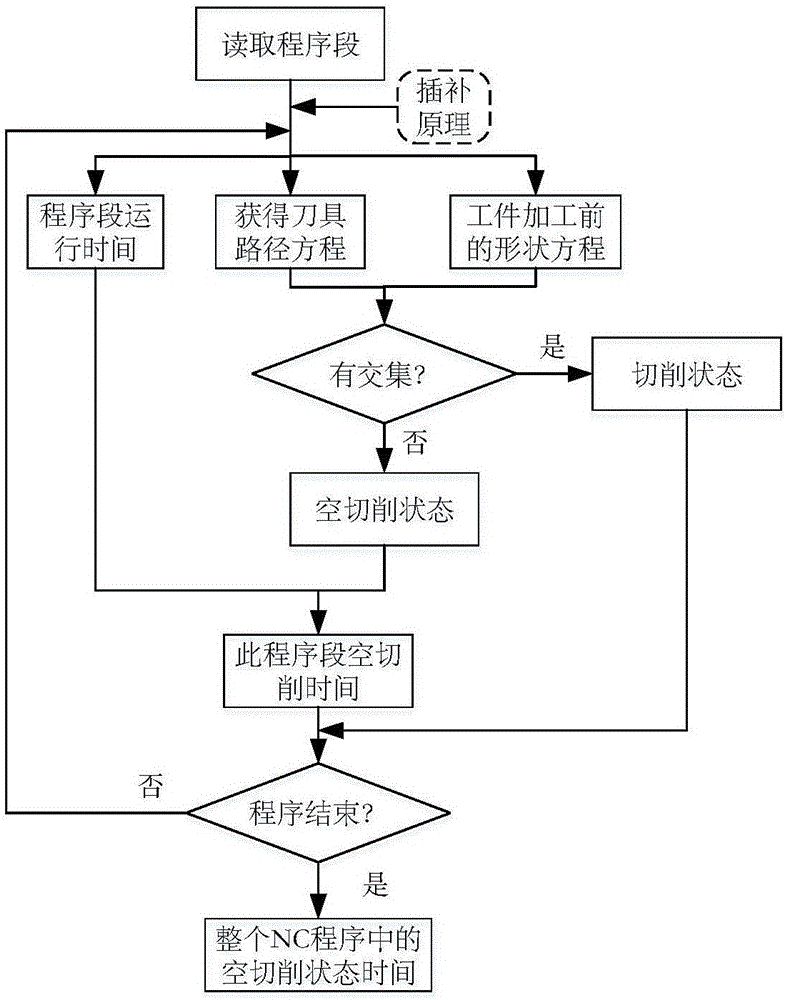

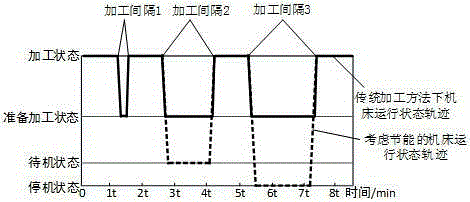

Numerical control machine tool processing stage energy conservation operation method, evaluation method, device and system

ActiveCN106249699AReduce energy consumption in idle cuttingImprove energy utilizationNumerical controlNumerical controlStart time

The invention discloses a numerical control machine tool processing stage energy conservation operation method, an evaluation method, a device and a system. Energy conservation of the numerical control machine tool in the processing stage is realized through stopping and starting an energy consumption part of the numerical control machine tool in an empty cutting state. The method comprises the following steps: operation information of the numerical control machine tool and parts is acquired based on NC code analysis, wherein the operation information of the numerical control machine tool and the parts is operation states of the numerical control machine tool and the parts and corresponding time periods, the operation state of the numerical control machine tool mainly refers to the operation state in the processing stage, and the time period corresponding to the empty cutting state is an energy conservation time period in need of energy conservation, the operation state of the parts of the numerical control machine tool mainly comprises the operation state of an energy consumption part controlled by a PLC; and as for each energy conservation time period, whether the sum of the stopping time and the starting time of the energy consumption part in each energy conservation time period is smaller than the energy conservation time period is judged, and if yes, the energy consumption part is controlled to be temporarily stopped in the corresponding energy conservation time period.

Owner:CHONGQING UNIV

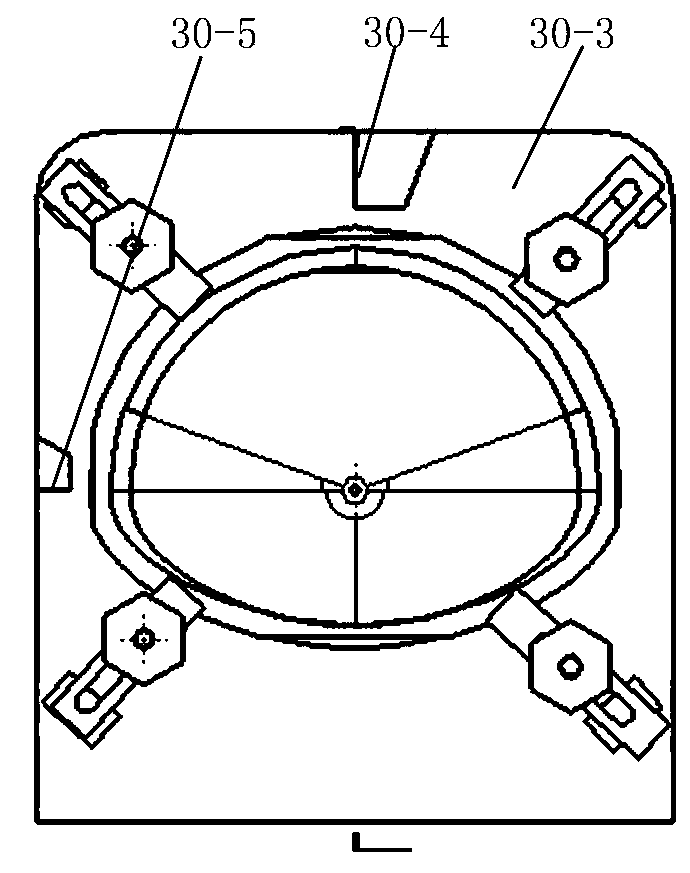

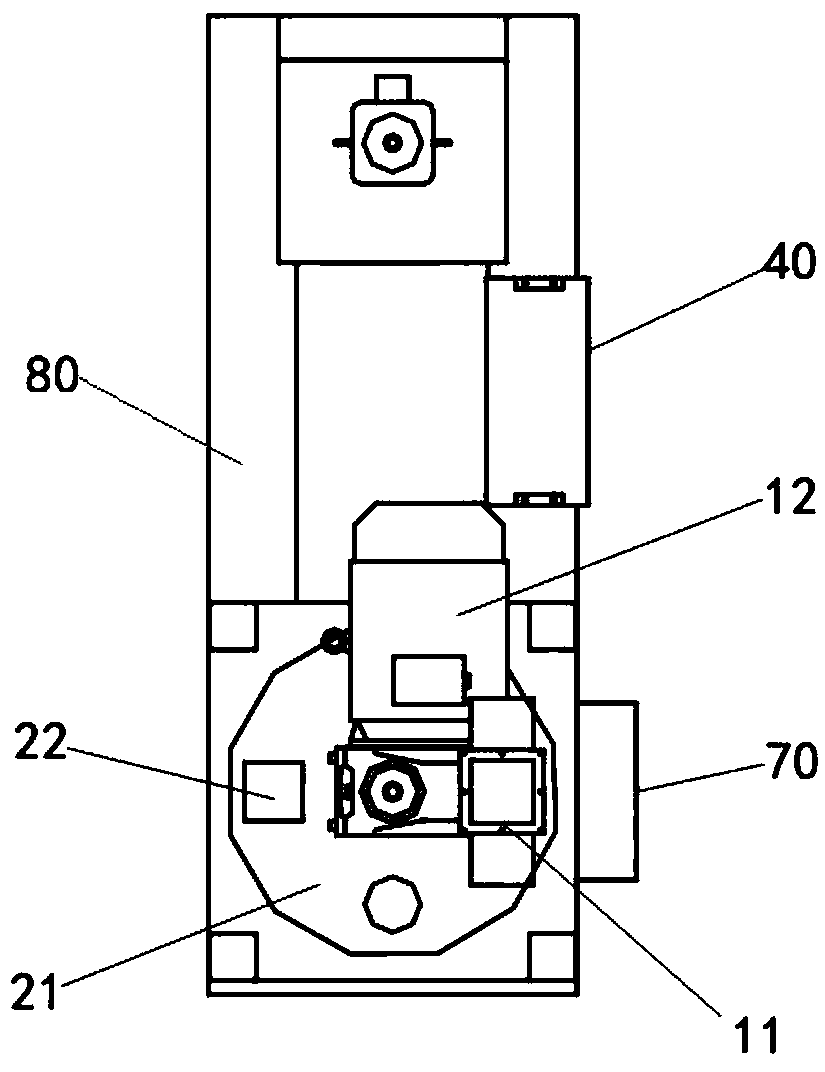

Special-shaped ceramic antenna cover machining device and method

ActiveCN109702605AUnified processing standardsControl machining accuracyRadiating element housingsWorking accessoriesMechanical engineeringEngineering

The invention provides a special-shaped ceramic antenna cover machining device and method. The device comprises a head cone supporting ring, an inner molded surface aligning ring, end face pressing plates and a plurality of outer supporting mechanisms. Each outer supporting mechanism comprises an outer support and an adjusting screw rod, and the inner molded surface aligning ring comprises an insertion end and a fixed end. According to the device and method, the machining reference of an antenna cover is determined through a primary alignment tool, it is guaranteed that the position of a clamping space of the antenna cover in all working procedures is free of deviation, the machining reference is unified, and the machining precision is effectively controlled.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

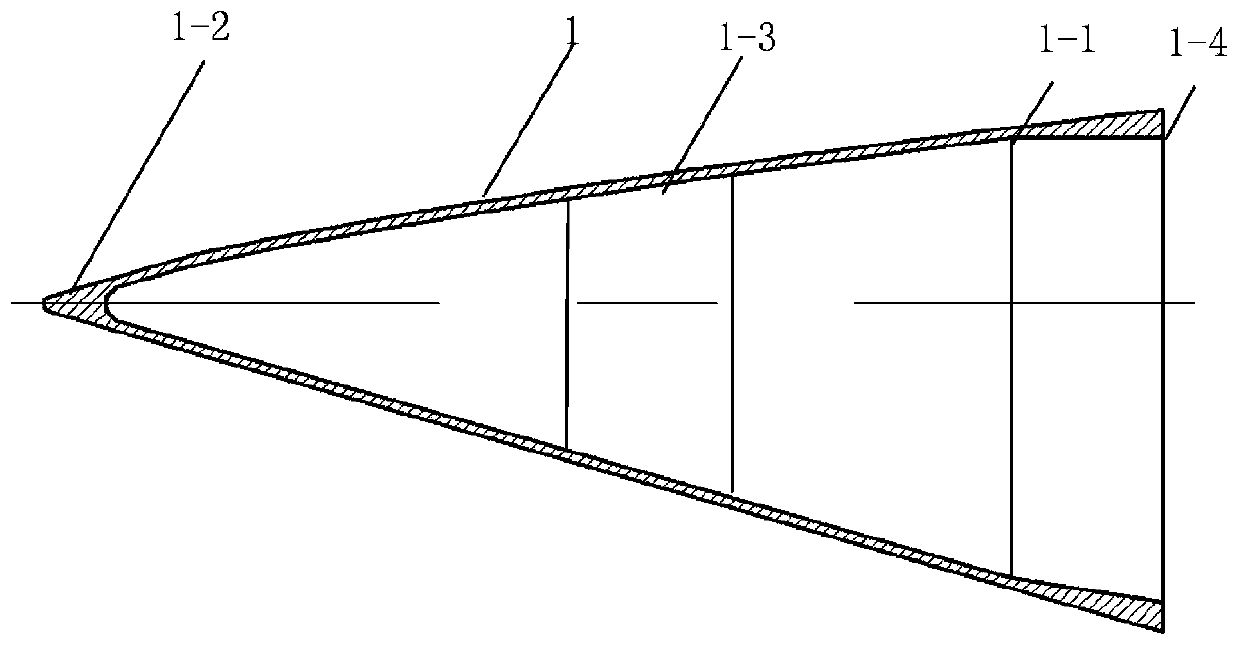

Method for improving position accuracy of mold core of integrated type ceramic mold

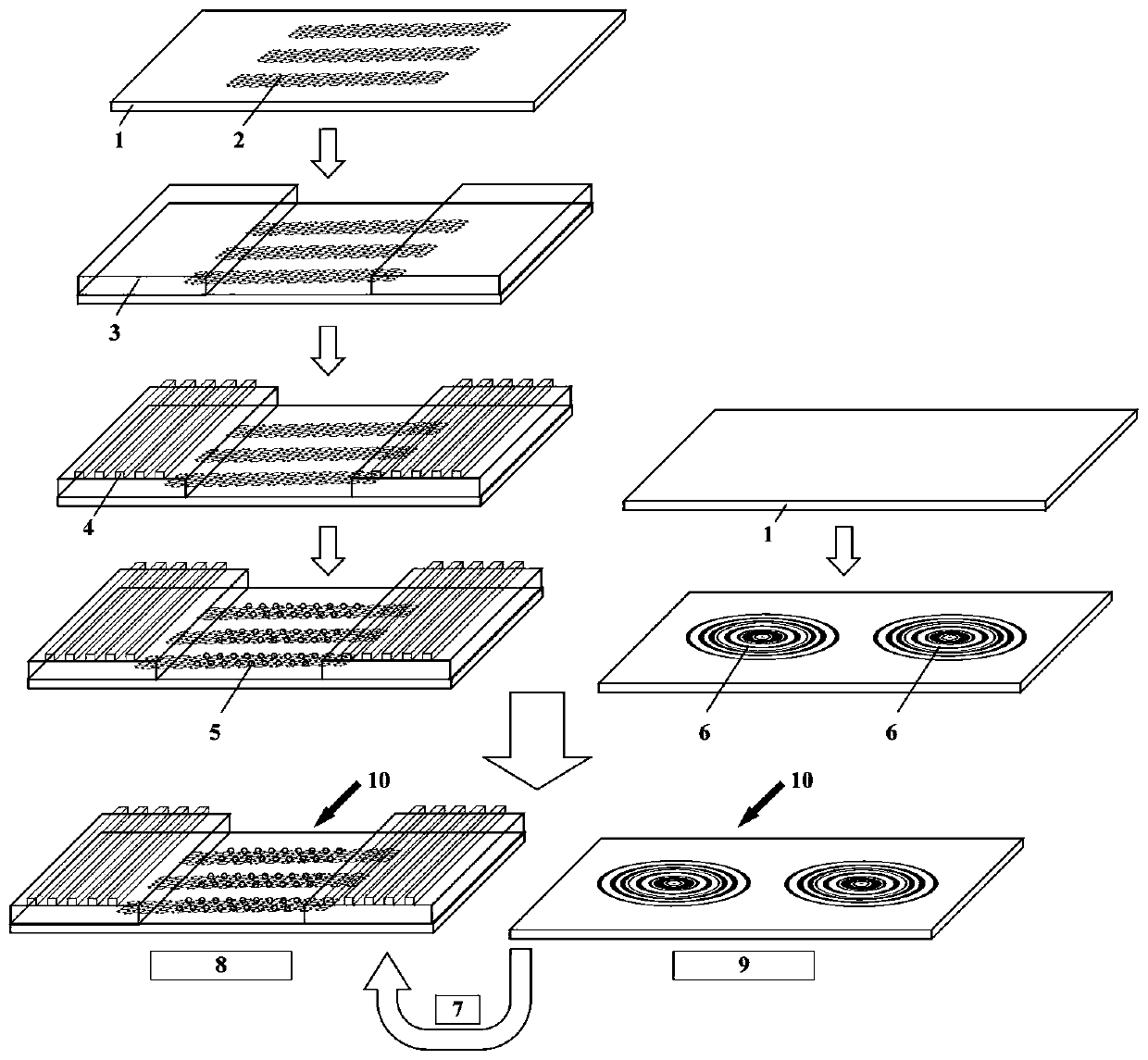

InactiveCN104526856AHigh positioning accuracyReduce the possibility of deformationCeramic shaping mandrelsCeramic shaping coresFiberLithographic artist

The invention discloses a method for improving the position accuracy of a mold core of an integrated type ceramic mold, and belongs to the field of rapid costing based on stereo-lithography technologies. The method comprises the steps that (1) three-dimensional software is utilized to design a resin mold, and a resin mold prototype with a positioning hole is manufactured by utilizing a stereo-lithography method; (2) a ceramic fiber or a ceramic bar penetrates into the positioning hole according needs; (3) ceramic slurry is poured into the resin mold prototype of turbine blades through a gel casting method to obtain a mold blank; (4) vacuum freeze drying and sintering are carried out on the mold blank to obtain the integrated type ceramic mold of the turbine blades. The position accuracy of the mold core of the integrated type ceramic mold can be effectively improved through the vertically through or non-through mold core, and the method is reasonable in design, is easy and convenient to operate, greatly improves the manufacturing integrity and accuracy of the mold and is suitable for practical production.

