Technology for preparing incomplete globe cased grate core of hot air furnace

A technology of hot blast stove and core assembly, which is applied in the field of casting, which can solve the problems of prolonging the molding time, prone to choking, and large amount of gas generation, and achieve the effects of speeding up the production cycle, shortening the core-making time, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

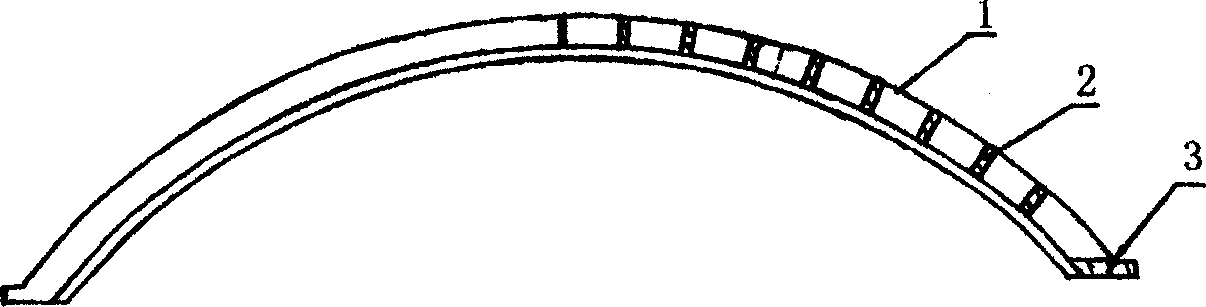

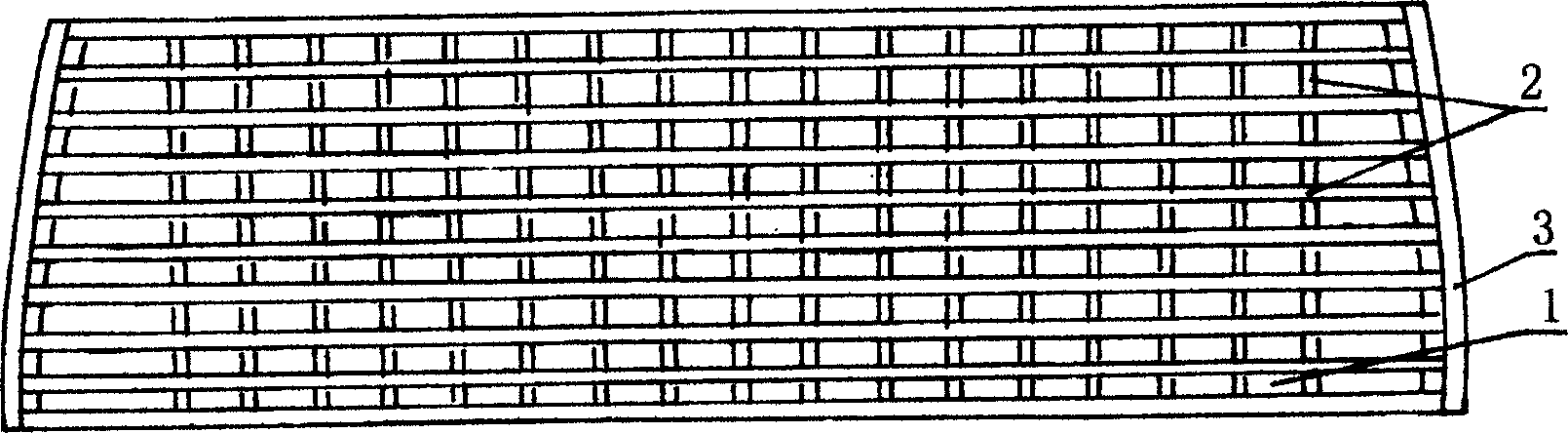

[0021] figure 1 , figure 2 Shown is a schematic diagram of the shape and structure of a spherical shell-shaped hot blast stove grate. The upper and lower sides of this kind of grate are arched, and the two ends are arc-shaped side bars 3, and the vertical and horizontal intersecting grate ribs 2, and the two ends are connected to the side bars 3. Integrating into one, the vertically and horizontally intersecting grating plates 2 enclose 162 grating holes 1 with different sizes and shapes. More than 160 chips need to be produced according to the conventional method of mandrel making, which is labor-intensive and time-consuming. The size of the core body is not easy to guarantee, and the phenomenon of core pouring and core embedding is easy to occur during the general assembly, resulting in a low yield.

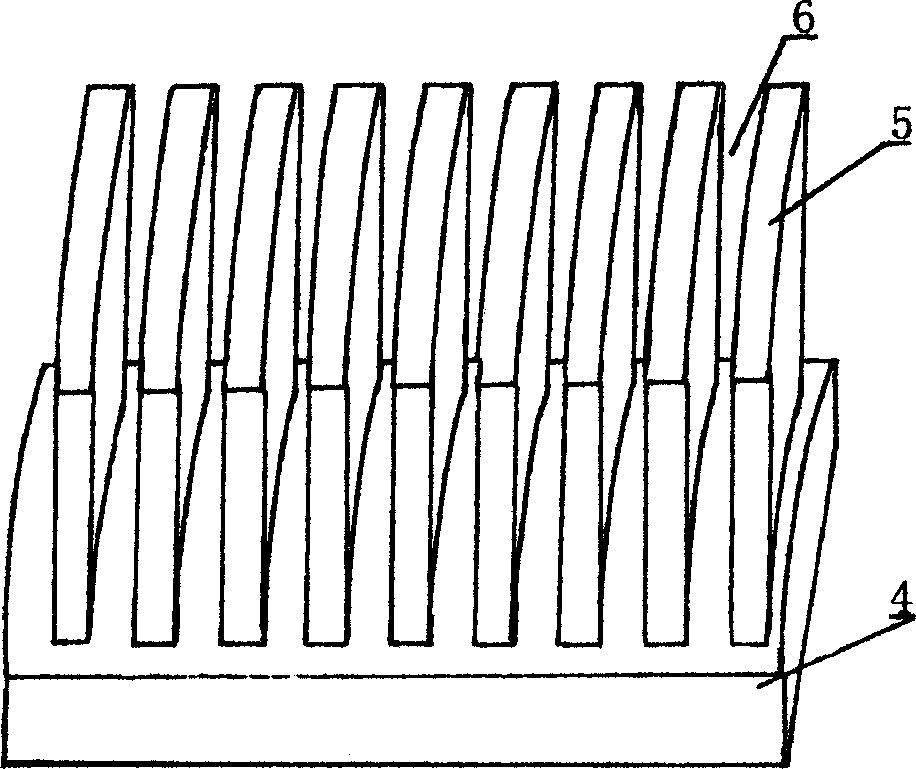

[0022] image 3 Shown is a schematic diagram of the shape and structure of a core assembly. Nine core plates 5 are arranged horizontally on the base 4. The upper surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com