Patents

Literature

89results about "Solid bar grate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

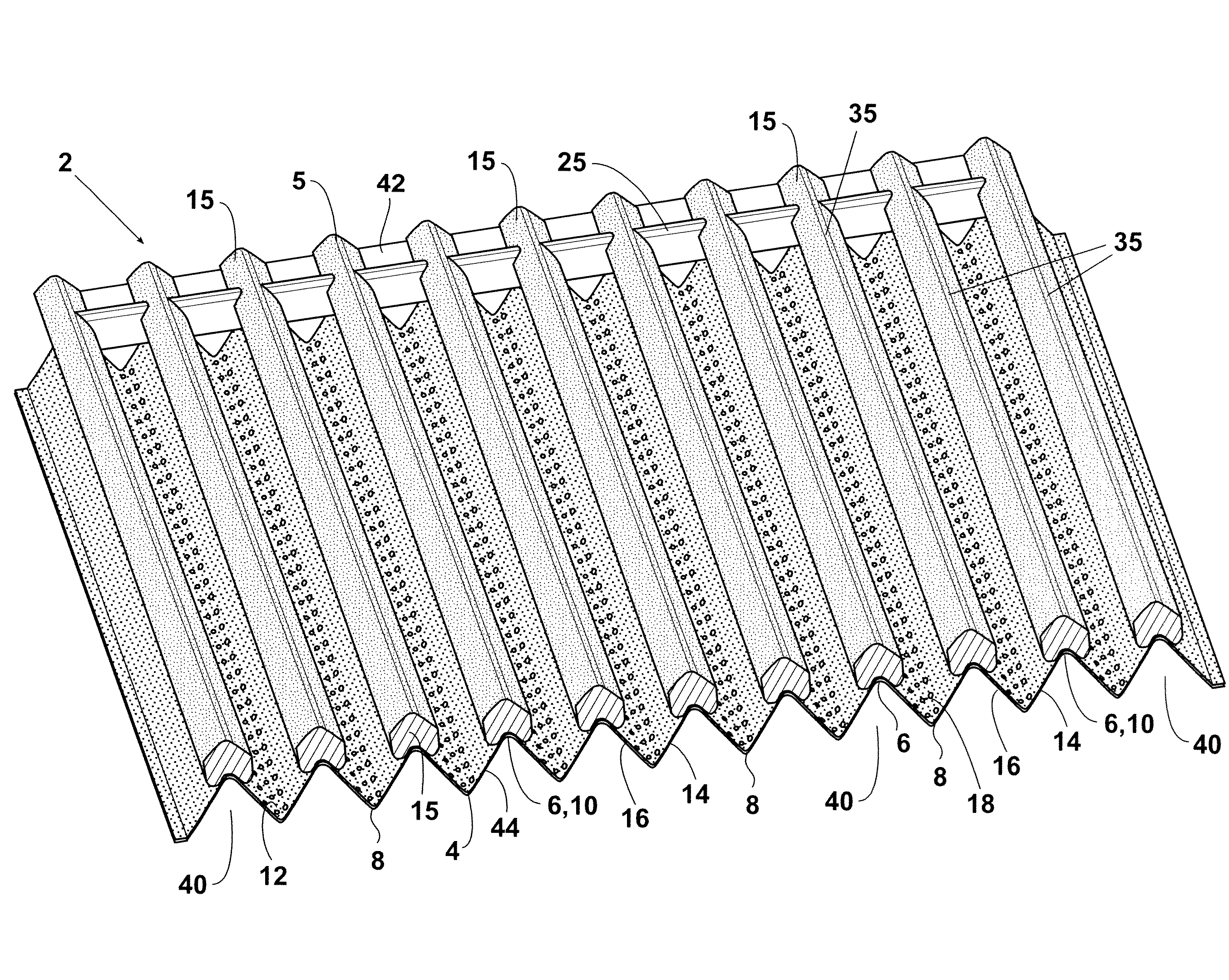

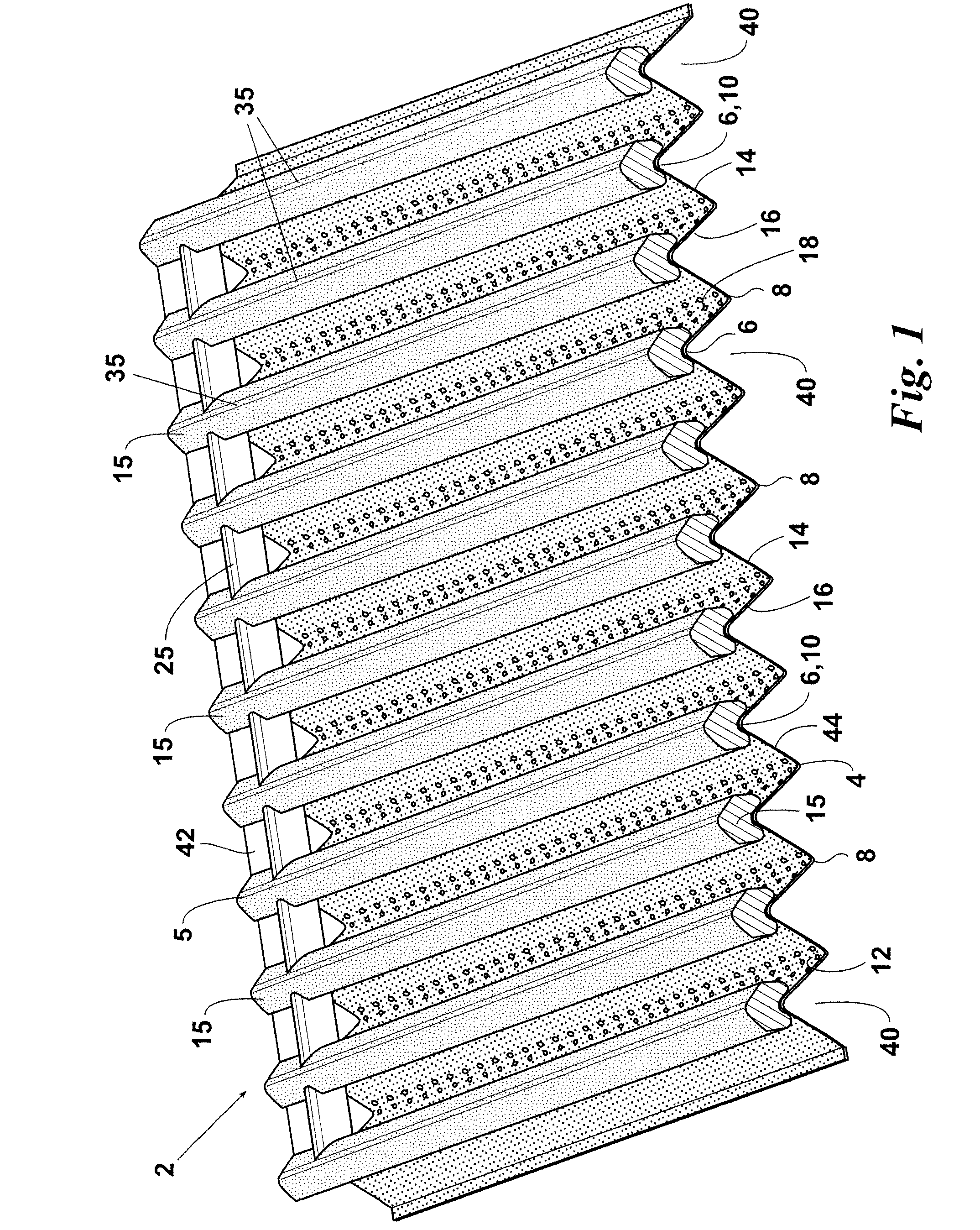

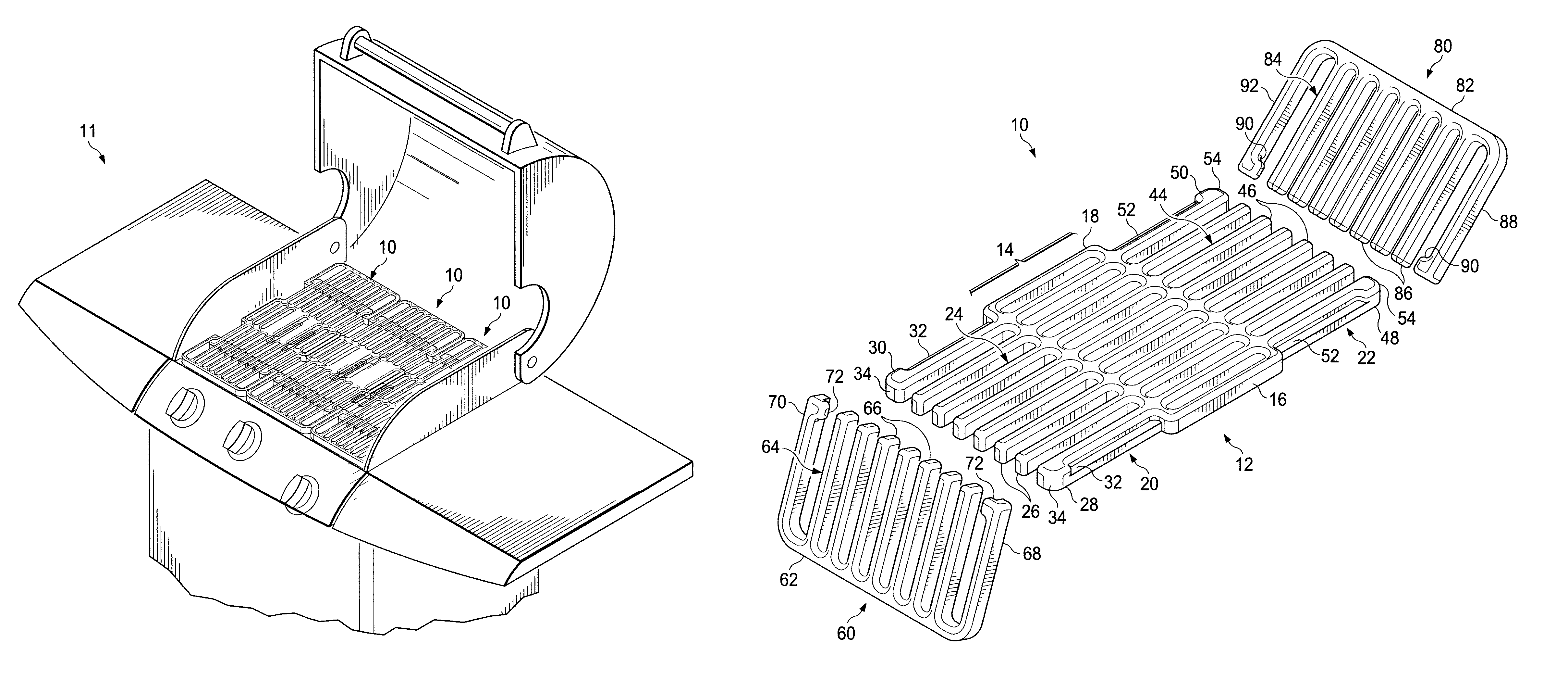

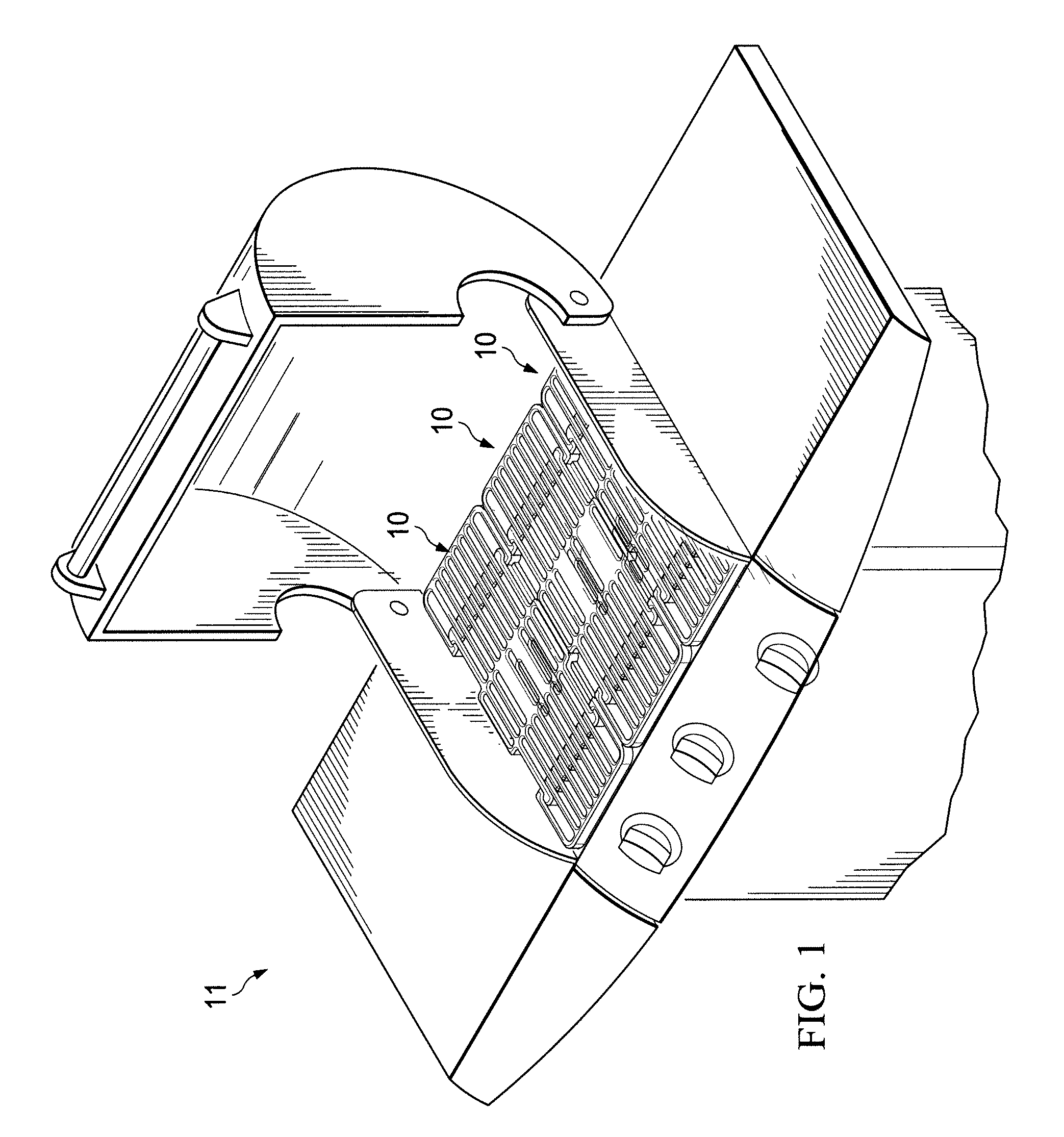

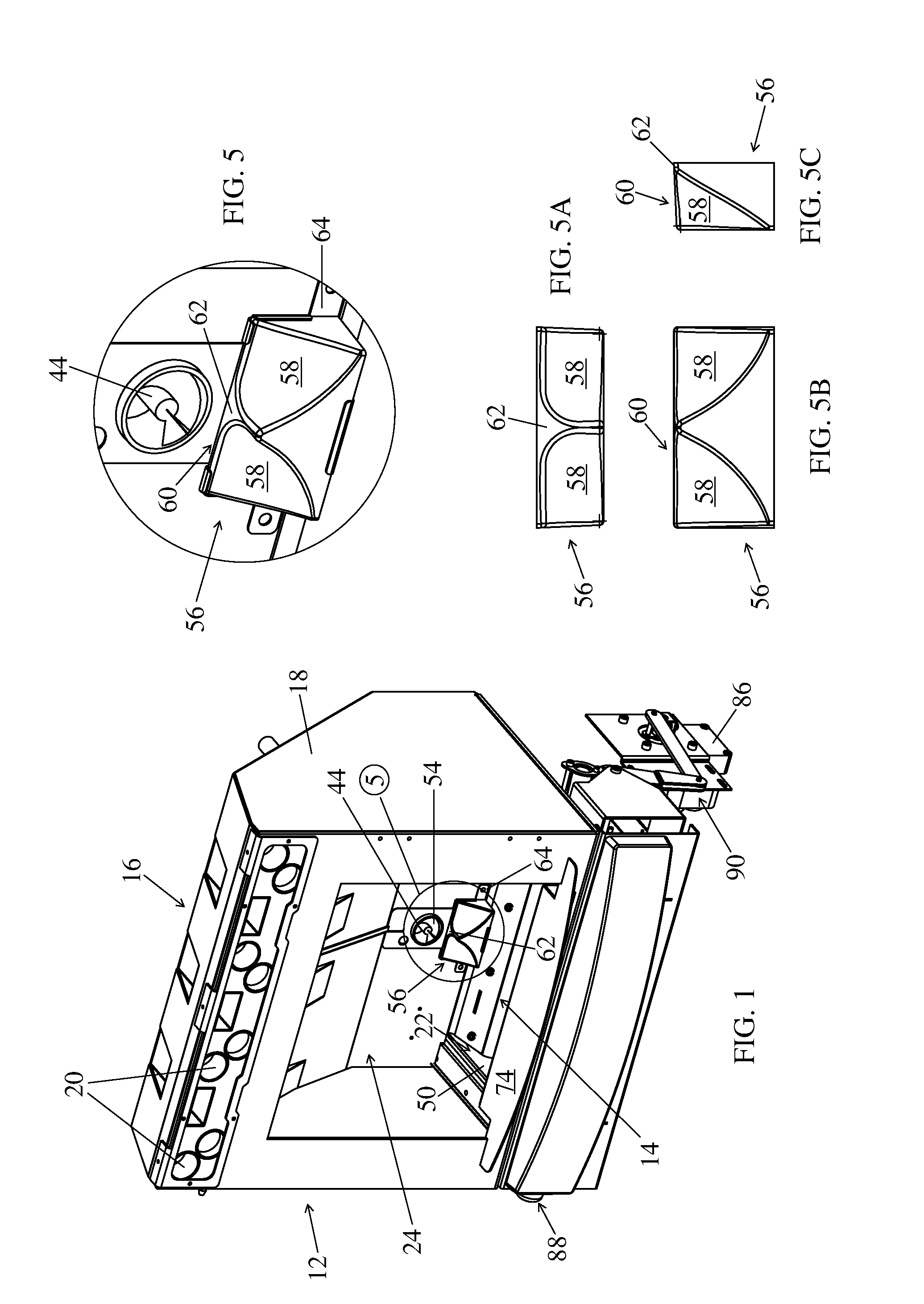

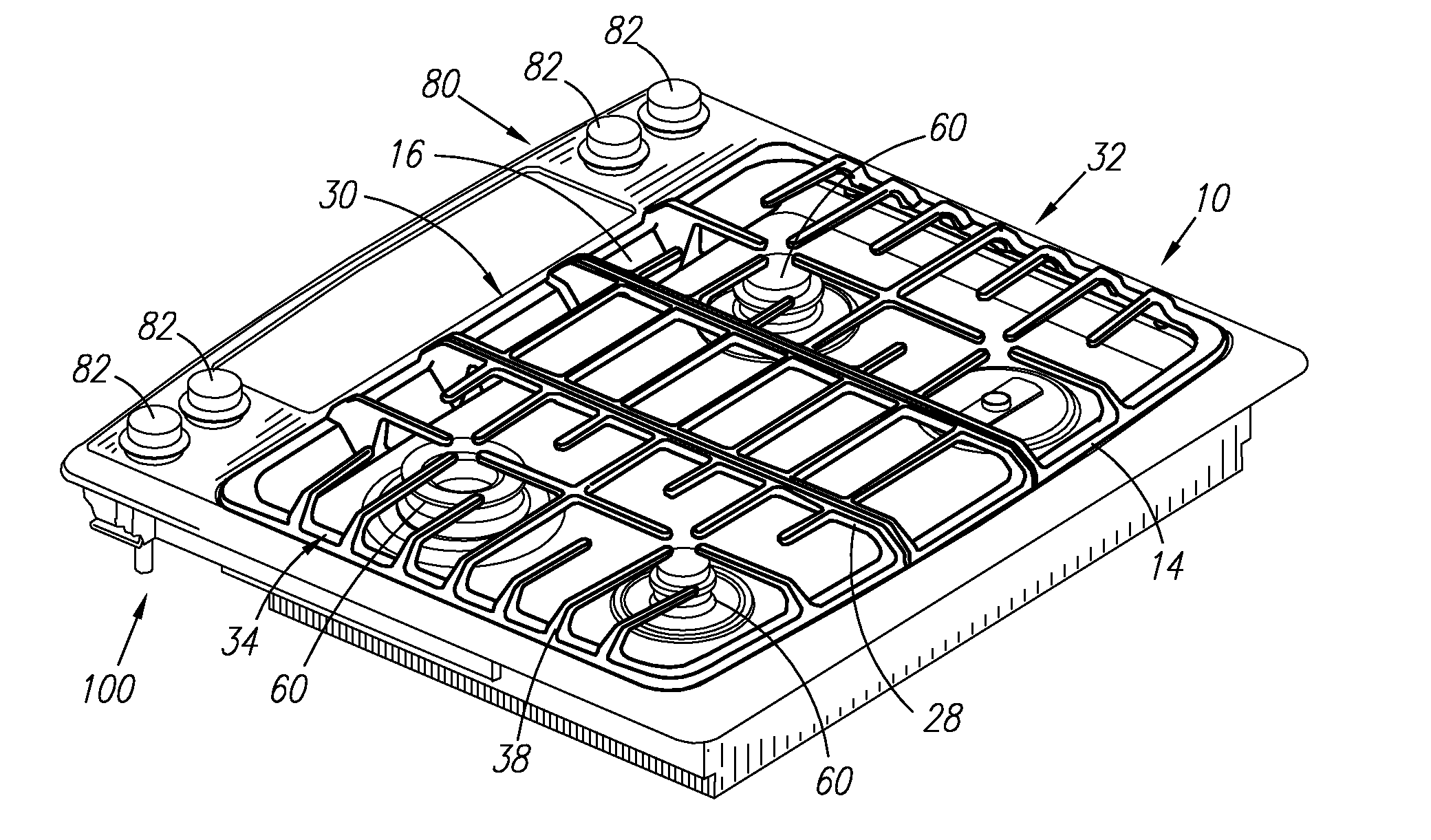

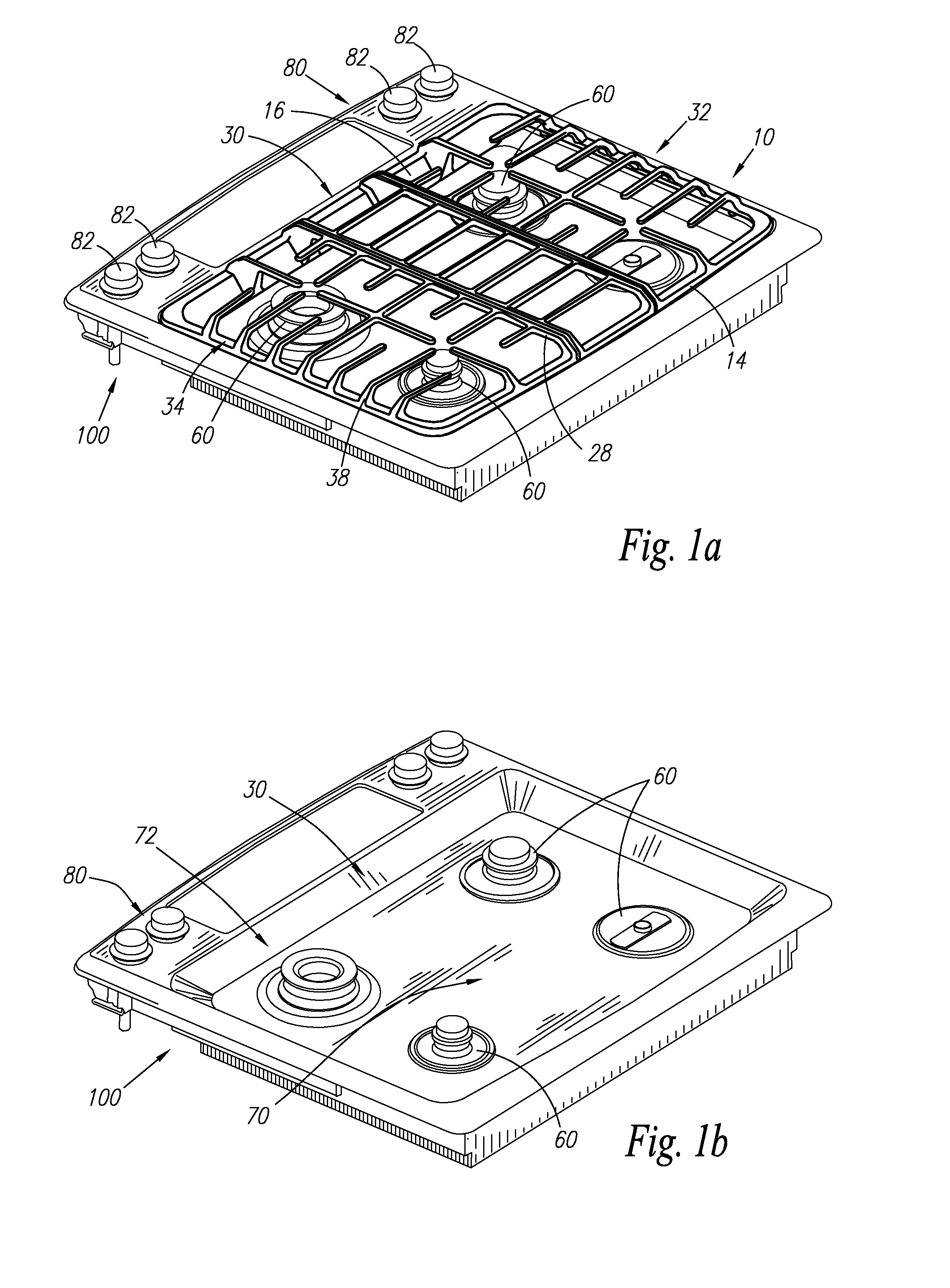

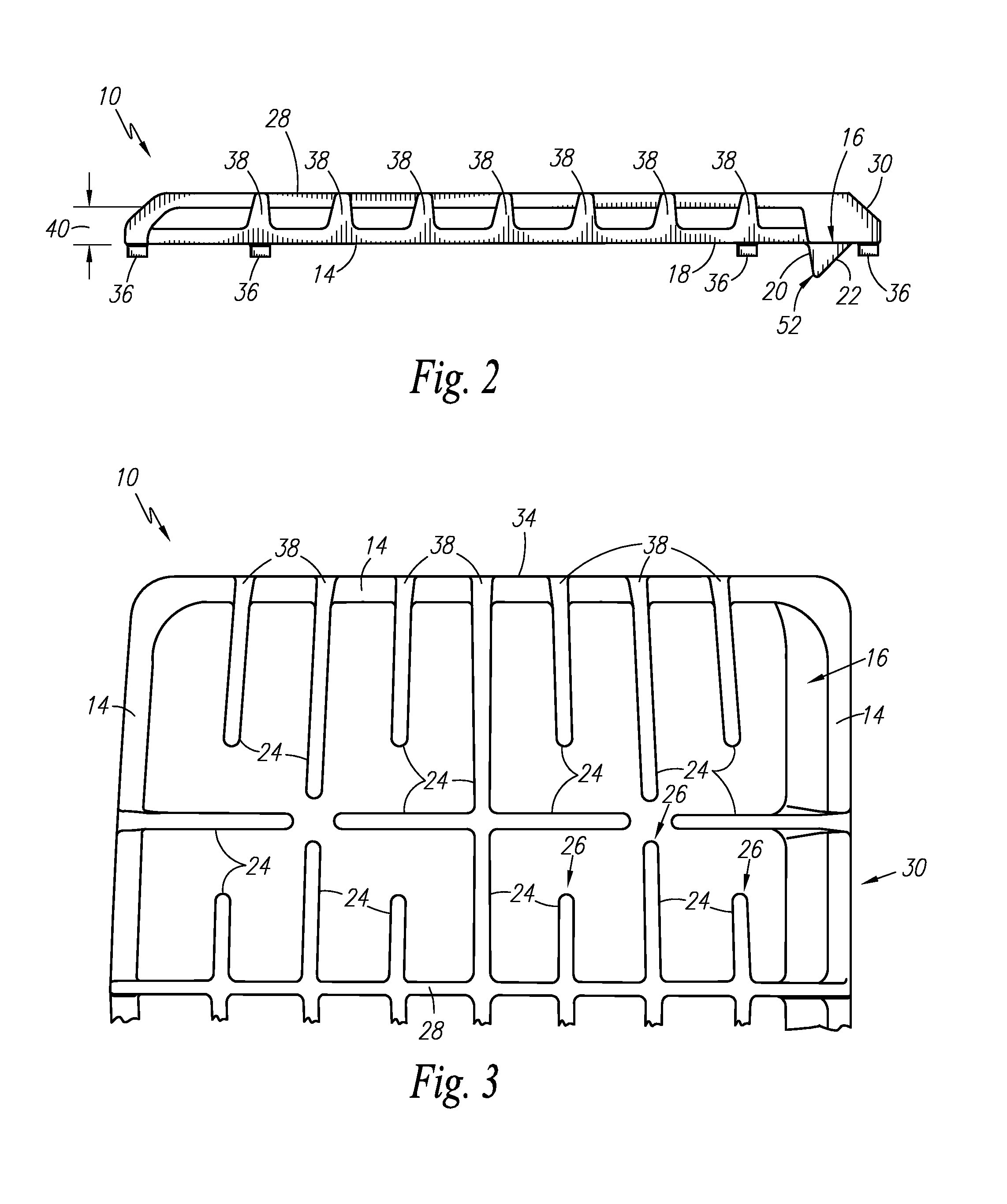

Cooking grate assembly and cooking apparatus

ActiveUS20120222665A1Reduces and eliminates occurrenceRust-free cookingDomestic stoves or rangesSolid bar grateEngineeringFood contact

