Patents

Literature

105results about How to "Improve dynamic mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing white carbon black/solution polymerized butadiene styrene rubber nano-composite material

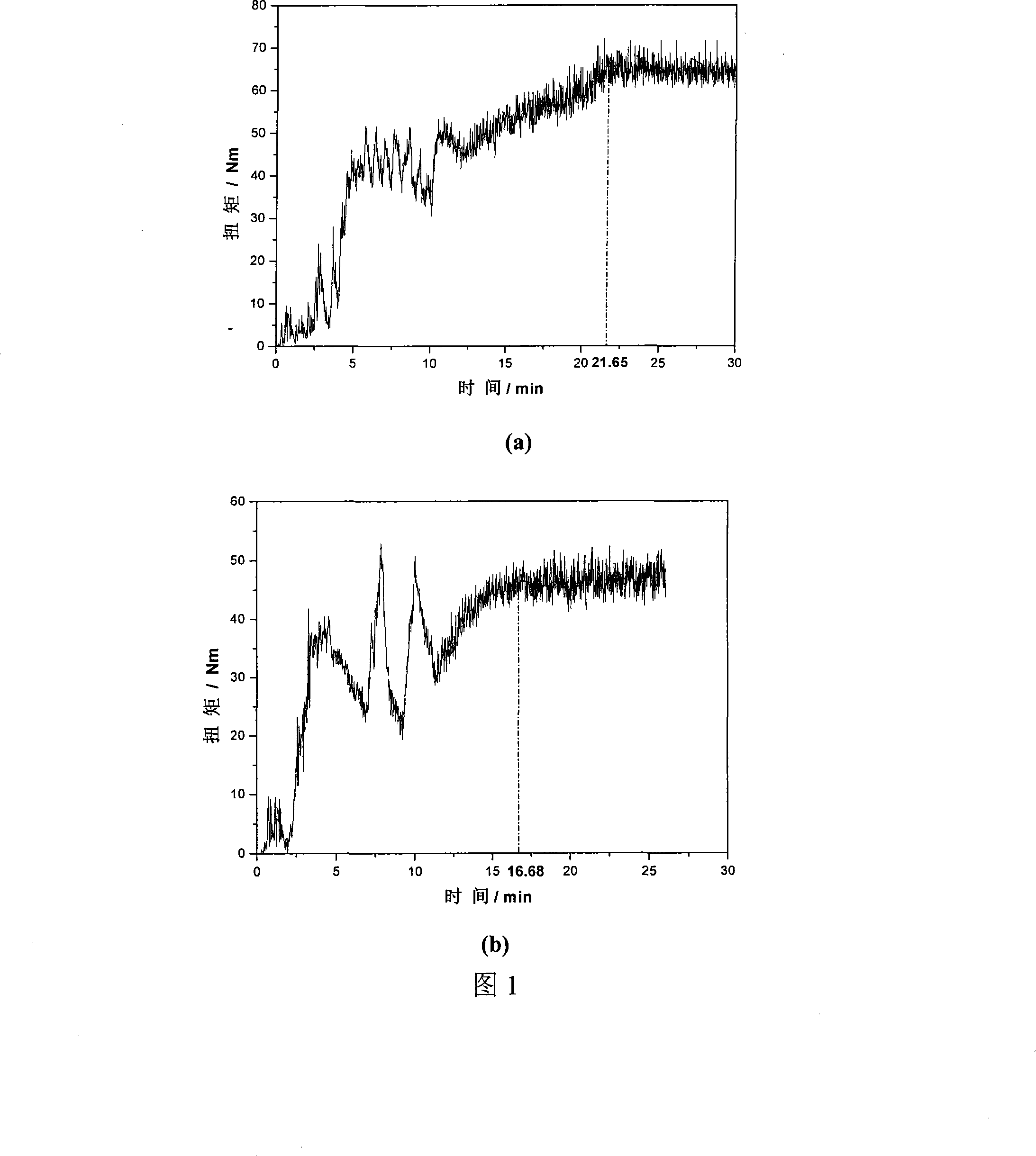

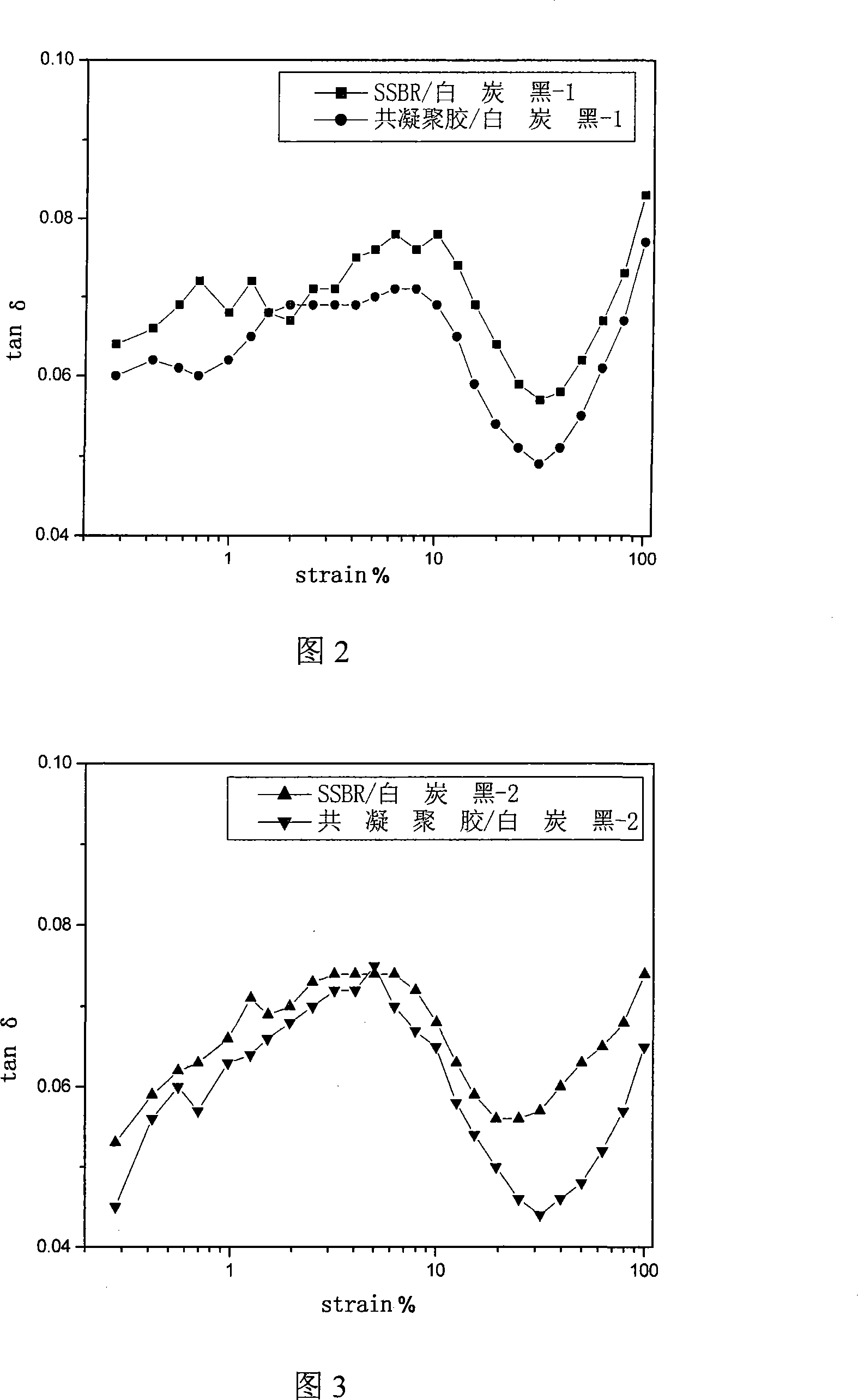

The invention relates to a method for preparing a white carbon black / solution-polymerized styrene-butadiene rubber nano composite material. In the invention, nano white carbon black powder and silane coupling agent are fully mixed and condensation reaction is carried out at high temperature, organic modified nano white carbon black powder is obtained and added into solution-polymerized styrene-butadiene; the mixture of the white carbon black powder and solution-polymerized styrene-butadiene is stirred and removes solvent and then dried, thus obtaining the silicon dioxide / solution-polymerized styrene-butadiene rubber nano composite material prepared by co-polymerization. The invention expands the range of methods for preparing the nano composite material with solution composition. The adopted method using the organically modified white carbon black is simple and easy for operation and the solution composite technique is fast and convenient with low cost. The prepared co-polymerized rubber can be taken as master batch and is added with the white carbon black or added with other fillings for preparing novel nano composite material. The physical and mechanical properties and dynamic mechanical property of the rubber prepared by the method are better than the properties of coordinative amount of filling prepared by mechanical mixing method and the composition speed of subsequent fillings of the rubber prepared by the method is faster than that prepared by the mechanical method.