Owner:XI AN JIAOTONG UNIV +1

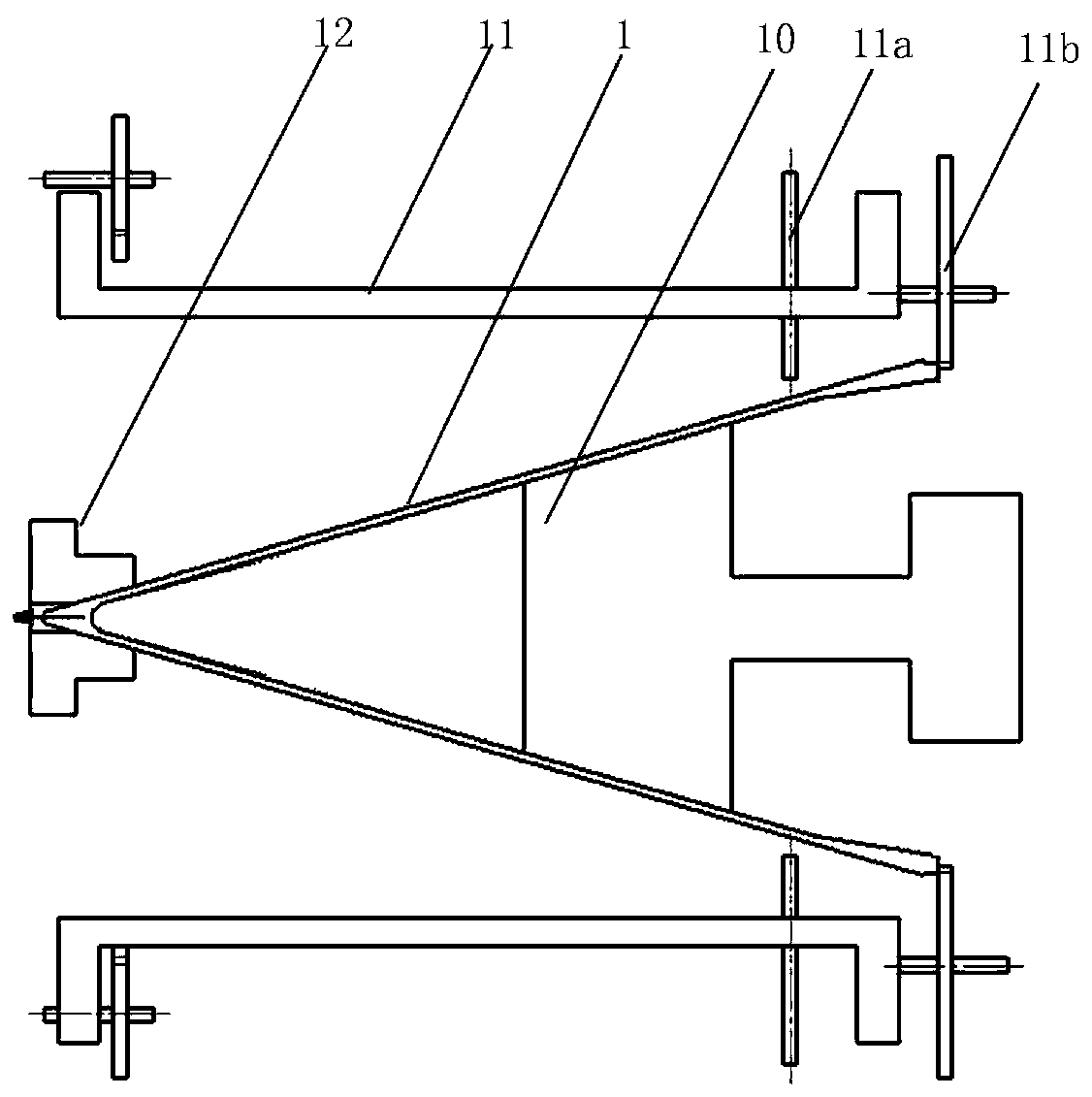

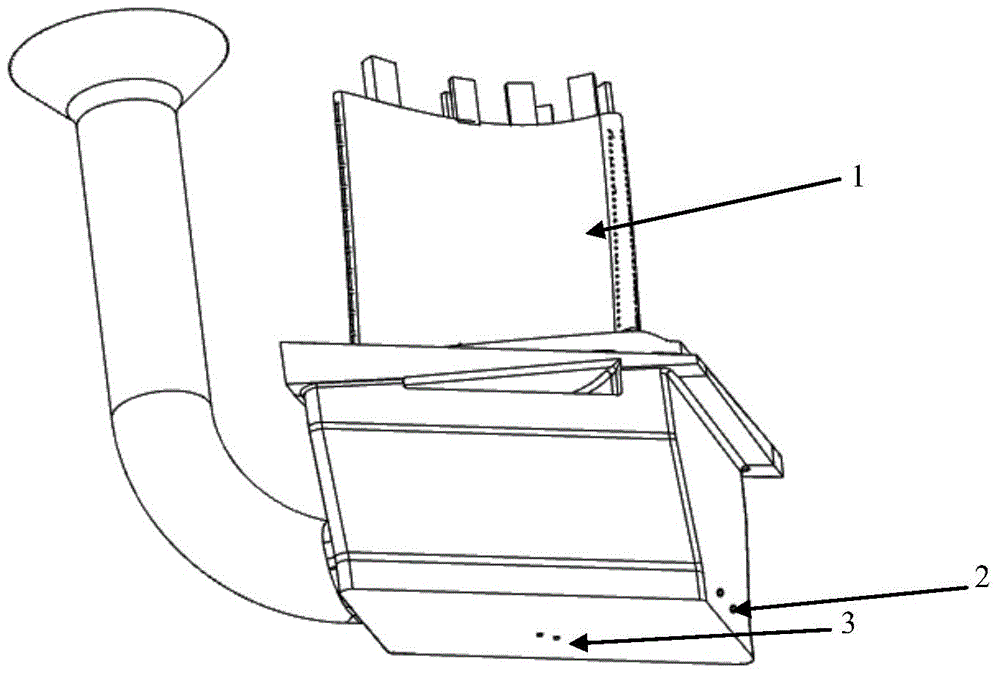

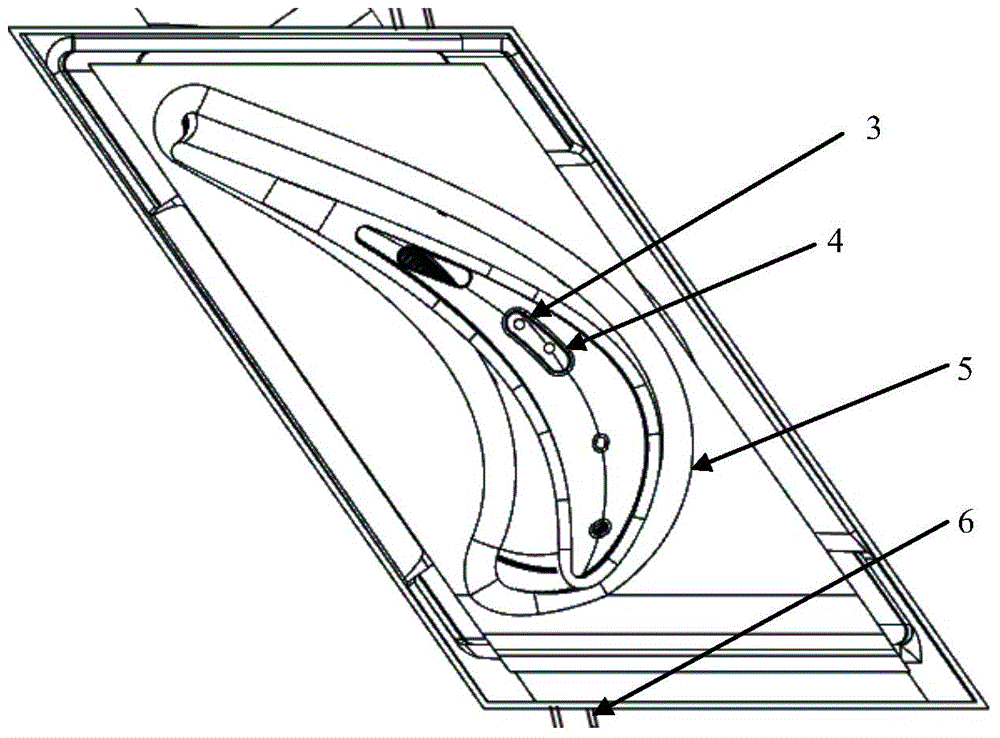

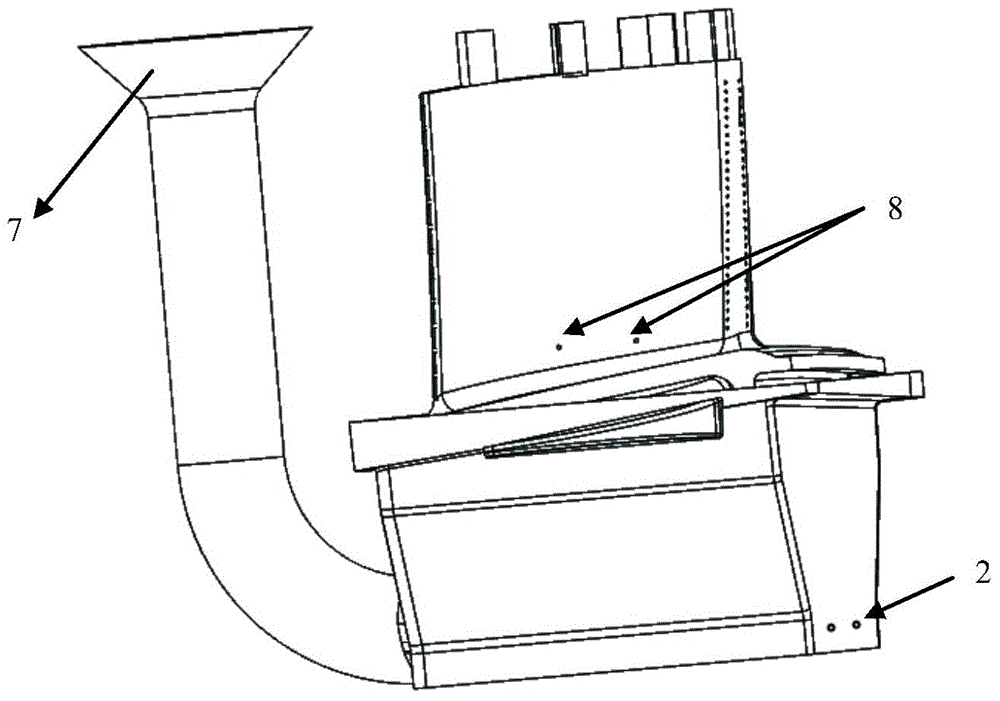

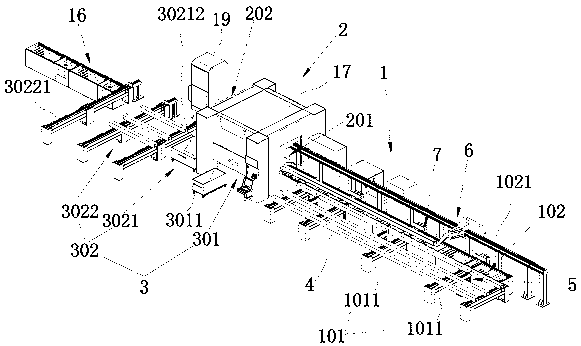

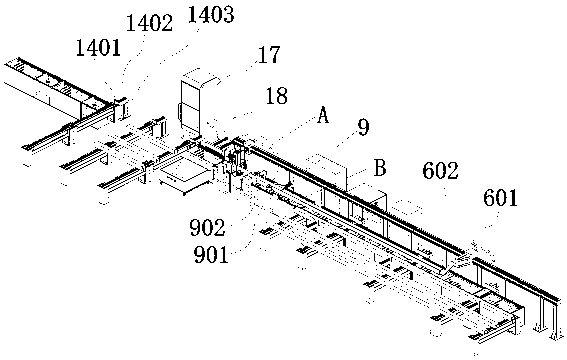

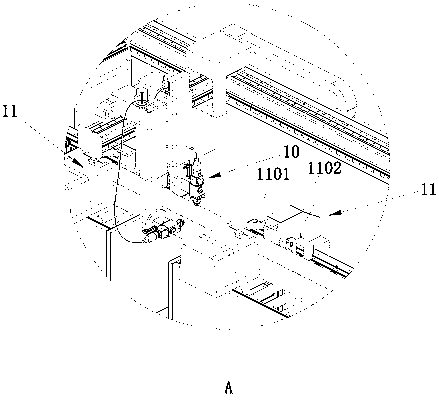

Profile cutting method for laser cutting automatic production line

ActiveCN111482719AEasy to distributeEasy to processWelding/cutting auxillary devicesAuxillary welding devicesPhysicsLaser cutting

The invention discloses a profile cutting method for a laser cutting automatic production line, and relates to the field of laser machining. The automatic production line comprises a feeding area, a cutting area and a blanking area, wherein a storage rack and a feeding table are arranged in the feeding area, a side pushing assembly used for pushing profiles to the feeding table is arranged on thestorage rack, the cutting area comprises a feeding end and a discharging end, one end of the feeding table is in butt joint with the feeding end, a forward pushing assembly is further arranged on thefeeding table, the blanking area comprises a first blanking area and a second blanking area, the first blanking area is positioned below the cutting area, and the second blanking area is in butt jointwith the discharging end. According to the method, the blanking area is divided into the first blanking area and the second blanking area, and the blanking of the cut profiles with length less than 1m and the cut profiles with length more than or equal to 1m is carried out through the blanking area and the second blanking area respectively, so that the profiles with different lengths are conveniently cut, classified blanking is carried out, machining is convenient, and the cutting efficiency of the profiles is high.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

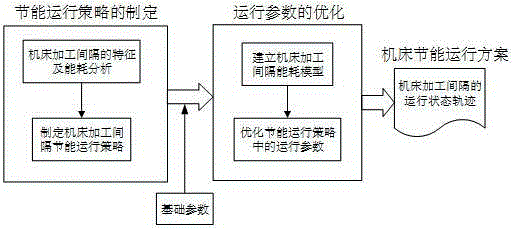

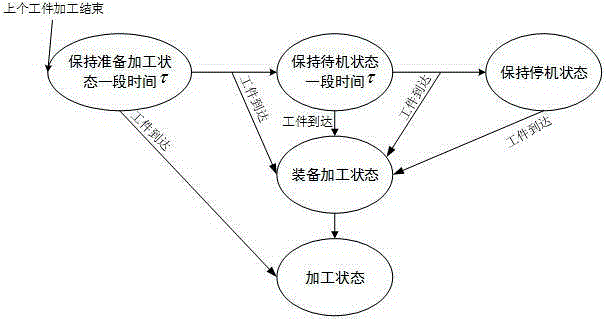

Machine tool energy-saving running method for switching machine tool states within random machining interval

ActiveCN105204433AReduce energy consumptionImprove energy efficiencyNumerical controlMachine toolMachining

The invention provides a machine tool energy-saving running method for switching machine tool states within a random machining interval. Firstly, a machine tool energy-saving running strategy is made according to the randomness of the machine tool machining interval; then, based on an established machine tool machining interval energy-consuming model, power of the running states and other basic parameters, running parameters in the made energy-saving running strategy are optimized; finally, according to the energy-saving strategy and the optimized running parameters, a machine tool energy-saving running scheme, namely the running state track of a machine tool within the machining interval, is acquired, and support is provided for saving energy of the machine tool within the machining interval. The method solves the problem how to make a machine tool energy-saving running method within the random machine tool machining interval caused when a workpiece reaches randomly and the problem of improving the energy utilizing rate within the random machining interval of the machine tool.