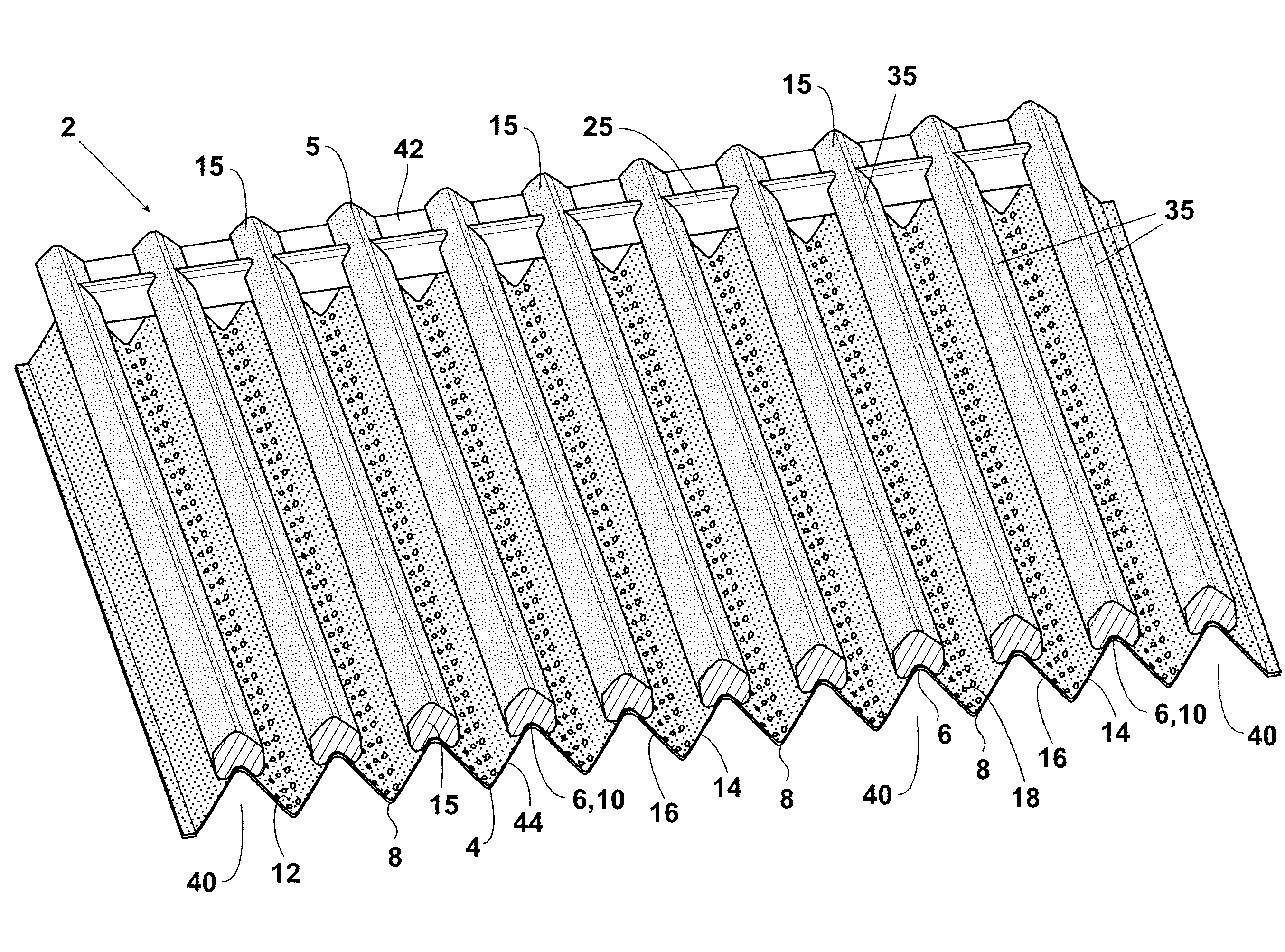

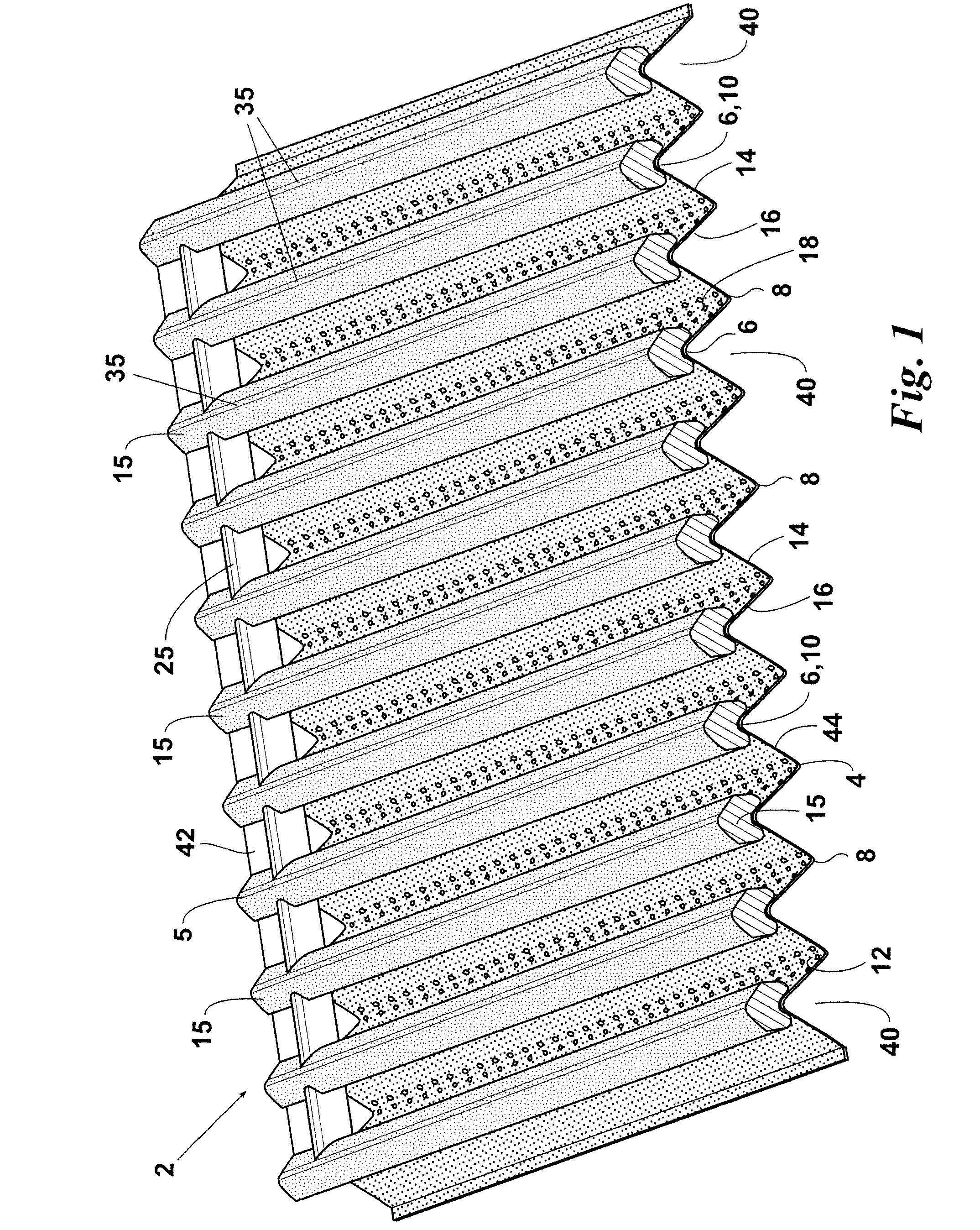

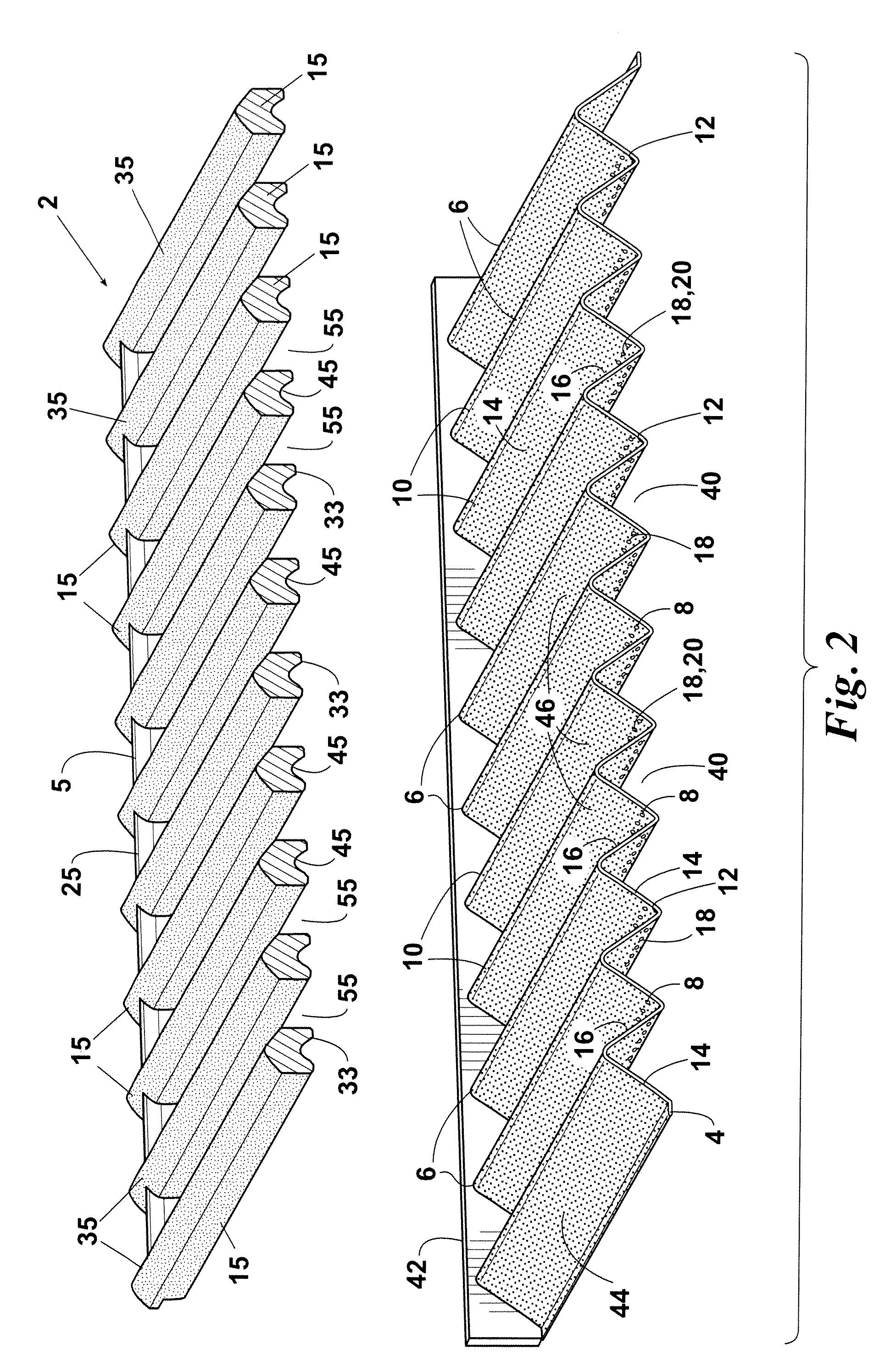

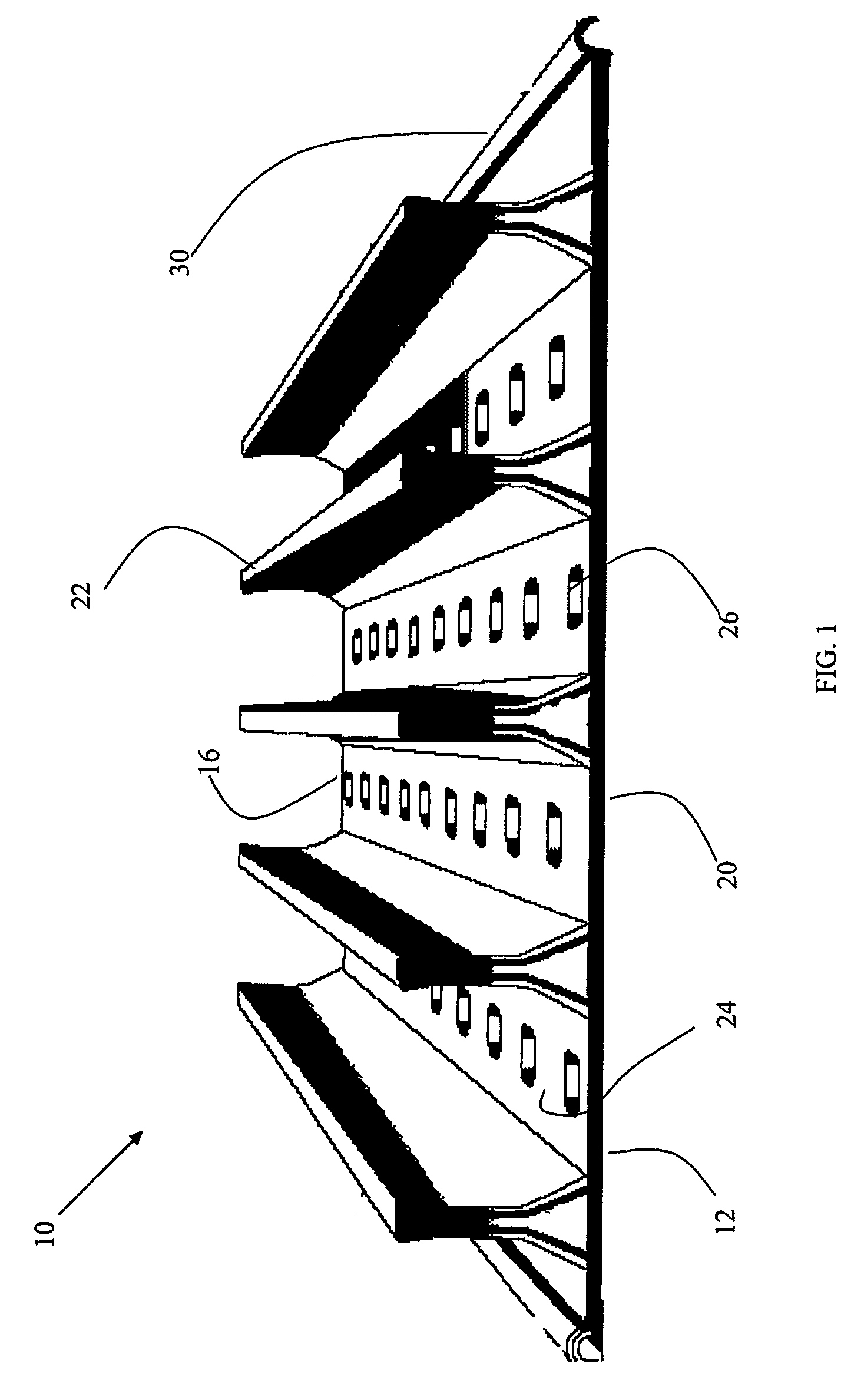

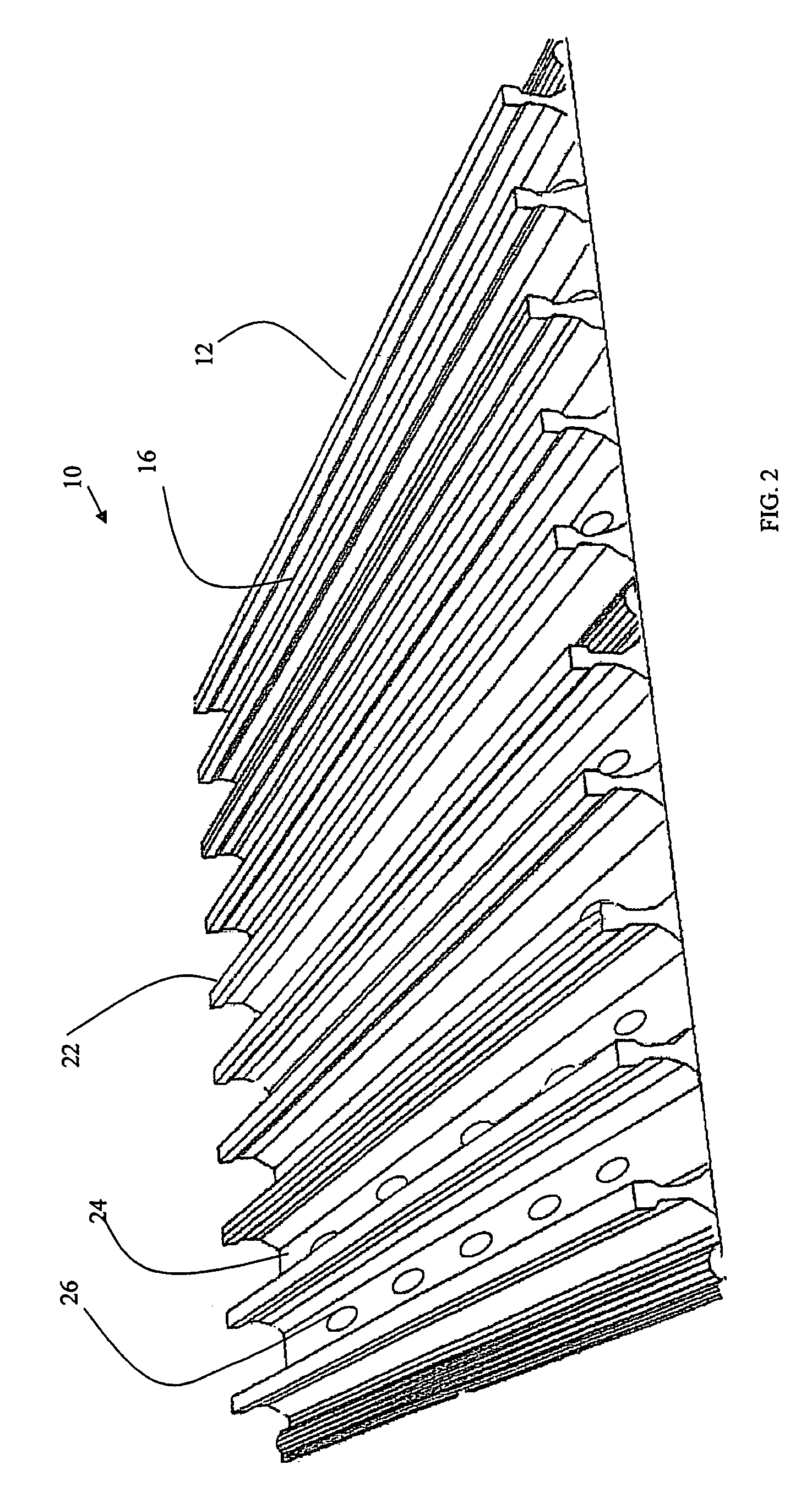

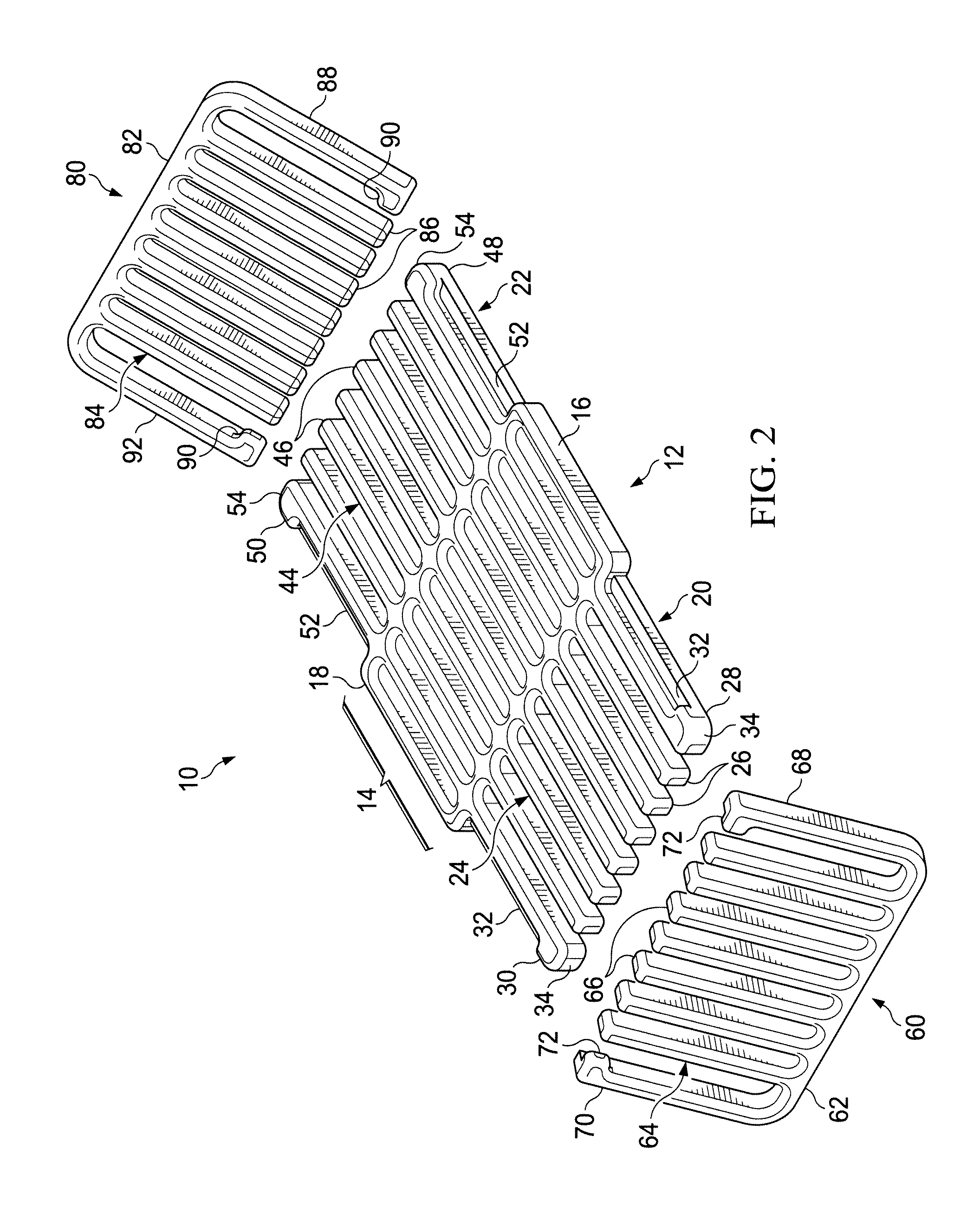

A grate assembly for cooking food products and a grilling apparatus which uses the grate assembly for supporting the food during cooking. The grate assembly comprises: (a) a lower grate element having a series of parallel peak structures with valleys therebetween and (b) an upper grate element having a series of parallel food support ribs which are sized and spaced such that each rib will be positioned over the top of a corresponding peak structure. The upper food contacting surfaces of the ribs will remain substantially rust-free at atmospheric and cooking conditions.

