Patents

Literature

292 results about "Non-stick surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A non-stick surface is a surface engineered to reduce the ability of other materials to stick to it. Non-stick cookware is a common application, where the non-stick coating allows food to brown without sticking to the pan. Non-stick is often used to refer to surfaces coated with polytetrafluoroethylene (PTFE), a well-known brand of which is "Teflon." In the twenty-first century other coatings have been marketed as non-stick, such as anodized aluminium, ceramics, silicone, enameled cast iron, and seasoned cookware. Superhydrophobic coating is the newest non-stick coating for sale.

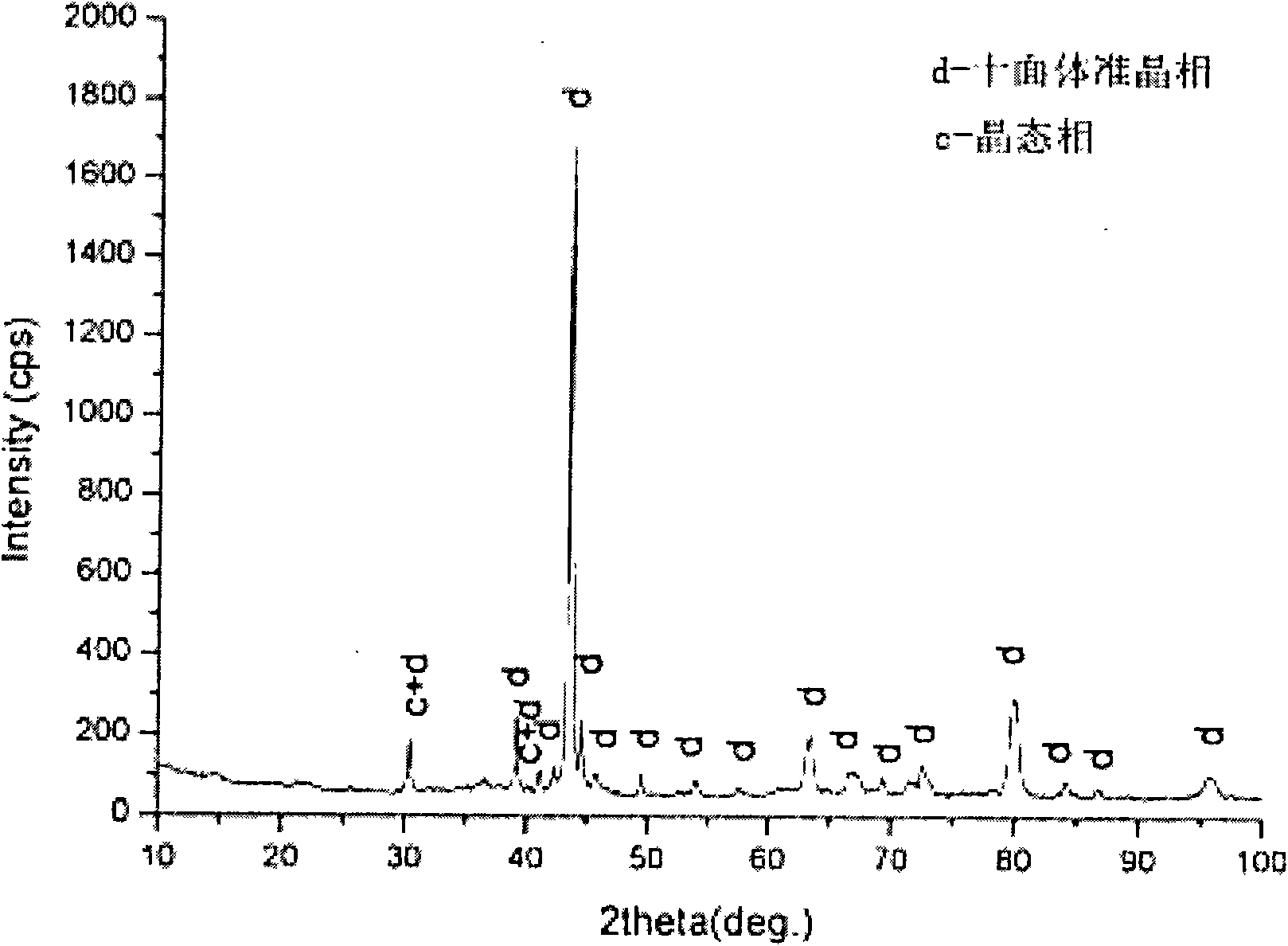

Non-stick pan coating layer and preparation method thereof

The invention provides a non-stick pan coating layer and a preparation method thereof. The coating layer comprises Al-Cu-Fe-Cr-B quasicrystalline alloy which has components as follows by the atomic percentage: 70-90 of Al, 1-15 of Cu, 5-15 of Fe, 5-15 of Cr, and the balance of B and unavoidable impurity. The method comprises the specific steps as follows: (1) smelting alloy materials with a spraying device at a temperature of 900-1100 DEG C to prepare alloy powder; (2) spraying the alloy coating layer on a boiler basal body with a plasma spraying device, with a main gas feed rate of 65 L / min, a secondary gas feed rate of 20-30 L / min, an arc current of 550-590A, an arc voltage of 45-60V, a powder delivering amount of 10-15 g / min, and a coating layer thickness of about 100-200 micro. At a cooking temperature, the invention has the advantages of stable chemical property, large rigidness, lower cost than Teflon or organic silicon, low surface friction coefficient, and the like.

Owner:鞠汉清

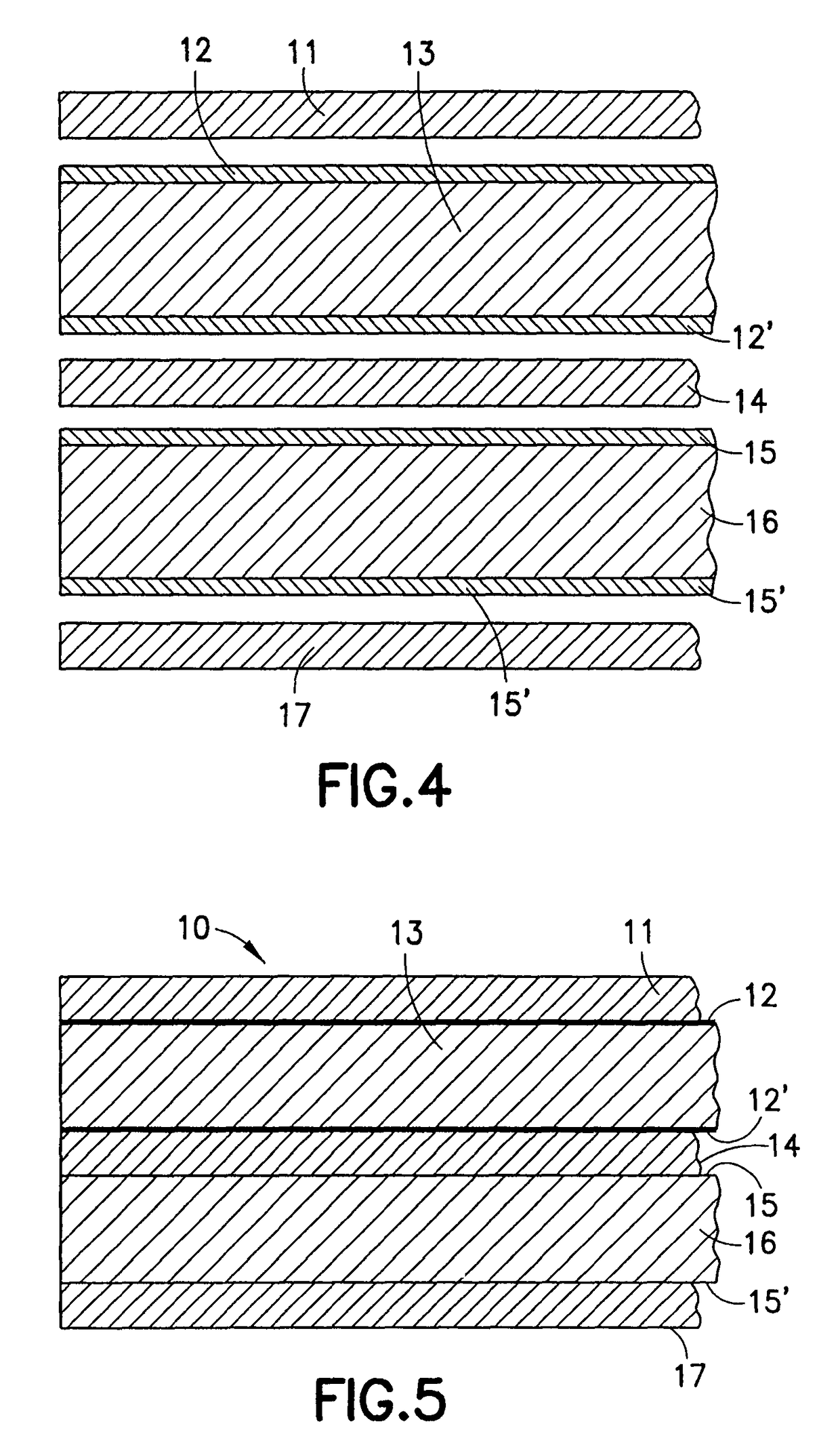

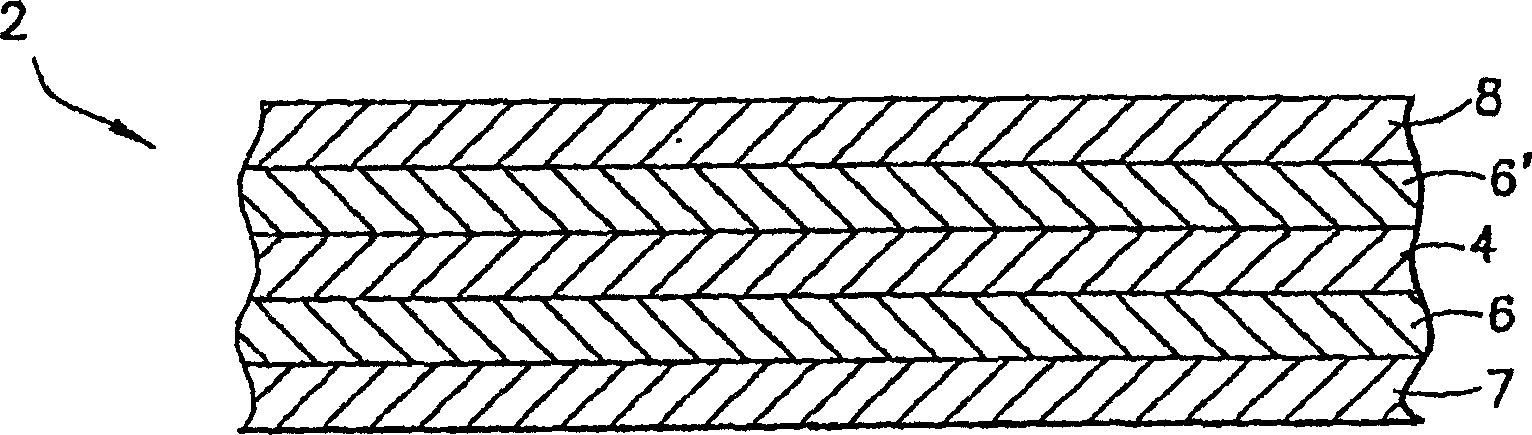

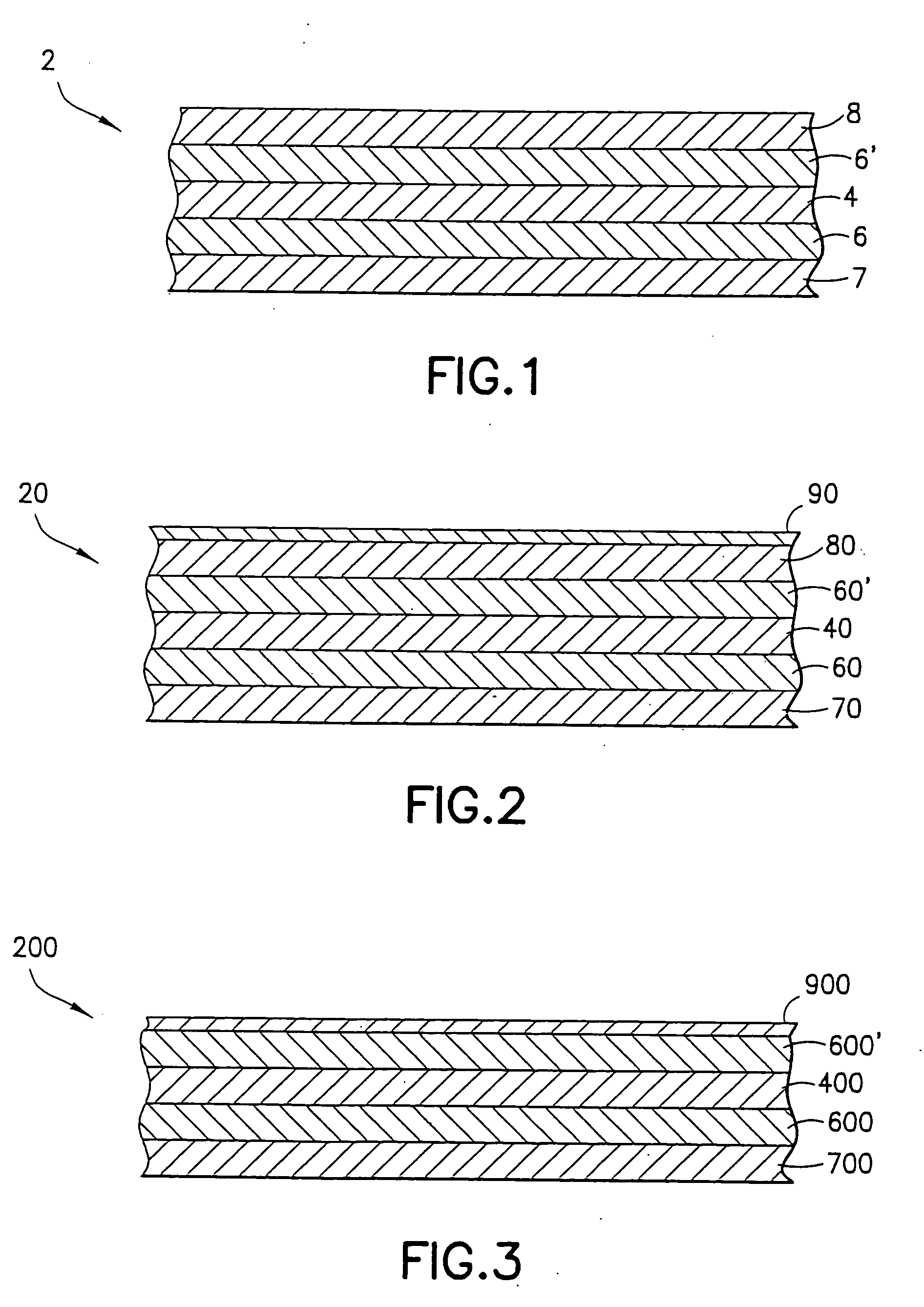

Bonded metal components having uniform thermal conductivity characteristics and method of making same

InactiveUS6926971B2High bonding strengthAvoid bondingHot-dipping/immersion processesCooking-vessel materialsTitaniumMetal

Cookware having improved uniform heat transfer over the entire cross section thereof, the cookware formed from a multi-layered composite metal having a layer of titanium roll bonded at or near the core of the composite. The titanium layer is roll bonded to layers of aluminum which, in turn, is roll bonded to layers of stainless steel. The layer of stainless steel adjacent to the cooking range may be a ferritic stainless steel if induction-type heating is desired. The multi-layered composite is also suitable for making a sole plate for an iron. Both the cookware and sole plate may include a non-stick surface applied thereto.

Owner:CLAD METALS

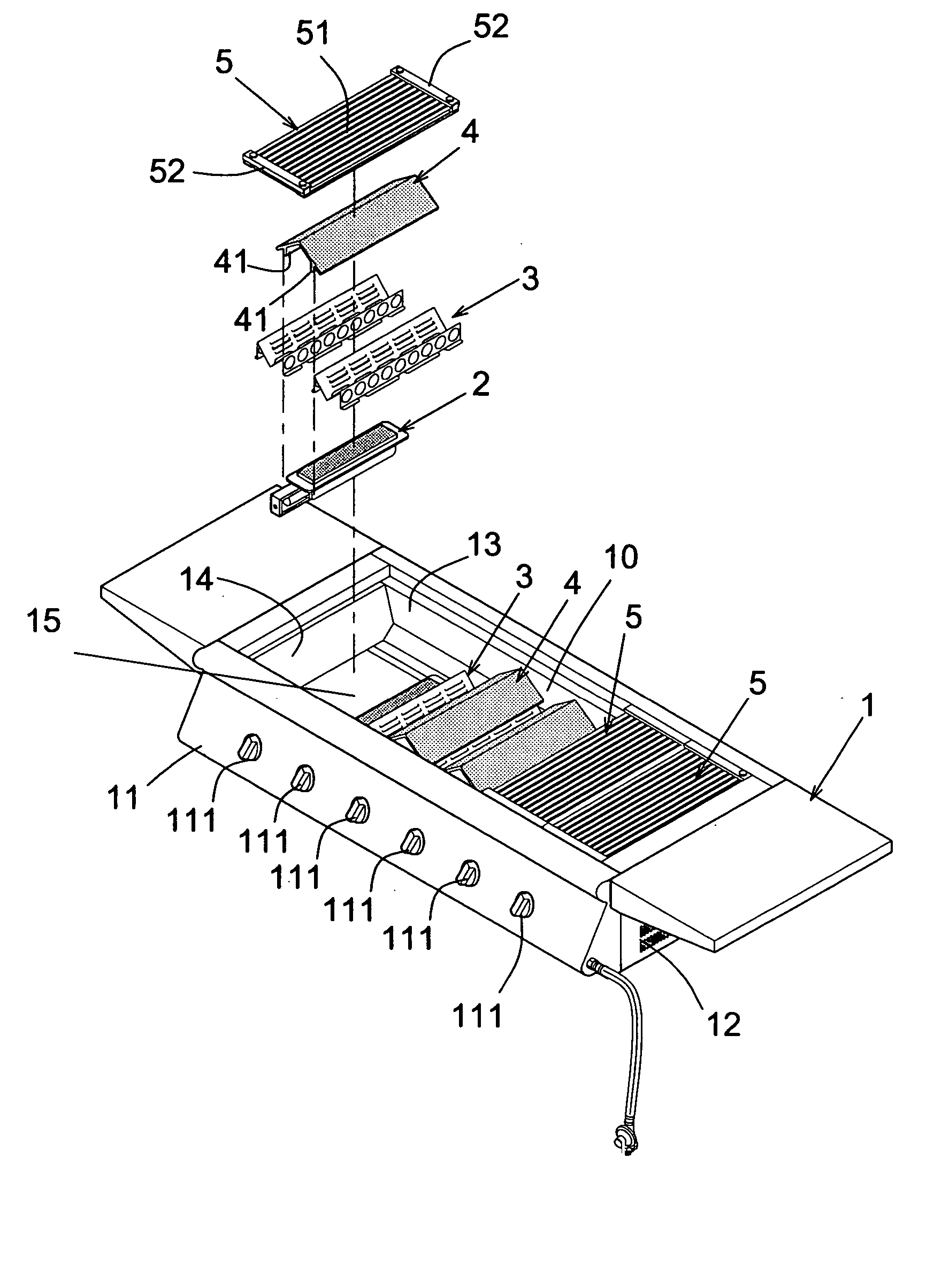

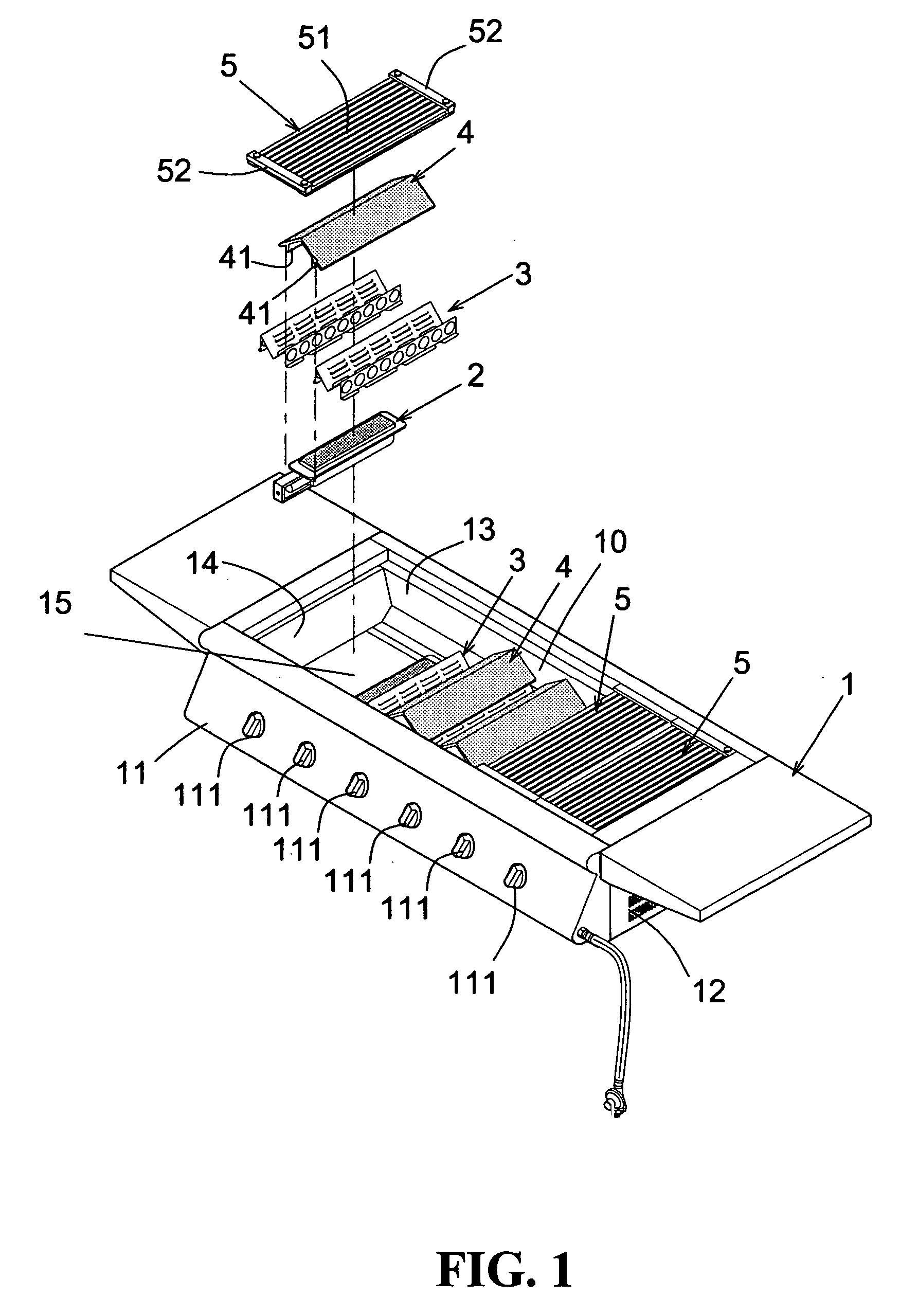

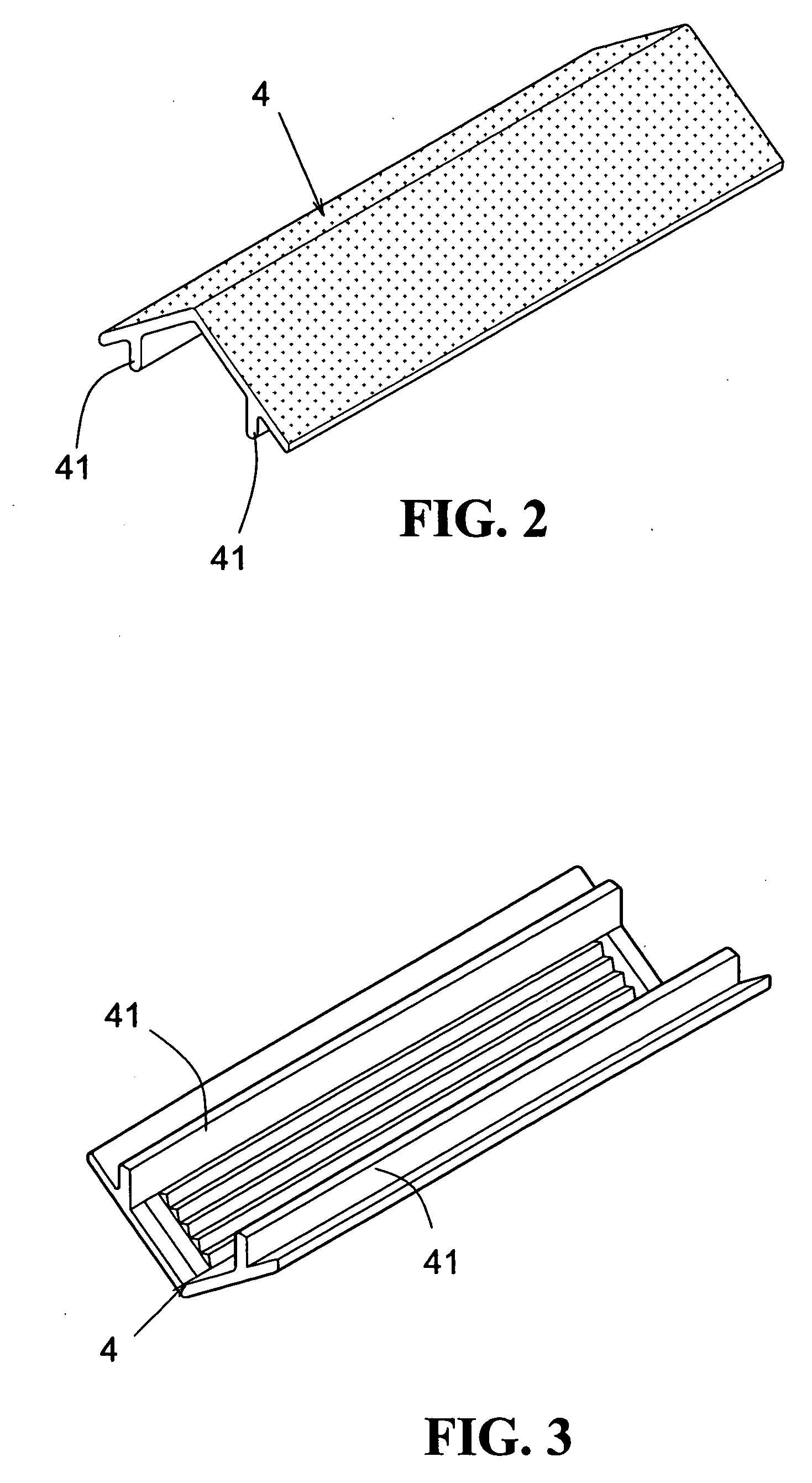

Far-infrared barbecue device

InactiveUS20050284461A1Increase the areaCook evenlyDomestic stoves or rangesLighting and heating apparatusFlavorCombustor

A far-infrared barbecue device includes a body having four sidewalls so as to form a barbecue area and a gas burner is transversely installed in the barbecue area. A plurality of support frames is located at an inner bottom of the barbecue area and the gas burner is located between the support frames. A plurality of far-infrared ceramic boards stand between the support frames and located above the gas burner. A food rack composed of a plurality of ceramic bars is installed above the far-infrared ceramic boards so that food is cooked by the far-infrared energy and maintains its flavor and nutrition. The food rack has non-stick surface and are durable high temperature and easily to be cleaned.

