Grate assembly

a technology of grate and assembly, which is applied in the direction of solid bar grate, combustion process, light and heating apparatus, etc., can solve the problems of poor air circulation throughout the pile, incomplete combustion of a pile of wood pellets, and substantial fir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Although other applications may be envisioned for the present invention, the application of the present invention is particularly advantageous for efficiently burning wood pellets. It will be appreciated by one skilled in the art that the present invention may also be used to burn pellets made of other biomaterials such as corn, switchgrass, or organic waste. Accordingly, without intending to limit the present invention to the embodiments described herein, the invention will be described below in further detail having regard to the system and in particular the varied assortment and arrangement of devices used in that system as shown in the attached drawings.

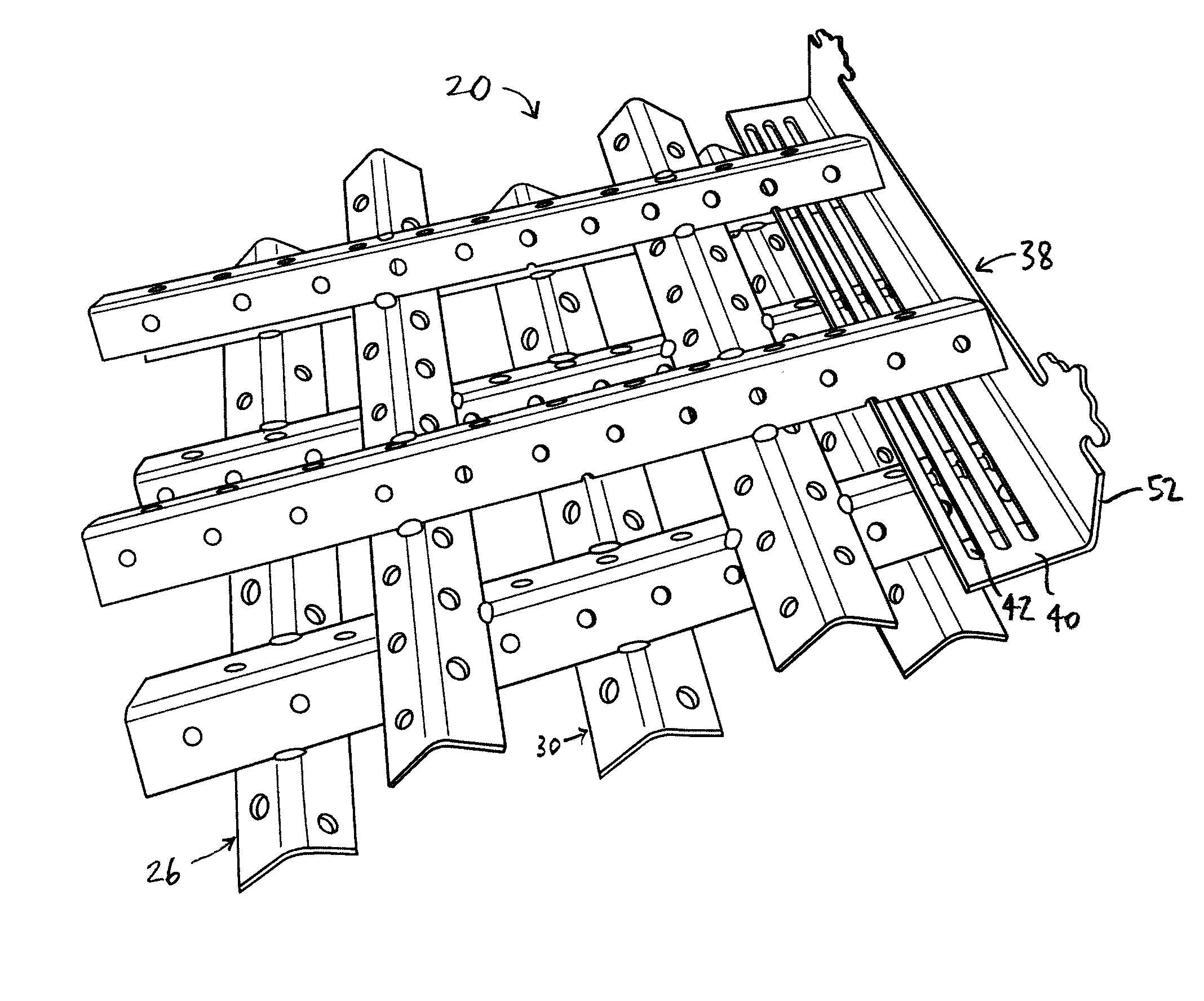

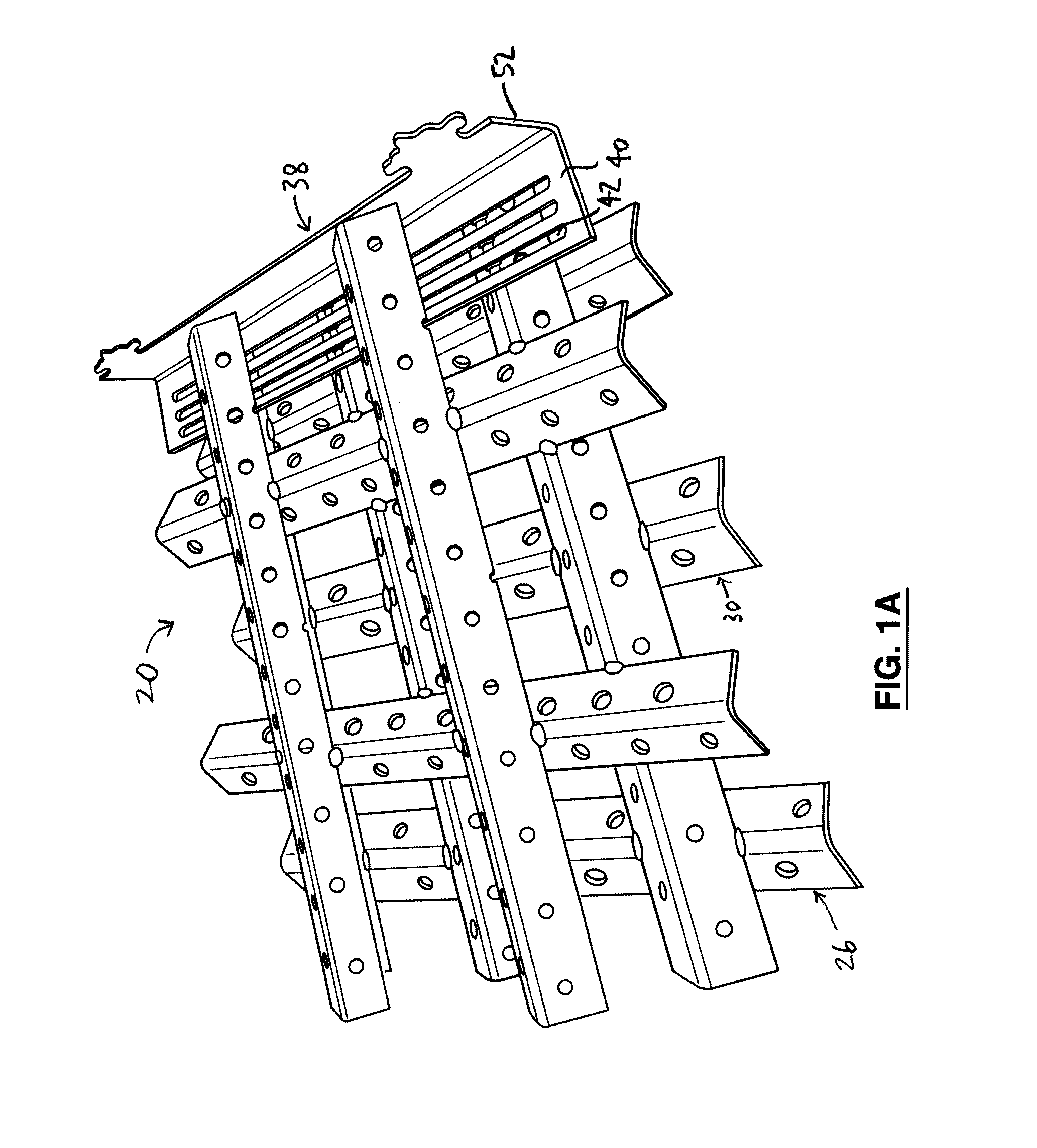

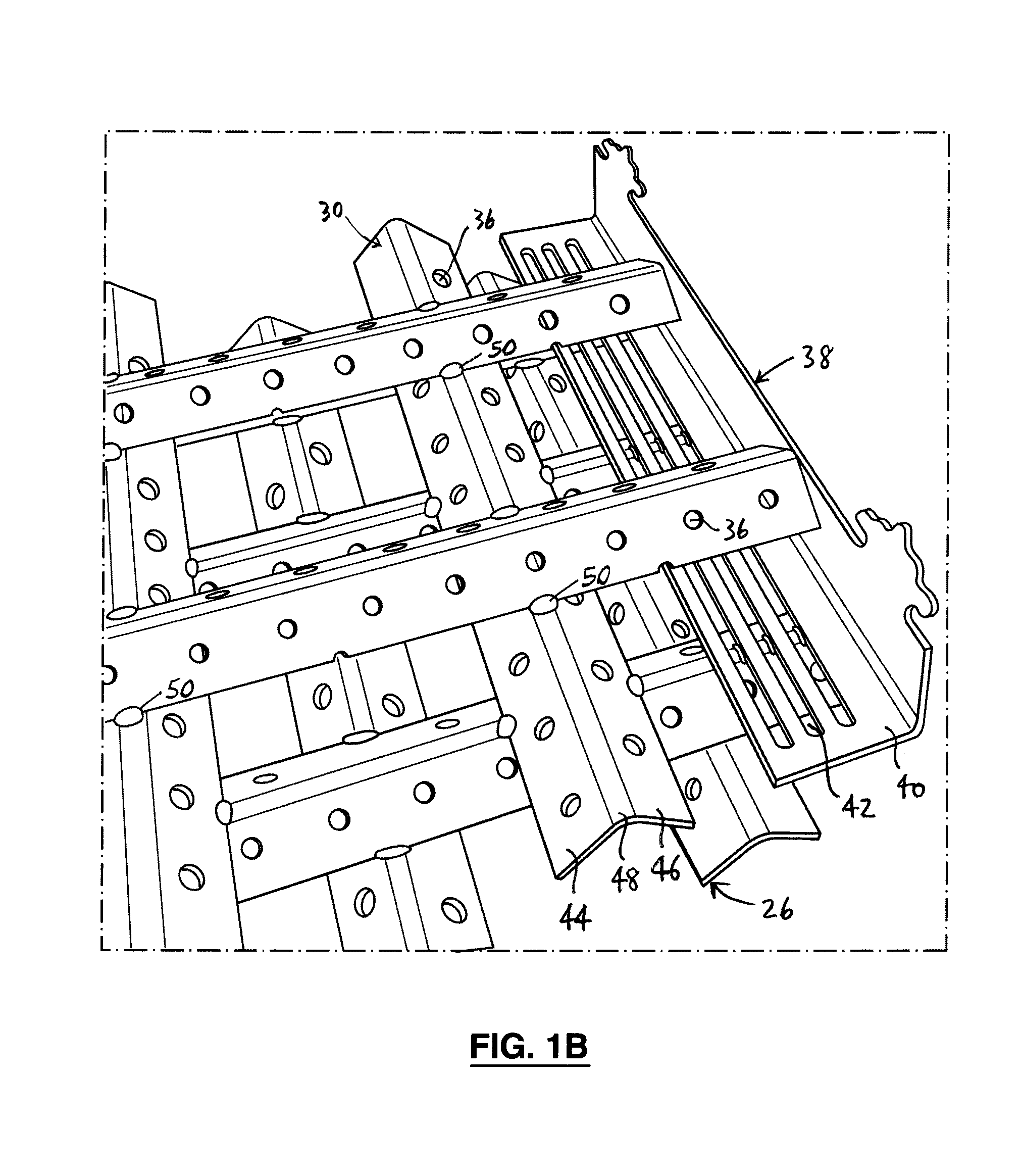

[0020]Reference is made to FIGS. 1A-5 to describe an embodiment of a grate assembly in accordance with the invention indicated generally by the numeral 20. The grate assembly 20 is for guiding air into a pile 22 of combustible wood pellets 24 for combustion thereof (FIGS. 3, 4). The grate assembly 20 preferably includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com