Owner:W C BRADLEY CO

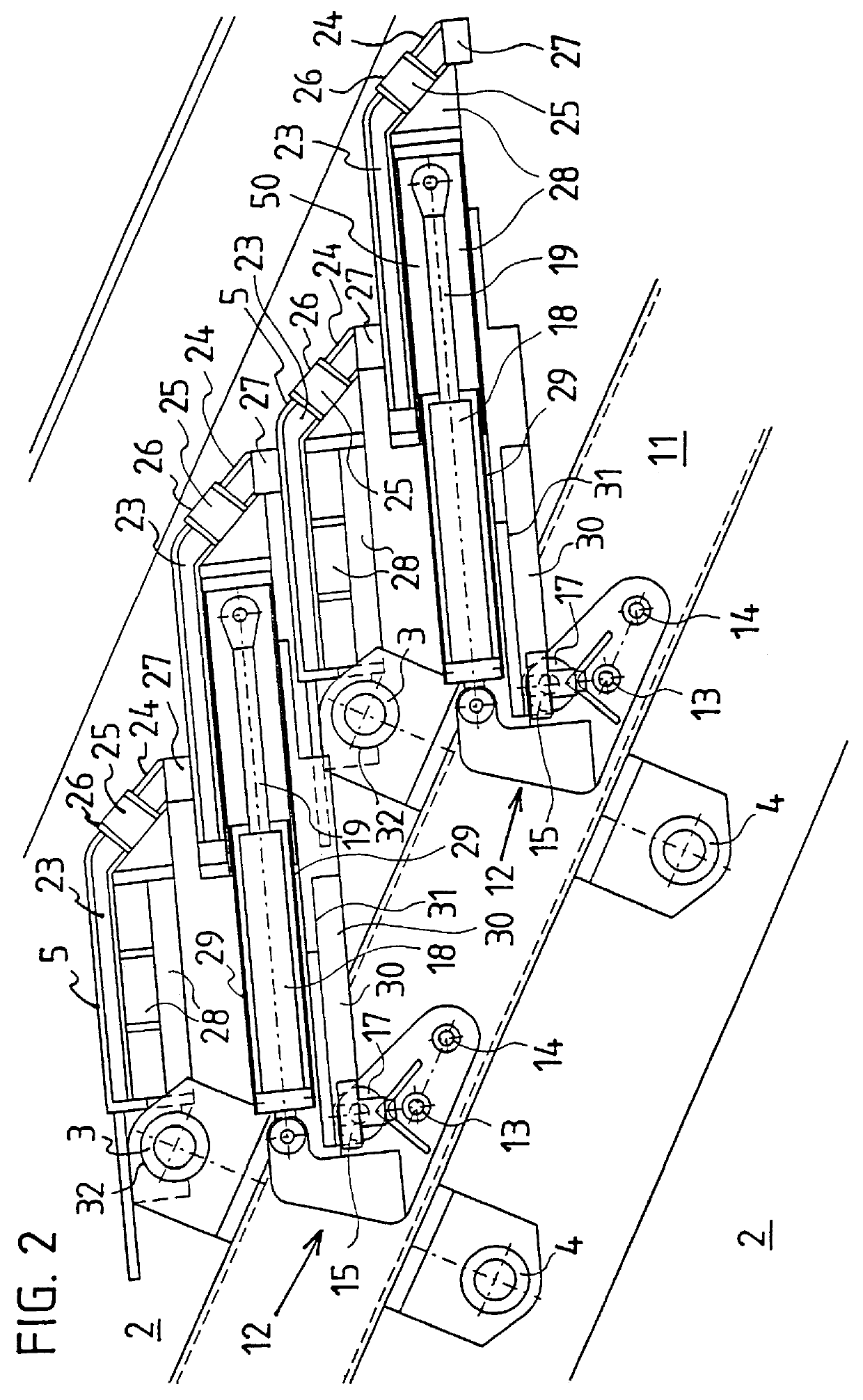

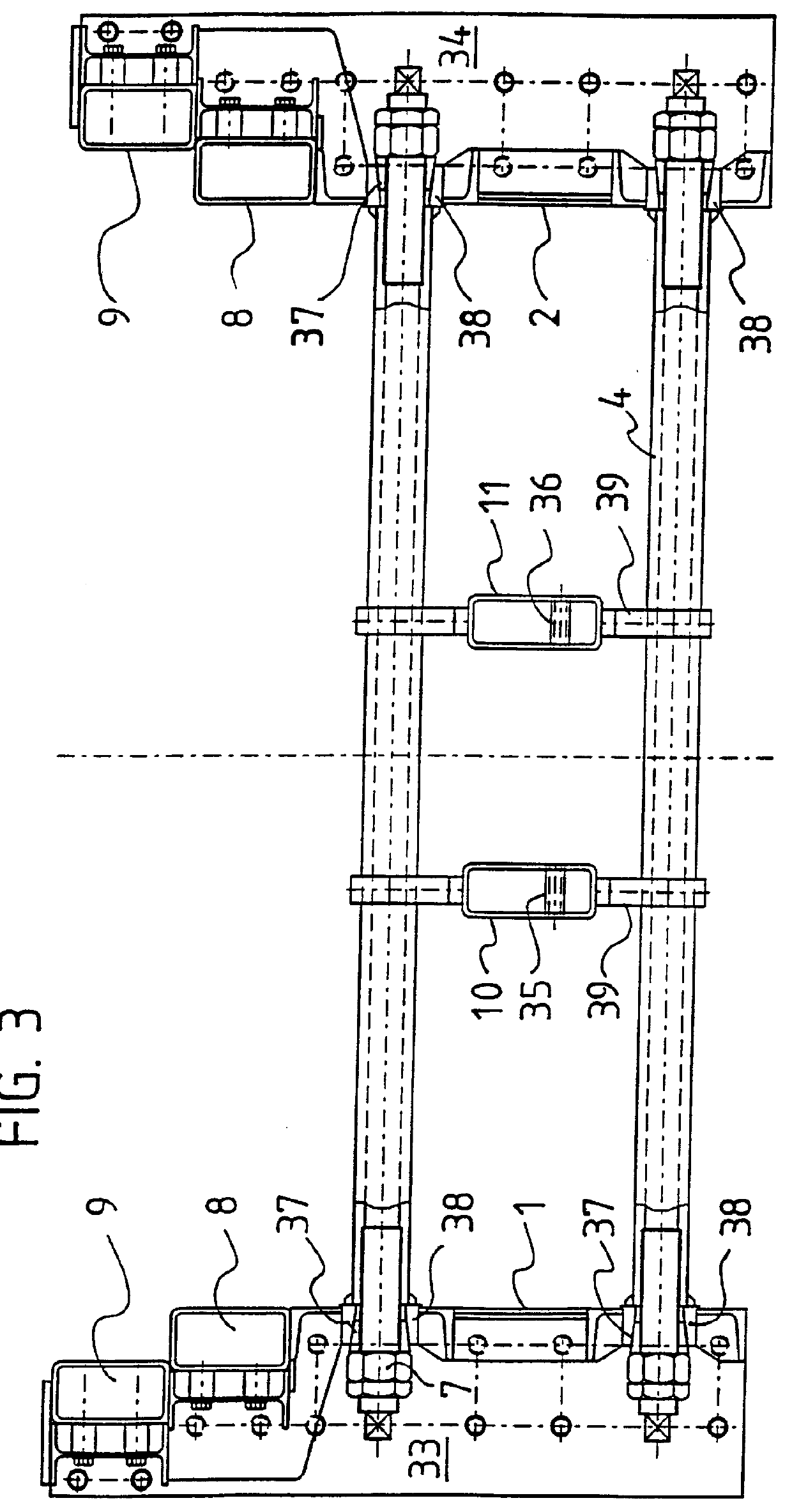

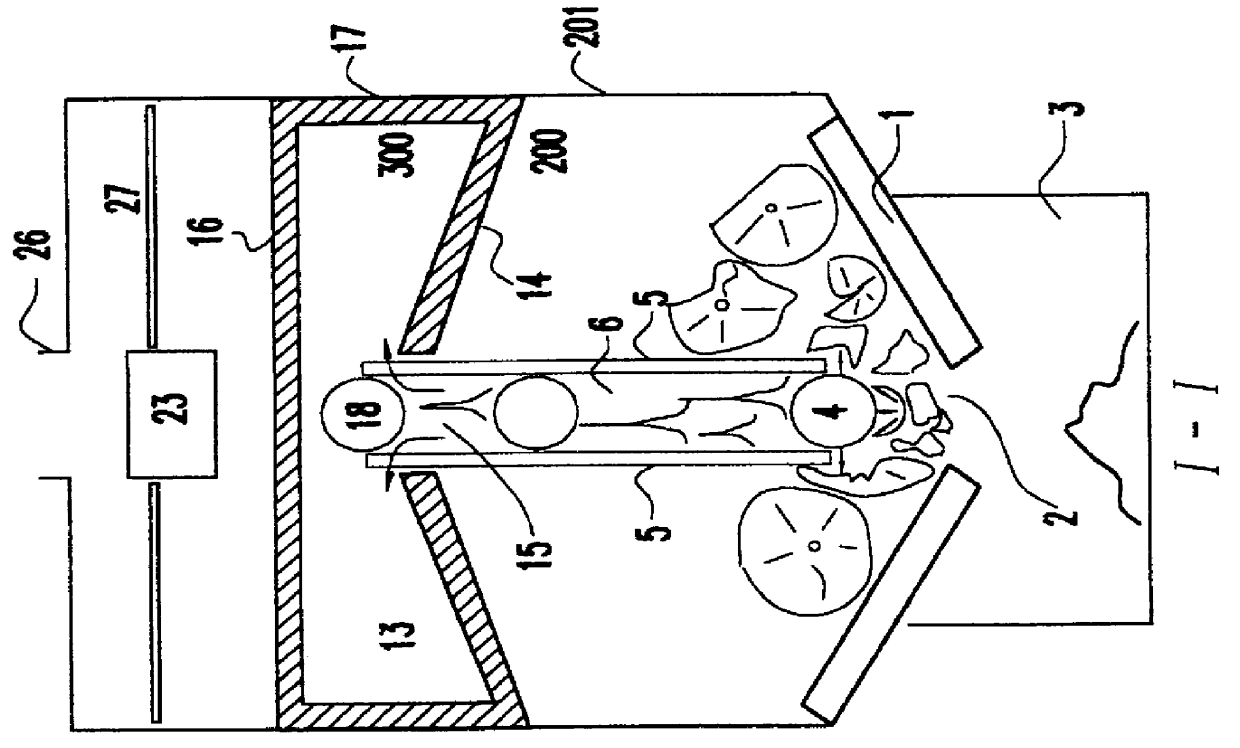

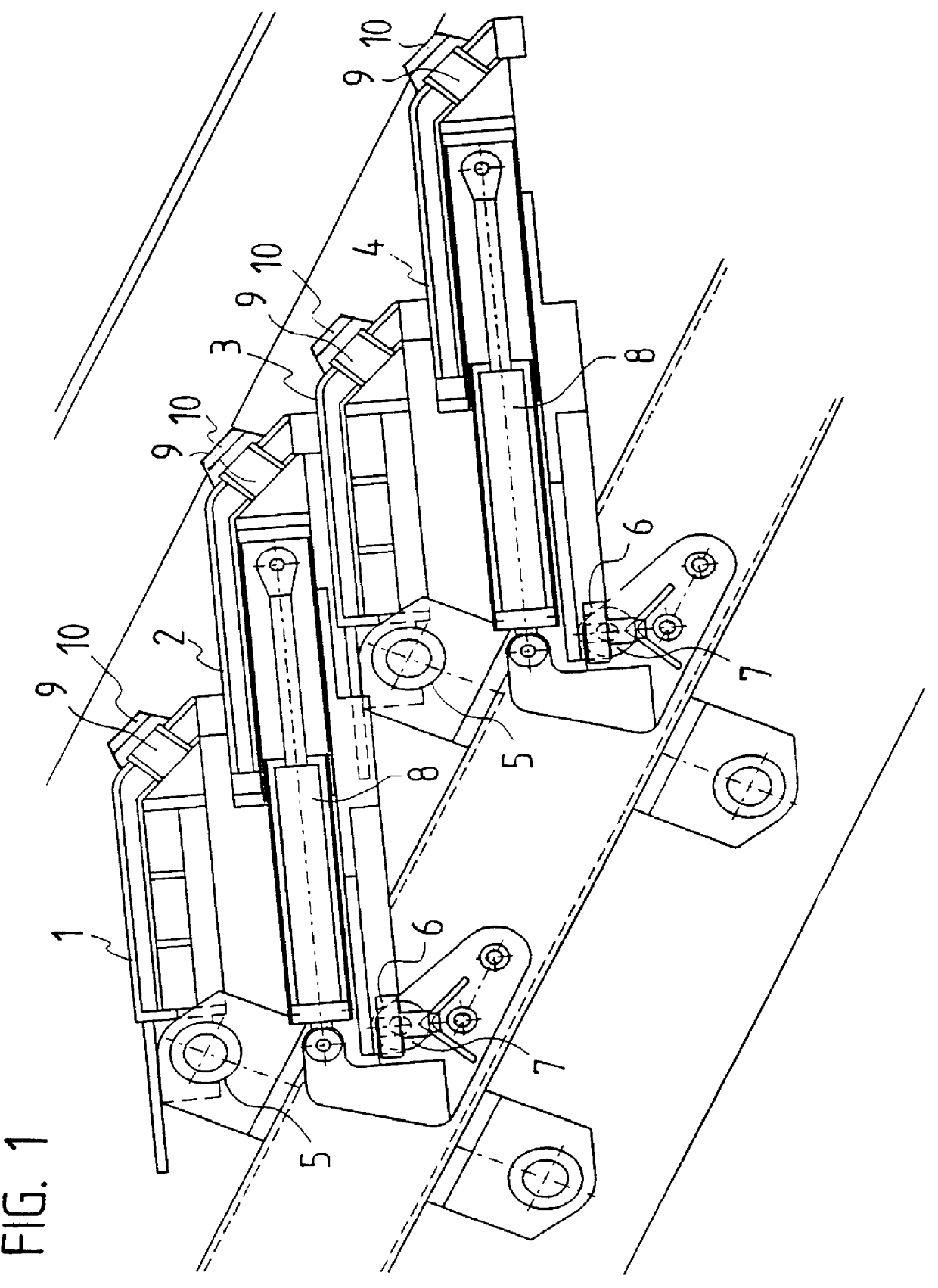

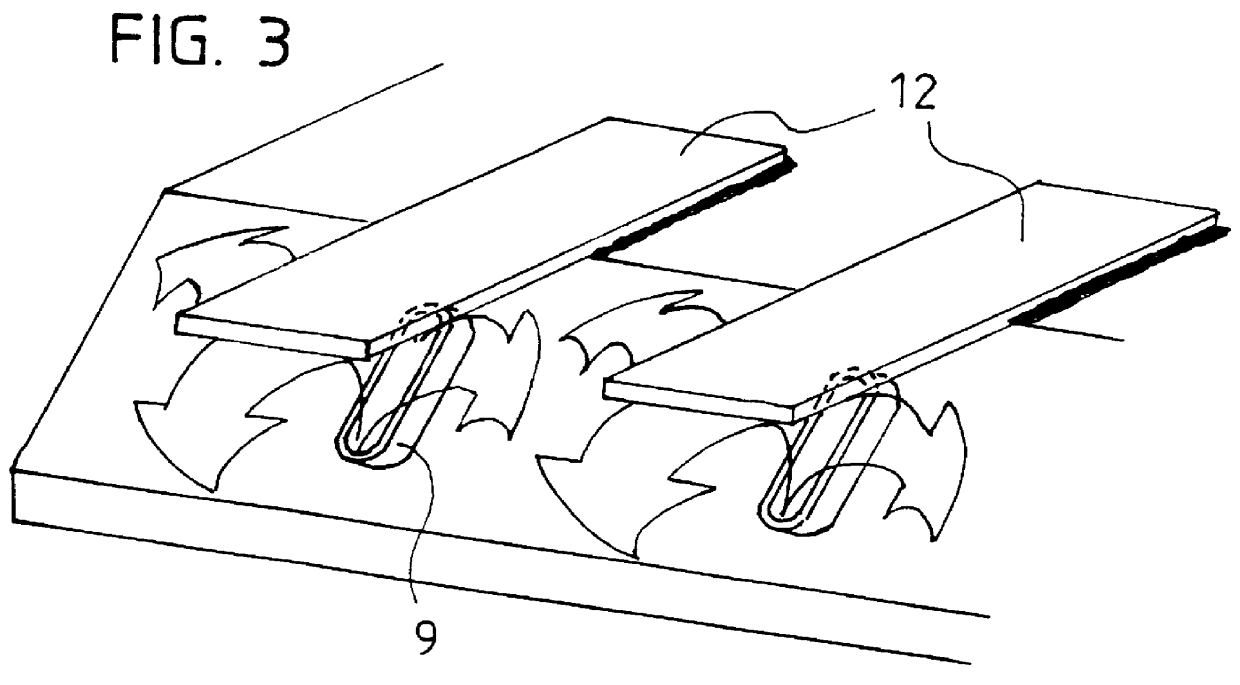

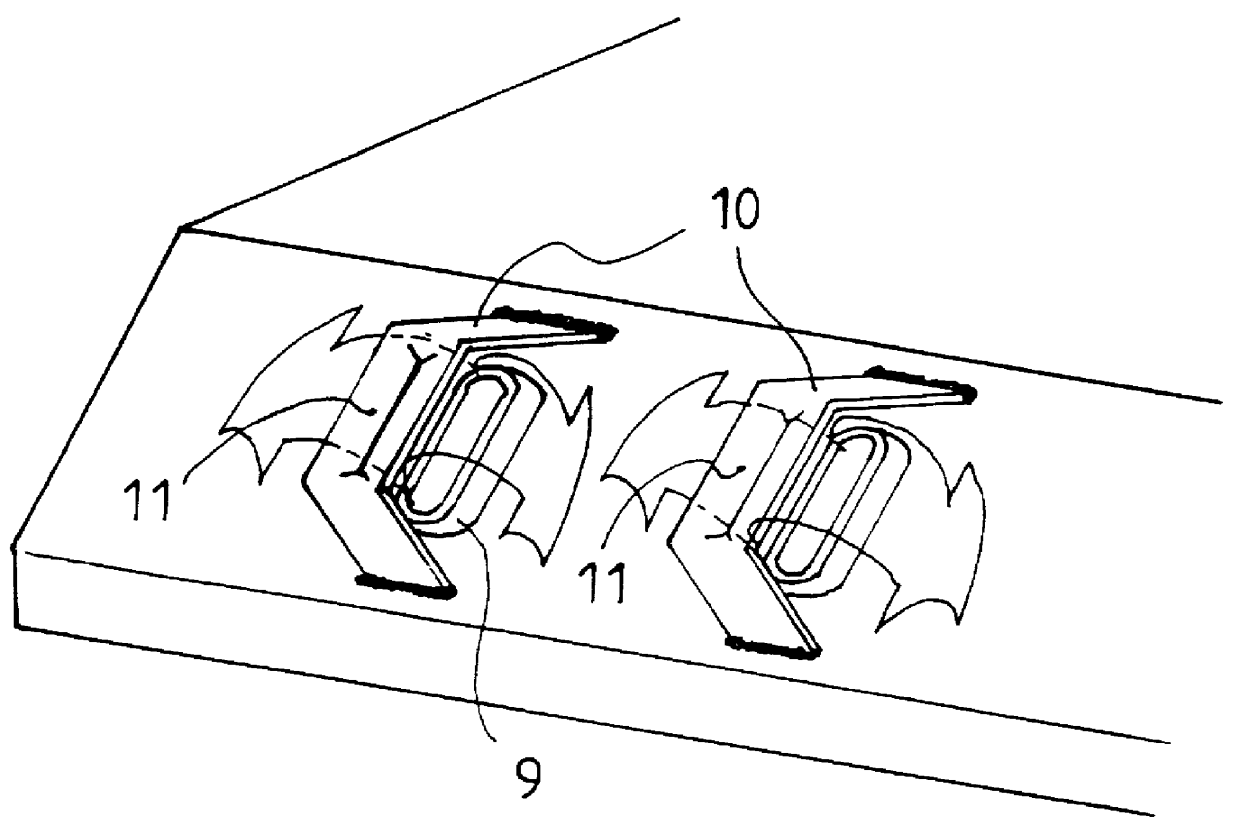

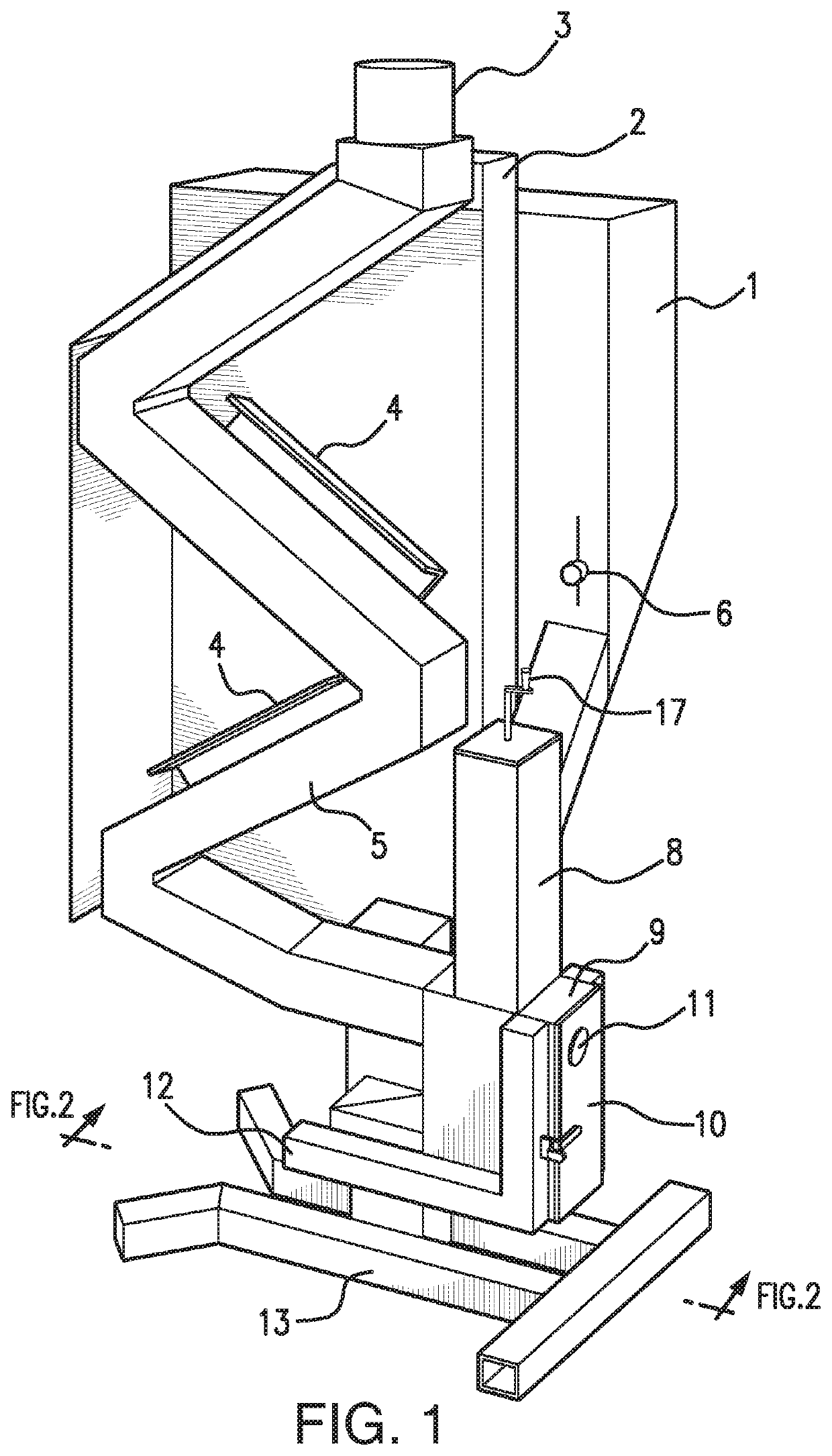

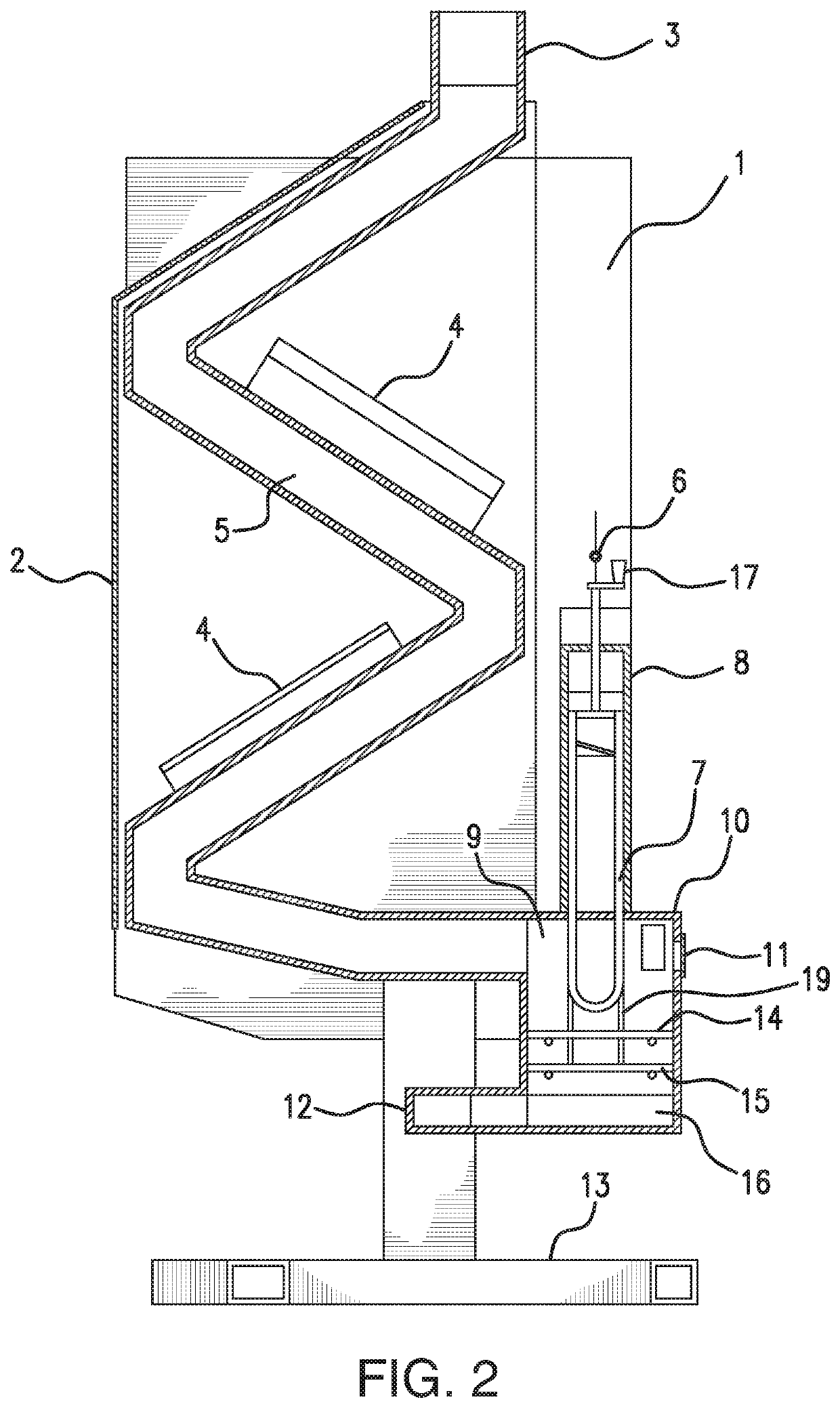

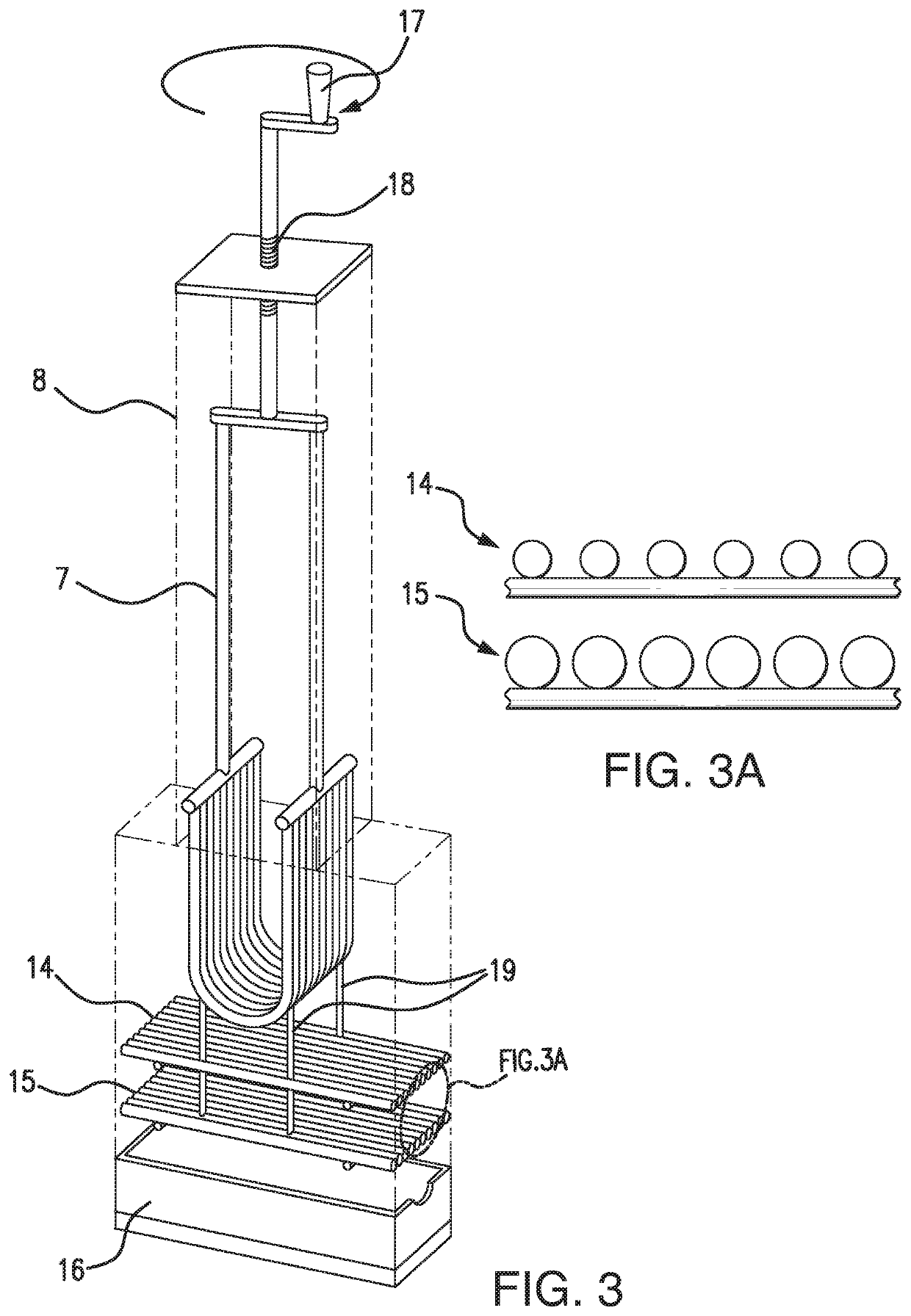

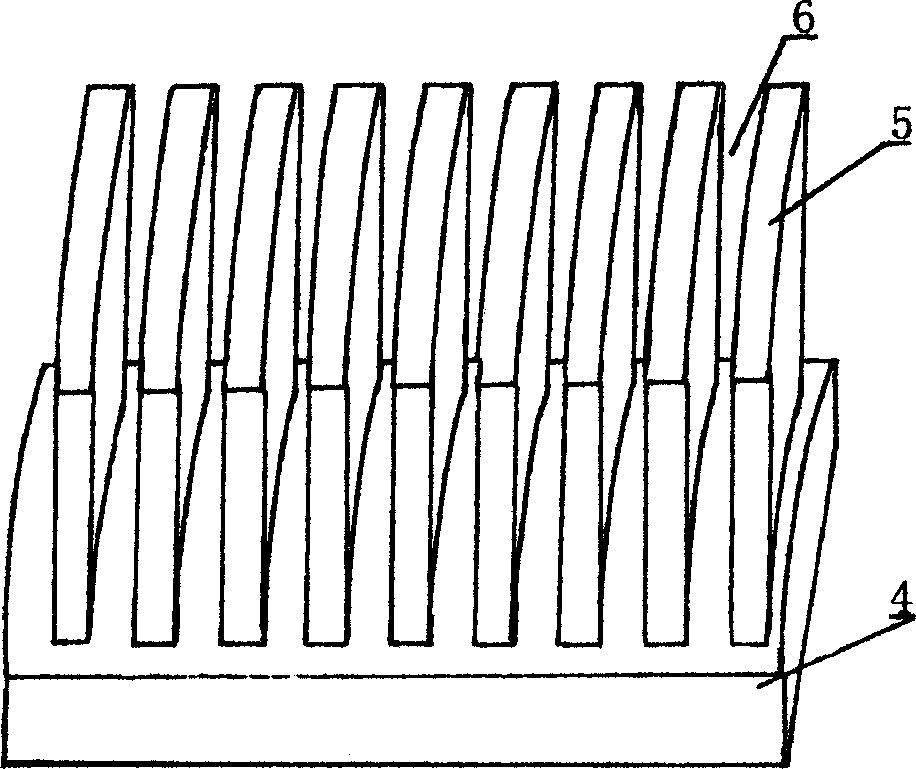

Water-cooled thrust combustion grate

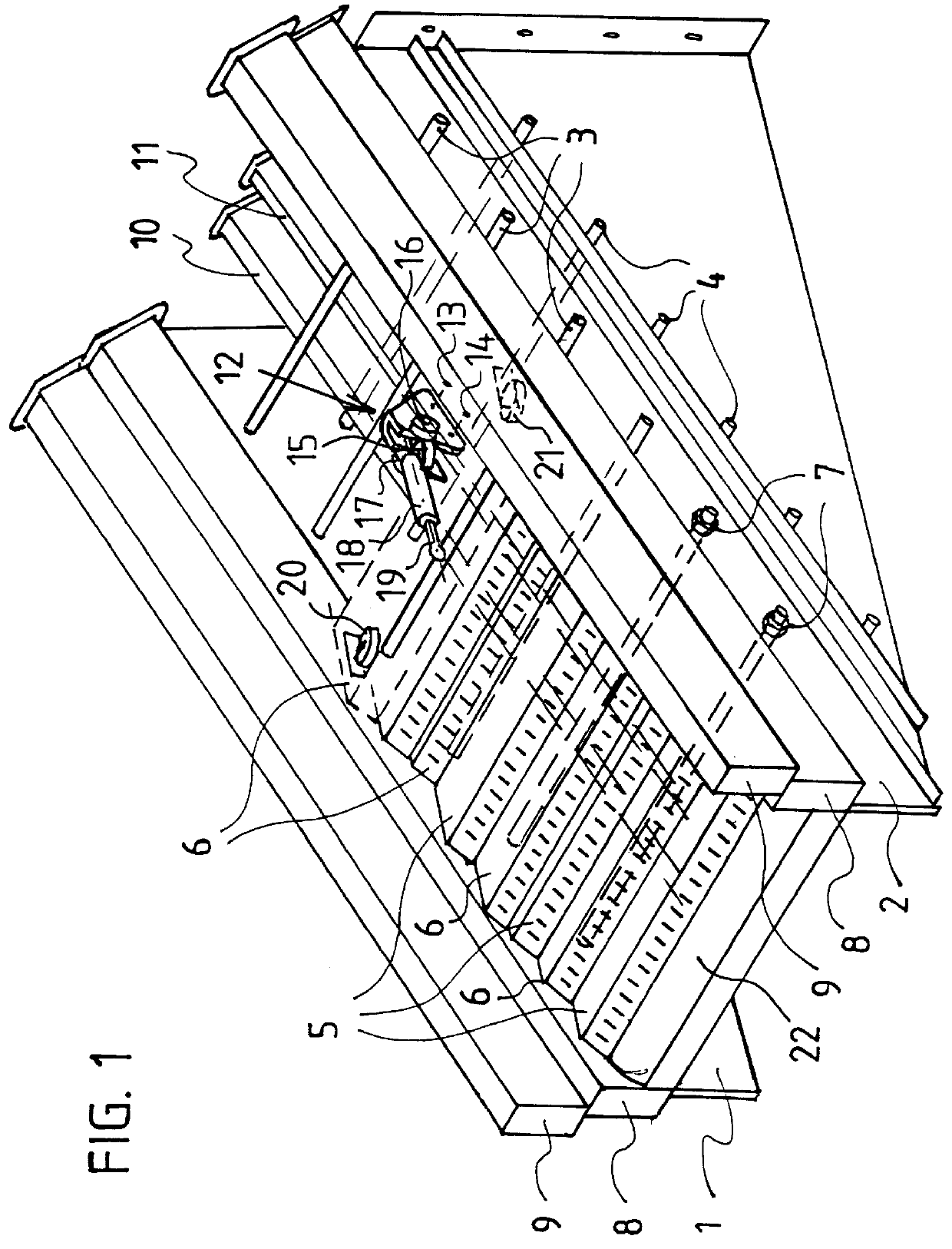

A thrust combustion grate for burning refuse having altemately stationary (5) and movable (6) hollow grate plates (5,6) in a stairway formation, that rest on each other with their front underedge. The grate plates extend across the entire width of the grateway. The movable grate plates (6) are each driven by a hydraulic cylinder-piston unit (18,19). To the sides, the grateway is limited by panels of water-cooled conduits (8,9), which, in the longitudinal direction, each consist of at least two sections sealingly flanged together. The panels are rigidly screwed to each other by a plurality of horizontally disposed distancing bars (3,4) running perpendicular thereto. Running between the panels are two additional conduits (10,11) flanged together in the same way, for feeding primary air and cooling water, which are fixed to certain individual distancing bars (3,4). The back sides of the stationary grate plates (5) each rest on one distancing bar (3) while the back sides of the movable grate plates (6) rest on at least one steel roller (16,17) with a horizontal axis, with each side of their front sides being guided along a steel roller (20,21) whose axis runs perpendicular to the grate plate (6). The front portions of the grate plates (6) form by primary air slots (25).

Owner:DOIKOS INVESTIMENTS LTD

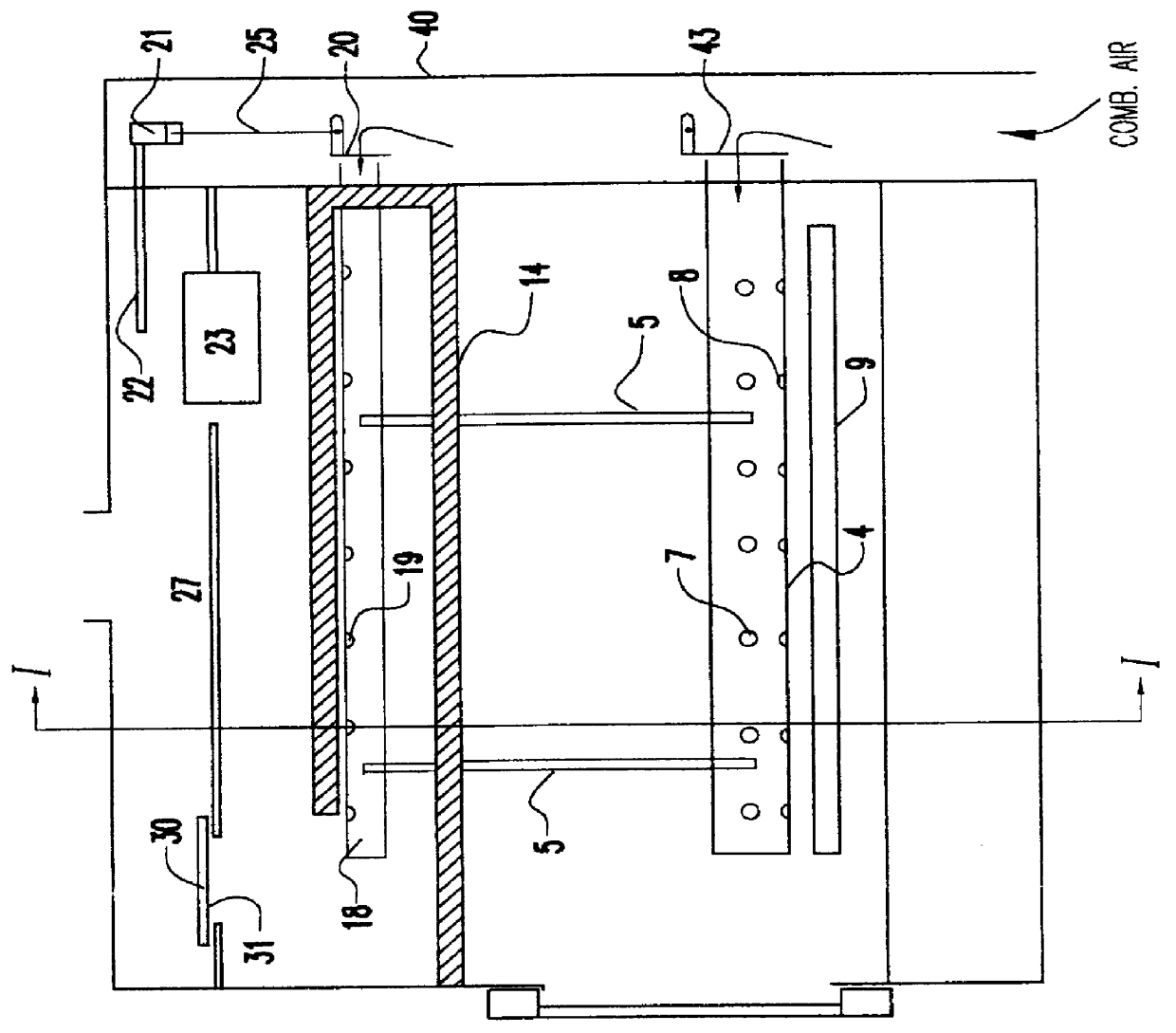

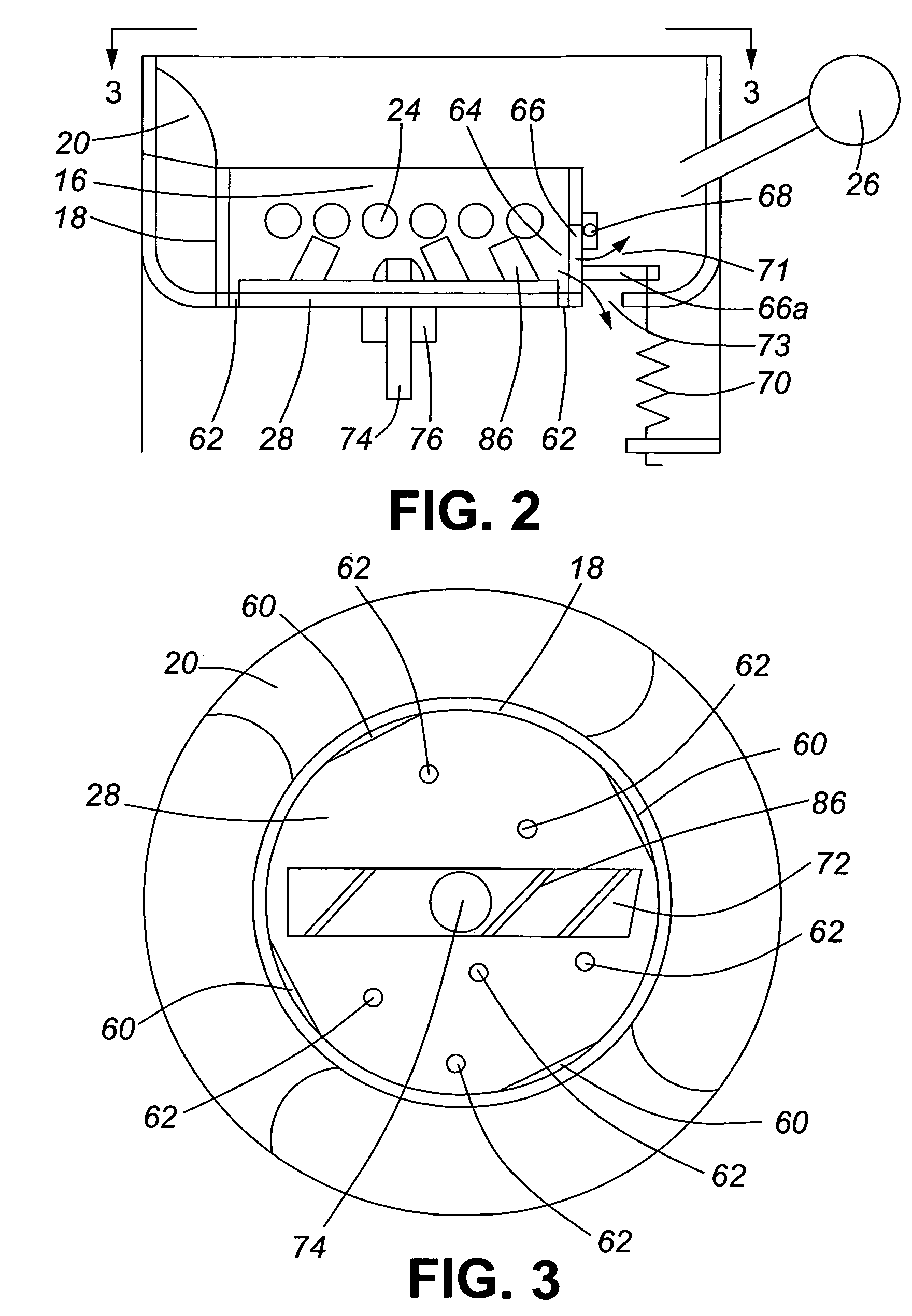

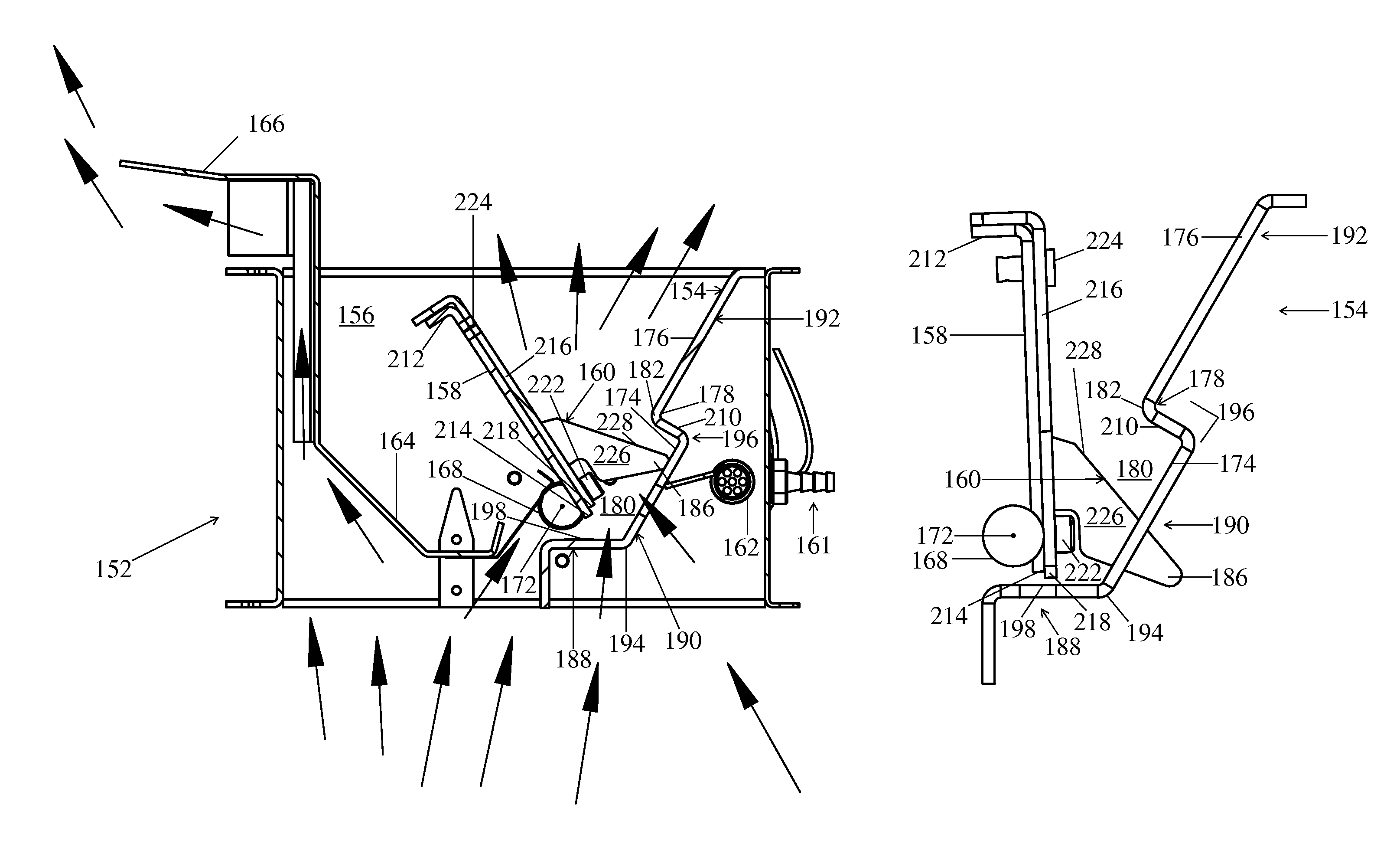

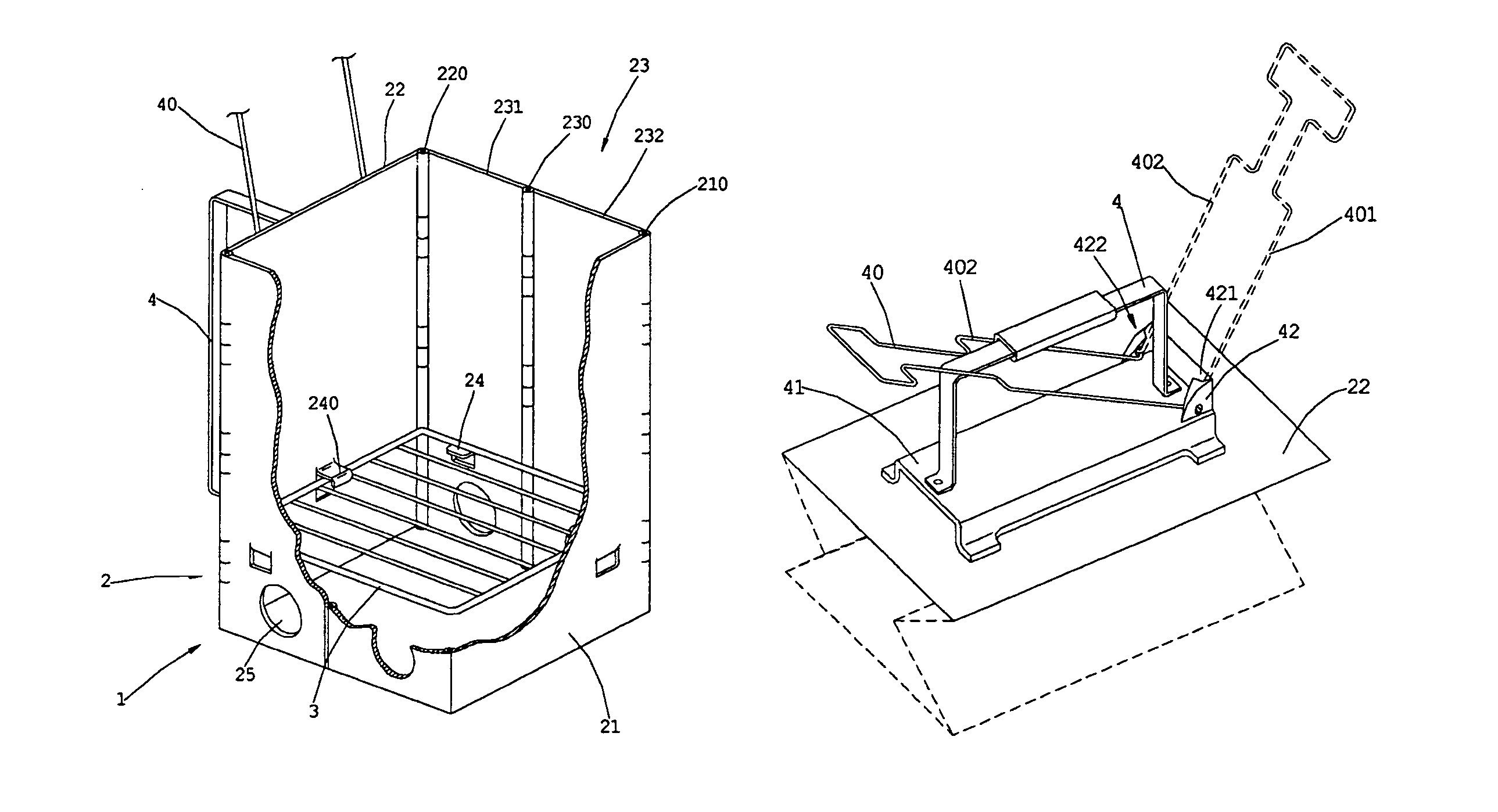

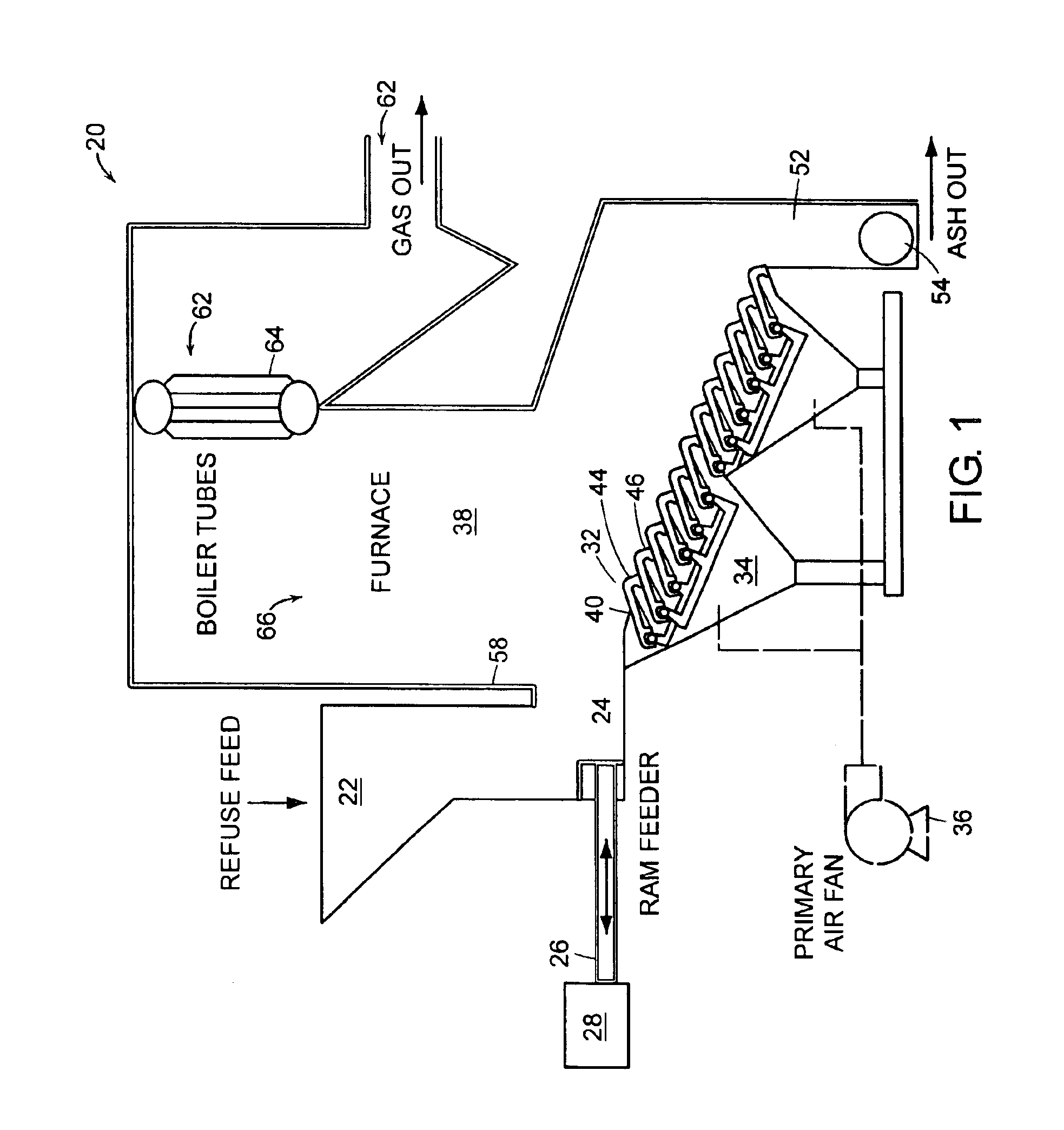

Combustion system

InactiveUS6067979AAvoid quenchingIncrease gasification rateSolid bar grateCombustion-air/flue-gas circulation for stovesCombustion systemCombustion chamber

A combustion system includes a primary combustion chamber divided into left and right sides by fuel-retaining standards defining a canyon or void extending into a secondary combustion chamber is provided. The floor of the primary combustion chamber and the fuel-retaining standards direct the burning solid fuel toward the lower part of the canyon, while at the same time retaining the non-burning solid fuel on either side of the fuel-retaining standards. The combustion system further includes an air delivery system having a lower air tube supplying high and low velocity air and an upper air tube. The lower air tube is positioned proximate to a firebox floor, while the upper air tube is positioned within the secondary chamber. Automatic air setting mechanisms are provided so that proper air settings can be maintained during various phases of a fire. The combustion system further includes a loading door having openings and a bypass system preventing the loading door from being fully closed unless the bypass is in the completely closed position. The secondary combustion chamber includes at least fuel protecting baffles and a secondary combustion chamber ceiling which extends partially over the entire length of the secondary combustion chamber or includes openings. A catalyst mounting system which minimizes canning and masking and a radiant catalyst heating system are also provided.