Owner:HSU SEN KUNG

Cookware Surface and Method for Forming Cookware Surface

InactiveUS20140004311A1Prevent surfaceAvoid contactLayered productsWork treatment devicesBiomedical engineeringCooker

A cookware surface comprises a corrugated surface. The corrugated surface is formed of a plurality of raised portions and a plurality of lower areas. The lower areas have a non-stick surface formed thereon, and the raised portions have a hard anodized finish formed thereon. The raised portions aid in preventing cooking utensils from rubbing off the non-stick surface of the lower areas. A method of forming a surface for cookware is disclosed comprising forging a predetermined pattern of corrugations on a surface of the cookware, applying a non-stick coating to the surface of the cookware, and removing the non-stick coating from the raised portions.

Owner:MASPION

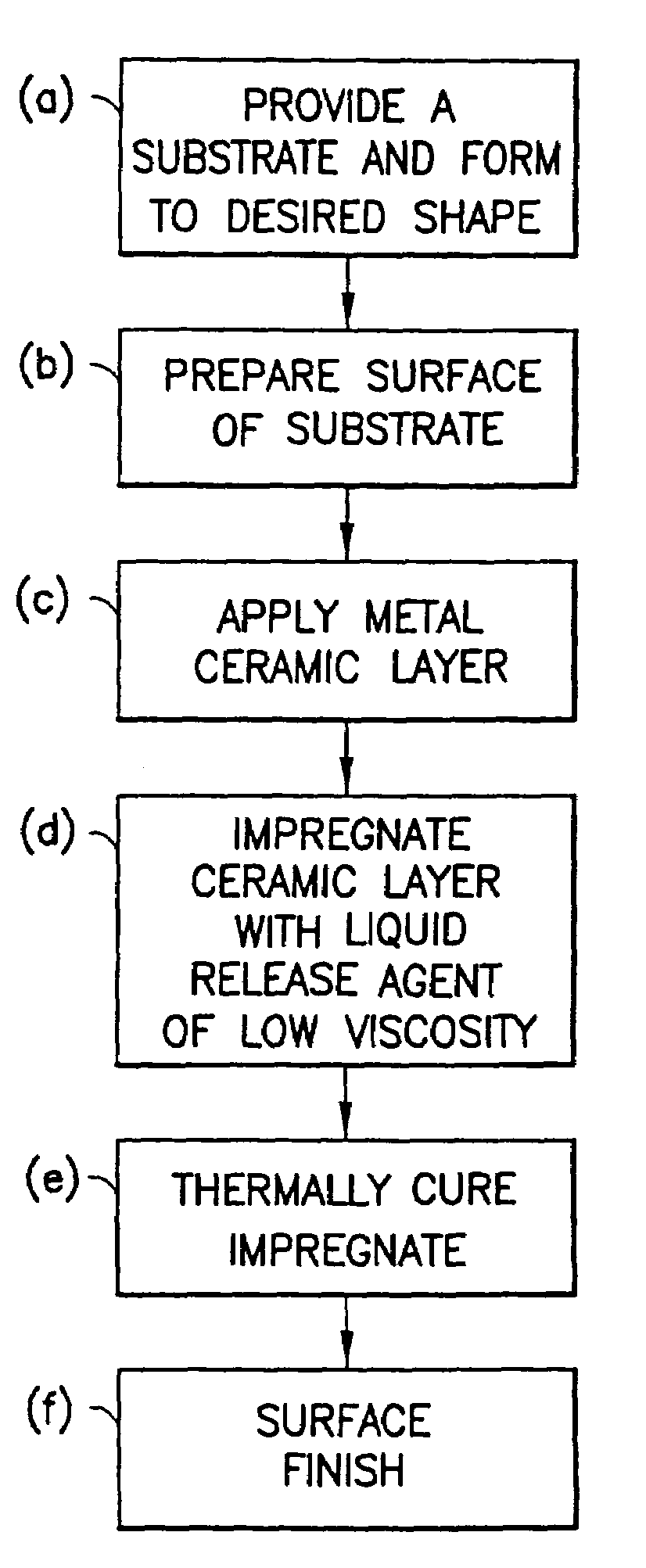

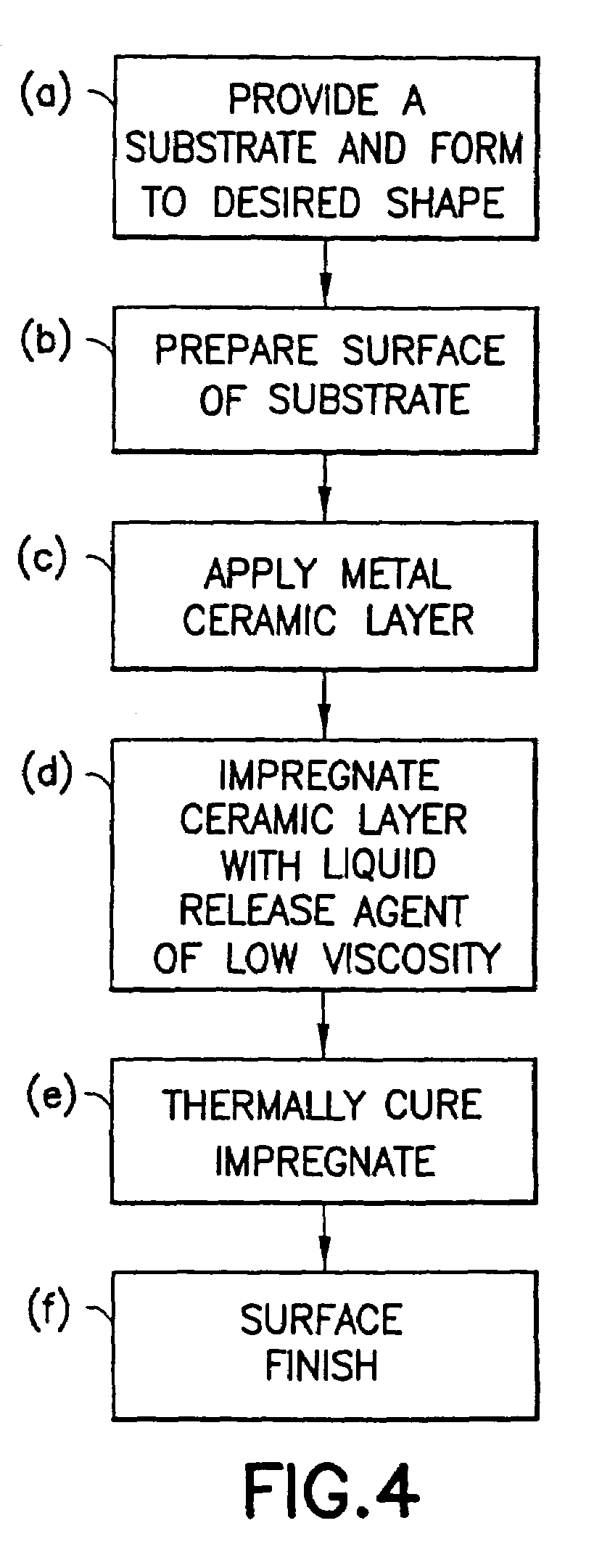

Method of making non-stick cookware

InactiveUS7488515B2Improve adhesionLow viscosityCooking-vessel materialsMolten spray coatingCeramic coatingHard metal

A non-stick surface comprising a porous, hard metal-ceramic coating such as chromium oxide applied to the cook surface of a cooking utensil by arc or plasma spraying. The pores of the coating are impregnated under vacuum with an inert release agent of low viscosity such as food grade liquid silicon resin. After vacuum impregnation, the impregnate is thermally cured and the cook surface is mechanically abraded / polished to remove the protruding peaks of metal-ceramic material to expose flattened bare metal portions interspersed between and substantially co-planar with the surfaces of the impregnated release agent residing in the valleys / pores.

Owner:CLAD METALS

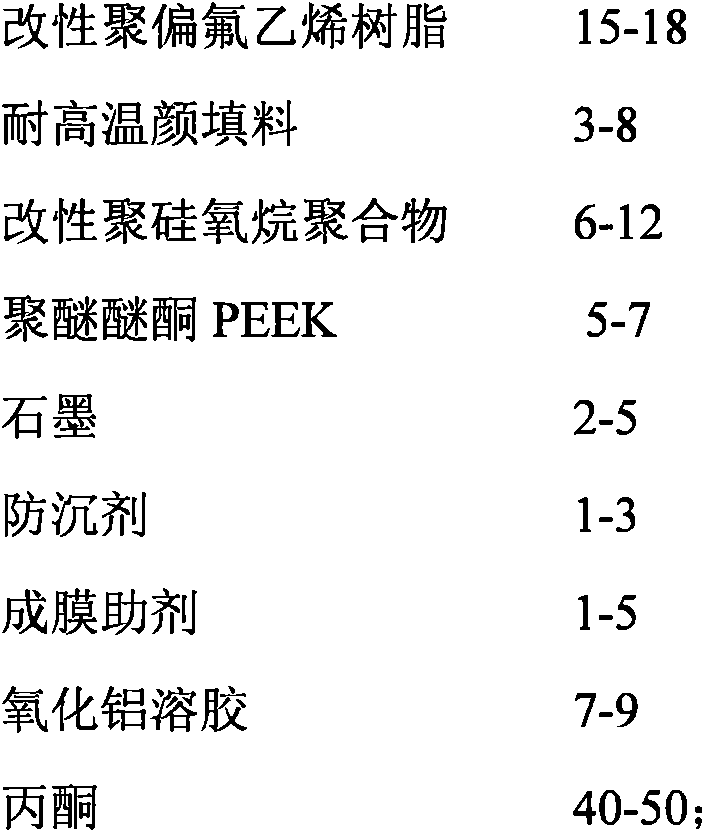

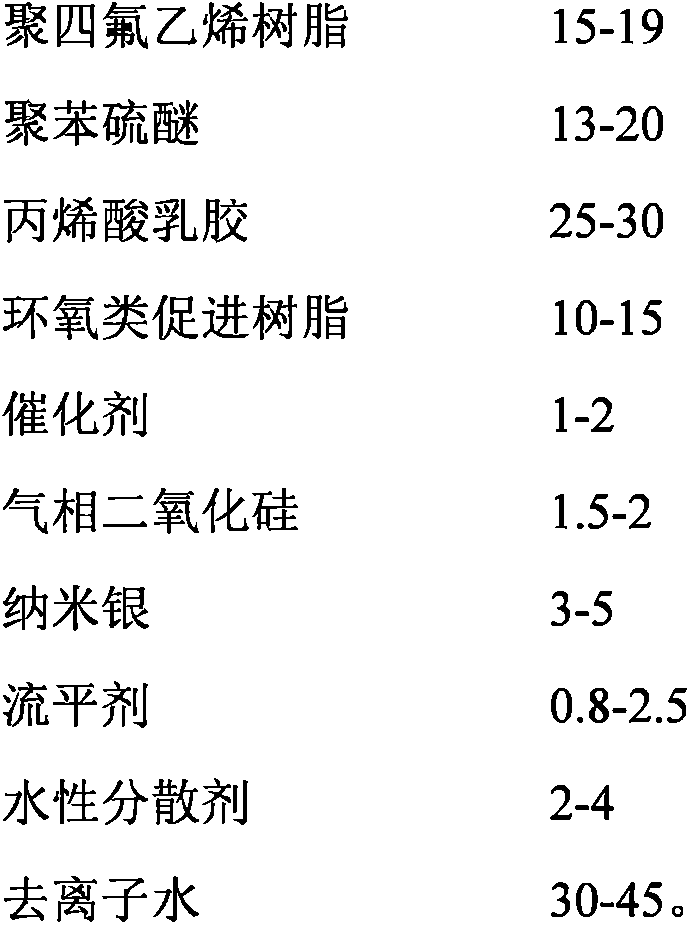

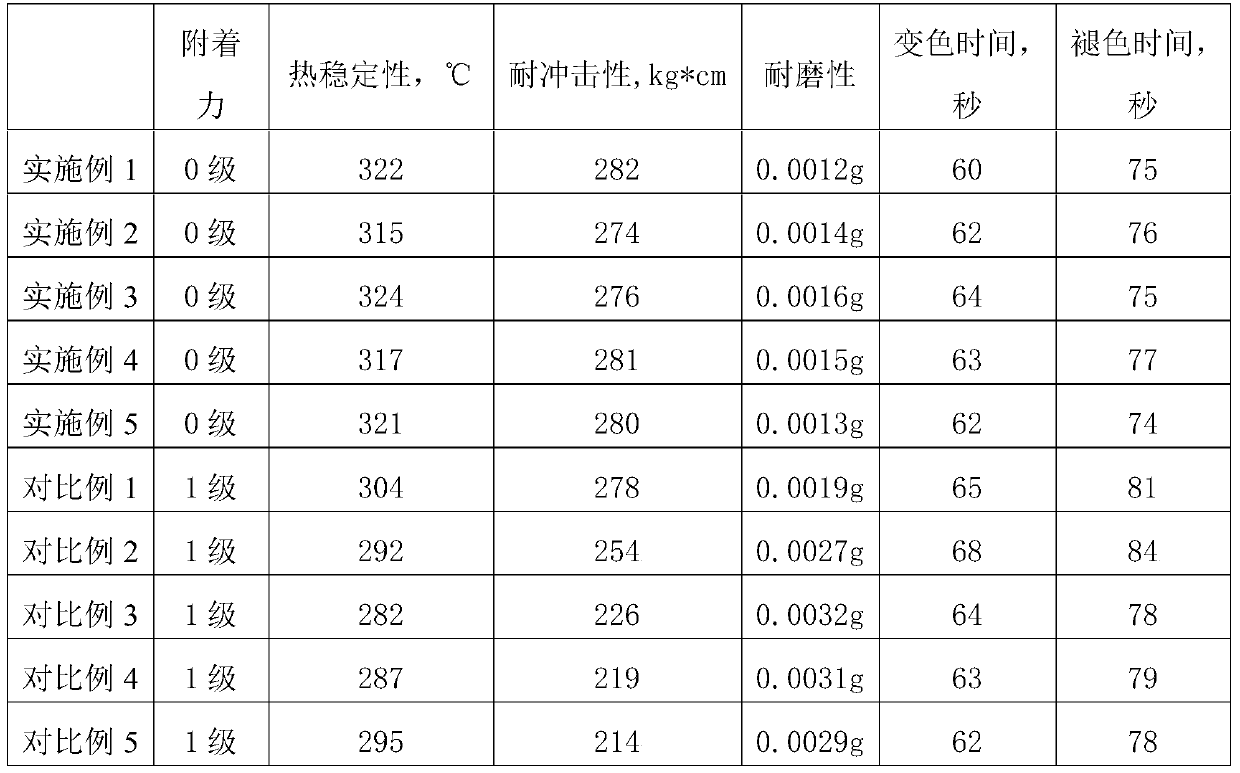

Wear-resistant and mildewproof non-stick pan coating

ActiveCN105111926AChemically stableDoes not generate PFOACooking-vessel materialsAntifouling/underwater paintsEpoxyWear resistant

The present invention relates to a wear-resistant and mildewproof non-stick pan coating. The coating comprises a bottom layer and a surface layer; The bottom layer consists of the following materials in parts by weight: polyimide resin, modified polyvinylidene fluoride resin, a high-temperature-resistant pigment filler, modified polyorganosiloxane polymer, polyetheretherketone PEEK and graphite. The surface layer consists of the following materials in parts by weight: polytetrafluoroethylene resin, phenylene sulfide, acrylate rubber latex, epoxy accelerated resin, a catalyst, fumed silica, nano silver and the like. The wear-resistant and mildewproof non-stick pan coating prepared in the invention is chemically stable at the cooking temperature and does not generate hazardous substance PFOA. The coating has relatively great hardness and the damages of spatulas or spoons to the surface coating of the non-stick pan can be avoided. The non-stick pan prepared from the coating has low cost and a long service life.

Owner:NINGBO GRAMMY KITCHENWARE

Antibacterial corrosion-resistant ceramic coating of non-stick pan and preparation method of coating

ActiveCN103483885AImprove mechanical propertiesImprove performanceAntifouling/underwater paintsPaints with biocidesEpoxyPolyester

The invention relates to an antibacterial corrosion-resistant ceramic coating of a non-stick pan and a preparation method of the coating, and belongs to the technical field of ceramic machining. The antibacterial corrosion-resistant ceramic coating comprises the components in parts by weight as follows: 35-40 parts of silicon oxide sol, 5-9 parts of aluminum oxide sol, 1-3 parts of zirconium oxide sol, 5-8 parts of a water soluble polyester modified epoxy resin, 1-3 parts of black iron oxide, 5-8 parts of spherical ceramic micro powder, 8-12 parts of absolute ethyl alcohol, 1-3 parts of silver nitrate, 1-3 parts of aluminum nitrate, 1-3 parts of and fluoride silicone oil and 10-15 parts of deionized water. The preparation method comprises the steps as follows: the materials are mixed according toin the ratio, stirred for 4-6 h in a sealing manner at a temperature of 35-42 DEG C and a rotating speed of 300-350 rpm (revolutions per minute), and then calcinated at a high temperature of 300-350 DEG C; and composite ceramic material powder is composited. The coating of the non-stick pan has good mechanical property, is high in strength, high-temperature-resistant, abrasion-resistant and scratch-resistant, and has an antibacterial function; and the preparation technology is simple, and the coating is non-toxic and harmless to the environment.