Owner:BEIJING UNIV OF CHEM TECH

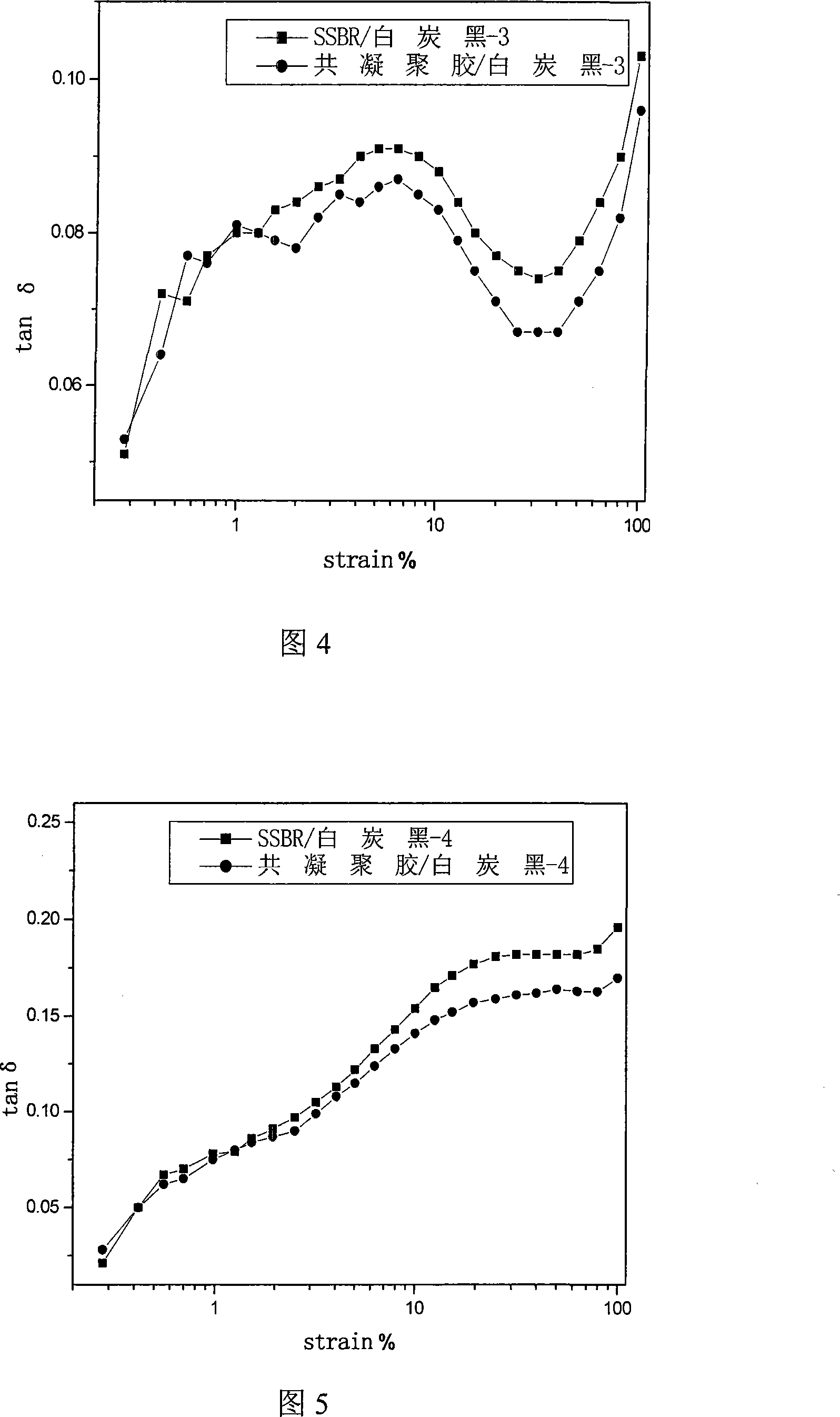

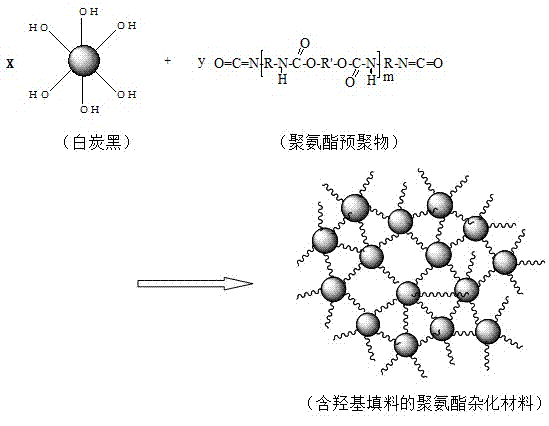

Method for preparing polyurethane hybridization material for hydroxyl-containing filler

