a car cab

A cab and automobile technology, which is applied in the structural field of automobile cabs, can solve the problems of insufficient threshold stiffness, side wall deformation, and unsatisfactory bending and torsional performance, so as to improve the lateral collision resistance and reduce deformation and cracking. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

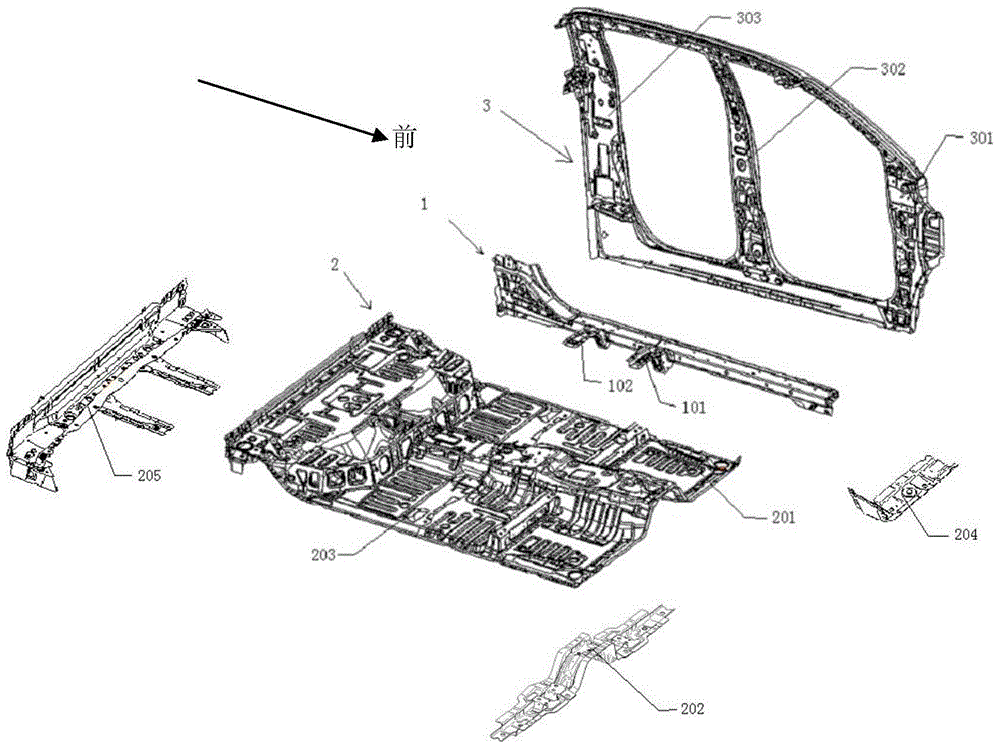

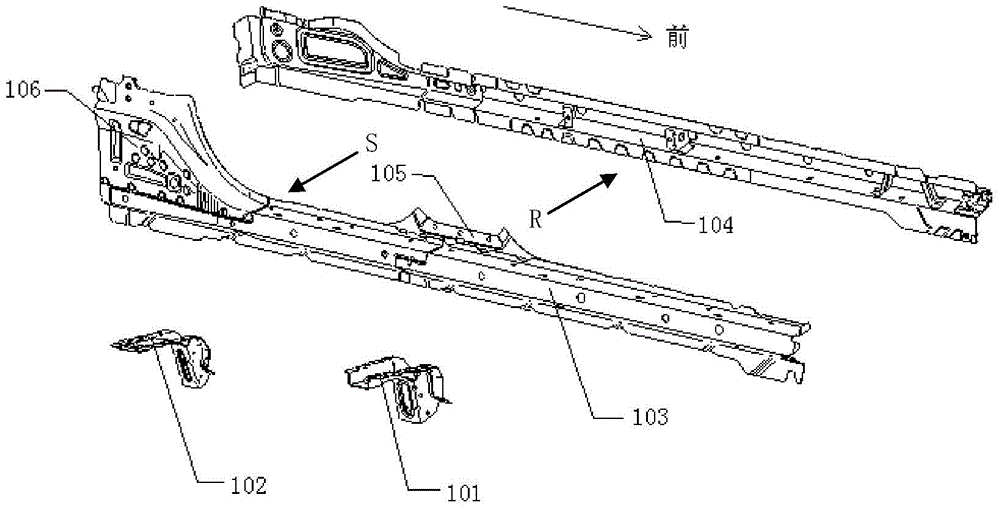

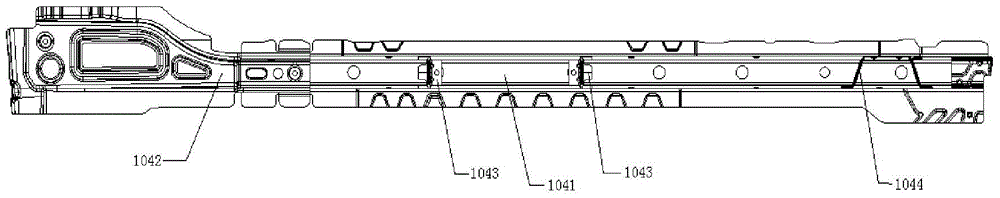

[0032] refer to figure 1 , which shows a part of a car cab, including a rocker assembly 1 , a floor assembly 2 and a side panel assembly 3 . The floor assembly 2 includes a central crossbeam 202 and a front floor sheet metal 201 and a rear floor sheet metal 203', a front crossbeam 204, a middle crossbeam 202 and a rear crossbeam 205 welded to the middle crossbeam 202. The middle beam 202 connects the front floor sheet metal 201 and the rear floor sheet metal 203, the front beam 204 is welded to the front end of the front floor sheet metal 201, the rear beam 205 is welded to the rear end of the rear floor sheet metal 203, the front beam 204, the middle beam 202 and the rear The beam 205 constitutes the skeleton of the floor assembly 2 and improves the overall strength of the floor assembly 2 . The side panel assembly 3 has a front pillar (A pillar) 301 , a center pillar (B pillar) 302 and a rear pillar (C pillar) 303 . The sill assembly 1 is welded to connect the floor assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com