Owner:CHONGQING UNIV

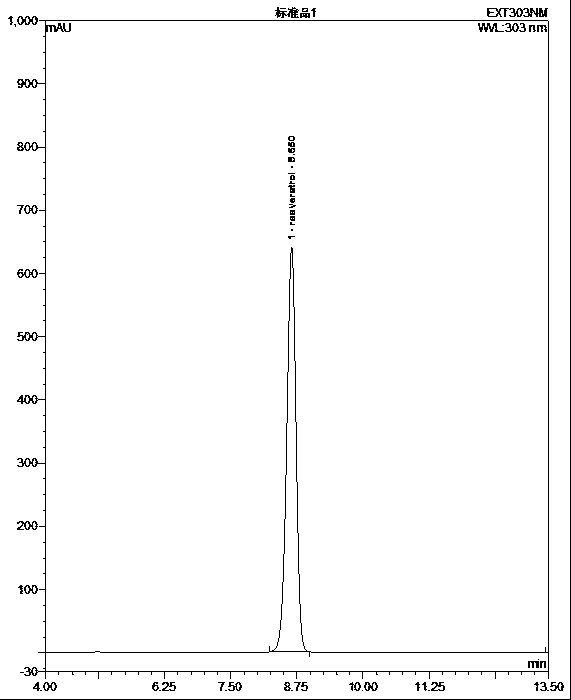

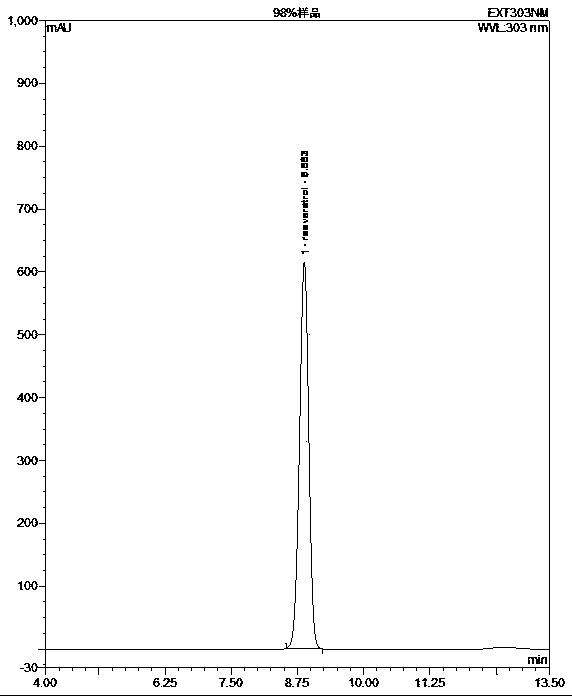

Method for extracting resveratrol from Polygonum cuspidatum

ActiveCN104341277AReduce lossesHigh yieldOrganic chemistryOrganic compound preparationPOLYGONUM CUSPIDATUMEnzyme

The invention relates to a method for extracting resveratrol from Polygonum cuspidatum. The method comprises six steps of enzyme deactivation, first enzymolysis, first extraction, secondary enzymolysis, secondary extraction and purification. The method has the advantages of simple operation and high extraction efficiency and is suitable for practical production.

Owner:内蒙古昶辉生物科技股份有限公司

Side detection system and method for glass substrate

ActiveCN106200038AImprove the efficiency of edge detectionSave energyNon-linear opticsProduction lineEngineering

The invention relates to a side detection system and method for a glass substrate. The glass substrate has a first side, a second side, a third side and a fourth side. The first side is parallel to the second side. The detection system comprises a driving device, a first detector, a second detector, a third detector and a fourth detector. The driving device is a driver or two drivers, the first detector is fixed to the second detector, and the third detector and the fourth detector are driven by the driving device to move. The detection method includes the steps that the first detector and the second detector detect the first side and the second side of the glass substrate to be detected respectively, and the third detector and the fourth detector detect the third side and the fourth side of the glass substrate to be detected respectively. By means of the method, the side detection efficiency of the glass substrate can be improved, the production efficiency of a whole production line can be improved, errors generated in the detection process are reduced, and the service life of the detectors is prolonged.

Owner:福州东旭光电科技有限公司 +3

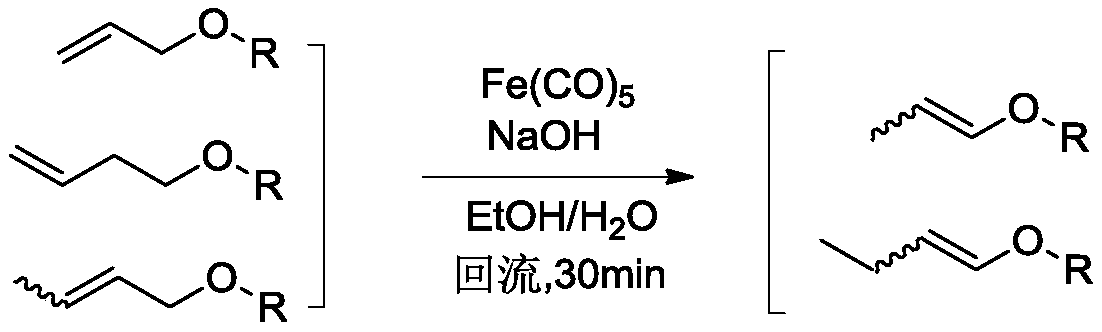

Method for preparing 3-methyl-3-butenal

ActiveCN109438197AImprove conversion rateAvoid high temperature conditionsOrganic compound preparationPreparation by dehydrogenationMethyl groupPalladium

The invention provides a method for preparing 3-methyl-3-butenal. The method includes: taking raw material 3-methyl-3-butenol as a hydrogen donor and a compound containing unsaturated bonds as a hydrogen receptor, and allowing intramolecular hydrogen transfer reaction under action of a catalyst system to obtain 3-methyl-3-butenal, wherein the catalyst system comprises azacycloligand, palladium carbon and metal carbonyl compound. The method is mild in reaction condition and easy in control, and product selectivity and raw material conversion rate are improved. Easy separation of 3-methyl-3-butenal can be realized by means of rectification; the method is simple and easy to implement and suitable for industrial production.

Owner:WANHUA CHEM GRP CO LTD

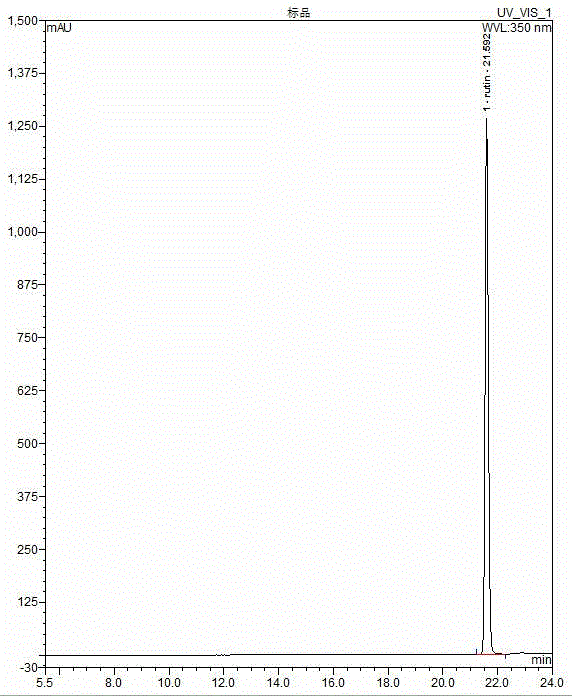

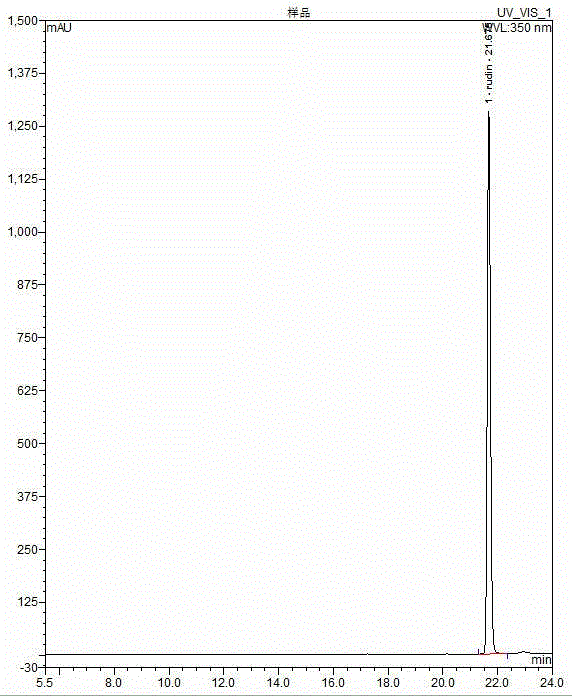

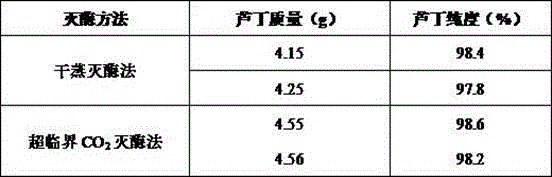

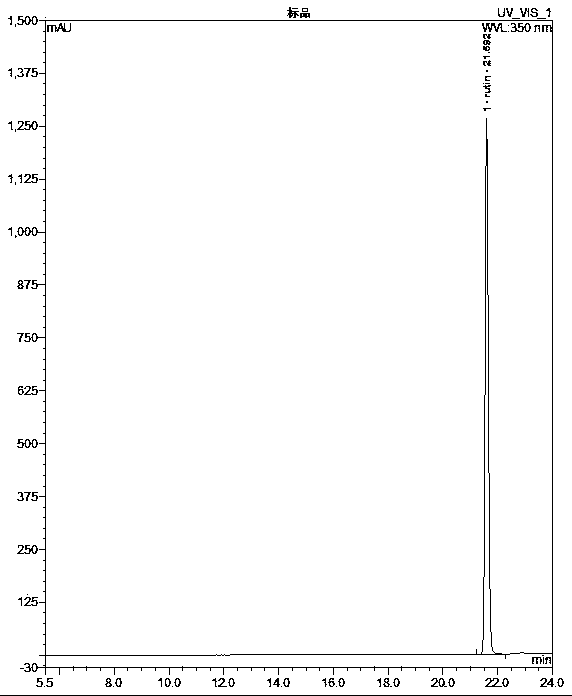

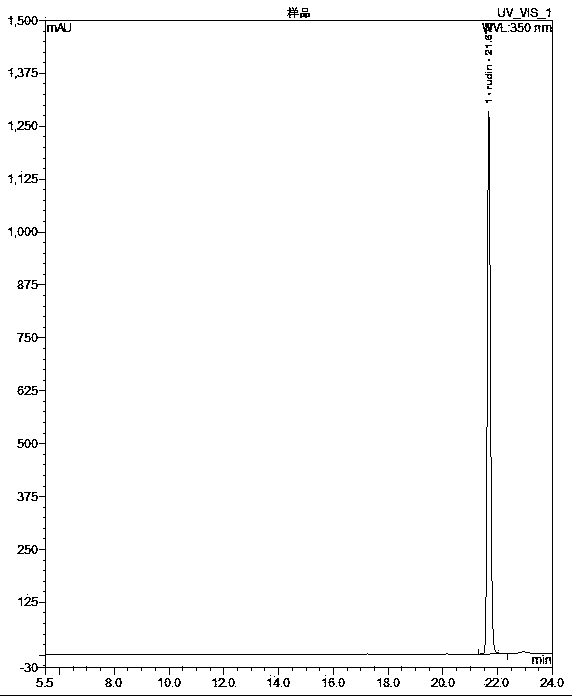

Method for extracting rutin from pagodatree flower bud

ActiveCN104130300ANot easy to dissolveDoes not cause hydrolysisSugar derivativesSugar derivatives preparationAlcoholUltrasonic assisted

The invention discloses a new method for extracting rutin from pagodatree flower bud. The method comprises the following steps: smashing the pagodatree flower bud, killing enzyme by adopting a supercritical CO2 method, carrying out ultrasonic-assisted extraction by using 60-70% ethyl alcohol under a certain condition to obtain an extracting solution, standing and crystallizing the extracting solution, carrying out suction filtration to obtain rutin crude products, refining the rutin crude products by using n-butanol, drying at the temperature of 130 DEG C to obtain rutin products with the purity being above 97% and the yield being above 22%. The method disclosed by the invention is simple and convenient to operate and high in extracting efficiency and is suitable for production practice.

Owner:内蒙古昶辉生物科技股份有限公司

Formation and capacity-grading method for lithium battery

ActiveCN110444826AEfficient screeningImprove pass rateSecondary cells charging/dischargingEngineeringOpen-circuit voltage

The invention discloses a formation and capacity-grading method for a lithium battery. The method comprises the processes of precharging, normal temperature ageing, formation, high temperature ageing,K value testing, capacity grading and sorting, wherein open-circuit voltage (OCV) detection is carried out in the processes of precharging, formation, K value testing, capacity grading and sorting. The formation and capacity-grading method is convenient to operate; the qualified rate of delivered products can be greatly improved; and the formation and capacity-grading method is suitable for practical production.