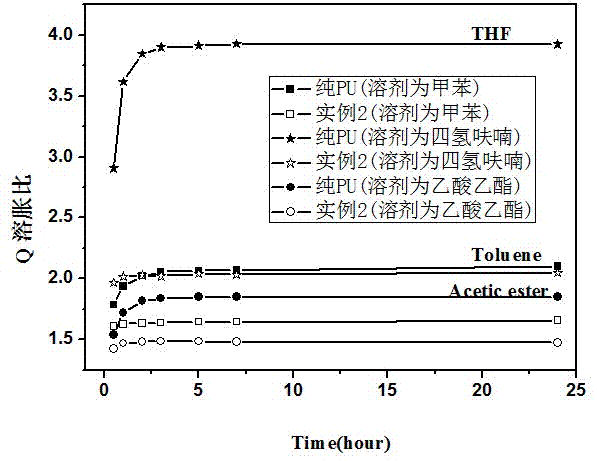

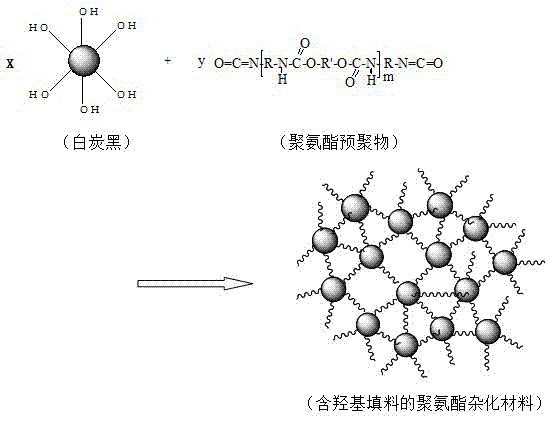

The invention relates to a method for preparing a polyurethane hybridization material for a hydroxyl-containing filler. The method comprises the following steps of: synthesizing polymer polyalcohol and isocyanate to form a polyurethane prepolymer of which the end group is isocyanato (-NCO), and mixing the polyurethane prepolymer with an inorganic filler of which the surface contains hydroxyl (-OH) fully; and reacting -OH on the surface of the inorganic filler and -NCO at the chain end of the polyurethane prepolymer at a certain temperature to prepare the polyurethane hybridization material for the hydroxyl-containing filler, which has excellent performance. According to the method, dihydric alcohol or diamine chain extenders are not needed to be added in the preparation process, and the hydroxyl-containing inorganic filler achieves an effect of the chain extenders and cross-linking agents. According to the method, particles of the inorganic filler are dispersed uniformly and not easy to agglomerate, and an interface between the inorganic particles and a polyurethane matrix is high in bonding; and the material has the characteristics of high strength and elasticity, abrasion resistance, heat resistance, oil resistance, solvent resistance and the like, and the preparation process is simple and low in cost.

Owner:SOUTH CHINA UNIV OF TECH

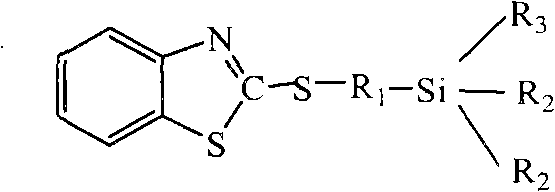

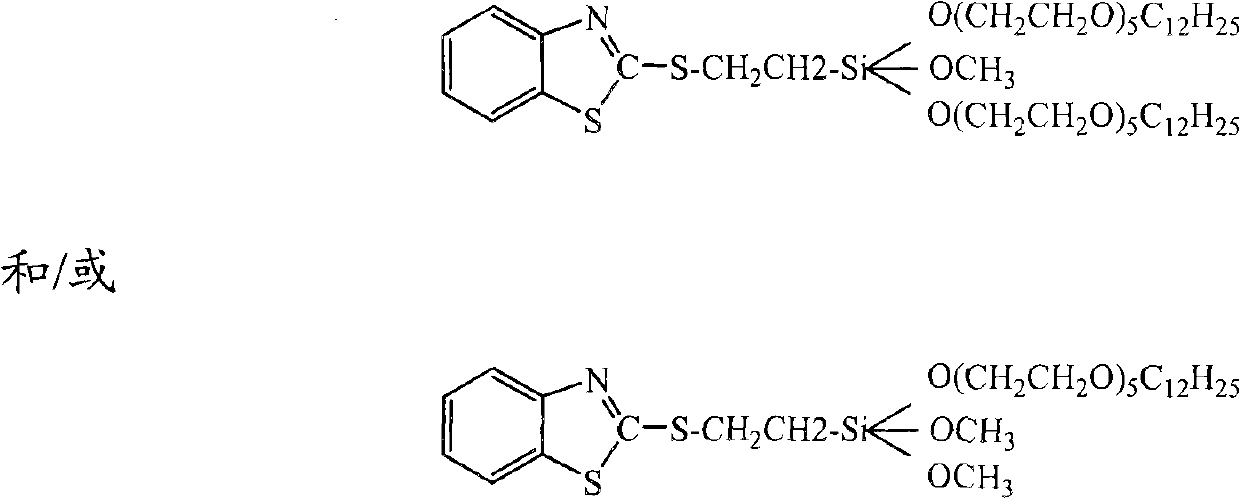

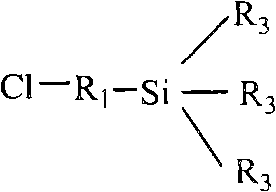

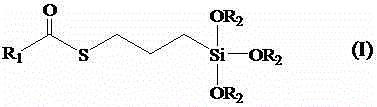

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

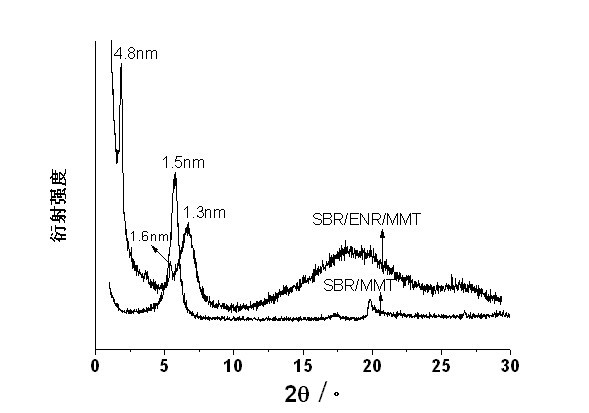

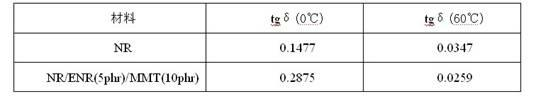

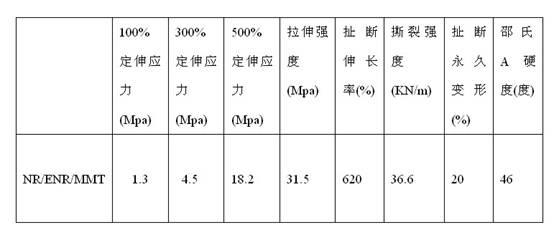

Method for preparing polymer/clay nano-composite

InactiveCN102153794AImprove performanceImprove modification efficiencyPolymer sciencePolymer chemistry

