Patents

Literature

34results about How to "Easy to distribute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

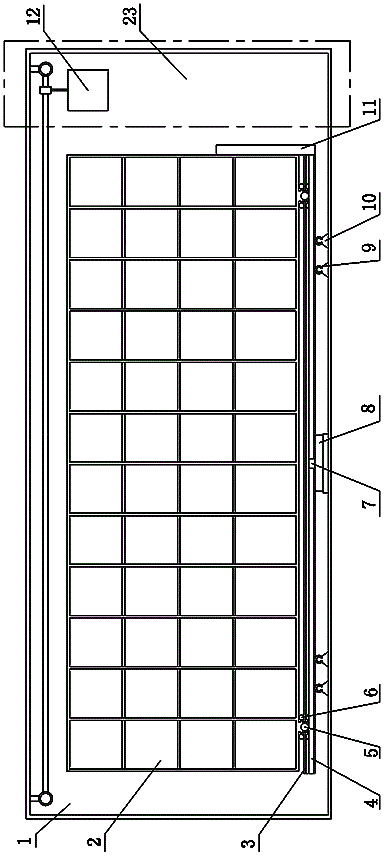

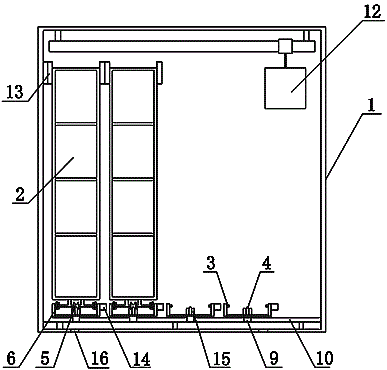

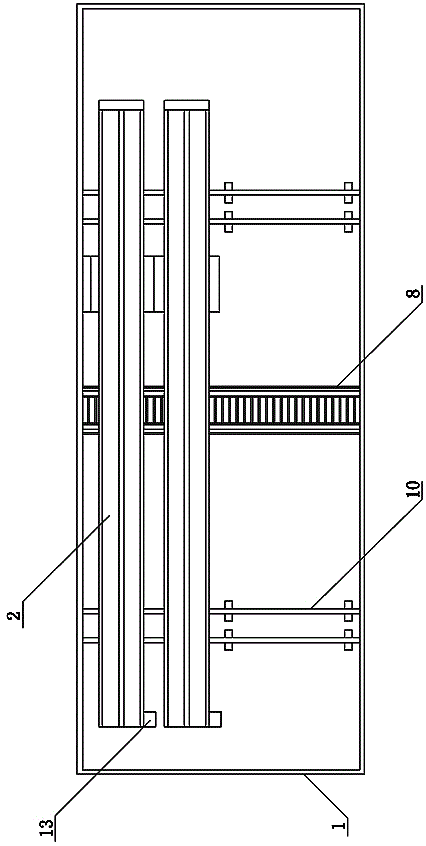

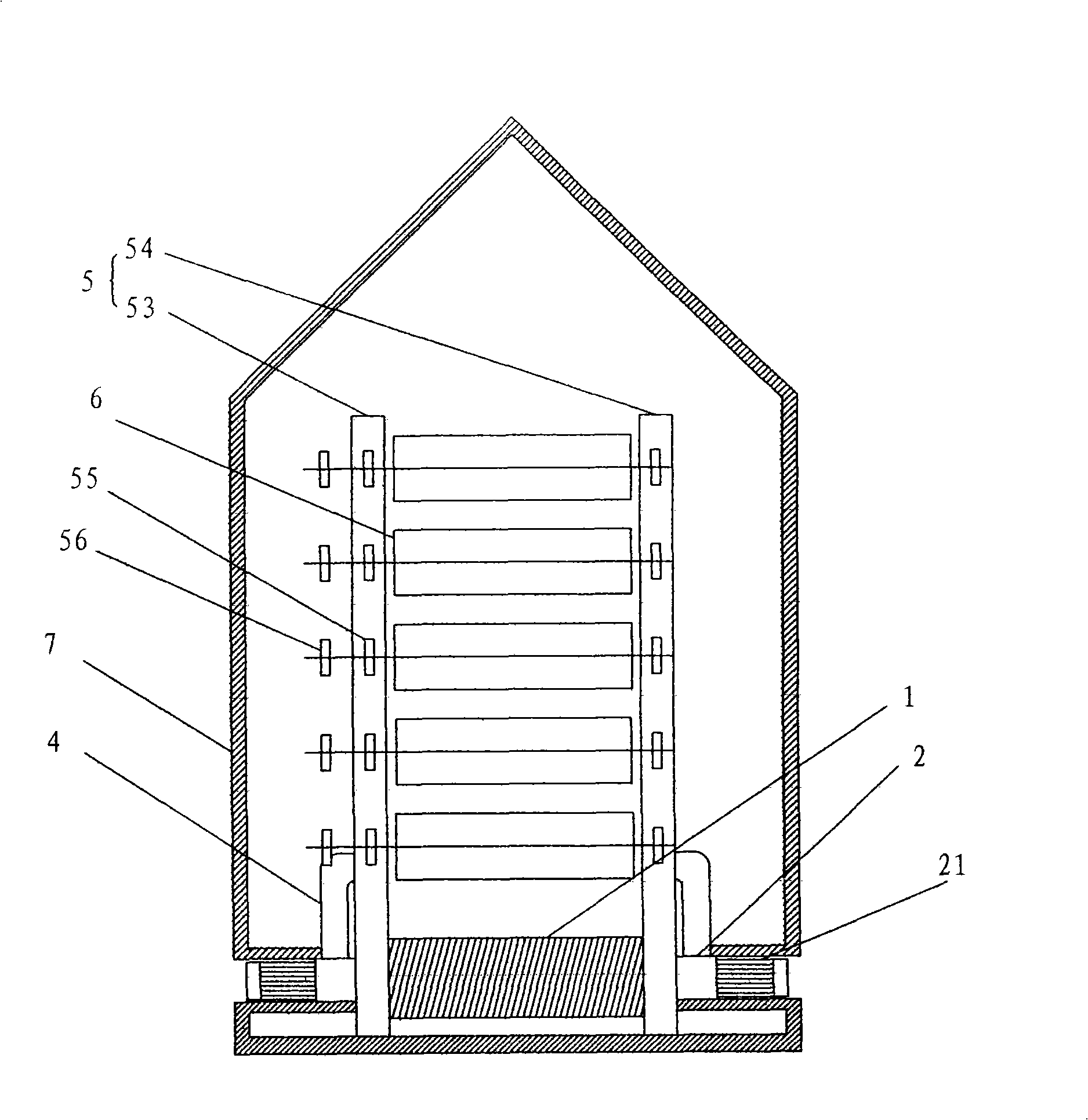

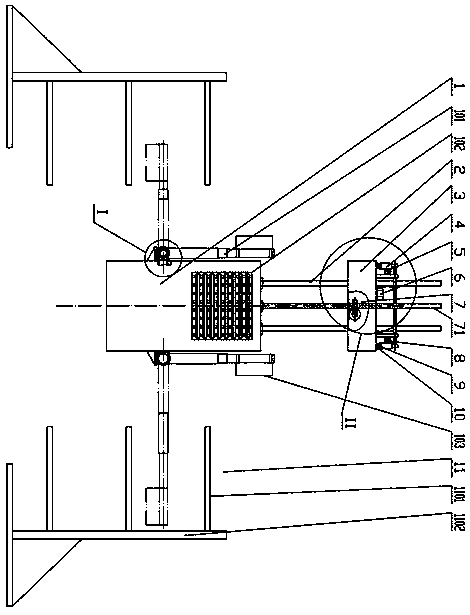

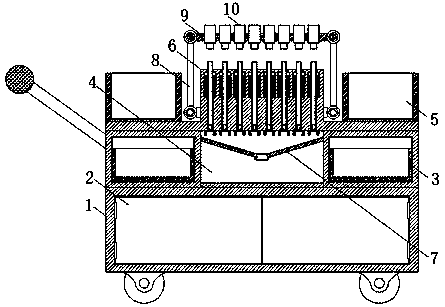

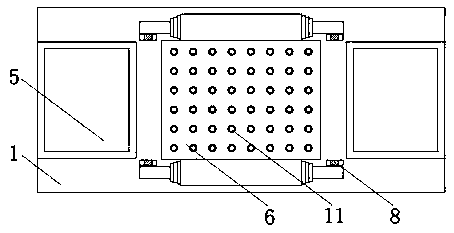

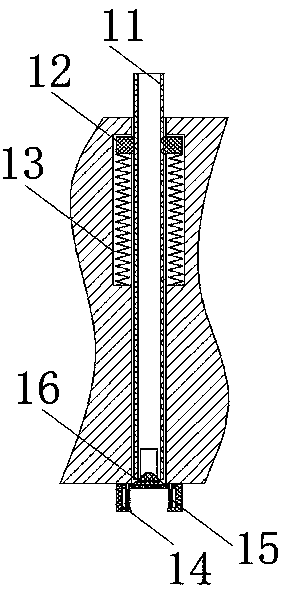

Intelligent express delivery distribution vehicle and use method thereof

ActiveCN105539248AGuaranteed tidyEasy loadingLoad securingItem transportation vehiclesButt jointHanging basket

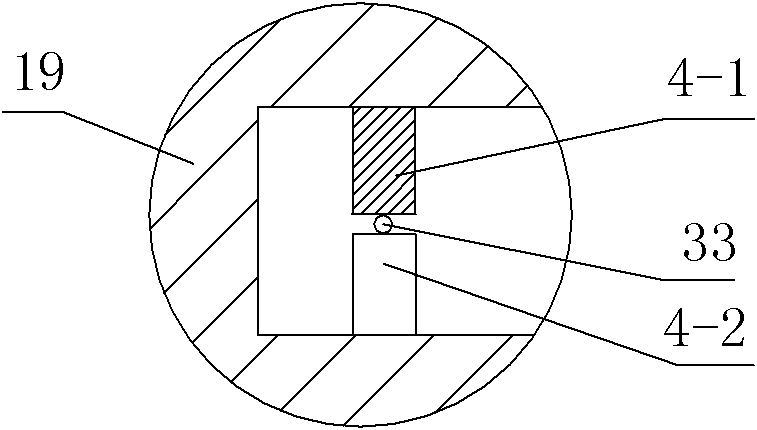

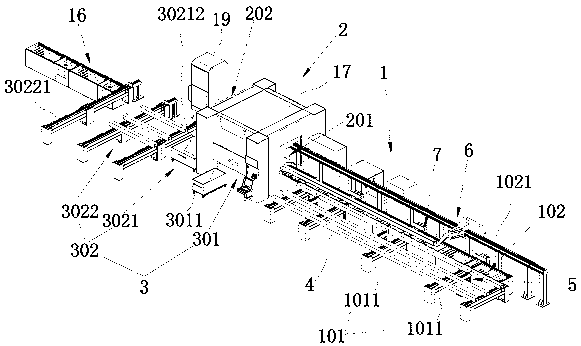

The invention relates to an intelligent express delivery distribution vehicle which comprises a carriage (1), a goods cabinet, a bottom moving mechanism and a hanging basket moving mechanism (12). The carriage (1) is of a hollow cuboid structure. The bottom moving mechanism is arranged on the bottom face of the inner side of the carriage (1). The goods cabinet is installed on the bottom moving mechanism in a matched manner. A hanging basket stop region (23) is arranged in the portion, on one side of the goods cabinet, of the carriage (1). The hanging basket moving mechanism (12) is installed above the hanging basket stop region (23). A ferry vehicle butt-joint module (16) is further arranged at the bottom of the carriage (1). The bottom moving mechanism comprises a load bearing sliding rail (4), a linear motor (8), transverse moving sliding blocks (9), transverse moving guide rails (10) and a bottom frame (11). The goods cabinet comprises drawer frames, multiple storage drawers (2) and magnetic seats (13) and load bearing idler wheels (5) are installed at the bottoms of the drawer frames. The intelligent express delivery distribution vehicle has the beneficial effects that the intelligence degree is high, loading is convenient, the distribution process is simple, and time and labor are saved.

Owner:SOUTHWEST PETROLEUM UNIV

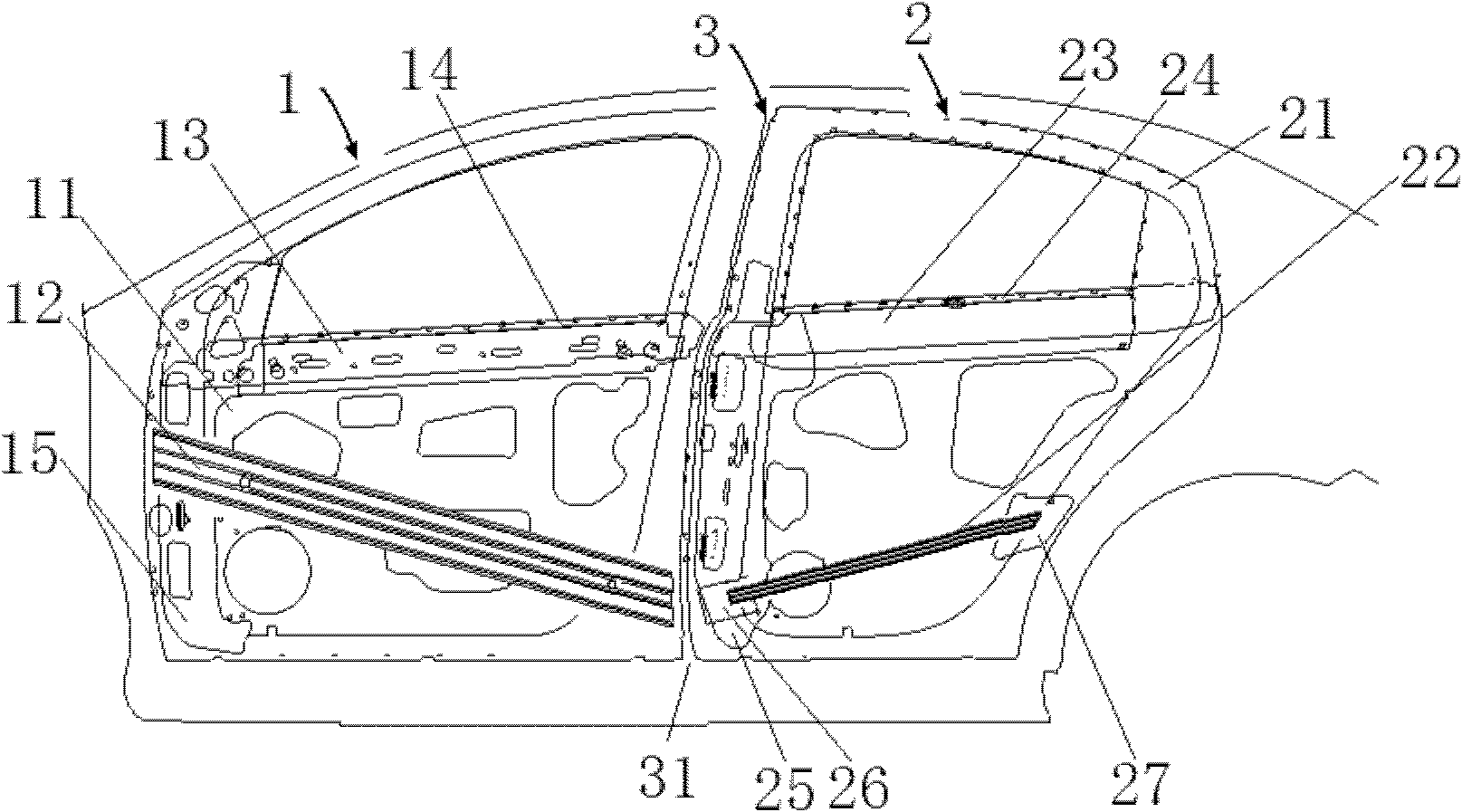

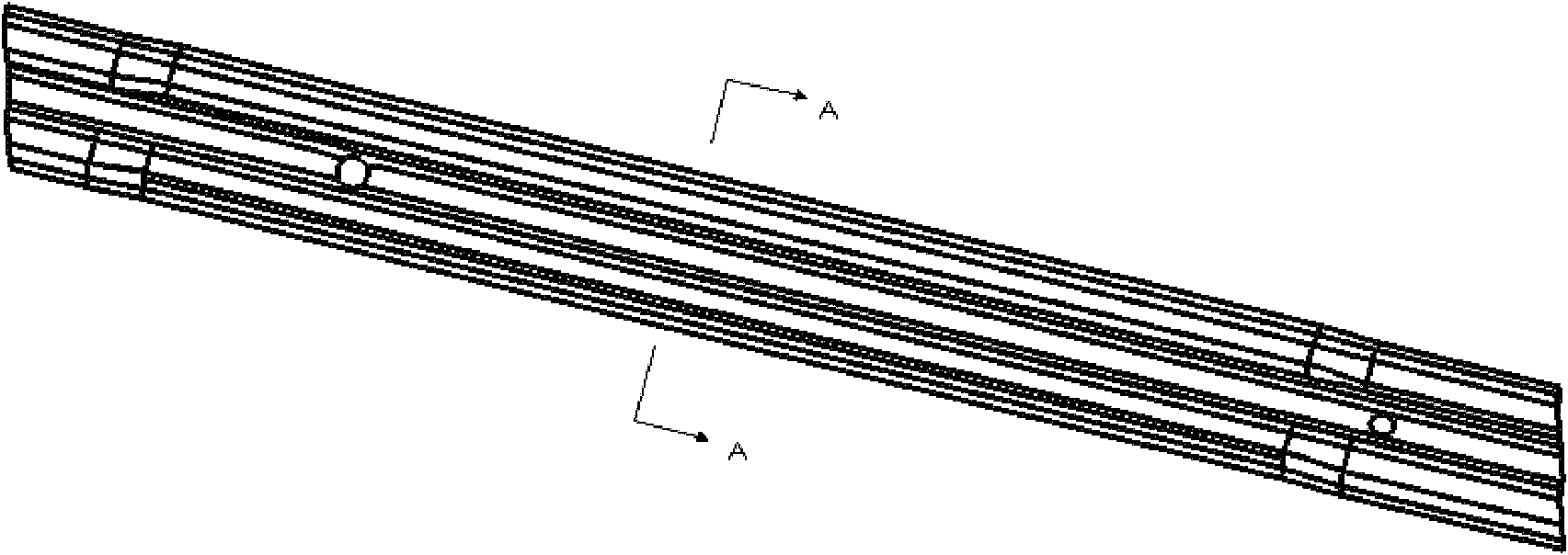

Car door anti-collision beam

The invention discloses a car door anti-collision beam. The car door anti-collision beam comprises front door anti-collision beams arranged on front car doors and rear door anti-collision beams arranged on rear car doors, wherein the front door anti-collision beams are obliquely arranged from front to rear; the front ends of the front door anti-collision beams are fixed between an upper hinge and a lower hinge at the front ends of front door inner plates and are close to the position of the upper hinge; the rear ends of the front door anti-collision beams are fixed at the positions close to the root parts of the lower ends of columns B on the front door inner plates; and the cross sections of the front door anti-collision beams are of bow-shaped structures. As the cross sections of the front door anti-collision beams are bow-shaped, the best energy absorbing effect of the whole anti-collision beam in a lateral collision process can be obtained, and much collision energy is absorbed; as the front door anti-collision beams are obliquely arranged, most of loads on front hinge columns in a forward collision process can be transferred to the root parts of the columns B through the car door anti-collision beam, and the rest of few loads are transferred to the lower parts of the columns B through car door window frame reinforced plates, so that the loads are favorably transferred in a dispersing way, therefore, the safety of front passengers can be guaranteed more comprehensively; and the columns B cannot be suffered with buckling deformation, so that car doors can be still opened in case of an accident.