Owner:JAASMA DENNIS R

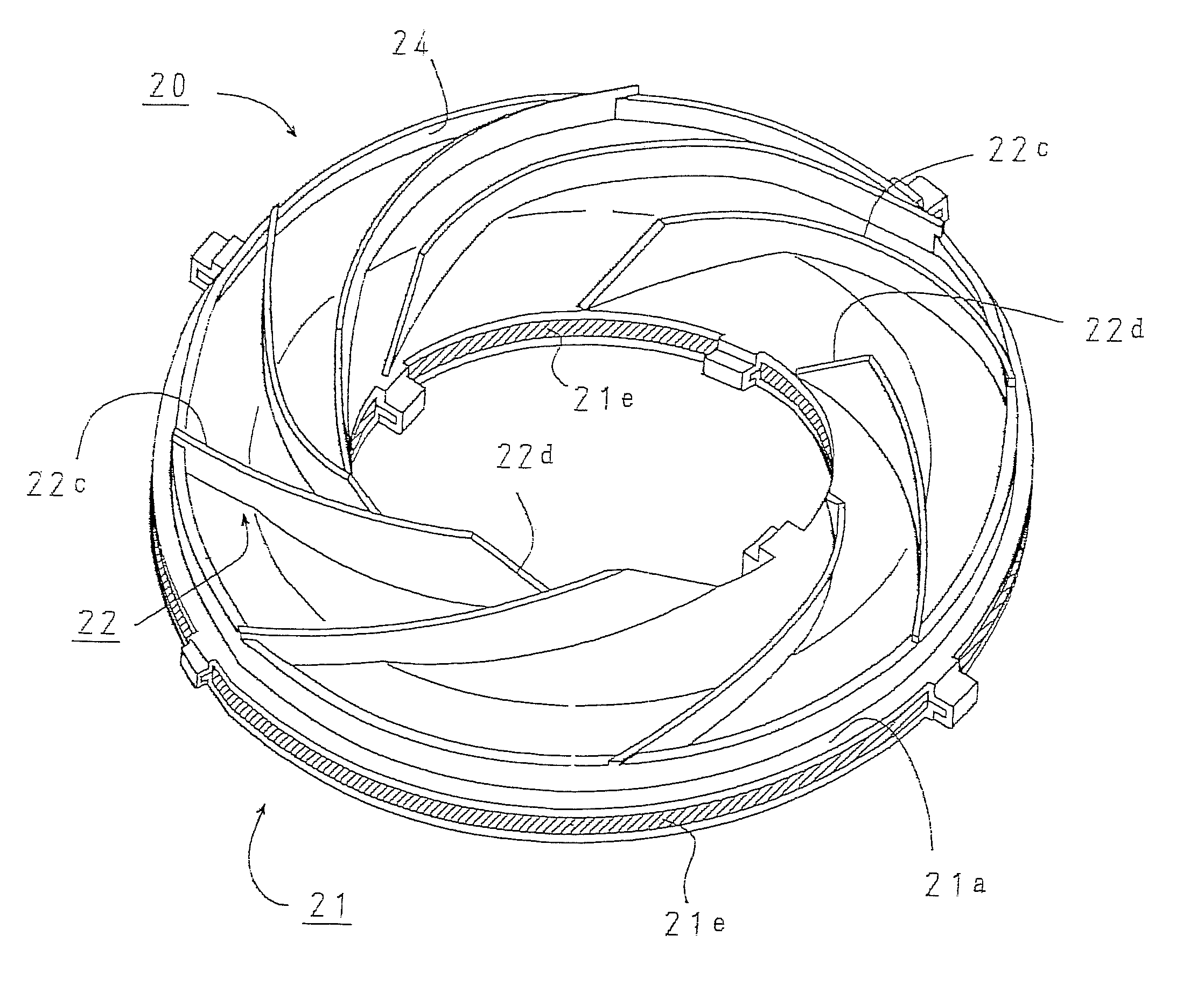

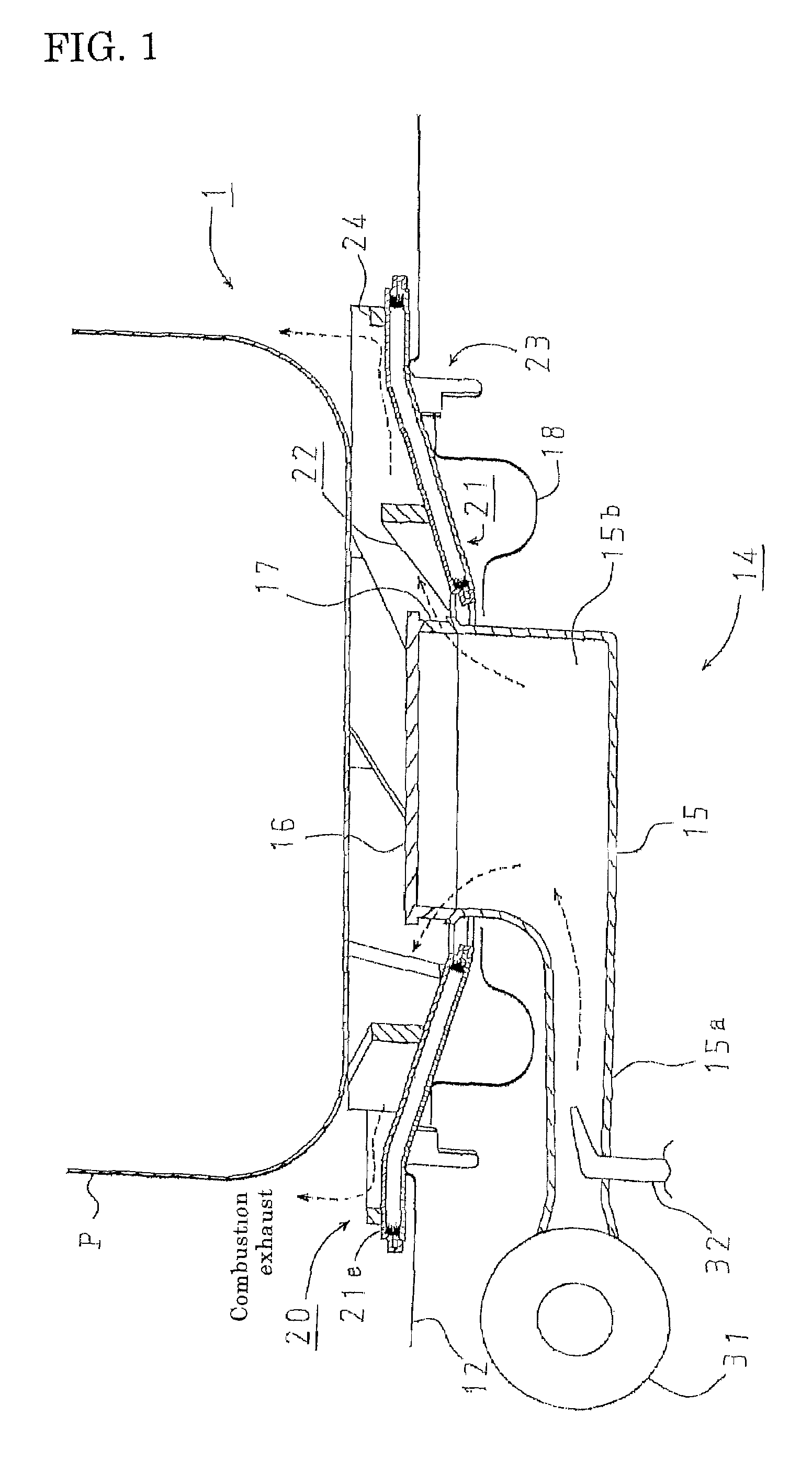

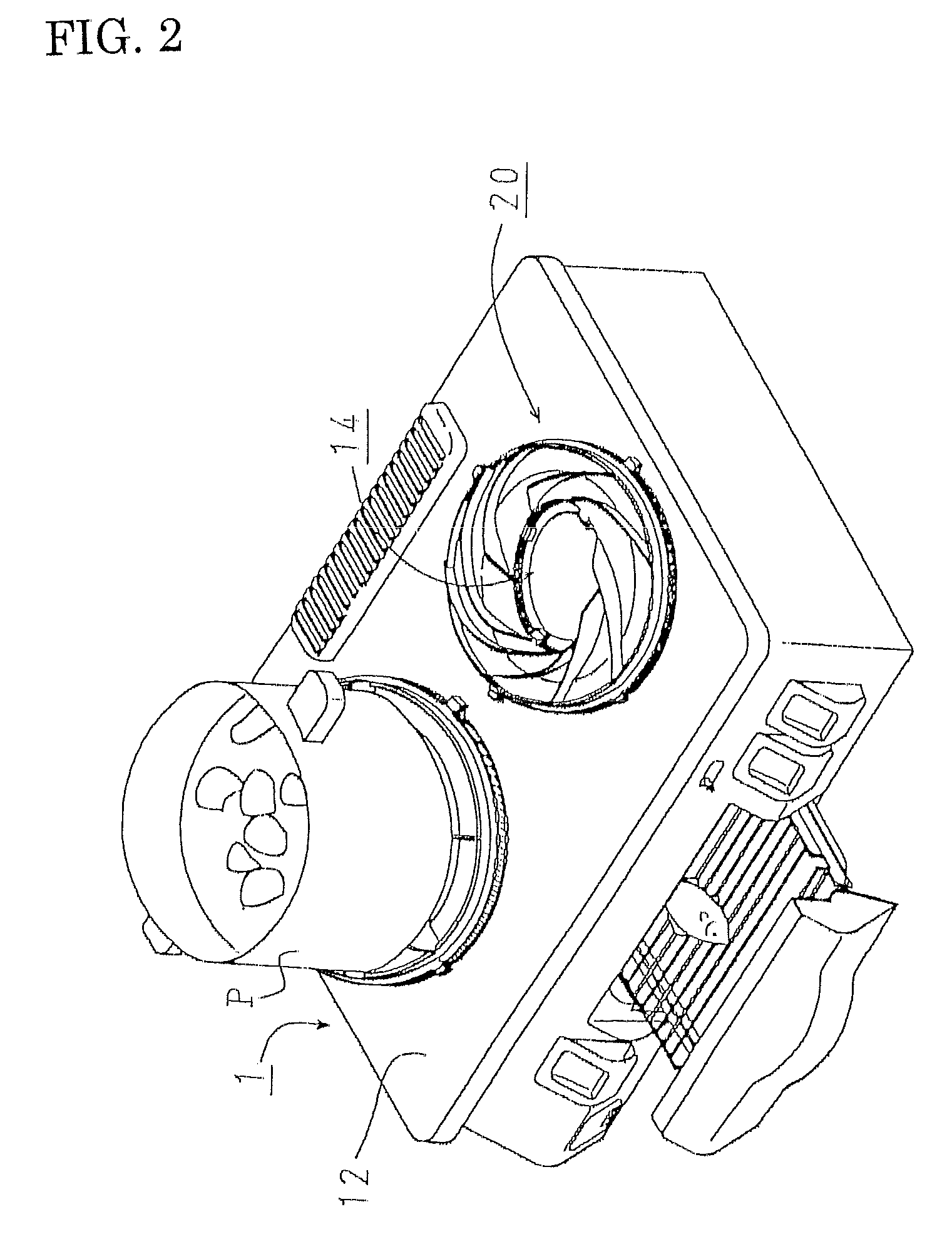

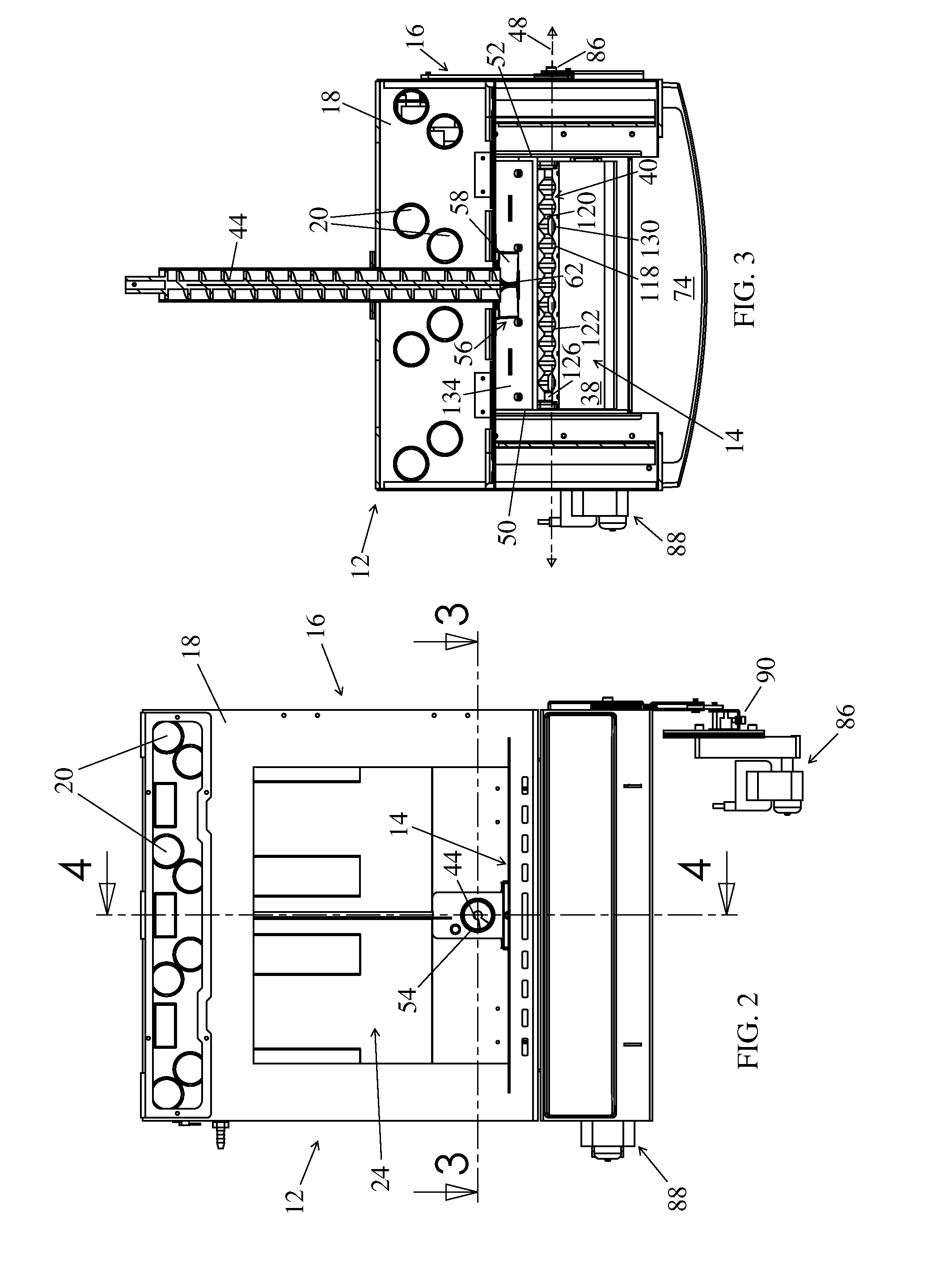

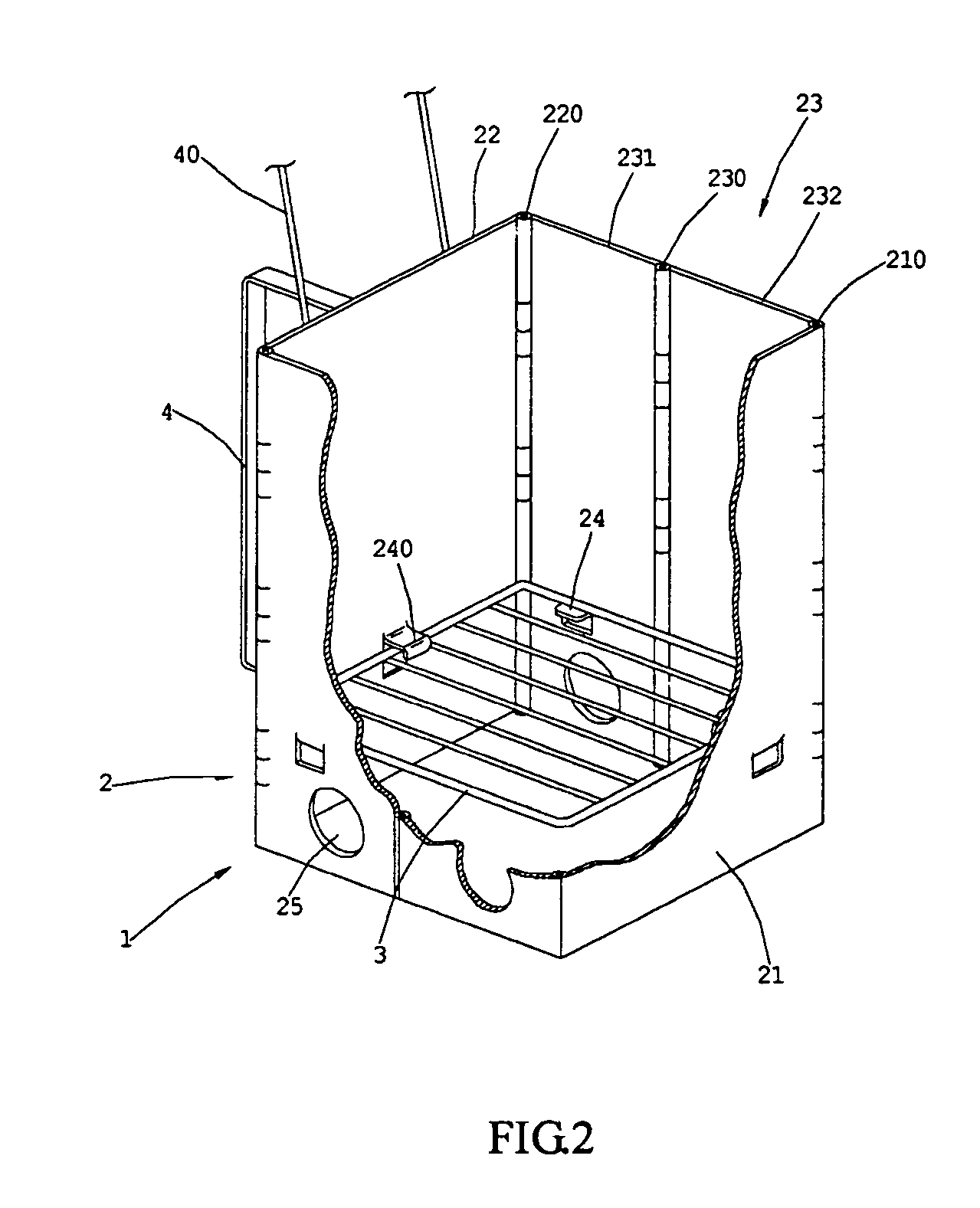

Cooking stove

InactiveUS7721727B2Improve heating efficiencyAvoid environmentDomestic stoves or rangesSolid bar grateCombustorHeat transmission

According to a gas table 1, combustion gas (including the flame) is jetted from a flame port 17 of a burner 14 diagonally upward entirely twisted in the burner circumferential direction. The combustion gas flows into plural combustion gas routes sectioned into spiral shape, and hits trivet claws 22, and goes through. That is, the combustion gas is guided in spiral shape by the trivet claws 22, and exhausted along a cooking container P bottom surface toward the outer circumferential direction. As a result, in the combustion gas route, the combustion gas is always subject to direction changing force and the flow thereof is disturbed, and accordingly, a heat transmission border film is unlikely to be formed on the cooking container P bottom surface, and the heat of the combustion gas is transmitted to the bottom surface of the cooking container P preferably.

Owner:PALOMA IND LTD

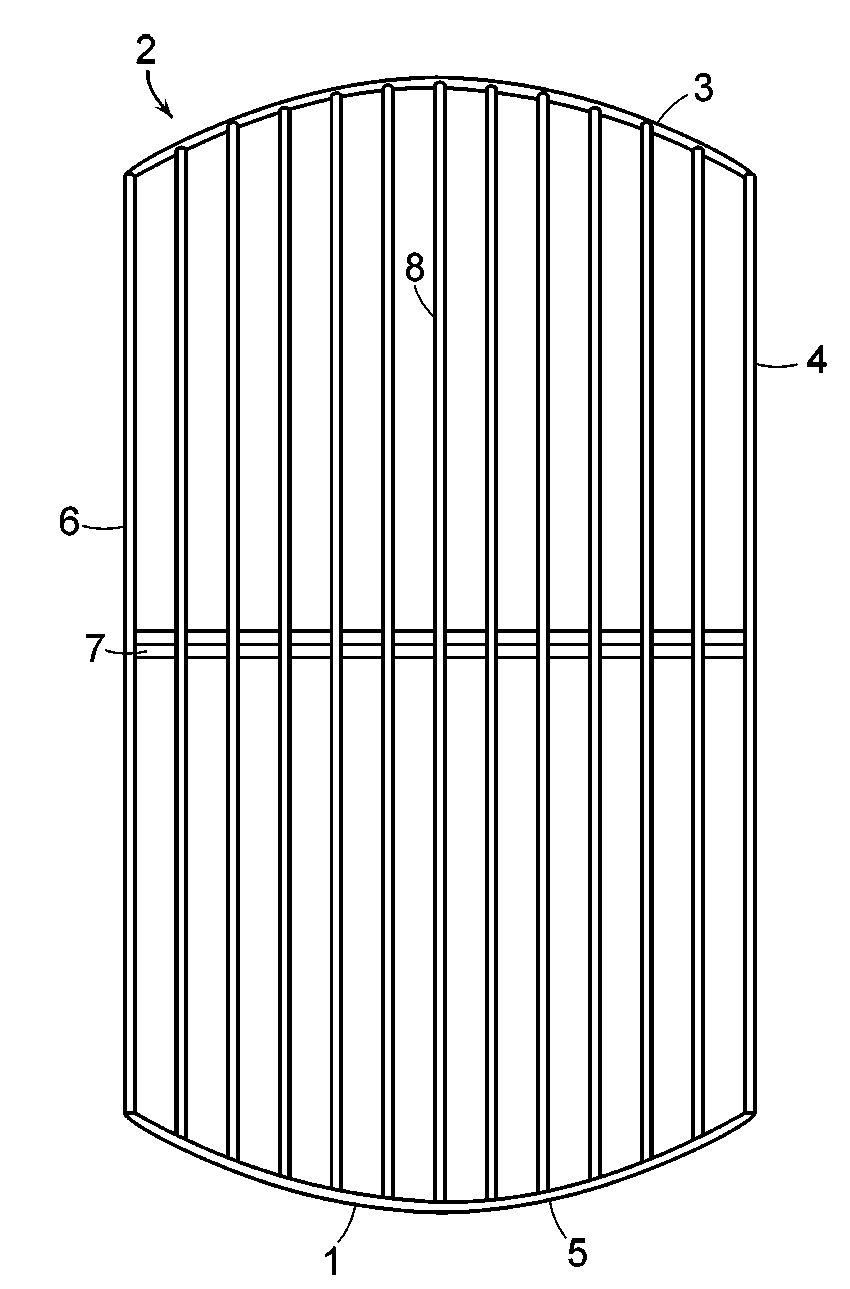

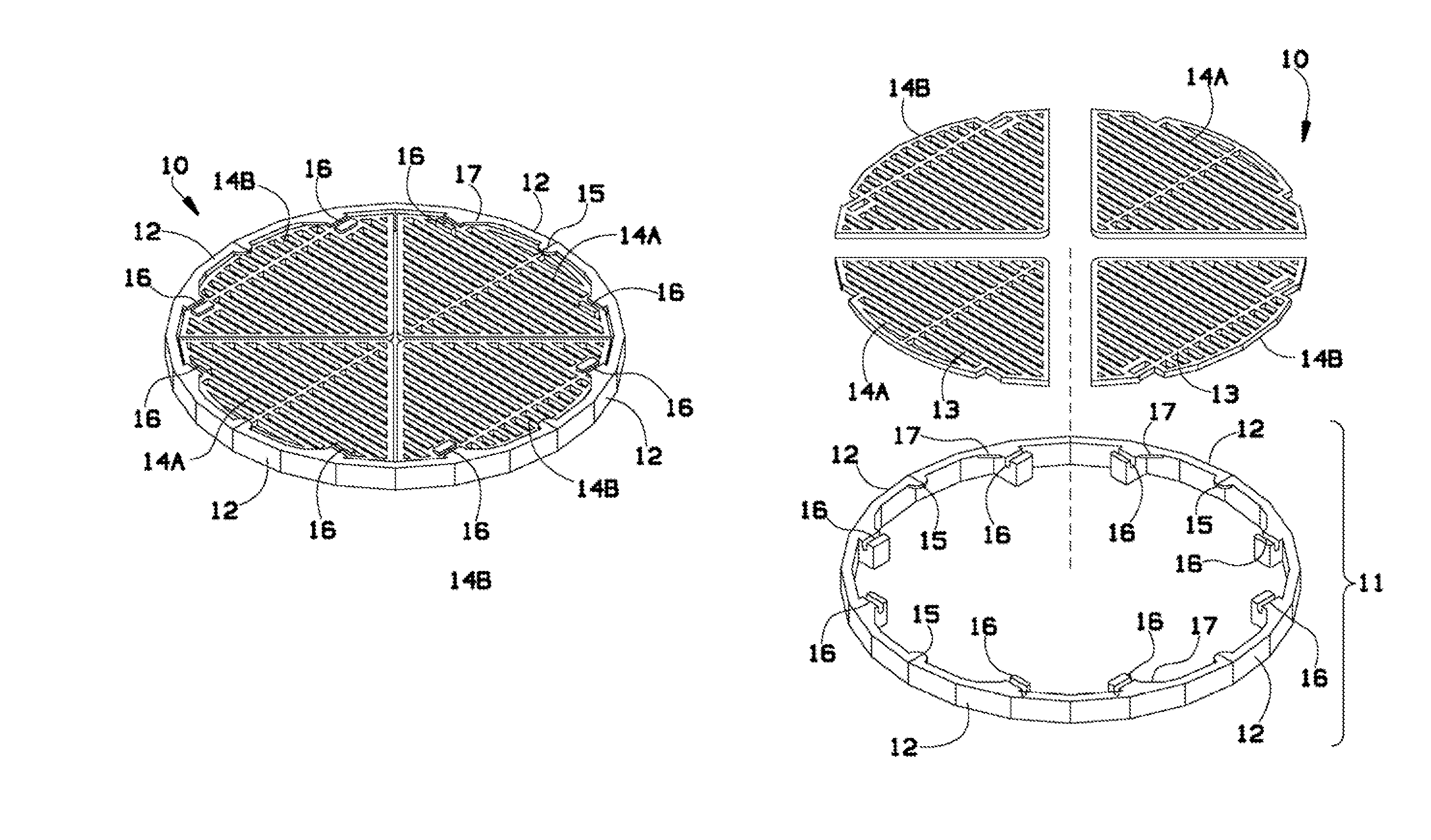

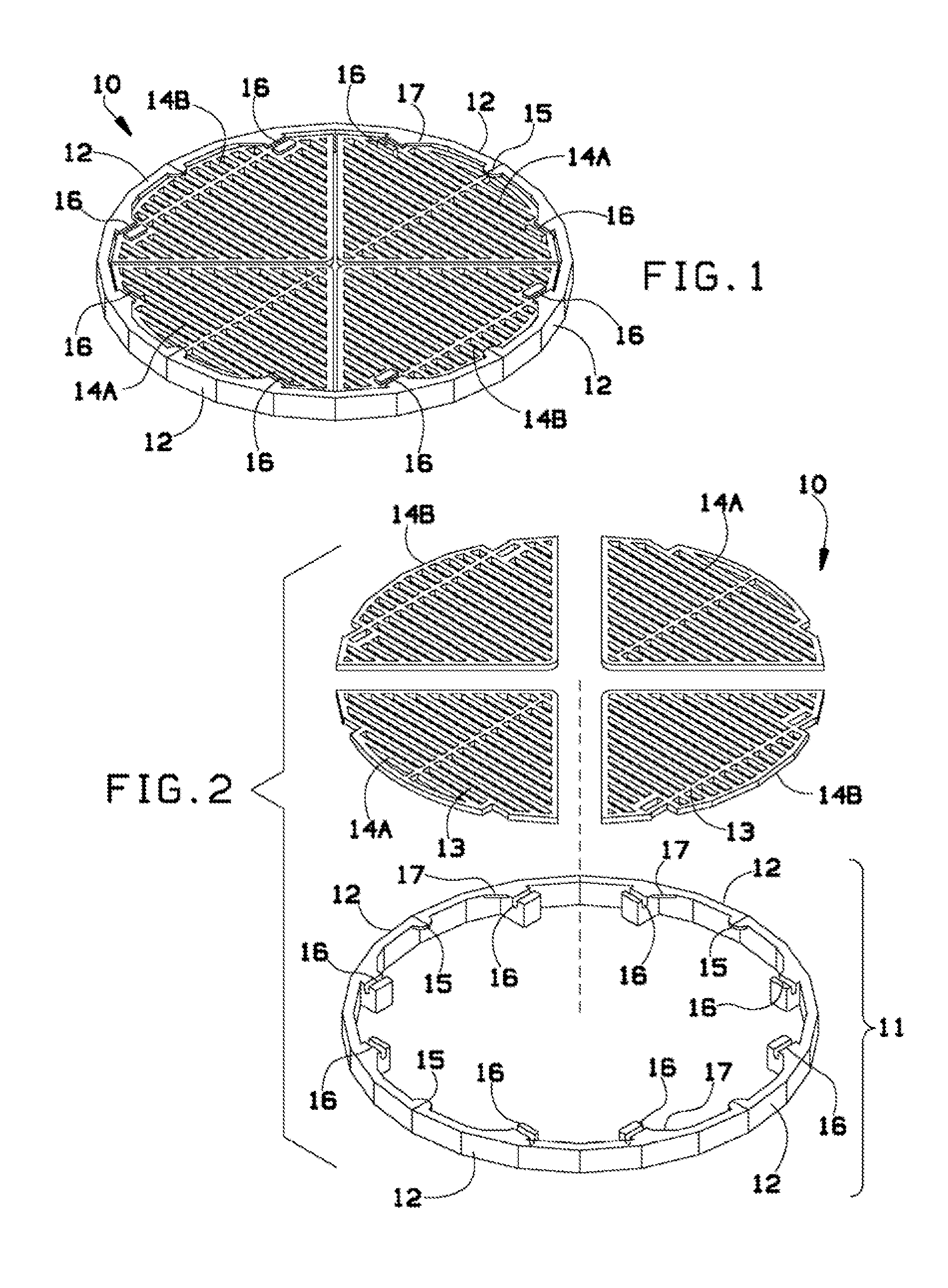

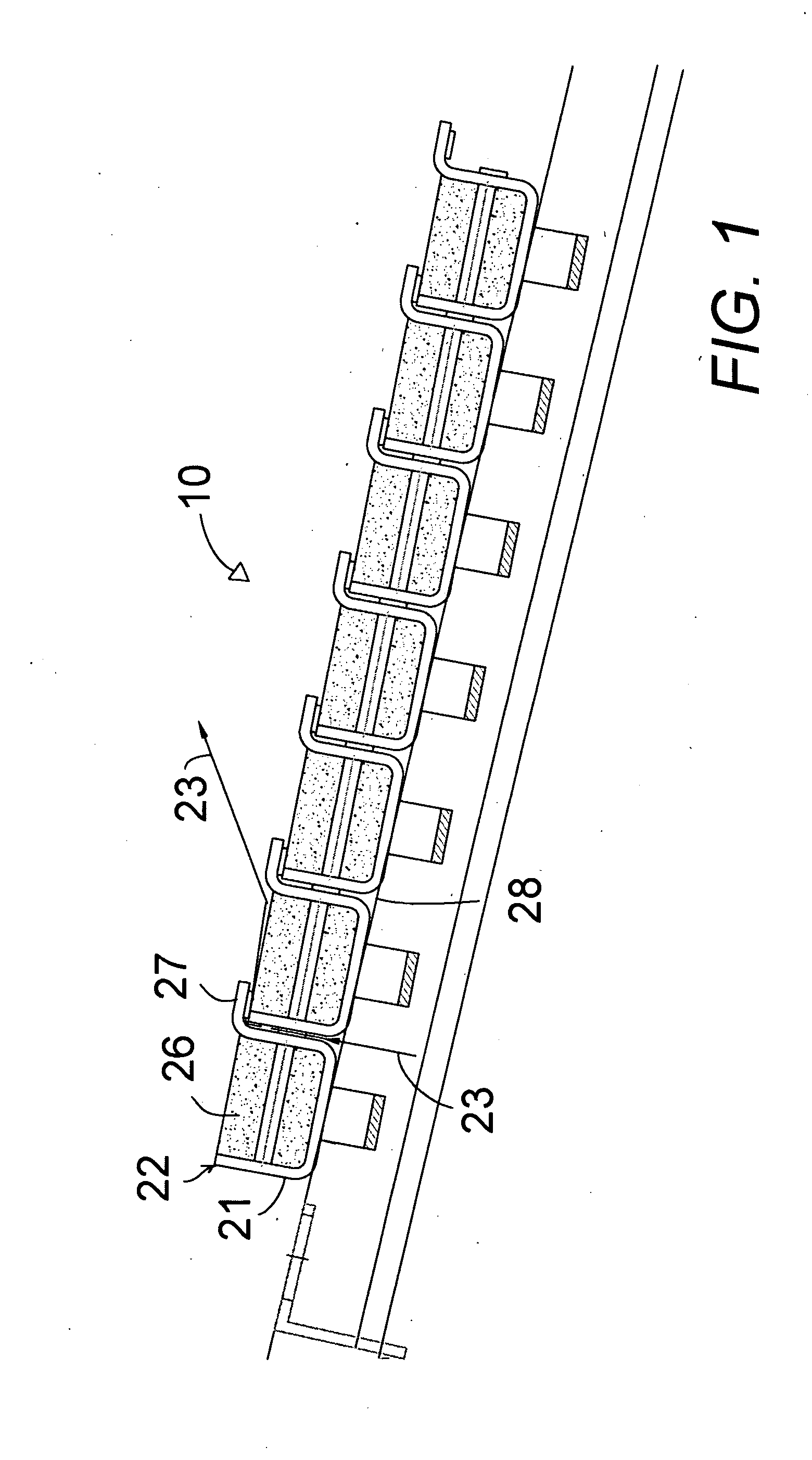

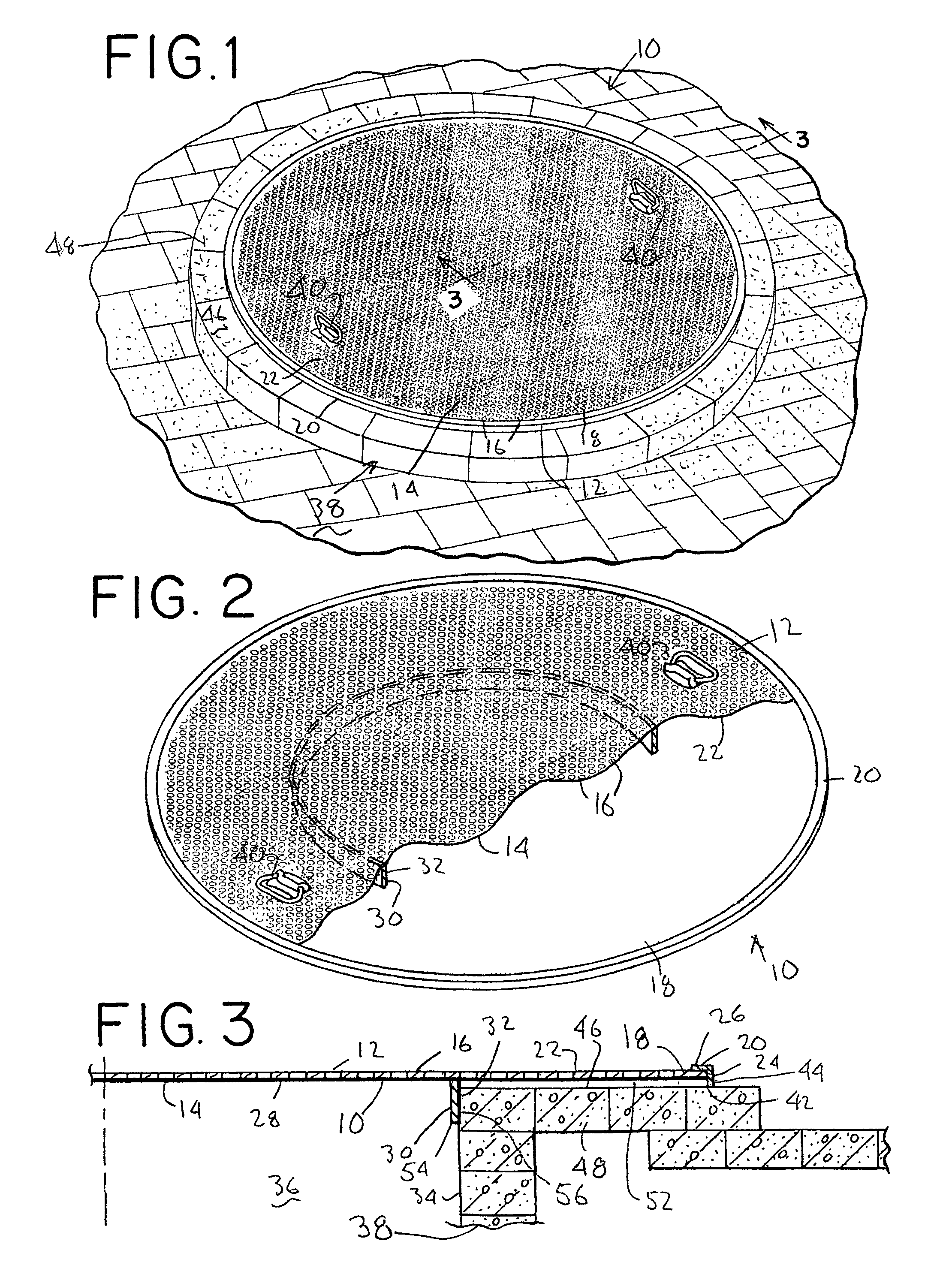

Multi-Sectioned Replacement Grill Grate Section

InactiveUS20090064872A1Easy to cleanSolid bar grateMetal working apparatusSupporting systemEngineering

A grill grate replacement system that has multiple, separately attachable grill grate sections. These grill grates are designed so that when all grill grates are used with one another they utilize the entire grilling area of the grill for which they are intended, while giving grillers easy access to the fuel source by allowing removal of only selected sections of the grill grate system. The system uses a material that provides strength and rigidity, such as cast-iron, and a coating material, such as porcelain, that protects against weathering and provides a non-stick surface. Support systems for this replacement grill grate system conform to the shape of the grill for which they are intended for use, and are made of a rigid material for strength, such as stainless steel.