The invention relates to a method for preparing polymer / clay nano-composite by using epoxidized natural rubber latex as compatilizer of clay and a polymer. On the one hand, an epoxidized natural rubber molecular chain is inserted between clay layers to be subjected to chemical reaction with the clay layers, and the on the other hand, unsaturated double bonds in epoxidized natural rubber and the matrix polymer can be subjected to crosslinking reaction. The effect of dispersing the clay in the matrix polymer can be improved and the interaction between the clay and the matrix polymer can be enhanced by using the bridging function of the epoxidized natural rubber latex, and the high-performance polymer / clay nano-composite is prepared. The prepared polymer / clay nano-composite has excellent physical and mechanical properties and greatly improved dynamic mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

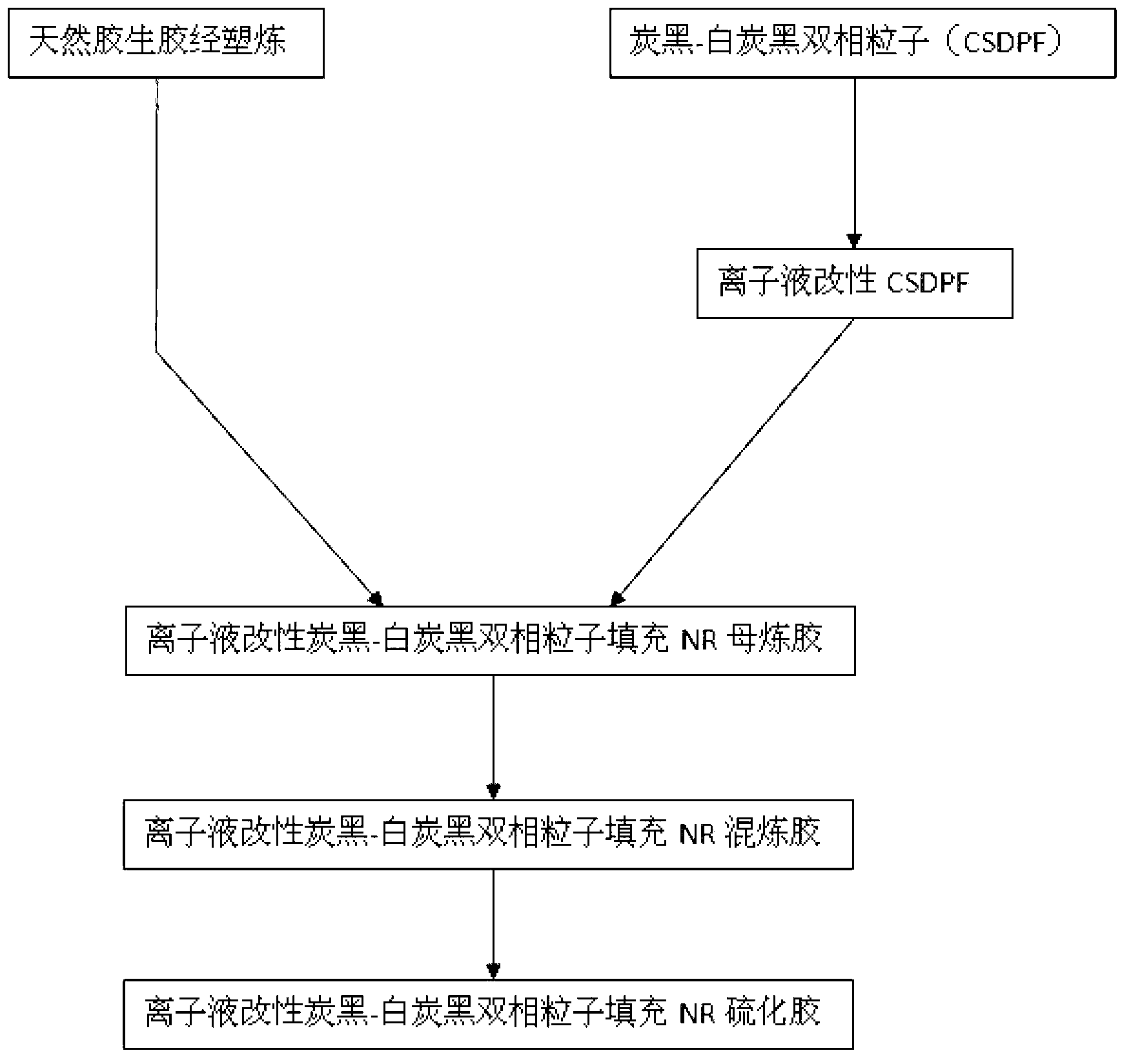

Ionic liquid modified carbon black-white carbon black double-phase particle filling natural rubber and preparation method thereof