Owner:CHERY AUTOMOBILE CO LTD

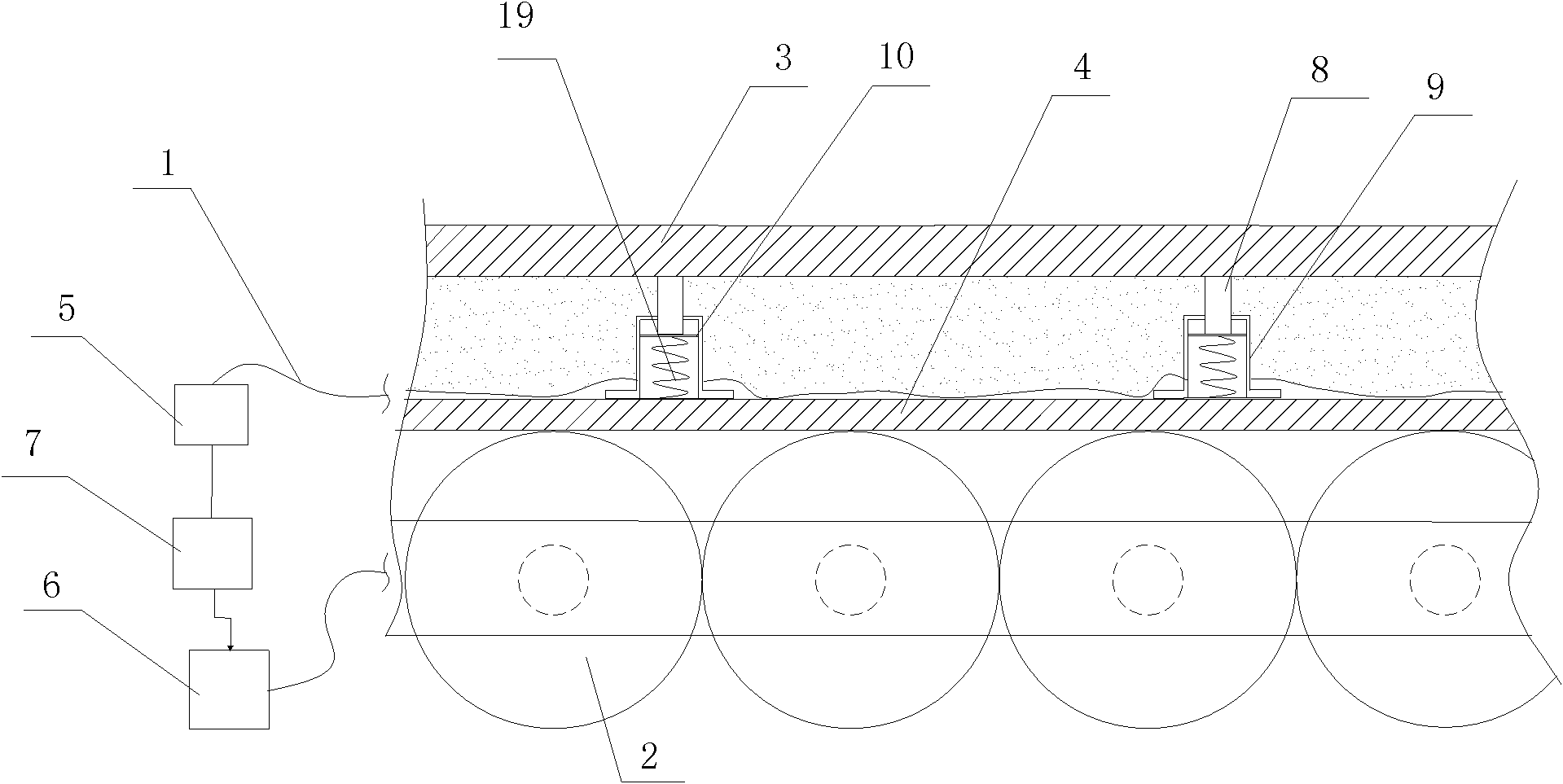

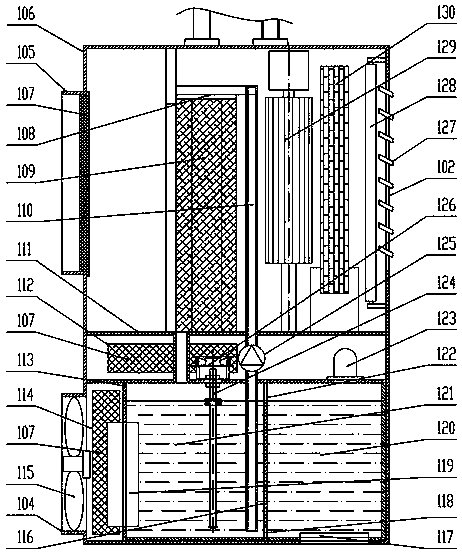

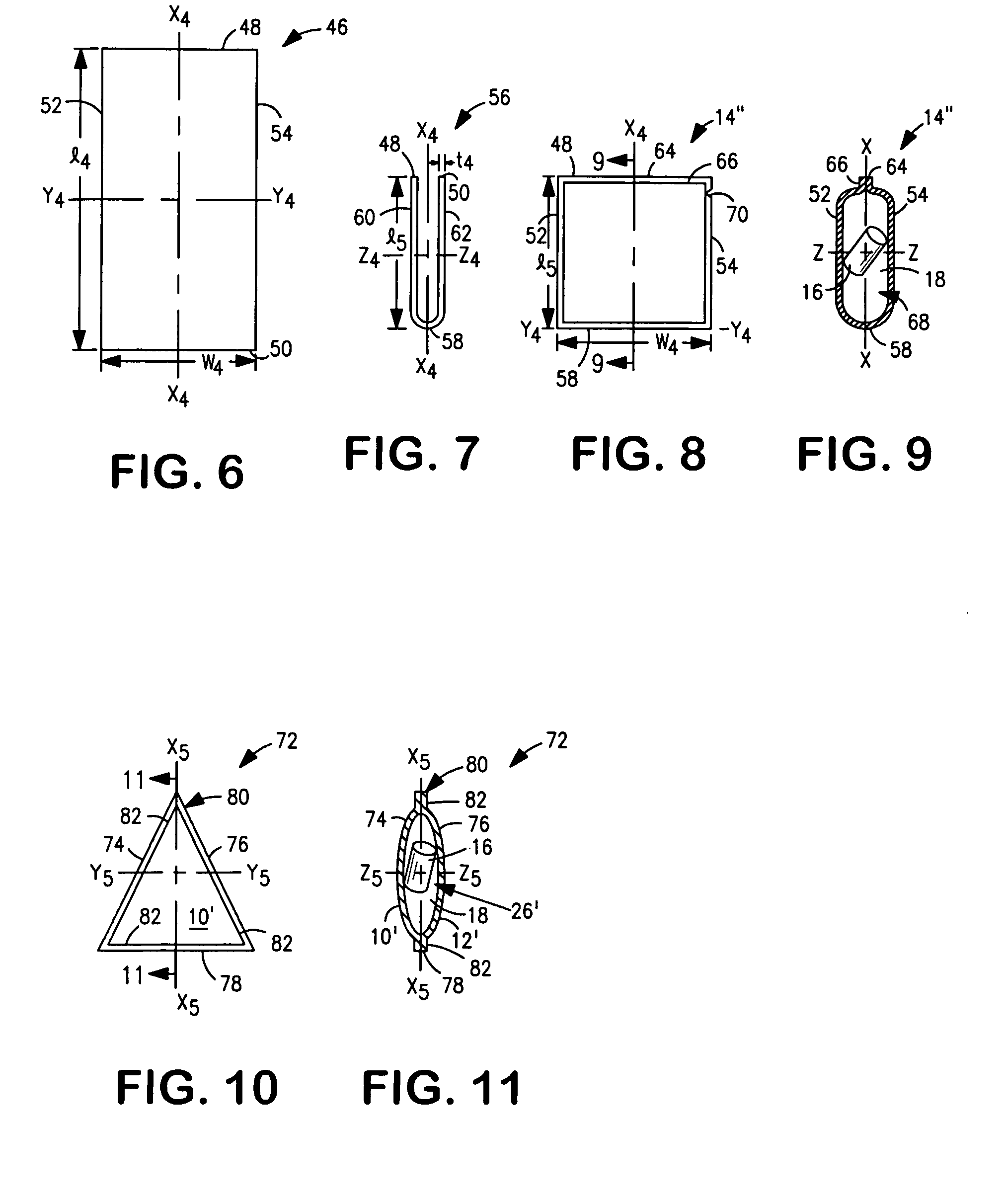

Air cushion device

InactiveCN102485120ASimple structureEasy to processForce measurement by measuring optical property variationFluid mattressesPlate pressureEngineering

The invention discloses an air cushion device. The device comprises: an elastic plate and a plurality of air bags, wherein the air bags are connected with a pump, the elastic plate which is positioned on upper surfaces of the air bags comprises an upper surface plate and a lower surface plate, a filler is arranged between the upper surface plate and the lower surface plate, a curve-shaped support is arranged in the filler, A-side deformed teeth and B-side deformed teeth are distributed on two opposite sides in the curve-shaped support, curve-shaped channels for one or more of signal optical fibers to traverse through are formed between heads of the A-side deformed teeth and the B-side deformed teeth, and the A-side deformed teeth and B-side deformed teeth are correspondingly distributed on two sides of the signal optical fiber; and a signal optical fiber connection testing unit and a testing unit connection processing unit, wherein the processing unit adjusts the amount of the gas filled in each air bag by controlling the air pump according to the elastic plate pressure distribution detected by the testing unit. The device of the invention has the advantages of simple structure, reasonable design, low cost, flexible use mode, high sensitivity, and good use effect.

Owner:XIAN JINHE OPTICAL TECH

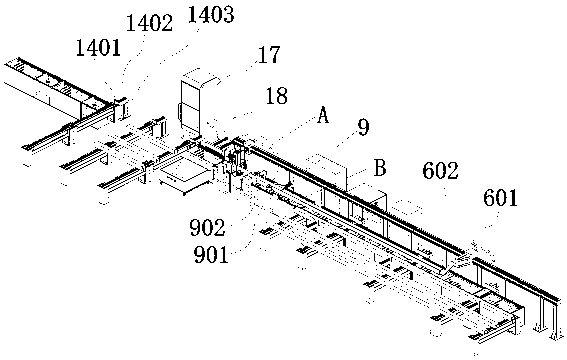

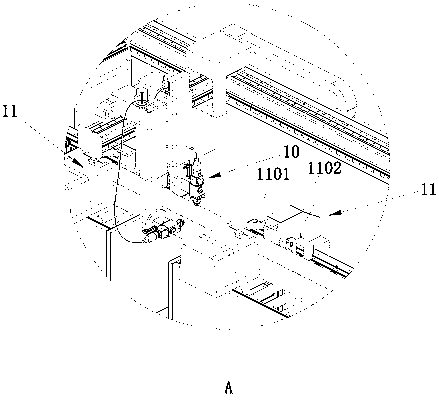

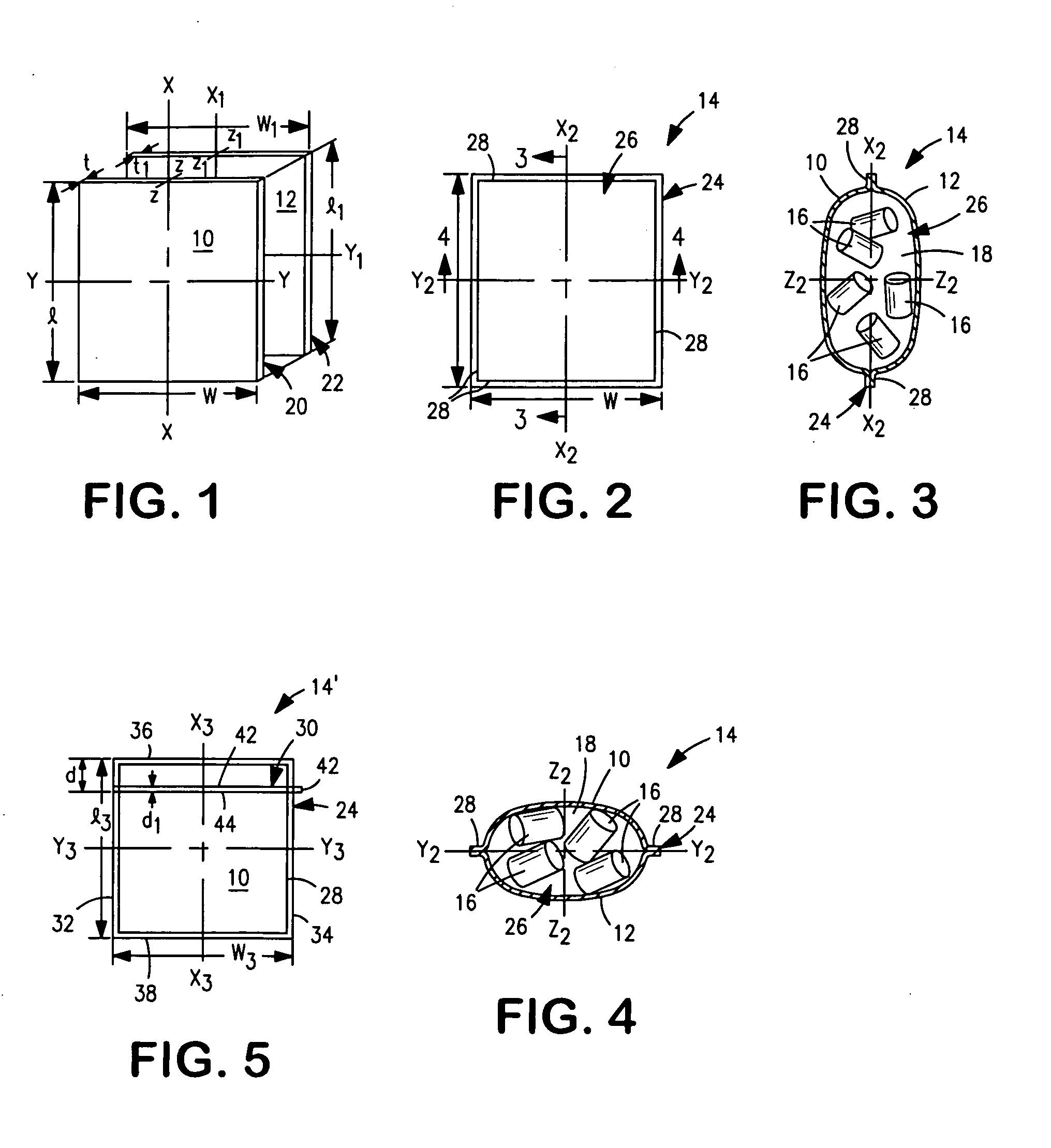

Profile cutting method for laser cutting automatic production line

ActiveCN111482719AEasy to distributeEasy to processWelding/cutting auxillary devicesAuxillary welding devicesPhysicsLaser cutting

The invention discloses a profile cutting method for a laser cutting automatic production line, and relates to the field of laser machining. The automatic production line comprises a feeding area, a cutting area and a blanking area, wherein a storage rack and a feeding table are arranged in the feeding area, a side pushing assembly used for pushing profiles to the feeding table is arranged on thestorage rack, the cutting area comprises a feeding end and a discharging end, one end of the feeding table is in butt joint with the feeding end, a forward pushing assembly is further arranged on thefeeding table, the blanking area comprises a first blanking area and a second blanking area, the first blanking area is positioned below the cutting area, and the second blanking area is in butt jointwith the discharging end. According to the method, the blanking area is divided into the first blanking area and the second blanking area, and the blanking of the cut profiles with length less than 1m and the cut profiles with length more than or equal to 1m is carried out through the blanking area and the second blanking area respectively, so that the profiles with different lengths are conveniently cut, classified blanking is carried out, machining is convenient, and the cutting efficiency of the profiles is high.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