Owner:LINKDATA NEW ENERGY CO LTD

Method for extracting rutin from Japanese pagoda tree flowers

ActiveCN104098636AHigh purityEfficient removalSugar derivativesSugar derivatives preparationPagoda treeUltrasonic assisted

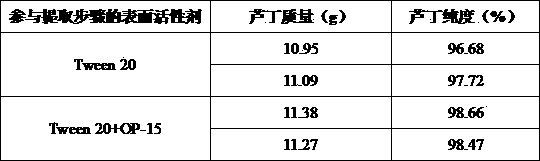

The invention discloses a novel method for extracting rutin from Japanese pagoda tree flowers. The method for extracting the rutin from the Japanese pagoda tree flowers comprises the following steps of processing dried Japanese pagoda tree flowers under 70 DEG C through a drying steaming method and airing and smashing the Japanese pagoda tree flowers; adding surface active agent with the reasonable ratio such as Tween 20 and OP-15, performing ultrasonic-assisted extraction through ethyl alcohol with the alcohol concentration to be from 60 to 70 % under a certain condition, standing extraction solution to be crystallized and obtaining rutin crude products through suction filtration; refining the rutin crude products through n-butyl alcohol, standing the rutin crude products to be crystallized and drying under 130 DEG C to obtain rutin products with the purity to be more than 98 %, wherein the yield is larger than 22 %. The method for extracting the rutin from the Japanese pagoda tree flowers is simple in operation, high in extraction efficiency and applicable to product and reality.

Owner:内蒙古昶辉生物科技股份有限公司

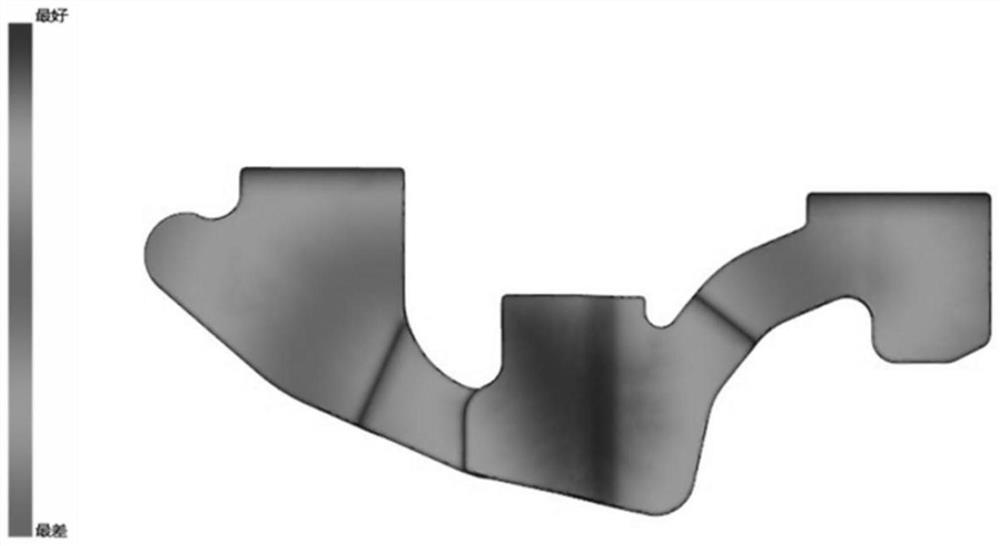

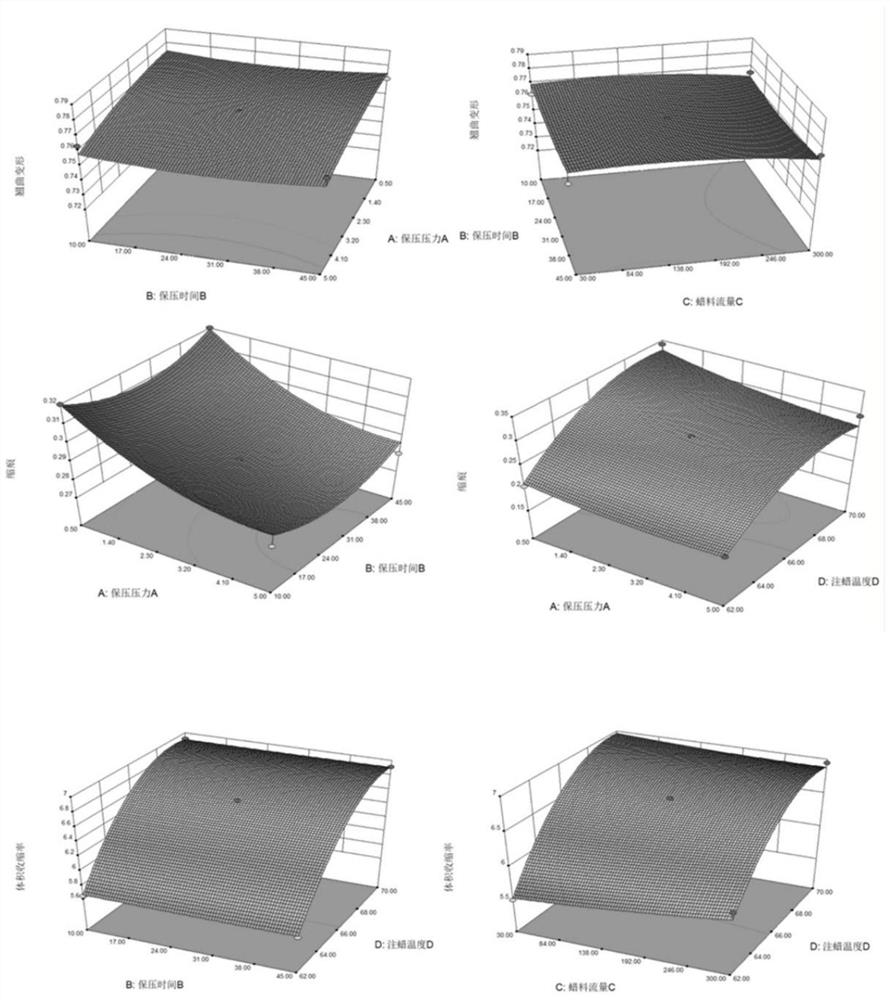

Wax mold injection process parameter determination method based on injection molding numerical simulation

PendingCN113158483AImprove reliabilityGet rid of manual trial and errorDesign optimisation/simulationSpecial data processing applicationsElement modelVolumetric shrinkage

The invention discloses a wax mold injection process parameter determination method based on injection molding numerical simulation. The wax mold injection process parameter determination method comprises the following steps: determining actual wax injection related conditions; establishing a finite element model, and dividing the finite element model by adopting a tetrahedral mesh; analyzing sprue matching performance through numerical simulation software Moldflow, and determining an optimal sprue; according to actual conditions, selecting a plurality of wax injection process parameters as test factors, determining the parameter range of the test factors, and taking buckling deformation, a volume shrinkage rate and sink marks as judgment results; According to the method, a Box-Behnken method is adopted in Design Expert to carry out experimental scheme design, and numerical simulation is carried out in Moldflow according to an experimental design scheme; data analysis is conducted by utilizing Design Expert to obtain an optimal wax injection process parameter; and a large amount of resources are saved, production efficiency is improved, and the phenomena of buckling deformation and volume shrinkage of the wax mold are effectively reduced, so the production quality of the wax mold is improved.

Owner:JIASHAN SINHAI PRECISION CASTING

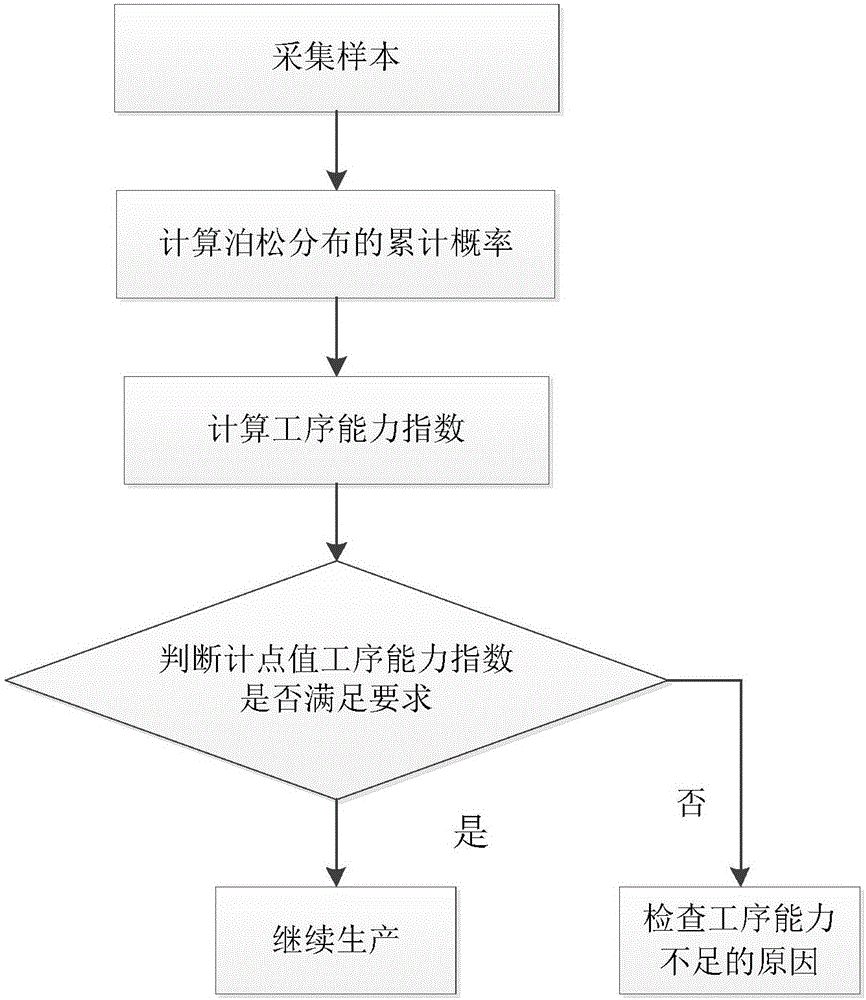

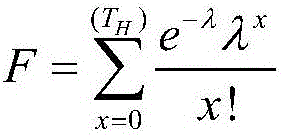

Evaluation method for true count capability-of-process meeting Poisson distribution

InactiveCN106485401AThe result is accurateApplicable to actual productionResourcesData miningProcess capability

The invention discloses an evaluation method for true count capability-of-process meeting Poisson distribution. The method comprises the specific steps of 1, collecting samples; 2, calculating a cumulative probability of the Poisson distribution; 3, calculating capability-of-process; 4, judging whether the true count capability-of-process meets the requirement or not; 5, continuing to perform production; and 6, checking reasons for process capability deficiency. The method has the advantages that a result is correct; the method is more suitable for actual production; a corresponding relationship between the obtained capability-of-process CPU and a corresponding process yield is completely same as a corresponding relationship between metric value capability-of-process and the corresponding process yield; the values of the process yields can be directly represented only by comparing the values of the capability-of-process of different processes; and the metric value and true count capability-of-process is subjected to unified quantification.

Owner:XIDIAN UNIV

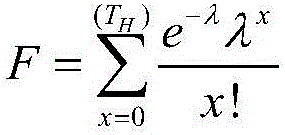

Manufacturing method of automobile spot welding fixture

The invention relates to a manufacturing method of an automobile spot welding fixture, comprising the following steps: Step 1: Modeling; Step 2: Assembling according to drawings and fixture list; Step 3: Solder spot analysis; Step 4: Determine according to the weld spot analysis result Workpiece placement; Step 5: Selection and modeling of welding tongs; Step 6: 2D drawing; Step 7: Processing and manufacturing according to 2D drawing; Step 8: Production line test of the manufactured fixture . The beneficial effects of the present invention are: through the coordination of components such as positioning pins, clamping arms, and lifting mechanisms on the fixture, the workpiece is installed and clamped at the position set by the process, so that the workpiece is not allowed to move and move, and the welding of the vehicle body is ensured. Consistency and stability of precision.

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

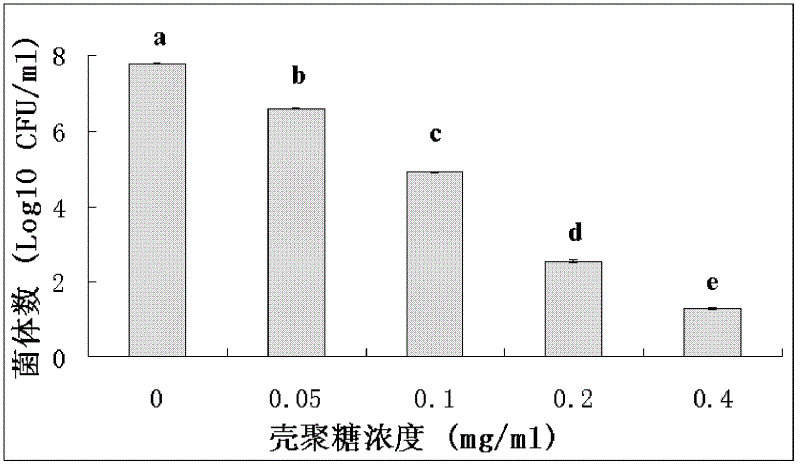

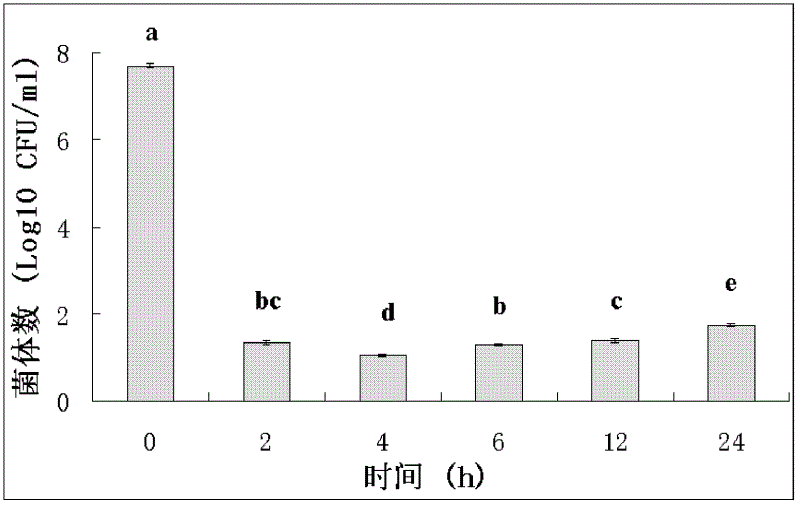

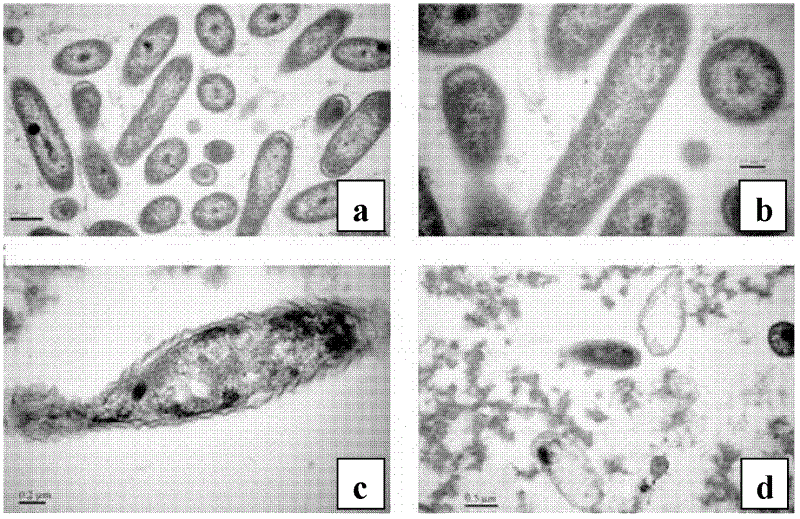

Application of chitosan in prevention and control of bacterial fruit blotch of plants

InactiveCN102613186APromote seedling growthRaw materials are easy to getBiocidePlant growth regulatorsPlanting seedCitrullus

The invention discloses application of chitosan in prevention and control of bacterial fruit blotch of plants, wherein the deacetylation degree of the chitosan is more than 85%. The plants are melon plants. The application comprises the steps of placing plant seeds in a chitosan solution to be soaked for 3-5 hours or using the chitosan solution to perform spraying treatment to leaves of the plants at a trefoil stage. The chitosan uses as a main raw material, the prepared and obtained chitosan solution can effectively inhibit the activity of the bacterial fruit blotch and prevent and control the bacterial fruit blotch of the plants. The chitosan solution with certain concentration further can effectively promote growth of watermelon seedlings. The raw material is easily obtained, the process is simple, the operation is convenient, and the chitosan is low in toxicity and harm and good in preventing and controlling effect on the bacterial fruit blotch of melon plants. In addition, the chitosan can further promote the growth of plant seedlings to some extent and is suitable for actual production and easy to popularize and apply.