ActiveCN103275365AGood mechanical propertiesImprove mechanical propertiesVulcanizationPolymer science

The invention relates to ionic liquid modified carbon black-white carbon black double-phase particle filling natural rubber and a preparation method thereof. The rubber comprises the following constituents: natural rubber, vulcanizing agent, ionic liquid, carbon black-white carbon black double-phase particles, zinc oxide, stearic acid, vulcanization accelerator, anti-aging agent and resin. The rubber has excellent stretch resistance and tear resistance performances, good fatigue resistance performance, good abrasive resistance, and good thermo-oxidative aging resistance performance, is low in dissipated heat, can prolong the service life of products during the use, can be applied to various rubber products, and particularly applied to tire tread rubber with high mechanical property requirements and good dynamic mechanical properties.

Owner:NANJING UNIV OF SCI & TECH

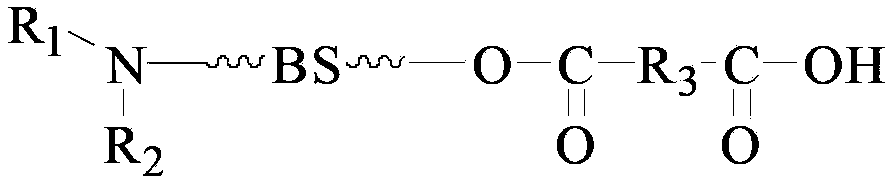

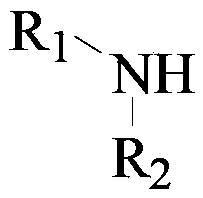

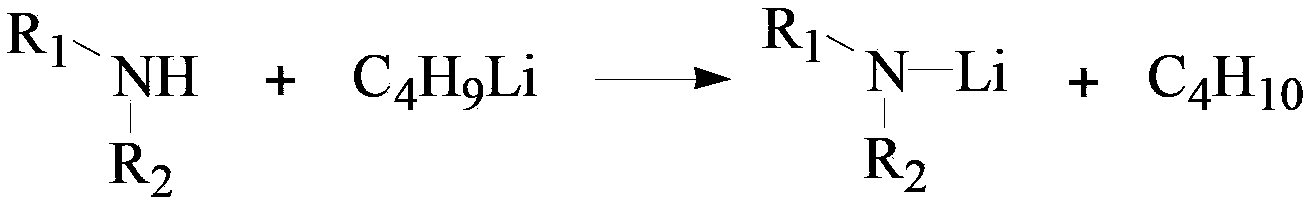

Terminal-modified solution-polymerized butylbenzene copolymer and preparation method and application thereof

ActiveCN104045772AIncrease productivityImproved shear resistanceRolling resistance optimizationSolventButyl lithium

The invention discloses a terminal-modified solution-polymerized butylbenzene copolymer and a preparation method and application thereof; terminals of the terminal-modified solution-polymerized butylbenzene copolymer comprise amino group and carboxy group; the preparation method is as follows: reacting a secondary amine with butyl lithium to prepare an active amino lithium compound; adding the prepared active amino lithium compound and a polymerization monomer into a reaction kettle filled with a solvent for initiation of polymerization reaction; after the polymerization reaction is completed, adding an anhydride for end capping reaction, after the end capping reaction is completed, adding a dilute acid solution for acidification to obtain the terminal-modified solution-polymerized butylbenzene copolymer. The active amino lithium compound prepared by reaction of the secondary amine and the butyl lithium can be used as an initiation agent with the structure regulation function in preparation of high branched butylbenzene copolymer containing terminal amino group; the preparation method has the advantages of simple operation and mild condition; the prepared polymer can be used in tire tread glue, is good in white carbon black bonding effect, can enhance strength, wear resistance and shear resistance of vulcanized rubber, reduces tire rolling hysteresis quality, reduces heat generation and resistance, and can be widely used in tire tread glue materials.

