Profile cutting method for laser cutting automatic production line

An automatic production line and cutting method technology, applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of low blanking efficiency, affecting profile processing and production, and achieve high blanking efficiency, convenient processing, The effect of easy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

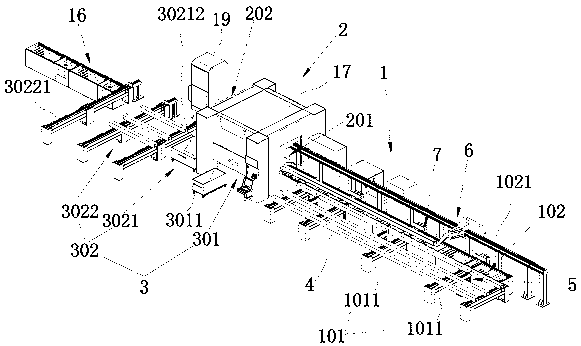

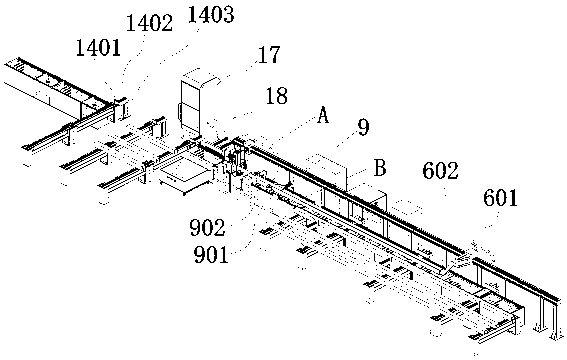

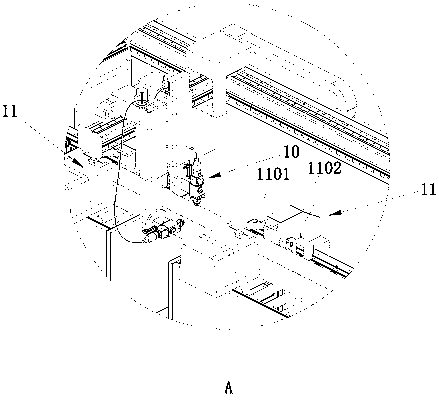

[0061] refer to figure 1 , this embodiment discloses a laser cutting automatic production line, including a feeding area 1, a cutting area 2 and a feeding area 3, a storage rack 101 and a feeding table 102 are arranged in the loading area 1, and the storage rack 101 is used for For storing the profile 4 to be processed, the profile 4 can be hoisted by a crane to the storage rack 101 for temporary storage;

[0062] refer to figure 1 , the storage rack 101 is also provided with a lateral pushing assembly 5 that pushes the profile 4 to the feeding table 102, the cutting area 2 includes a feeding end 201 and a discharging end 202, and one end of the feeding table 102 is docked with the feeding end 201 The forward pushing assembly 6 is also arranged on the loading table 102, and the forward pushing assembly 6 pushes the profile 4 on the loading table 102 to the cutting area 2, and the unloading area 3 includes the first unloading area 301 and The second blanking area 302, the fir...

Embodiment 2

[0085] This embodiment discloses a profile cutting method, refer to Figure 1~Figure 7 , based on the laser cutting automated production line disclosed in embodiment 1, comprising the following steps:

[0086] Step 1: hoisting the profiles 4 to the storage rack 101 for storage by a crane, placing the profiles 4 on the feeding conveyor chain 101111, and keeping the adjacent profiles 4 at intervals;

[0087] Step 2: Loading, the feeding driving motor drives the feeding conveying sprocket group to rotate, and then drives the feeding conveying chain 101111 to move towards the direction close to the feeding platform 102, thereby conveying the profile 4 towards the direction close to the feeding platform 102, After the profile 4 passes through the feeding push plate 502, the feeding lifting member 503 drives the feeding horizontal telescopic member 501 to rise, so that the feeding horizontal telescopic member 501 is higher than the upper surface of the feeding conveyor chain 101111,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com