Owner:ZHEJIANG UNIV

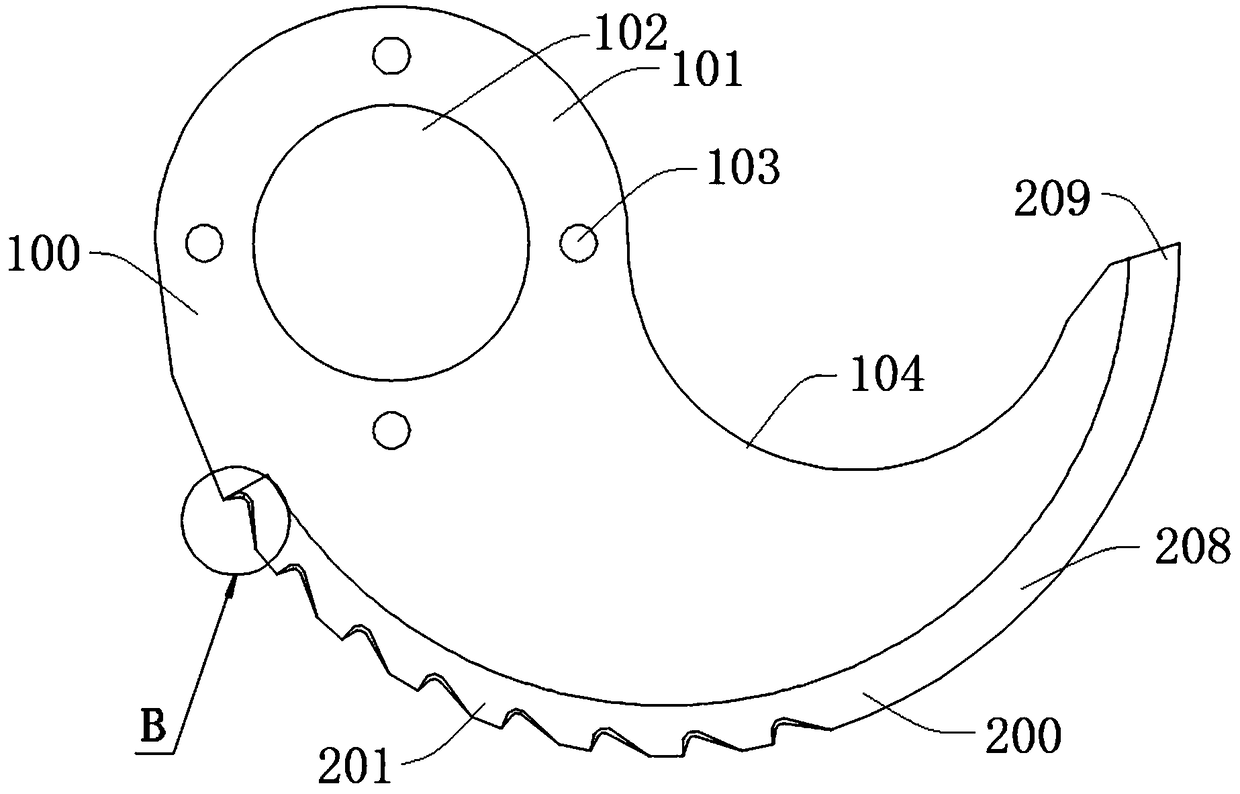

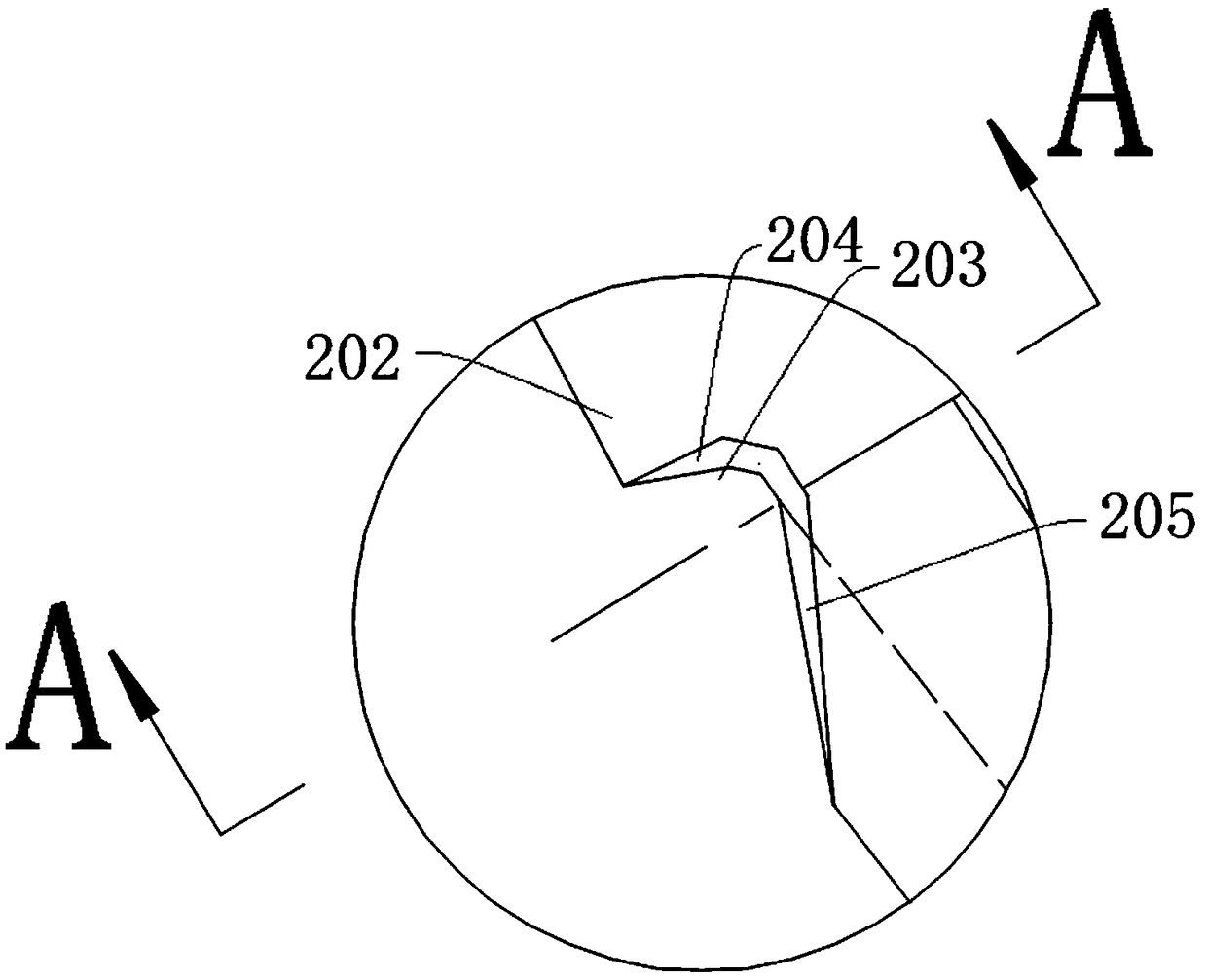

Food cutter and manufacturing method thereof

PendingCN109483623AImprove cutting effectNot easy to dullMetal working apparatusEngineeringMechanical engineering

The invention discloses a food cutter and a manufacturing method thereof and belongs o the field of cutter machining. The food cutter comprises a cutter body and a cutter blade. The cutter body and the cutter blade form a food cutter body. The cutter body comprises a mounting portion located at one end of the cutter body. The profile of the cutter blade is in an arc shape and is a single-face arc-shaped blade. The arc-shaped blade comprises a toothed blade end and a non-toothed blade end. The toothed blade end and the non-toothed blade end are connected to form a cutter blade body. The side, not connected with the non-toothed blade end, of the toothed blade end is connected with the mounting portion. The food cutter can be used for cutting food smoothly and uniformly, food does not stick to the cutter, abrasion of the cutter blade edge is small, the service life is long, the manufacturing method of the food cutter is easy and convenient to implement and combined with practical production, and manufacturing is easy.

Owner:安徽华天机械股份有限公司

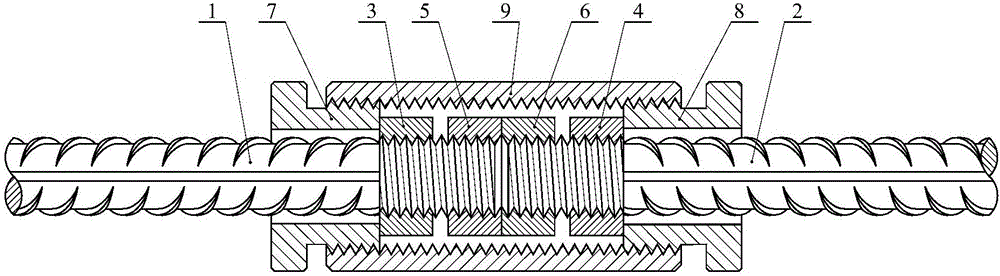

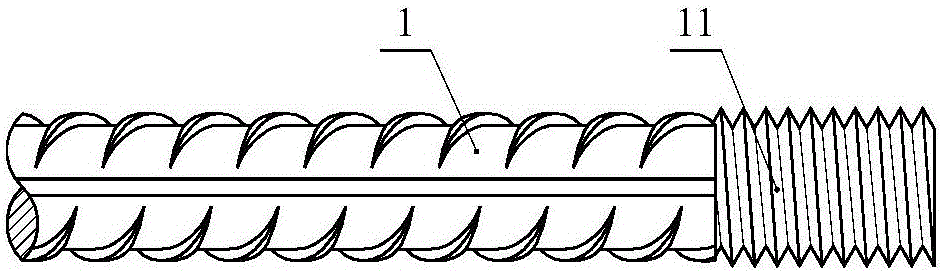

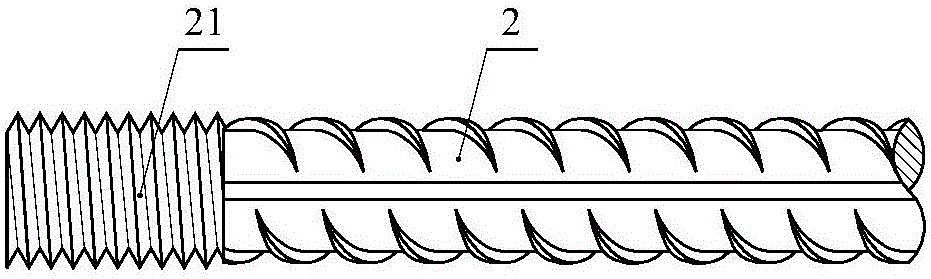

Casing pipe combination type rebar connecting device and method

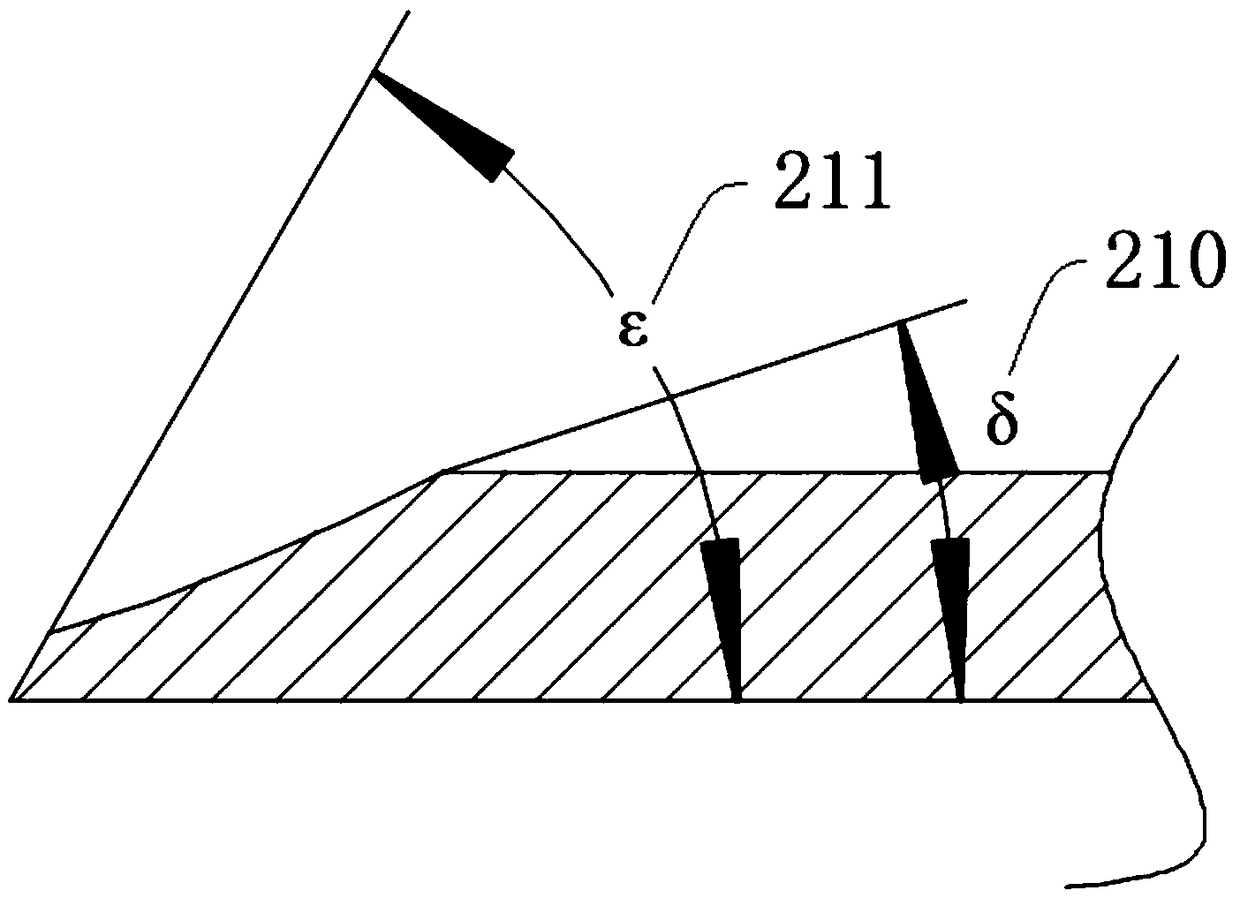

InactiveCN106836652AAchieve connectionApplicable to actual productionBuilding reinforcementsRebarScrew thread

The invention relates to a casing pipe combination type rebar connecting device and method. The connecting device comprises a casing pipe, locking screw sleeves and screw sleeves. Threads are arranged inside a first cavity part of the casing pipe and outside second cavity parts of the locking screw sleeves, and the threads of the first cavity part are matched with the threads of the second cavity parts; and threads are arranged inside the screw sleeves and matched with rebar heads. According to the connecting method, one end of the casing pipe is connected with one locking screw sleeve; the casing pipe is connected with one rebar head, and the other screw sleeve is used for being connected with the other rebar head; and the other locking screw sleeve is used for being connected with the other end of the casing pipe, and then a rebar is obtained after connection. According to the casing pipe combination type rebar connecting device and method, two to-be-connected rebars can be connected without rotating the rebars.