Owner:浙江飞哲科技股份有限公司

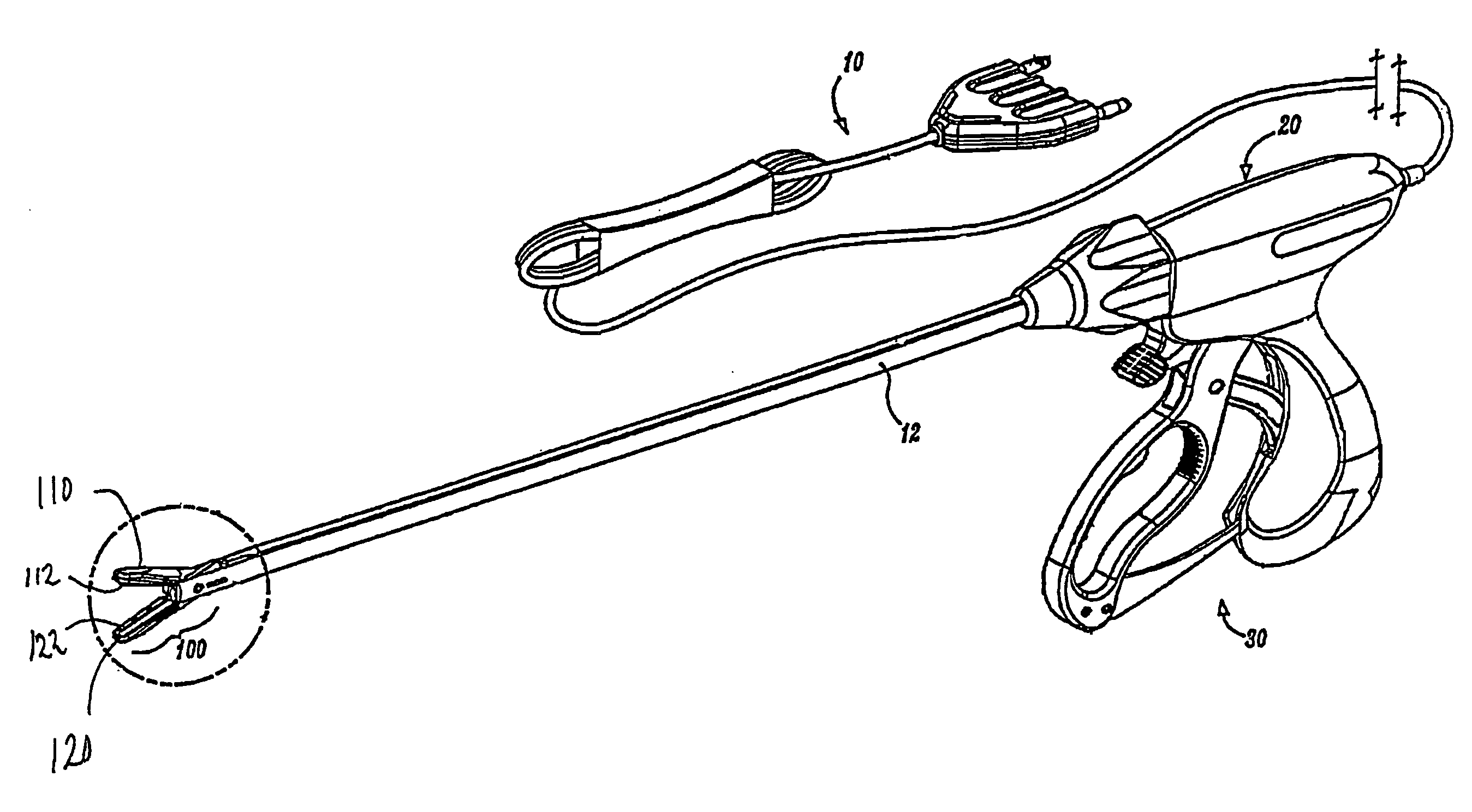

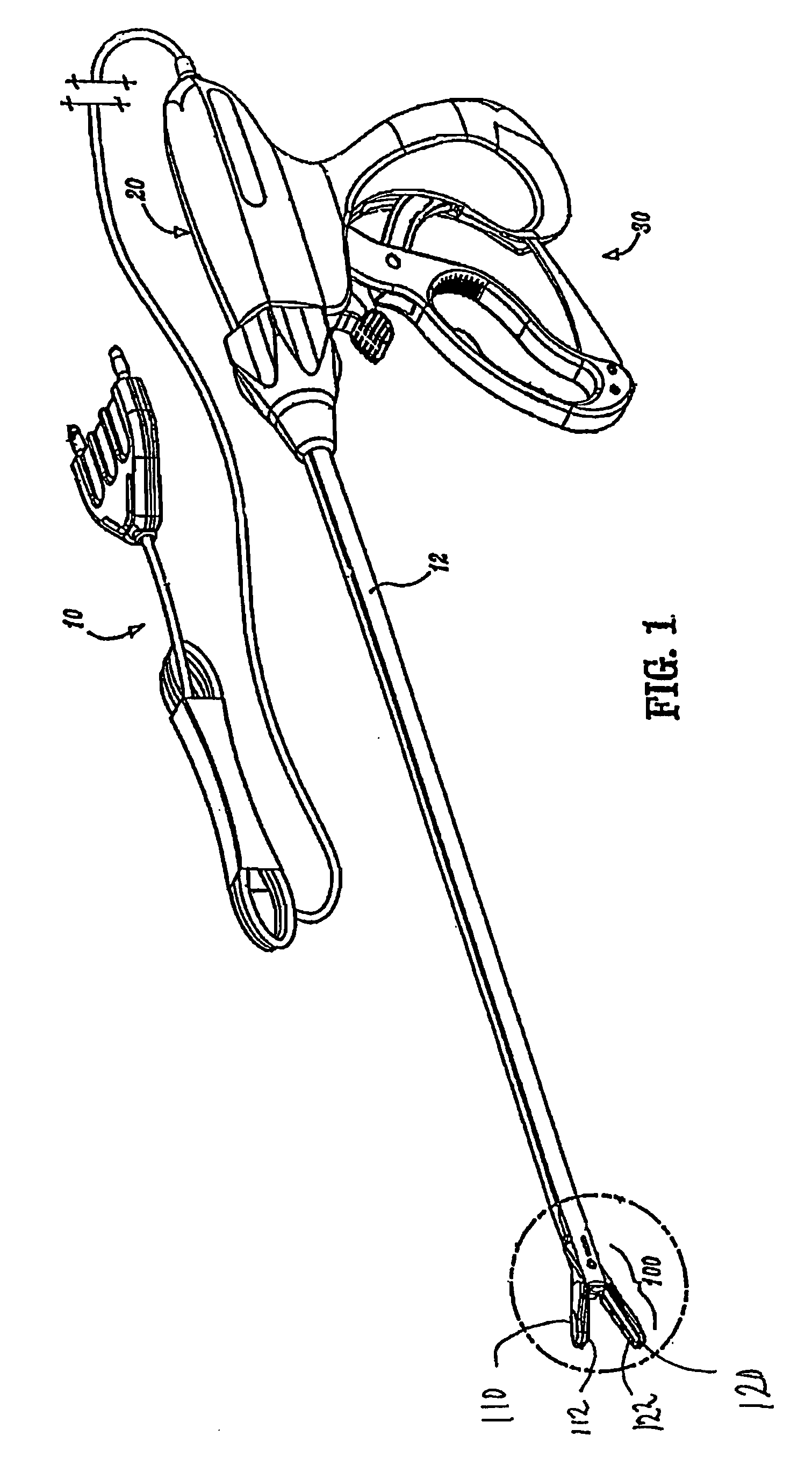

Non-stick surface coated electrodes and method for manufacturing same

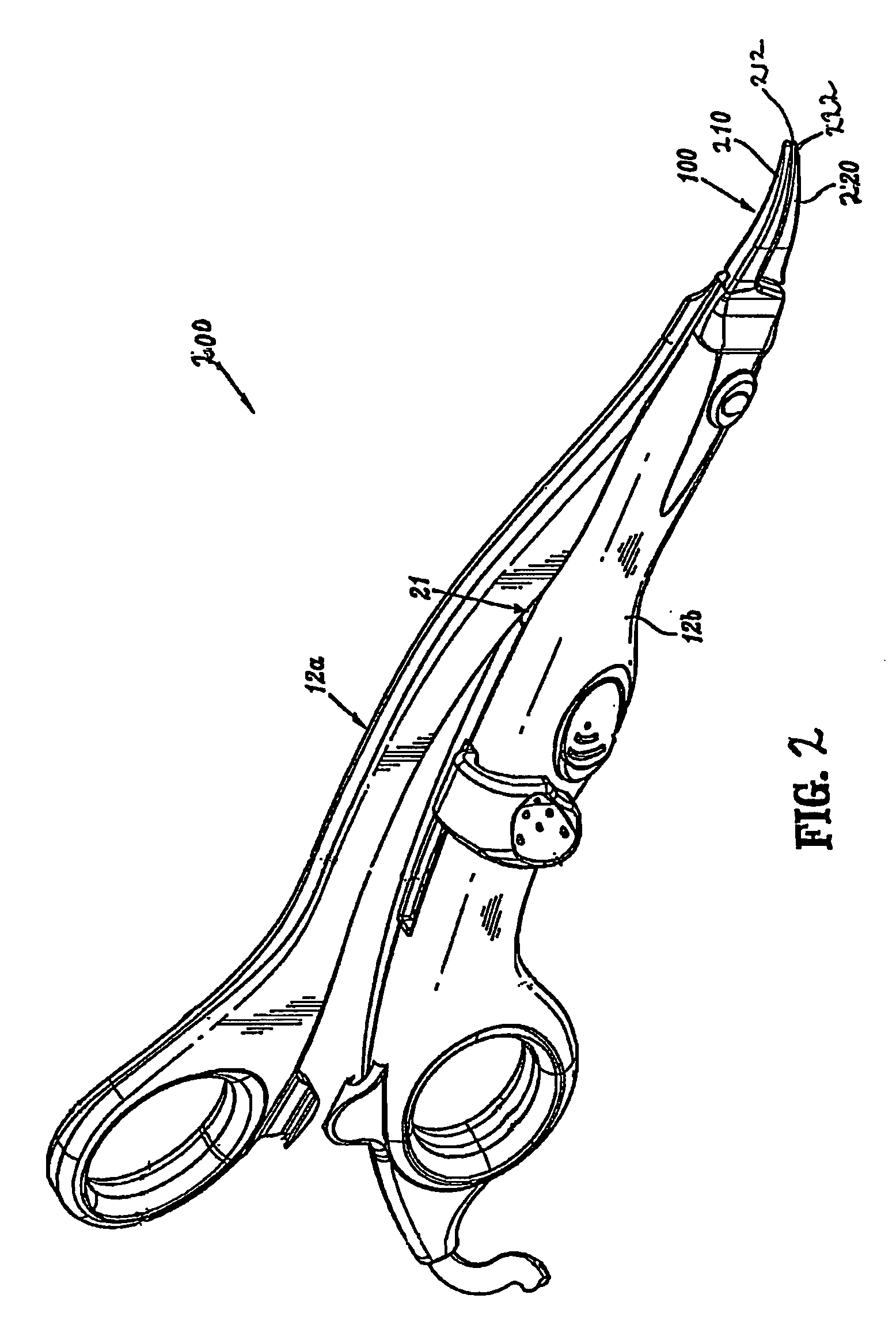

InactiveUS20080234672A1Line/current collector detailsSurgical instruments for heatingElectrical conductorCoated electrodes

A method of manufacturing an electrosurgical instrument includes the steps of: providing an electrosurgical instrument having at least one conductor, applying a lipid coating onto at least a portion of at least one conductor on an electrosurgical instrument, and curing the lipid coating. An electrosurgical instrument manufactured by the method disclosed herein is also provided.

Owner:TYCO HEALTHCARE GRP LP

Coated pipes for harsh environments

InactiveUS7588058B2Restriction is minimized avoidedMinimize or eliminate pluggage of the oil pipeHeat exhanger conduitsSynthetic resin layered productsFluoropolymerEngineering

Owner:THE CHEMOURS CO FC LLC

Wear-resistant coating non-stick pan

ActiveCN102835891ASimple designIngenious designCooking-vessel materialsEnvironmental resistanceWear resistant

The invention relates to a metal ceramic wear-resistant coating non-stick pan. The non-stick pan comprises a pan body, as well as a graphitic layer and a metal ceramic coating which are positioned on the surface inside the pan, wherein the metal ceramic layer comprises a titanium carbide metal ceramic coating. According to the wear-resistant coating non-stick pan provided by the invention, an uneven bulged structure is arranged on the inner surface of the pan bottom, so that the contact area between the pan bottom and foods can be reduced; and titanium-based metal ceramic has stable characteristics at high temperature and does not pollute foods, and metalized particles are closely combined with a base material along with high adhesion and fine wear resistance, so that the aim of preventing foods from sticking the pan in a high-temperature cooking process can be achieve, and the titanium-based ceramic can replace the existing Teflon non-stick pan. The metal ceramic wear-resistant coating non-stick pan prepared in the invention is smart in design, excellent in performance, and non-toxic and environment-friendly, is more in accordance with the requirements of 'safety, health, energy saving and environmental-friendliness' provided by the World Environmental Organization and nations currently. The process provided by the invention has a simple method, and is suitable for large-scale production.

Owner:FUJIAN HUAXIA VAJRA TECH CO LTD

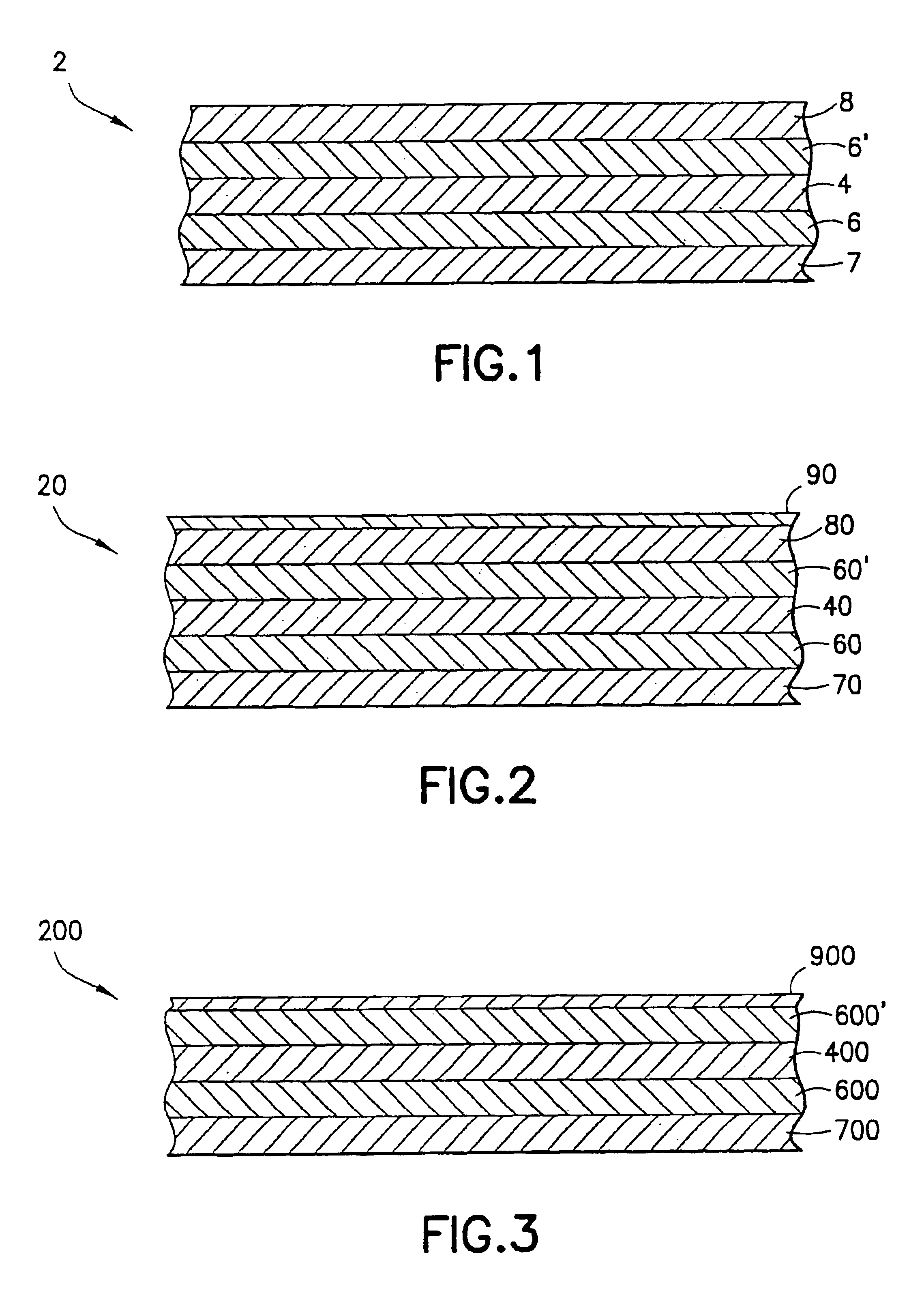

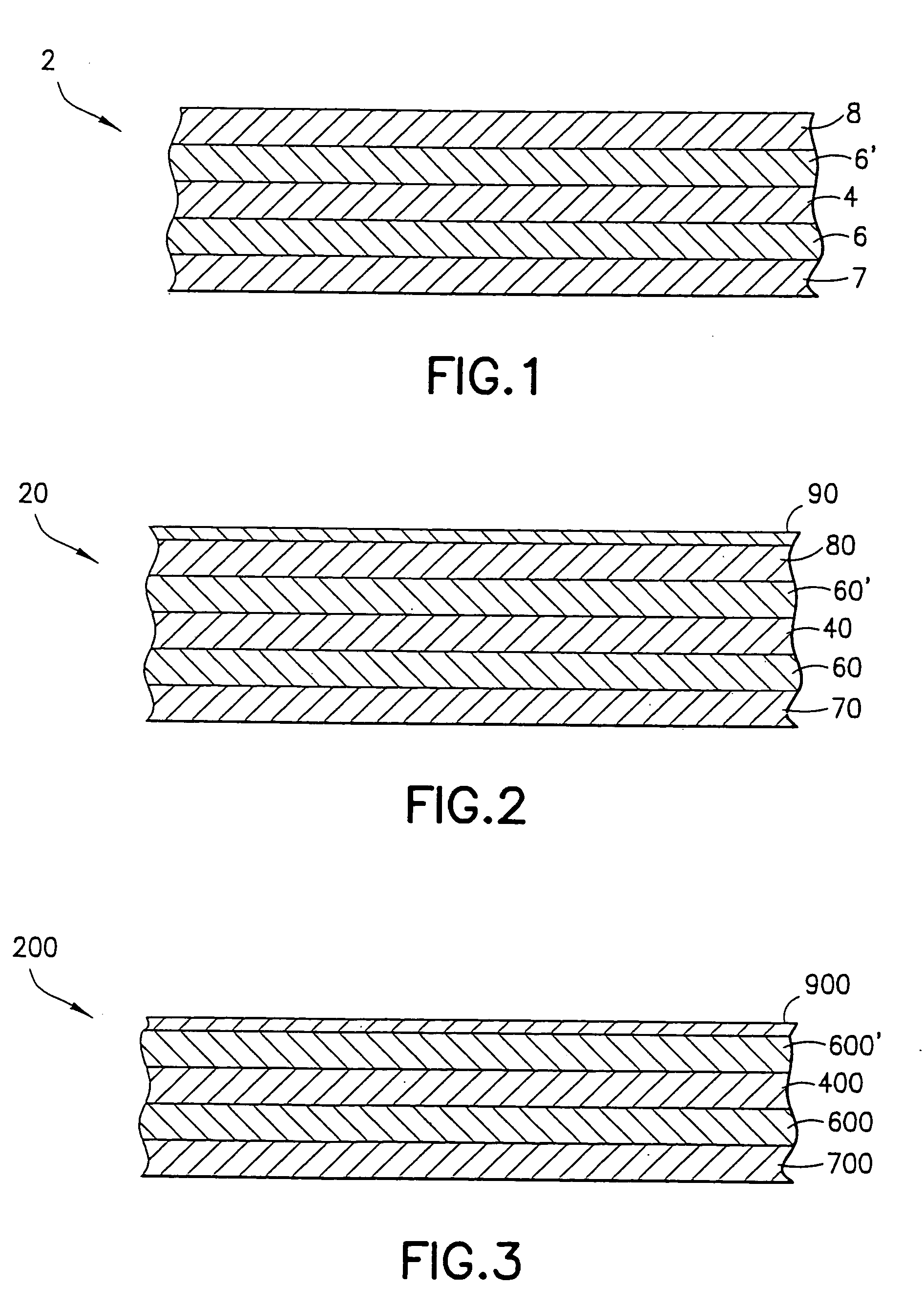

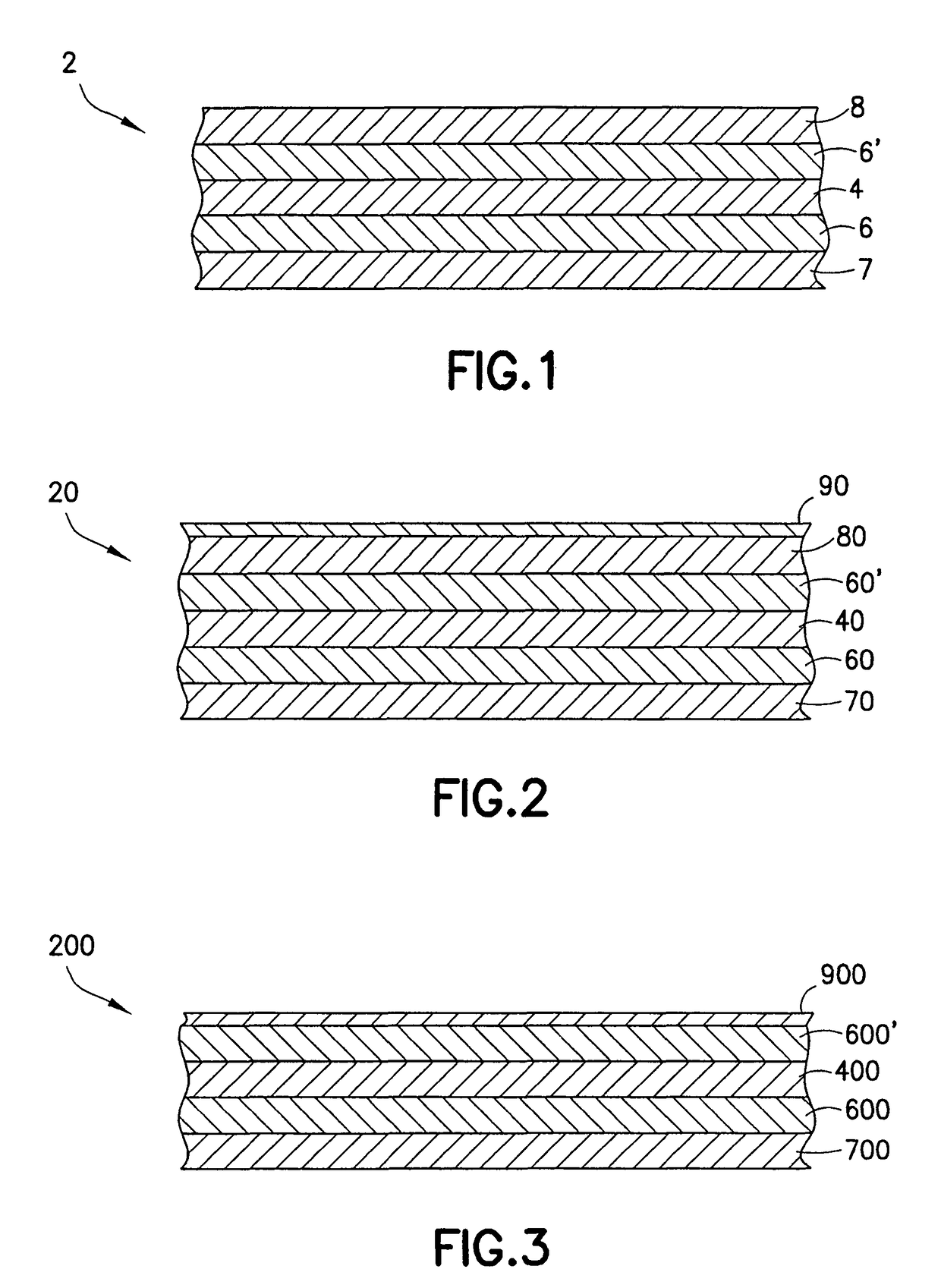

Bonded metal components having uniform thermal conductivity characteristics and method of making same

InactiveUS7208231B2Avoid bondingHigh bonding strengthCooking-vessel materialsHot-dipping/immersion processesMetalThermal conductivity

Cookware having improved uniform heat transfer over the entire cross section thereof, the cookware formed from a multi-layered composite metal having a layer of stainless steel roll bonded at or near the core of the composite. The stainless layer is roll bonded to layers of aluminum which, in turn, is roll bonded to layers of stainless steel or aluminum. The layer of stainless steel adjacent to the cooking range may be a ferromagnetic grade of stainless steel if induction-type heating is desired. The cookware may include a non-stick surface applied thereto.