Owner:CHINA PETROLEUM & CHEM CORP

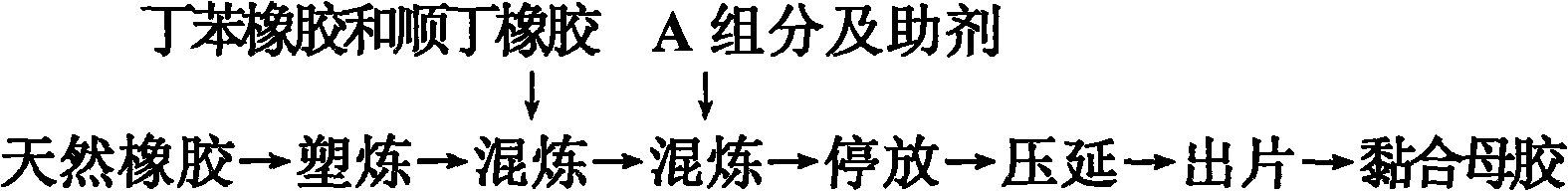

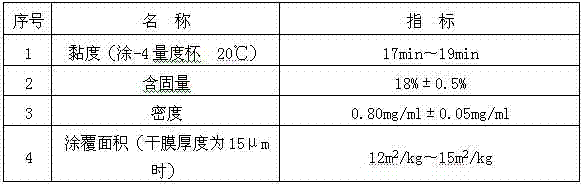

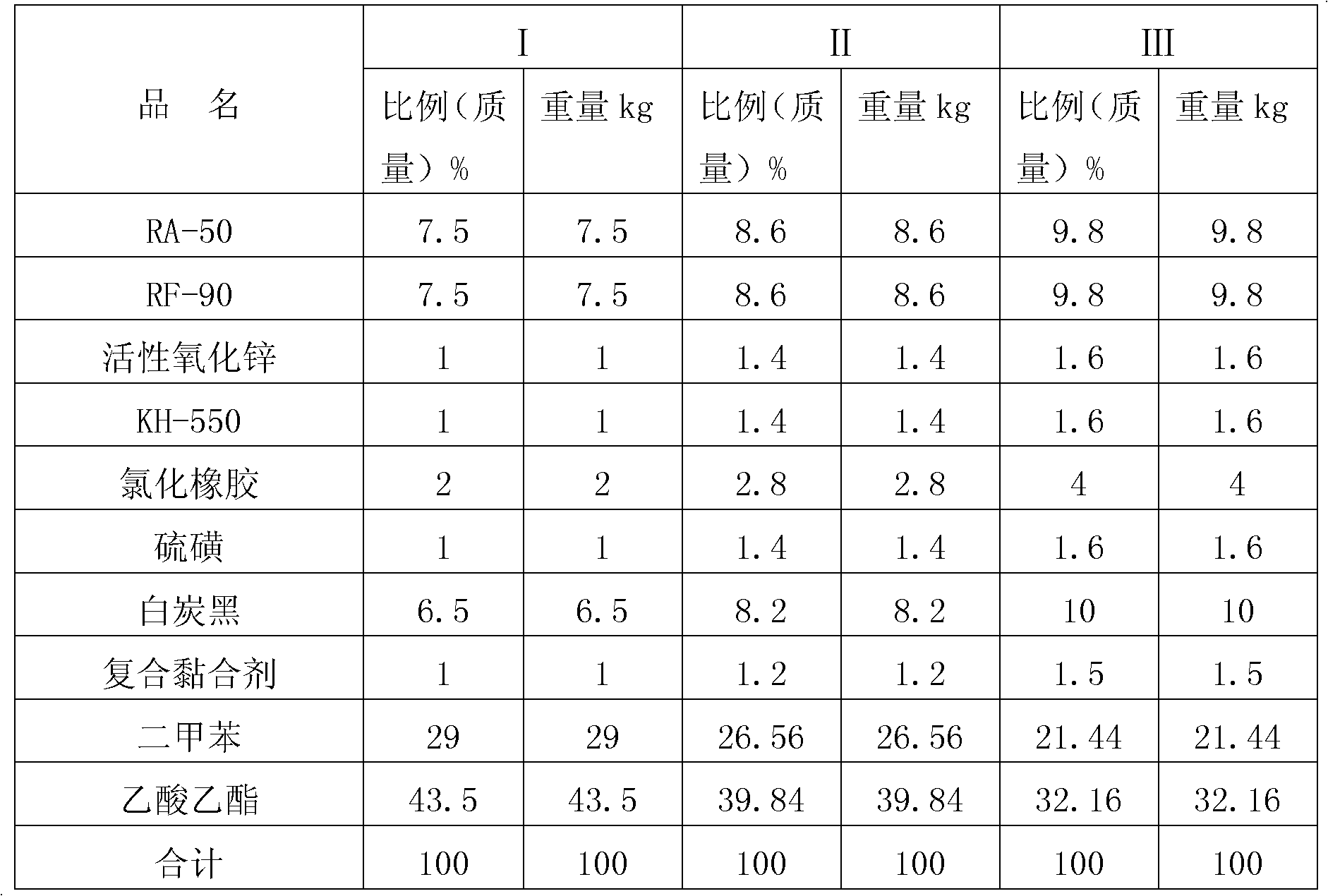

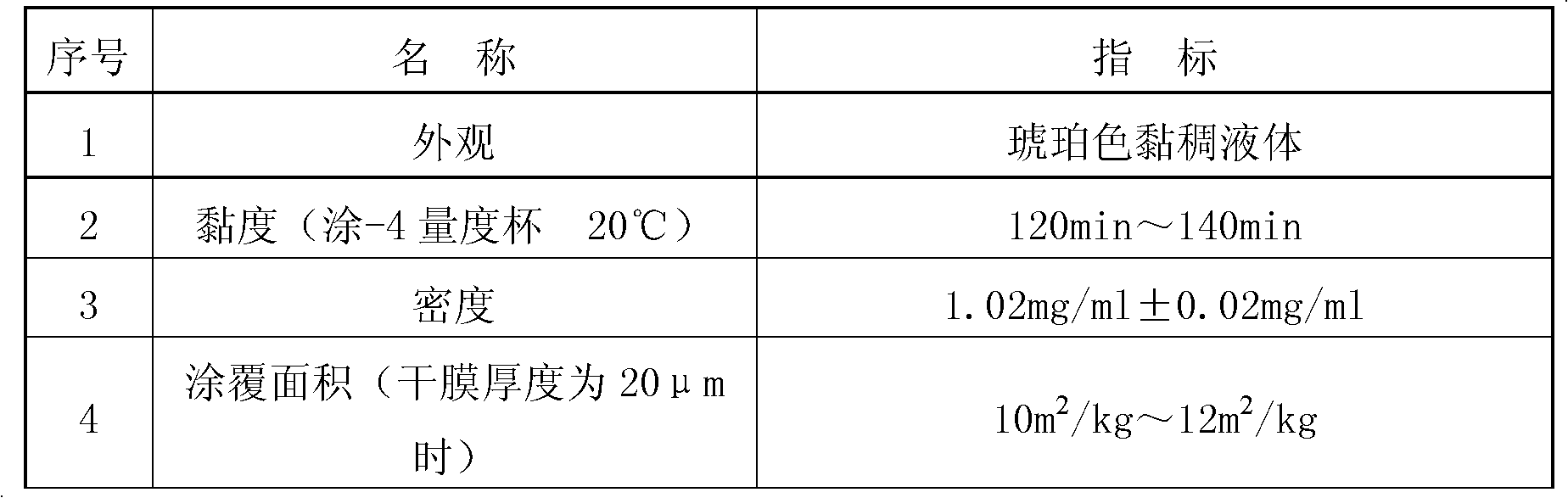