Owner:建研建硕(北京)科技有限公司 +1

Method of improving high-temperature strength of integral alumina-based ceramic mold through chemical vapor infiltration

ActiveCN106083205AImprove high temperature strengthHigh temperature strengthCeramicwareChemical reactionSurface layer

The invention discloses a method of improving high-temperature strength of an integral alumina-based ceramic mold through chemical vapor infiltration, and belongs to the field of photocuring forming technology quick casting. The method includes the steps that 1, a resin mold is manufactured through the photocuring quick forming technology; 2, ceramic slurry is poured into a resin mold prototype of turbine blades through a gelcasting method to obtain a cast blank; 3, a porous alumina-based ceramic mold is obtained after vacuum freeze drying and ungrease treatment; 4, the alumina-based ceramic mold is subjected to chemical vapor infiltration, SiO2 generated after pyrolytic reaction of a silicon source precursor and matrix alumina react chemically to generate high-temperature strengthened phase mullite, the pore structure of the mold is filled with SiC generated through the pyrolytic reaction, a functional gradient material with the porosity gradually improved from the surface layer to the core part of the mold, and the porosity of the mold is reduced to improve the high-temperature strength of the mold. The method is reasonable in design and convenient to operate, and the high-temperature strength of the alumina-based ceramic mold is enhanced remarkably.

Owner:XI AN JIAOTONG UNIV

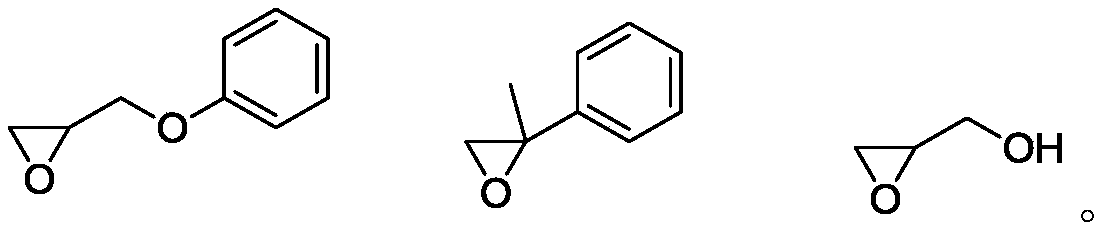

Composite-structure dual-absorption layer graphene detector and fabrication process thereof

ActiveCN110233182AIncrease the receiving areaImprove photoelectric responseFinal product manufactureSemiconductor devicesGratingLight energy

The invention discloses a composite-structure dual-absorption layer graphene detector and a fabrication process thereof. The detector comprises a silicon dioxide substrate, a graphene nanobelt, a metal electrode, a nanometer grating antenna, a metal quantum dot, a metal film annular belt and a transparent adhesive. A sub-wavelength nanometer grating antenna is used for coupling and conducting a light beam and simultaneously generating plasma resonance so as to improve receiving efficiency and improving photoelectric response, the metal quantum dot is used for simulating surface plasmon polariton and generating surface plasmon resonance to improve photoelectric response, and the metal film annular belt is used for focusing an incident light beam so that incident light energy acts on a detection region in a concentrated way and the photoelectric response is improved. With a front-surface and back-surface detector structure, the front surface and the back surface are used for simultaneously receiving and converting to photocurrents, the receiving area is effectively expanded, and the photoelectric response is further improved; and the corresponding fabrication process is simple to operate and is high in reliability. By the detector, the technical bottleneck of graphene weak photon energy detection is favorably broken through.

Owner:XI AN JIAOTONG UNIV

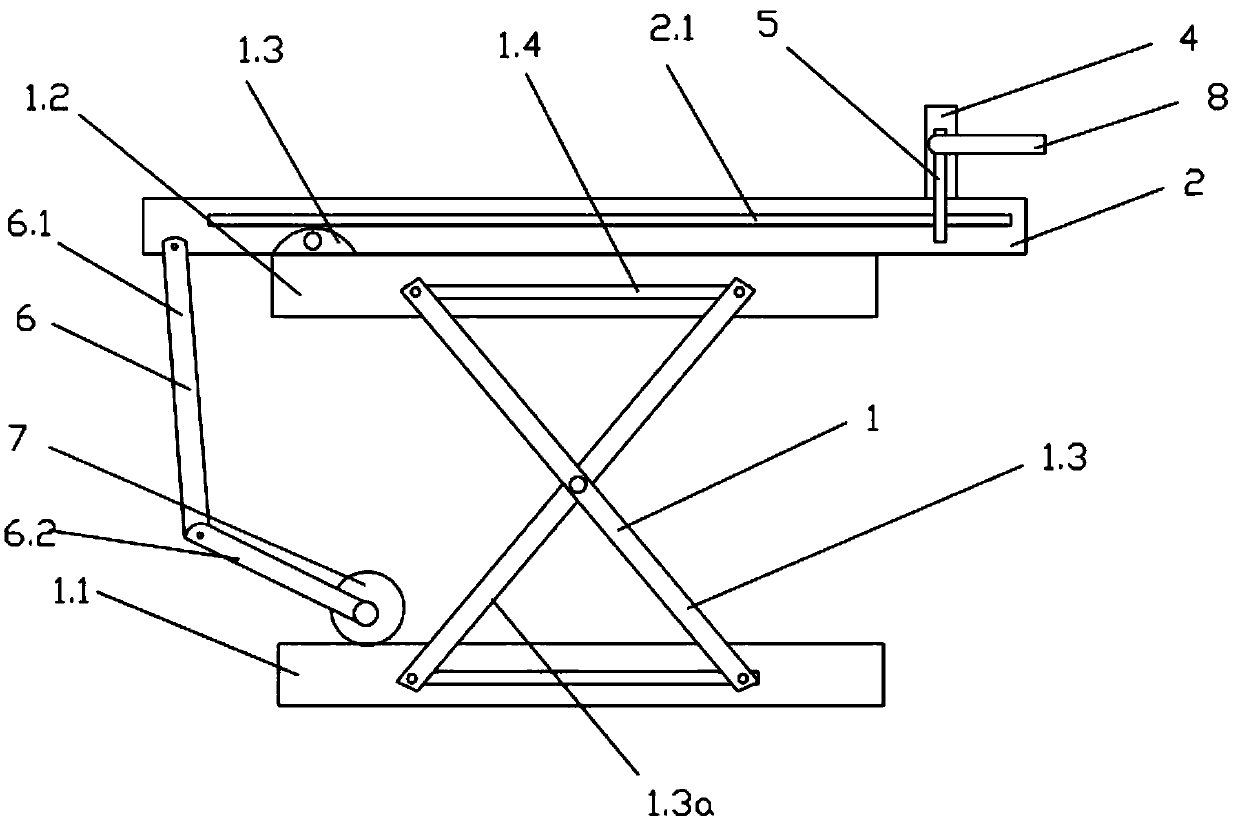

Machine manufacturing workbench

InactiveCN108673432ASimple structureEasy to useCleaning using toolsWork benchesWaste materialChassis

The invention discloses a machine manufacturing workbench. The machine manufacturing workbench comprises a supporting framework, and the supporting framework comprises a bottom frame, a top frame anda lifting assembly connected between the bottom frame and the top frame; the top frame is provided with a working platform, one end of the top frame is movably connected with the bottom of the workingplatform through a rotating piece, the upper part of the working platform is provided with a slidable scraping plate, the two ends of the slidable scraping plate are movably connected with the two sides of the working platform through sliding rods, the end, close to the rotating piece, of the working platform is provided with a pull rod assembly, and a driving device for driving the pull rod assembly is arranged on the bottom frame. According to the machine manufacturing workbench, the height of the workbench can be adjusted through the lifting assembly, and the angle of the workbench can beadjusted through the pull rod assembly so that waste material and rubbish on the surface of the workbench can be cleared under the cooperation of the slidable scraping plate in a relative convenient mode; and the machine manufacturing workbench is simple in structure and convenient to use and is suitable for practical production.

Owner:XUZHOU MASTER MECHANICAL TECH CO LTD

Sheep immunopotentiation functional additive, preparation method and application thereof

InactiveCN106578453AImprove immunityPromote growthAccessory food factorsWorking-up animal fodderAstragalus polysaccharideSelenium methionine

The invention relates to a sheep immunopotentiation functional additive, and a preparation method and an application thereof. 1 kg of the functional additive includes 30-100 g of lycium barbarum polysaccharide, 30-80 g of astragalus polysaccharide, 100-400 kIU of vitamin A, 10-38 kIU of vitamin D, 1200-3500 IU of vitamin E, 2.0-4.0 g of zinc methionine, and 1.0-2.0 g of selenium methionine. The preparation method includes the steps of: ultramicro-pulverizing and stirring the lycium barbarum polysaccharide, the astragalus polysaccharide, the zinc methionine and the selenium methionine to obtain a first mixture; adding the vitamin A, the vitamin D and the vitamin E to the first mixture with stirring to obtain a powder of the sheep immunopotentiation functional additive. The additive is applied by being added to a feed or drinking water for sheep. The additive can improve growth of sheep and enhance immunity of the sheep.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

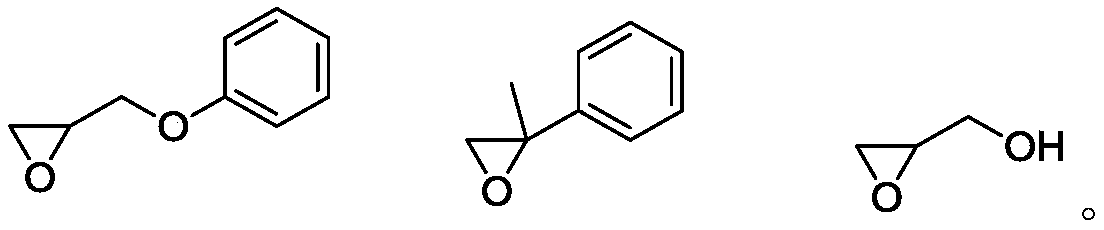

A kind of method preparing 3-methyl-2-butenol

ActiveCN107141197BAvoid generatingHigh activityPreparation by isomerisationOrganic compound preparationEpoxyIsomerization

The invention provides a method for preparing 3-methyl-2-butenol (prenyl alcohol) through isomerization of 3-methyl-3-butenol. The catalyst reaction system comprises: 1) carbonyl iron compound; 2) organic base; 3) epoxy ligand. Adding a solvent with an ether structure in the isomerization reaction can improve the catalyst activity and product selectivity. In the catalytic process and separation, carbon monoxide (CO) and nitrogen (N 2 ), wherein the volume content of CO is 100ppm‑100000ppm. The catalyst and the raw material 3-methyl-3-butenol are separated from the product isopentenol by rectification without additional separation of the catalyst. The catalyst maintains high activity and long-life operation.