Owner:ZISSERSON KENNETH

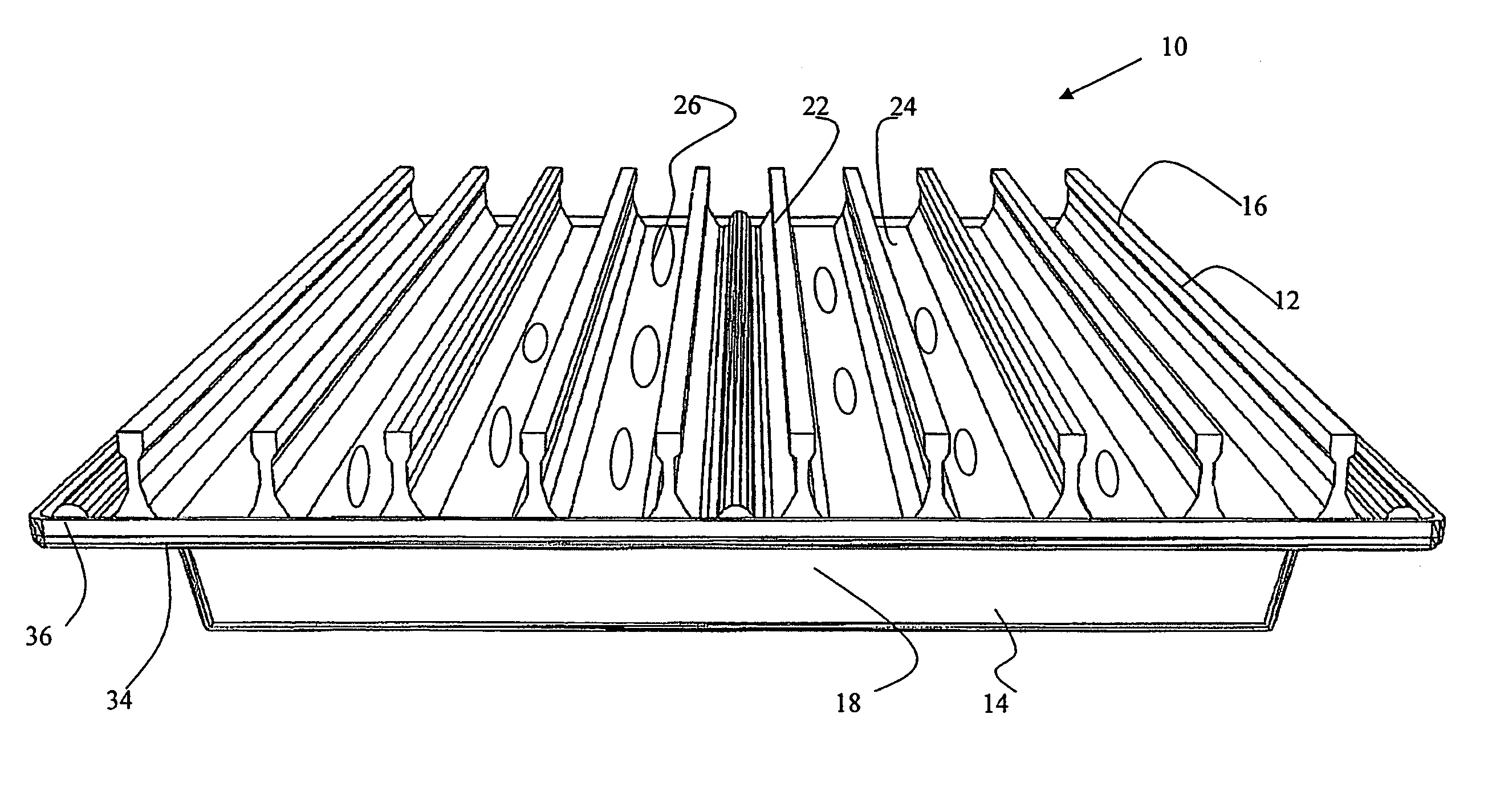

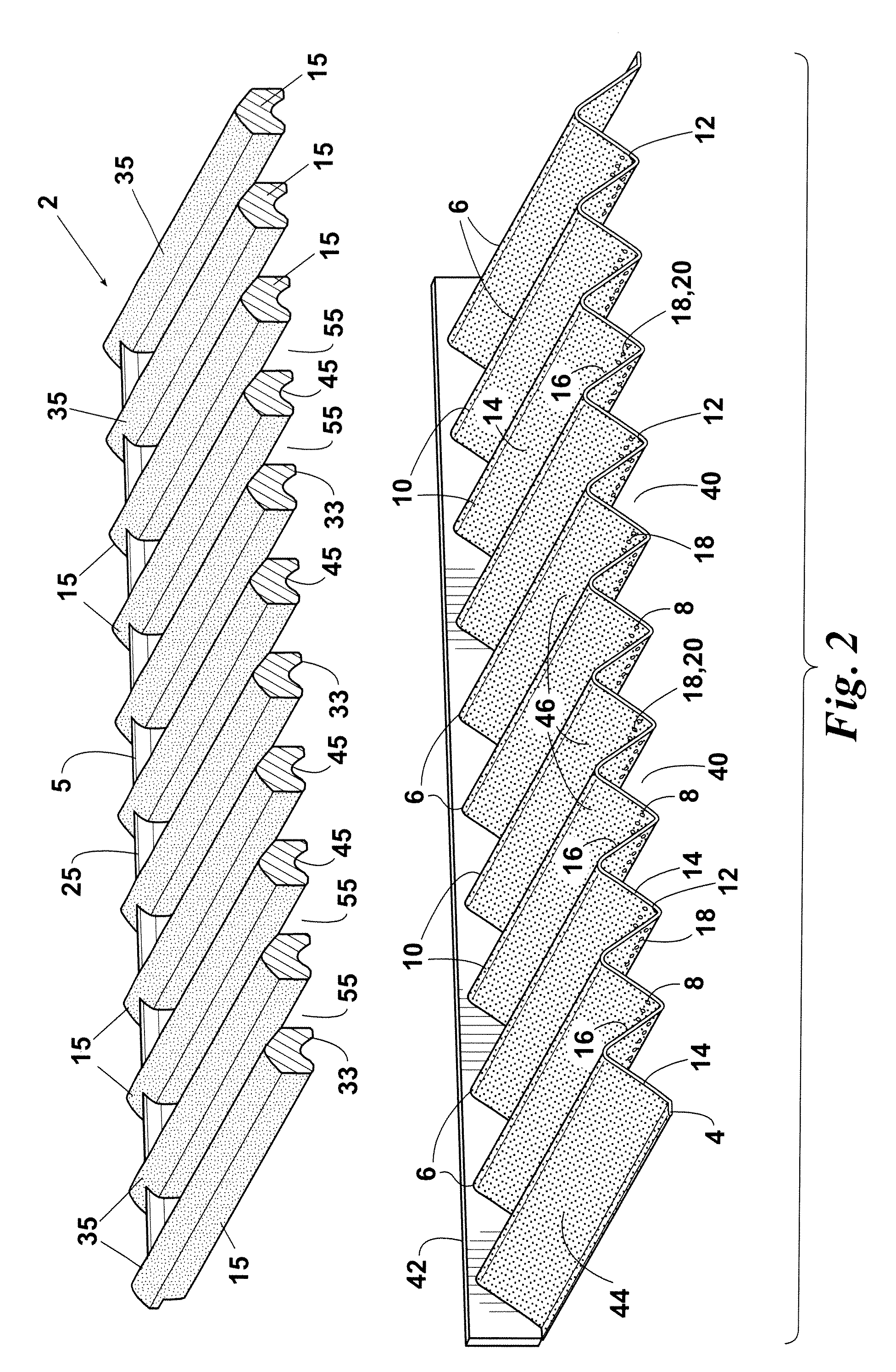

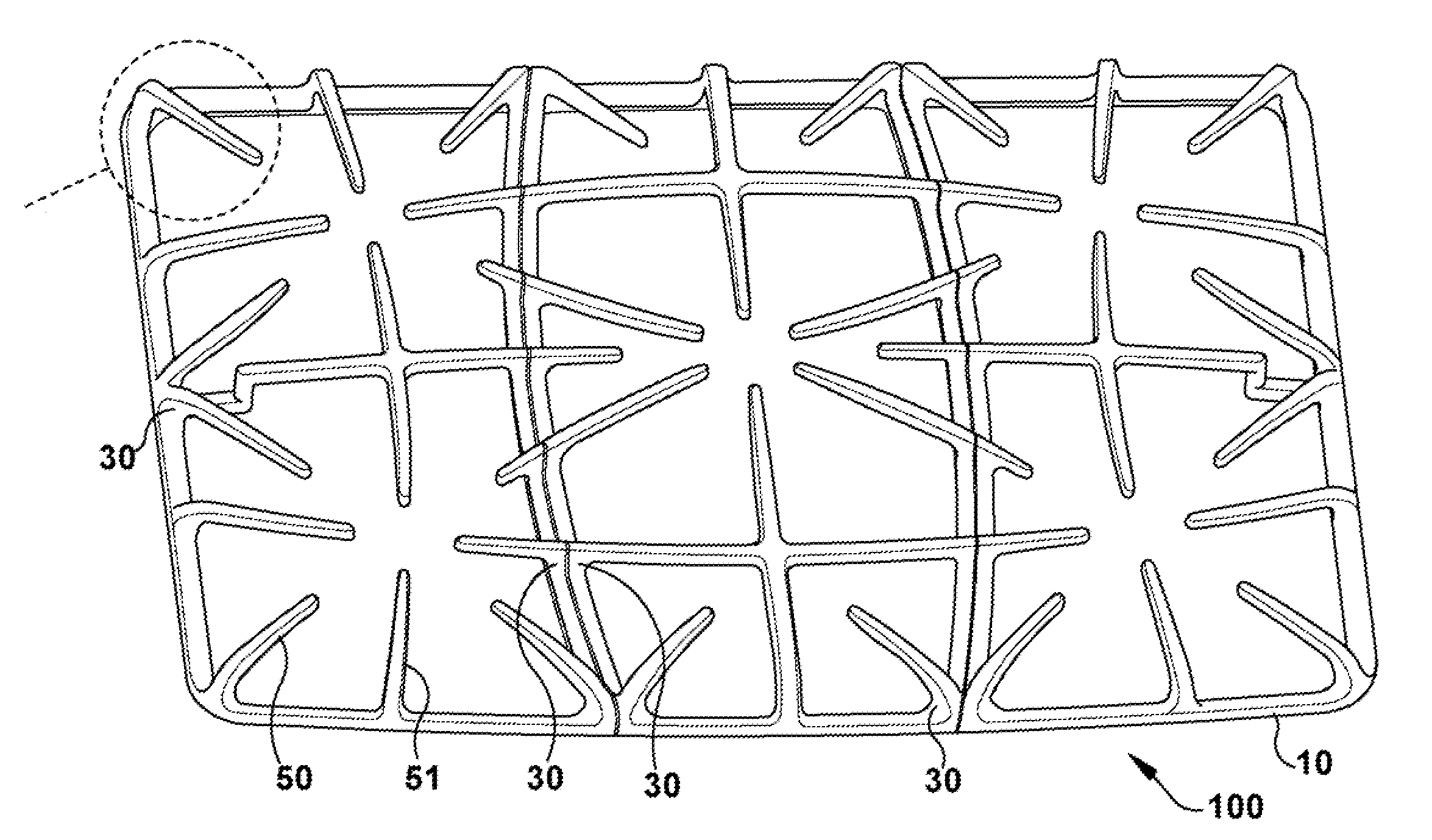

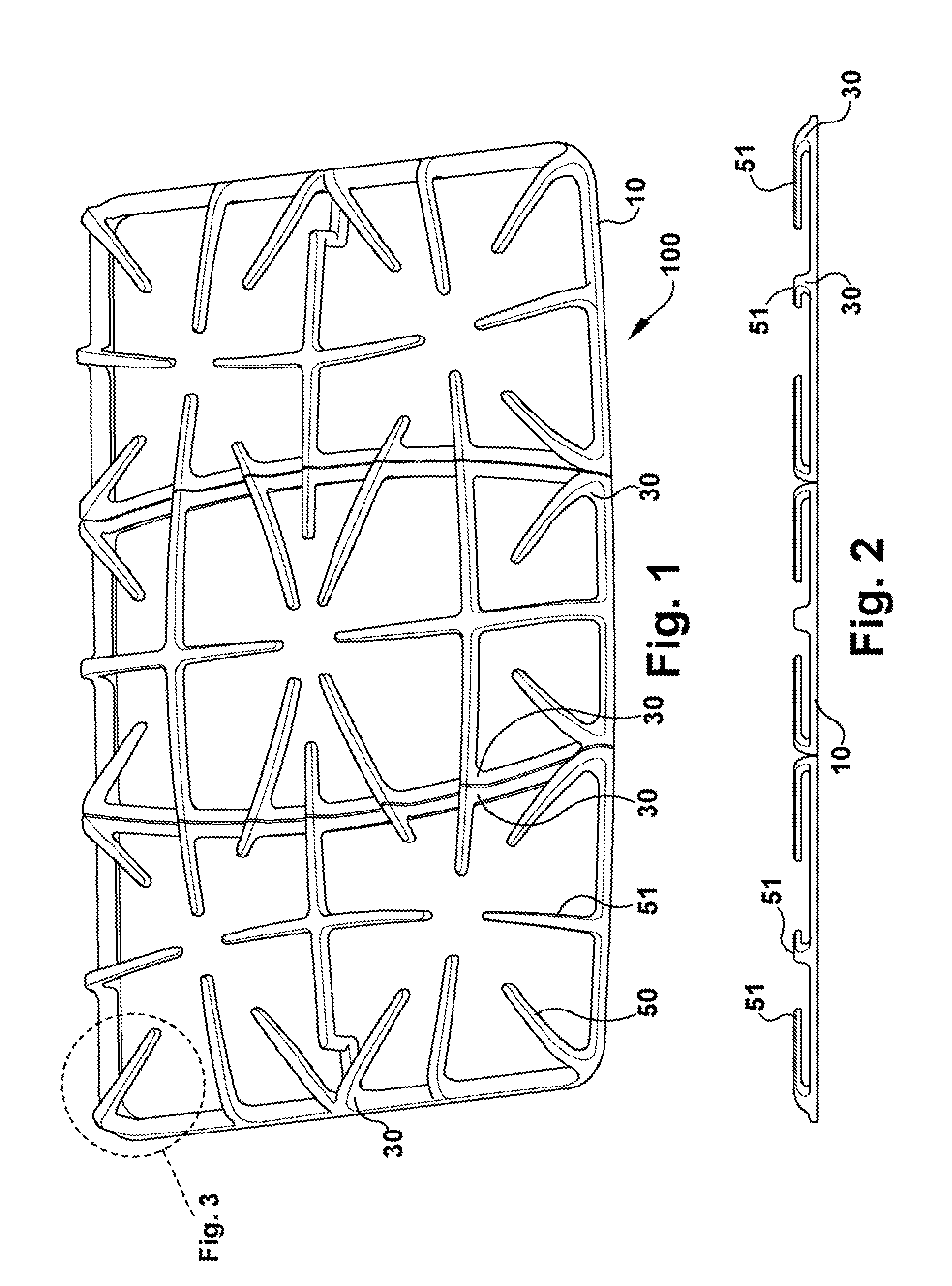

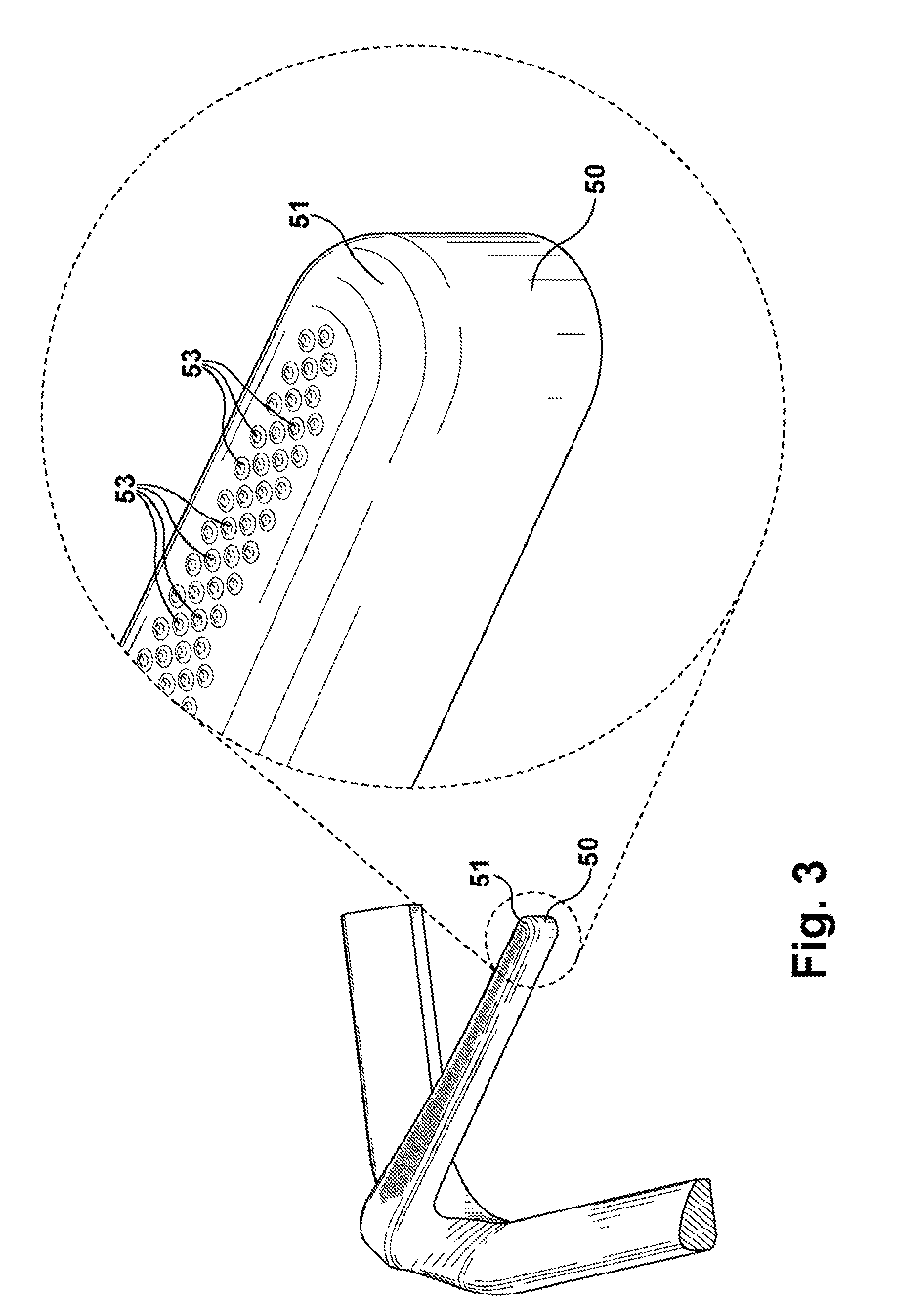

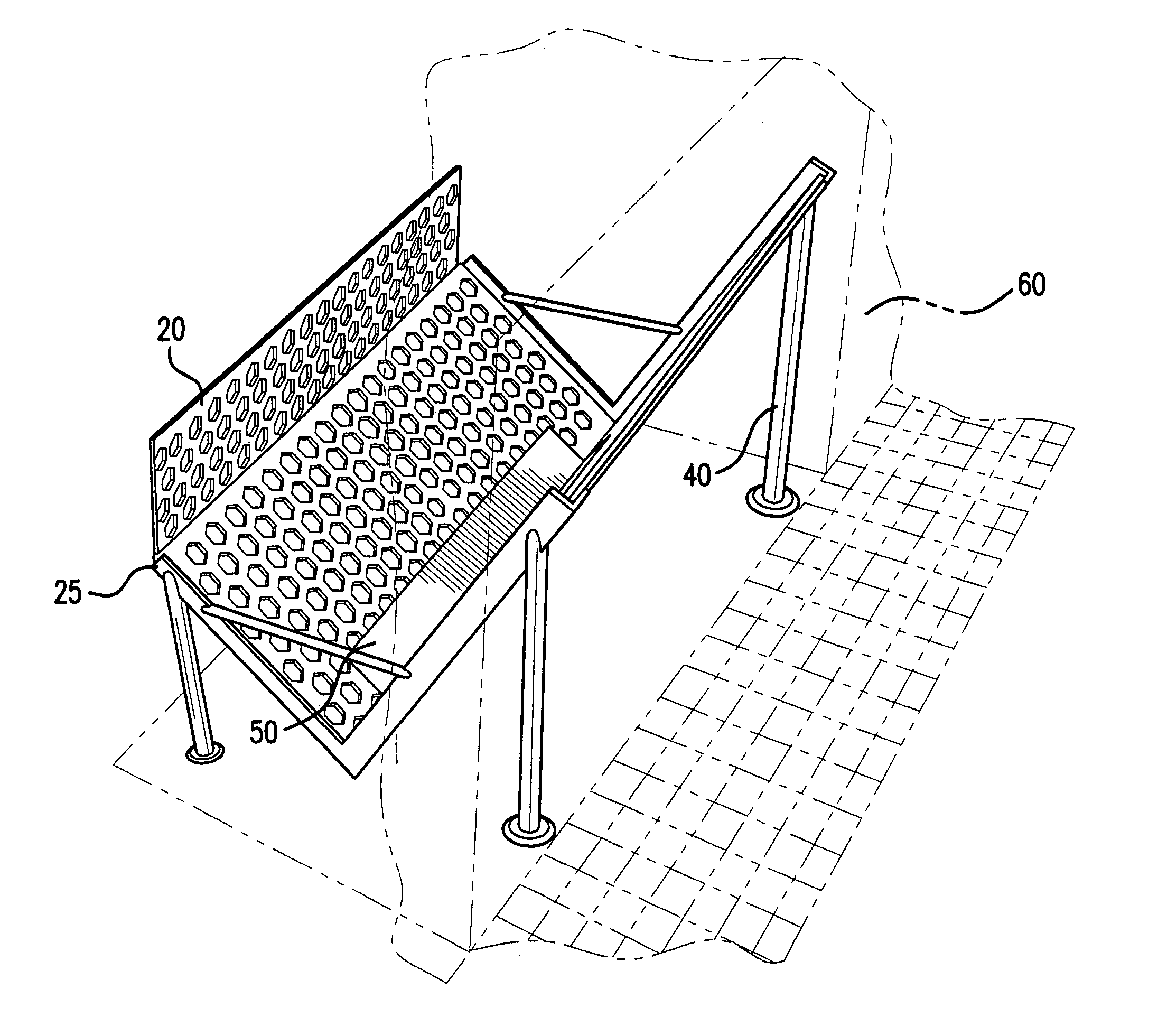

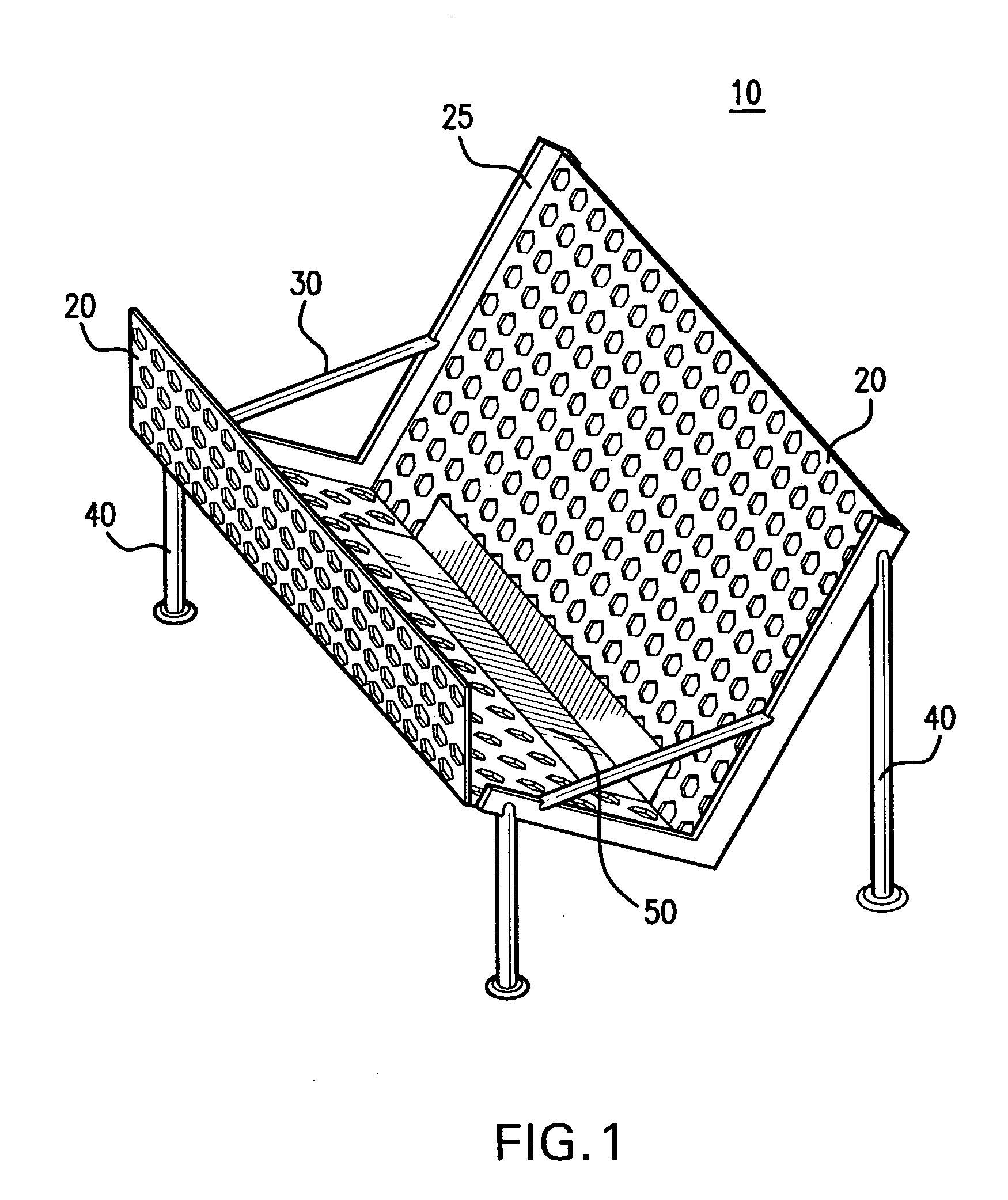

System and device for grilling foods

A system of modular, interlocking, raised-rail grate panels and a complementarily-shaped basin for supporting and peripherally-containing the base of the grate panels while continuing to allow the passage of gasses lengthwise between the raised rails and the passage of gases and liquids through the base of the grate panels, such that delivery of searing and reflective heat to a cooking food is facilitated, wherein the grate panels and basin are coated with an abrasion-resistant, high-temperature, easy-to-clean, non-stick coating for ease of use, and wherein accessory features such as integrated, stylized food branding irons and raised-rail adaptive cooking tools are optionally provided.

Owner:AHV HLDG LLC

Burner for combustion of fuel in pellet or granular form

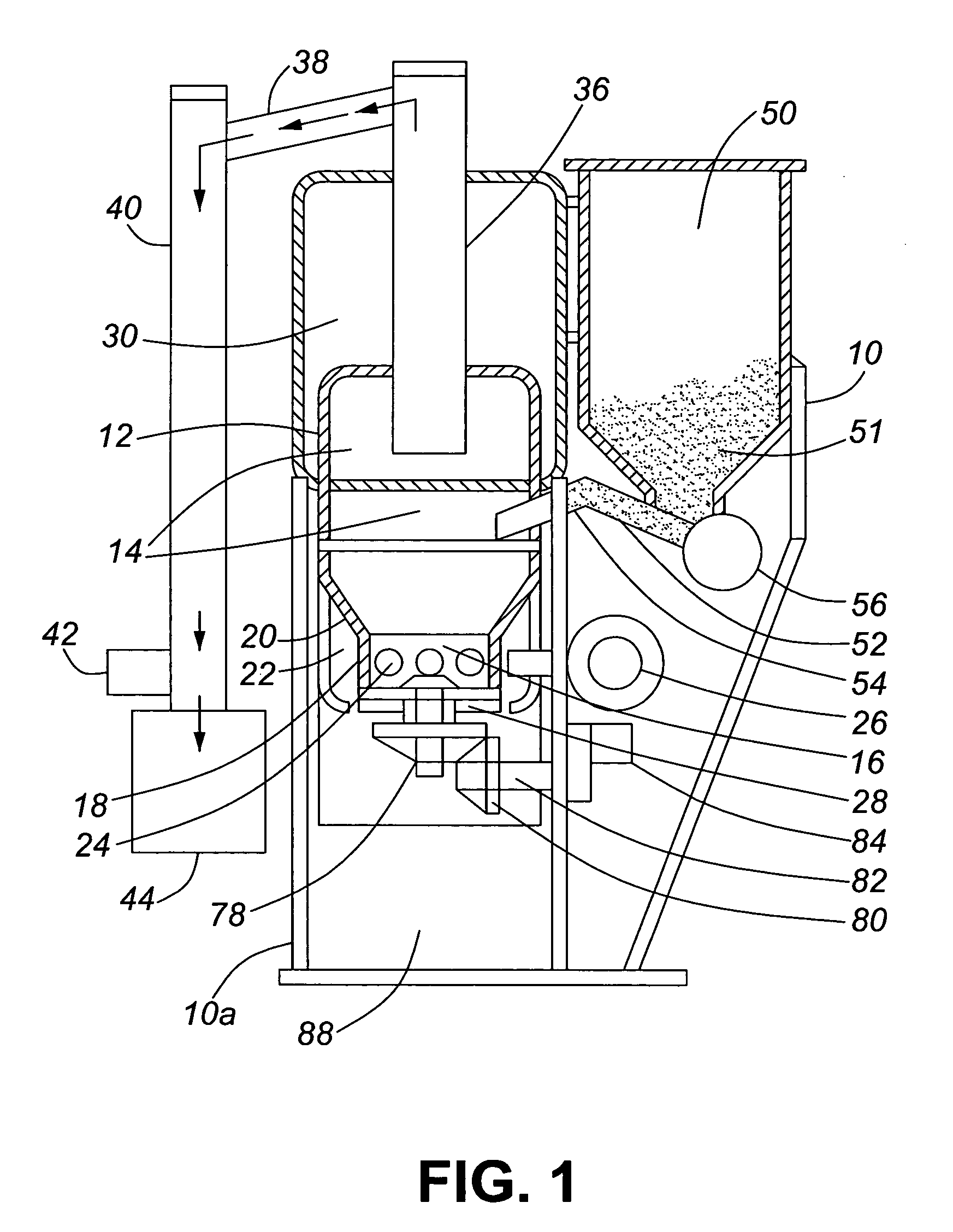

A burner for fuel in pellet or granular form in which the fuel has a high ash content, for example grass or hay pellets in which the ash content is 5% or more. The burner has a combustion chamber with a grate at its lower end, into which fuel and air are fed, the combustion chamber having a hot gas outlet for exhausting combustion gases. The grate is provided with a rotary member having upstanding vanes which is adapted to continually move ash or clinker on the grate through outlet apertures spaced around the grate. The grate is a generally planar, horizontal surface which is imperforate apart from the outlet apertures; air inlet ports are arranged in a circumferential wall surrounding the grate.

Owner:SWANSON HAROLD ANGUS

Modular-hinged grilling grate system

A modular-hinged grilling grate system may include a modular outer support structure and at least one attachable swivel grill grate section.