Owner:CLAD METALS

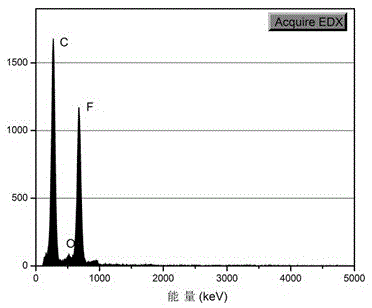

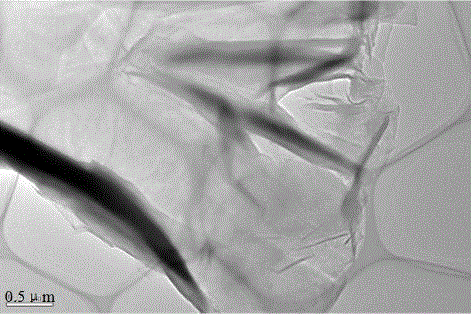

Preparation method of ultrathin fluorinated graphene composite lubrication film

InactiveCN105602298ALower surface energyReduce adhesionNon-macromolecular adhesive additivesFinal product manufacturePolymer scienceWear resistant

The invention discloses a preparation method of an ultrathin fluorinated graphene composite lubrication film. The method comprises (i) preparation of a fluorinated graphene dispersion liquid; (ii) preparation of a poly-dopamine bonding-buffering layer; (iii) preparation of a fluorinated graphene composite lubrication film. The stable fluorinated graphene dispersion liquid is prepared with convenient melting alkali treatment and ultrasonic dispersion methods and is spin-coated to form the film, the film is composited with a saline coupling agent and the poly-dopamine bonding layer, and the anti-friction and wear-resistant lubrication film which has the ultrathin thickness and uniform and continuous distribution is obtained; the lubrication film also has low surface energy and low adhesive force and shows dependence on the fluorine content; the lubrication film has bright application prospect in aspects of anti-friction, wear-resistant, hydrophobic and non-stick surface engineering and the like due to these characteristics.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD +1

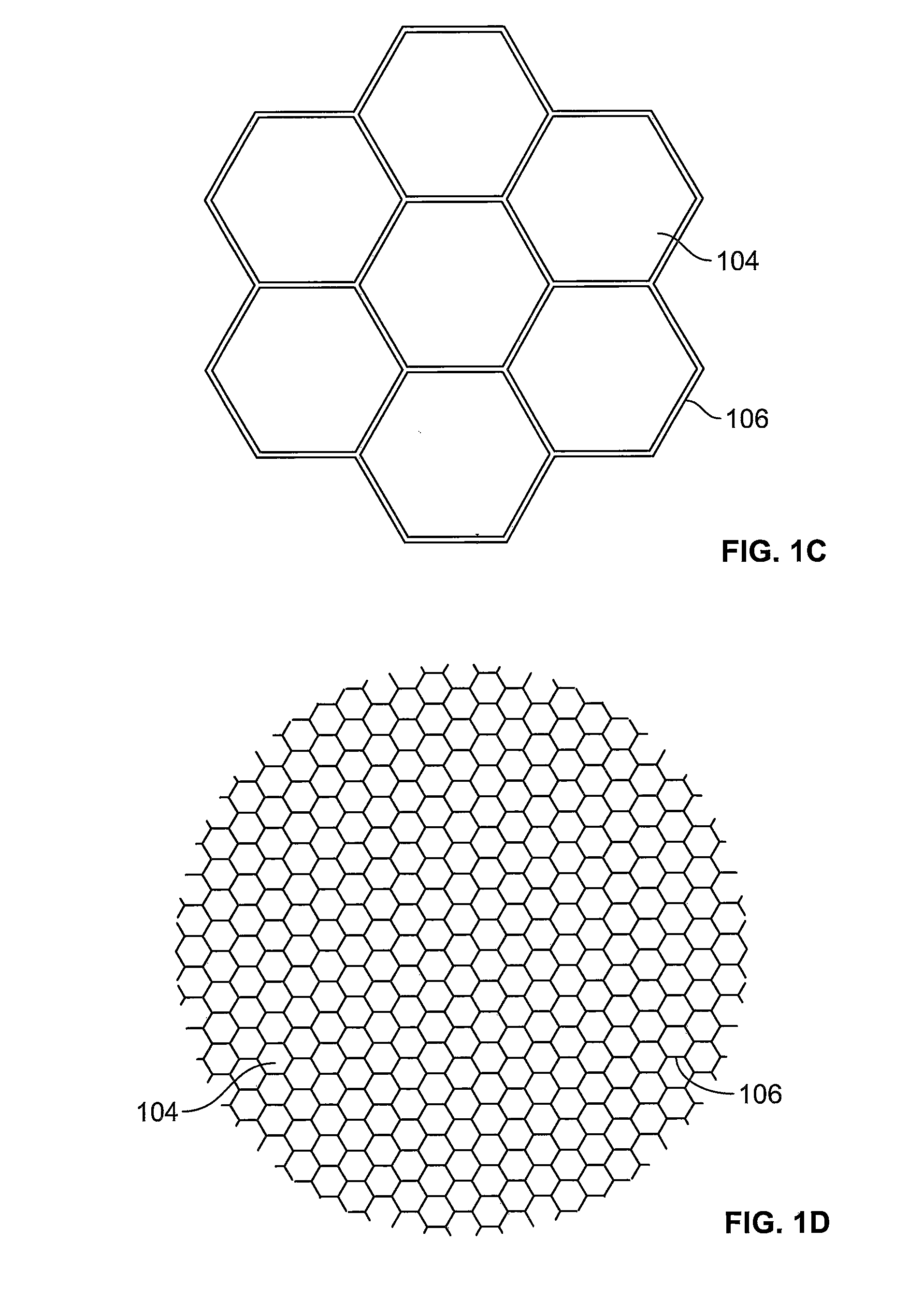

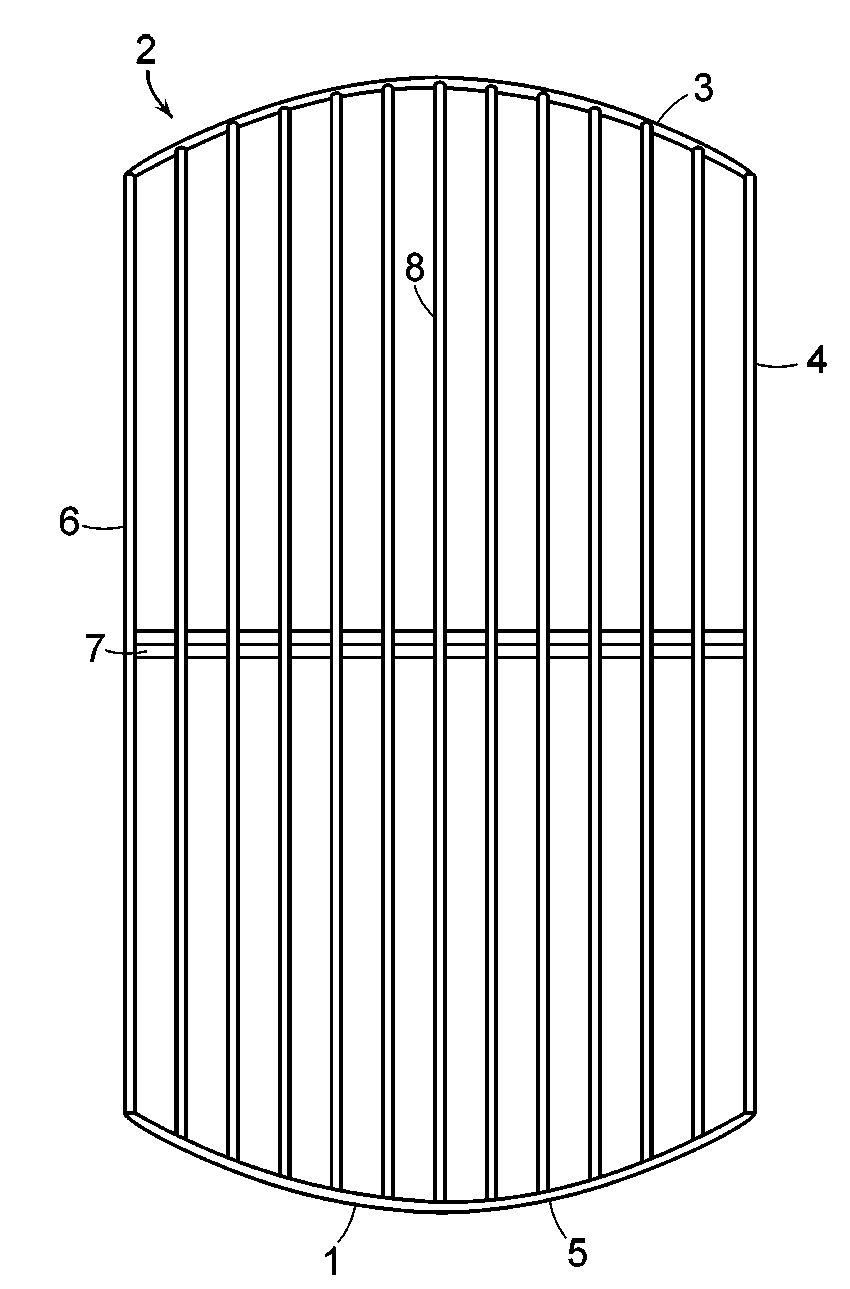

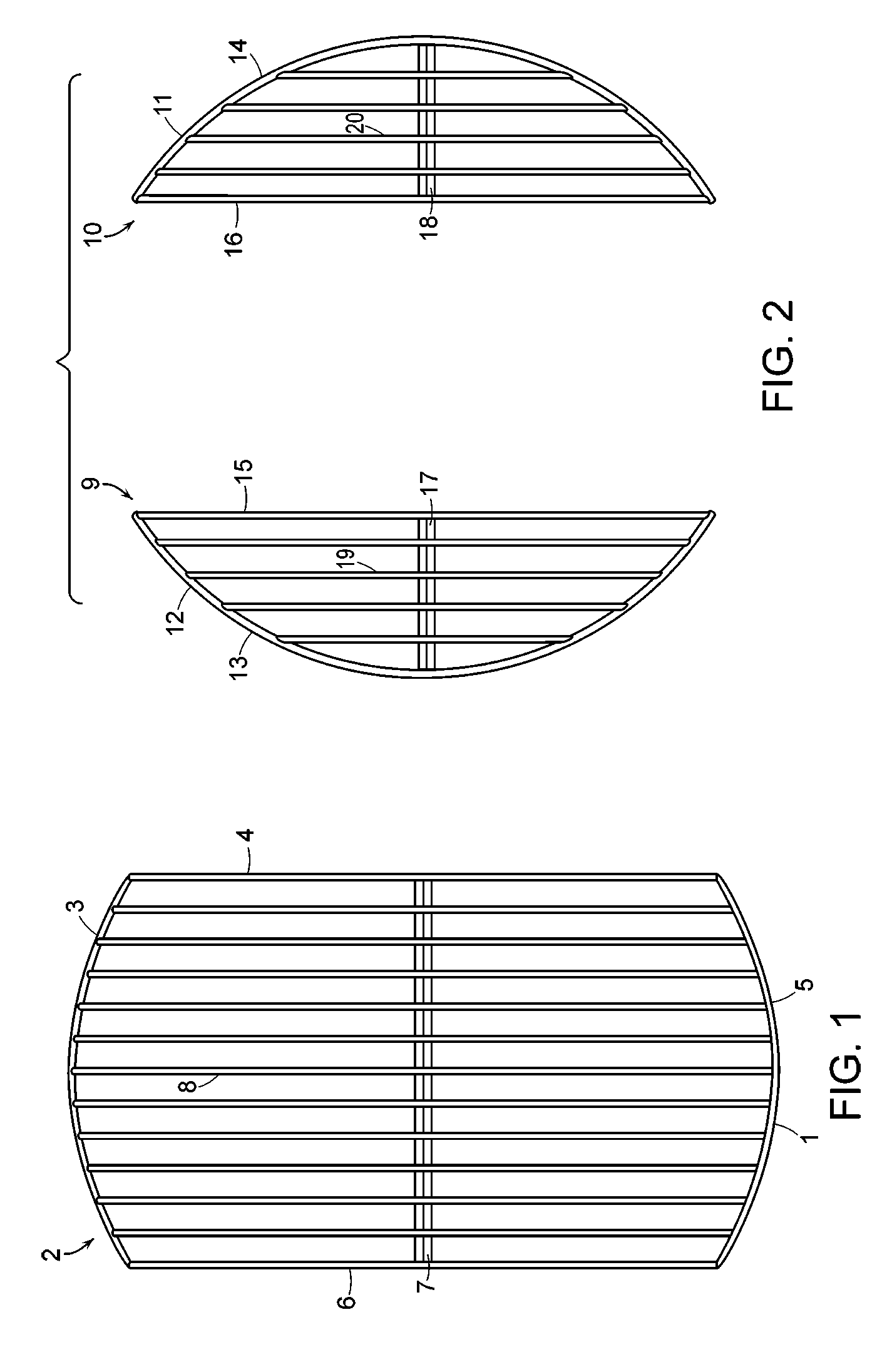

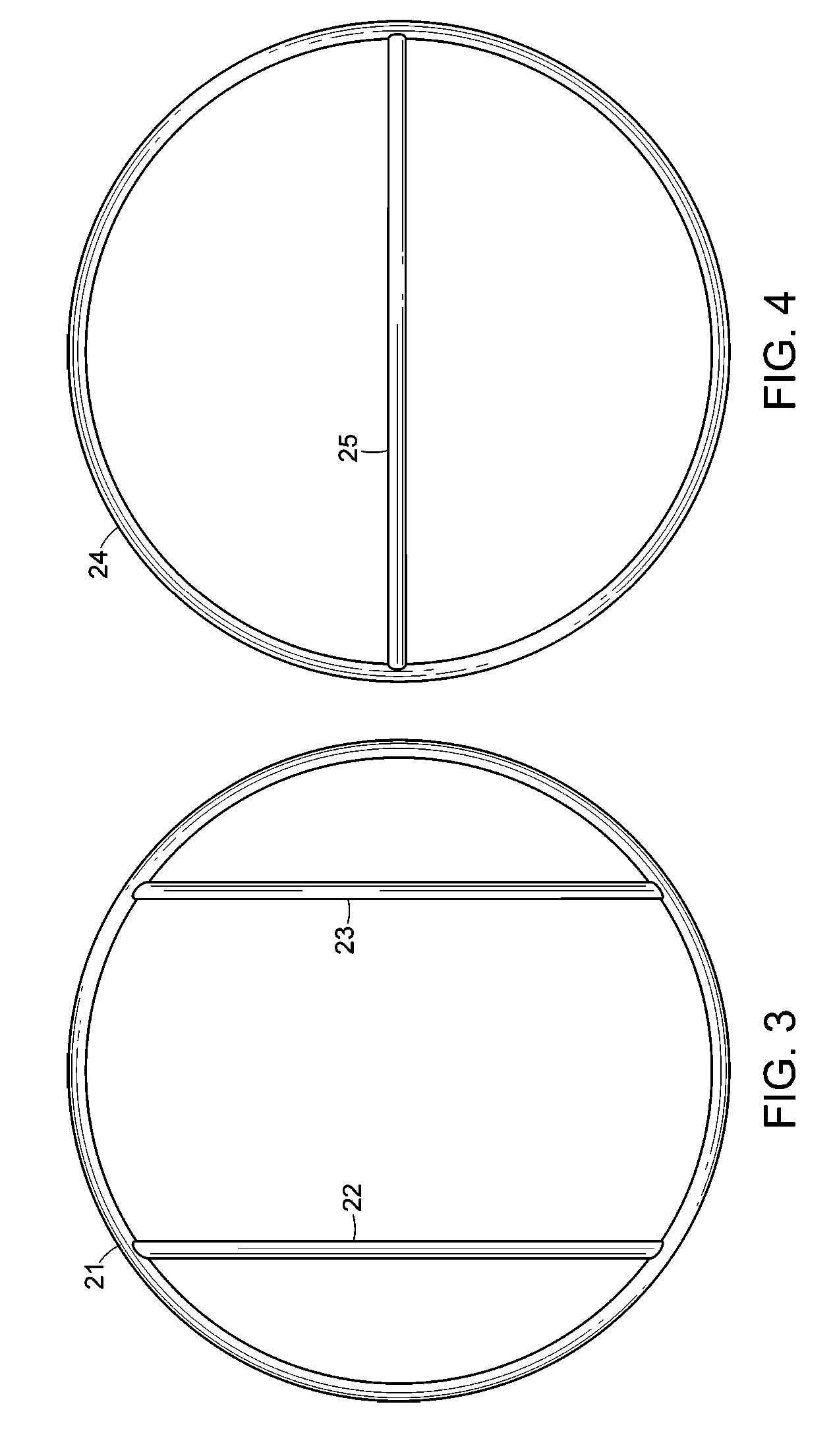

Multi-Sectioned Replacement Grill Grate Section

InactiveUS20090064872A1Easy to cleanSolid bar grateMetal working apparatusSupporting systemEngineering

A grill grate replacement system that has multiple, separately attachable grill grate sections. These grill grates are designed so that when all grill grates are used with one another they utilize the entire grilling area of the grill for which they are intended, while giving grillers easy access to the fuel source by allowing removal of only selected sections of the grill grate system. The system uses a material that provides strength and rigidity, such as cast-iron, and a coating material, such as porcelain, that protects against weathering and provides a non-stick surface. Support systems for this replacement grill grate system conform to the shape of the grill for which they are intended for use, and are made of a rigid material for strength, such as stainless steel.

Owner:ZISSERSON KENNETH

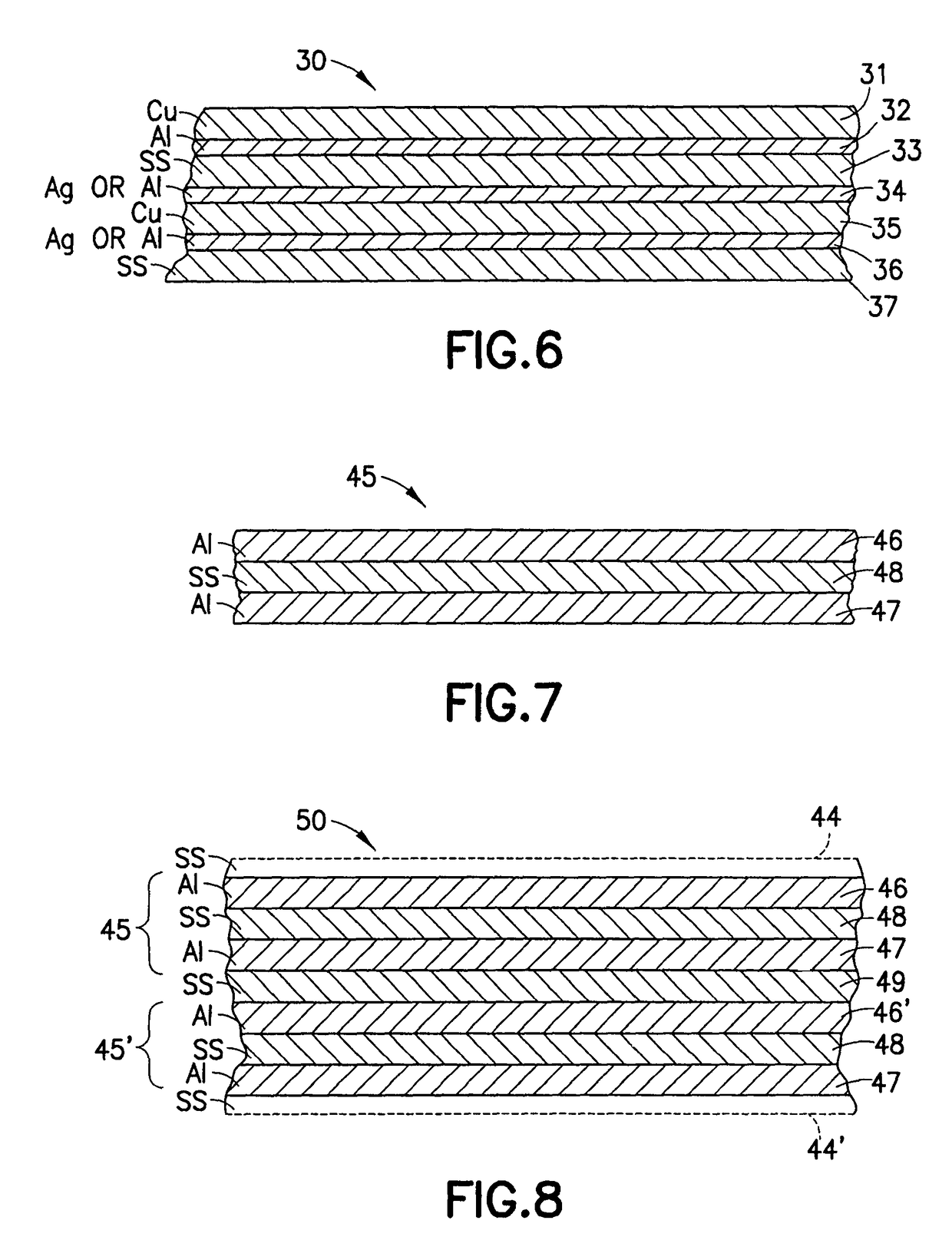

Bonded metal components having uniform thermal conductivity characteristics

InactiveUS7906221B2Avoid bondingHigh bonding strengthHot-dipping/immersion processesCooking-vessel materialsCopperMetal

Cookware having improved uniform heat transfer over the entire cross section thereof, the cookware formed from a multi-layered composite metal having a layer of stainless steel roll bonded at or near the core of the composite to act as a thermal barrier and provide more uniform heat distribution on the cook surface. The stainless layer is roll bonded to layers of aluminum which, in turn, is roll bonded to layers of stainless steel or aluminum or copper. The layer of stainless steel adjacent to the cooking range may be a ferromagnetic grade of stainless steel if induction-type heating is desired. The cookware may include a non-stick surface applied thereto.