Owner:WANHUA CHEM GRP CO LTD

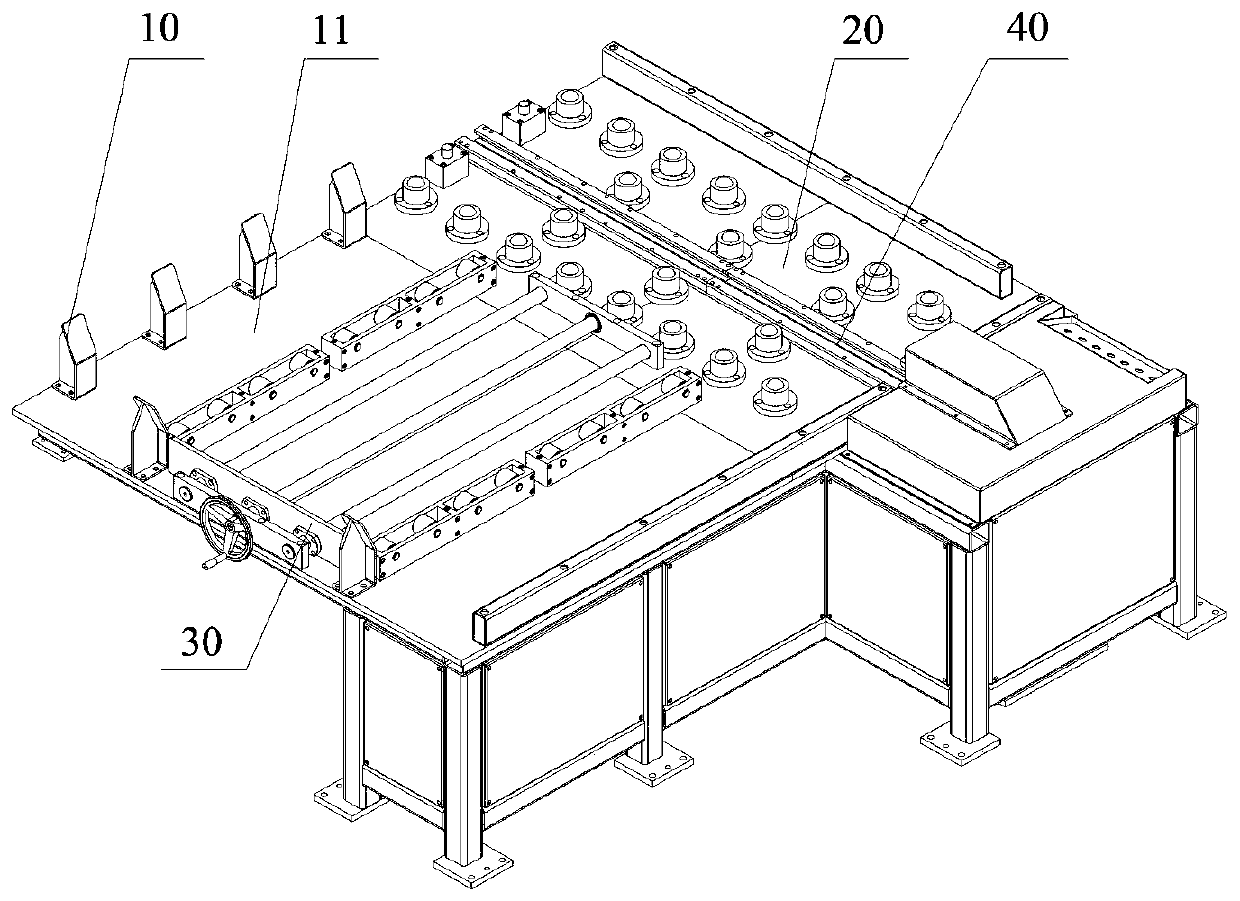

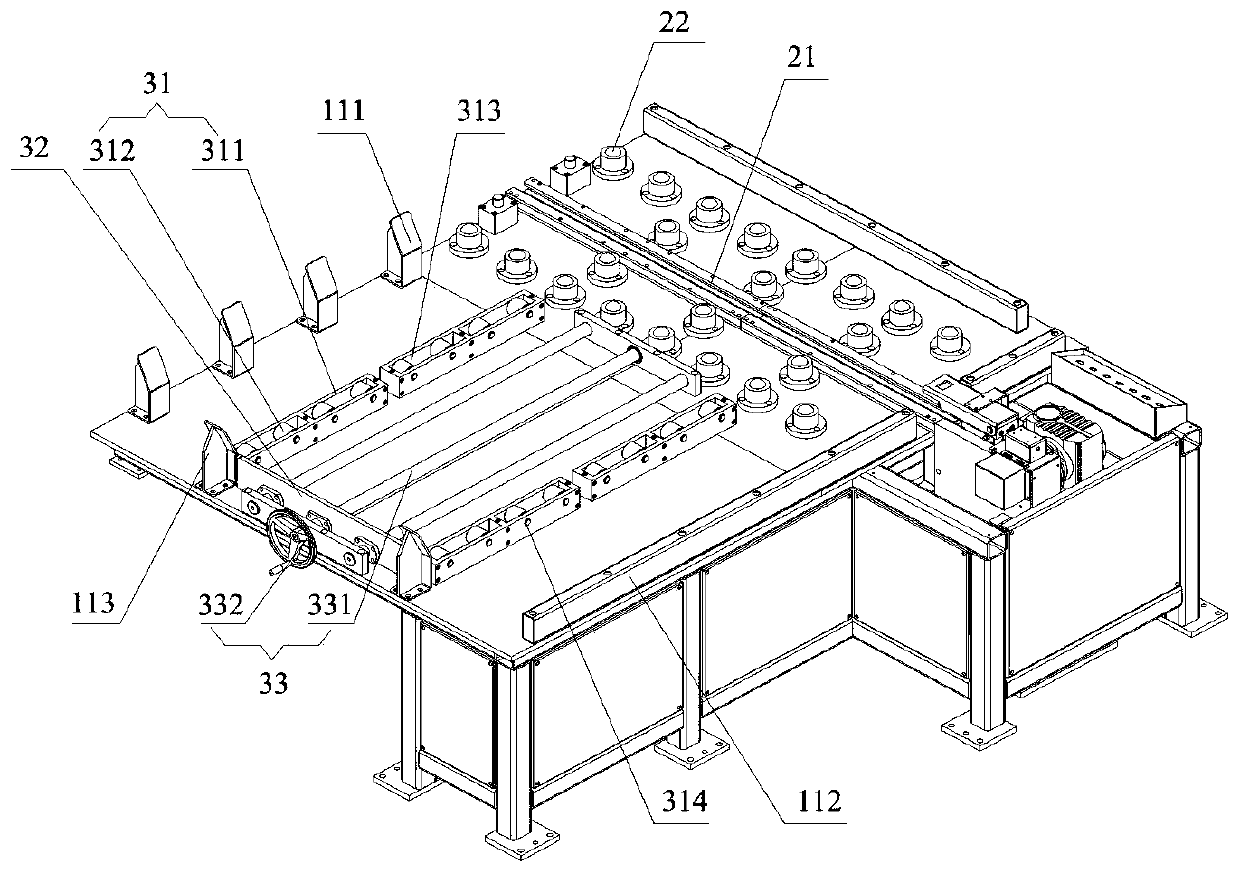

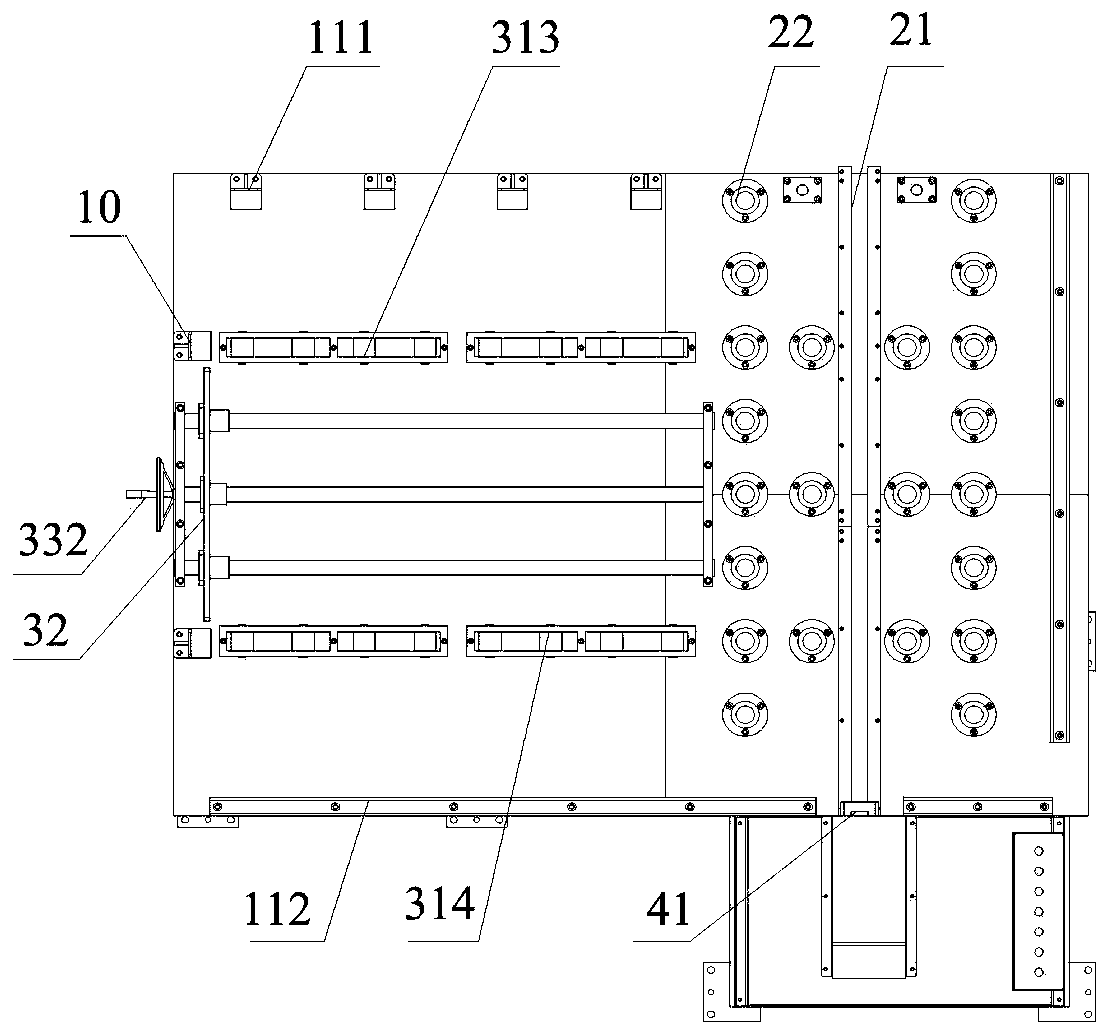

Dual-table die-changing trolley and die-changing method thereof

The invention discloses a dual-table die-changing trolley and a die-changing method thereof. The dual-table die-changing trolley comprises a die loading table for replacing a die to be punched, a dieconveying table which is connected to the die loading table and used for placing the die to be punched, a die pushing device which is arranged on the die loading table and used for pushing the die tobe punched from the die loading table to the die conveying table, and a die conveying device which is connected to the die conveying table and used for conveying the die to be punched from the die conveying table to a punching machine. The dual-table die-changing trolley and the die-changing method thereof are simple and convenient for die-changing operation; the loading and die conveying devicesare simple to modify and have good process adaptability; the requirements for working objects and matching conditions are low, and die loading of different process cycles can be adapted; and the production line has a high degree of generality, different production lines without adjustment or slight adjustment can be adapted, and practical production is suitable.

Owner:湖南大捷智能装备有限公司

Fluorite-magnesium grain cored wire, application of fluorite-magnesium grain cored wire and production process for high heat input welding steel

The invention discloses a fluorite-magnesium grain cored wire, application of the fluorite-magnesium grain cored wire and a production process for high heat input welding steel. The cored wire comprises an outer layer and a clad core. Low-carbon steel serves as the outer layer, and the thickness ranges from 0.5 mm to 1.0mm; sustained-release passivated magnesium grains serve as the clad core, and the clad core comprises a sustained-release agent and passivated magnesium grain bodies; and fluorite serves as the sustained-release agent, the sustained-release agent accounts for 5%-90% of the clad core, and the passivated magnesium grain bodies account for 10%-95% of the clad core. The application refers to application of the cored wire in manufacturing of the high heat input welding steel. According to the production process, the sustained-release passivated magnesium grain cored wire with the fluorite serving as the sustained-release agent is fed into molten steel, the absorption rate of Mg is stable, the effect and the utilization rate of Mg are high, slag inclusions are dispersed and abundant, and the slag inclusions containing Mg reach over 80%. By the adoption of the fluorite-magnesium grain cored wire, application and the production process, control is easy, production cost is low, and industrialized mass production of the high heat input welding steel can be achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method and system for detecting looseness of bolt joints based on nonlinear excitation characteristics

The invention discloses a bolt joint part looseness detecting method and system based on a nonlinear shock excitation feature. The method comprises the following steps: carrying out simulated modal analysis on a three-dimensional model of a test piece, and determining the arrangement positions of a vibration exciter and a sensor of a local part of a bolt joint part; arranging the vibration exciterand the sensor according to the determined arrangement positions of the vibration exciter and the sensor, and determining a vibration excitement parameter of the vibrator exciter according to the simulated modal analysis result of the three-dimensional model; maintaining the vibration excitement parameter unchanged, carrying out preliminary experiment on the same kind of test pieces to obtain a corresponding relation between a bolt pretightening force and a high harmonic scaling factor, and generating a relation data base; and carrying out test on a test piece to be tested to obtain a high harmonic scaling factor, querying the relation data base, determining the bolt pretightening force of the test piece to be tested, and judging whether the bolt joint part of the test piece to be testedis loosen or not according to the bolt pretightening force of the test piece to be tested. The method has the advantages of wide applicability, flexibility and convenience in use, high sensitivity andthe like, implements nondestructive detection, and is suitable for actual production.