Owner:BURKLE ROLF

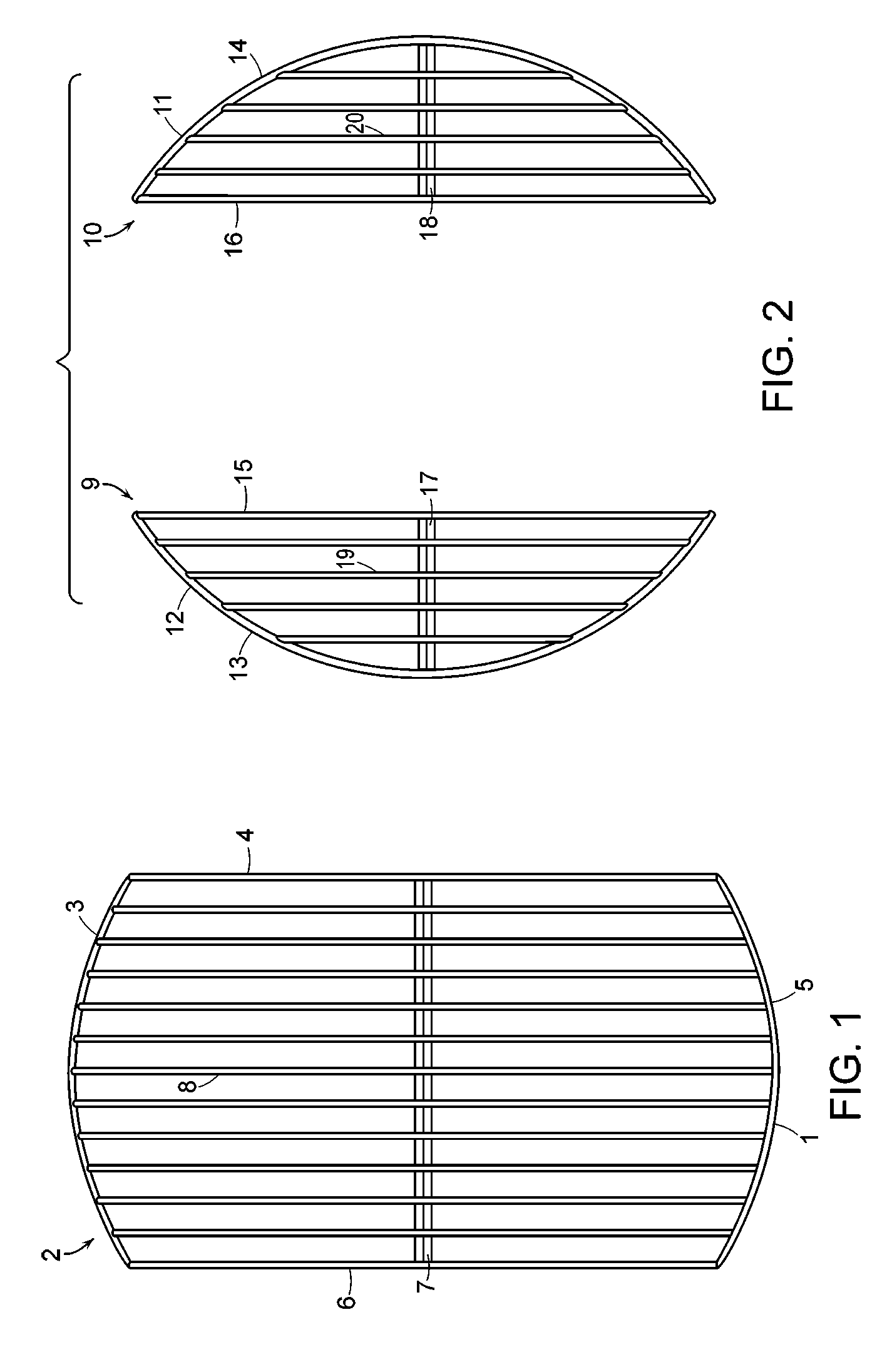

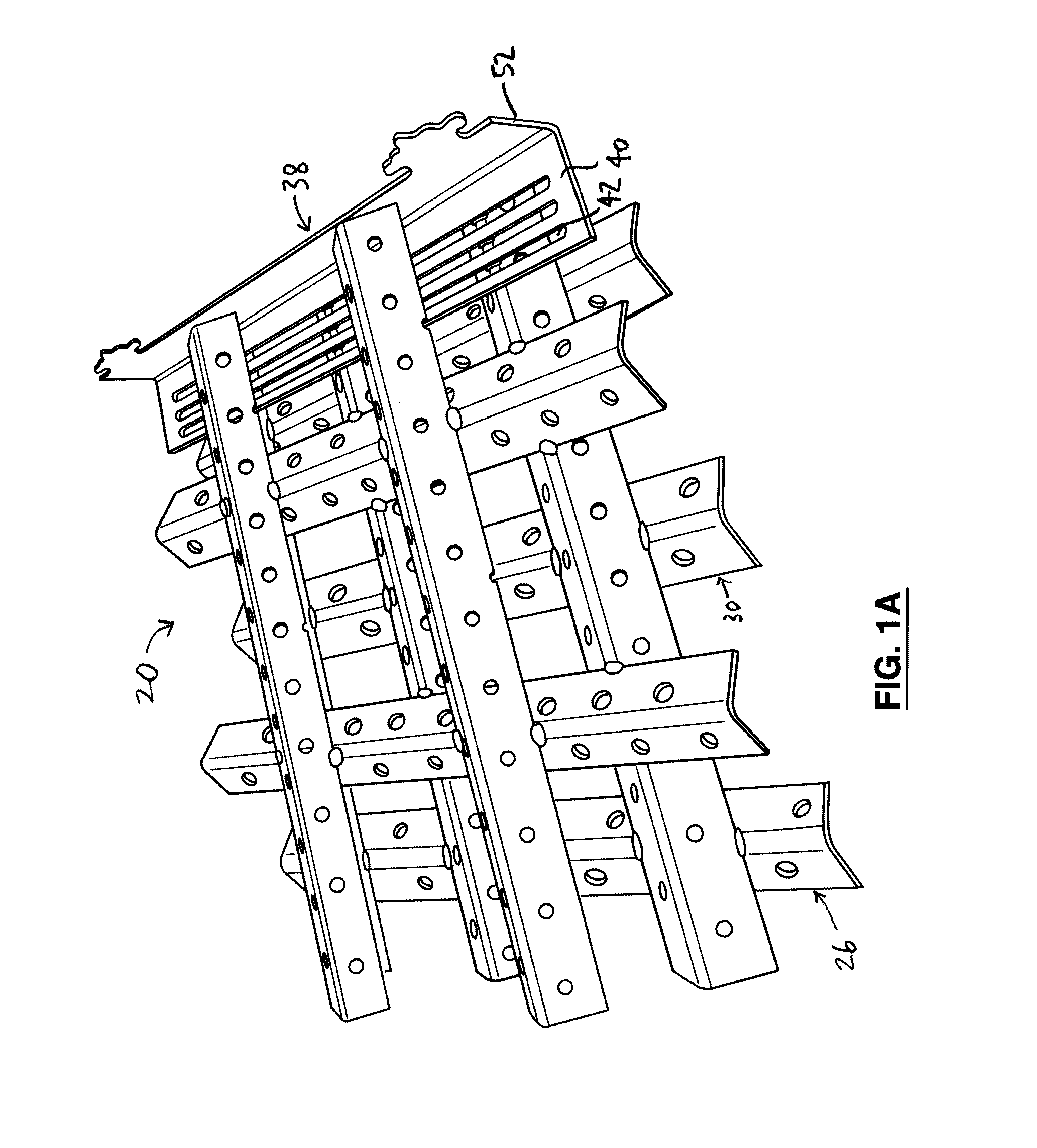

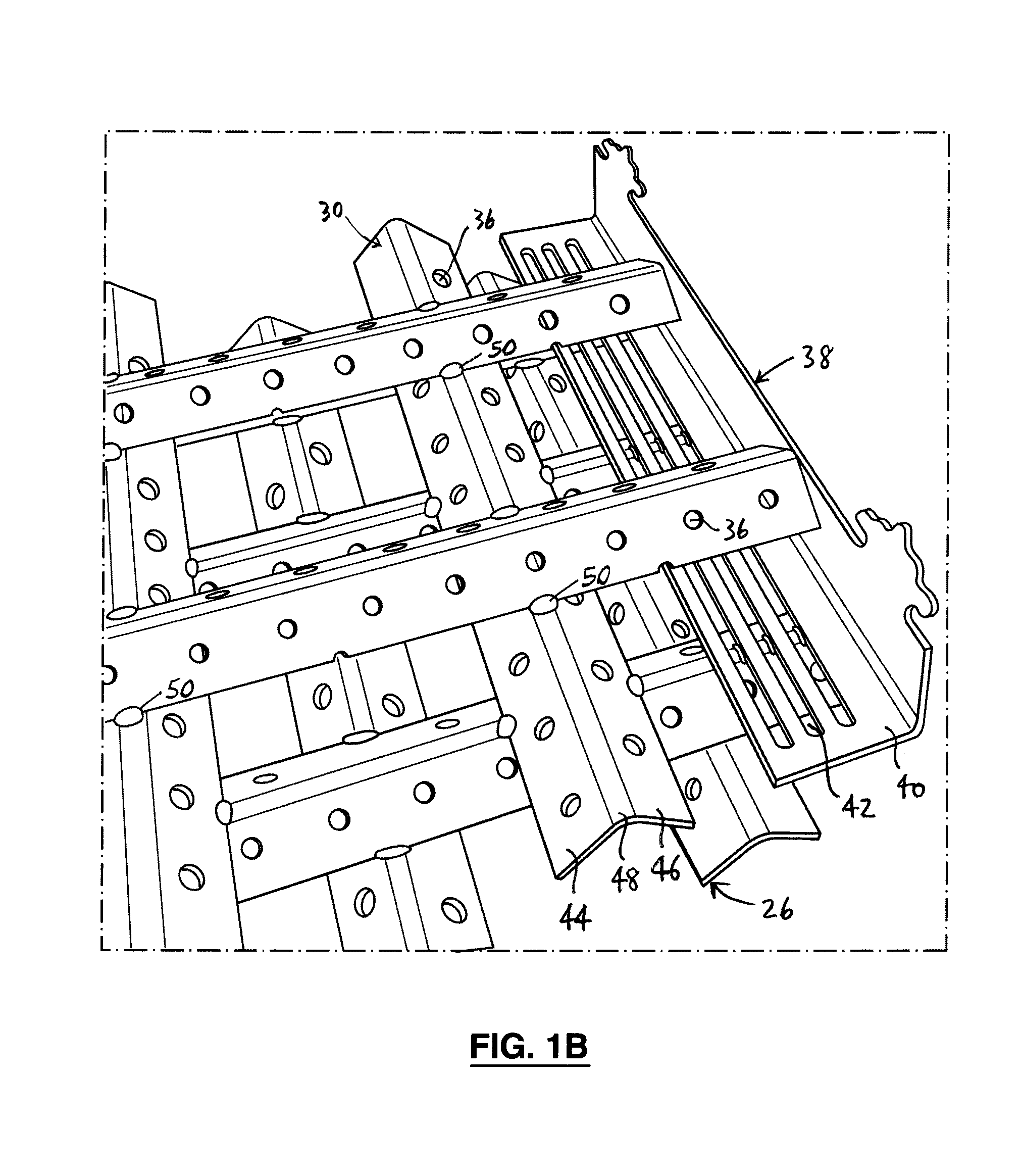

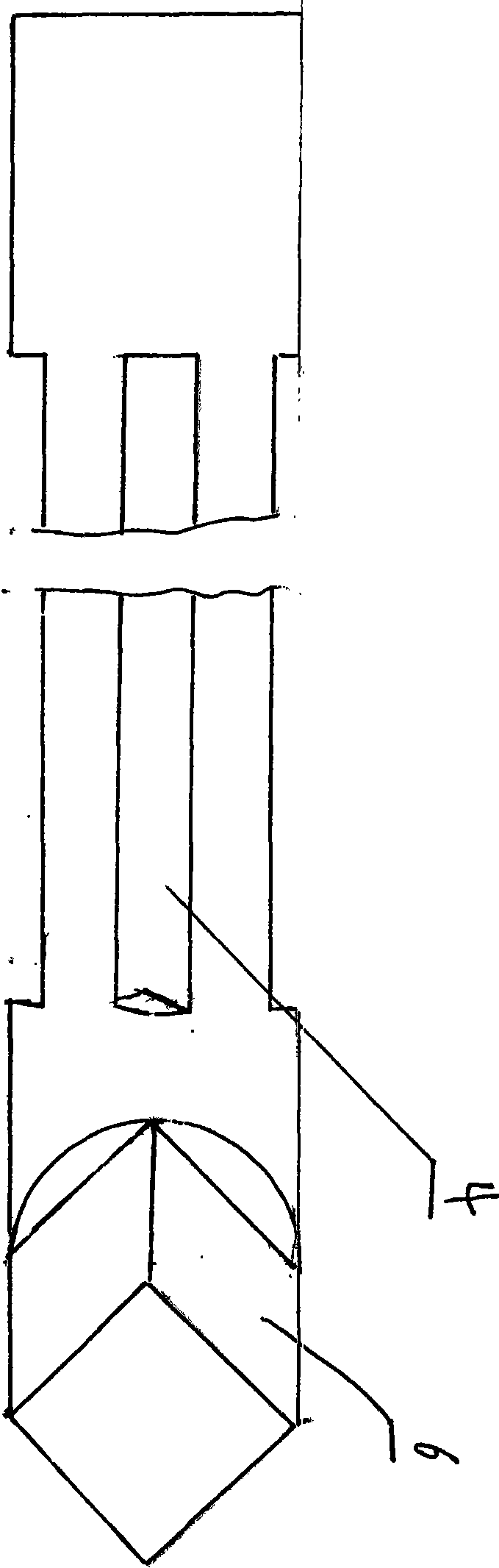

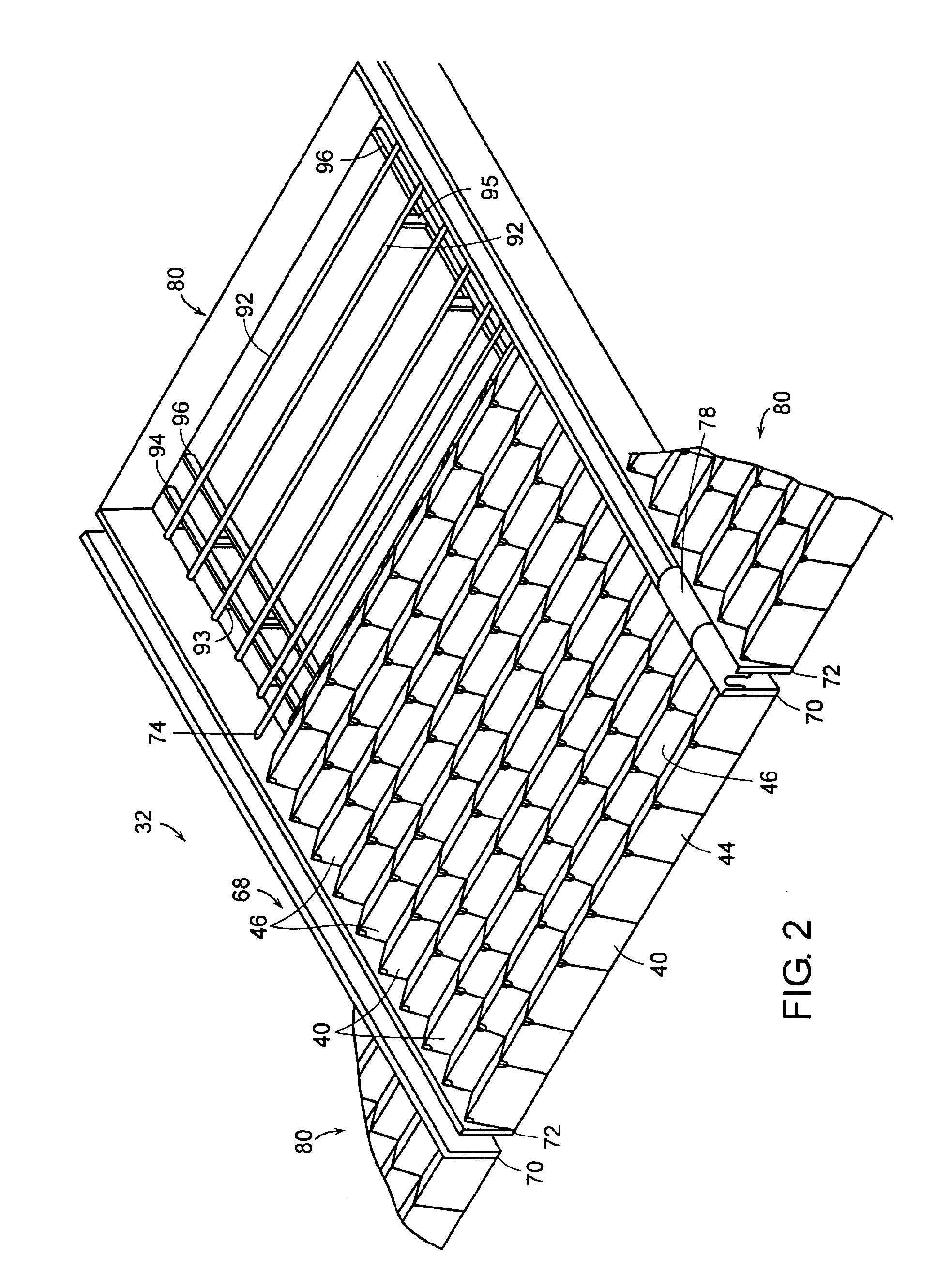

Cooking grate assembly and cooking apparatus

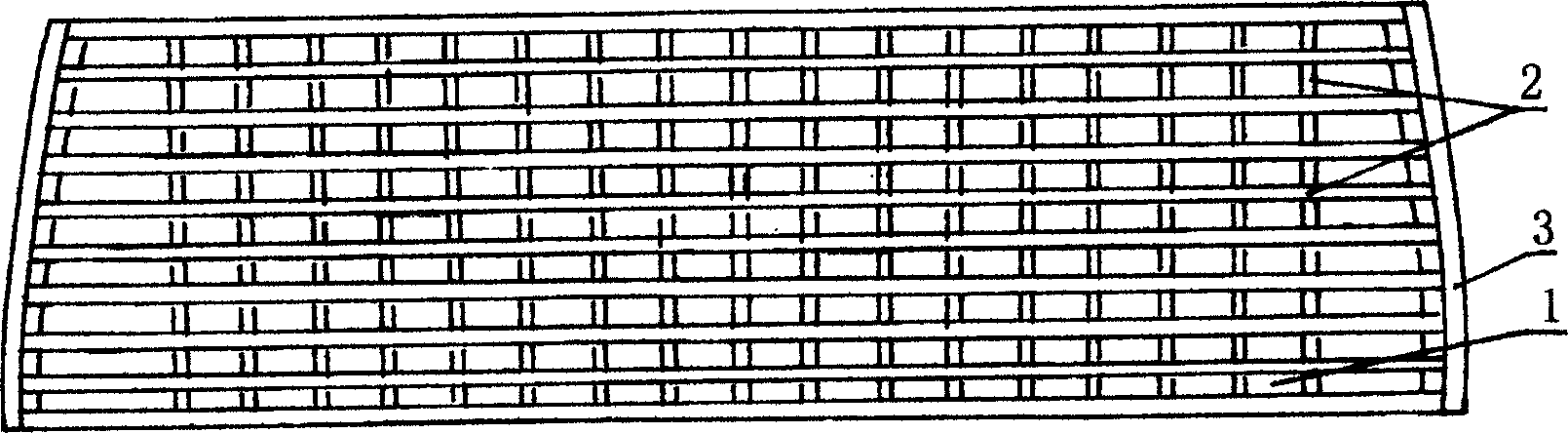

ActiveUS8813738B2Reduces and eliminates occurrenceRust-free cookingDomestic stoves or rangesSolid bar grateFood contactMechanical engineering

A grate assembly for cooking food products and a grilling apparatus which uses the grate assembly for supporting the food during cooking. The grate assembly comprises: (a) a lower grate element having a series of parallel peak structures with valleys therebetween and (b) an upper grate element having a series of parallel food support ribs which are sized and spaced such that each rib will be positioned over the top of a corresponding peak structure. The upper food contacting surfaces of the ribs will remain substantially rust-free at atmospheric and cooking conditions.

Owner:W C BRADLEY CO

Process for incinerating solids on a water-cooled thrust combustion grate, and a grate plate and grate for accomplishing the process

A process wherein primary air supplied to the combustion bed through the thrust combustion grate is deflected after exiting from a surface of the thrust combustion grate by deflector elements mounted on the surface of the thrust combustion grate. The grate required for this purpose has grate plates made from a permeable hollow element with connection pieces for supplying and draining cooling water, with primary air supply ducts that run through the grate plate from a bottom to a top. Deflector elements against which the primary air exiting the outlet is intended to impact, are disposed over openings of the primary air supply ducts.

Owner:DOIKOS INVESTIMENTS LTD

Adjustable cooking grate for barbeque grills

An adjustable grate is described herein that may be easily adjusted to fit within variously sized grills. The adjustable grate includes a main plate having a plurality of fingers extending from a front side and a rear side. A front slide plate has a plurality of fingers that slidably engage with the fingers on the front side of the main plate. A rear slide plate has a plurality of fingers that slidably engage with the fingers on the rear side of the main plate. The front slide plate, the rear slide plate and the main plate define a cooking surface. The front slide plate and the rear slide plate may be slidably adjusted with respect to the main plate to expand or contract the cooking surface.

Owner:W C BRADLEY CO

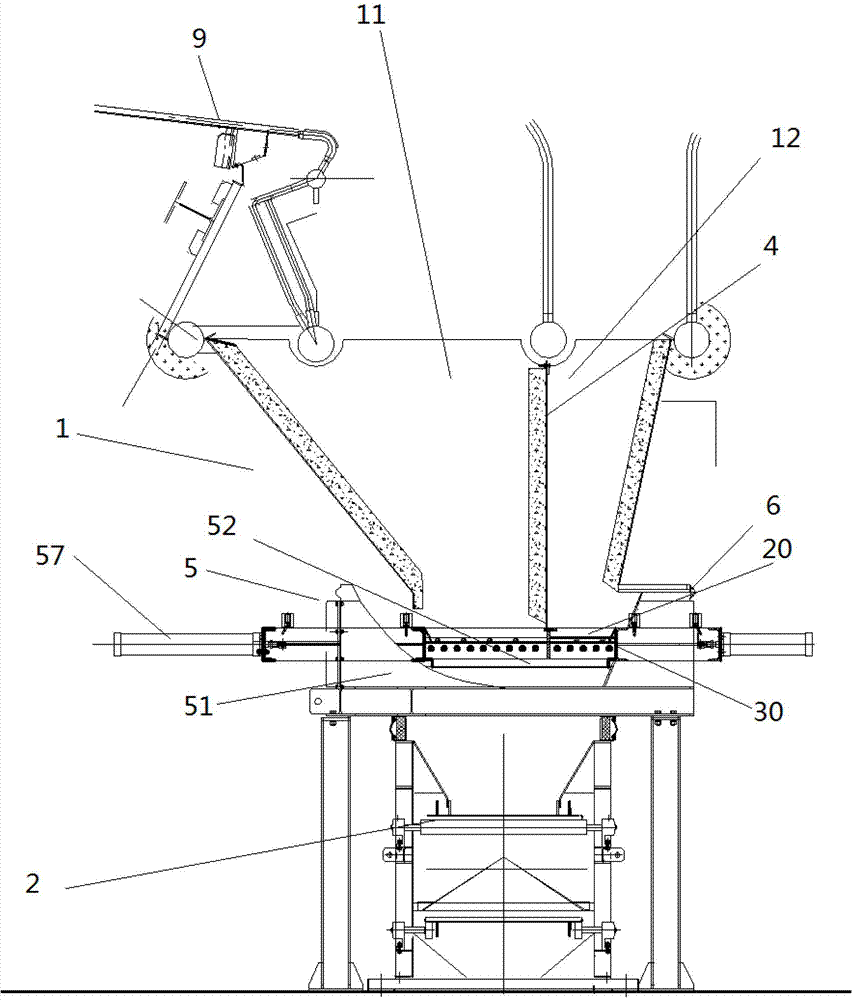

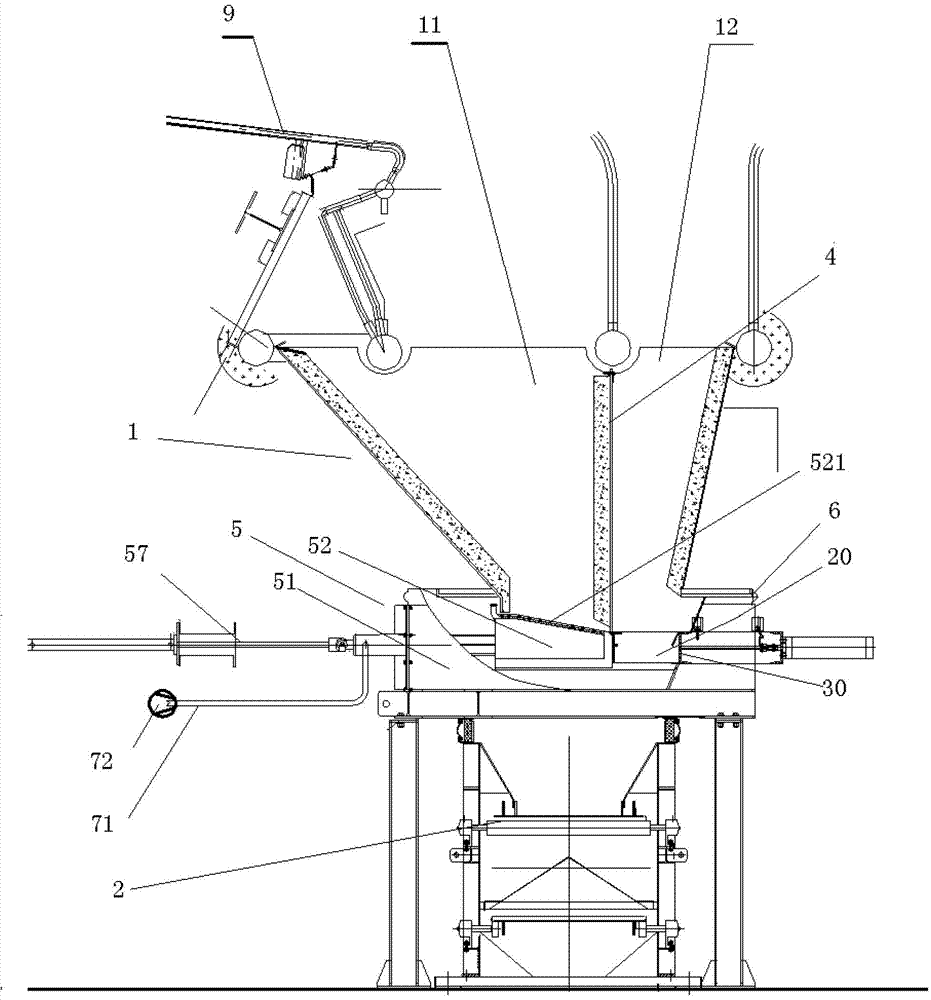

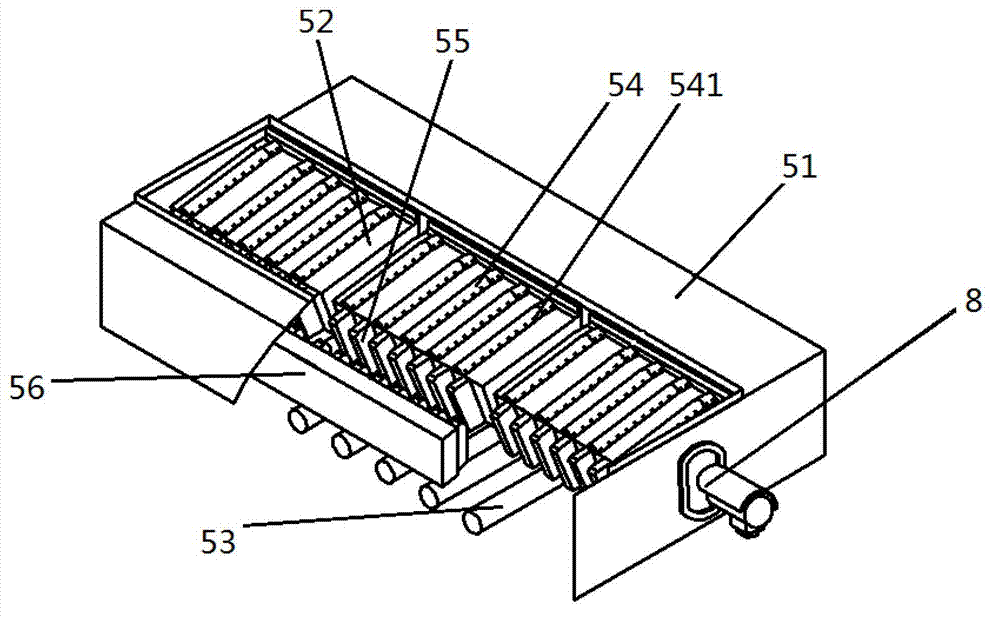

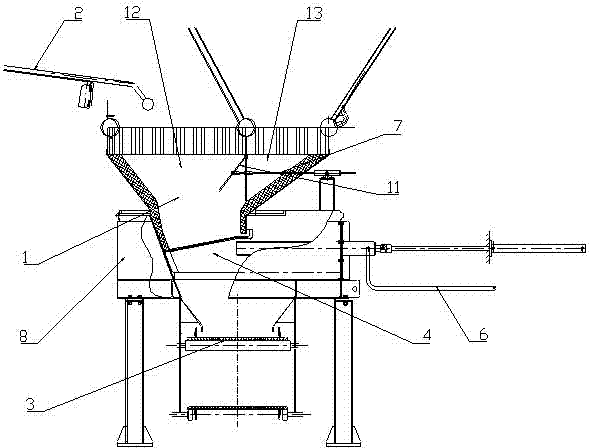

Slag treatment system and method of biomass boiler

InactiveCN102818254AImprove efficiencyFull burn timeSolid bar grateSolid waste disposalSlagBiomass boiler

The invention discloses a slag treatment system and a slag treatment method of a biomass boiler. The system comprises a slag groove, a slag conveyer and a reburning device. The reburning device is hermetically arranged between the slag groove and the slag conveyer and can move along a horizontal direction. The reburning device is controlled to be closed, the slag falls onto the reburning device through the slag groove so that the reburning of carbon in the slag is realized. Heat generated by burning of carbon in the slag returns to a hearth. The reburning device is controlled to be opened, and the slag falls onto the slag conveyer and is discharged. The method comprises the steps of: closing the reburning device so that the slag falls onto the reburning device through vibration of a fire grate, the fire grate stops vibrating, and heat generated by reburning of carbon in the slag returns to the hearth; opening the reburning device so that the slag falls onto the slag conveyer and is discharged; and repeating the steps to realize the reburning of carbon in the slag and recycling of the heat. According to the slag treatment system and the slag treatment method of the biomass boiler provided by the invention, heat of the slag is recovered and the boiler efficiency is improved through the reburning of unburned carbon in the slag by the reburning device.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