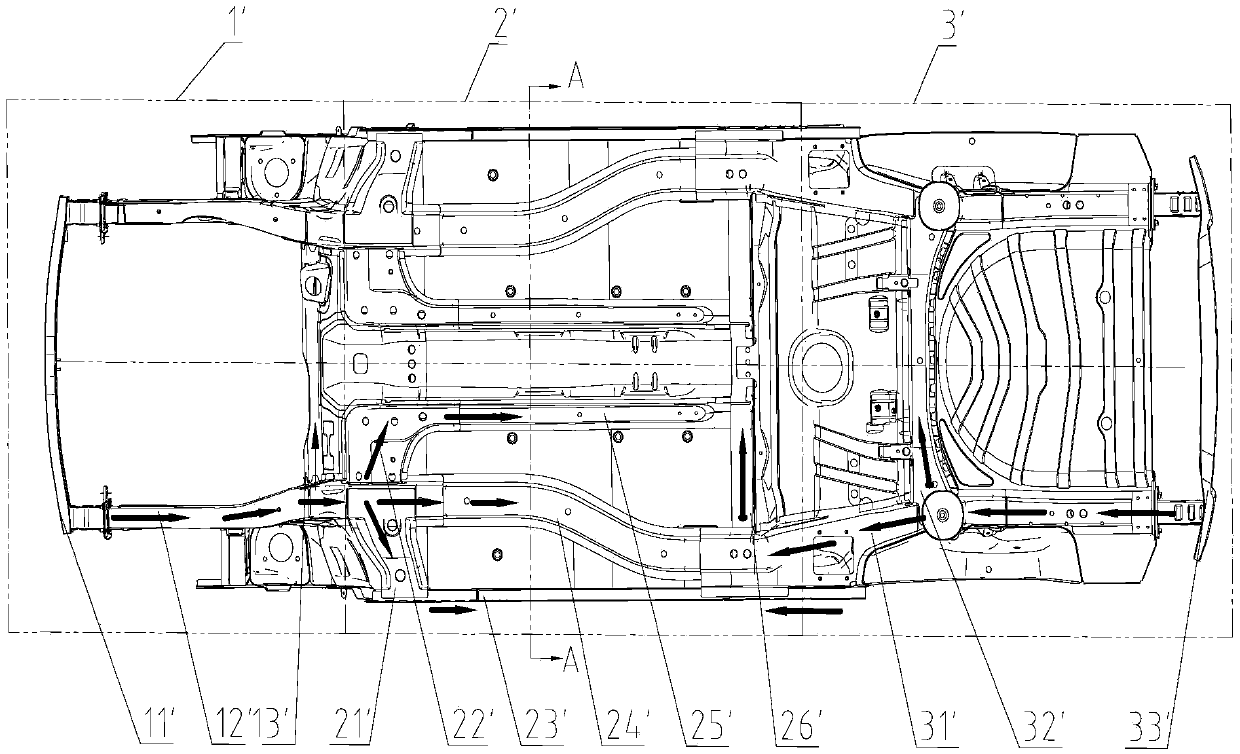

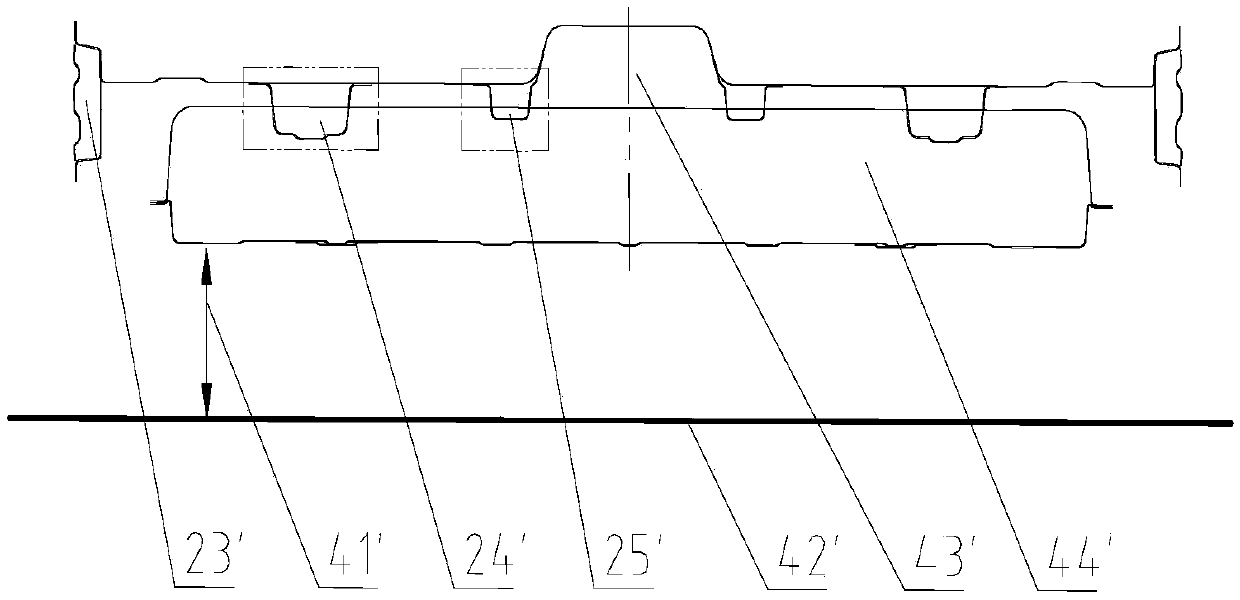

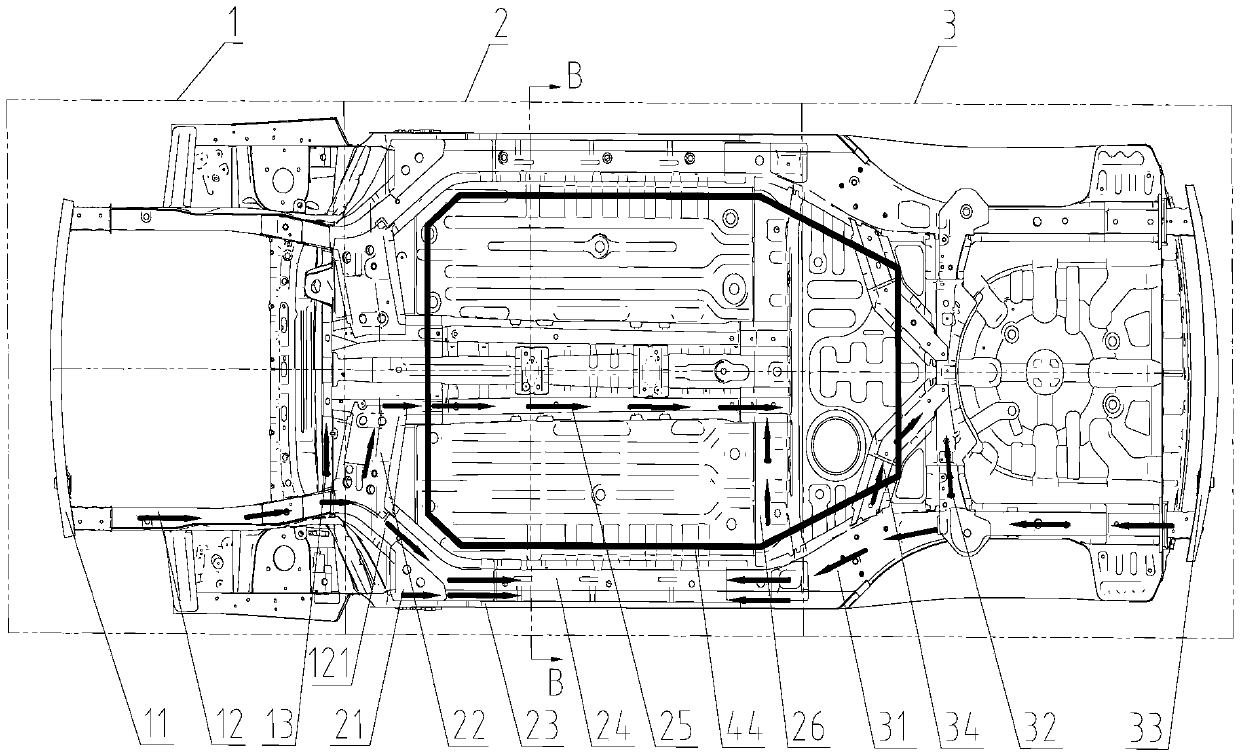

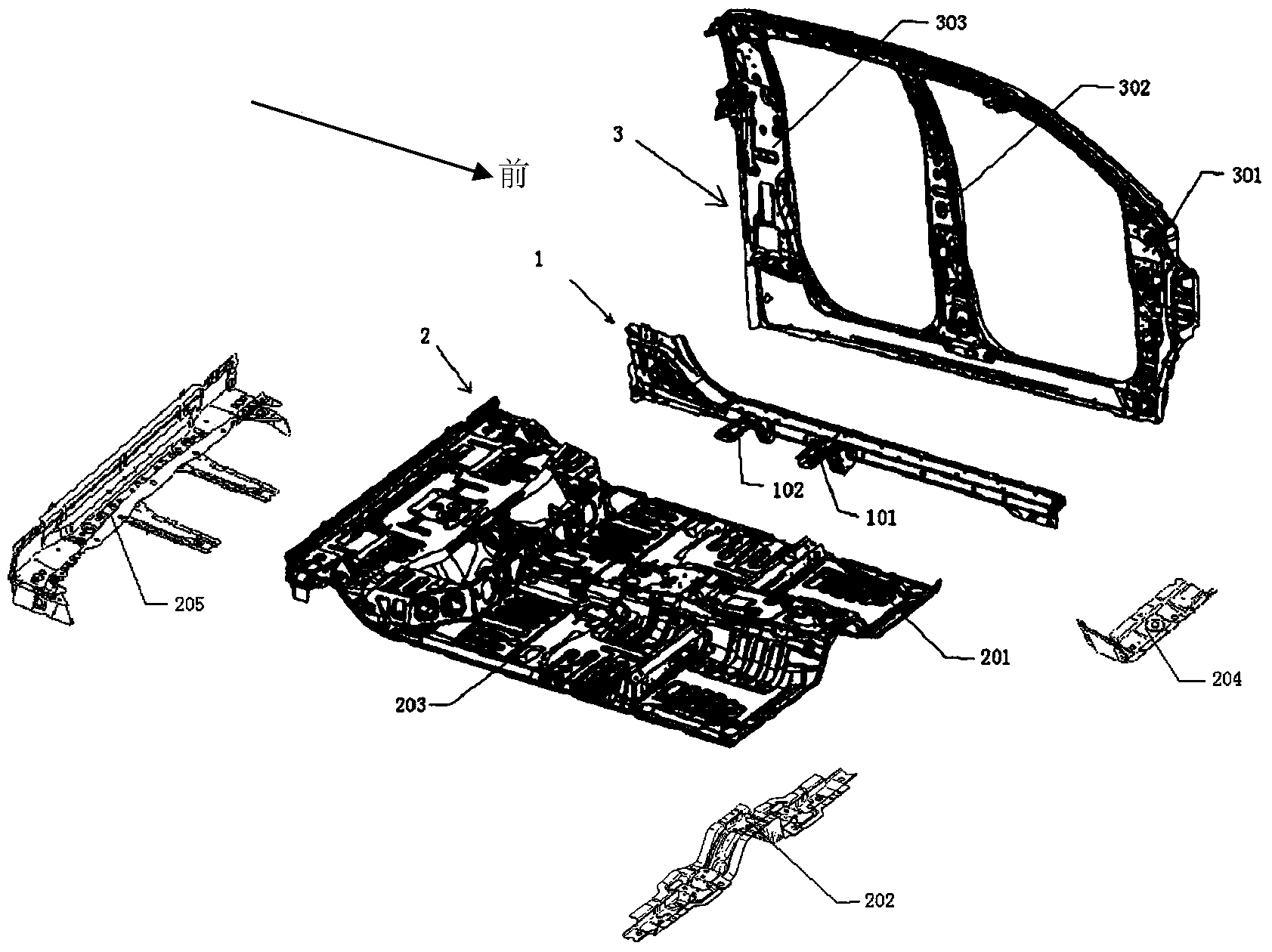

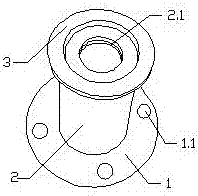

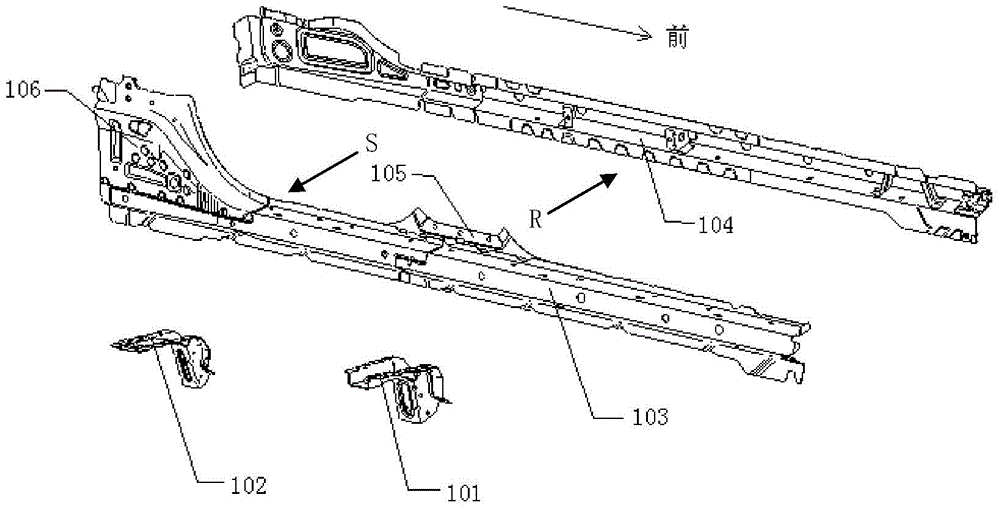

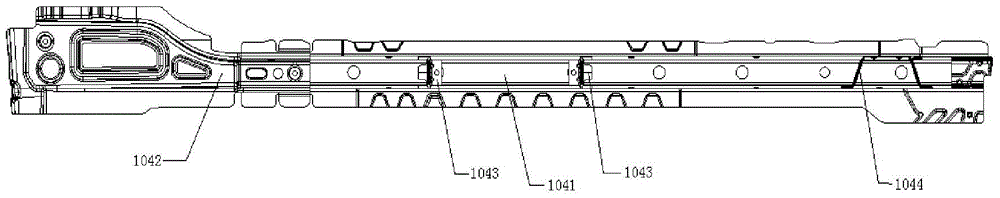

Electric automobile body frame bottom structure

PendingCN109552022AEasy to fixEasy to distributeElectric propulsion mountingSuperstructure subunitsPower batteryBody frame

The invention discloses an electric automobile body frame bottom structure. The electric automobile body frame bottom structure comprises an engine compartment assembly (1), a front floor assembly (2)and a rear floor assembly (3) which are arranged in sequence; the front floor assembly (2) comprises a front floor (45), a longitudinal floor central passage cavity (43), two central passage longitudinal beams (25), a power battery (44), two front floor longitudinal beams (24) and two threshold beams (23), wherein the longitudinal floor central passage cavity (43) is formed in the center of the floor; the two central passage longitudinal beams (25) are accommodated in the longitudinal floor central passage cavity (43) and symmetrically arranged on the two sides of a center axis of the longitudinal floor central passage cavity (43); the power battery (44) is arranged under the longitudinal floor central passage cavity (43); and the two front floor longitudinal beams (24) and the two threshold beams (23) are symmetrically arranged on the two sides of the power battery (44) and arranged in sequence from inside to outside. According to the electric automobile body frame bottom structure,the placing space demand of the large-duration power battery is satisfied, and meanwhile, the collision safety performance and continuous integrity of the automobile body frame bottom structure are also taken into account.

Owner:WM MOTOR TECH GRP CO LTD

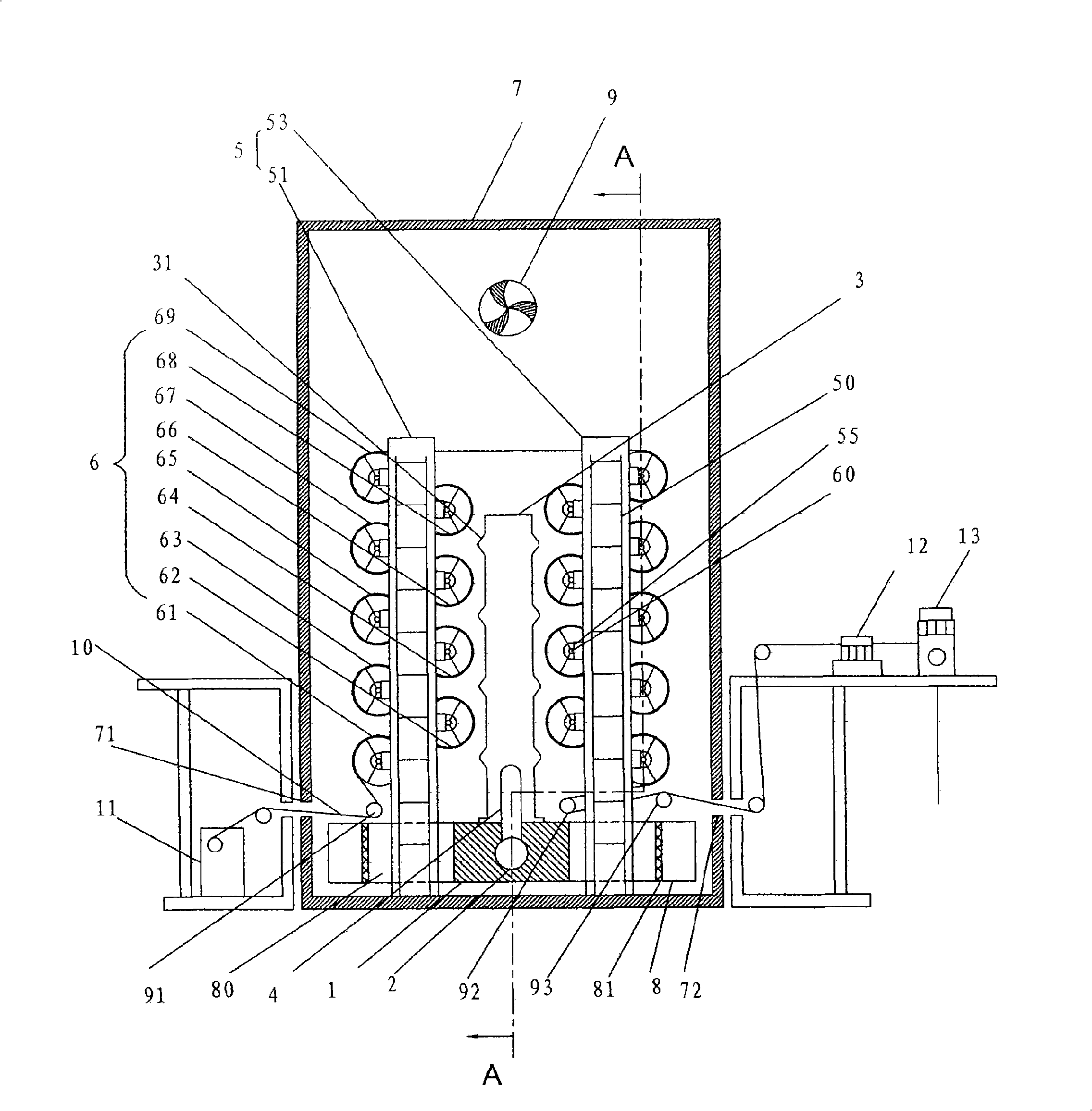

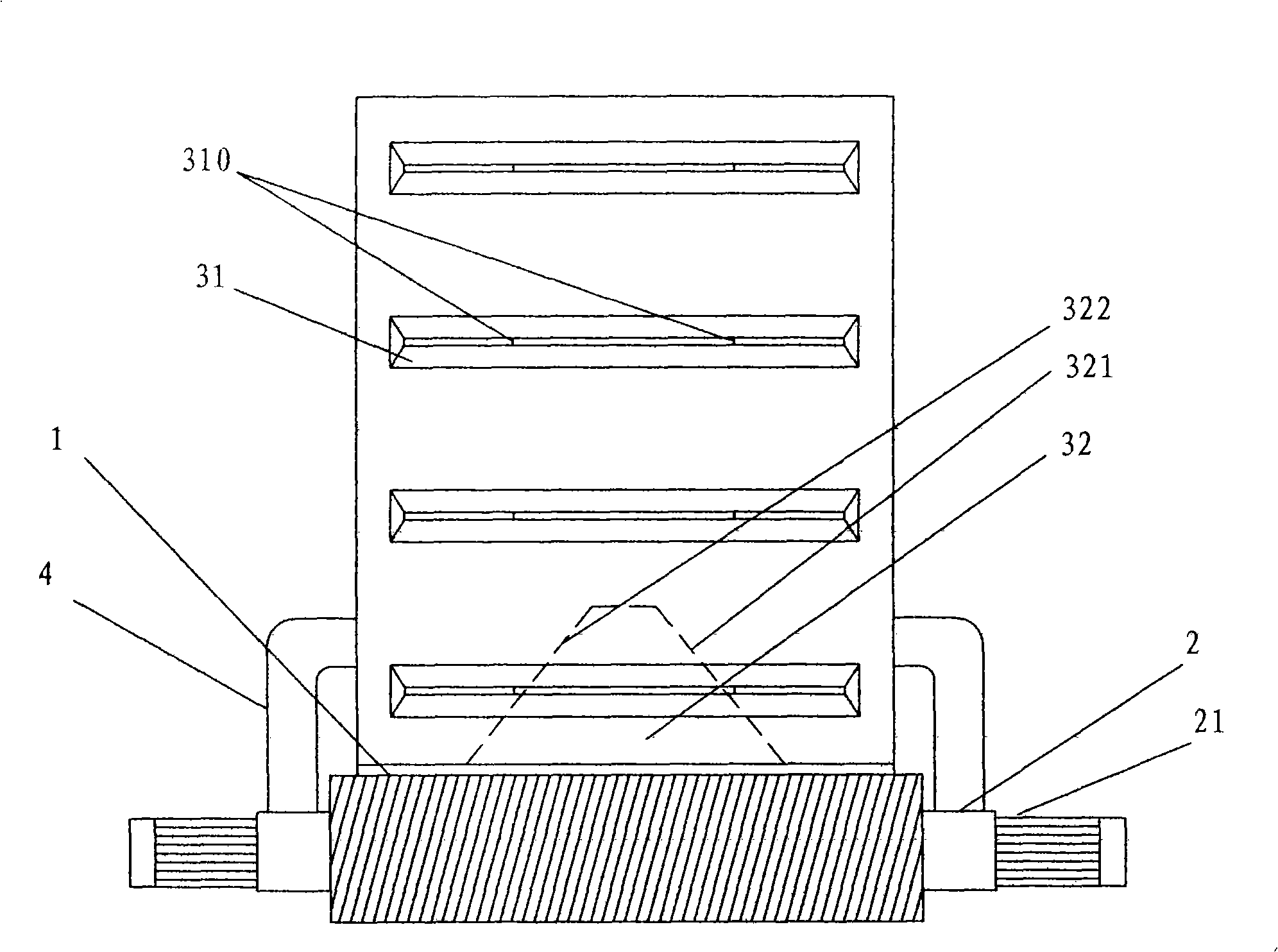

Hot-air drier

InactiveCN101514867AEasy to distributeGood energy saving effectDrying solid materials with heatDrying gas arrangementsElectric machineryFrequency conversion

The invention discloses a hot-air drier, comprising a heat-retaining housing, and drying cylinder columns, hollow drying cylinders, a radiator, a circulating blower fan, a circulating wind adapter, a hot-air channel, a pipe and an electrostatic dehydrator which are arranged in the heat-retaining housing. The heat-retaining housing has a feed inlet and outlet. More than one pair of drying cylinder columns are distributed in the heat-retaining housing, two rows of high-low staggered hollow drying cylinders are arranged between each pair of drying cylinder columns. The hollow drying cylinders are driven by a transmission mechanism. At least one radiator for heat generation is arranged in the heat-retaining housing. The circulating blower fan driven by the motor frequency conversion control is arranged on the radiator. The hot-air channel is hollow and provided with a hot-air nozzle. The circulating wind adapter is connected with the circulating blower fan and the hot-air channel. The electrostatic dehydrator is connected with the radiator through the pipe, the electrostatic dehydrator is used for absorbing the stream, filtering out water and sending air to the radiator by the pipe to form a circulation. The invention has lower cost, environmental protection, energy conservation, safety and the like.

Owner:ZHEJIANG JINGBAO MACHINERY

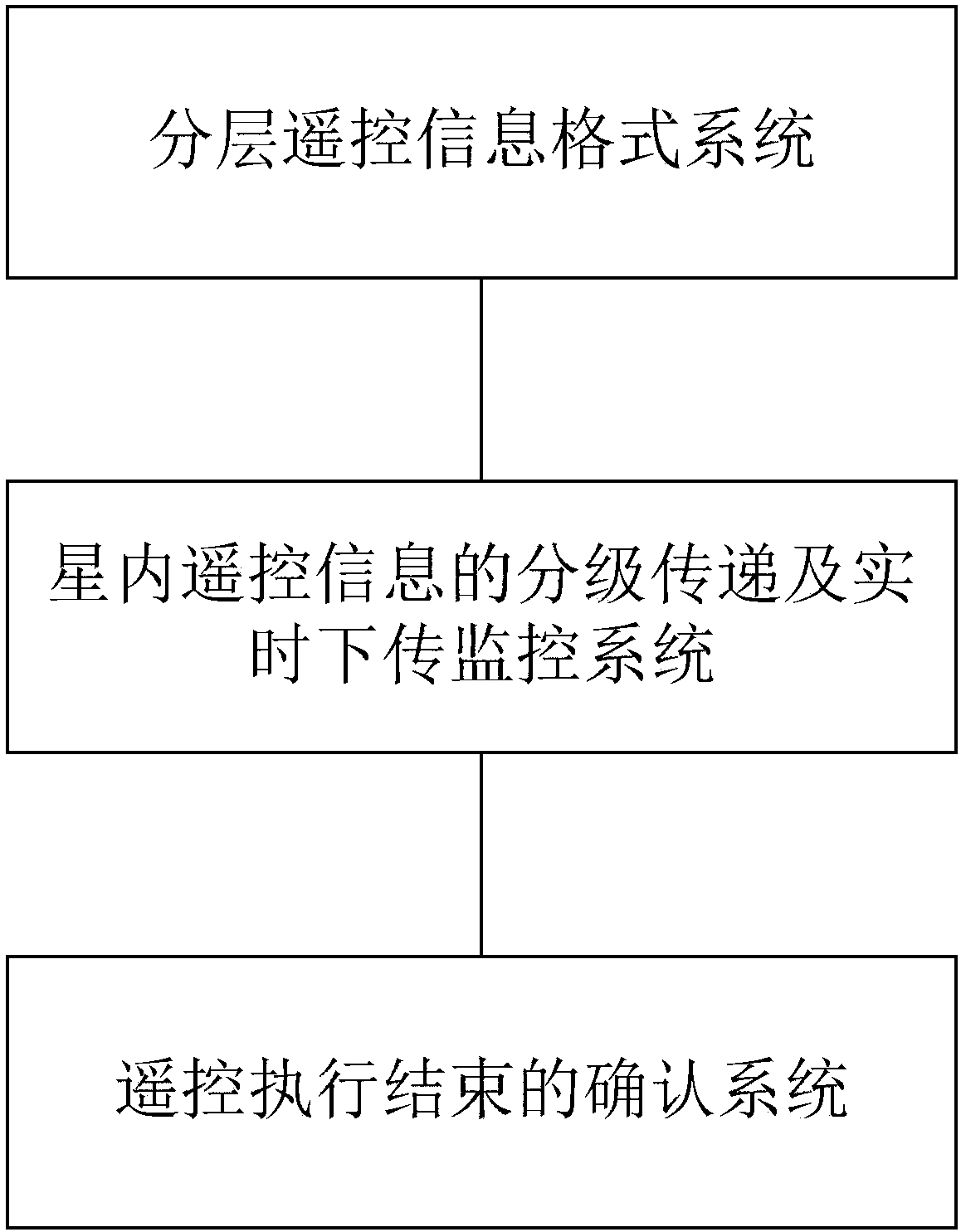

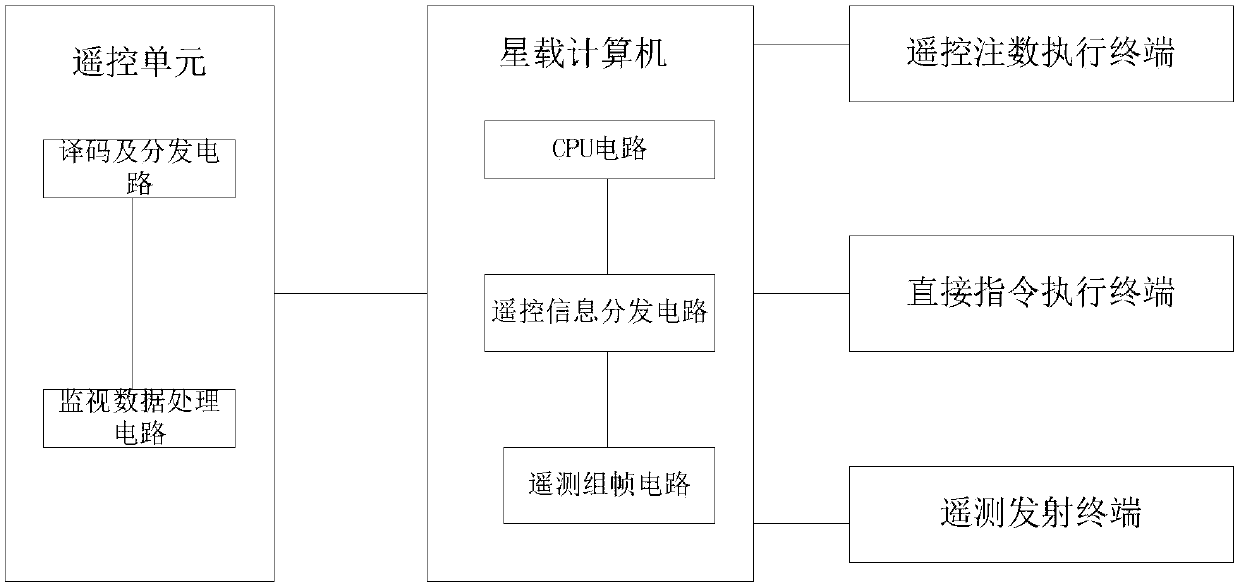

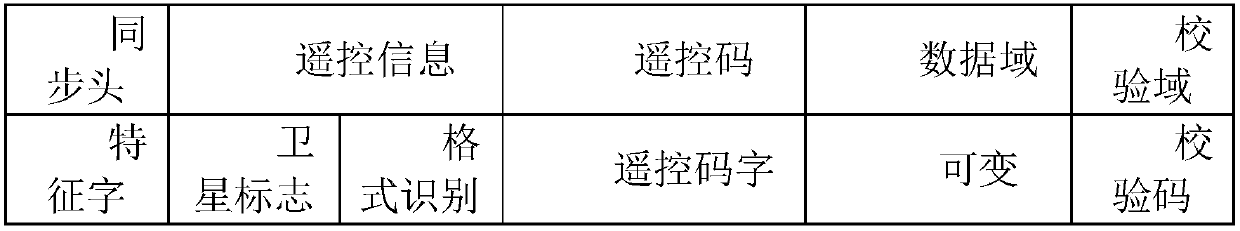

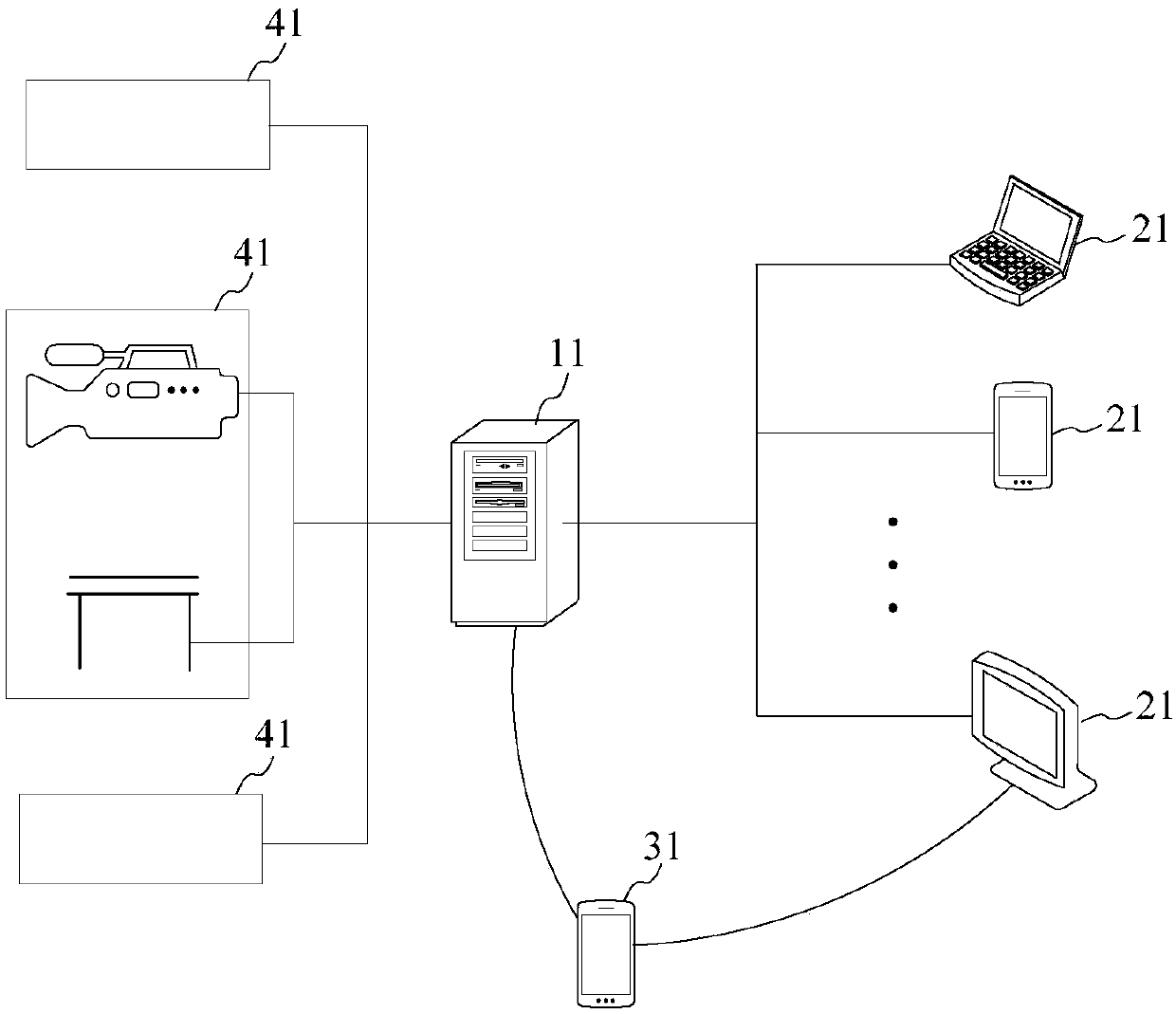

Satellite remote control monitoring system

ActiveCN107769838AEasy to distributeEasy to monitorTransmission systemsRadio transmissionRemote controlMonitoring system

The invention discloses a satellite remote control monitoring system. The system comprises a hierarchical remote control information format system, a grading transmission and real-time downloading monitoring system of in-satellite remote information, and a confirmation system of the end of the remote control execution; the hierarchical remote control information format system is connected with thegrading transmission and real-time downloading monitoring system of the in-satellite remote information and used for the step-by-step transmission of the remote information in the satellite, and facilitates the transmission process of the monitoring information; the each of the direct instruction and the remote control number can use this format system. By using the system disclosed by the invention, the unification of the direct instruction and the remote control number on the format can be realized, and the unified distribution and the process monitoring of the in-satellite remote control transmission system are convenient.