Owner:CLAD METALS

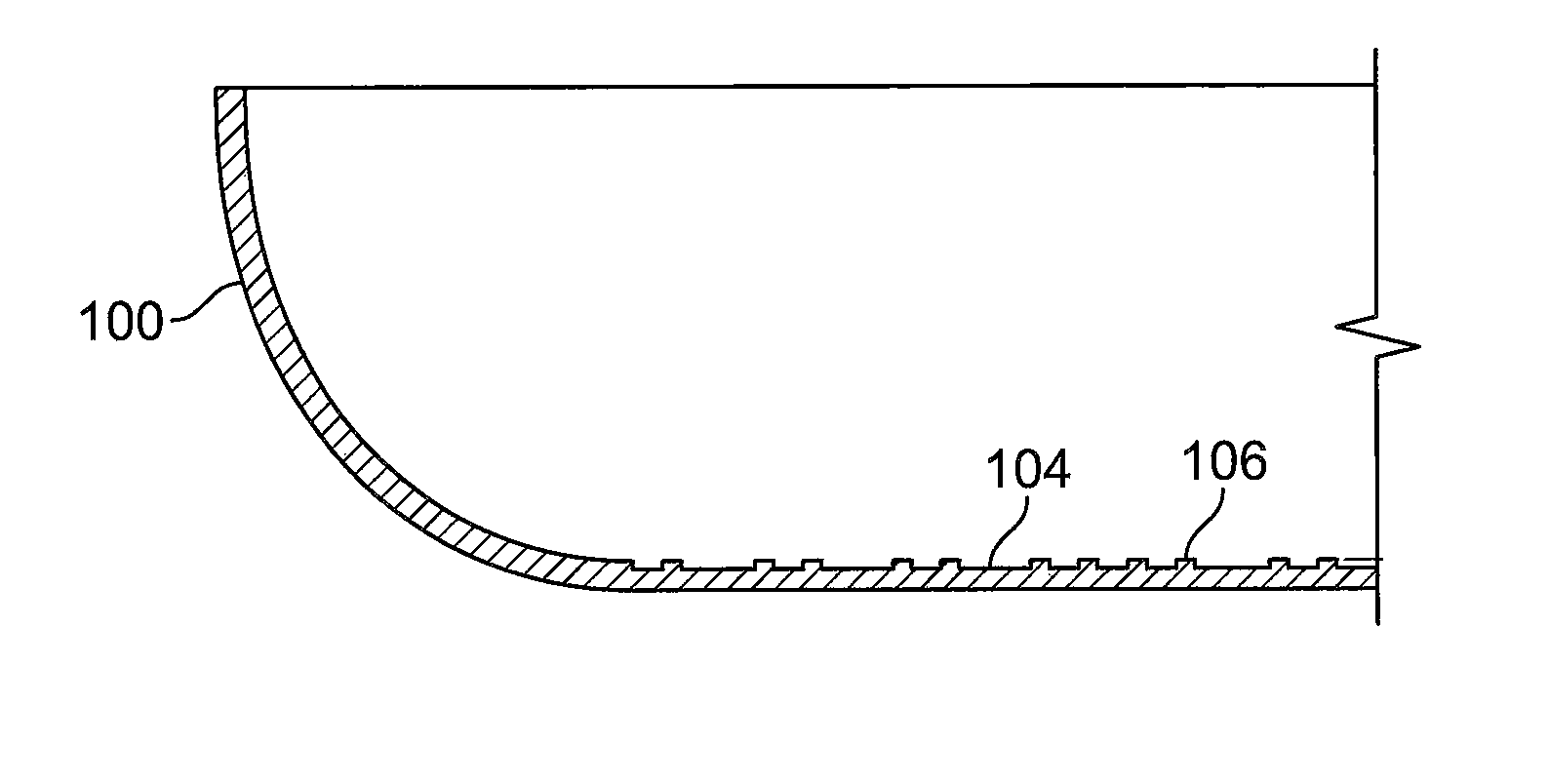

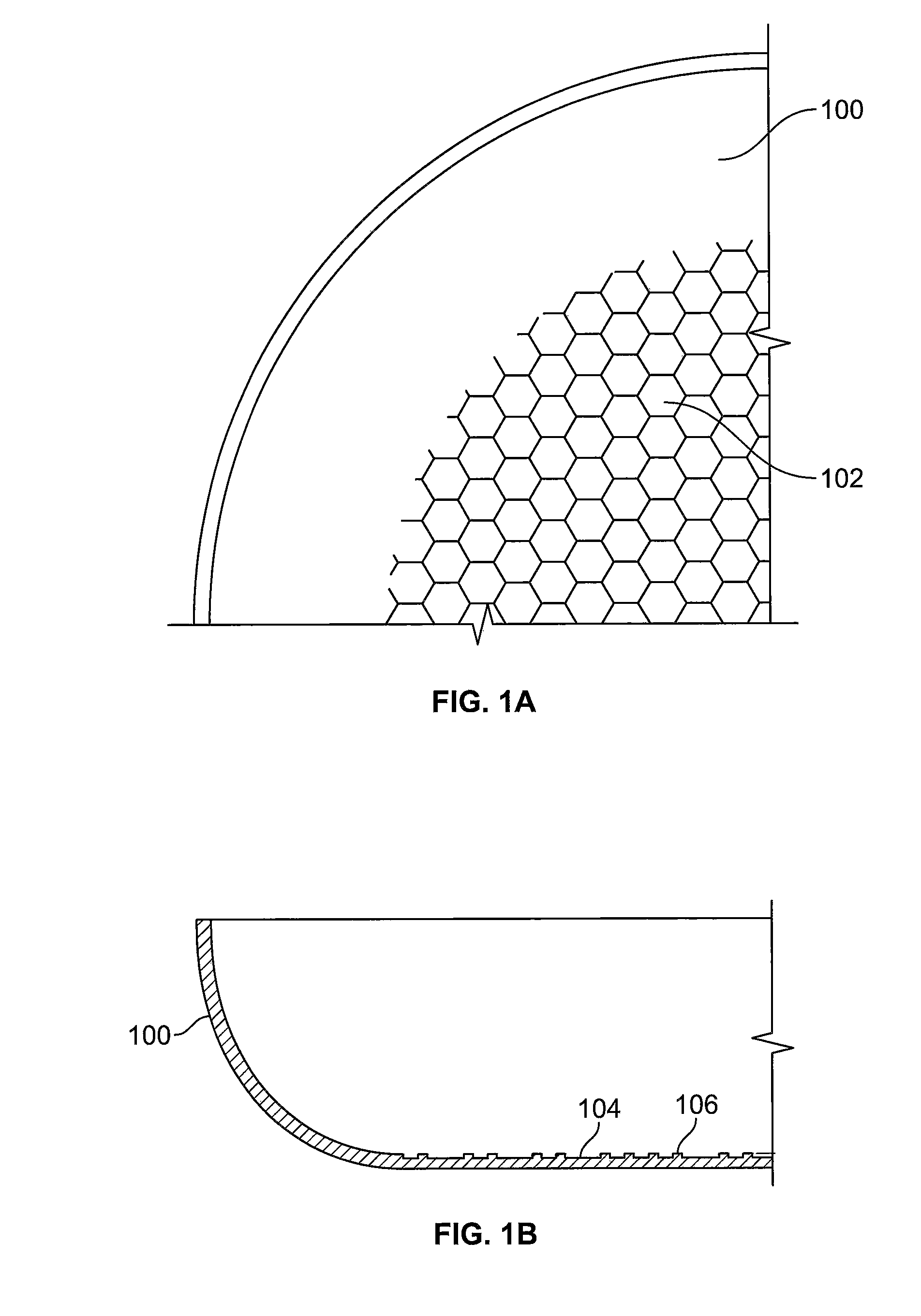

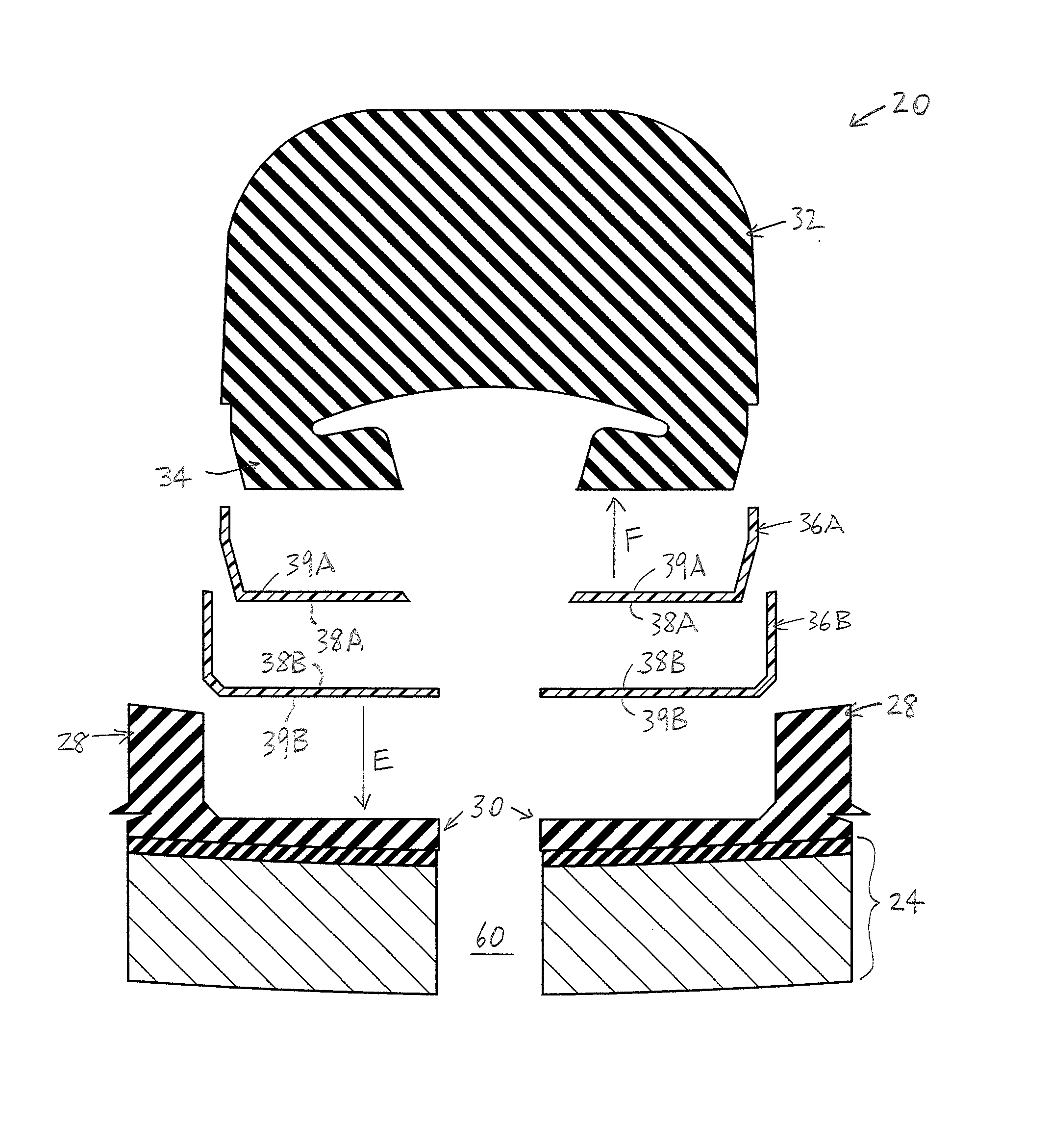

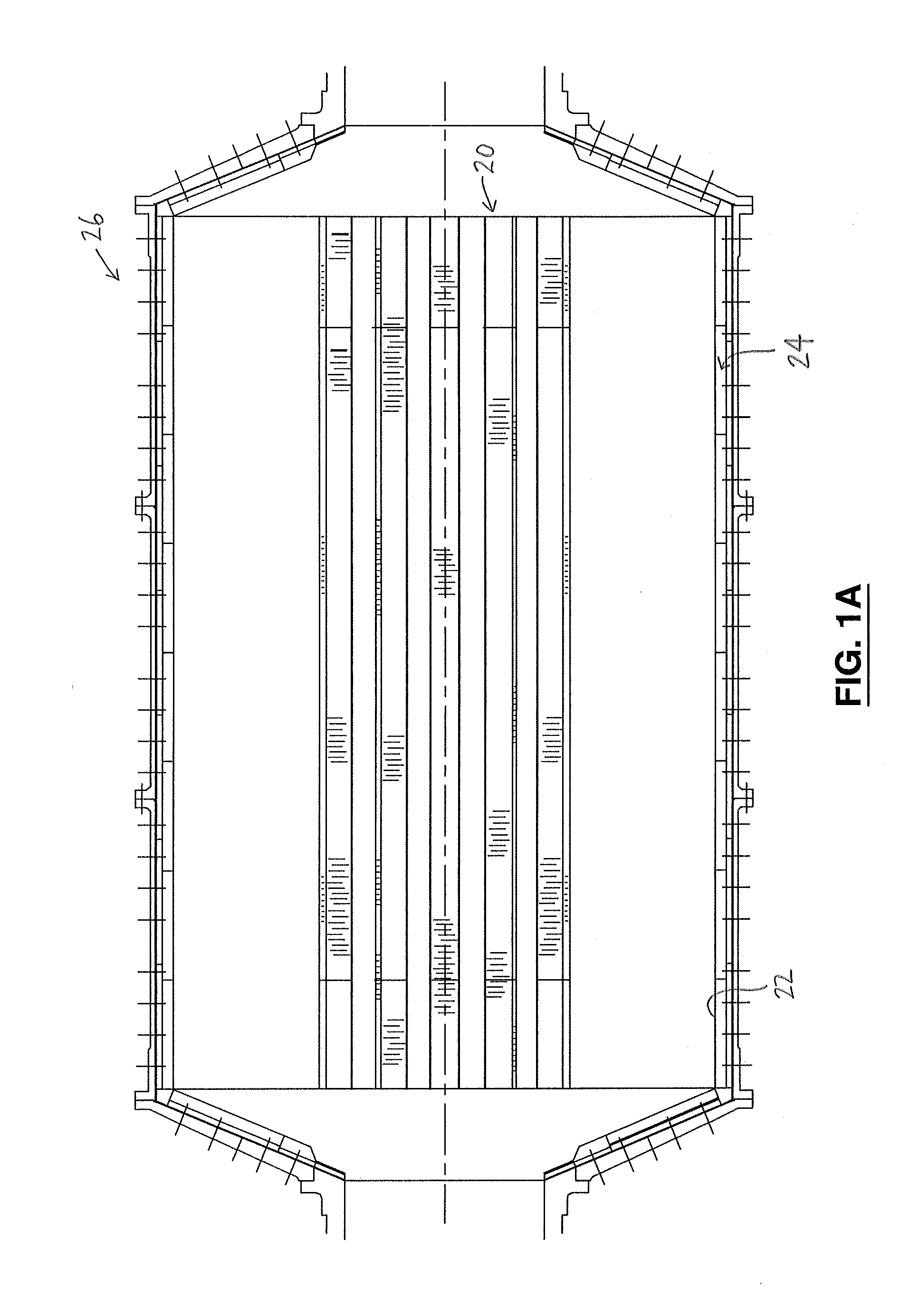

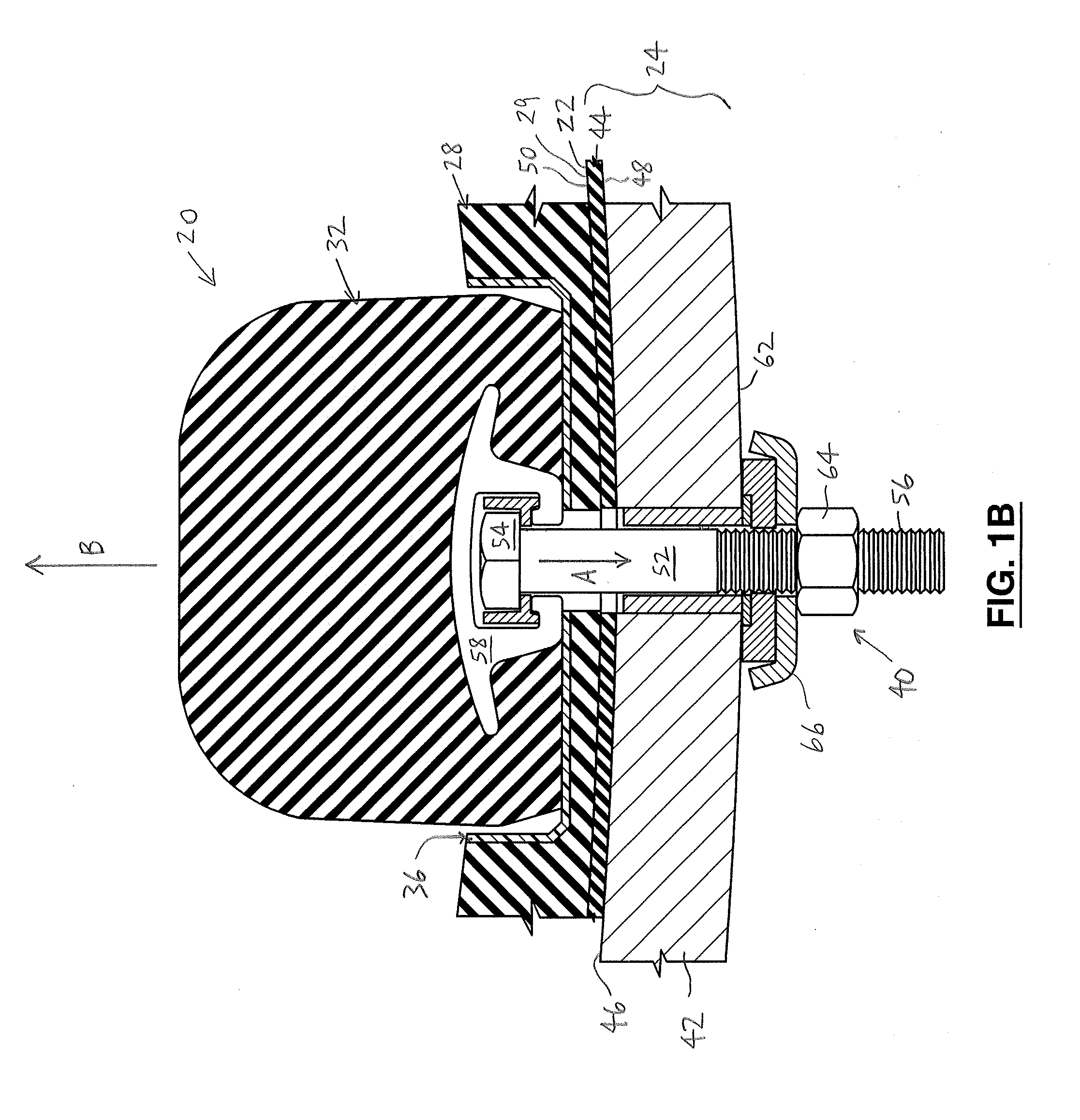

Mill liner assembly

A mill liner assembly for mounting on an inner diameter of a shell of a grinding mill. The mill liner assembly includes one or more shell plates for engagement with the shell, each of the shell plates having a cooperating portion thereof, and one or more lifter bars, each of the lifter bars having a mounting portion thereof, the mounting portion being receivable on the cooperating portion. The mill liner assembly also includes one or more layers having one or more substantially non-resilient materials and a substantially non-sticking surface. The layer is at least partially positioned on at least a first selected one of the cooperating portion and the mounting portion, to position the non-sticking surface thereof for engagement with a second selected one of the cooperating portion and the mounting portion, to impede adhesion of the shell plate and the lifter bar to each other.

Owner:POLYCORP

Nonstick coating containing graphene material, and preparation method thereof

ActiveCN110358442ASensitive over-temperature reminder effectReversible over-temperature reminder effectFireproof paintsCooking-vessel materialsFatty alcoholAmmonium sulfate

The invention discloses a nonstick coating containing a graphene material. The nonstick coating is formed by a bottom layer and a surface layer; the bottom layer comprises, by weight, 50-90 parts of apolytetrafluoroethylene / polysulfone blend, 0.5-2 parts modified graphene oxide, 1-5 parts of a thermochromic pigment, 0.8-1.2 parts of modified silicon carbide whiskers, 1.5-3 parts of an additive and 15-35 parts of deionized water; and the surface layer comprises, by weight, 35-75 parts of polytetrafluoroethylene resin, 1.5-5 parts of modified calcium carbonate whiskers, 3-8 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 5-10 parts maleic anhydride and 35-60 parts deionized water. Different raw material components of the bottom layer and the surface layer are reasonably combined, so the obtained nonstick coating has the advantages of good over-temperature prompting function, facilitation of control of the cooking heat, excellent high temperature wear resistance, and prolongation of the service life of a nonstick pan.

Owner:宁波市金象厨具有限公司

Inorganic ceramic non-stick pan composite coating and manufacturing method thereof

InactiveCN109321007AImprove hydrophobicityGood non-stickCooking-vessel materialsLiquid surface applicatorsCeramic coatingMetallurgy

The invention discloses an inorganic ceramic non-stick pan composite coating and a manufacturing method thereof. The inorganic ceramic non-stick pan composite coating is prepared from a bottom coatingand a surface coating, wherein the bottom coating is an inorganic ceramic coating which is 15 to 50 mum in thickness, is more than or equal to 1.2 and is less than or equal to 3.5 mum in roughness Ra; the surface coating is an inorganic ceramic coating which is 3 to 10 mum in thickness, and is more than or equal to 0.6 and is less than 1.2 mum in roughness Ra. By adopting the inorganic ceramic non-stick pan composite coating, the long-effect non-stick property of the non-stick pan is improved effectively. In particular, when the surface film is slightly damaged, high non-stick property can bekept.

Owner:浙江宇达新材料有限公司

Fish tank powerhead magnetic holder

A fish tank powerhead holding device is taught, the device comprising a first magnetic assembly with a first permanent strong magnet and a non-stick surface adhered to one side, a second magnetic assembly with a second permanent strong magnet that is magnetically attracted to the first magnetic assembly and a non-stick surface adhered to one side, and a commercially available powerhead that is permanently affixed to said first magnetic assembly opposite from said non-stick surface such that the powerhead can be positioned to effectively aerate a fish tank.

Owner:PHIL&DON

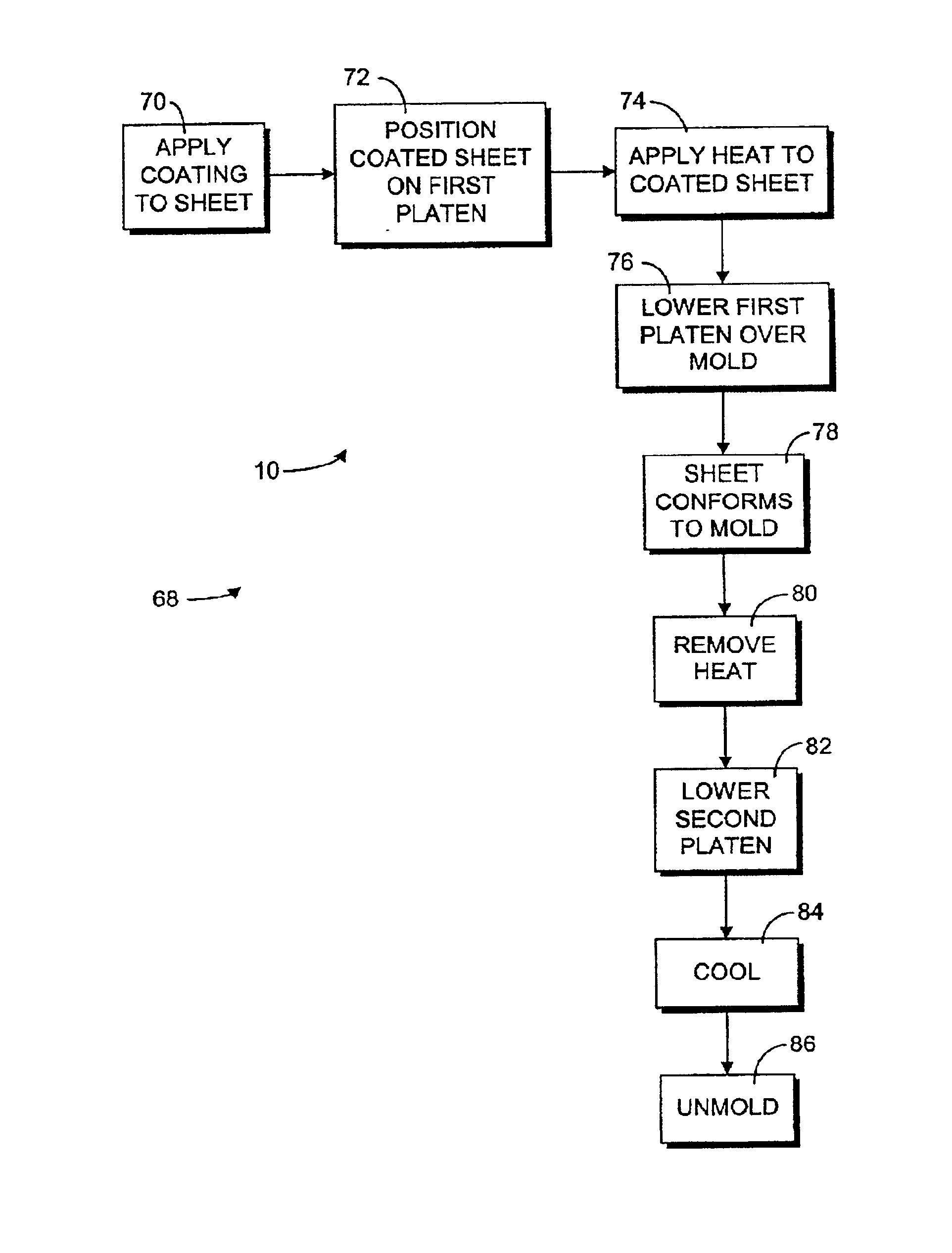

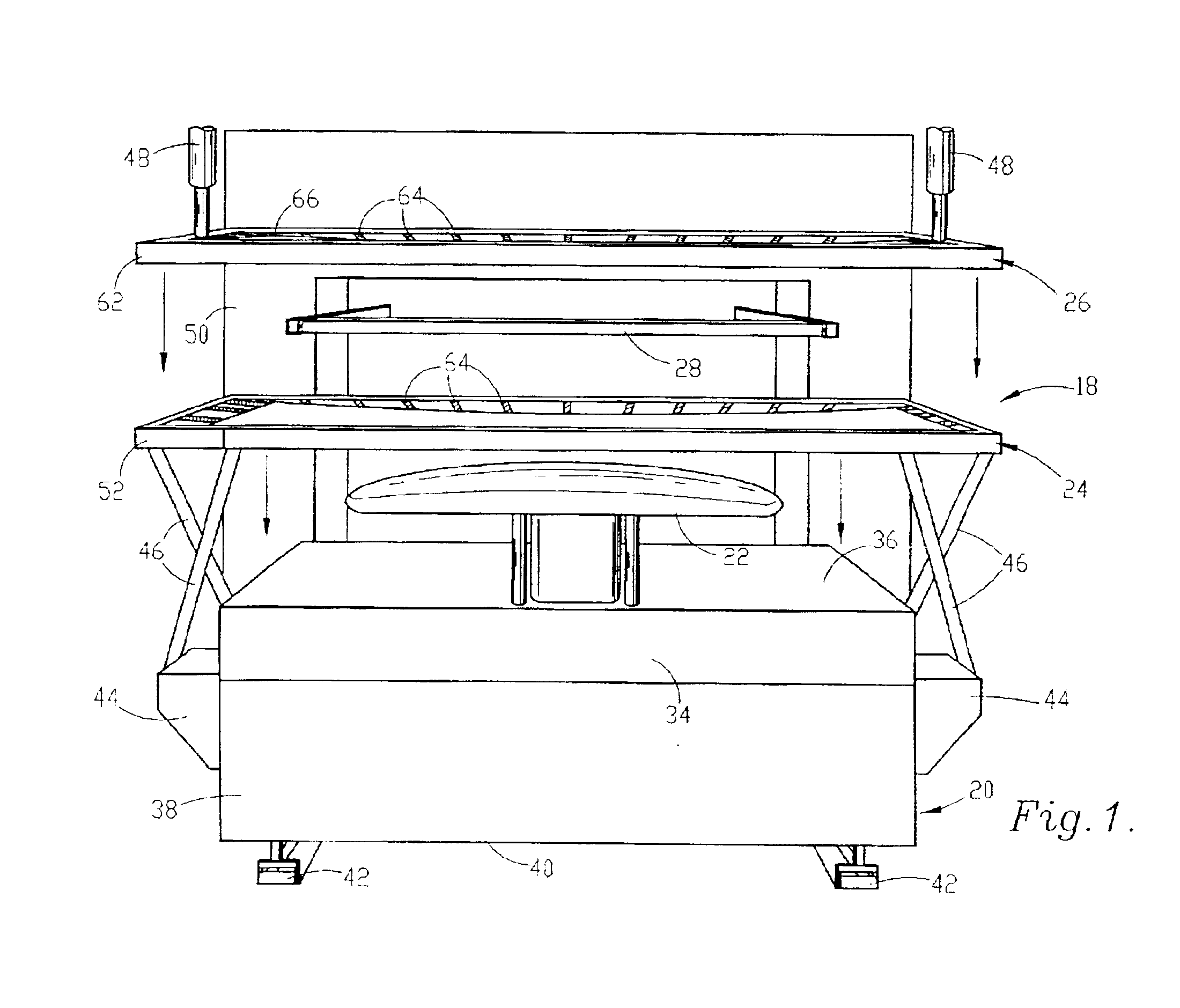

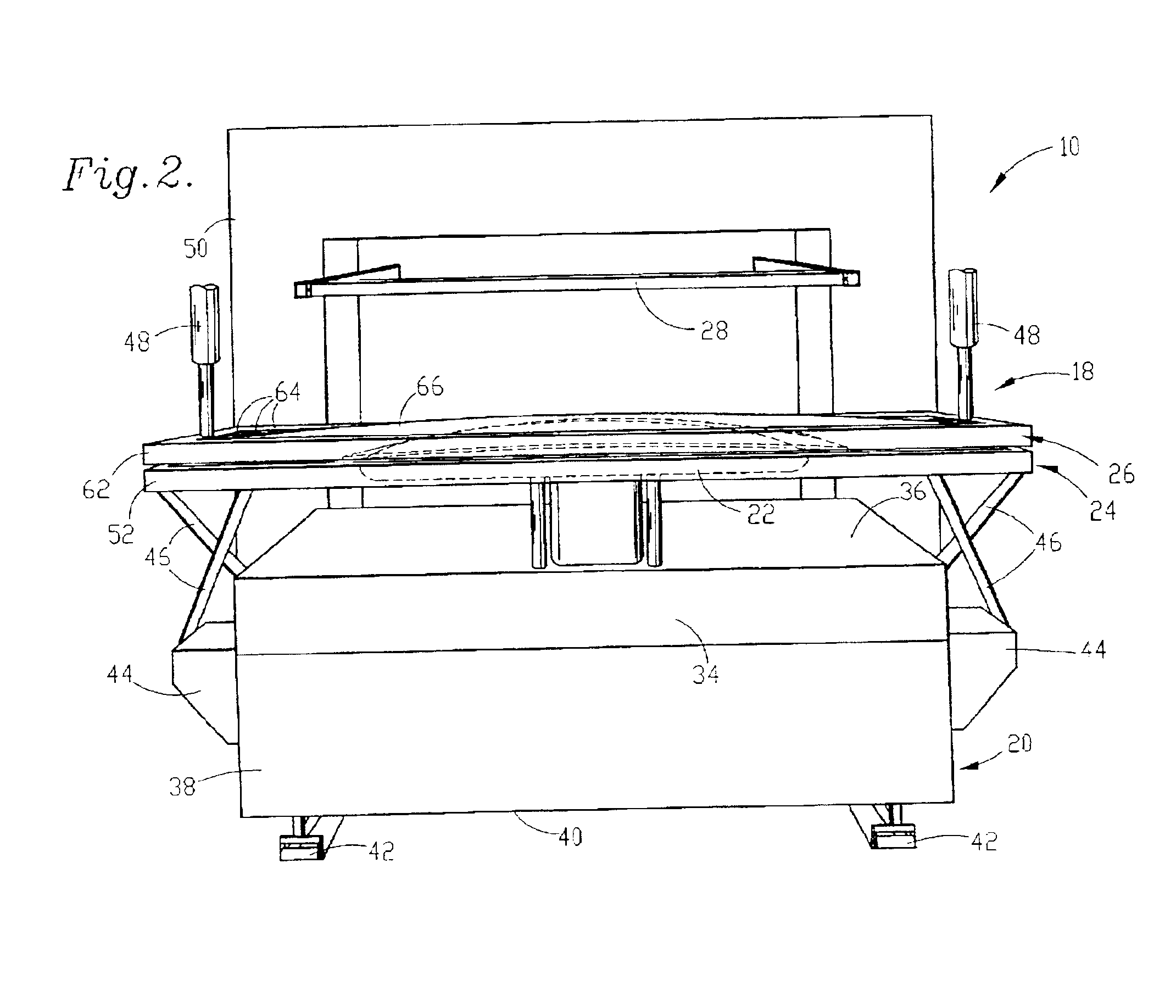

Thermoforming process for masked polymers

InactiveUS6808665B1Good optical clarityEnergy efficiencyLamination ancillary operationsLaminationThermoformingPolymer substrate

In a thermoforming system for masked polymer substrate sheets, a temperature resistant, non-stick coating is applied to a sheet of a polymer substrate material. The coated sheet is positioned on a flexible platen positioned over a mold having a predetermined shape. Heat is applied until the polymer reaches a thermoforming temperature and softens, whereupon the platen is lowered to stretch over and cover the mold. When the sheet begins to conform to the mold, the heat is withdrawn and a second platen is lowered over the sheet to urge it into conformance with the mold. The temperature resistant coating can be applied over an existing polymer film masking, and rapidly cures to form a non-stick surface which prevents adhesion of the masked polymer sheet to the platen surfaces.