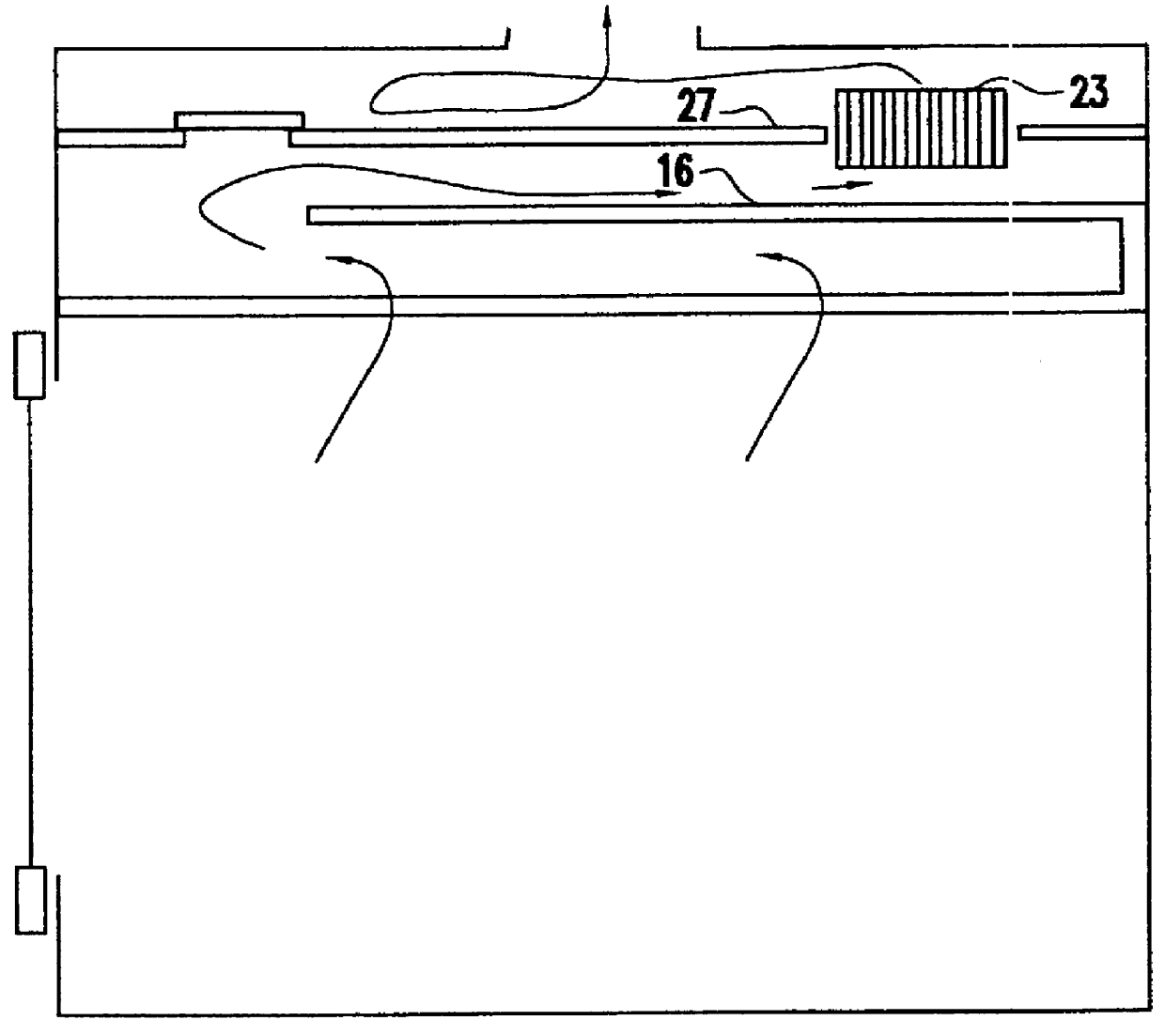

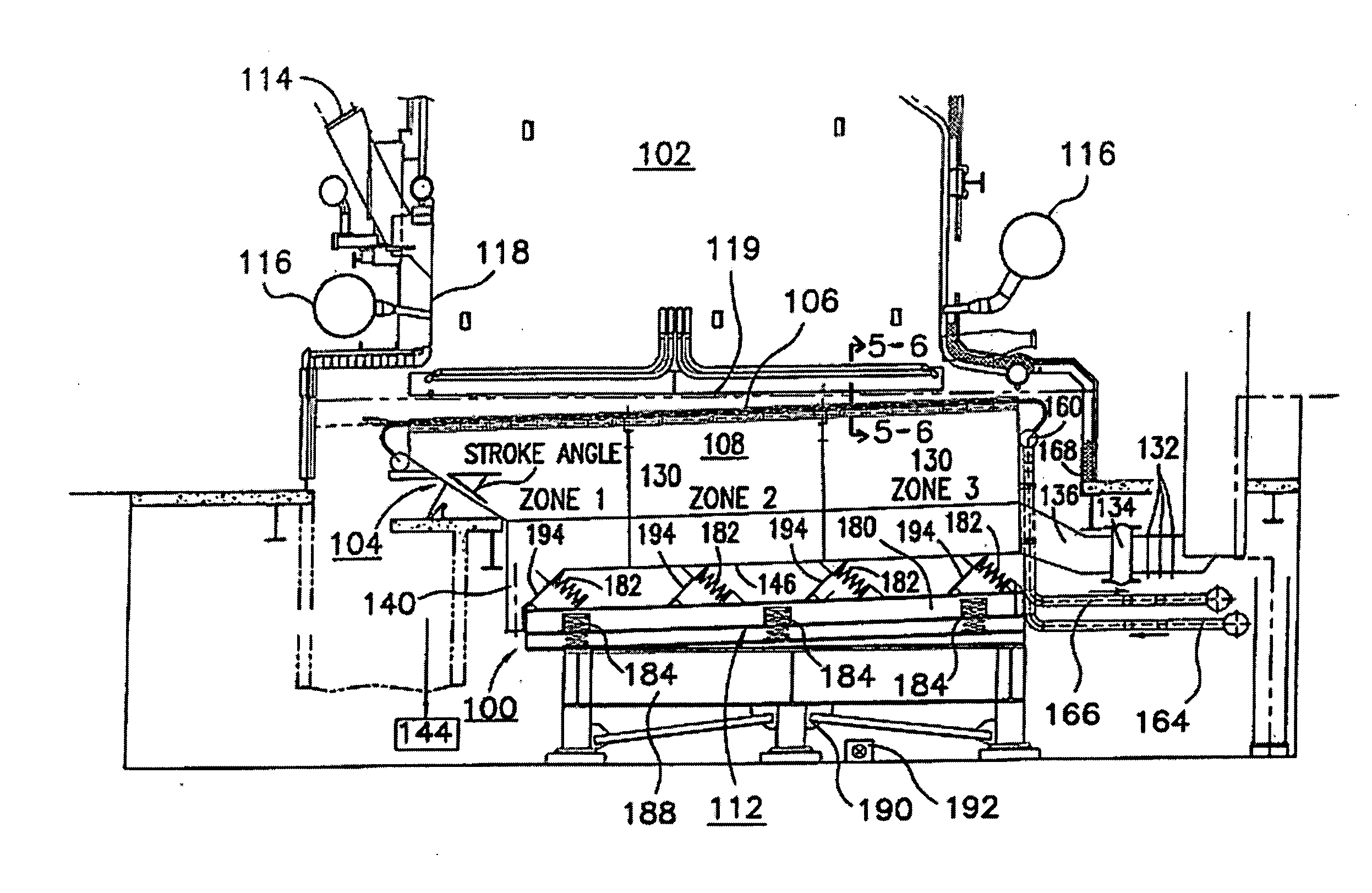

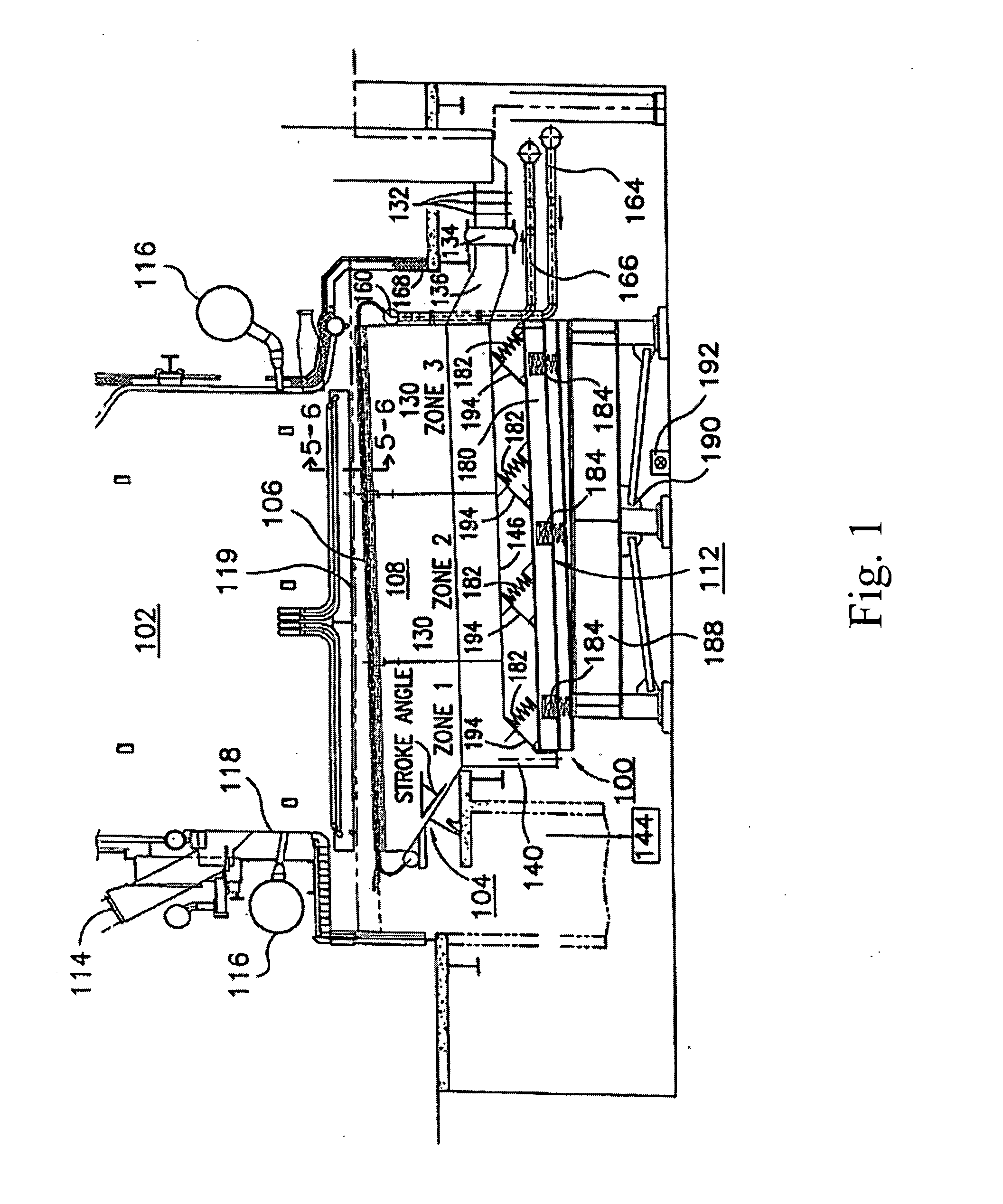

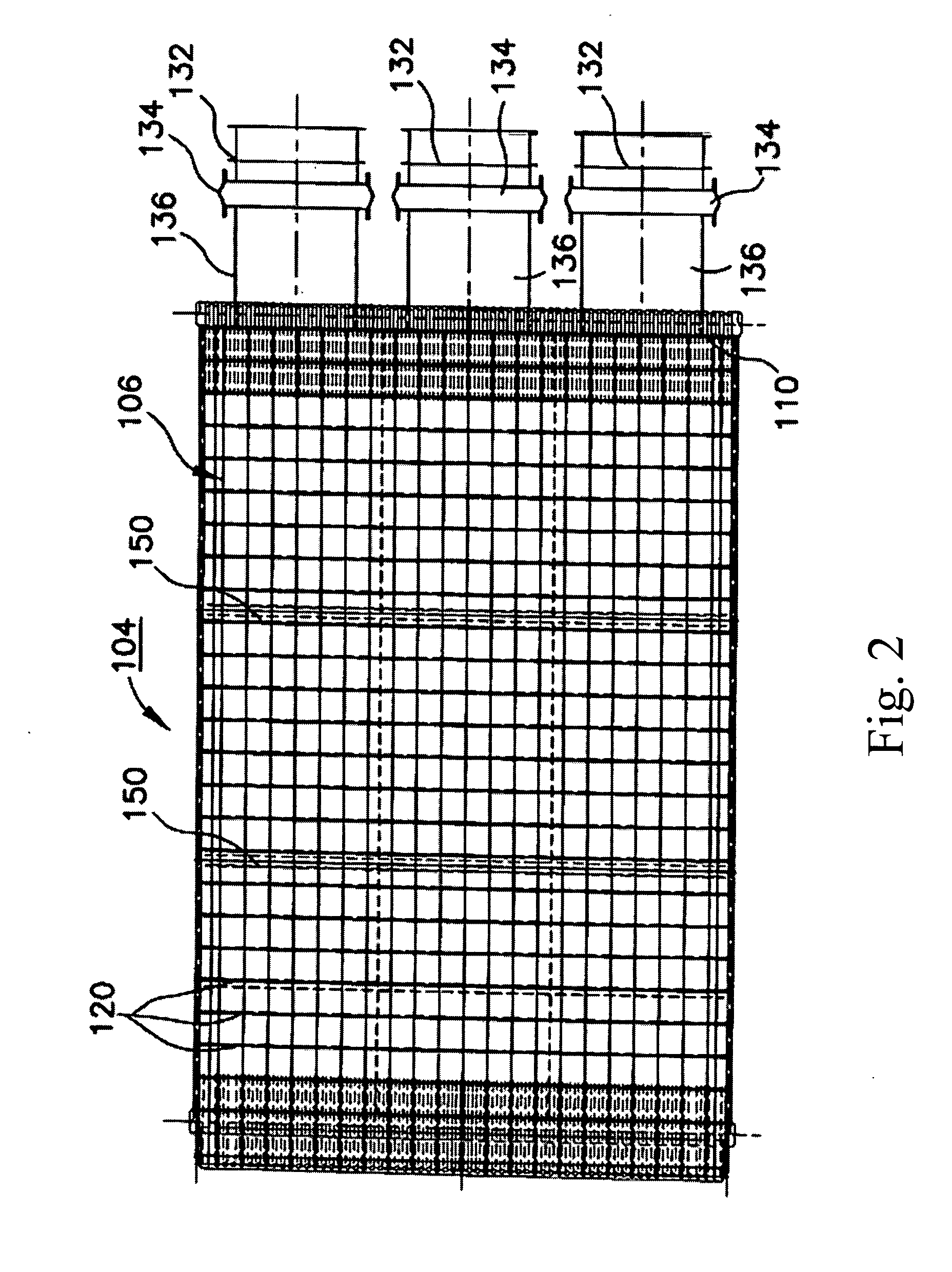

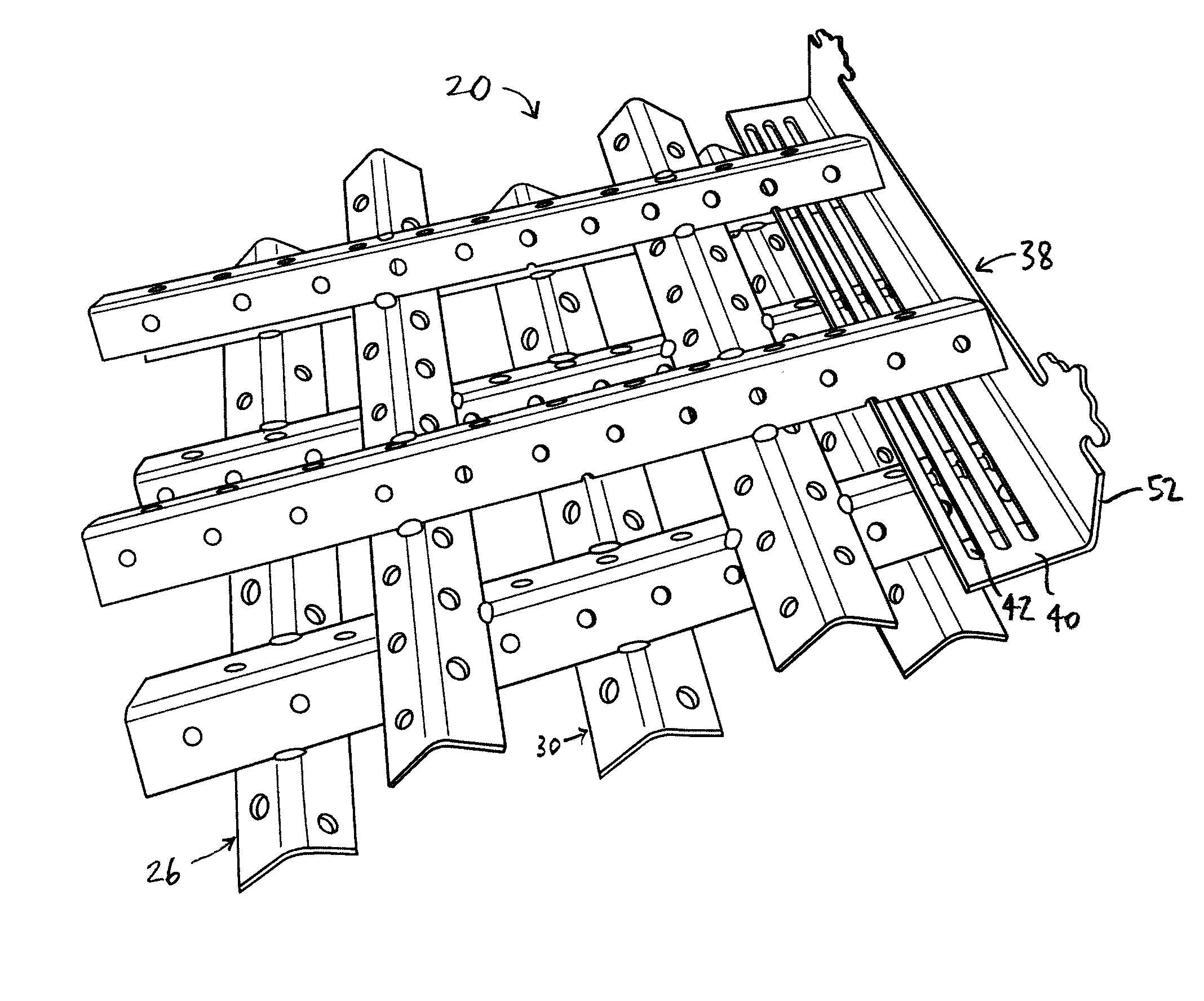

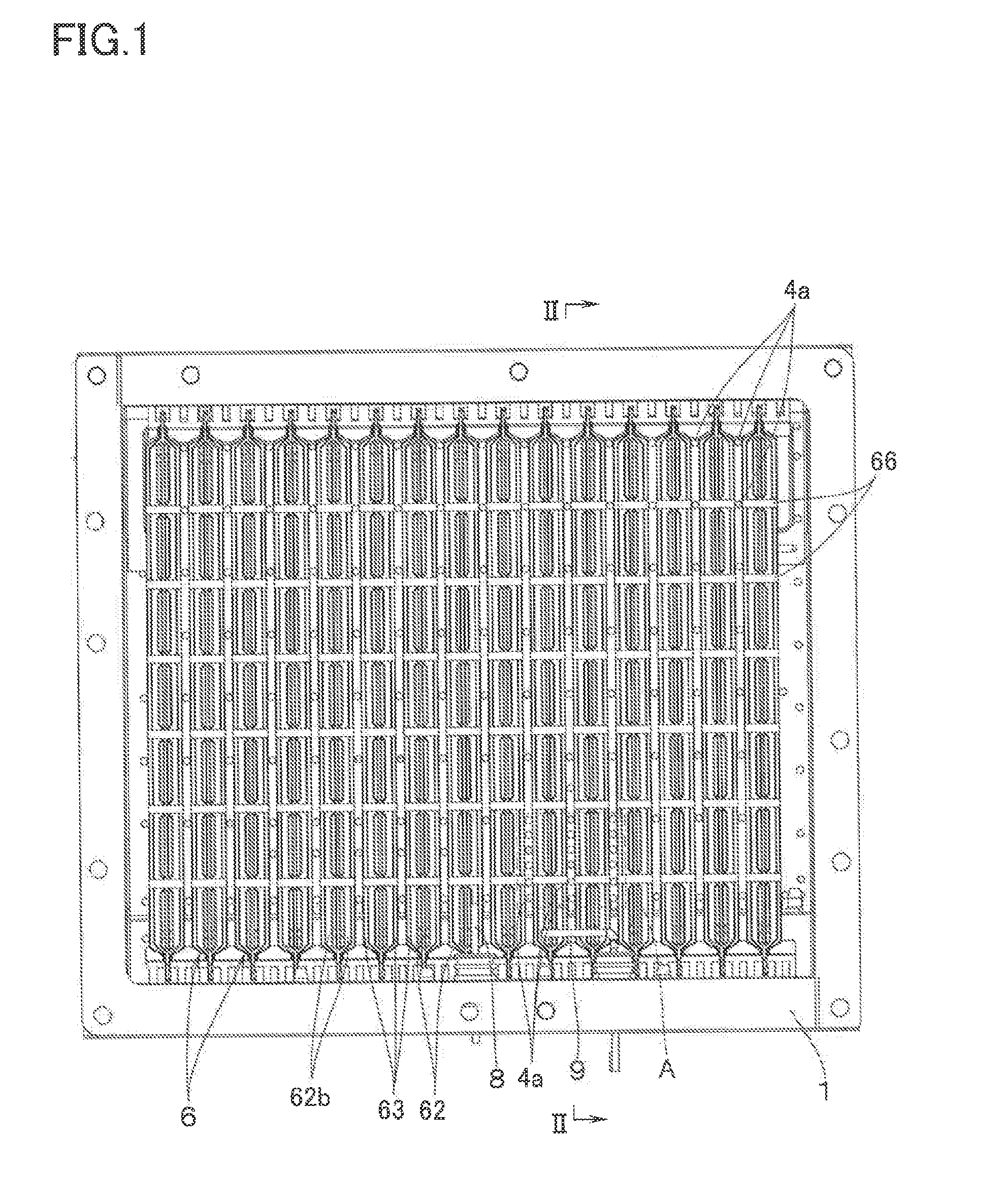

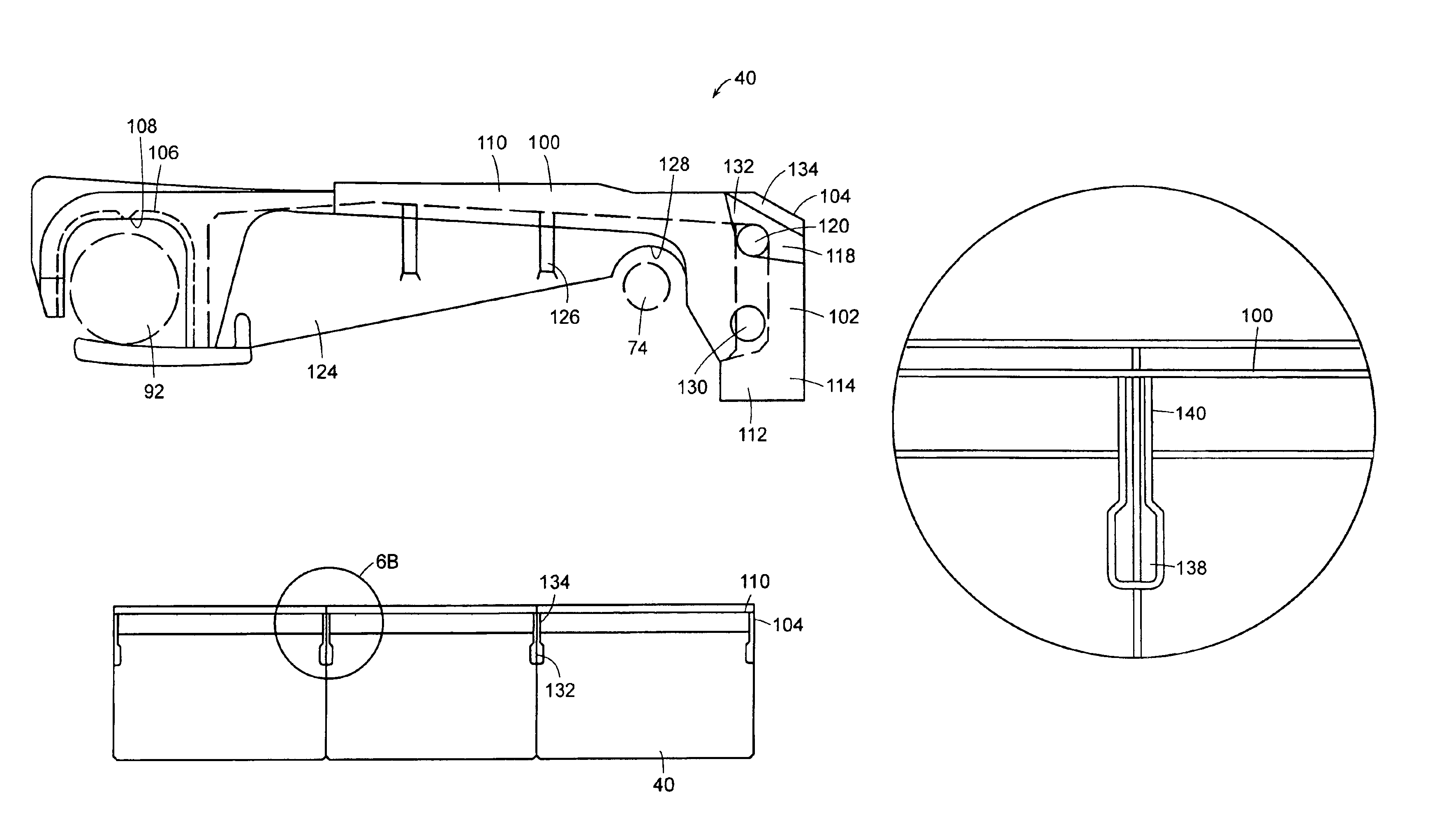

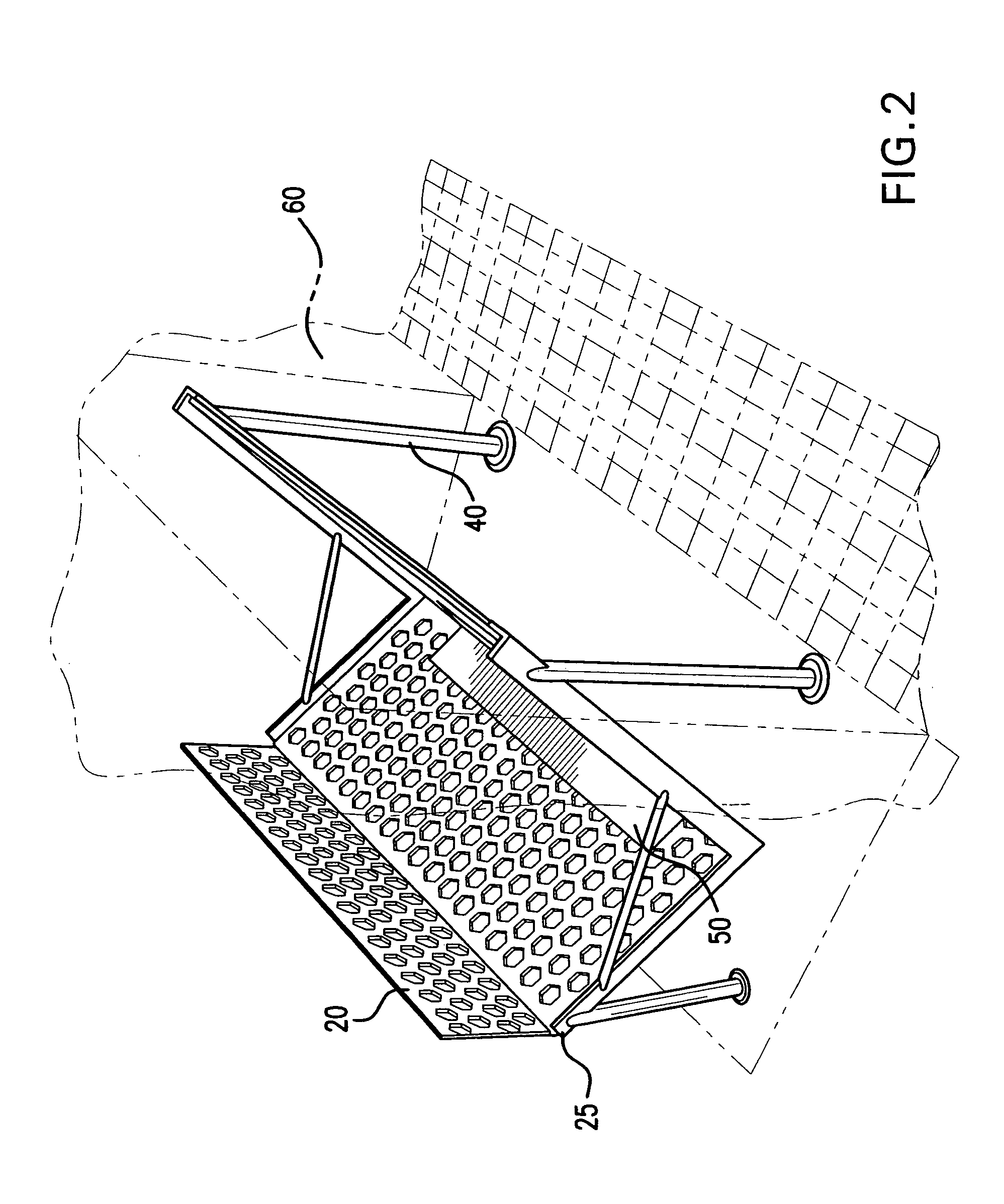

Grating system and sidewall seal arrangement for oscillating grate stoker

InactiveUS20080276843A1Obstruct passageGood vibration isolationSievingSolid bar grateGratingCombustion

The invention includes a grate system for a boiler. The grate system includes a grate unit and a side header guard. The grate unit supports fuel during combustion thereof, and has an upper surface, a lower surface, and upturned lateral edges. The side header guard is arranged along a side wall of the boiler and has upwardly and downwardly projecting fin portions. The upwardly projecting fin portion is adapted and configured to extend over and protect the boiler side wall from abrasion by fuel. The downwardly projecting fin portion is adapted and configured to extend over the upturned lateral edge of the grate unit, inhibiting passage of fuel therebetween.

Owner:RILEY STOKER

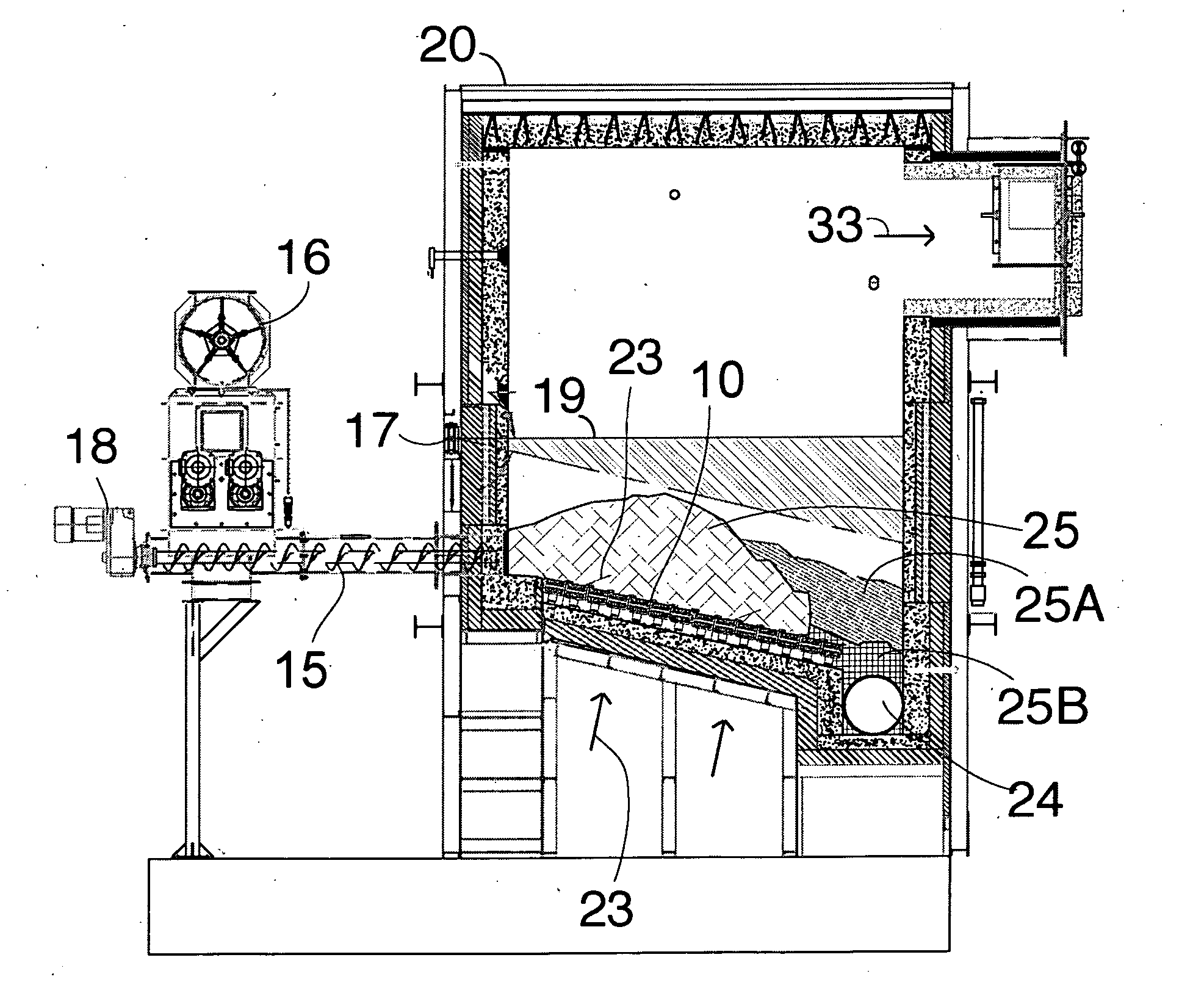

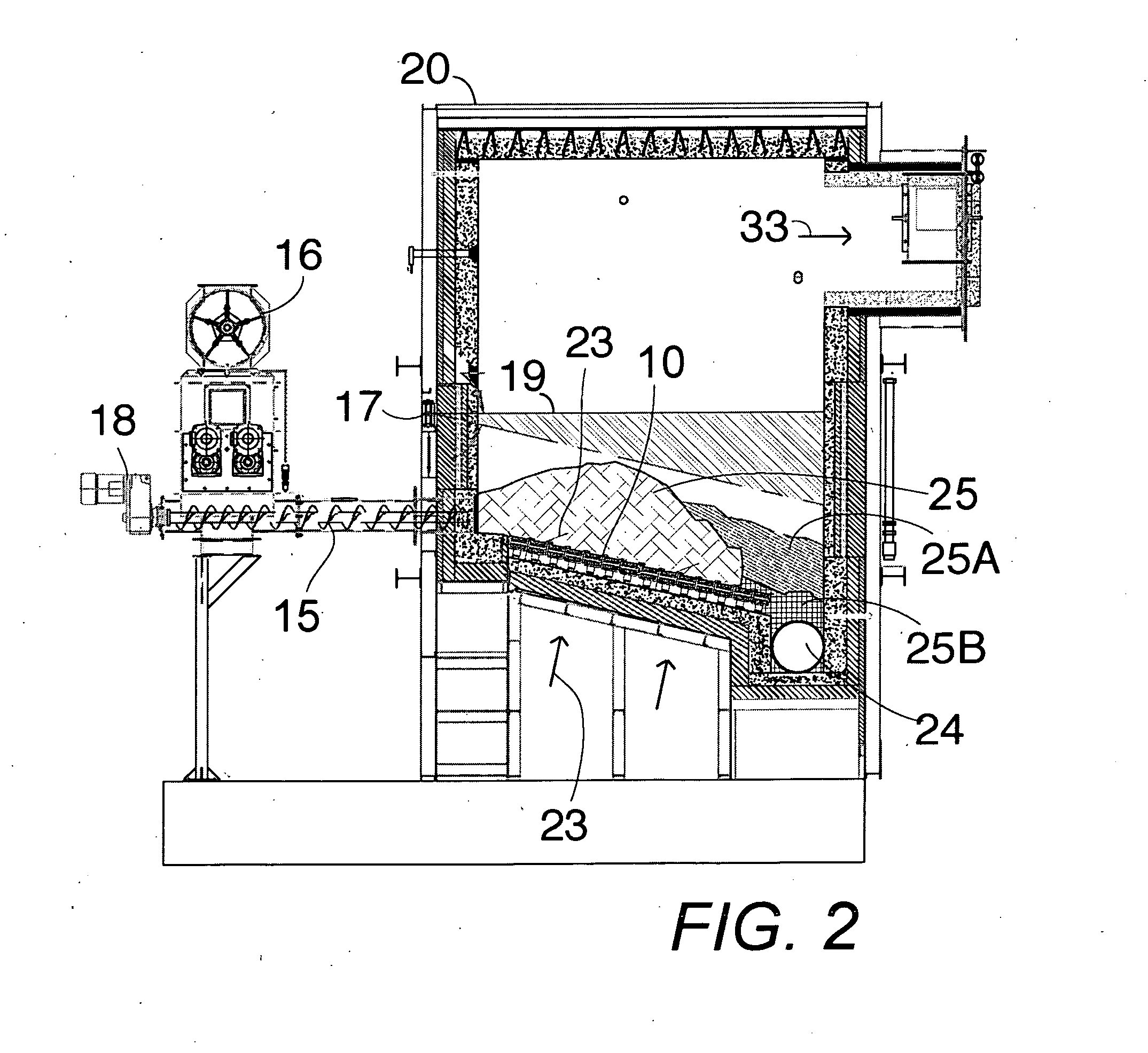

Grate clearing and ash removal system for gasification furnace

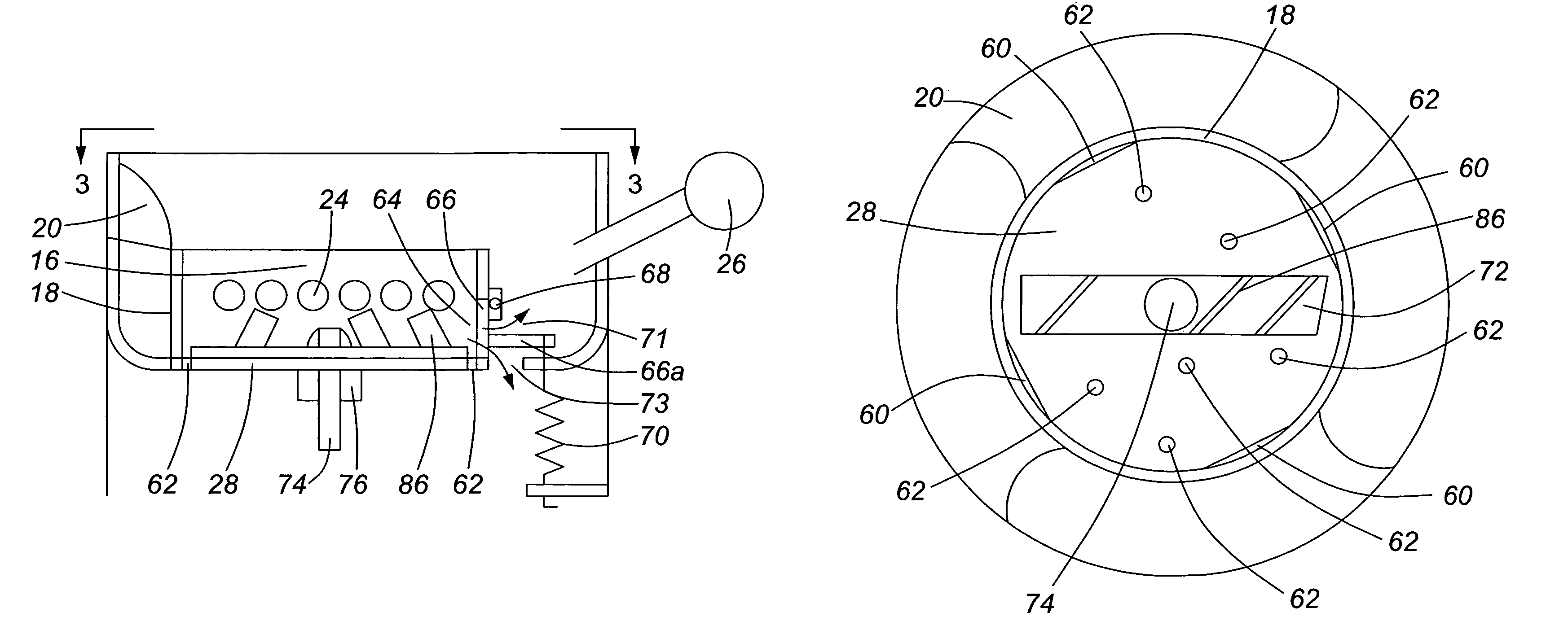

A relatively level fuel grate surface angle cooperates with multiple feed screws that press solid fuel material into and across the grate surface to continually clear off the grate. Air spaces between each pair of adjacent grate elements for under fire air each have a ninety degree deflector flange at the top of the air space extending from one grate element across the air space and up and over an adjacent grate element to deflect under fire airflow across the adjacent grate element to act as a grate sweeper. The smooth curved surface of the deflector flange between grate elements facilitates movement of the fuel and ash material and prevents from one grate element to the next and prevents clogging of the airflow space.

Owner:BENDER ROBERT J +2

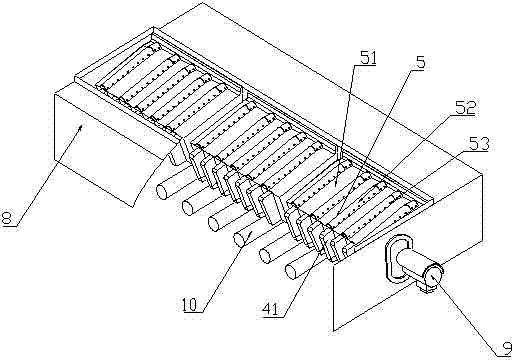

Slag combustion apparatus of biomass boiler

InactiveCN102829466AImprove efficiencyReduce consumption costSolid bar grateSolid waste disposalSlagGrate firing

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

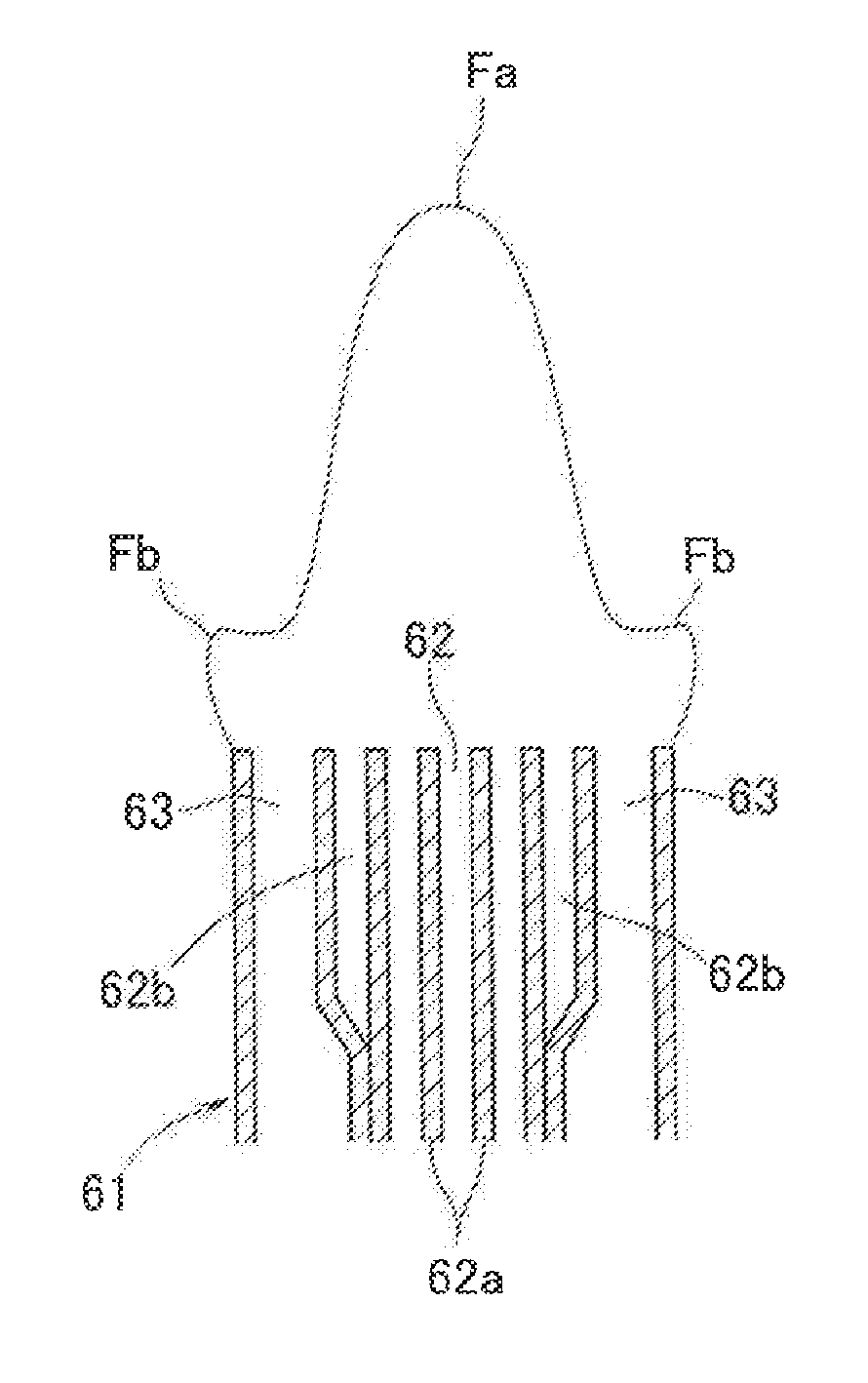

Grate assembly

A grate assembly for guiding air into a pile of combustible wood pellets for combustion thereof. The grate assembly includes a structural subassembly having at least two sets of elongate members, a first one of the two sets forming a lower layer for at least partially supporting a second one of the two sets forming an upper layer. The grate assembly also includes a support element attached to the structural subassembly. Each member includes a body at least partially defining one or more channels and a number of holes in fluid communication with the channel(s) to guide air into the pile of the wood pellets. The support element includes a base portion with a plurality of apertures, for ignition of the pellets therethrough

Owner:PALMER BRADLEY C

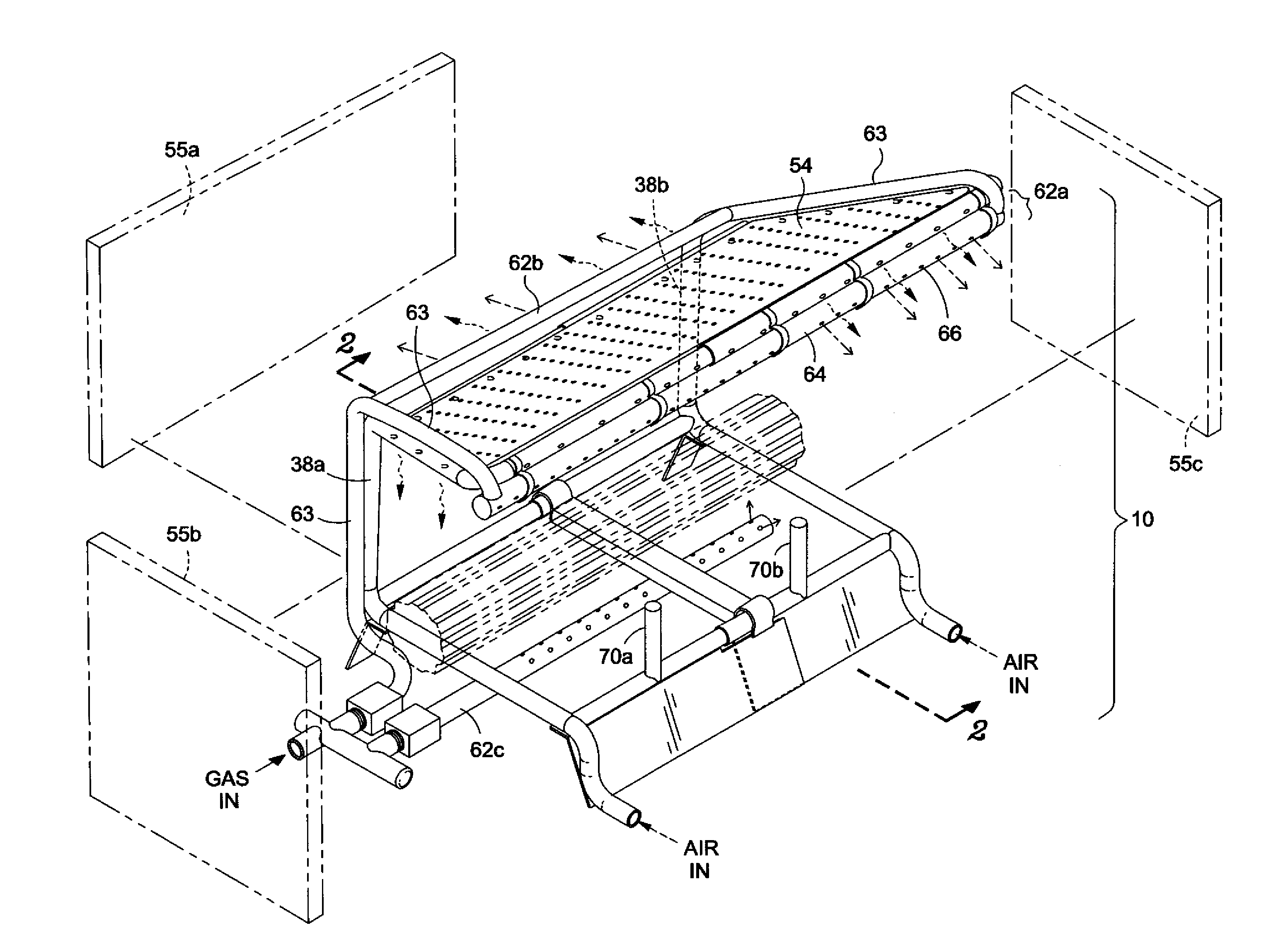

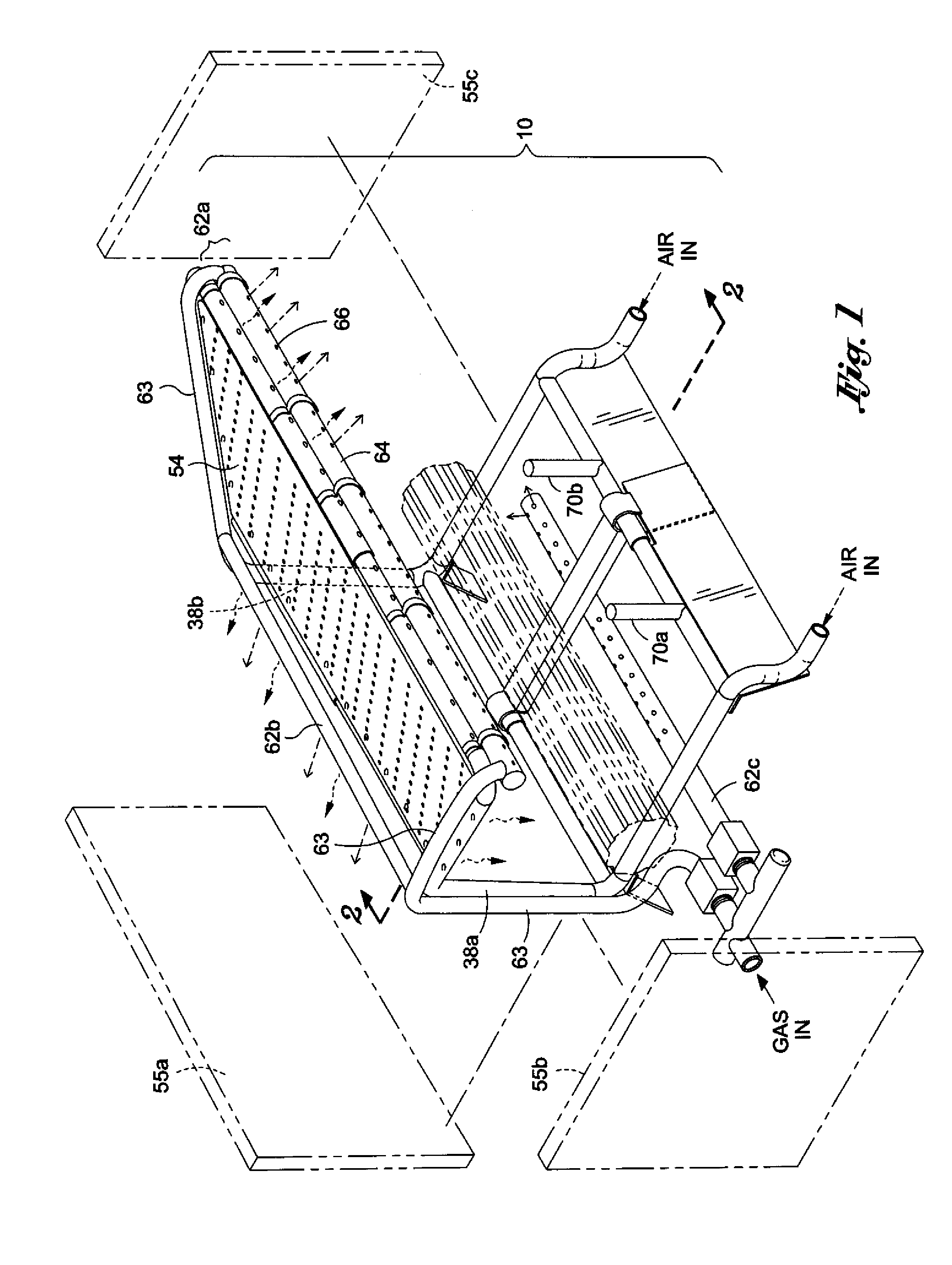

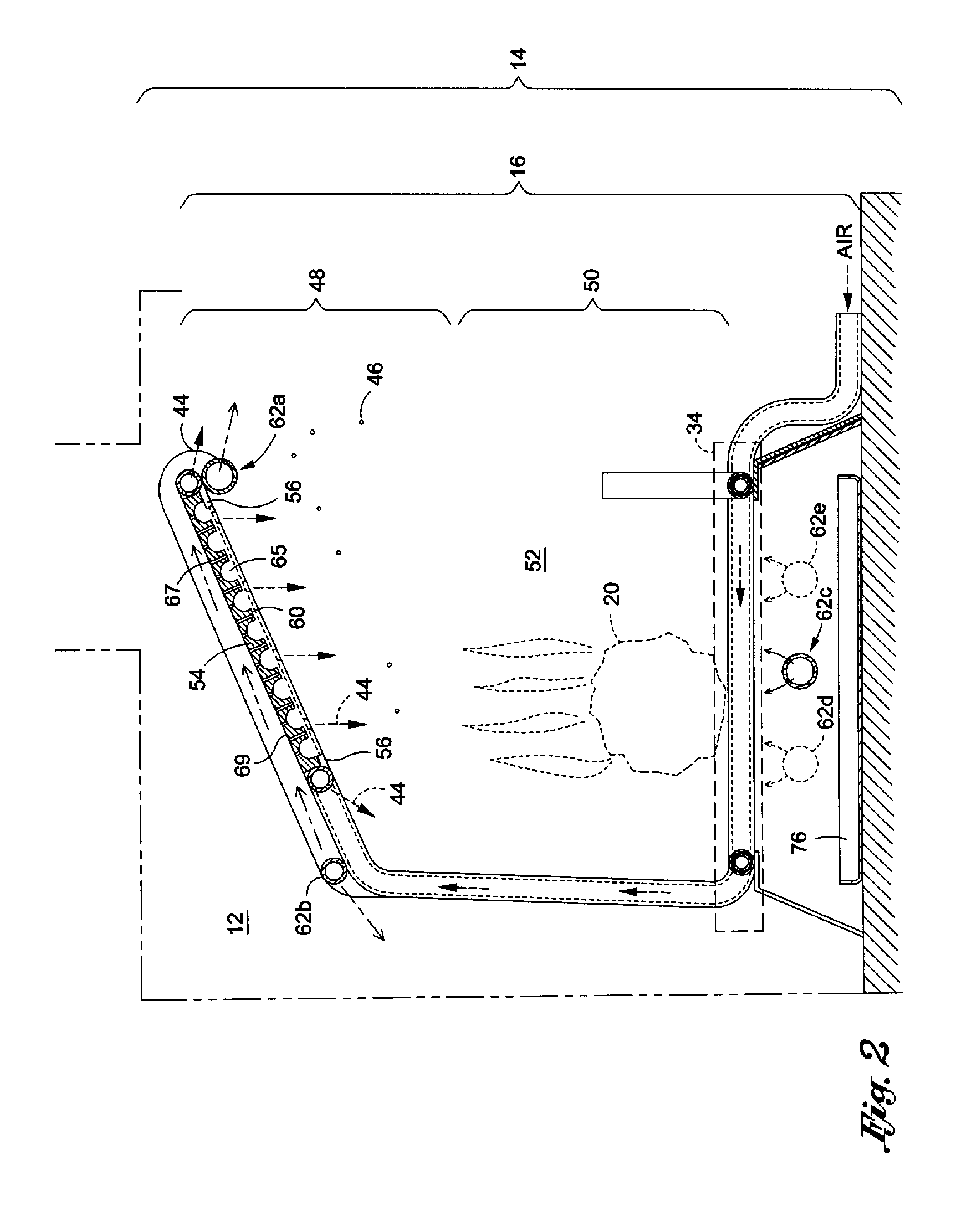

Apparatus for combustion of biofuels

InactiveUS8210110B2Avoid excess smokingReadily and efficiently converts pelletized, minimally processedSolid bar grateRevolving grateCombustionBiofuel

An apparatus for combustion of biomass is provided. The apparatus generally includes opposingly paired sidewalls, a fixed panel traversing the opposingly paired sidewalls, an actuatable panel opposite the fixed panel, and a fuel platform supported by a panel of either of the panels. A portion of the fuel platform is reversibly receivable through a portion of a panel opposite the panel supporting the fuel platform in furtherance of fuel conditioning upon actuation of the actuatable panel.