Owner:SHANGHAI SATELLITE ENG INST

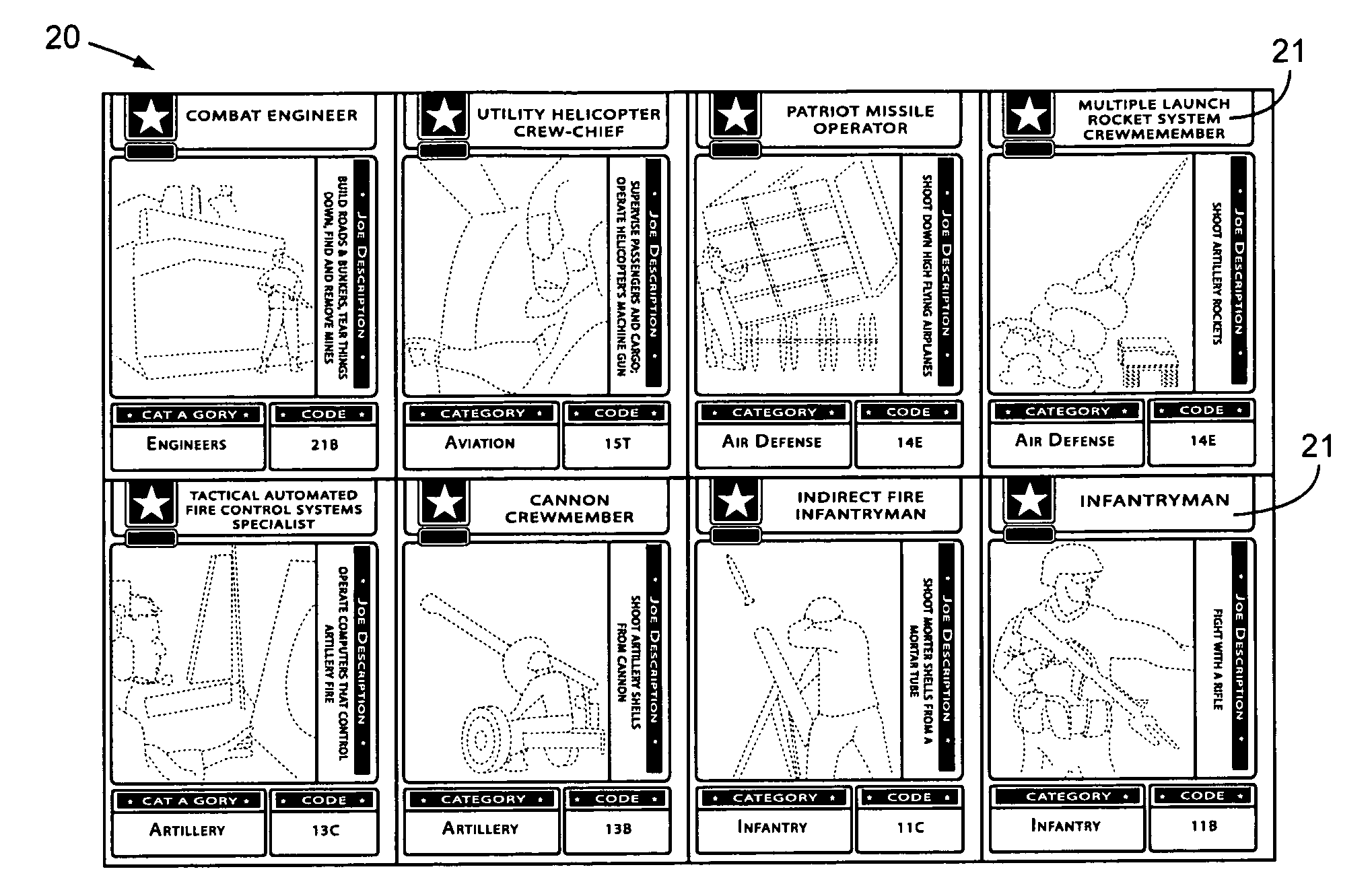

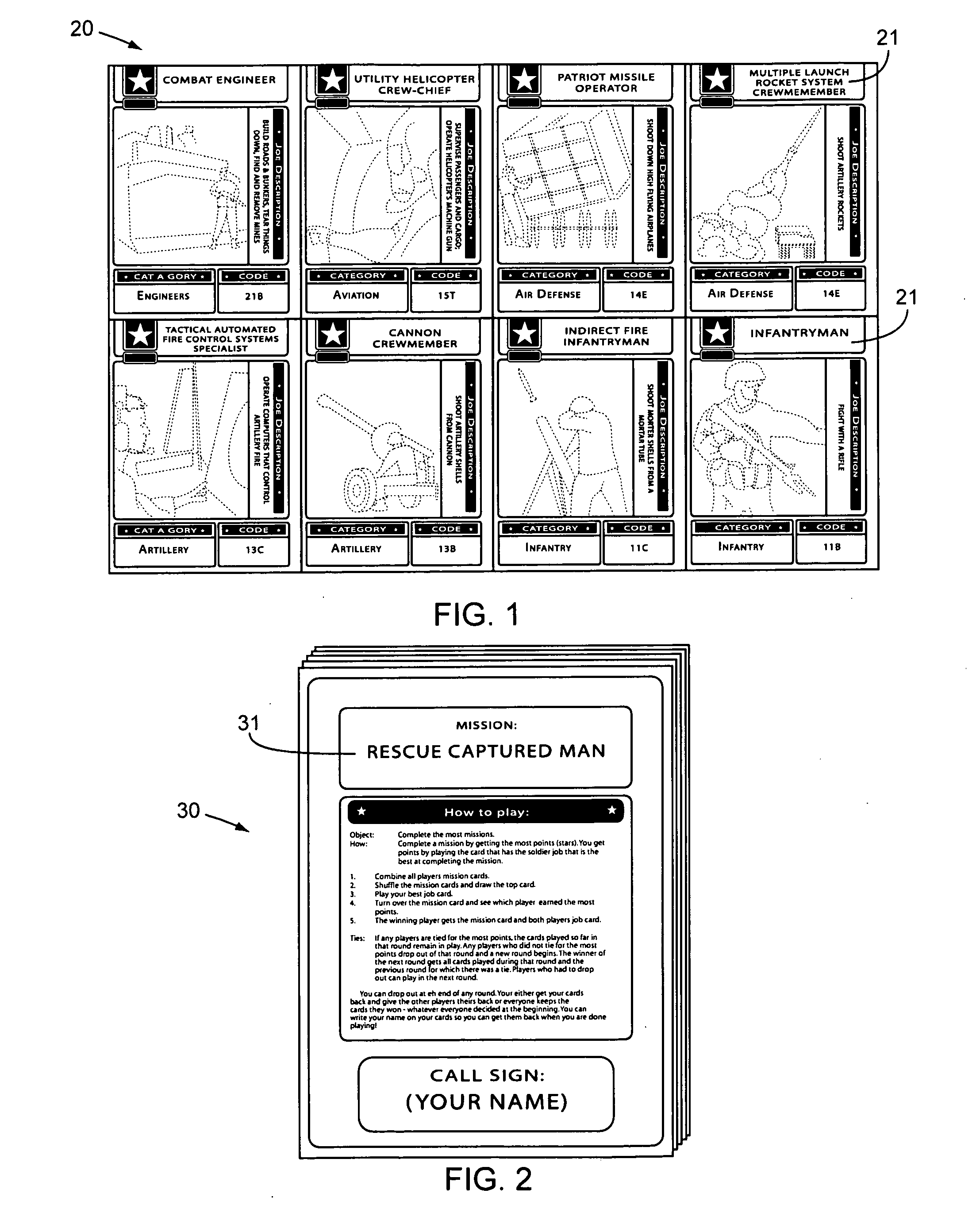

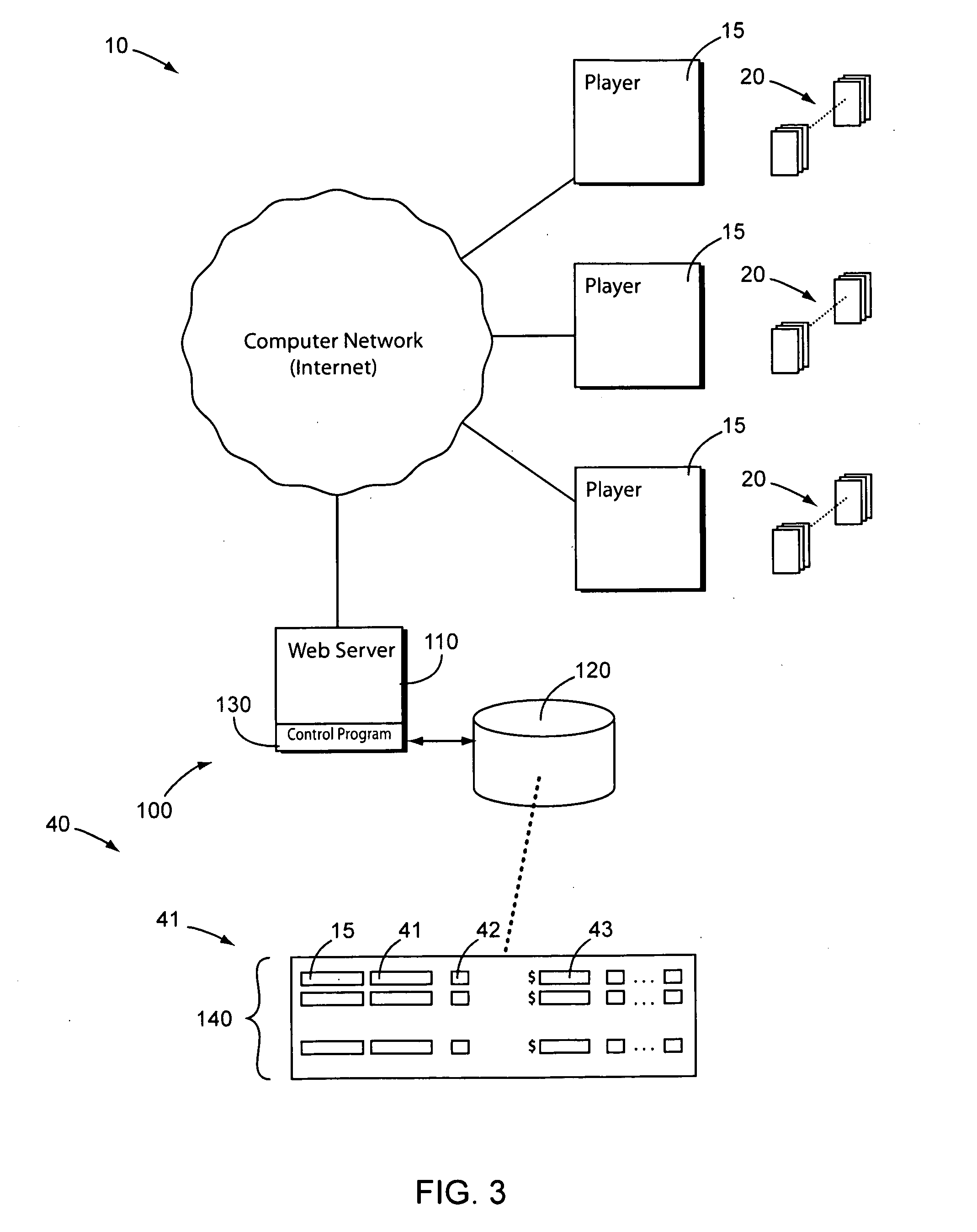

Military card game

Owner:CAREY BRENT A

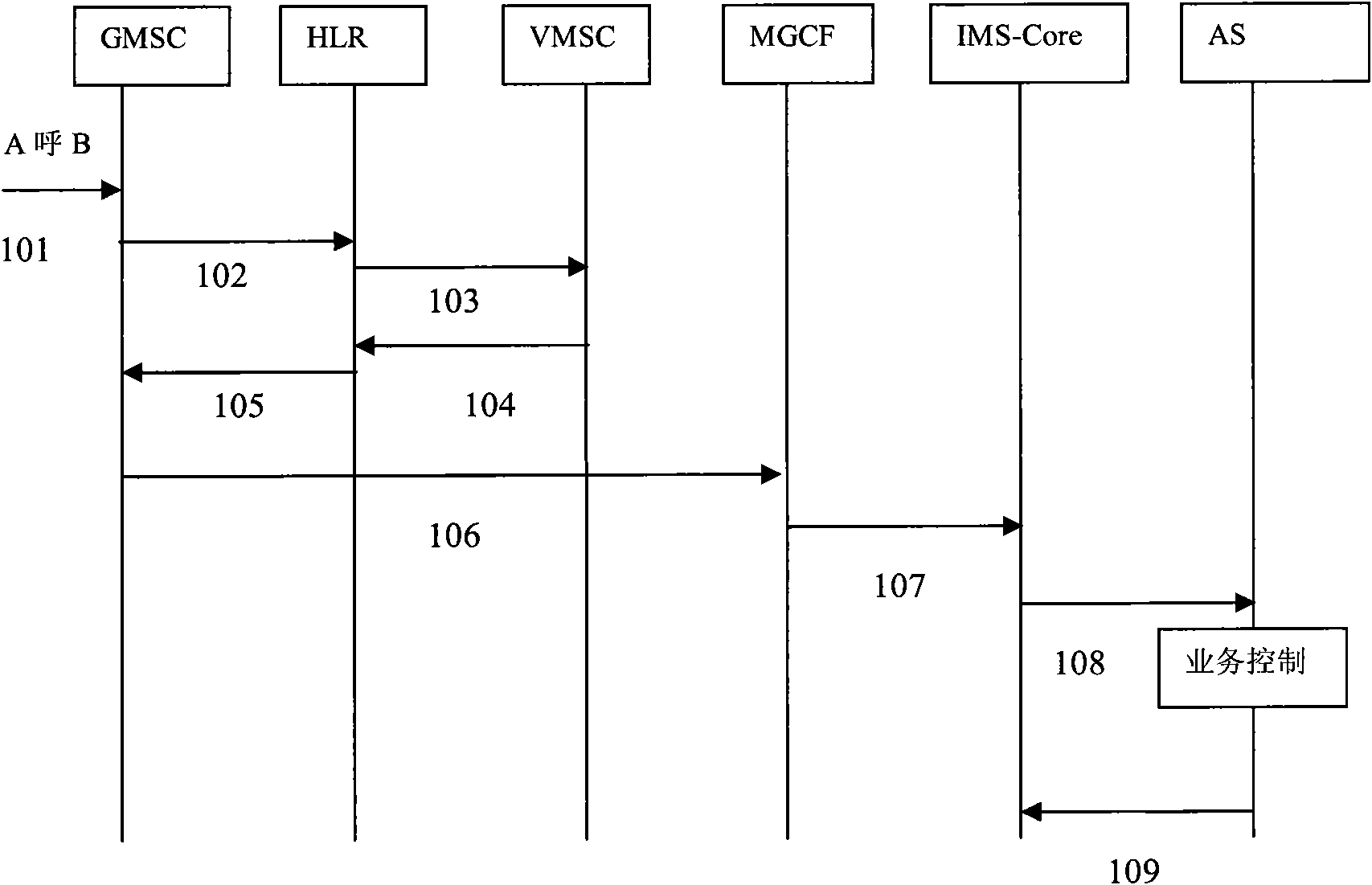

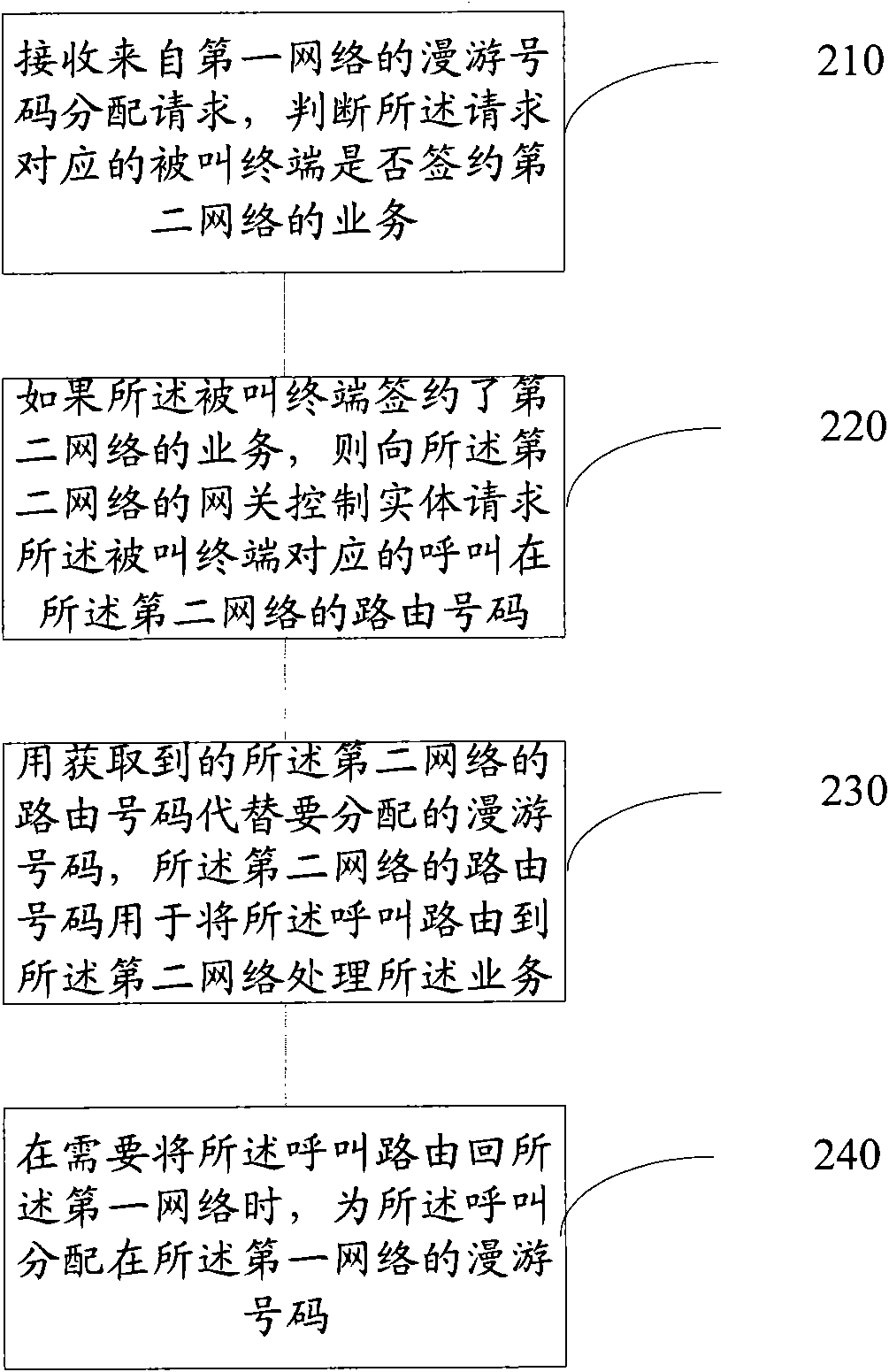

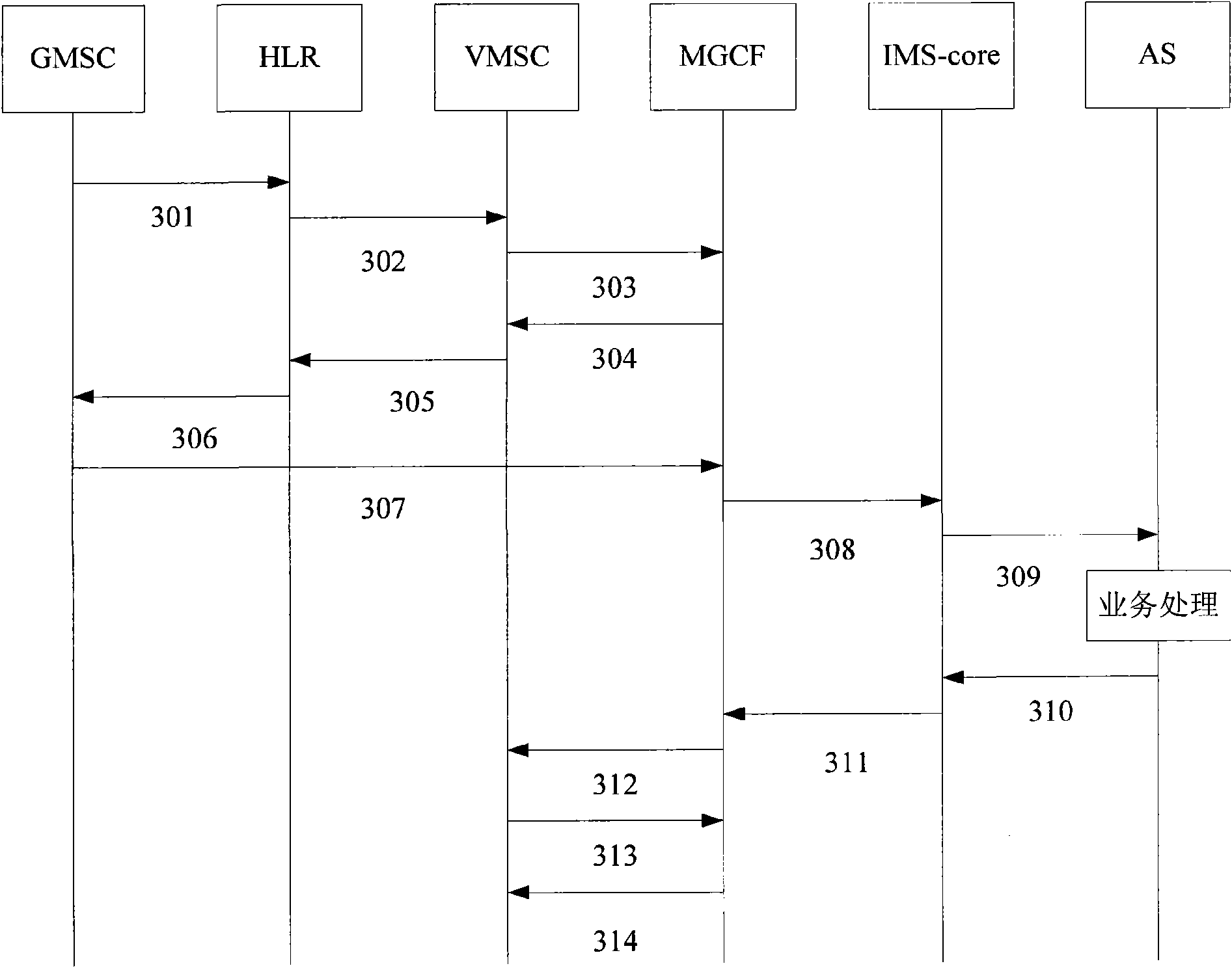

Method, system and device for allocating roaming numbers

InactiveCN101600182AEasy to manageAvoid wastingSpecial service for subscribersCommmunication supplementary servicesTelecommunicationsCall routing

