Non-sticky heat-insulation grooved-surface flanged pipe fitting used for small workshop

A flange-based, small-scale technology is applied in the direction of heat preservation, flange connection, and pipeline protection through heat insulation. It can solve the problems of easy dust accumulation on the surface, easy scalding of the pipe wall, and loose bolt holes, etc., so that it is not easy to accumulate dust, Not easy to spread, strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

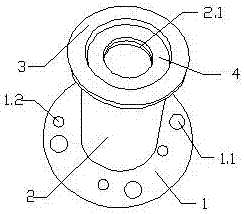

[0016] see figure 1 , a flanged pipe fitting for a small workshop with non-stick heat preservation tank surface of the present invention, it includes a chassis 1 and a pipe body 2, the cross sections of the chassis 1 and the pipe body 2 are ring-shaped, and the bottom of the pipe body 2 is welded to the chassis 1, a large through hole 1.1 is provided on the chassis 1, a small through hole 1.2 is provided beside the large through hole 1.1, an internal thread 2.1 is provided on the inner diameter of the pipe body 2, and the outer surface of the pipe body 2 An insulating layer is provided, a flange 3 is provided on the top of the outer wall of the pipe body 2, a non-stick layer is provided on the surface of the flange 3, and a groove 4 is provided between the flange 3 and the top of the pipe body 2 .

[0017] After the small through hole 1.2 is set, the connection between the equipment and the equipment, the pipe body and the pipe body is more firm, the groove 4 makes the equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com