Hot-air drier

A hot air dryer and hot air technology, applied in dryers, drying, progressive dryers and other directions, can solve the problems of waste of resources, high physical exertion of staff, steam burns, etc., to prevent injuries and save energy. , the effect is not easy to spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

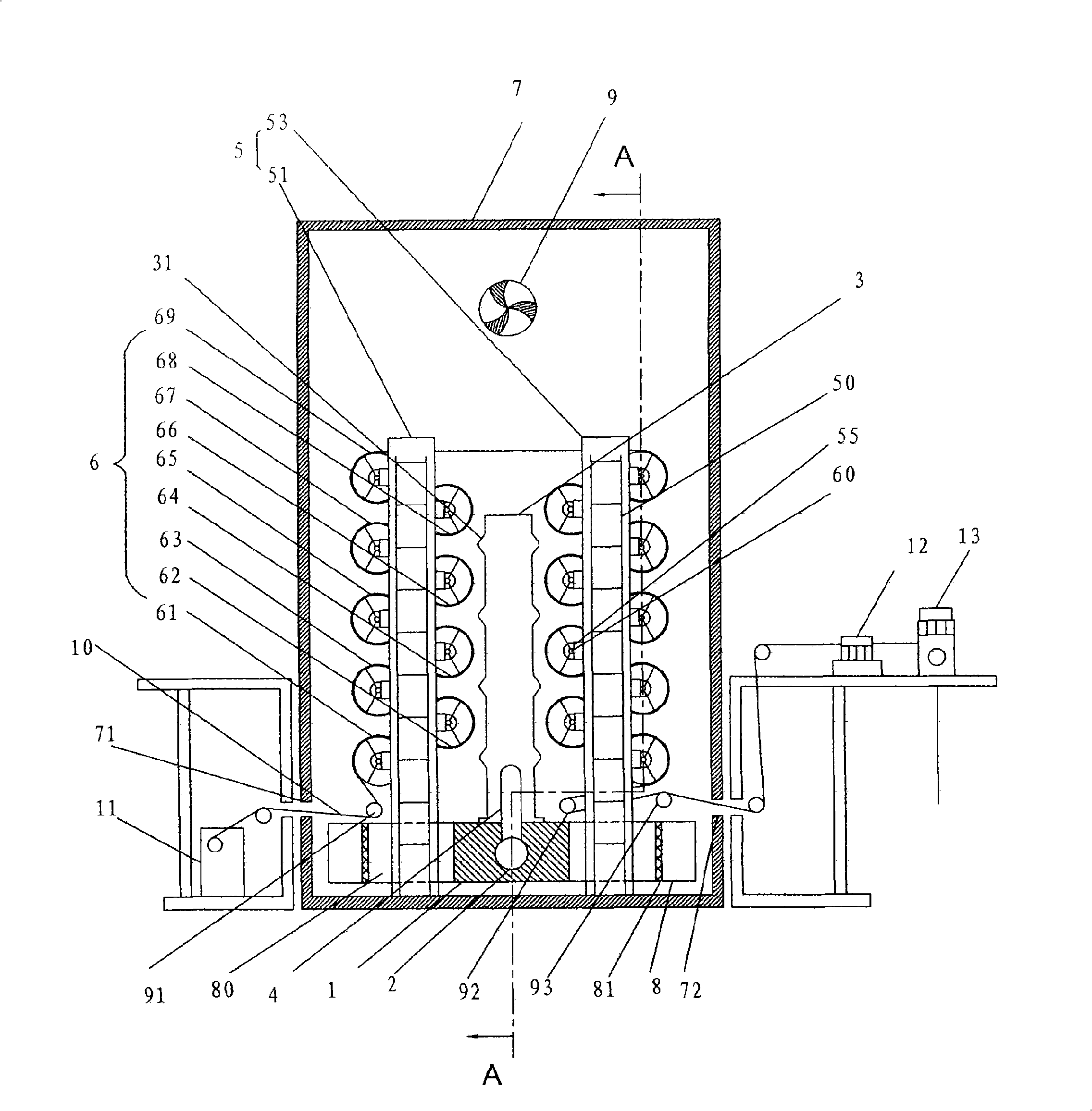

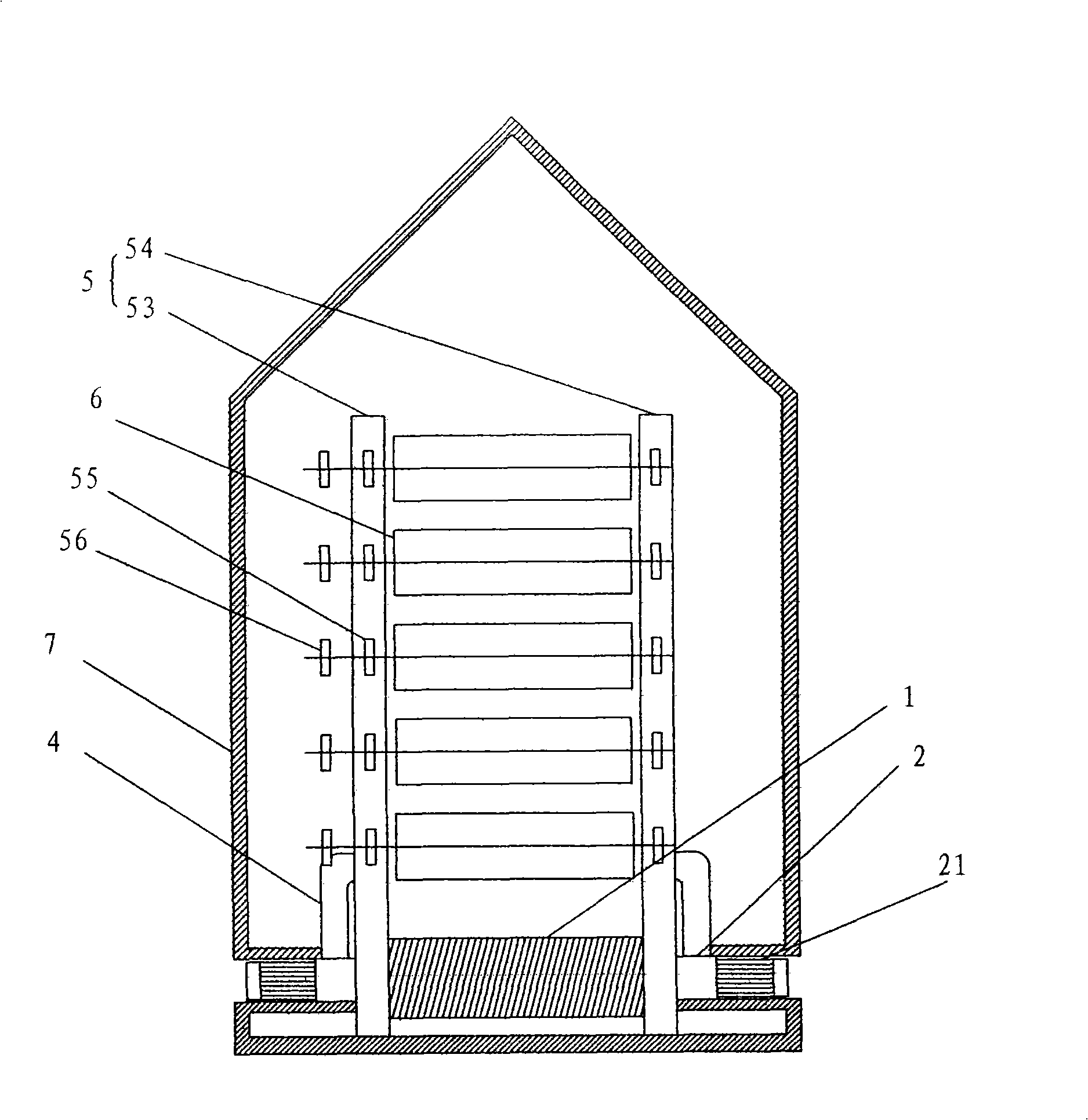

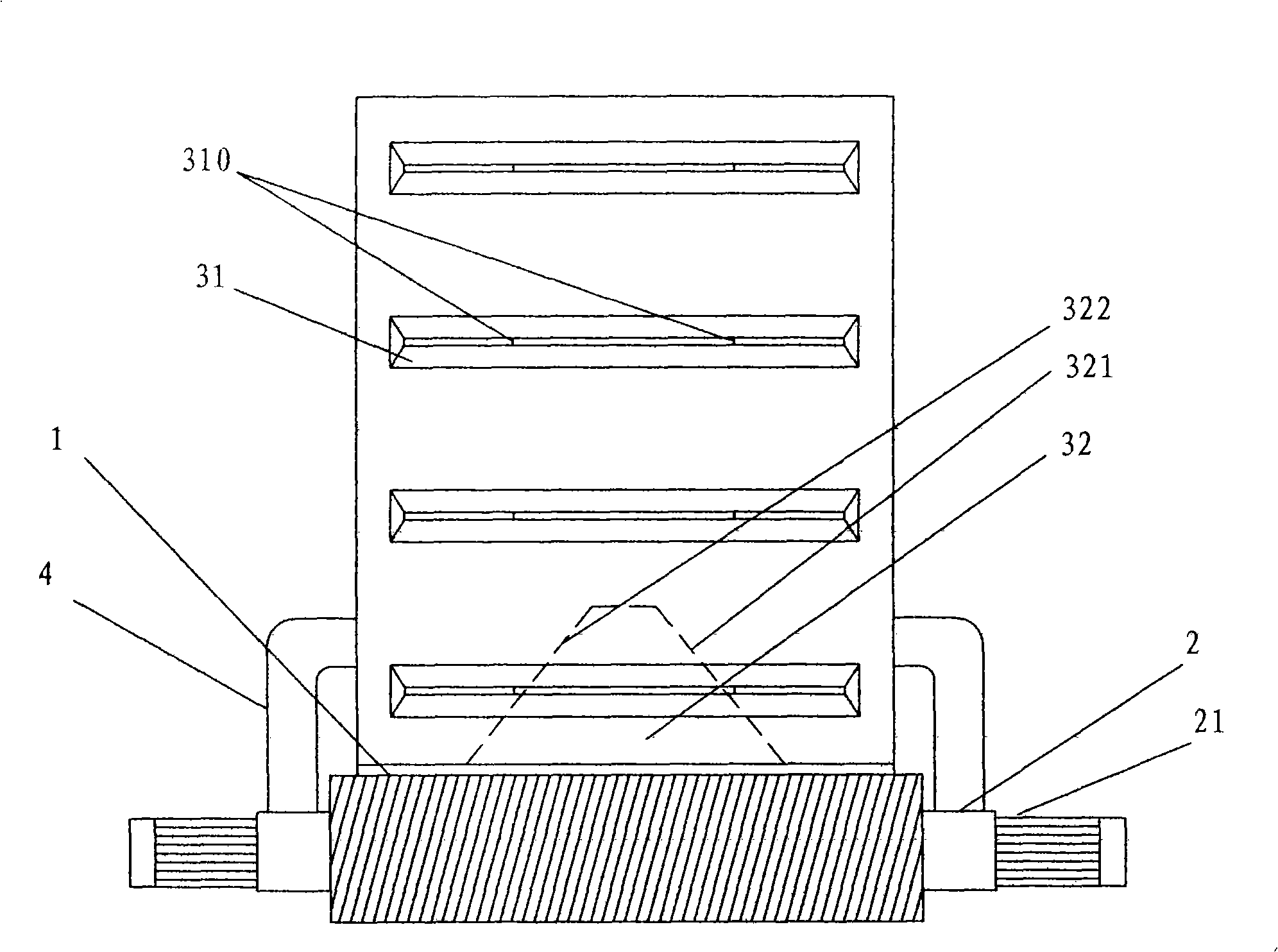

[0026] to combine figure 1 , figure 2 and image 3 , is a preferred embodiment of the present invention.

[0027] The hot air dryer includes a radiator 1, a circulating fan 2, a hot air duct 3, a circulating air connecting pipe 4, a drying cylinder column 5 and a hollow drying cylinder 6. In this embodiment, there are two pairs of drying cylinder columns 5 and one radiator 1 . Of course, the number of drying cylinder columns 5 and radiators 1 can be increased or decreased according to needs, for example, the pattern of three pairs of drying cylinder columns 5 and two radiators 1 can also be used.

[0028] The radiator 1 is located at the center of the bottom. The radiator 1 in this embodiment is a heat transfer oil radiator, and the heat transfer oil is installed inside to generate heat. Radiator 1 can be other types, such as electric heat pipe radiator and steam radiator. The two sides of the radiator 1 are equipped with the same circulating fan 2, and the circulating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com