Owner:TSINGHUA UNIV

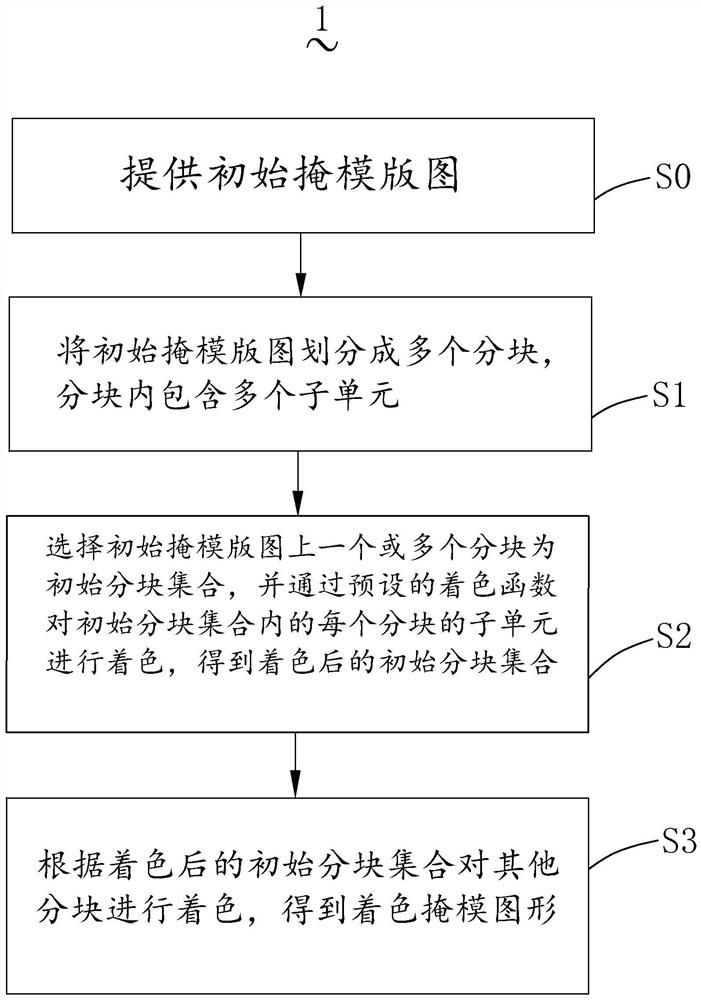

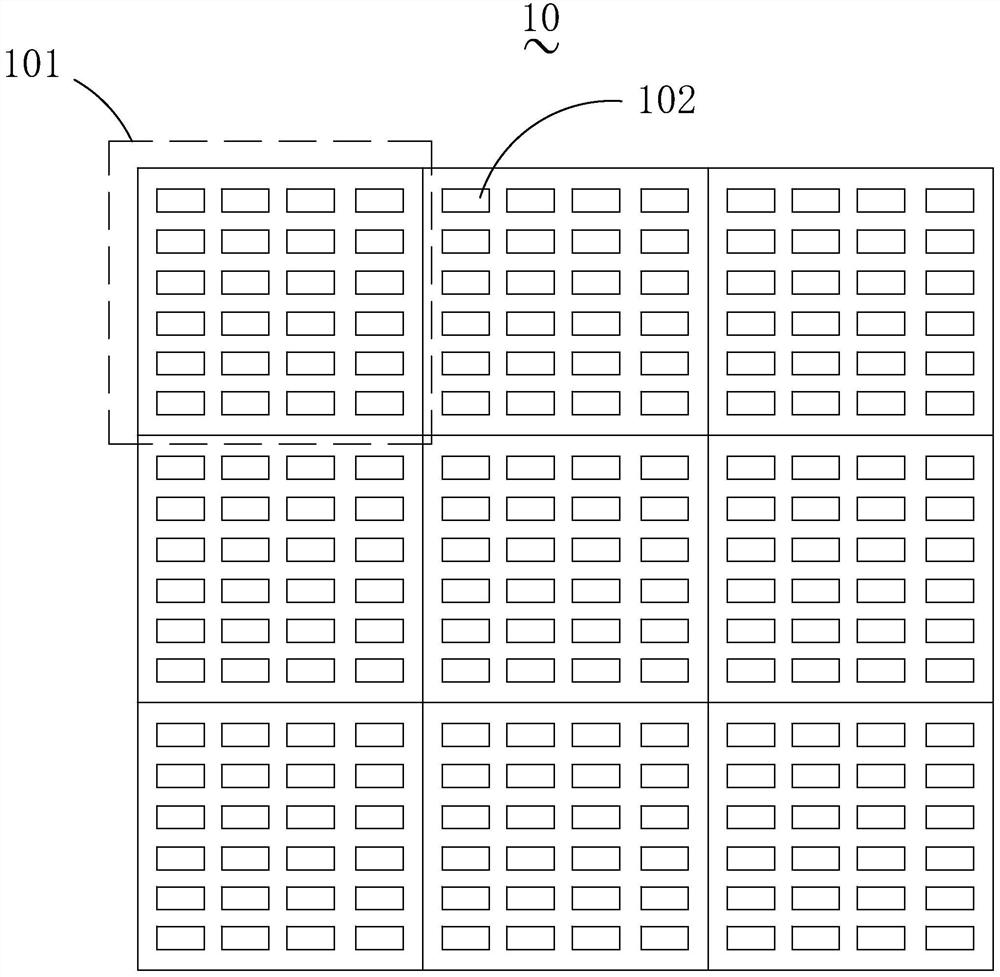

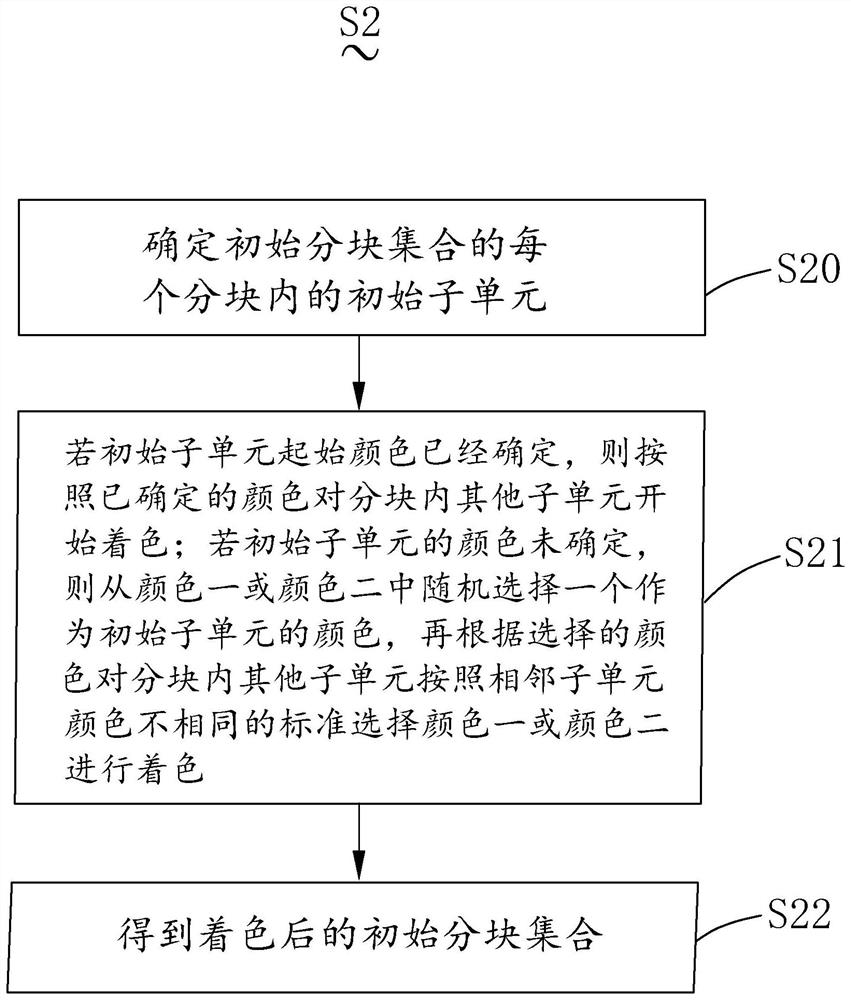

Method and device for solving mask coloring boundary conflict and computer equipment

PendingCN114638189AReduce wasteSave resourcesTexturing/coloringPhotomechanical exposure apparatusGraphicsAlgorithm

The invention relates to the technical field of photoetching, in particular to a method and device for solving coloring boundary conflicts and computer equipment, and the method comprises the following steps: S0, providing an initial mask pattern; the method comprises the steps that S1, an initial mask plate graph is divided into a plurality of blocks, each block comprises a plurality of subunits, and each block comprises an initial subunit and a key subunit; s2, selecting a predetermined area of the initial mask plate graph as an initial block set, the initial block set comprising at least one block, and coloring a subunit of each block in the initial block set through a preset coloring function to obtain a colored initial block set; and S3, coloring other blocks through the coloring function and the key subunit of each block in the initial block set after coloring to obtain a colored mask pattern. According to the method provided by the invention, the efficiency of solving the coloring boundary conflict problem is improved.

Owner:DONGFANG JINGYUAN ELECTRON LTD

Skin care matrix containing folium artemisiae argyi extract and preparation method of skin care matrix

The invention discloses a skin care matrix containing a folium artemisiae argyi extract and a preparation method of the skin care matrix. The skin care matrix comprises a folium artemisiae argyi extract liposome and skin nourishing element liposome, wherein the folium artemisiae argyi extract liposome is prepared from the olium artemisiae argyi extract, a green tea extract, a rose extract, a mulberry leaf extract and a radix ginseng extract as raw materials; the skin nourishing element liposome is prepared from a ginger extract. The skin care matrix disclosed by the invention realizes the comprehensive skin care effects of moisturizing, whitening, resisting inflammation and inhibiting bacteria by synergism of folium artemisiae argyi, green tea, rose, mulberry leaf and radix ginseng; meanwhile, the skin care matrix also contains the skin nourishing element liposome which promotes the folium artemisiae argyi extract liposome to absorb and timely discharge metabolic products, avoids deposition and skin damage and realizes deep nourishment and metabolism discharge of skin; an original one-way action mechanism is changed, and two-way transdermal absorption of the skin care matrix is realized. The preparation method provided by the invention is simple and easy to operate, is suitable for industrial production and can be widely applied to the production of the skin care matrix.

Owner:GUANGDONG AUTHENTEA BIOTECH INC

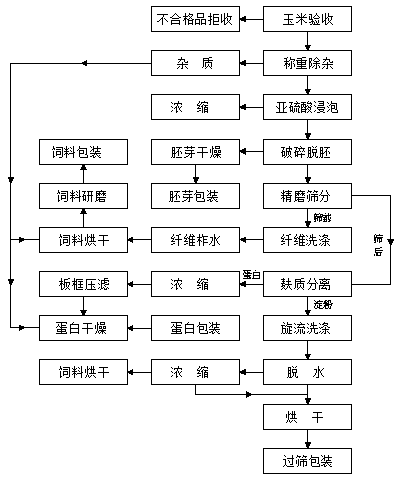

Preparation method of corn starch

InactiveCN111303304ACorn fiber retentionEasy to keepPeptide preparation methodsProcess engineeringGluten

The invention discloses a preparation method for preparing starch from corn, and relates to the technical field of corn deep processing. The specific operation method comprises seven steps of impurityremoval and soaking, crushing and degerming, fine grinding and screening, gluten separation, nine-stage cyclone washing, dehydration and drying, and screening and packaging. According to the invention, the technological process is complete, and in the preparation process of corn starch, corn fibers and corn protein are well reserved and prepared into a feed to be reused, so that the yield of terminal products is greatly increased, the economic value of total products is increased, and resource waste is also avoided; and the technological process is compact, and through long-time actual operation, the screened technological conditions are low in energy consumption and high in yield, so that the method is suitable for actual production.

Owner:HEILONGJIANG HAOTIAN CORN DEV

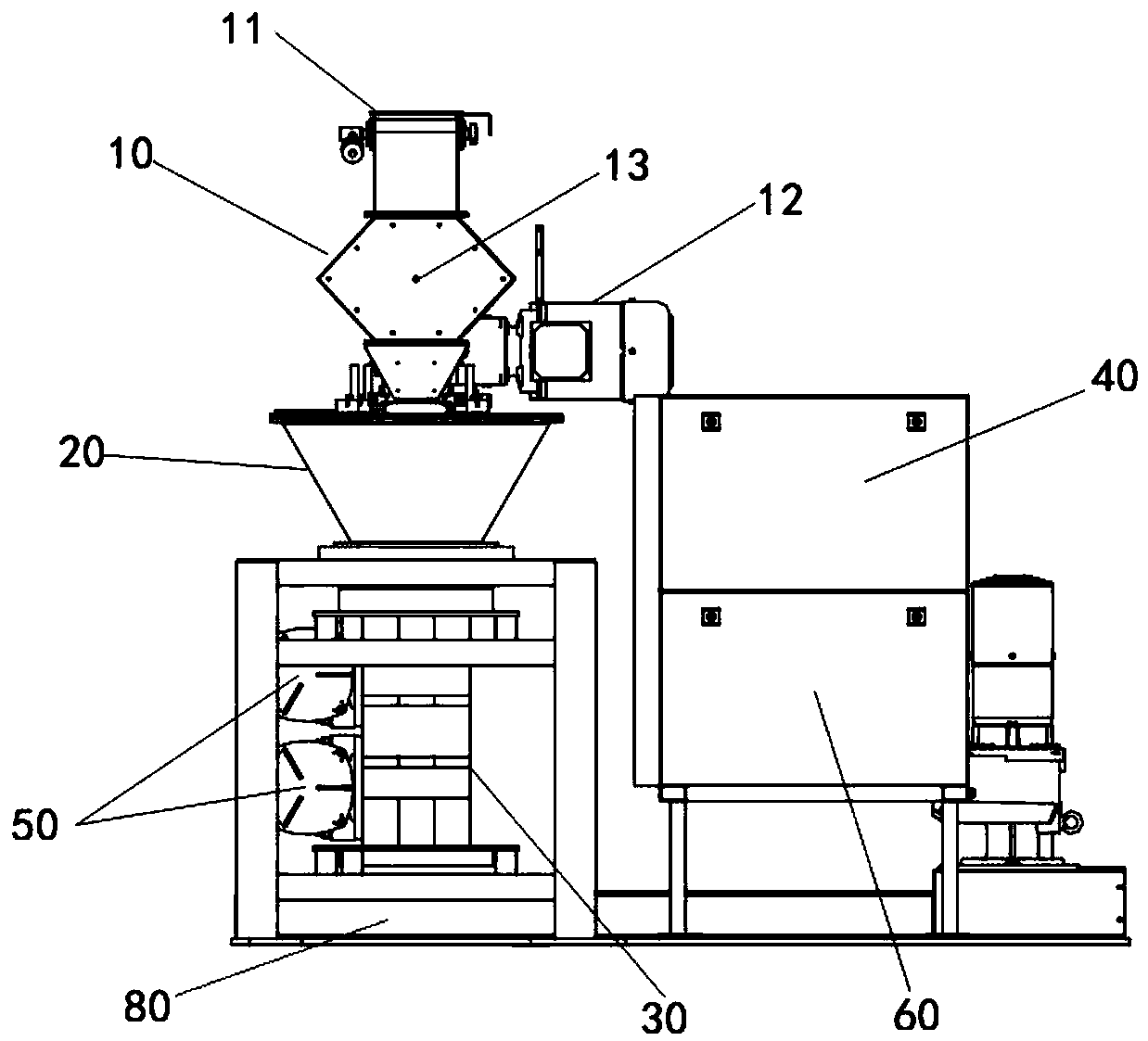

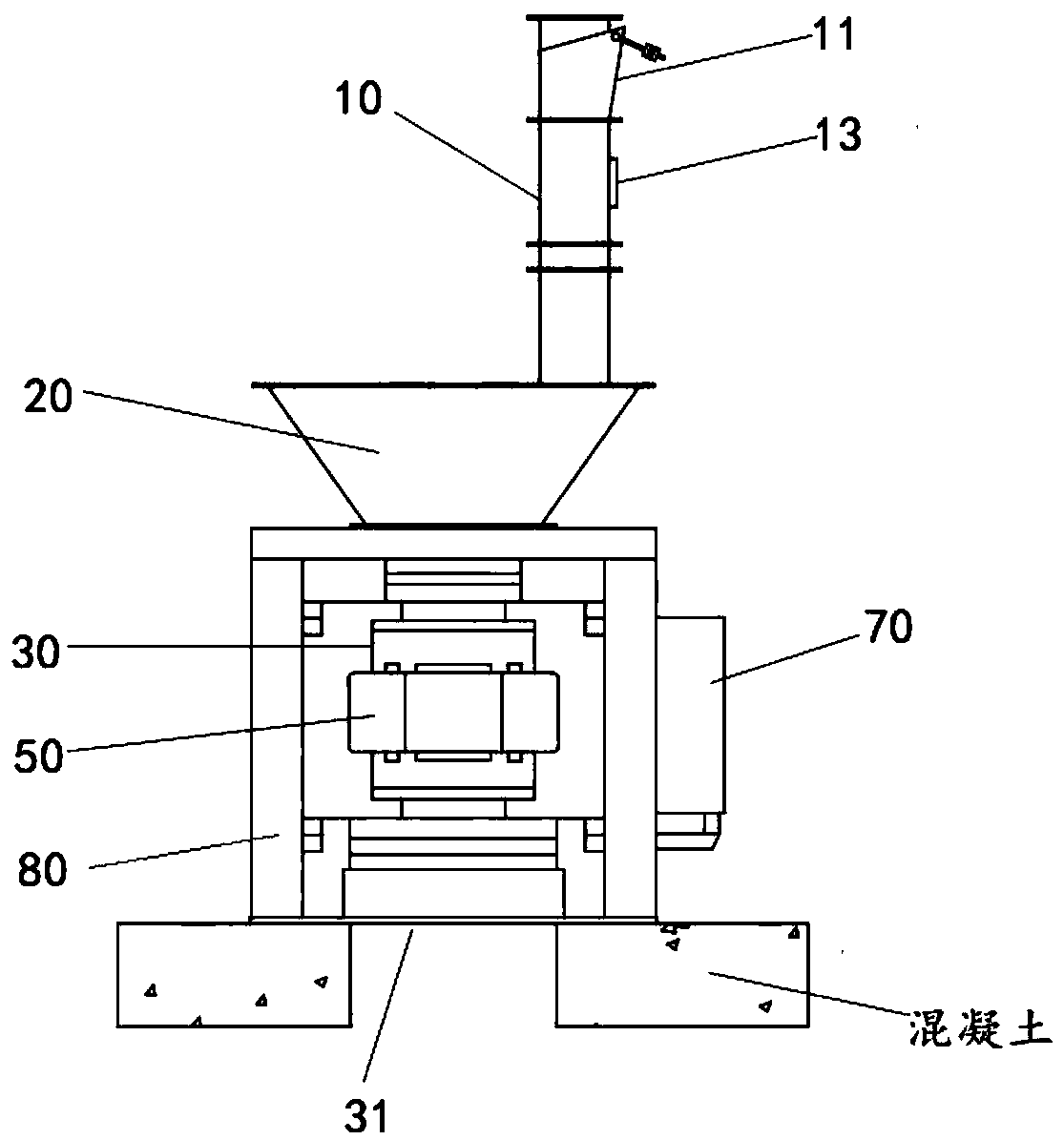

Intelligent and efficient dampener

The invention provides an intelligent and efficient dampener. The intelligent and efficient dampener comprises a feeding bin, a water adding bin, a vibrating bin and a water supply mechanism. A flap valve is arranged at the top of the feeding bin, an opening of the flap valve is a feeding port, and feeding rolls are arranged in the feeding bin. The vibrating bin is connected with a vibrating device, and discharging ports are arranged at the bottom of the vibrating bin. The water supply mechanism is provided with a flow rate control assembly used for adjusting the flow rate of water. The feeding bin, the water adding bin and the vibrating bin communicate in sequence. The water adding bin is connected with the water supply mechanism. The intelligent and efficient dampener is provided with the water adding bin, corns enter into the water adding bin through the feeding bin, water is fed into the water adding bin, and the corns and the water are mixed sufficiently. The dampener is providedwith the vibrating bin, the mixture of the corns and the water enters into the vibrating bin, and the vibrating bin vibrates and enables the water to be distributed evenly. The water supply mechanismof the dampener is provided with the flow rate control assembly, the water inflow of the water adding bin can be effectively controlled through the flow rate control assembly, and the dampener is suitable for actual production.

Owner:大连市高昌机器制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com