The embodiment of the invention discloses a method, a system and a device for allocating roaming numbers. Aiming at the problem that in the prior art, the roaming numbers are occupied for a long time to cause the waste of roaming number resources, the embodiment of the invention discloses the method, the system and the device for allocating the roaming numbers. According to the technical proposal given by the embodiment, when a called terminal from a first network signs a contract with a service of a second network, before processing the service of the second network, the roaming numbers of the first network are not allocated temporarily, and when the processing of the service of the called terminal on the second network is finished and the calls corresponding to the called terminal are required to be routed back to the first network, the roaming numbers corresponding to the calls are reallocated, thus not only the problem that the roaming numbers in the first network are occupied for a long time can be avoided, but also the problem of the waste of the roaming number resources caused by the call interrupt in the second network is also avoided, and the utilization rate of the roaming number resources is improved.

Owner:HUAWEI TECH CO LTD

Merchant terminal, server terminal, and parking voucher management method and system

InactiveCN107864205AEasy to distributeImprove distributionDiscounts/incentivesRoad vehicles traffic controlParking areaDistribution method

The application discloses a merchant terminal, a parking voucher distribution method, a server terminal, a parking voucher management system and a parking voucher management method, related to the parking vouchers. The parking voucher management system comprises at least a server terminal and at least one merchant terminal connected with the server terminal; the merchant terminal is used to obtainthe parking vouchers of the parking area where the merchant is in, and distribute the parking vouchers to users according to the business strategy of the merchant; and the server terminal is used tomanage the conditions such as issuing the parking vouchers to the merchant terminal and monitoring the merchant terminal to distribute the parking vouchers to the users. According to the parking voucher management system disclosed by the application, at least one parking voucher is issued to the merchant terminal by the server terminal, and the at least one parking voucher is distributed to the user by the merchant terminal when applying, therefore, the issuing and distribution of the parking vouchers can be realized; the management is convenient, the efficiency is high, good promotion of using the parking vouchers can be provided, and the user experience is improved.

Owner:上海喜泊客信息技术有限公司

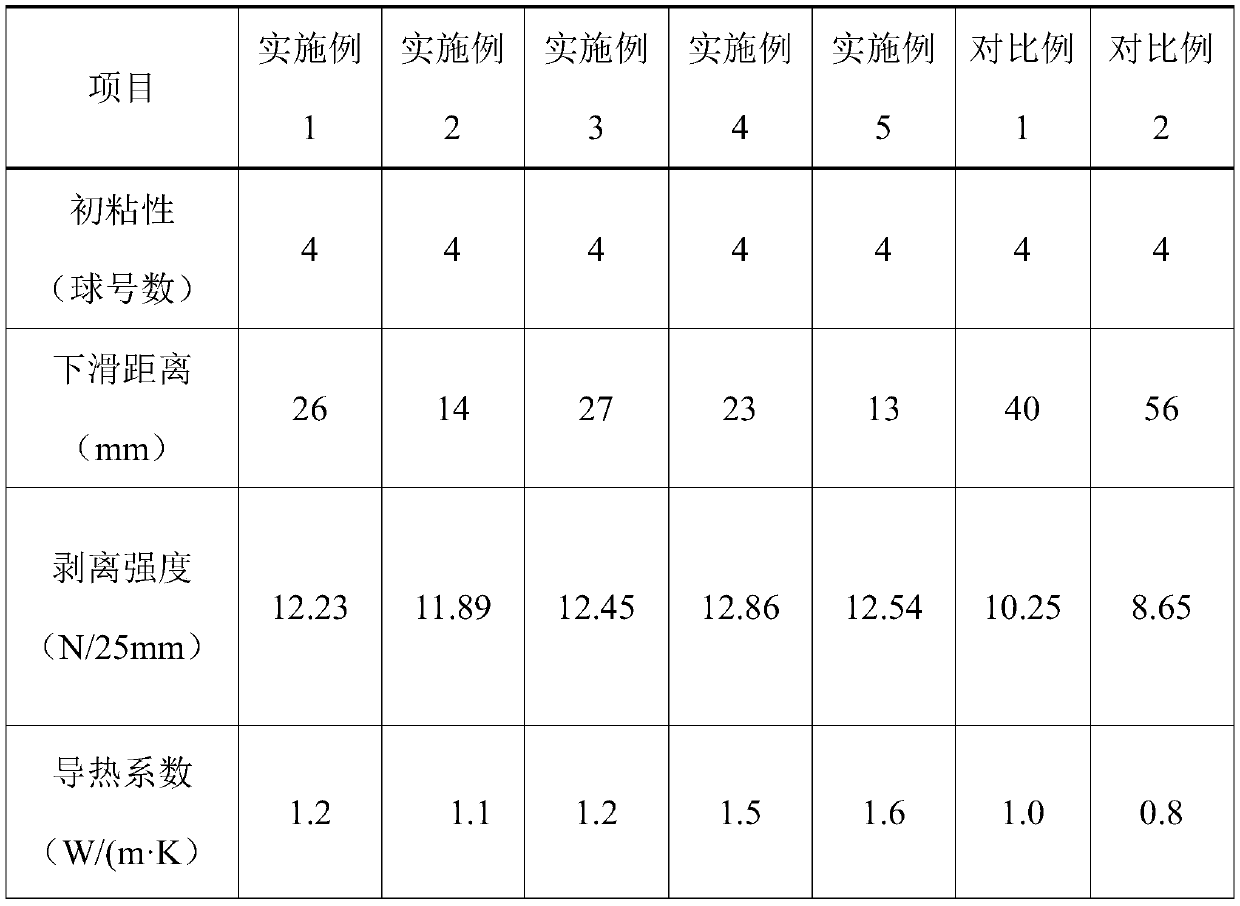

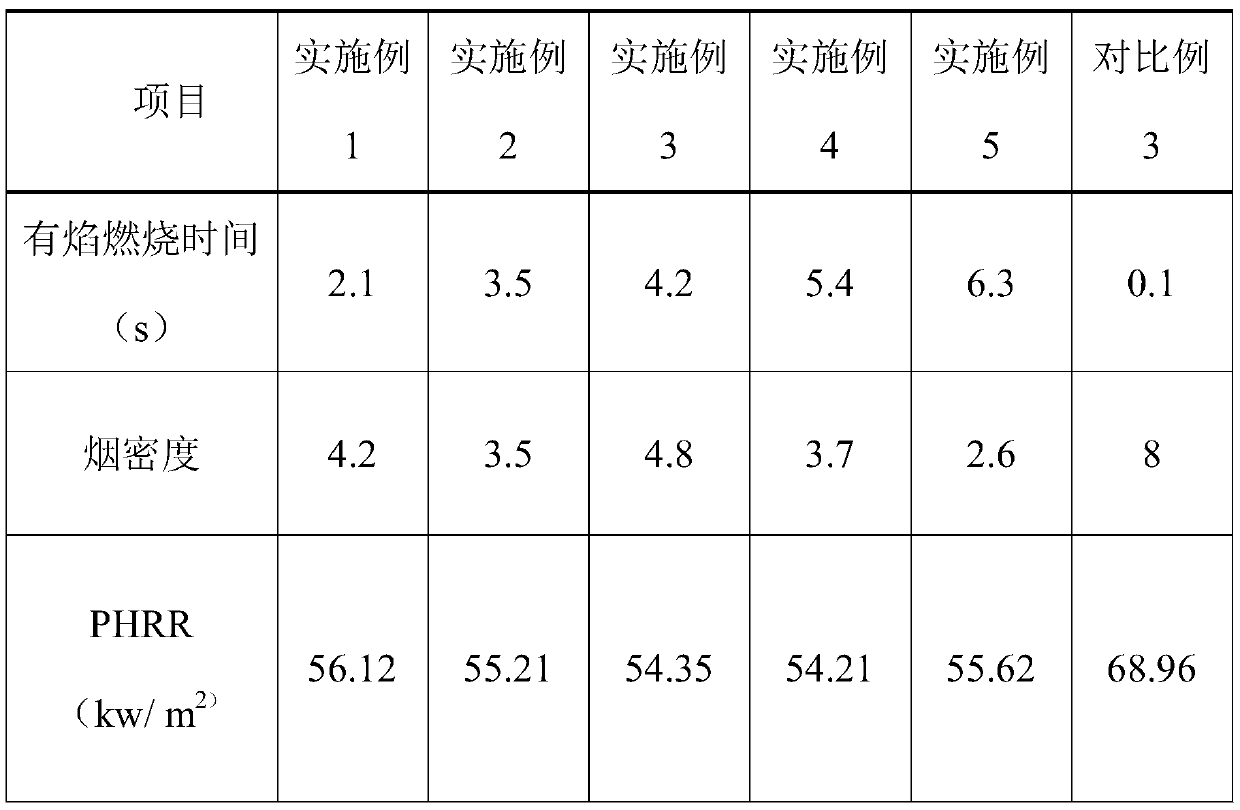

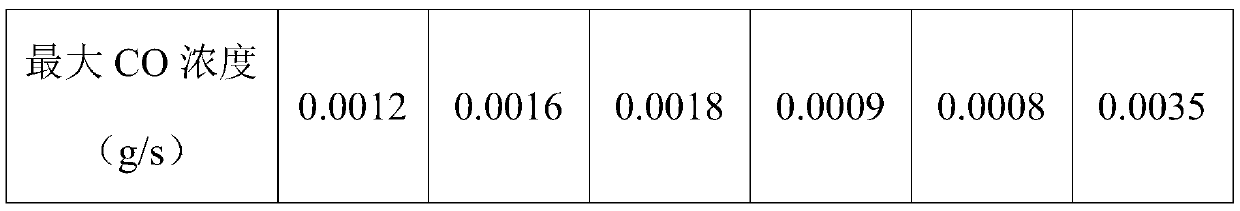

Preparation method of carbon nanotube modified flame-retardant waterborne polyurethane coating and adhesive

ActiveCN111117466AImprove mechanical propertiesImprove flame retardant performanceFireproof paintsNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention relates to a preparation method of a carbon nanotube modified flame-retardant waterborne polyurethane coating and adhesive. The preparation method comprises the following steps: firstly,preparing a modified heat-conducting filler by utilizing a coupling agent, deionized water, tannic acid and a boron nitride nanosheet layer; then preparing a component A by utilizing polymer polyol and the modified heat-conducting filler; finally, adding a modifier, a polyol chain extender, a cross-linking agent and a filler polymerization chain to the component A, isocyanate and dibutyltin dilaurate to prepare polyurethane A, and adding a tackifier to the polyurethane A to prepare the carbon nanotube modified flame-retardant polyurethane coating and adhesive. The obtained polyurethane coating and adhesive have the outstanding advantages that the combustion smoke performance is better reduced, and the pressure-sensitive performance is improved.

Owner:YANTAI UNIV

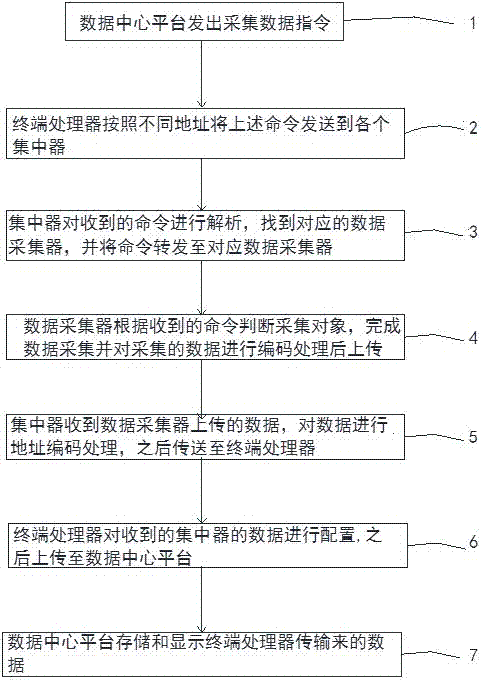

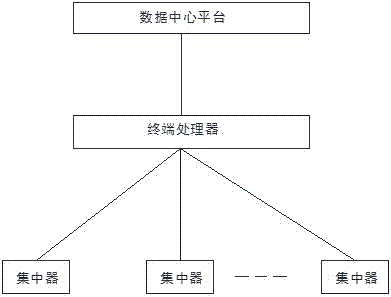

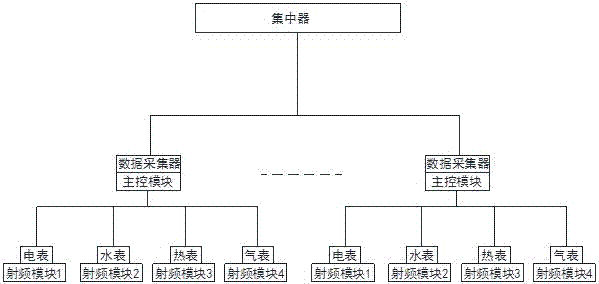

Wireless meter reading system and method based on micro-power wireless network

InactiveCN107240242AReduce duplicationReduce redundancyTransmission systemsData centerData acquisition

The invention discloses a wireless meter reading system based on a micro-power wireless network. The wireless meter reading system comprises an electricity meter, a water meter, a heat meter, a gas meter, a data acquirer, a concentrator, a terminal processor and a data center platform. The data acquirer acquires data of the electricity meter, the water meter, the heat meter and the gas meter, processes and stores the acquired data of the electricity meter, the water meter, the heat meter and the gas meter and transmits the processed data to the concentrator; data interaction is performed between the concentrator and the data acquirer, and the concentrator receives data transmitted by the data acquirer, processes the received data and transmits the processed data to the terminal processor; data interaction is performed between the terminal processor and the concentrator, and the terminal processor receives data transmitted by the concentrator, matches data needing to be reported and transmits the matched data to the data center platform; the data center platform transmits meter reading commands to the terminal processor, stores and displays data transmitted by the terminal processor.

Method for making quick frozen divided chicken baked foods packaged by vanilla binding paper bags

The invention belongs to a food processing and manufacturing technique, and in particular relates to a method for making quick frozen divided chicken baked foods packaged by vanilla binding paper bags. The method comprises the following steps: binding pre-pickled chicken divided products directly by using natural vanillas, packaging each single product tightly by using edible oil paper bags, performing vacuumizing external package by using plastic bags, and performing quick freezing at a temperature of between 36 and 18 DEG C below zero to obtain the finished products. During cooking, the plastic bag external packages are removed, and the chicken divided products are heated to be cooked by a microwave oven. The method for making the quick frozen divided chicken baked foods packaged by the vanilla binding paper bags adopts the natural vanillas instead of prefabricated ceramic bowls and woven vanilla bags to bind the chicken divided products directly to keep the natural flavor and reduce the production cost, thus the method is more convenient for small quantity of baking and distribution, changes the whole chicken baking modes of ceramic bowl chicken baking and vanilla bag chicken baking, and is more advantageous for the industrialization and commercialization of chicken foods.

Owner:傅中星

Inorganic powder highly filled polyolefin fiber paper and production method thereof

PendingCN108864521AEasy to distributeHigh surface glossWater-repelling agents additionPaper-making machinesSurface finishPolymer science

The invention discloses inorganic powder highly filled polyolefin fiber paper and a production method thereof. The polyolefin fiber paper is prepared from the raw materials in proportion: 10% to 20% of polyolefin, 0.1% to 2% of coupling agent, 0.1% to 1% of dispersing agent, 1% to 10% of compatibilizer, 0.1% to 2% of plasticizer, 1 to 5% of hot-melt type adhesive, 0.1% to 2% of surface active agent, 0.1% to 1.5% of rheology modifier and 75% to 85% of inorganic powder. The production method comprises the steps of evenly mixing and stirring polyolefin and the rheology modifier under the assistance of a technology to improve a melt index and fluidity of polyolefin; sequentially adding the compatibilizer and the plasticizer to be evenly stirring and mixed; then sequentially adding the activated inorganic powder and the activated hot-melt type adhesive and evenly mixing and stirring; processing through the work procedures of mixing, kneading, drawing fiber, preparing a finished product fromfiber stuff and the like to obtain the inorganic powder highly filled polyolefin fiber paper. According to the inorganic powder highly filled polyolefin fiber paper disclosed by the invention high filling of inorganic powder is achieved, a resin use amount is reduced, tensile strength, impact strength and surface smoothness of the product are enhanced, and a filler retention rate is improved.

Owner:福建省大投科技有限公司

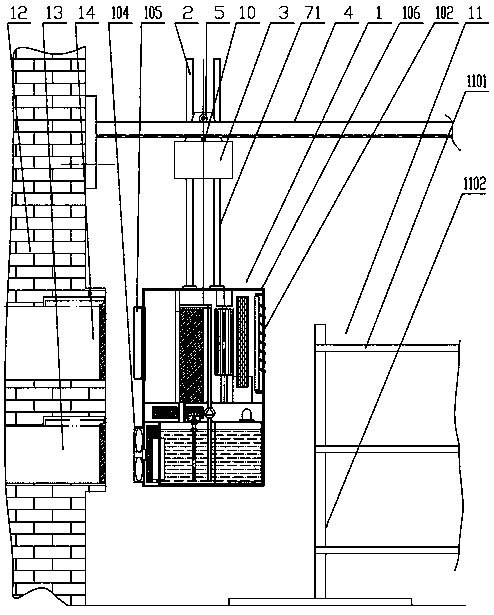

Intelligent silkworm room

The invention discloses an intelligent silkworm room. The intelligent silkworm room comprises a silkworm room body, silkworm frames and an environment control device. A water tank and an evaporator are arranged in a machine enclosure of the environment control device, the water tank is provided with an ultrasonic atomization transducer and a semiconductor chilling plate, and the evaporator is communicated with the water tank. A draught fan and a heater are arranged on the front side of the evaporator; an air outlet is formed in the portion, on the front side of the evaporator, of the machine enclosure; an air inlet is formed in the portion, on the back side of the evaporator, of the machine enclosure; a heat dissipation outlet facing the semiconductor chilling plate is formed in the machine enclosure; a heat dissipation air channel facing the heat dissipation outlet and an air inlet channel facing the air inlet are formed in the silkworm room body; stretchable humidifying pipes communicated with the water tank are supported on the left side and the right side of the machine enclosure in a swinging manner, and silkworm medicine vibration dispensers are connected to the front ends ofthe humidifying pipes; the machine enclosure is movably supported on a machine base through guiding rods and a lifting driving device, the machine base is movably supported on two guiding rails, power-supplying bus bars are arranged on the two guiding rails, and an intelligent control device is arranged in the machine base. By means of the intelligent silkworm room, it can be guaranteed that airin the silkworm room is fresh, temperature and humidity are even, and silkworm medicine is automatically and evenly dispensed.