Owner:PERCYS PERFORMANCE PLASTICS

Aluminum alloy non-stick pan with hard surface and processing technology thereof

InactiveCN102871529AHigh hardnessReduce generationCooking-vessel materialsHeat resistanceHigh wear resistance

The invention discloses an aluminum alloy non-stick pan with a hard surface. The aluminum alloy non-stick pan comprises an aluminum alloy pan body; a hard oxide film is arranged on the surface of the aluminum alloy pan body; a sintering non-stick layer is adhered to the surface of the oxide film of the aluminum alloy pan body; and the aluminum alloy non-stick pan is processed by a technology which comprises the following steps of: forming, performing finish turning, oxidizing, spraying and sintering. The aluminum alloy non-stick pan can be a stir pan, a steamer, a soup tureen, a frying pan, a milk pan, a pressure cooker, a rice cooker, an electric cooker, and other aluminum alloy cookers. According to the technical technology, the aluminum alloy non-stick pan has the advantages that the finish turning process replaces the conventional chemical cleaning process, so that production efficiency can be effectively improved, and wastewater produced in the production process can be reduced. Meanwhile, by reasonably matching other process steps, the capacity of adsorbing the non-stick layer to the surface of the aluminum alloy non-stick pan can be improved, and the hardness of the pan body can be improved; and the hardness can be 350 to 800 HV, the wear resistance and the thermal resistance can be improved, the corrosion resistance of the surface of the aluminum alloy non-stick pan can be improved, and the service life of the aluminum alloy non-stick pan is prolonged.

