Grate clearing and ash removal system for gasification furnace

a gasification furnace and ash removal technology, which is applied in the direction of lighting and heating apparatus, combustion types, incinerator apparatus, etc., can solve the problems of feed screws pushing out over the top of the fuel pile, not moving the material successfully, and insufficient gravity alone to keep the grate clean, etc., to achieve the effect of longer run times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

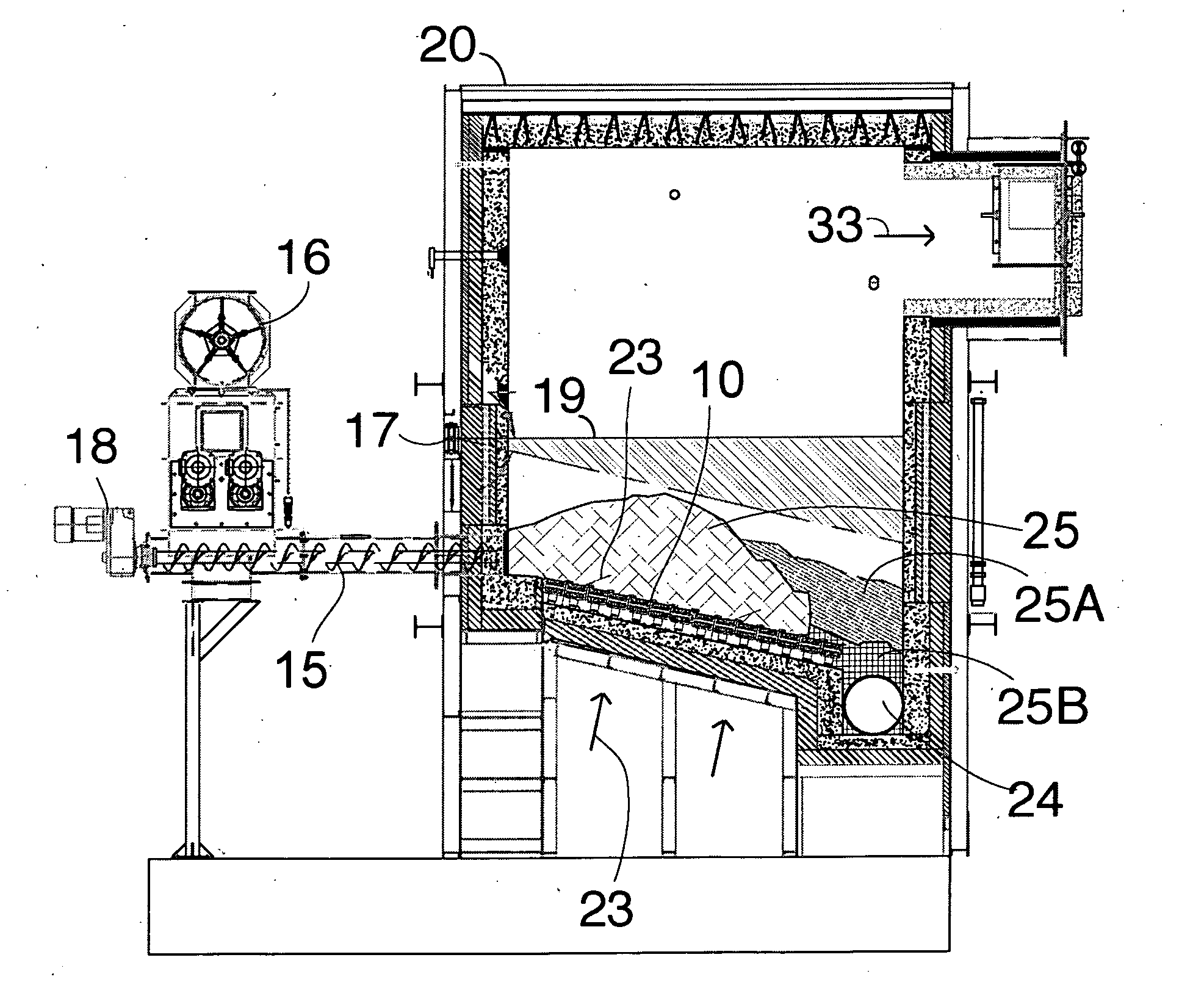