Owner:DONGTAI HONGRI ELECTRONICS

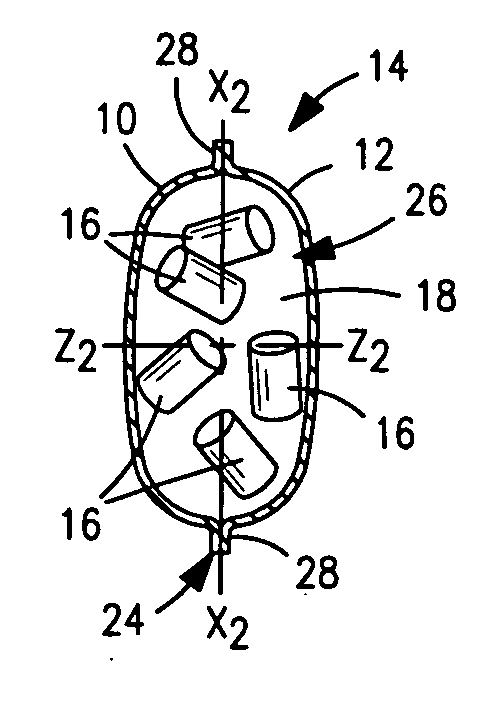

Pre-packaged, flexible container of ice and air

InactiveUS20090293536A1Easy to distributeEfficiently distributedDomestic cooling apparatusLighting and heating apparatusCubic inchMechanical engineering

Owner:S I INC DBA SERV ICE

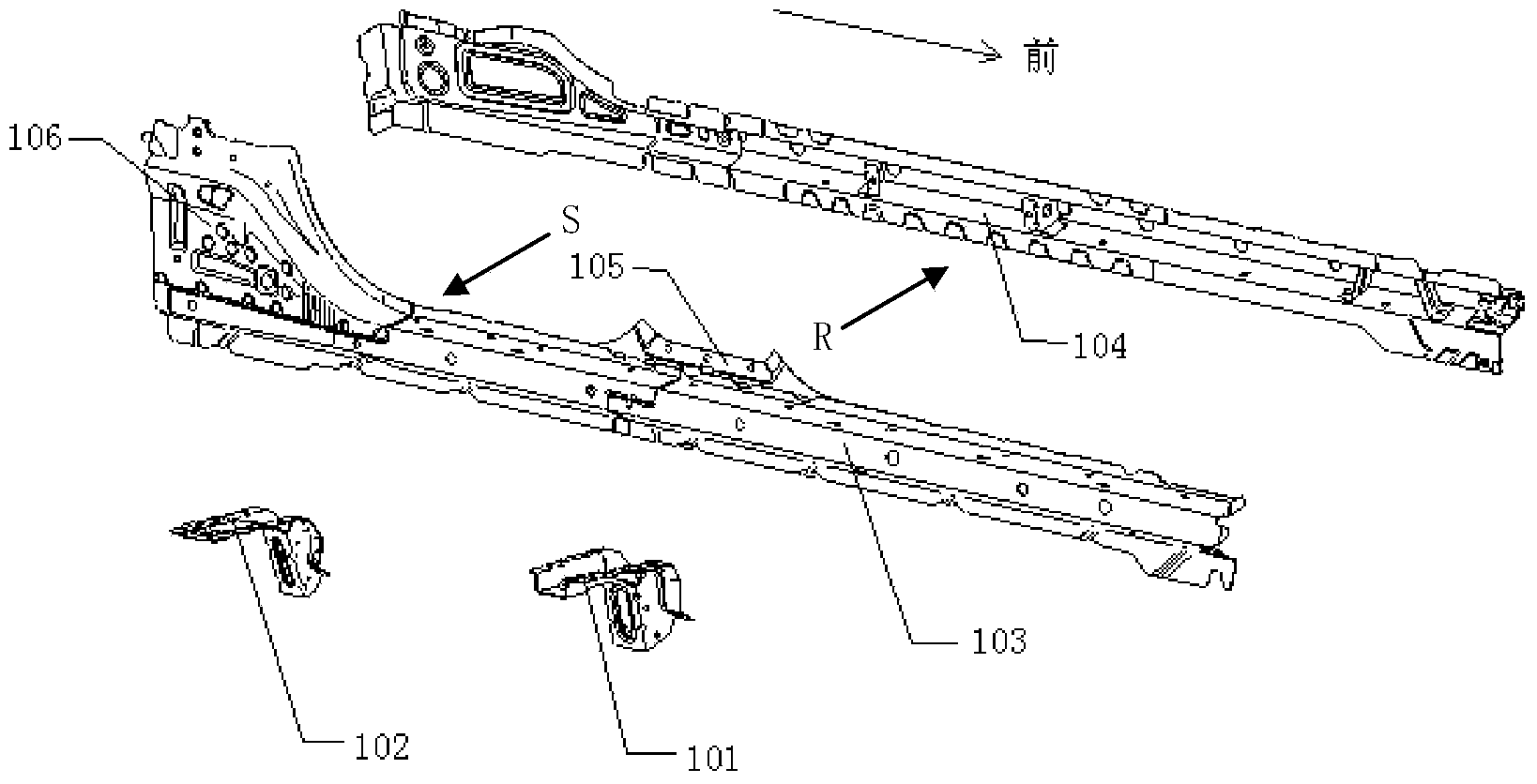

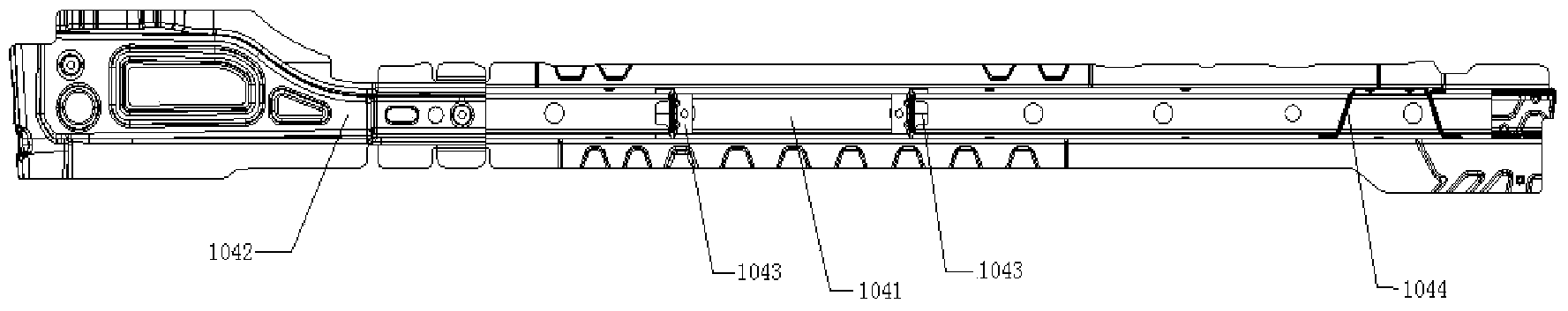

Automobile cab

ActiveCN103707938AHigh strengthReduced risk of deformation crackingSuperstructure subunitsEngineeringSquare cavity

The invention provides an automobile cab. The automobile cab comprises a threshold assembly, a side wall assembly and a floor assembly, wherein the threshold assembly is of a square cavity structure which is formed by an inner threshold body and an outer reinforcing plate in a welded mode, the side wall assembly is provided with a front vertical column, a middle vertical column and a rear vertical column, and the floor assembly comprises a front floor metal plate, a rear floor metal plate, a middle cross beam connected with the front floor metal plate and the rear floor metal plate, a front cross beam welded to the front end of the front floor metal plate and a rear cross beam welded to the rear end of the rear floor metal plate. The threshold assembly is welded to the floor assembly. The threshold assembly is welded to the side wall assembly at the positions corresponding to the front vertical column, the middle vertical column and the rear vertical column. A front floor reinforcing beam is welded to the position, corresponding to the middle vertical column, of the inner threshold body. A rear floor reinforcing beam is welded behind the front floor reinforcing beam. The front floor reinforcing beam is connected with the middle cross beam in a welded mode. The rear floor reinforcing beam is connected with the rear floor metal plate in a welded mode. According to the automobile cab, the stress performance is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Automatic medicine dispensing device for hospitals

ActiveCN111599098AEasy to distributeImprove efficiencyApparatus for meter-controlled dispensingElectric machineryEngineering

Owner:曹端海

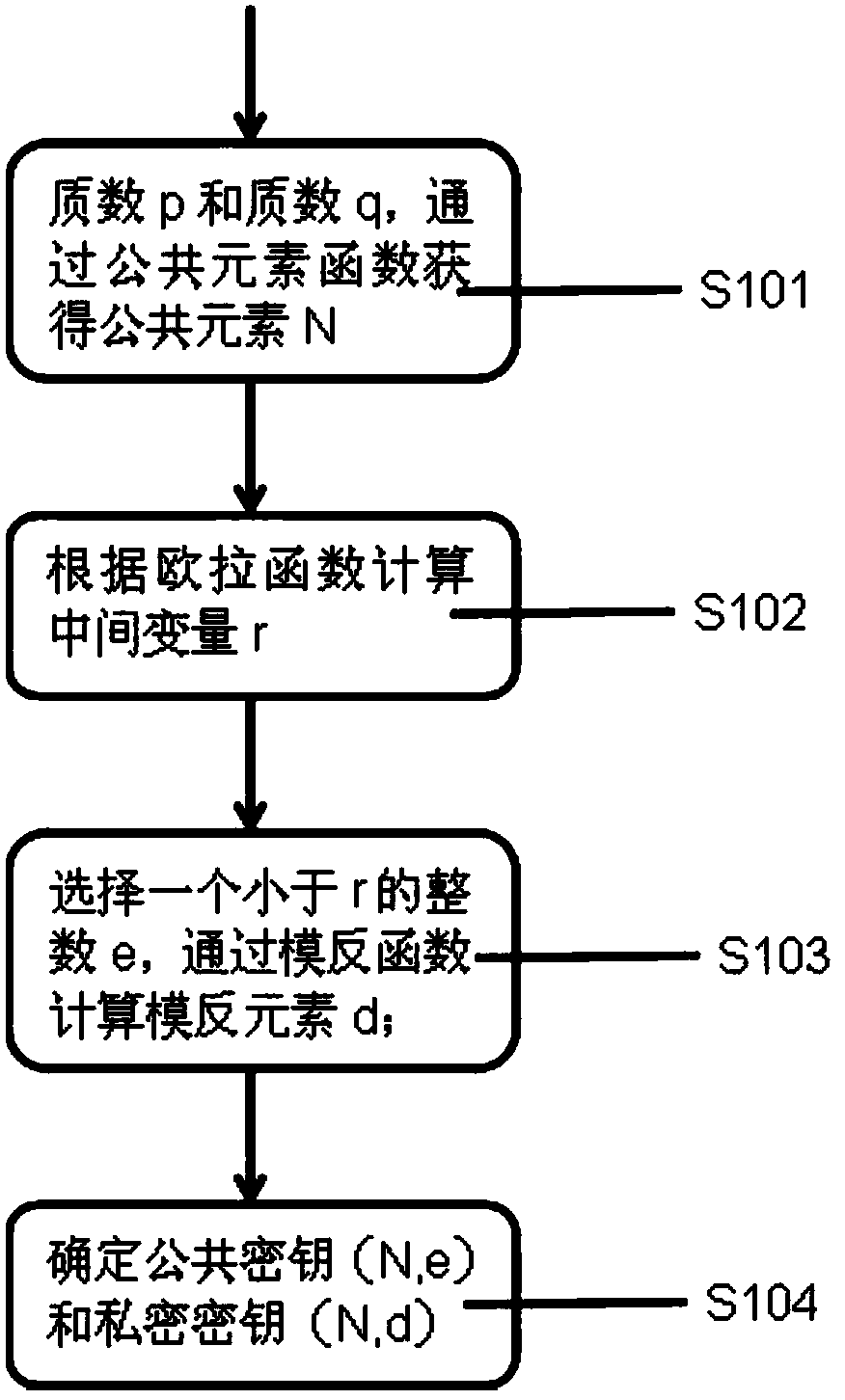

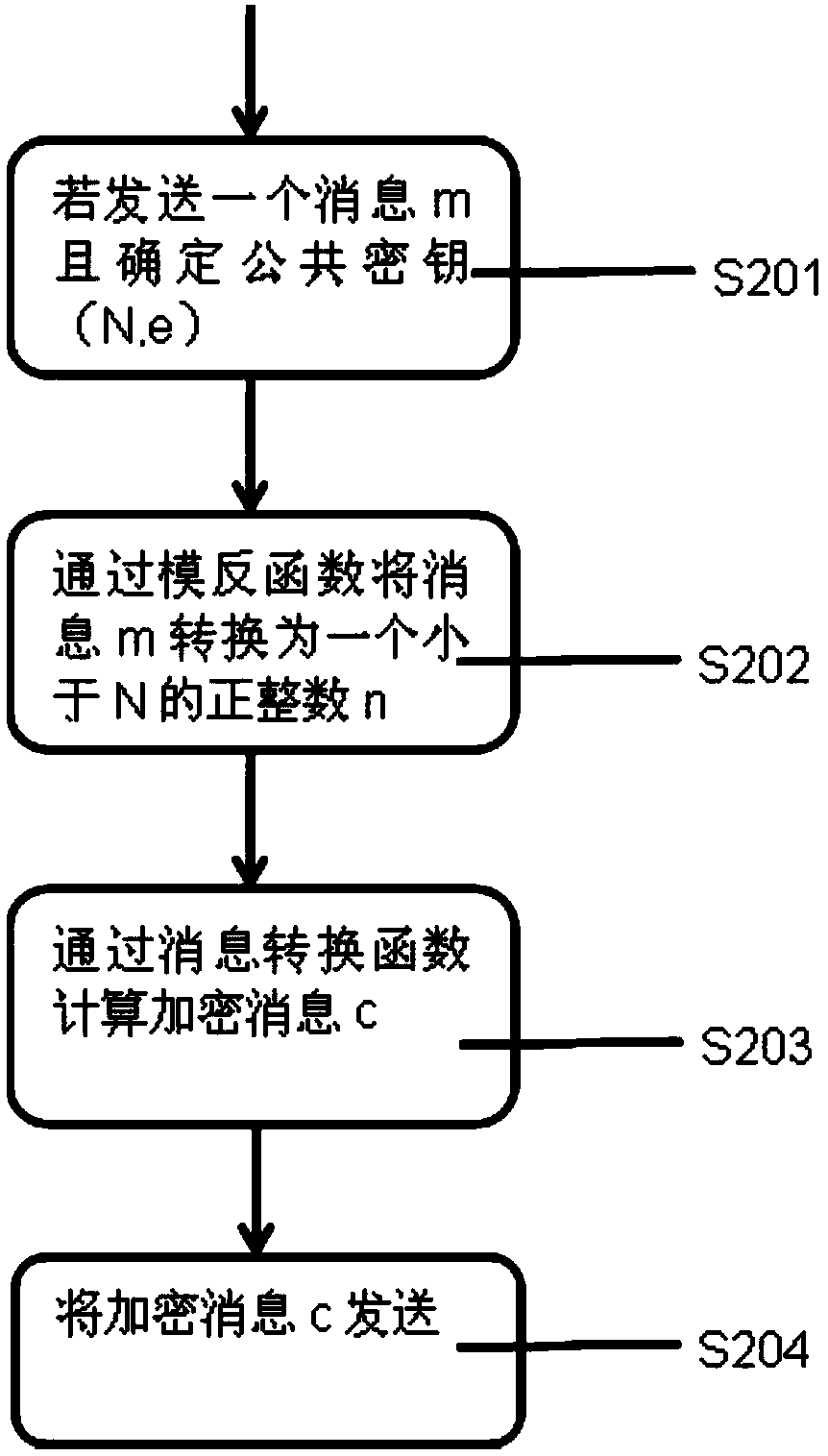

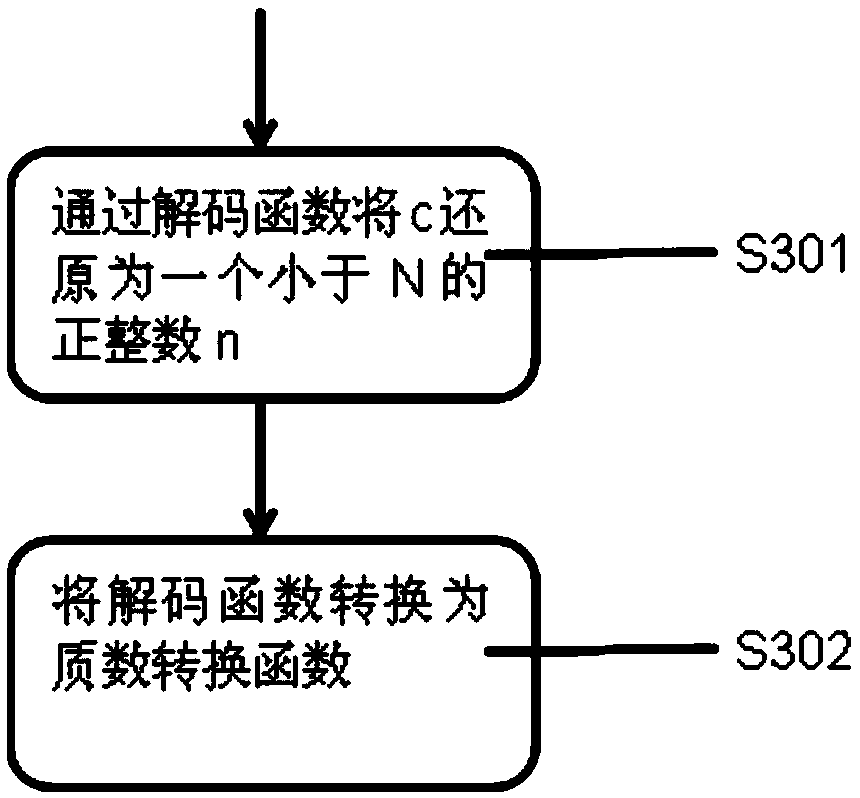

Big data information security processing method and system of variable-length key RSA encryption algorithm

InactiveCN109245892AEasy to distributeSecurity CodecPublic key for secure communicationData informationVariable length

The invention belongs to the technical field of data information security, in particular to a big data information security processing method of a variable length key RSA encryption algorithm, the invention also provides a large data information security processing system of variable length key RSA encryption algorithm. The method comprise generating a key: prime number p and prime number q, obtaining a common element N by a common element function, calculating an intermediate variable r according to an Euler function, selecting an integer e that is less than r, calculating the modulo-inverseelement d by the modulo-inverse function, and determining a public key (N, e) and a private key (N, d). The invention solves the problem that both parties of a transaction use the same key because thesymmetrical encryption algorithm uses the same key in the prior art, and the security is not guaranteed. The invention has the effects of high system security, simplicity and practicality, variable length transmission and signature security.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY +1