Owner:JINYUN COUNTY TAI JI KE JI

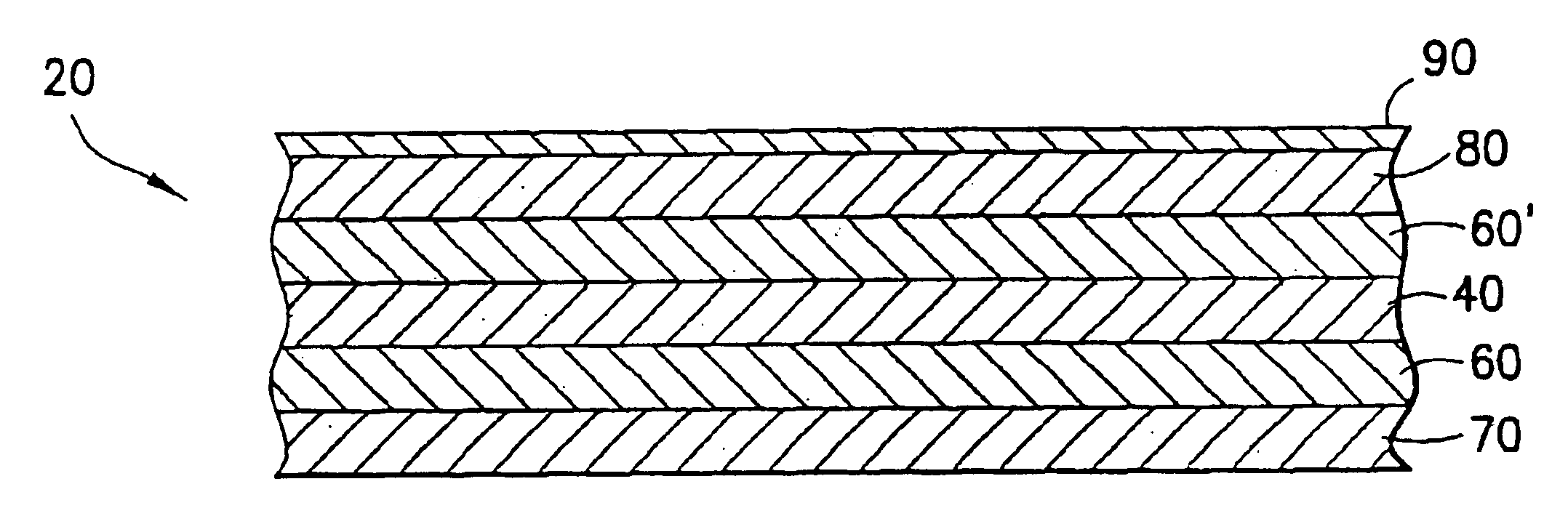

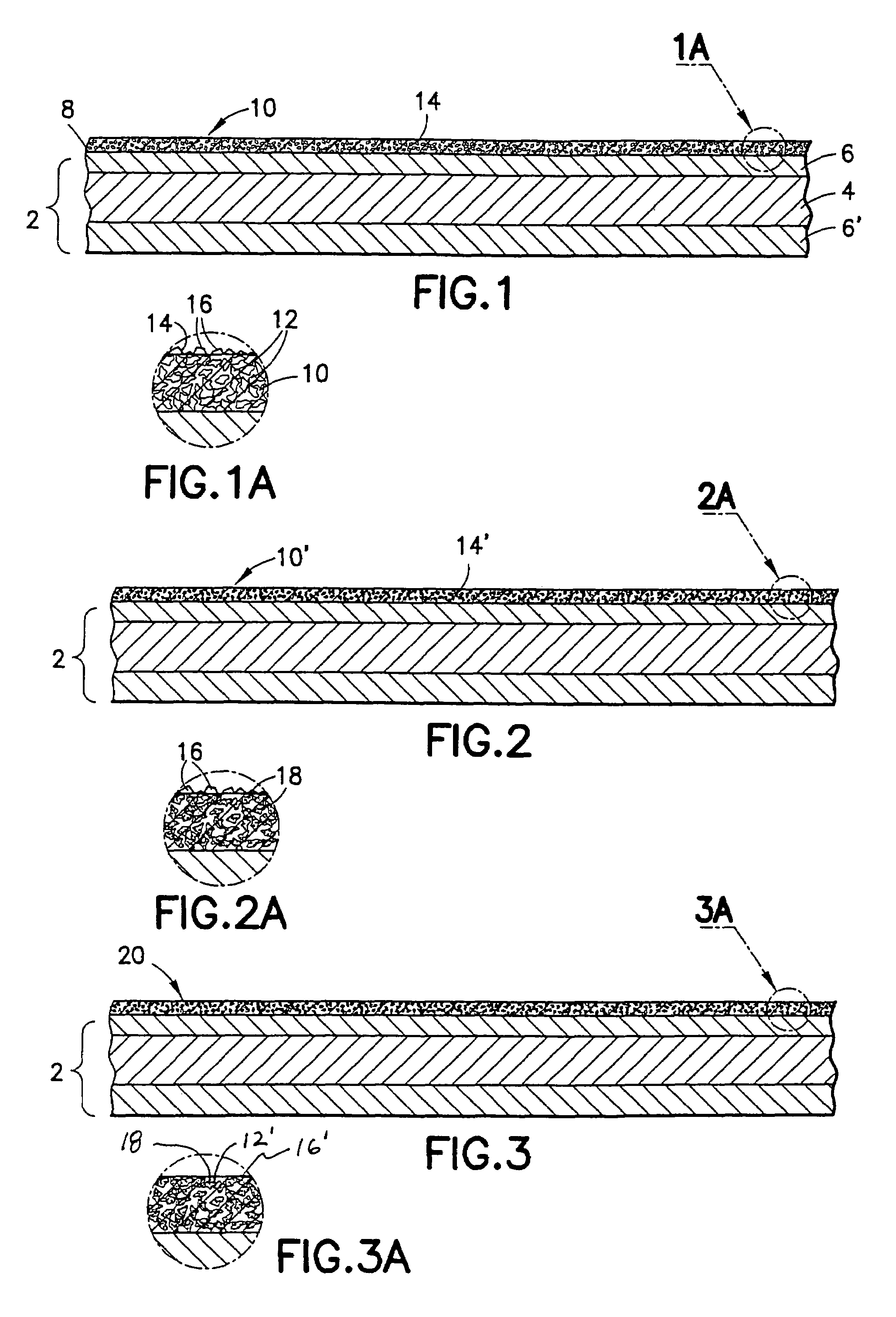

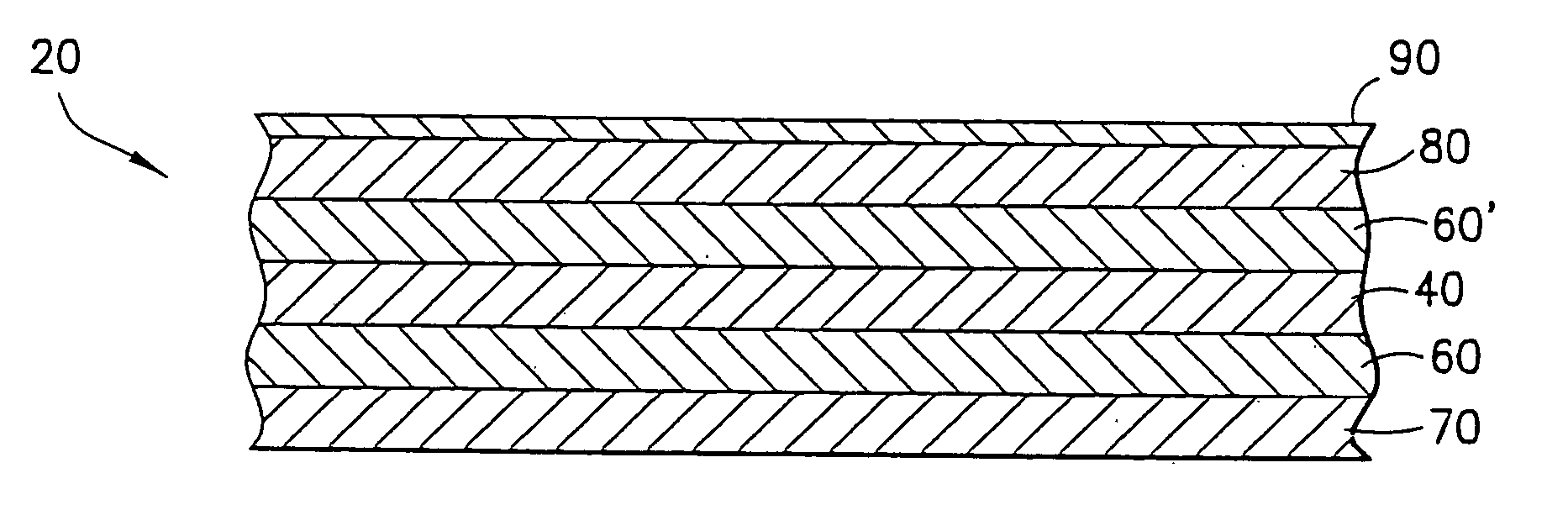

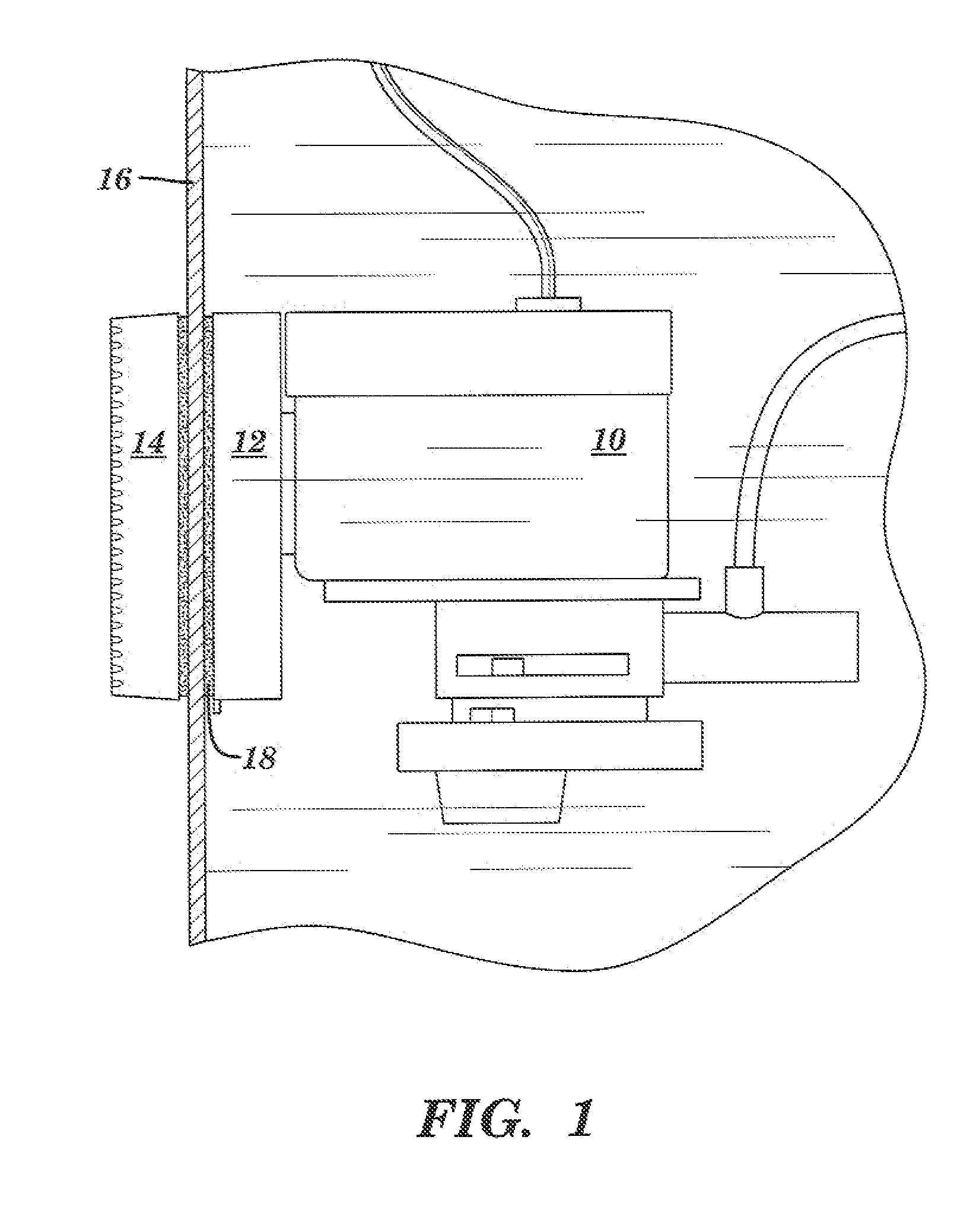

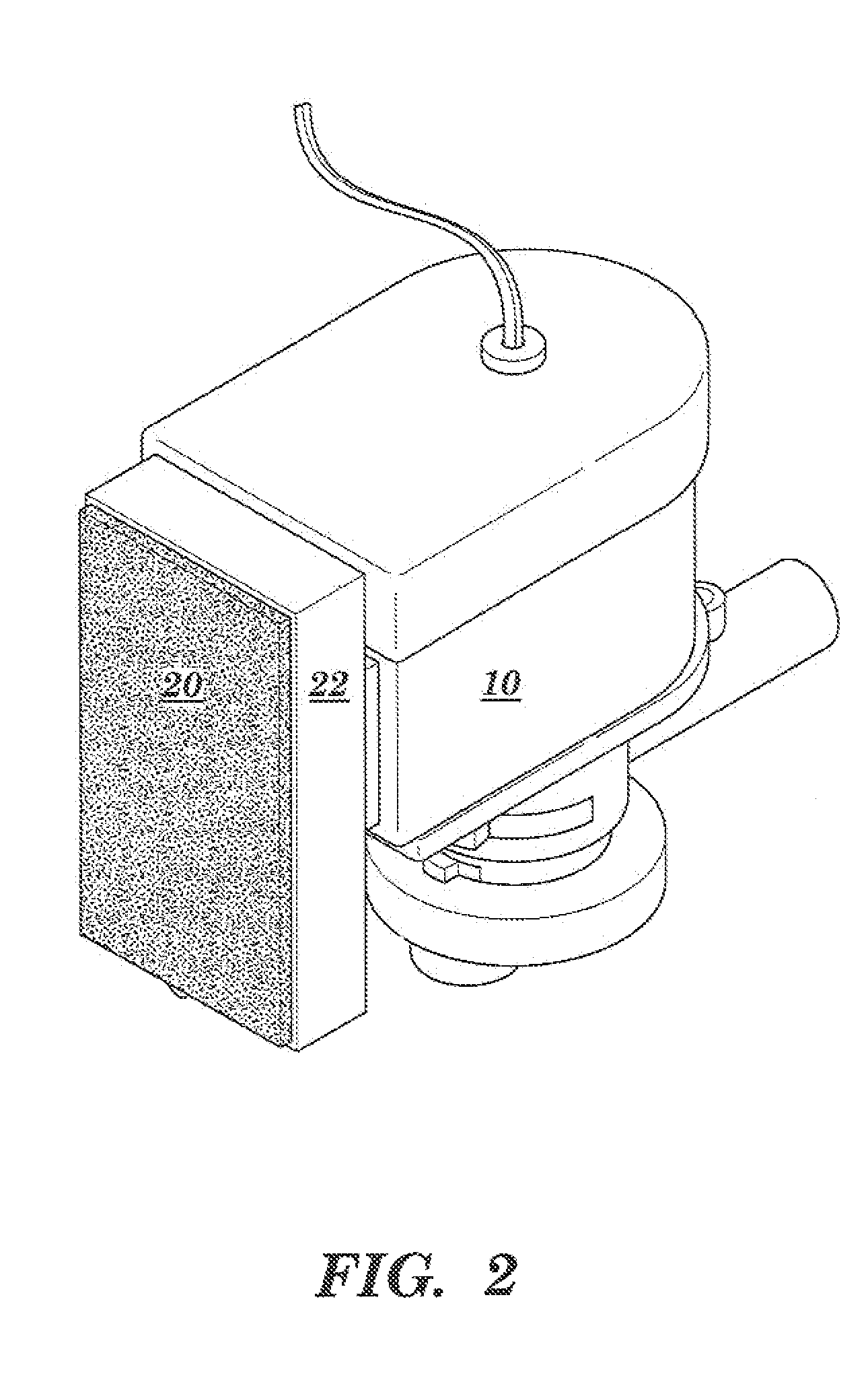

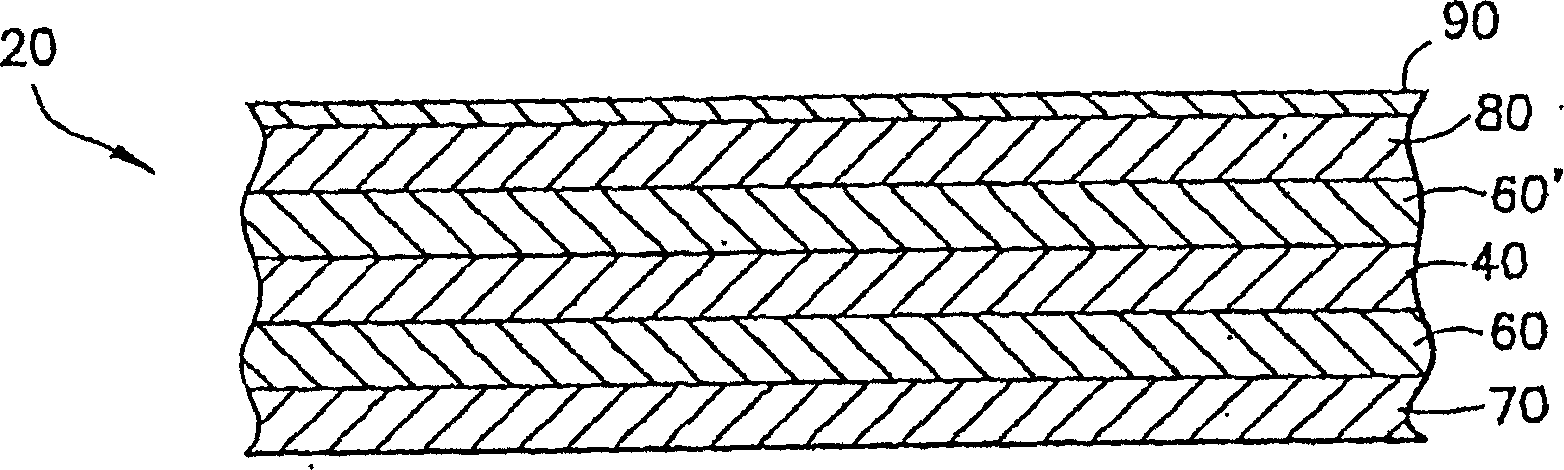

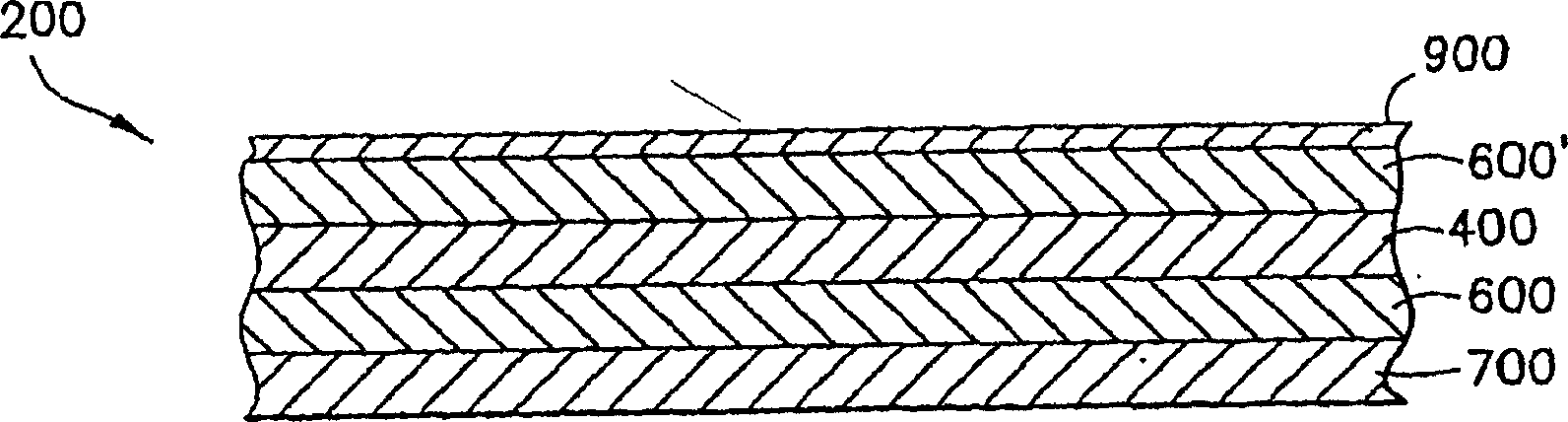

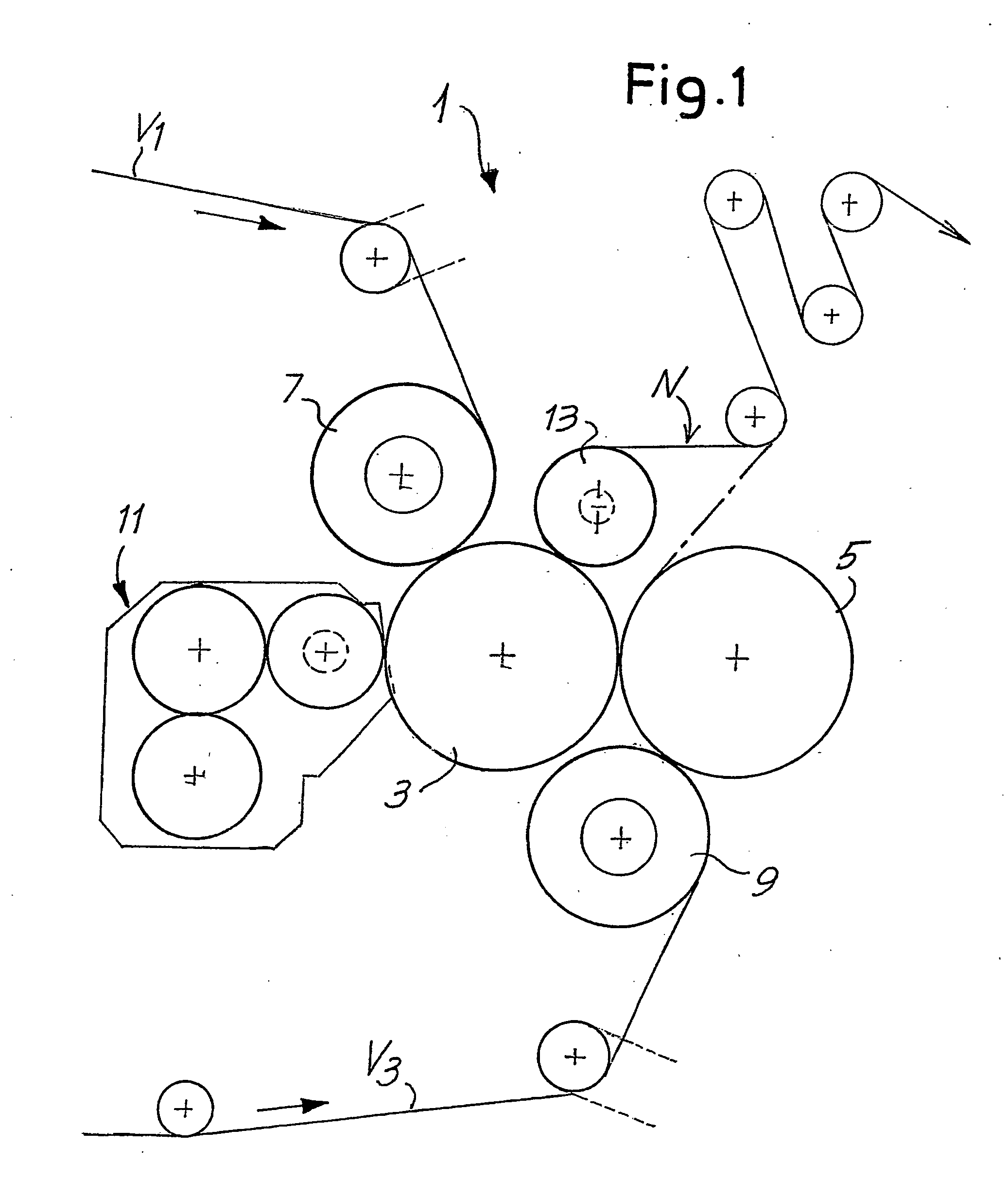

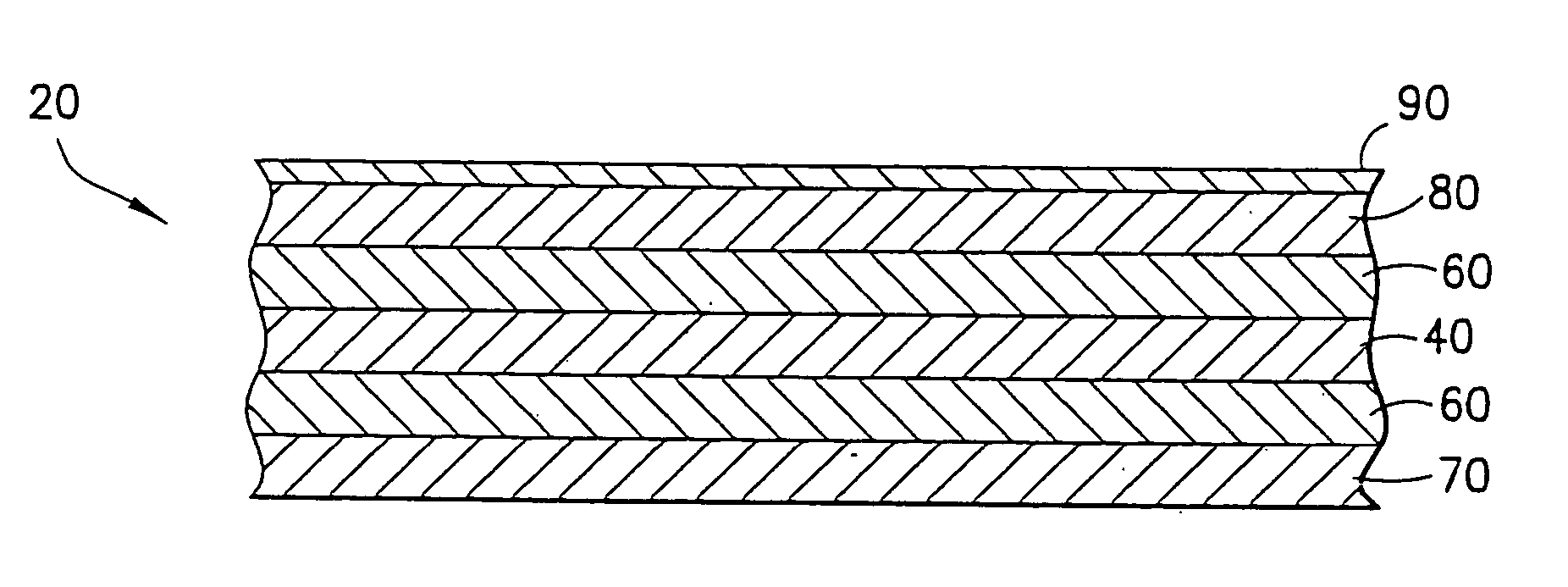

Bonded metal components having uniform thermal conductivity characteristics and method of making same

Cookware having improved uniform heat transfer over the entire cross section thereof, the cookware formed from a multi-layered composite metal (20) having a layer (40) of titanium or other metal having a lower coefficient of thermal conductivity than that of the adjacent layers at or near the core of the composite. The titanium layer is roll bonded to layers (60), (60') of aluminum which, in turn, is roll bonded to layers (70), (70') of stainless steel. The layer of stainless steel adjacent to the cooking range may be a ferritic stainless steel if induction-type heating is desired. The multi-layered composite is also suitable for making a sole plate for an iron. Both the cookware and sole plate may include a non-stick surface (90) applied thereto.

Owner:CLAD METALS

Method for applying polyether-ether-ketone heat-conducting insulating coating

InactiveCN102139263AHigh thermal conductivityImprove toughnessPretreated surfacesSpecial surfacesInorganic saltsPolymer science

The invention discloses a method for applying a polyether-ether-ketone heat-conducting insulating coating. The method for applying a polyaryletherketone film comprises the steps of directly coating prepared polyether-ether-ketone h heat-conducting insulating coating which is uncooled on base material, cleaning the coated base material with water, removing solvent and inorganic salt, drying in a baking oven for 3-5 hours at the temperature of 180 DEG C, and then placing the material into a vacuum sintering furnace and sintering for 5-10 minutes at the temperature of 380-400 DEG C to obtain thebase material of which the surface is coated with polyether-ether-ketone. The polyether-ether-ketone heat-conducting insulating coating is obtained by adding a heat-conducting inorganic filler in thesynthetic process of polyether-ether-ketone. The coating has good thermal conductivity, insulativity and toughness and can be widely applied to a non-sticky cookware and chemical anticorrosion. By adopting the application method, the traditional construction process is simplified, and PEEK (polyether-ether-ketone) coating material with smooth surface and excellent toughness and durability can be more easily obtained.

Owner:KINGFA SCI & TECH CO LTD +1

Antibacterial wear-resistant ceramic paint for non-stick pan and preparation method thereof

InactiveCN107011792AExtended service lifeImprove mechanical propertiesFireproof paintsAntifouling/underwater paintsAdhesiveWear resistant

The invention discloses an antibacterial wear-resistant ceramic paint for a non-stick pan and a preparation method thereof. The antibacterial wear-resistant ceramic paint comprises the following raw materials by weight: 20 to 40 parts of organosilane, 10 to 30 parts of manganese-alumina spinel powder, 10 to 30 parts of modification quartz powder, 5 to 25 parts of mica powder, 4 to 12 parts of polyacrylate, 5 to 25 parts of a filling material, 4 to 8 parts of an adhesive, 1 to 5 parts of a leveling agent, 1 to 5 parts of a dispersing agent, 1 to 5 parts of a titanate coupling agent and 20 to 40 parts of ethanol. Quartz powder is weighed and then preheated and dried in a drying box at 85 to 150 DEG C for 1 to 2 h; and the modified quartz powder is prepared by adding ammonia water and a coupling agent and then carrying out mixing under stirring, filtering, vacuum drying and the like. The preparation method comprises the following steps: uniformly mixing a part of the raw materials including organosilane, mica powder and the like, then adding ethanol, the filling material and the adhesive, carrying out uniform mixing under stirring, finally adding the rest raw materials, and carrying out uniform mixing under stirring. The ceramic paint for the non-stick pan has good mechanical properties, high-temperature resistance, wear resistance and an antibacterial function, is simple to prepare and poses no toxicity and harm to human beings and environment.

Owner:HEFEI HUAGAI BIOTECH CO LTD

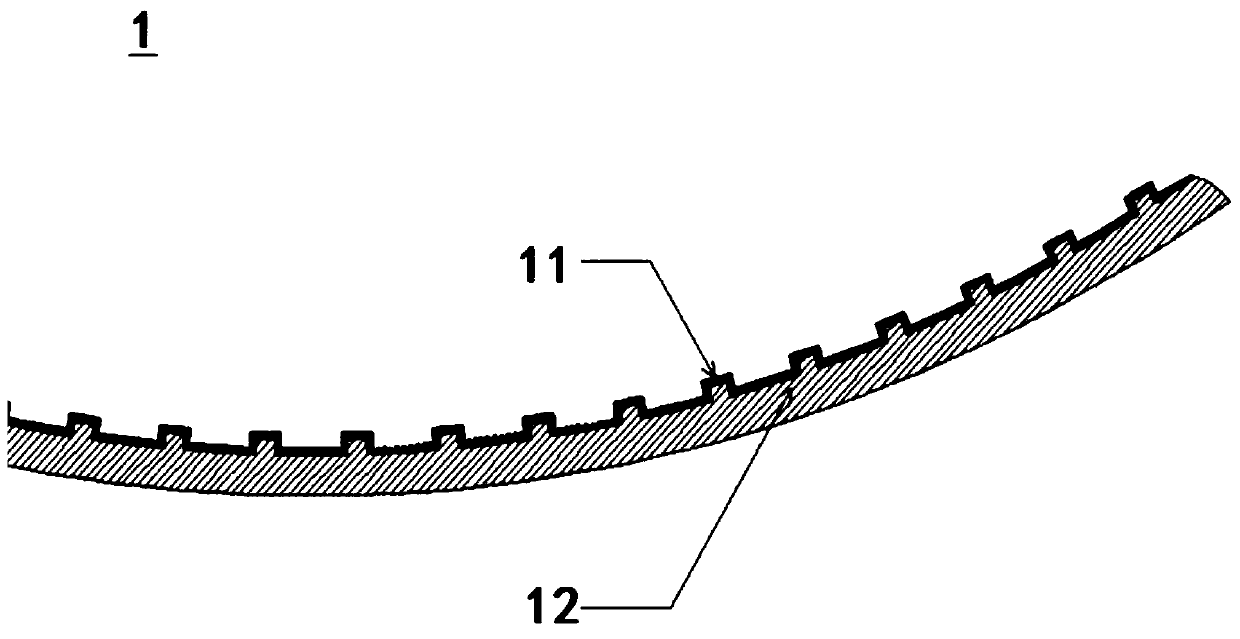

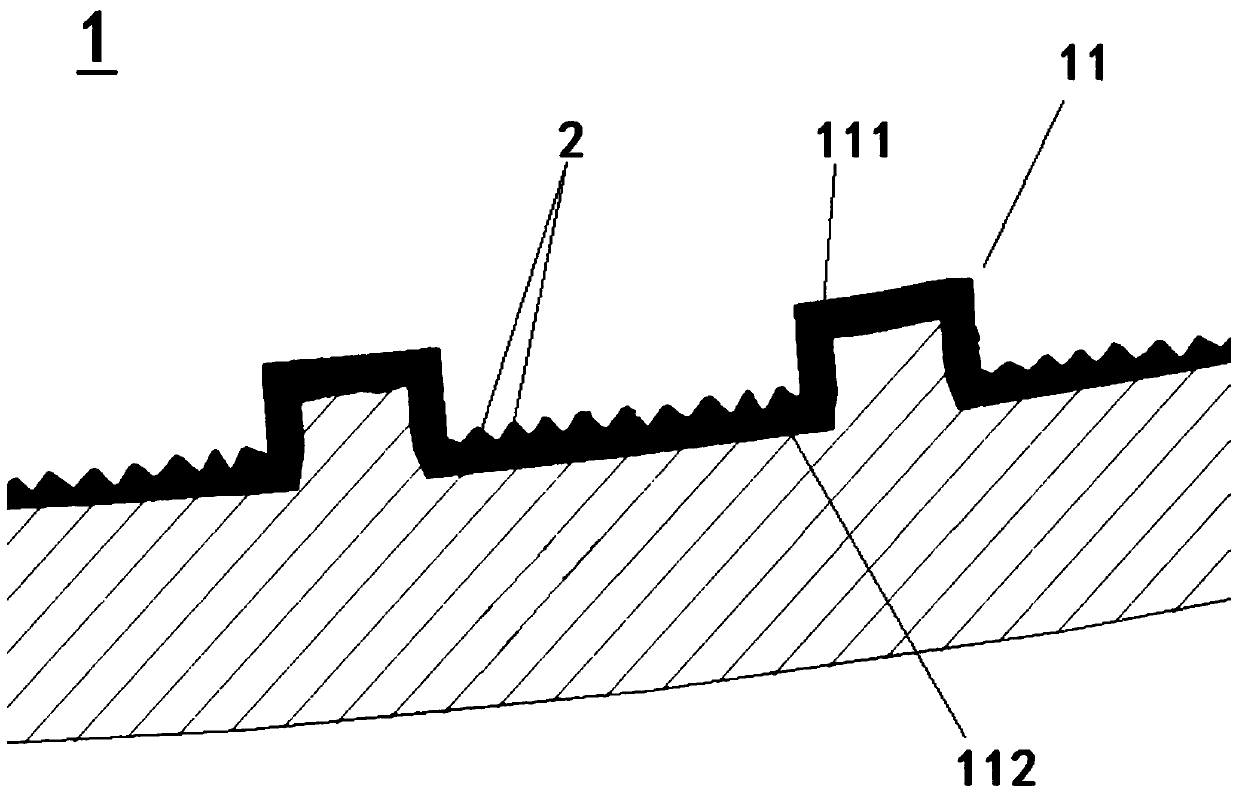

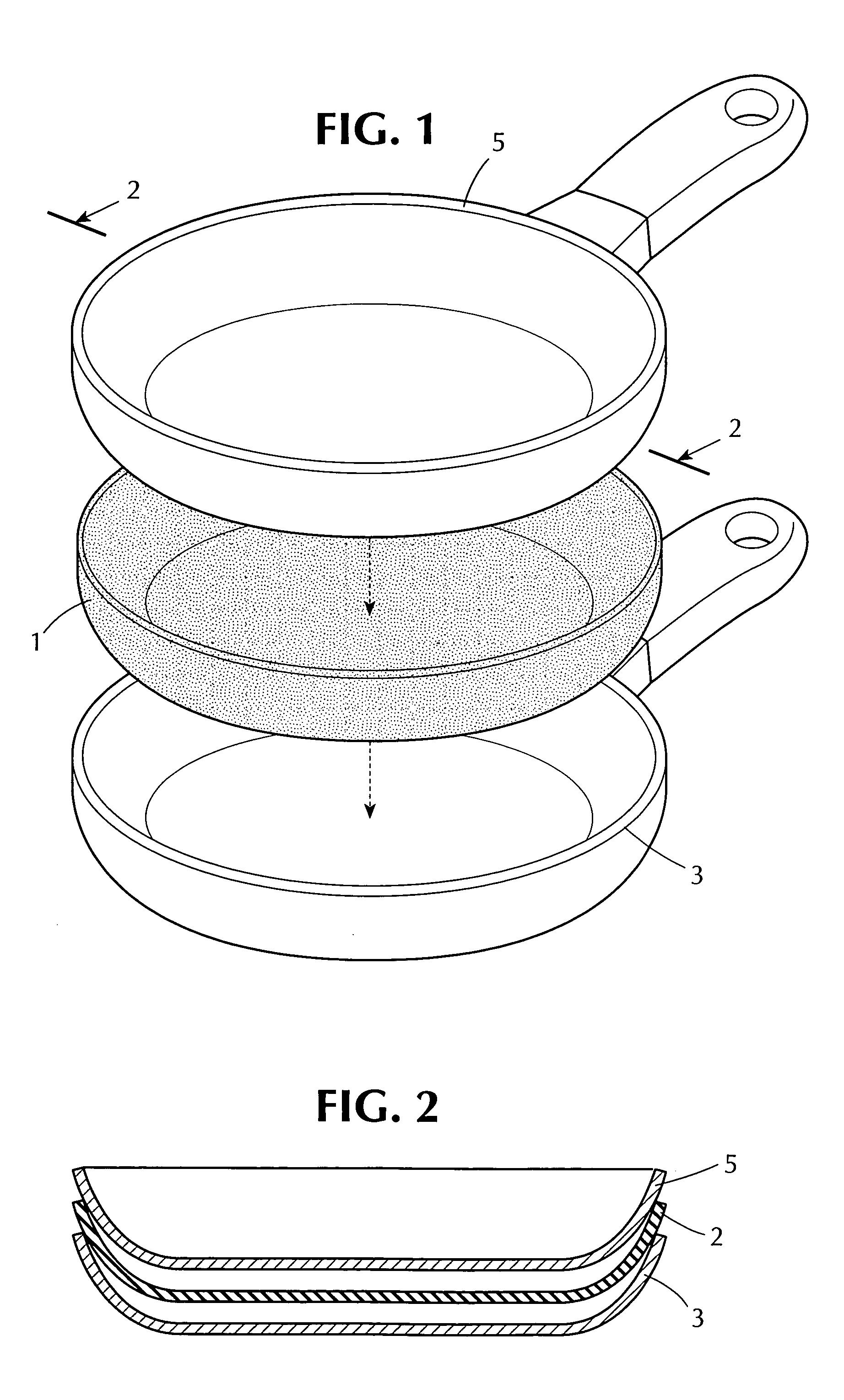

Physical non-stick pan with concave-convex structure and preparation method thereof

PendingCN111387795AAchieve hydrophobic effectRealize oil lock functionCooking-vessel materialsPolishing machinesConvex structureEngineering

The invention, which belongs to the field of kitchen supplies, relates to a non-stick pan, in particular to a physical non-stick pan with a concave-convex structure and a preparation method thereof. The non-stick pan comprises a pan body and is characterized in that a concave-convex structure is formed on the inner surface of the pan body. The concave-convex structure comprises convex edges protruding out of the inner surface of the pan and a concave area defined by the convex edges, and a physical non-stick layer is at least arranged on the inner surface of the pan body in the concave area. The concave-convex structure is arranged, the convex edges protect the non-stick layer arranged in the concave area, so that direct friction between the pancake turner and the non-stick layer is reduced, and the non-stick effect of the pan body is prolonged.

Owner:ZHEJIANG BAHE KITCHENWARE CO LTD

Surface treatment method of aluminum product

The invention relates to the filed of process of aluminum products, and provides a surface treatment method of the aluminum product which is greater in non-stick surface performance as well as abrasive resistance. The specific technology comprises the following step of: sequentially treating the surface of the aluminum product by grinding, surface degreasing, anodizing and film coating and surface polishing. According to the surface treatment method of the aluminum product, the surface of the aluminum product is treated by anodizing, so that a layer of alumina films is coated on the surface of the aluminum product, and as a result, the wear resistance and corrosion resistance of the aluminum product are improved, the high temperature up to 450 DEG C can be resisted, and the heat absorptivity is higher; the surface of an oxide film is polished, therefore, the non-stick effect of the surface of the aluminum product is improved, and the problem that the surface of the aluminum product, in particular the surface of an aluminum table ware, is easily sticked is solved; and the polished surface of the aluminum is nicer.