Owner:HESTIA HEATING PRODS

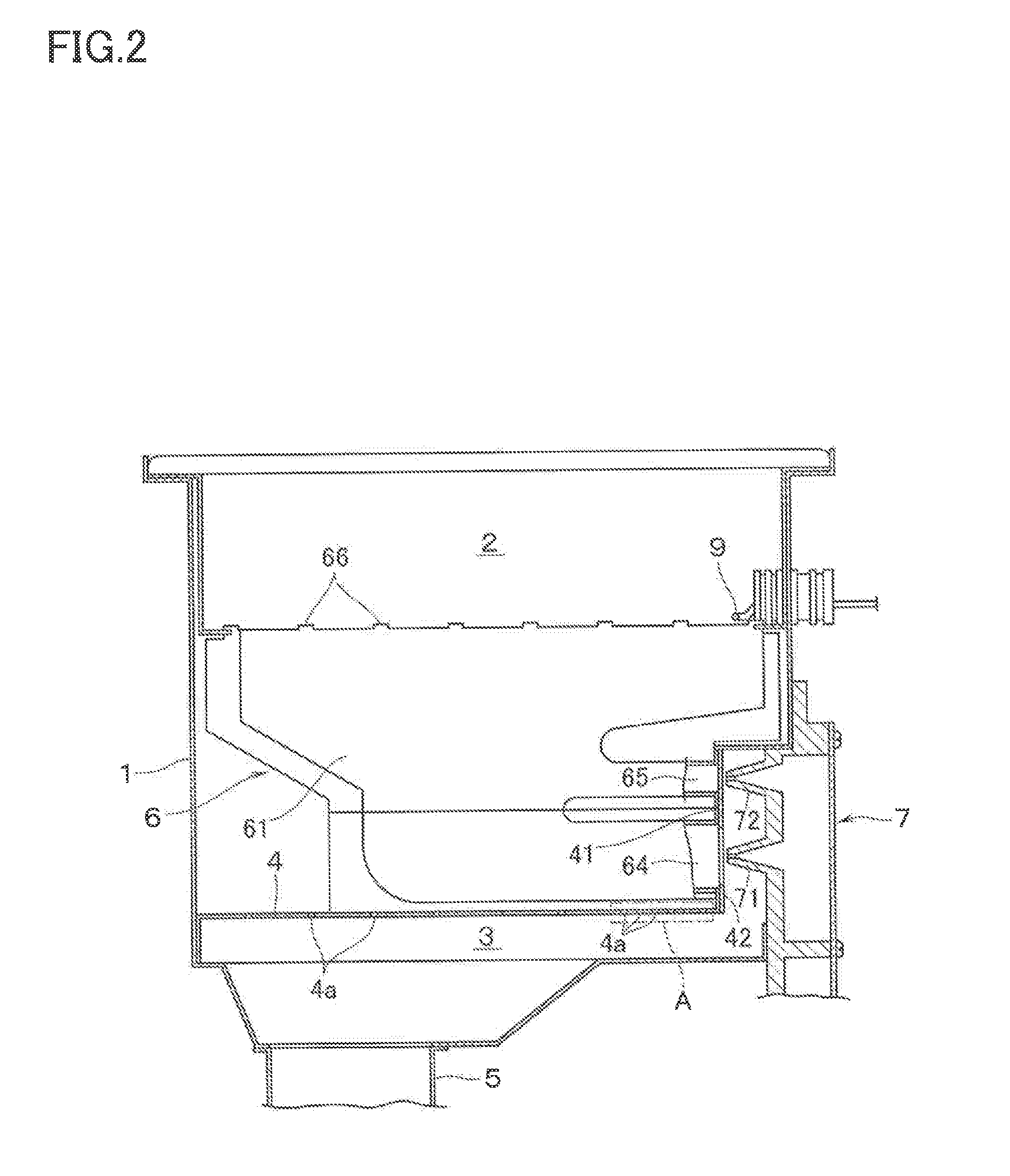

Combustion apparatus

InactiveUS20110297059A1Combustion velocityEasy to liftSolid bar grateHollow bar grateCombustion chamberLeft direction

A combustion apparatus has: a combustion housing; a partition plate provided in the combustion housing to partition a space in the combustion housing into a combustion chamber and an air supply chamber; and a plurality of rich-lean burners arranged in a right-left direction of the combustion chamber. A multiplicity of distributed holes are formed in the partition plate through which distributed holes secondary air is supplied from the air supply chamber to the combustion chamber. A flame rod facing to an upper side of a part of the rich-lean burners stops combustion when the flame rod does not detect any flames owing to a flame lift at a time of an oxygen deficiency. A supply quantity of the secondary air to the part of the rich-lean burners to which part the flame rod faces is larger than those to other parts.

Owner:RINNAI CORP

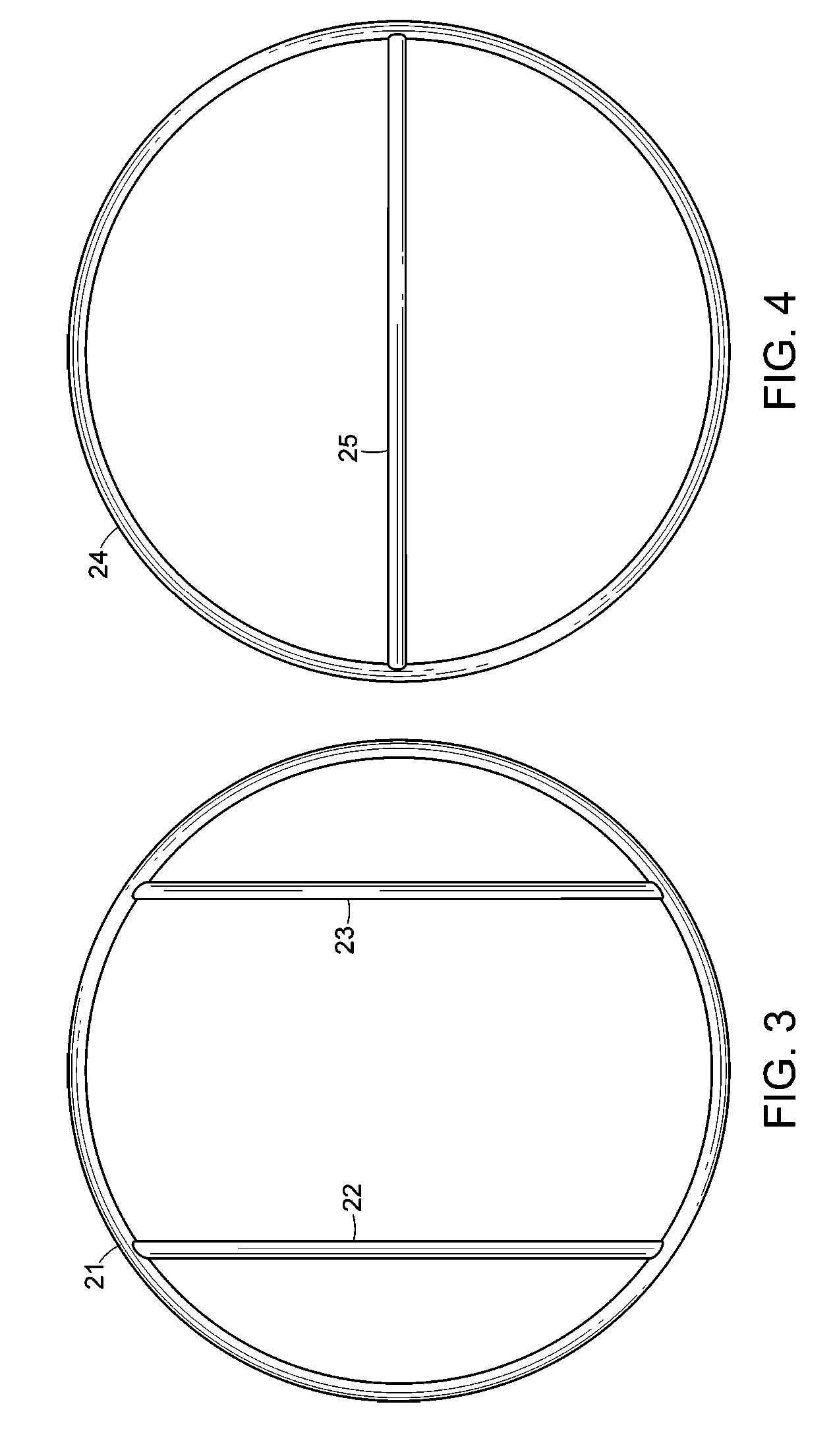

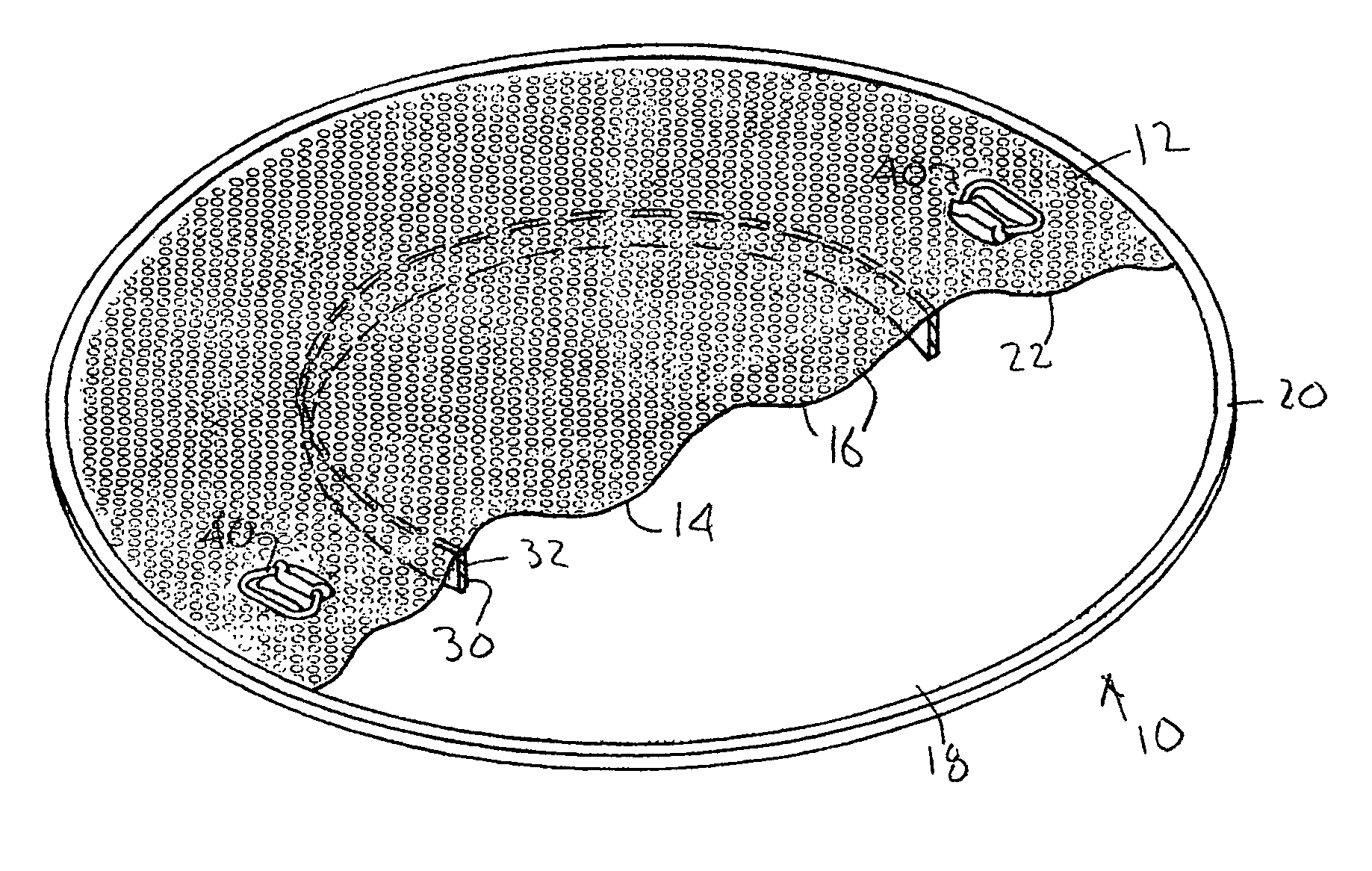

Fire pit cover

InactiveUS7841334B1Reduce weightThin materialDomestic stoves or rangesSolid bar grateInterference fitEngineering

A cover particularly adapted to extend over outdoor recreational fire pits when not in use includes a circular perforated center plate. Attached to an outer edge of this center plate is an angle-shaped rim having a downward extending vertical flange. Then, attached to a bottom side of the center plate is a centering ring. For use, a pair of spaced apart handles attached to a top side of the center plate may be used to remove the cover so that a fire may be built in the pit and then used to replaced the cover after pit use. In this latter case, the cover is positioned over the pit so that the centering ring extends into the pit next to a vertical sidewall of the pit. Any inadvertent cover movement is inhibited by an interference fit between the cover ring and the pit sidewall.

Owner:DEPAUL BRIAN WILLIAM

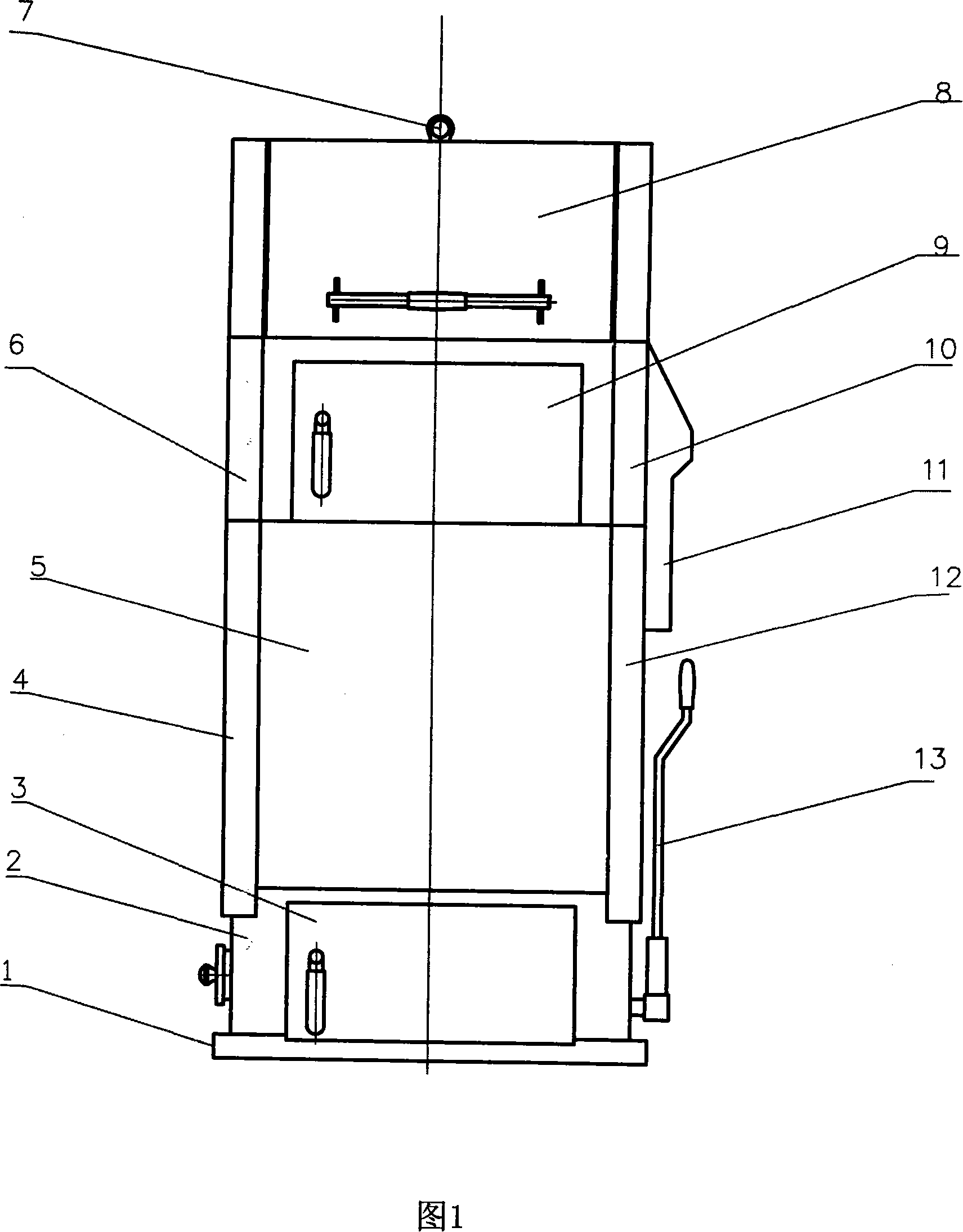

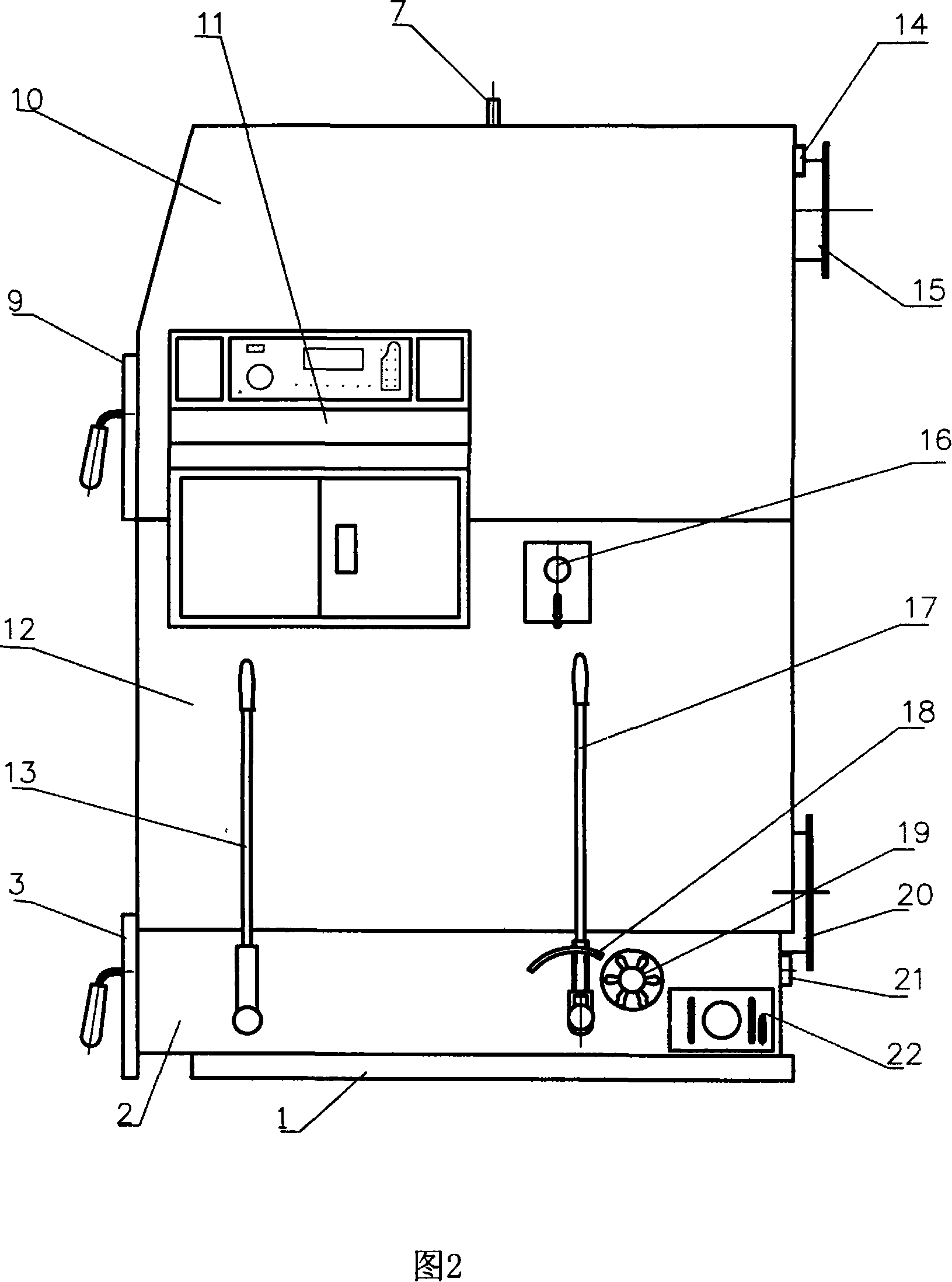

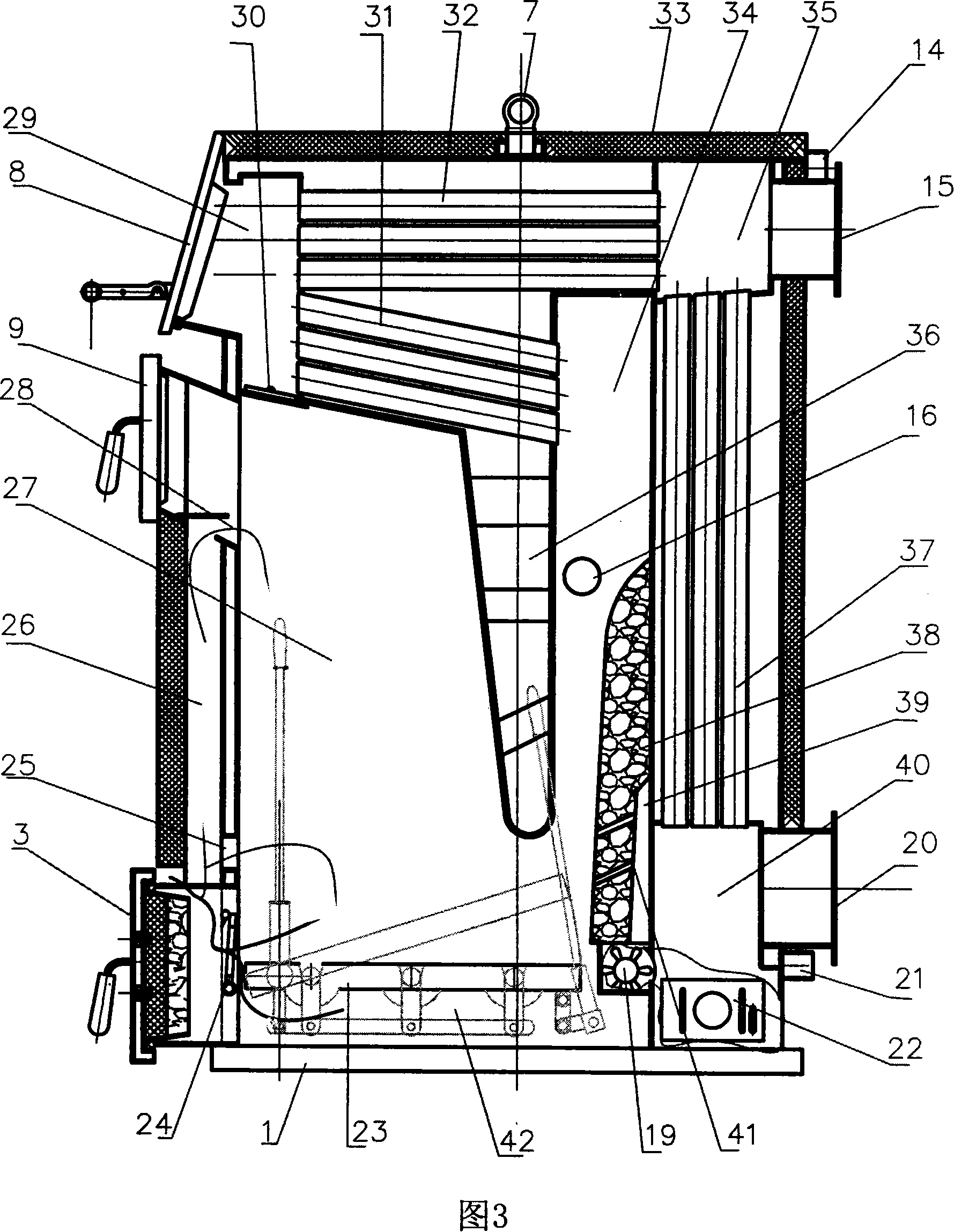

Biomass gasification automatic-control boiler

InactiveCN101122417AReduce the overall heightReduce generationSolid bar grateSolid fuel combustionAutomatic controlCombustion chamber

The invention discloses a biomass gasification automatic control boiler. A furnace is arranged above an ash removal grate. A secondary combustion chamber is arranged above the back of the ash removal grate. The middle is equipped with a fireproof plate with a sandwich structure. A flue gas channel is arranged between the lower end of the fireproof plate and the ash removal grate. Sandwich water jackets, which are mutually communicated, are arranged on the periphery and the top of the furnace, the fireproof plate and the secondary combustion chamber. A primary air is supplied into the furnace from a plurality of directions of the furnace. A secondary air is supplied into the secondary combustion chamber through a secondary air channel and a ventilating hole on a spoiler. An upper settling chamber is arranged above the furnace, which is communicated with the secondary combustion chamber through a fire tube. In addition, a settling and flue conversion chamber and a lower settling chamber, which are communicated through a fire tube is arranged above the furnace. The ash removal grate is a lifting grate, which can rotate around an anterior location pin and is used to adjust the height of the opening arranged between the lower end of the fireproof plate and the ash removal grate. A microcomputer control device can automatically control the operation of the boiler according to the set requirements. Using biomass fuels and coals, the invention has the advantages of high efficiency and low emission, which accords with the requirements of environmental protection and energy saving.

Owner:SHANDONG DUOLE HEATING EQUIP

Grates with heat shield

ActiveUS20090260614A1Well formedStoves/ranges foundationsSolid bar grateProcess engineeringHeat shield

Owner:ELECTROLUX HOME PROD CORP NV

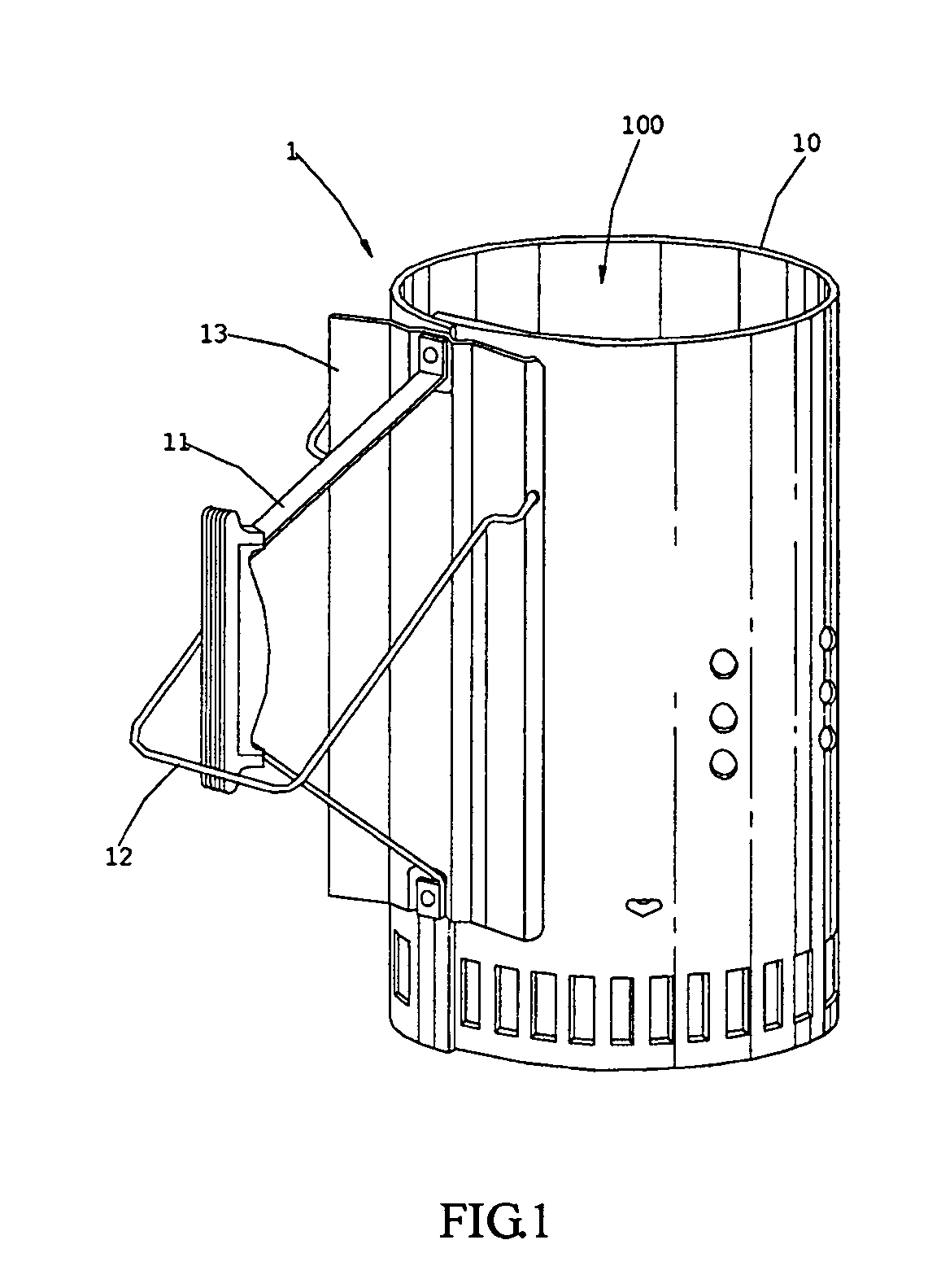

Fire igniter of carbonaceous fuel

Owner:CHANG FREDDIE

Grate apparatus and method

InactiveUS20080115778A1Overcome disadvantagesDomestic stoves or rangesSolid bar grateEngineeringMechanical engineering

Owner:GENERAL ELECTRIC CO

Hearth rotary furnace bar

InactiveCN101655242ABurn fullyRealize home appliancesDomestic stoves or rangesSolid bar grateMicromotorEngineering

The invention relates to the stove and discloses a hearth rotary furnace bar. The furnace bar is connected with the hearth through a rotating device arranged on the inner wall of the bottom base of the hearth, one end of the furnace bar is driven by outside force to rotate, a groove or a damping tooth can be arranged at the part of the furnace bar which is opposite to the hearth, and handle is arranged on the furnace bar for manual rotation or the furnace bar can be also driven by a micromotor to rotate. The technical scheme of the invention is used to ensure that coal and other comburents canbe fully burnt, the operation is convenient and sanitary and the furnace can be used as furniture.

Owner:李仕清

Grate block for a refuse incineration grate

InactiveUS6964237B2Minimizes cutting through trashEasy to moveSolid bar grateHollow bar grateLitterEngineering

Owner:HEPP MARK P

Grate for efficiently burning fuel

InactiveUS20060260604A1Efficiently burning fuelDomestic stoves or rangesSolid bar grateEngineeringMechanical engineering

Owner:HATA RICHARD

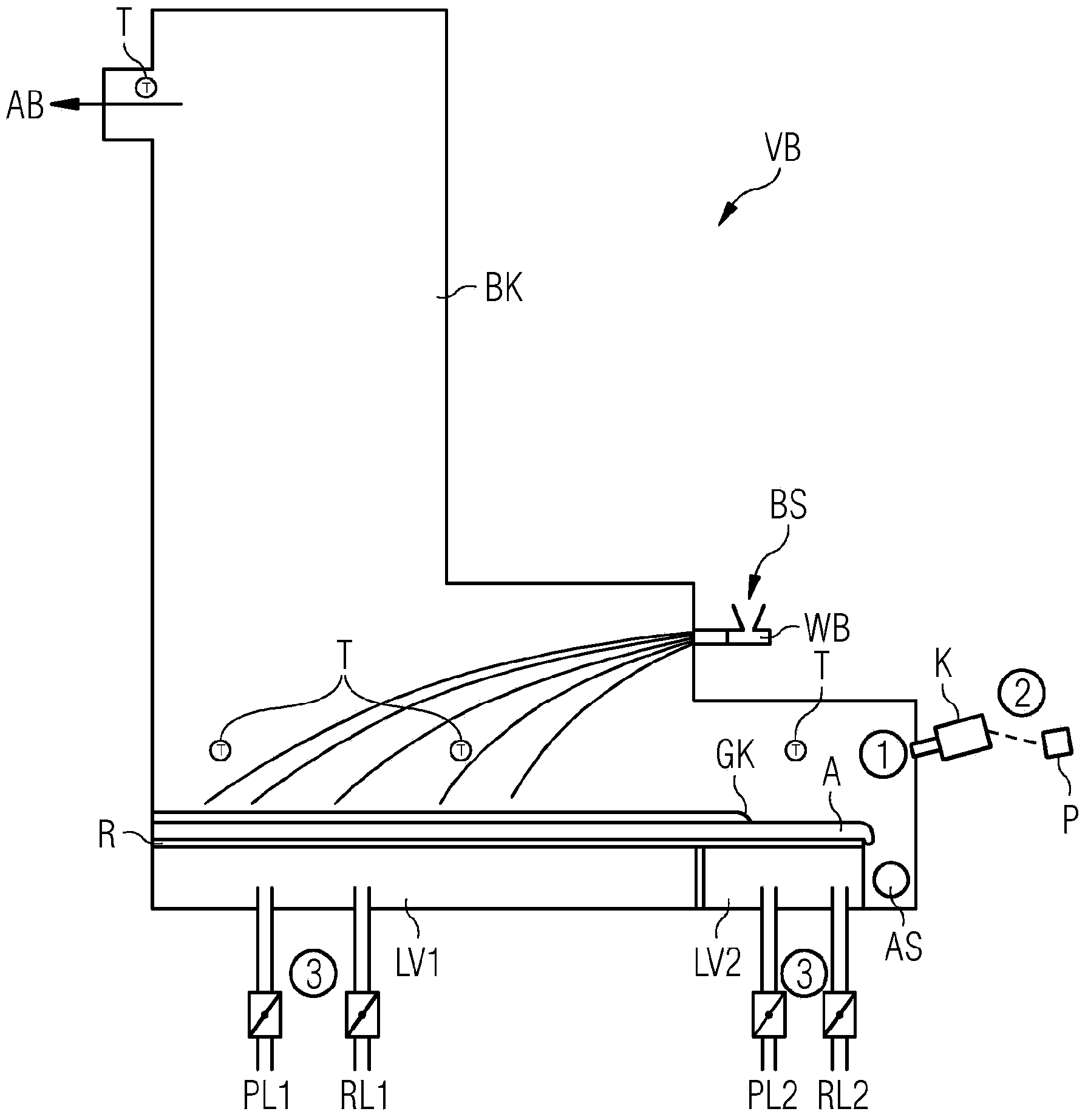

Method for controlling a combustion and/or gasification device

Combustion and / or gasification devices for the thermal utilisation of different solid fuels, and a method for controlling a combustion and / or gasification device for small-size solid fuels with throw-feeding. A combustion and / or gasification device includes at least one combustion or gasification chamber and a grate with at least two grate zones which are arranged in a longitudinal direction of the grate. A glowing fire edge is formed in one of the grate zones, especially in the so-called burnout zone.

Owner:CHRISTOF INT MANAGEMENT

Fire grate for enhanced combustion with vertical and horizontal expansion sleeves

ActiveUS8602020B2Harmful emissionStay longerDomestic stoves or rangesSolid bar grateParticulatesCombustion chamber

An improved fire grate may provide fresh oxygen rich air to a secondary combustion zone, created by the improved fire grate, of a combustion chamber where a combustion gas stream is typically oxygen starved assisting in the burning process of incompletely burned particulates and reducing other harmful emissions. A baffle plate may be introduced in the secondary combustion zone to increase a combustion chamber temperature, encourage mixing of oxygen starved air with oxygen rich air and increase a residence time of the combustion gas within the combustion chamber. These aspects of the baffle plate promote more efficient burning of the biomass / fuel. Additionally, log lighter(s) may be disposed in the secondary combustion zone to increase a temperature of the combustion chamber for the purposes of reducing harmful emissions. The improved fire grate may be horizontally and vertically adjusted to fit within different sized fireplace combustion chambers.

Owner:EARTHS FLAME

Pellet stove

ActiveUS20190383491A1Control burning rateImprove efficiencyDomestic stoves or rangesSolid bar grateCombustionEngineering

A pellet stove includes a hopper for storing pellets, a basket for receiving the pellets by gravity, a duct for conveying combustion air to the basket, and a conduit for conducting heated air away from the basket. The position of the basket is adjustable, such as by raising and lowering it, or by rotating it, so as to control the number of pellets in the area of most intense combustion. One or more optional burn plates, positioned below the basket, provide platforms on which pellets falling through the basket can burn down to a smaller size. The pellet stove requires no external source of power. The stove so constructed enables quiet, efficient and clean burning of the pellets.

Owner:HILL RICHARD L +1

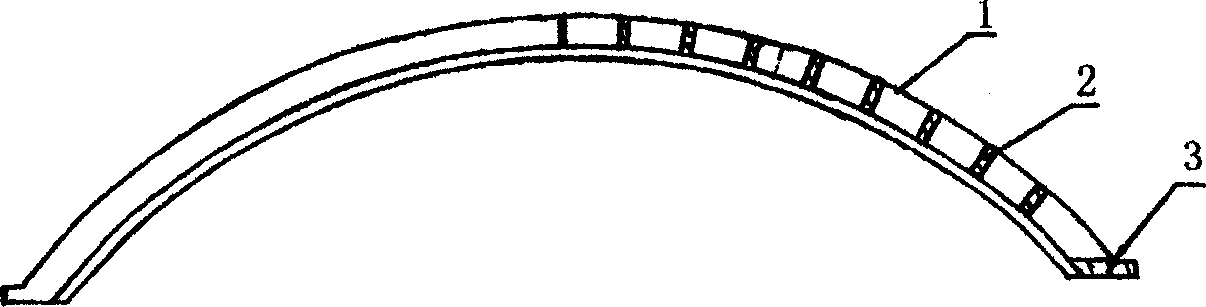

Technology for preparing incomplete globe cased grate core of hot air furnace

InactiveCN1343538AImprove yieldMaking Wooden Models SimplifiedSolid bar grateFoundry mouldsMaterials scienceCasting

A technology for manufacturing the grouped core of incomplete global grate for hot air furnace includes dividing the grate into bars according to the shape and position of grate plate and grate hole,longitudinal grouping, making grouped cores, numbering them, and casing with novel casting sand. Its advantages are saving labour and time, high percentage of finished products and smooth surface of castings.

Owner:河北津西钢铁集团重工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com