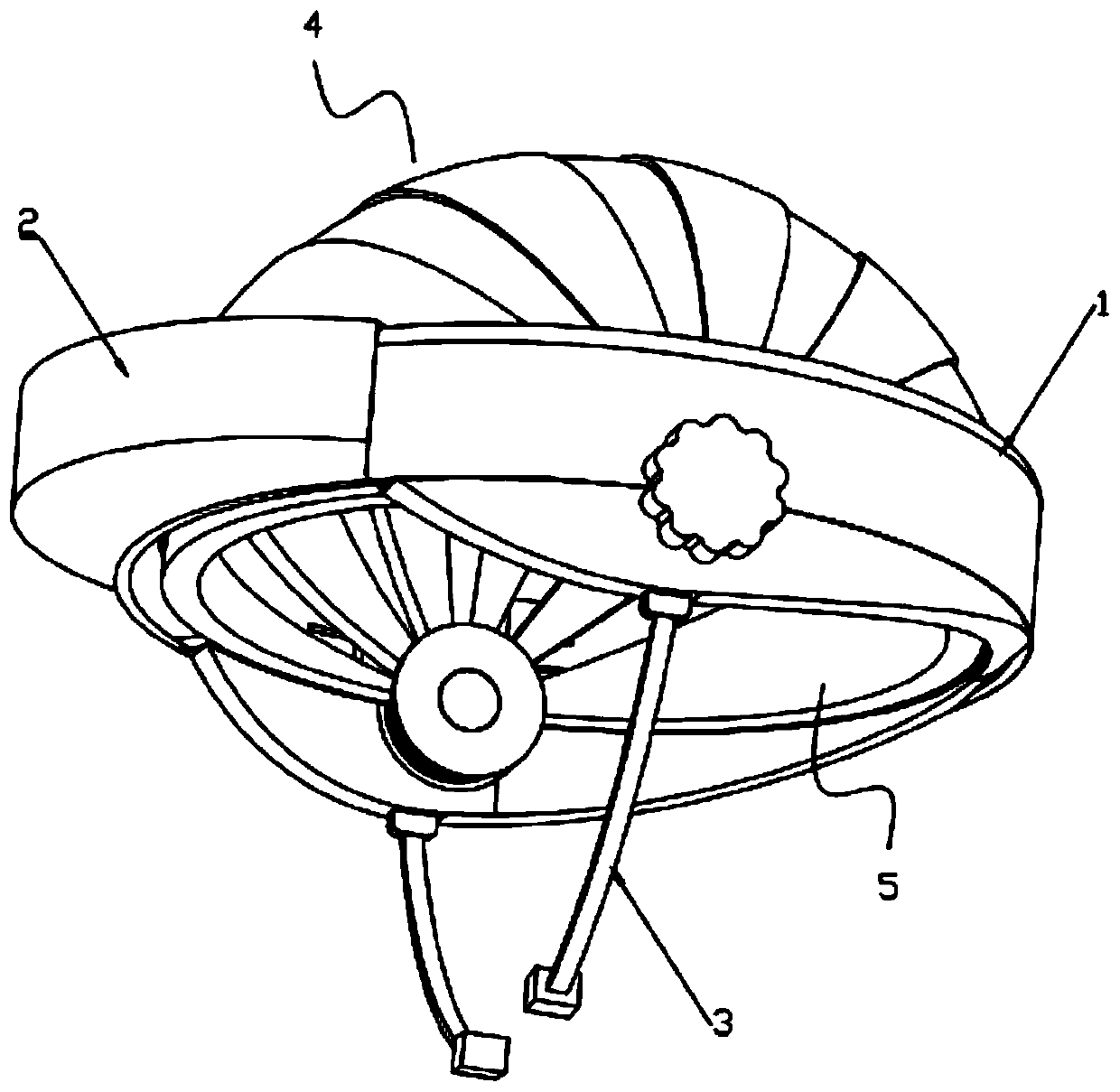

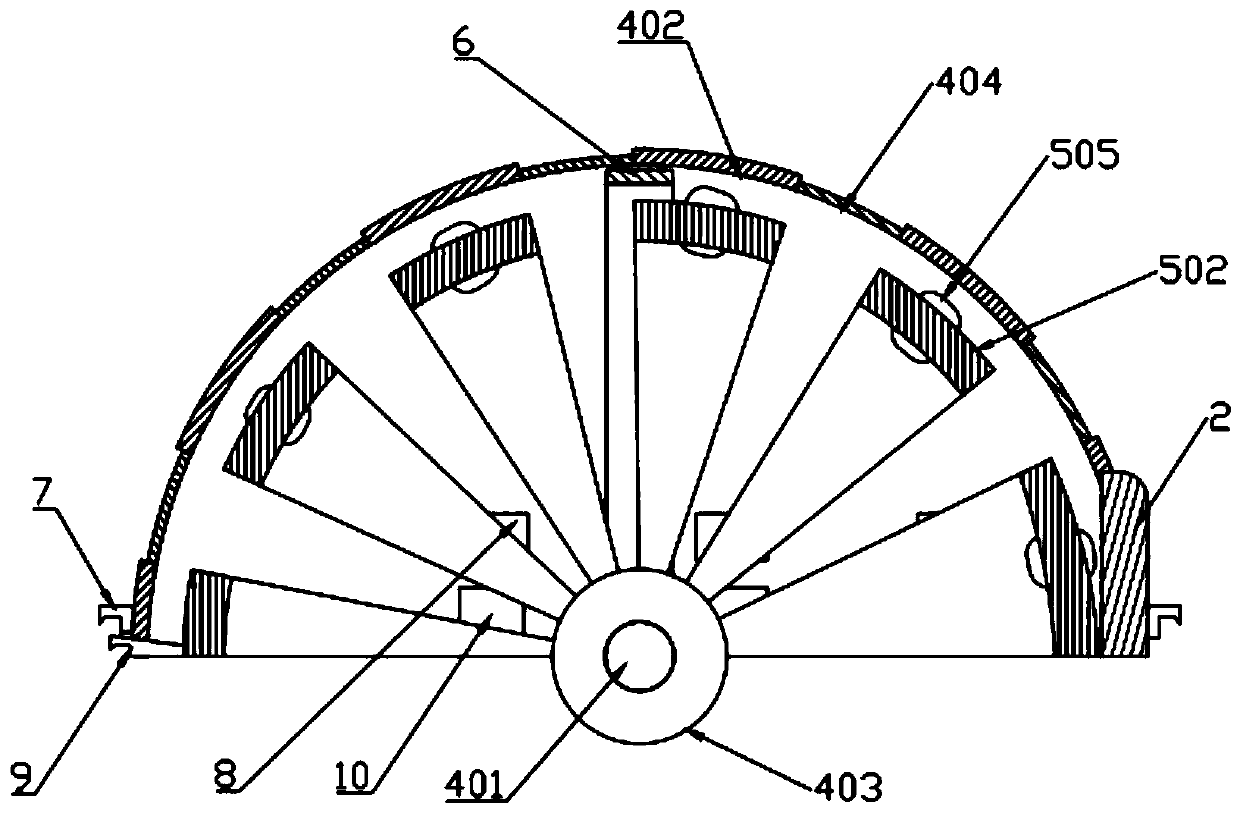

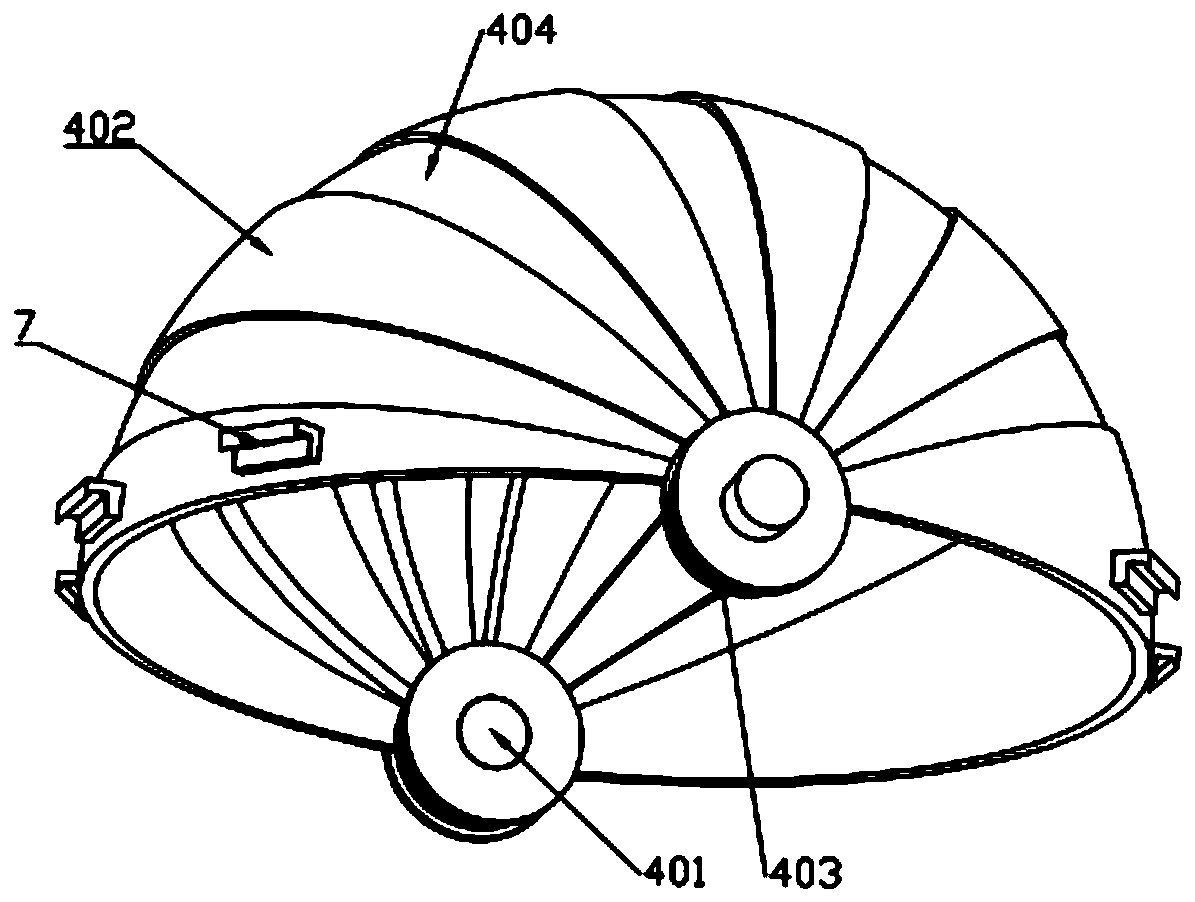

Foldable damping helmet with non-Newtonian fluid lining

PendingCN111466671AFast evaporationTo achieve the purpose of foldingHelmetsHelmet coversClassical mechanicsStructural engineering

The invention discloses a foldable damping helmet with a non-Newtonian fluid lining, relating to the technical field of helmets. The helmet comprises a helmet body and a helmet front eave, the helmetbody is of a notch ring belt structure, the helmet front eave is fixed to an upper end of a notch of the helmet body, two symmetrically-arranged buckling belts are fixed to a lower end of the helmet body, a first rotating assembly and a second rotating assembly are installed on an inner side of the helmet body, and the first rotating assembly and the second rotating assembly are connected througha main supporting frame. According to the invention, a breathable waterproof cloth is arranged on a foldable helmet shell, an all-around ventilation environment is achieved at a side end and a top endof the helmet, the purpose that sweat stains on a head are brought away so that the sweat stains can be evaporated more rapidly is achieved, and meanwhile, the head of a rider can be massaged; the first rotating assembly and the second rotating assembly are arranged such that the helmet shell and the helmet lining can be folded; and by arranging a non-Newtonian fluid vibration reduction capsule,the effect of rapid vibration reduction can be achieved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

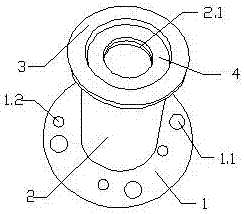

Non-sticky heat-insulation grooved-surface flanged pipe fitting used for small workshop

InactiveCN107304882AFirmly connectedEasy to distributeFlanged jointsThermal insulationThermal insulationDevice to device

The invention relates to a flanged pipe fitting for a small workshop with non-stick heat preservation tank surface, which includes a chassis (1) and a pipe body (2). The inner diameter of the pipe body (2) is provided with an internal thread (2.1), the outer surface of the pipe body (2) is provided with an insulating layer, and the top end of the outer wall of the pipe body (2) is provided with a flange (3), A non-stick layer is provided on the surface of the flange (3), and a groove (4) is provided between the flange (3) and the top of the pipe body (2). A flange pipe fitting for a small workshop with a non-stick heat preservation tank surface of the present invention makes the connection between equipment and equipment, pipe body and pipe body more firm, and ensures the temperature in the pipe body well, the heat is not easy to dissipate, and prolongs the service life of the equipment. Long service life, can avoid dust and other long-term stays on the surface of flanged pipe fittings, it is not easy to accumulate dust, and it is easy to clean.

Owner:江阴市云润机械厂

Wear-resistant heat-insulation flanged pipe fitting

InactiveCN107269959AEasy to distributeExtend your lifeFlanged jointsThermal insulationWear resistantEngineering

The invention relates to a wear-resistant and heat-preserving flange pipe fitting, which includes a chassis (1) and a pipe body (2), the cross sections of the chassis (1) and the pipe body (2) are both ring-shaped, and the pipe body (2) ) is welded to the inner diameter of the chassis (1), the chassis (1) is provided with a large through hole (1.1), the inner diameter of the pipe body (2) is provided with an internal thread (2.1), and the internal thread ( 2.1) A wear-resistant layer is provided on the surface, an insulation layer is provided on the outer surface of the pipe body (2), and a flange (3) is provided on the top of the outer wall of the pipe body (2). The wear-resistant and heat-preserving flange pipe fitting of the present invention can well ensure the temperature in the pipe body, the heat is not easy to dissipate, and the service life of the equipment is prolonged. It will not fall off, and the threads on the surface will not be worn out after long-term use.

Owner:江阴市云润机械厂

a car cab

ActiveCN103707938BHigh strengthReduced risk of deformation crackingSuperstructure subunitsCar drivingEngineering

The invention provides an automobile cab. The automobile cab comprises a threshold assembly, a side wall assembly and a floor assembly, wherein the threshold assembly is of a square cavity structure which is formed by an inner threshold body and an outer reinforcing plate in a welded mode, the side wall assembly is provided with a front vertical column, a middle vertical column and a rear vertical column, and the floor assembly comprises a front floor metal plate, a rear floor metal plate, a middle cross beam connected with the front floor metal plate and the rear floor metal plate, a front cross beam welded to the front end of the front floor metal plate and a rear cross beam welded to the rear end of the rear floor metal plate. The threshold assembly is welded to the floor assembly. The threshold assembly is welded to the side wall assembly at the positions corresponding to the front vertical column, the middle vertical column and the rear vertical column. A front floor reinforcing beam is welded to the position, corresponding to the middle vertical column, of the inner threshold body. A rear floor reinforcing beam is welded behind the front floor reinforcing beam. The front floor reinforcing beam is connected with the middle cross beam in a welded mode. The rear floor reinforcing beam is connected with the rear floor metal plate in a welded mode. According to the automobile cab, the stress performance is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

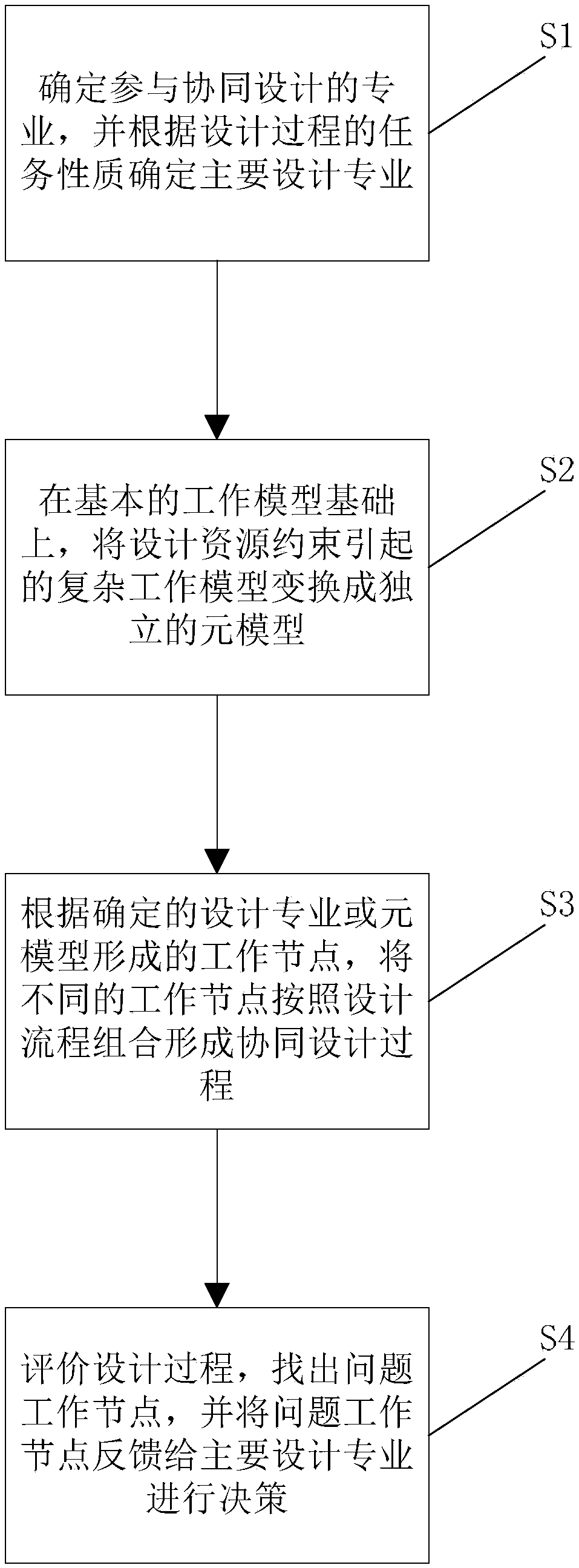

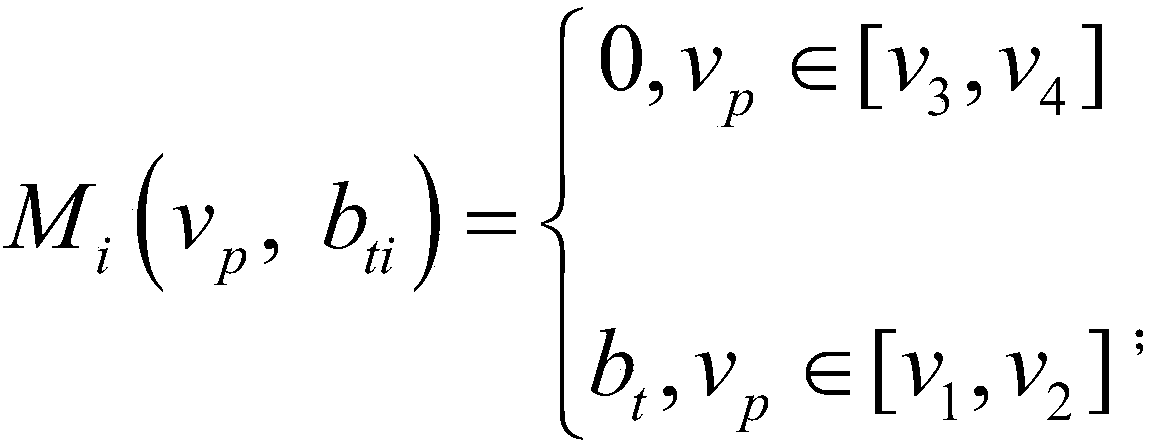

Aviation product collaborative design method

InactiveCN108389032AEasy to distributeExact range of confirmationOffice automationSpecial data processing applicationsAviationResource constraints

The invention provides an aviation product collaborative design method. The method comprises the following steps of determining professions participating in collaborative design, and determining maindesign professions according to tasks of a design process; based on a basic working model, converting a complex working model caused by design resource constraints into an independent meta model; according to the determined design professions or working nodes formed by the meta model, combining different working nodes according to the design process to form a collaborative design process; and evaluating the design process, finding out problem working nodes, and feeding back the problem working nodes to the main design professions for performing decision making. Multiple professions of aviationproduct research and development are convenient for the design data issuing, management and understanding collaborative design process; any design change or problem in the design process is independently solved by a meta model or a working node, so that the influence on global design is reduced; and a confirmation range of feedback information in the collaborative design process is made accurate.

Owner:CHONGQING UNIV +1

Pingyu mushroom cultivating method with rice or wheat straw

InactiveCN1099228CBacteriaSolve the problem of hydrationMicrobiology processesHorticultureAgaricusSmall footprint

Agaricus tabularis cultivation includes the steps of cultivation medium preparation, seed preparation, inoculation, mushroom growth, picking, etc. During seed preparation, mushroom seed with rich nitrogen content is prepared and this eliminates the problem of replenishing nitrogen and prevents hybrid mushroom pollution effectively. The wood-imitating stereo cultivation process has no mushroom burning trouble, low cost and high yield. Contracting the rice or wheat bundle as culture medium after each picking makes it possible to produce agaricus tabularis continuously.

Owner:姜春明

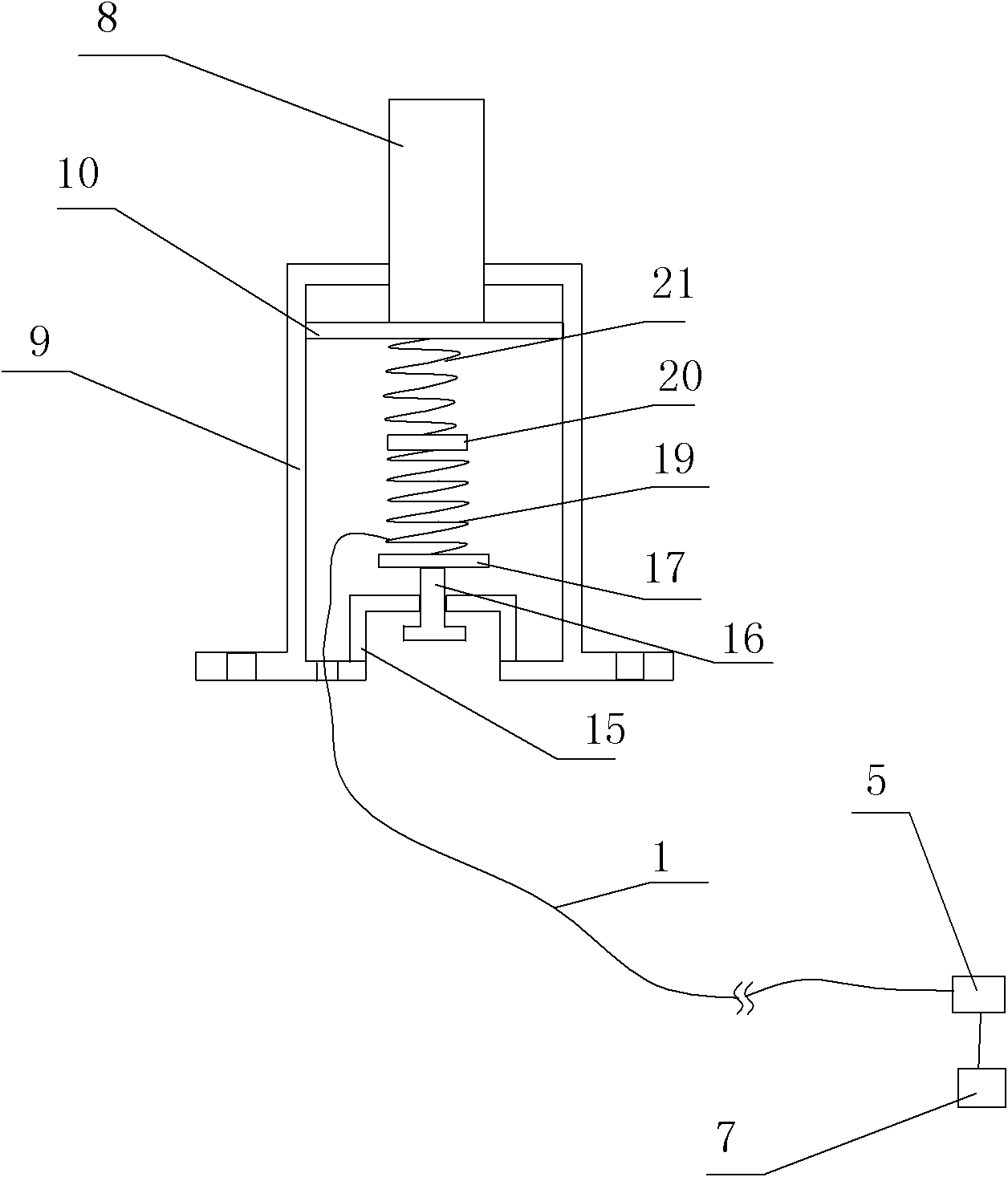

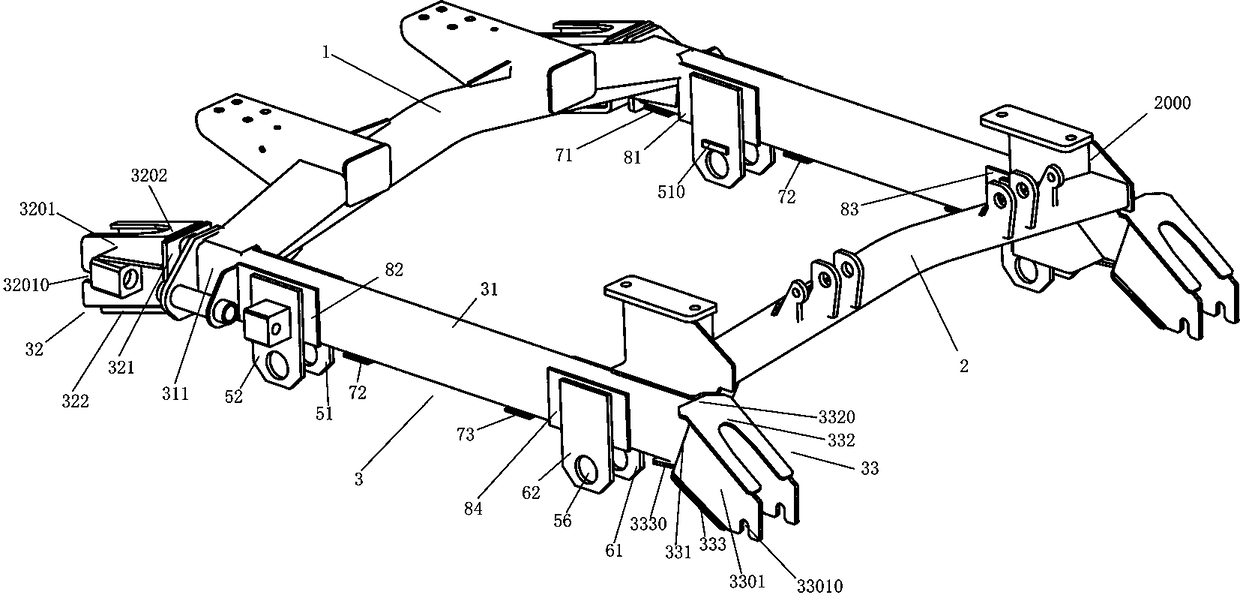

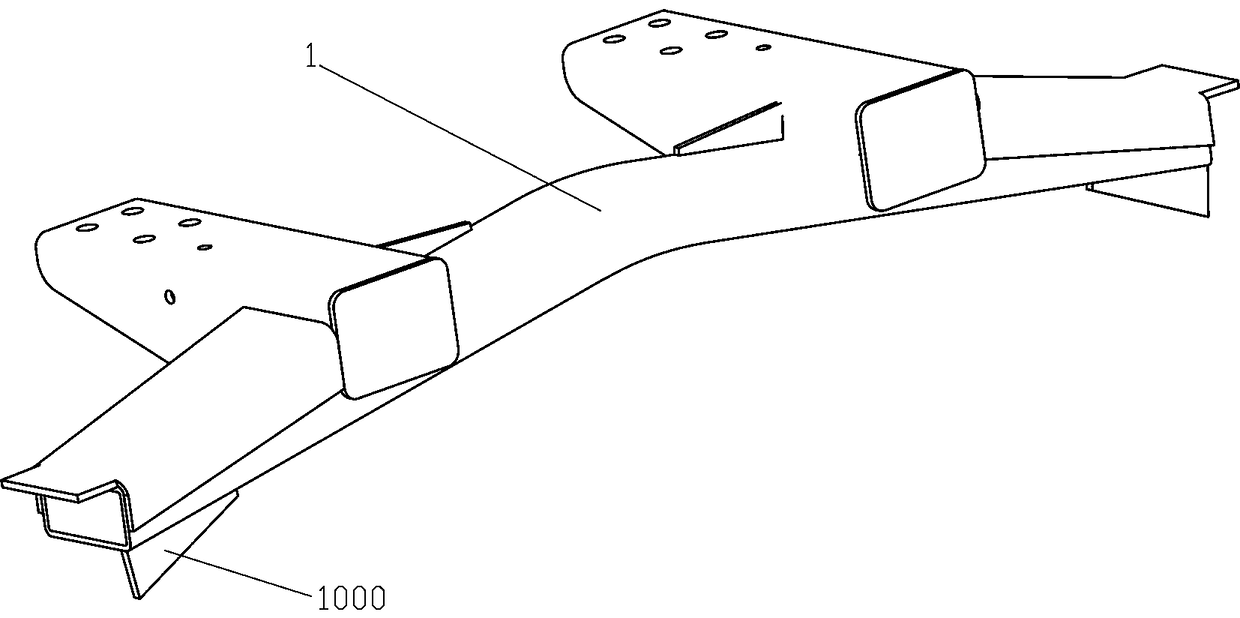

Tractor frame and traveling wheel system

ActiveCN108327794AImprove enduranceImprove reliabilityUnderstructuresEndless track vehiclesStructural engineeringTractor

The invention relates to the technical field of tractors, in particular to a tractor frame and a traveling wheel system. The tractor frame comprises a front supporting cross beam and a rear supportingcross beam which are disposed opposite to each other. Side supporting longitudinal beams are fixed between the left end of the front supporting cross beam and the left end of the rear supporting cross beam and between the right end of the front supporting cross beam and the right end of the rear supporting cross beam. The intermediate portion of the front supporting cross beam is arched upwards,and the intermediate portion of the rear supporting cross beam is arched upwards. The side supporting longitudinal beams include main supporting beams, front oblique beams and rear oblique beams, wherein the main supporting beams extend forwards and backwards in a linear mode, the front oblique beams extending obliquely forwards and downwards are fixed to the front ends of the main supporting beams and used for mounting tensioning wheels, and the rear oblique beams extending obliquely backwards and downwards are fixed to the rear ends of the main supporting beams and used for mounting fixed wheels. The structure is more stable, an operator is more comfortable to use, and the operation is more cheerful.

