Wax mold injection process parameter determination method based on injection molding numerical simulation

A technology of numerical simulation and parameter determination, applied in special data processing applications, computer-aided design, design optimization/simulation, etc. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

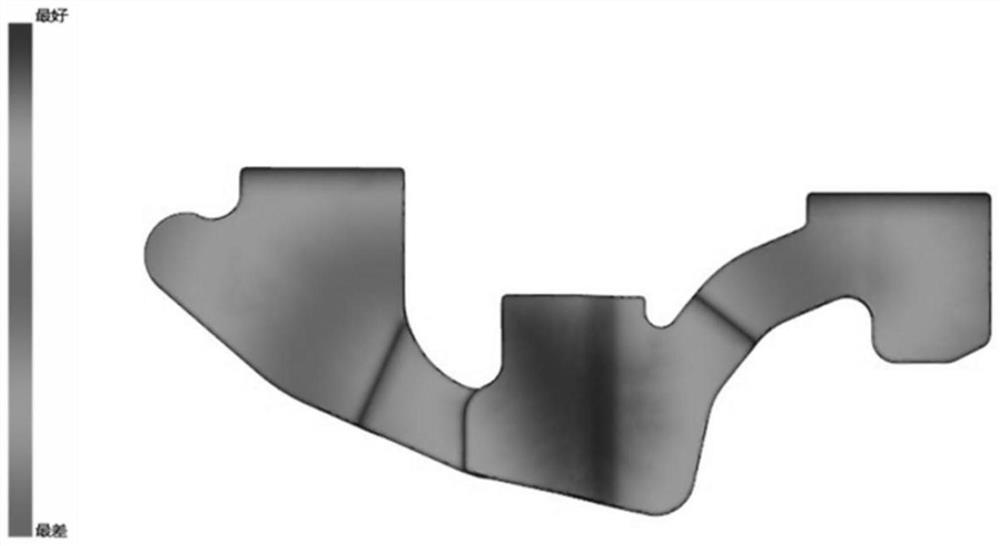

[0021] Step 1: The overall size of the selected wax model is: length 168.2mm, width 63mm, height 23mm, wall thickness 7mm. Set the parameters of the wax injection machine in the Moldflow software: set the maximum injection rate to 300cm3 / s, the maximum injection pressure to 7Mpa, the maximum clamping force to 100 metric tons, the mold material to choose Aluminum Al, the mold temperature to 23°C, and the ambient temperature The mold-melt thermal conductivity coefficient is 22°C, the filling coefficient is 2500, the pressure holding coefficient is 1000, the separation coefficient is 500, and the injection wax material is KC4017B medium temperature wax material.

[0022] Step 2: Establish a finite element model in the Moldflow numerical simulation software according to the size and structure of the actual wax model, and divide the three-dimensional finite element model grid by tetrahedral mesh.

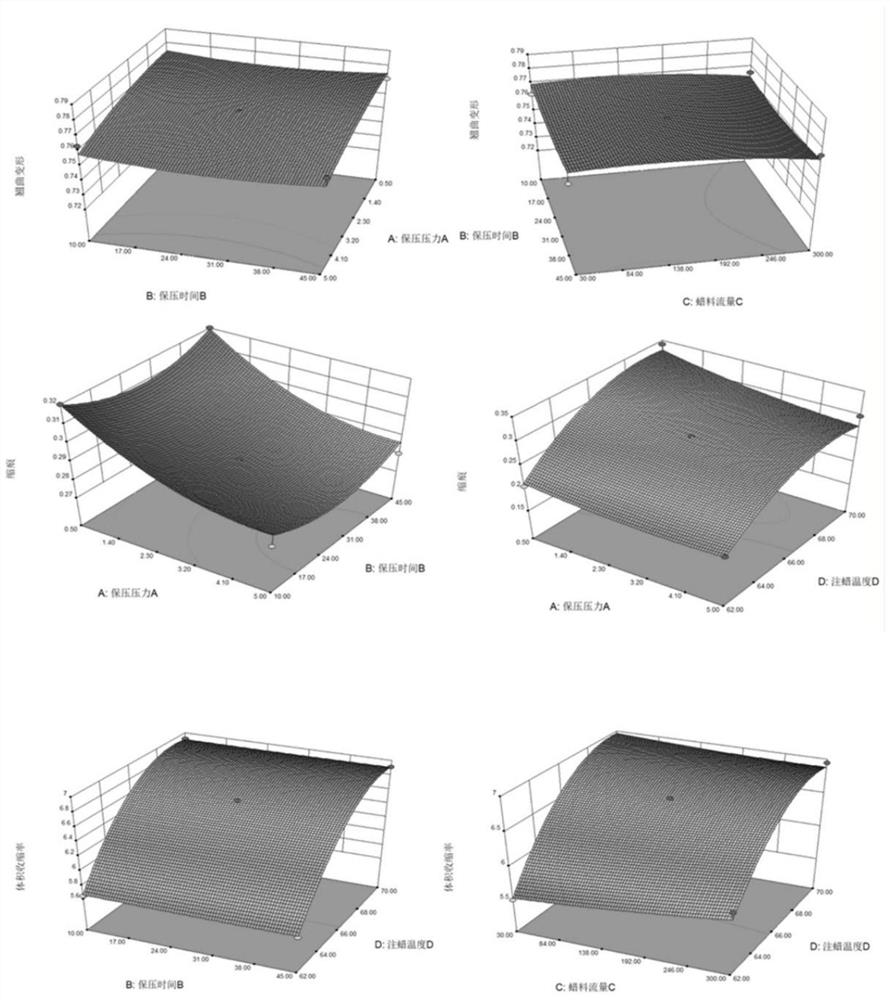

[0023] Step 3: In the Moldflow numerical simulation software, the gate analysis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com