Slag combustion apparatus of biomass boiler

A biomass boiler and combustion device technology, applied in combustion methods, combustion equipment, exhaust gas devices, etc., can solve problems such as combustion chamber damage, and achieve the effect of improving boiler efficiency, reducing fuel consumption and operating costs, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

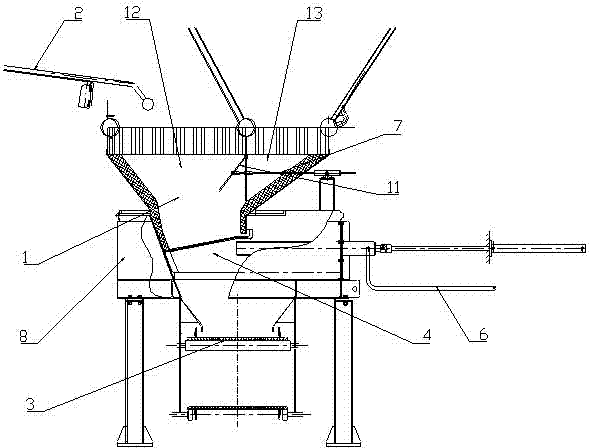

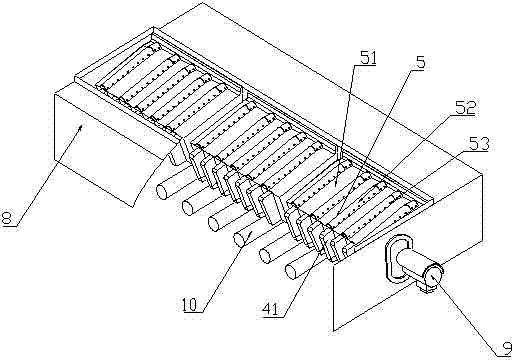

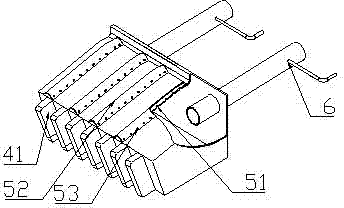

[0036] figure 1 It is the slag combustion device of the biomass boiler of the present invention, which includes a slag tank 1, which is arranged at the lower end of the grate 2, and is used to receive the slag after the grate is burned; a swinging partition 11 is arranged in the slag tank 1, The swinging partition 11 divides the slag tank 1 into a slag tank 12 communicating with the boiler combustion chamber and a fine ash tank 13 communicating with the boiler superheater side, and the inner wall of the slag tank 1 is poured with heat-resistant concrete. In order to ensure that the outer wall of the slag tank is not overheated or deformed during the combustion process of the slag in the slag tank. In this embodiment, the swing partition 11 is driven by a hydraulic cylinder to swing to realize the communication and isolati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com