Owner:XINGGUANG AGRI MACHINERY

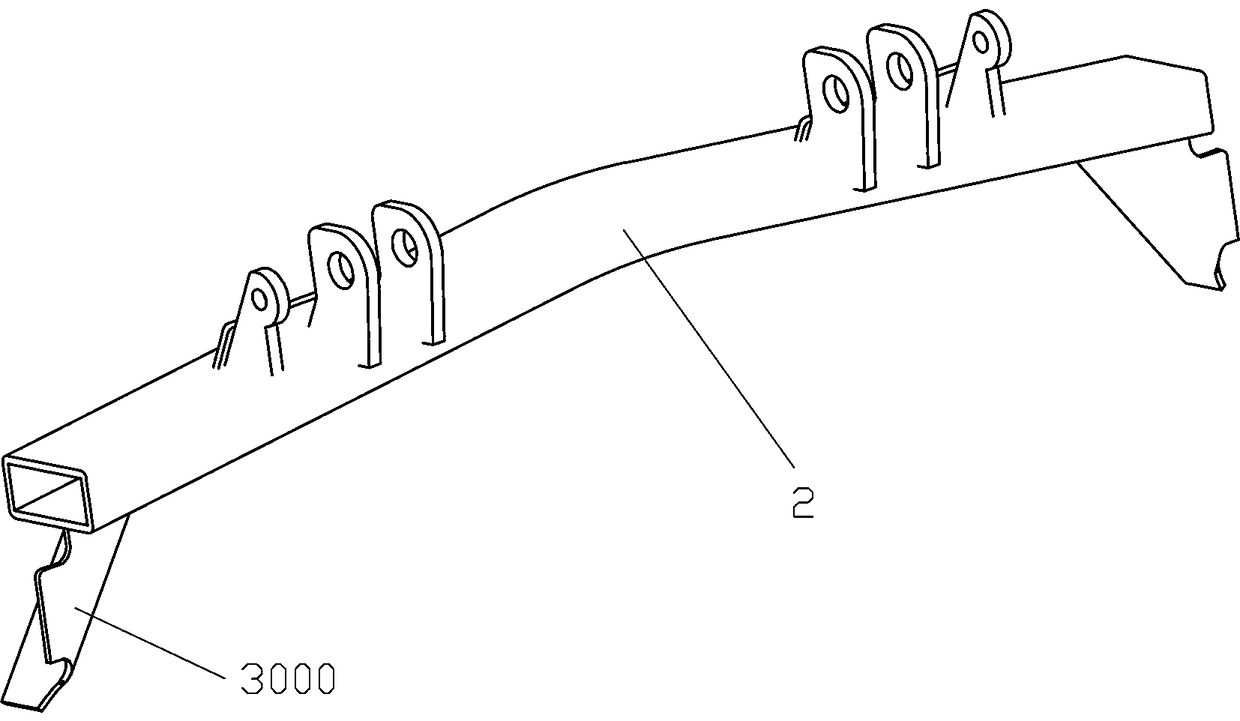

Car trailing arm car body reinforcing plate

InactiveCN107444492AImprove support stiffnessIncreased contact areaSuperstructure subunitsStructural reliabilityTrailing arm

The invention provides a car trailing arm car body reinforcing plate capable of enhancing the strength of trailing arm mounting points and improving the reliability and safety of a trailing arm mounting structure. Side flanges are arranged on the two sides of the car trailing arm car body reinforcing plate; a front end flange and a rear end flange are arranged at the front end and the rear end of the car trailing arm car body reinforcing plate correspondingly; a first transition flange used for being welded to the inner wall of a longitudinal beam is arranged between the rear end flange and one side flange, and a second transition flange used for being welded to a threshold reinforcing plate is arranged between the rear end flange and the other side flange; and the rear end flange, the side flanges, the first transition flange and the second transition flange are connected integrally. According to the car trailing arm car body reinforcing plate, a trailing arm has more force transmitting paths during bearing, disperse transmitting of loads is facilitated, stress of metal plate areas near the mounting points and welding points can be reduced, and accordingly the trailing arm car body mounting points meet the strength performance requirements.

Owner:CHERY AUTOMOBILE CO LTD

Filtration and separation process and device for soil for agricultural planting

InactiveCN109833956AImprove the growth effectEffective filtration and separationGrain treatmentsFiltrationAgricultural engineering

The invention relates to a filtration and separation process and device for soil for agricultural planting. The filtration and separation device comprises a material crushing container, a feeding container is connected to the upper portion of the material crushing container, a left power mechanism and a right power mechanism are arranged on the left side and the right side of the material crushingcontainer correspondingly, a left mashing rotating mechanism and a right mashing rotating mechanism are arranged on the left side and the right side of the interior of the material crushing containercorrespondingly, a material returning pipe is connected to the lower portion of the left side of the material crushing container, the left side of the material returning pipe is connected with a material collecting container, the lower portion of the material crushing container is provided with a separation mechanism, the lower portion of the separation mechanism is provided with a material discharging container, the right side of the material discharging container is connected with a lifting container, the upper portion of the lifting container is provided with an upper power mechanism, thelower portion of the upper power mechanism is connected with a power mechanism shaft, the side surface of the power mechanism shaft is provided with a stirring mechanism, and the upper portion of theright side of the lifting container is connected with a feeding pipe. According to the filtration and separation process and device, the system can be used for effectively filtering and separating soil for agricultural planting, moreover, distribution use is facilitated, so that agricultural planting use are facilitated, and the growth effect of agricultural plants is improved.

Owner:成诚

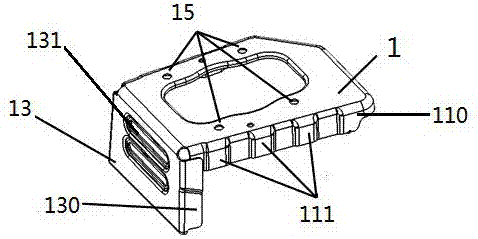

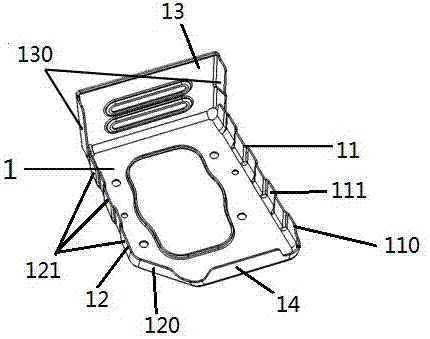

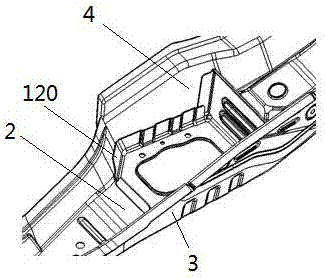

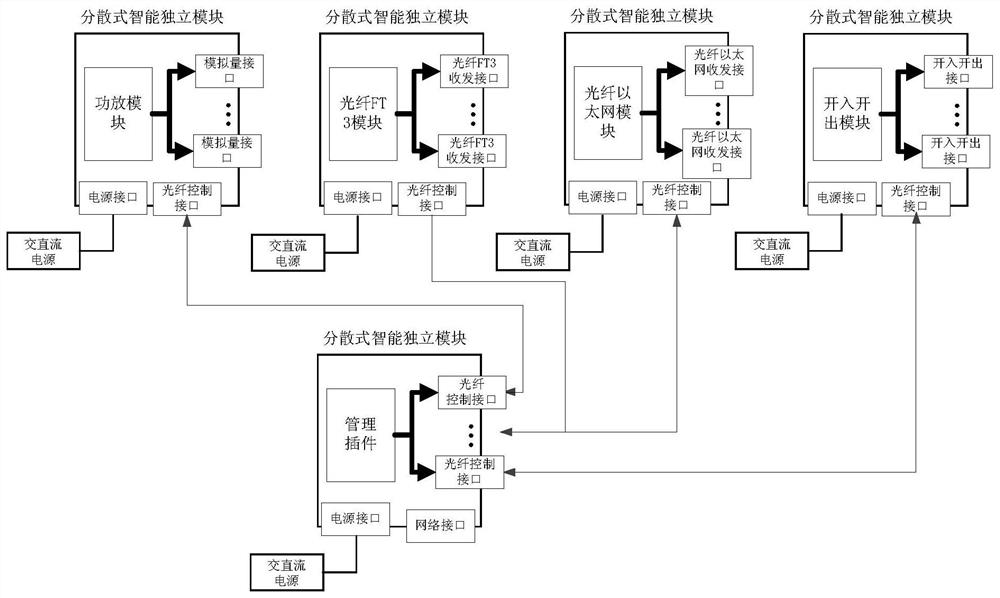

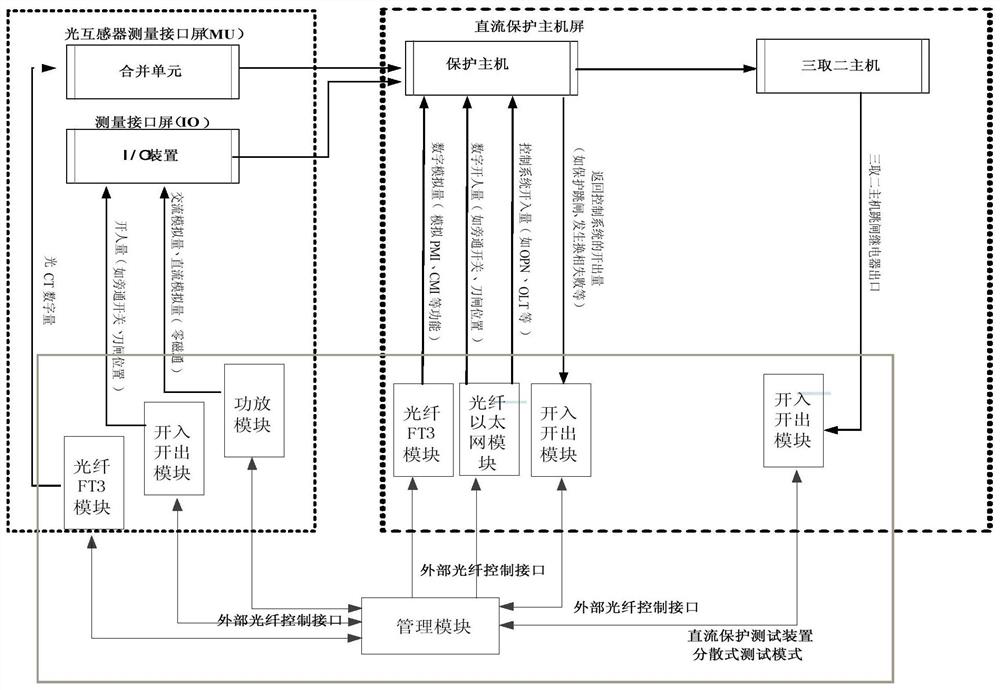

Distributed novel direct current testing device

PendingCN114578180AEasy to distributeEasy to implementFault locationElectromagnetic transmissionCentralized managementTest set

The invention discloses a distributed novel direct current testing device which adopts distributed distribution, all functional modules are distributed near a tested device, centralized management is performed through a management module, testing of a direct current system can be completed without a plurality of testing devices, implementation is rapid and convenient, and a complex testing environment does not need to be set up. Meanwhile, the optical fiber interface is adopted, the situation that on-site standby optical fibers of a direct-current system are sufficient can be fully utilized, the modules are convenient to arrange in a distributed mode, the method is more suitable for the characteristics of on-site device cross-floor and cross-interval arrangement, and the method is lighter and easier to implement.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

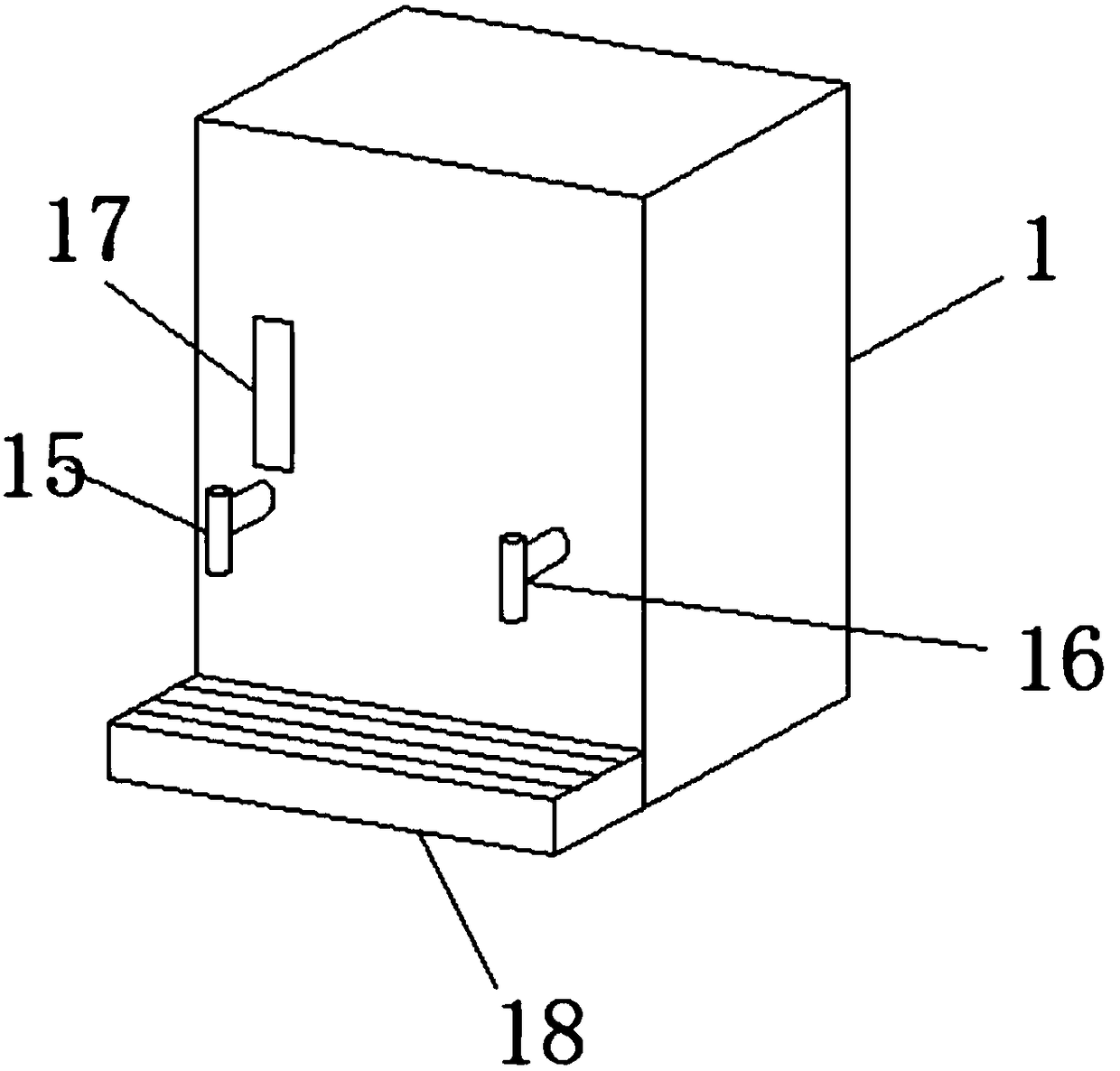

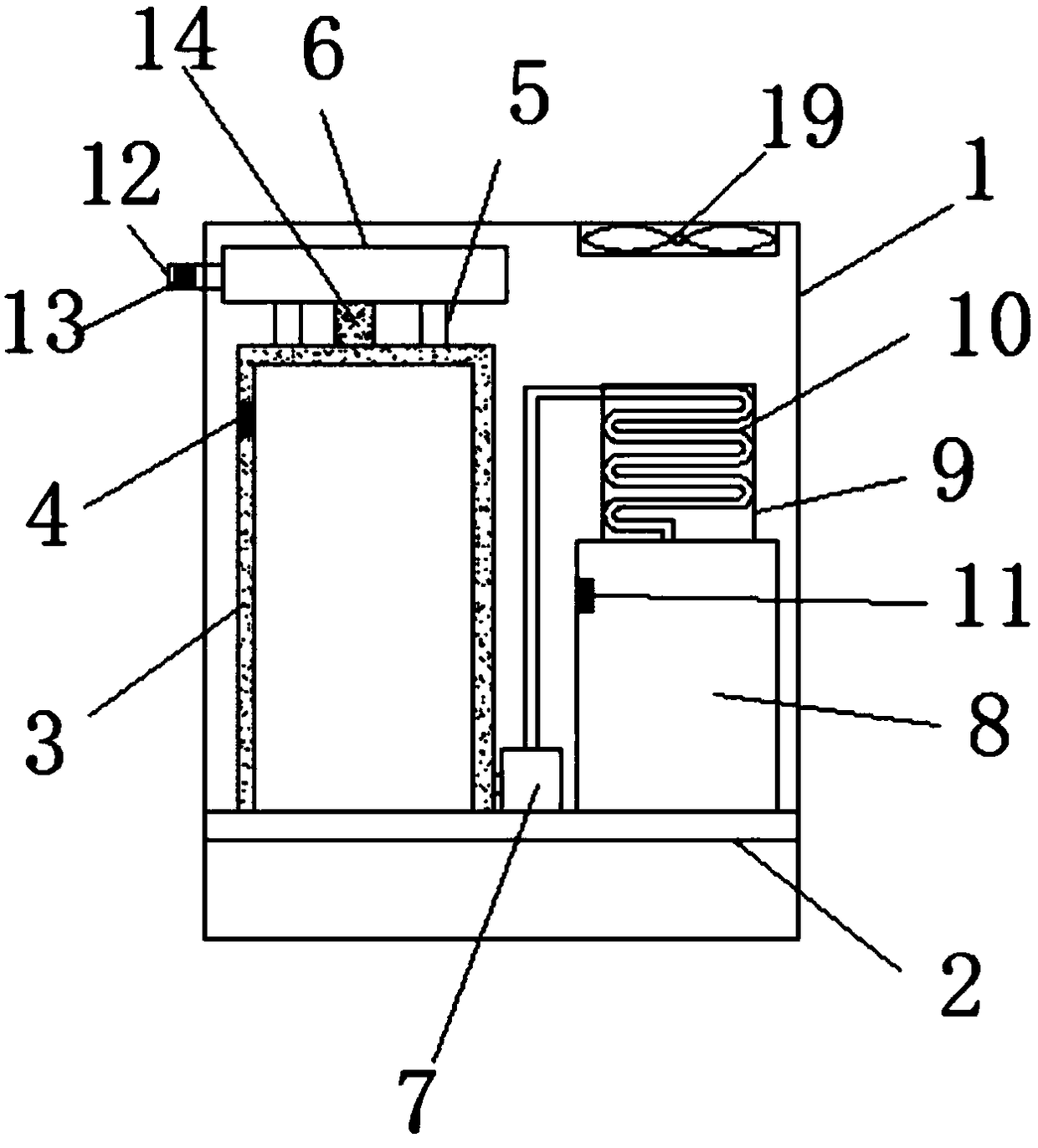

Large-capacity high-temperature hot water machine

InactiveCN108444108AGood insulation effectEasy to distributeWater heatersWater storage tankLiquid level sensor

The invention discloses a large-capacity high-temperature hot water machine. The large-capacity high-temperature hot water machine comprises a machine shell. A support plate is fixedly connected withthe interior of the machine shell. A hot water storage tank is fixedly connected to the top end of the support plate. A first liquid level sensor is fixedly connected to the inner side wall of the hotwater storage tank. Support columns are fixedly connected to the top end of the hot water storage tank. A heater is fixedly connected to the top ends of the support columns. A water pump is fixedly arranged on one side of the hot water storage tank. A cold water storage tank is fixedly arranged on one side of the water pump. A second liquid level sensor is fixedly arranged on the inner side wallof the cold water storage tank. A condensation tank is fixedly connected to the top end of the cold water storage tank. The large-capacity high-temperature hot water machine is novel in design, simplein structure, large in capacity, capable of easily containing a large amount of hot water, high in heat preservation effect and capable of preventing heat from being quickly dissipated and wasting resources; and moreover, the large-capacity high-temperature hot water machine has a good cooling function, can meet different needs of people, is convenient for people to use and has good practical performance.

Owner:ZHEJIANG HAILAIFU ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com