Owner:汤锦练

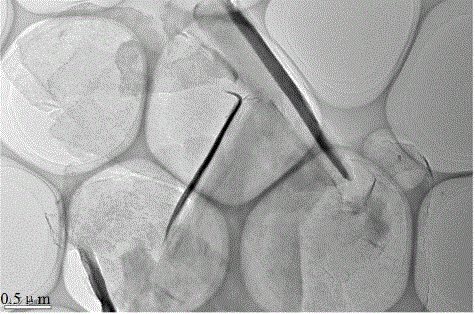

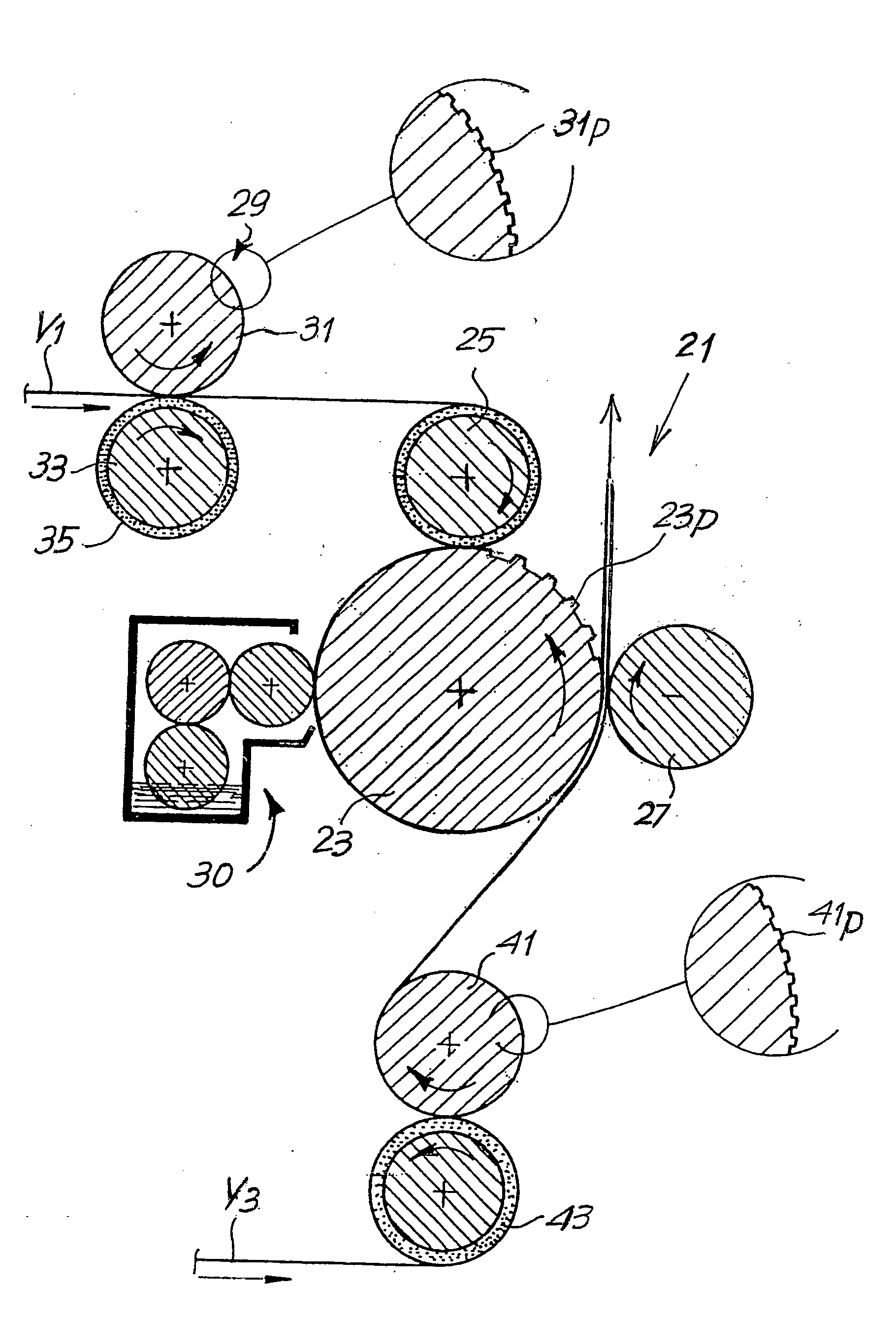

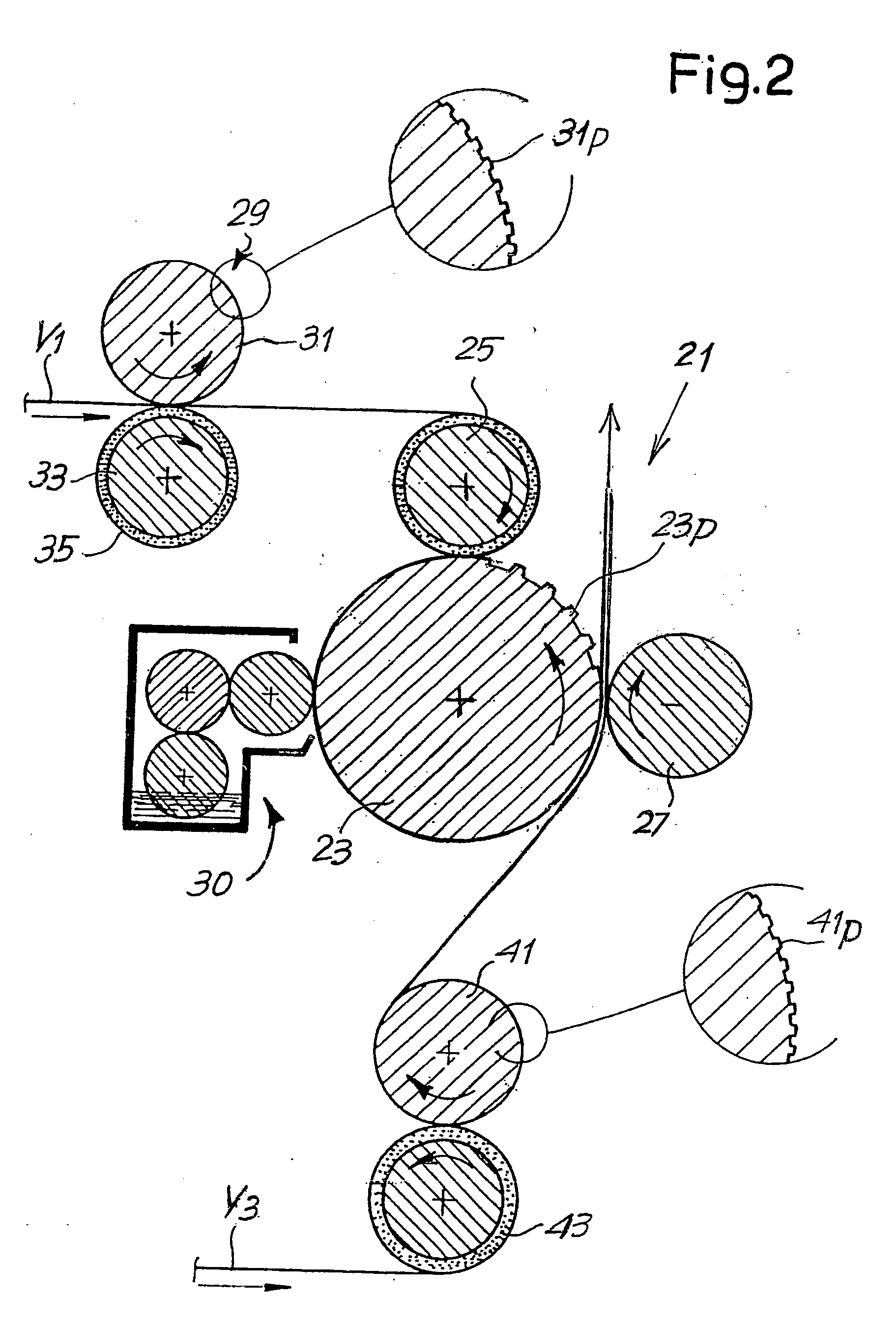

Embossing Rollers with Surface Treatment, Method for the Production Thereof and Embossing Unit Comprising said Rollers

InactiveUS20080248206A1Overcomes and reducesLess subjectMechanical working/deformationLaminationPorosityBiomedical engineering

Disclosed is an embossing roller (3) comprising an essentially cylindrical surface provided with a plurality of protuberances (3P), with non-stick surface treatment (51, 53), comprising an anchoring layer (51) having a porous structure and a non-stick material (53) filling the surface porosities of the anchoring layer.

Owner:PERINI ENGRAVING S R 1 VIA PER MUGNANO 815

Bonded metal components having uniform thermal conductivity characteristics and method of making same

InactiveUS20050271894A1Avoid bondingHigh bonding strengthHot-dipping/immersion processesCooking-vessel materialsMetalThermal conductivity

Owner:CLAD METALS

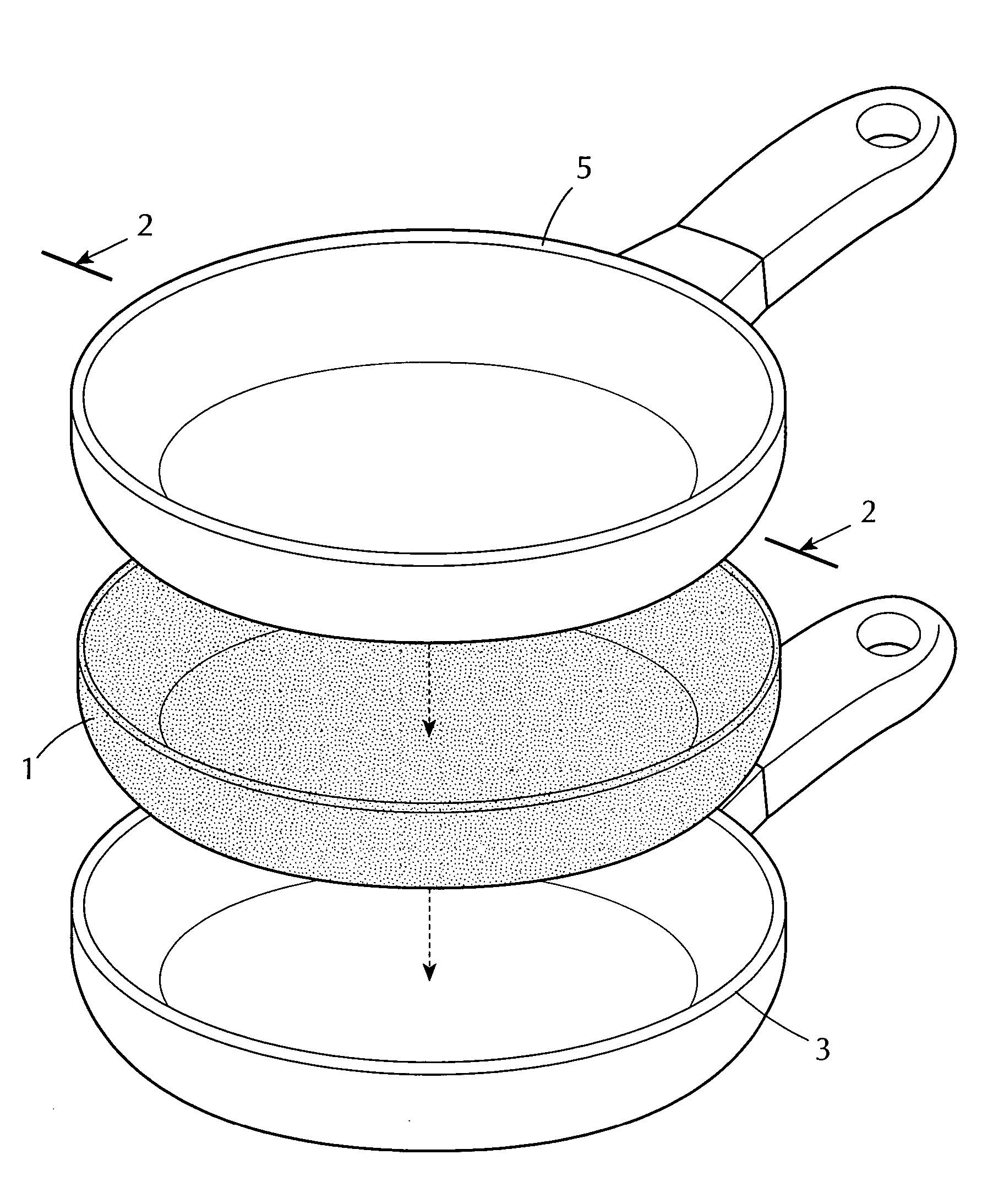

Pot & pan savers/organizers

InactiveUS20070199943A1Protective coatingReduce areaBaking vesselsCooking vessel supportEngineeringCooker

The nature of the invention deals with stacking and storing cookware with polytetrafluoroethylene, sold under the trademark TEFLON. safely on top of each other, without damaging their non-stick coatings. The cookware protector comprises a separator which positioned between two stacked cookware. The separator is made of a flexible material to conform to the different sizes and shapes of the cookware preventing scratching the non-stick surface on the bottom pan. In addition to functioning as a cookware protector, the separator made be used to function as a potholder, and / or as a table mat to protect furniture from hot cookware. Additionally, another embodiment of the cookware protector is flame retardant / resistant properties for safe usage in the kitchen.

Owner:WALDMAN CAROL +1

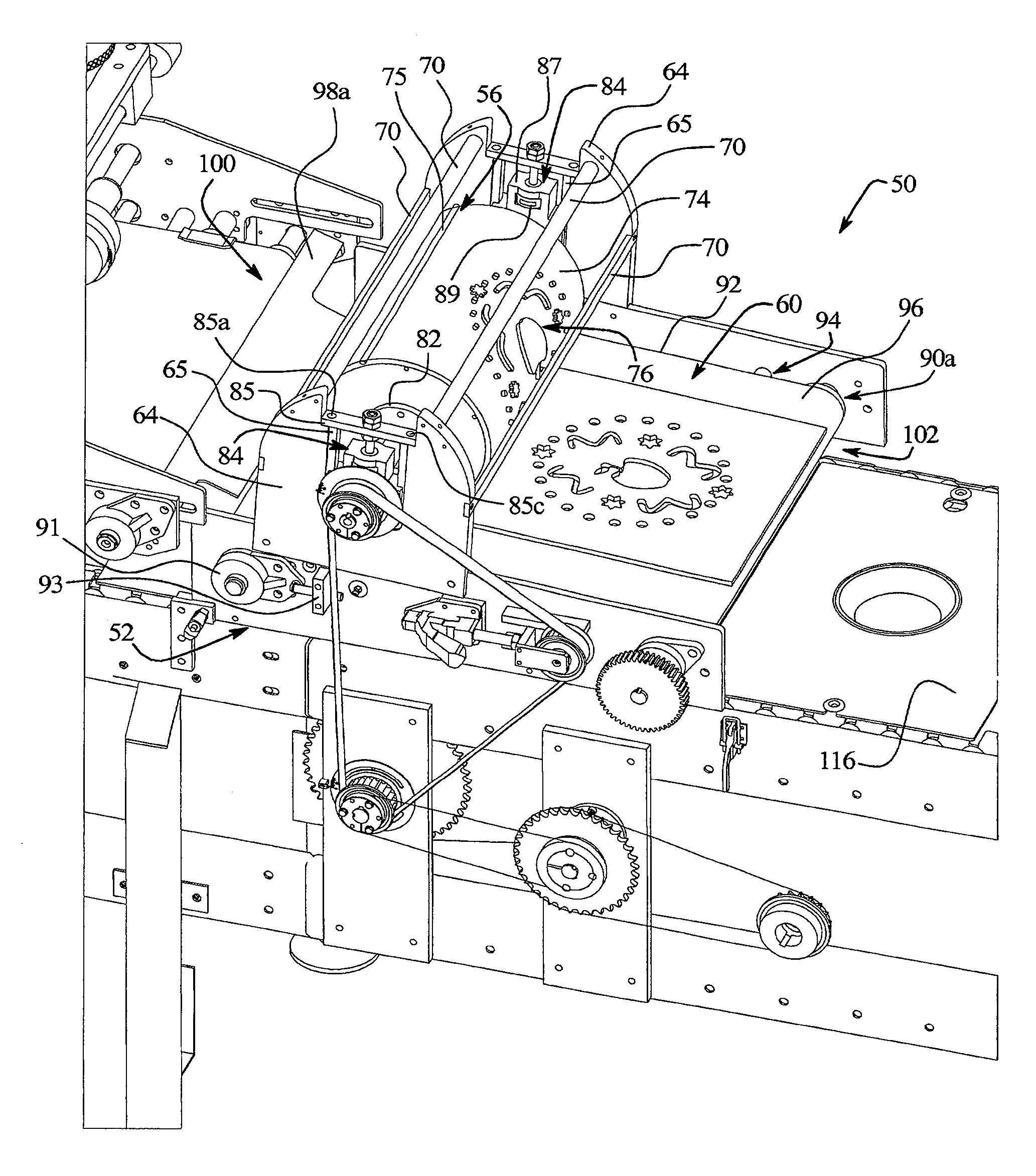

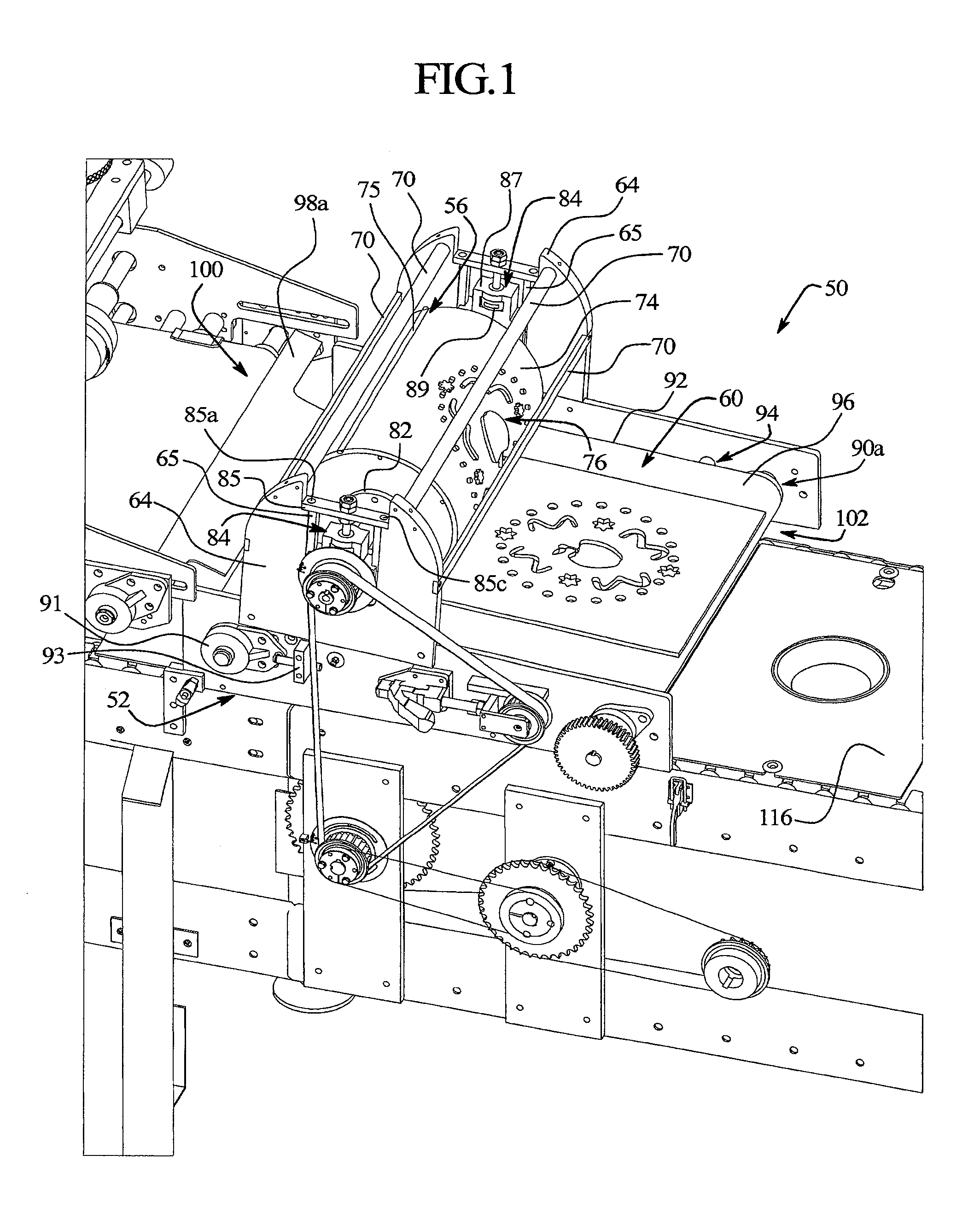

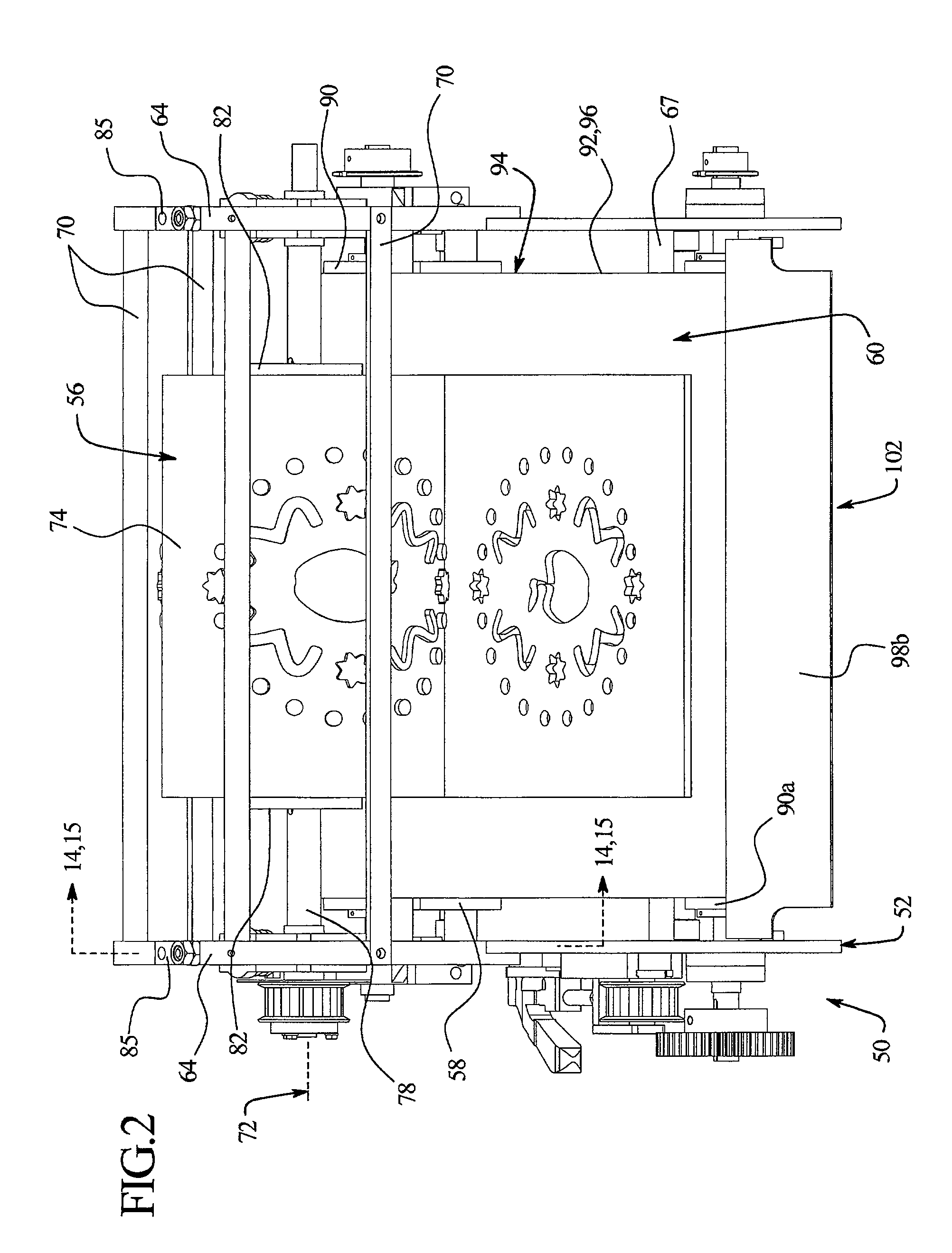

Pie top forming apparatus and method

InactiveUS20070275143A1Facilitated releaseDough treatmentDough embossing machinesEngineeringPaper sheet

Owner:COLBORNE

Non-stick pan with ceramic wear-resistant coating and production process thereof

ActiveCN107080468AQuality improvementExtended service lifeCooking-vessel materialsPolycarbonate coatingsHardnessAluminium alloy

The invention discloses a non-stick pan with a ceramic wear-resistant coating and a production process thereof. The non-stick pan comprises a pan body and ceramic coatings. The pan body is manufactured with aluminium alloy and prepared from, by weight, 0.45-1.2wt% of Si, 0.20-1.05wt% of Fe, 0.15-2.40wt% of Cu, 0.10-3.50wt% of Mn, 0.30-4.60wt% of Zn, 0.06-0.48wt% of Cr, 0.011-0.24wt% of Ni, 0.04-0.16wt% of Ti and the balance Al and unavoidable impurities. The ceramic coatings are prepared from, by weight, 20-40 parts of organosilane, 15-35 parts of titanium powder, 10-30 parts of steel fiber, 10-30 parts of talcum powder, 5-25 parts of polycarboxylate, 5-25 parts of stuffing, 4-12 parts of additives and 20-40 parts of ethyl alcohol. The production process of the non-stick pan with the ceramic wear-resistant coating comprises the steps that firstly, the pan body is manufactured through the processes such as smelting, pouring and heat treating, then, the ceramic coatings are prepared into slurry and the surface of the pan body is coated with the slurry, and finally, a finished product is prepared through the steps such as irradiation and enhanced treatment. The non-stick pan with the ceramic wear-resistant coating is compact in pan body organization structure, good in physical and chemical properties, high in hardness and strength, long in service life and green and environmentally friendly and has obvious heat stability and non-stick property, and the ceramic wear-resistant coating on the non-stick pan is scratch-resistant.

Owner:浙江鸿泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com