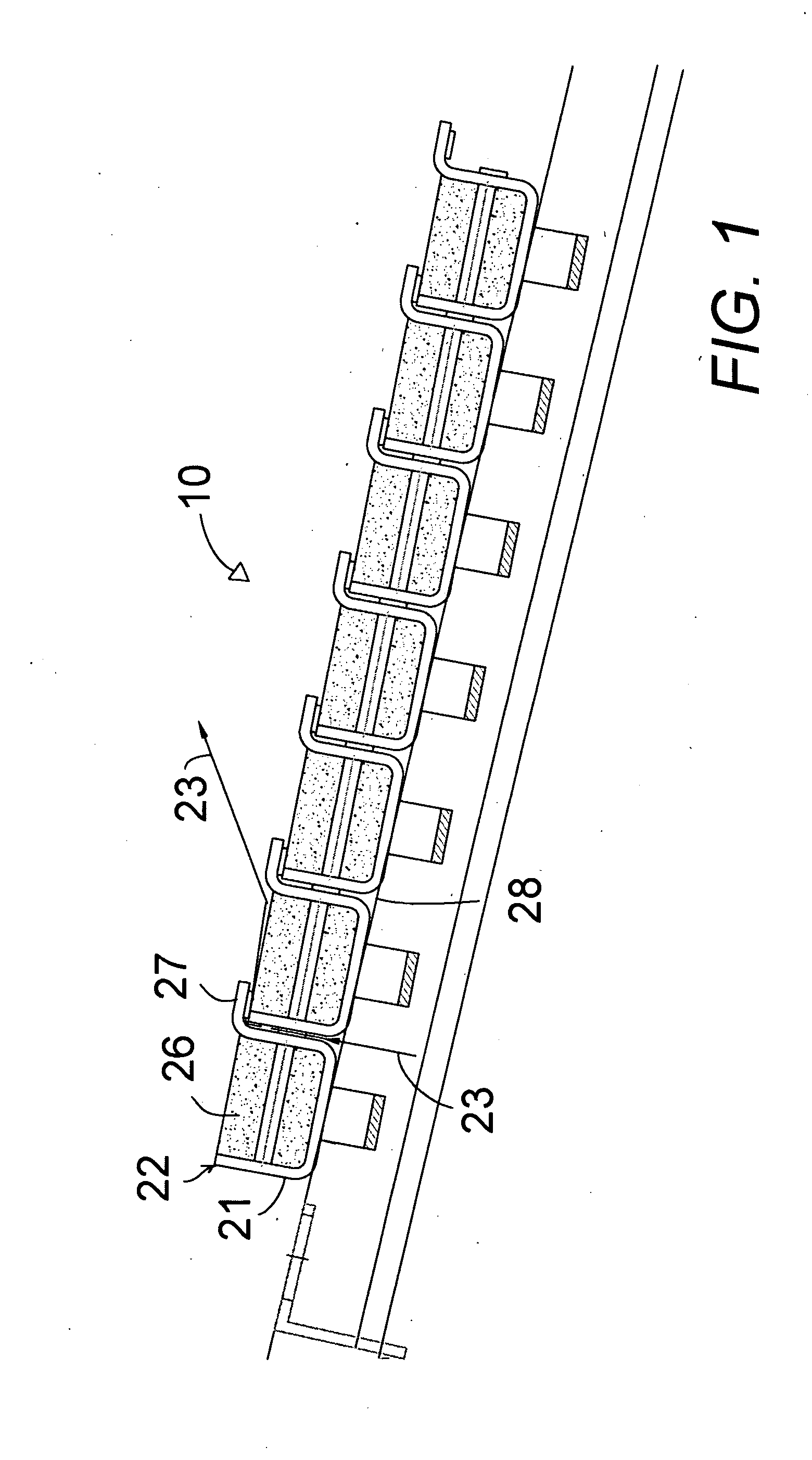

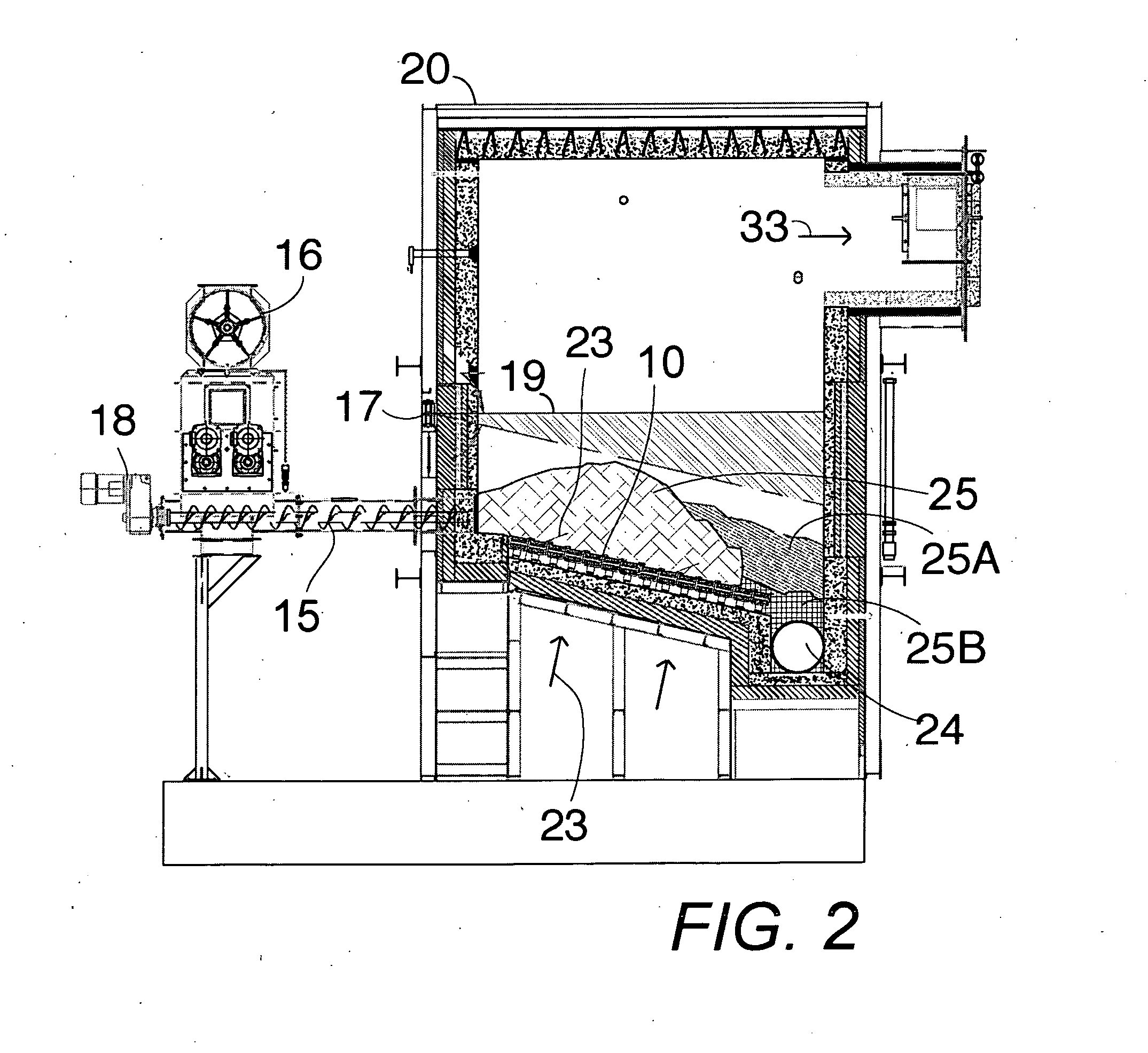

[0024]In FIGS. 1 and 3, an integrated system combines fuel grate structure 10 and angle and multiple feed auger 15 fuel movement components and under-fuel air flow directing components 27 for a grate clearing and fuel movement integrated system in a biomass gasification furnace.

[0025]In FIG. 1, the multiple feed screws 15 feed biomass fuel material 25 through a biomass fuel feed opening into a gasification chamber 20 of the biomass gasification furnace.

[0026]In FIG. 2, the fuel grate 10 comprises a series of interconnected grate elements 22 aligned in a linear array having aligned top surfaces 26. The grate extends from the biomass fuel feed opening through which the multiple feed screws 15 pass into and across the gasification chamber 20 angled downwardly at a slight acute angle from the horizontal so that the feed screws 15 press the fuel material 25 into and across the aligned top surfaces 26 of the grate elements to keep the bottom of the solid fuel moving along the aligned top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com