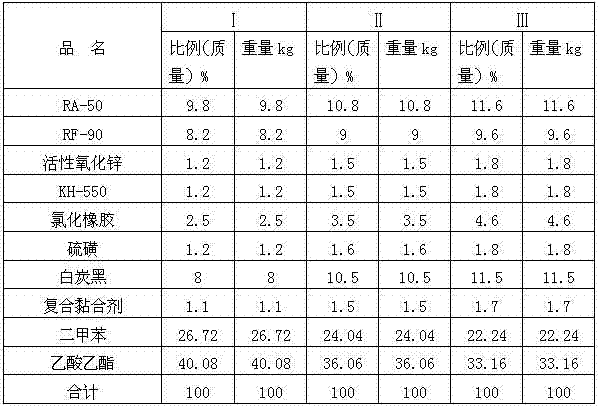

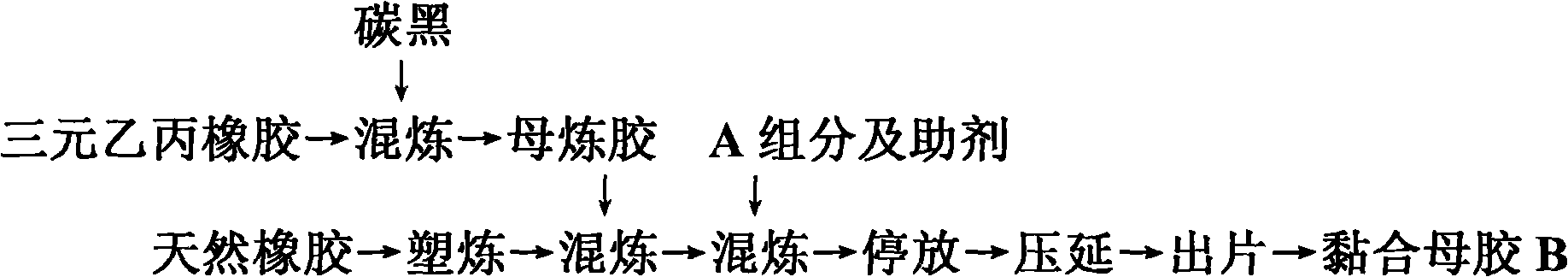

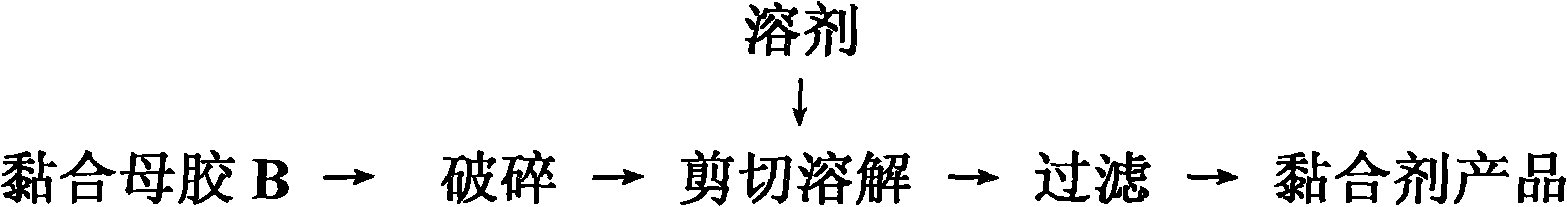

Coating-type binder used for bounding nitrile butadiene rubber and metal framework and preparation method

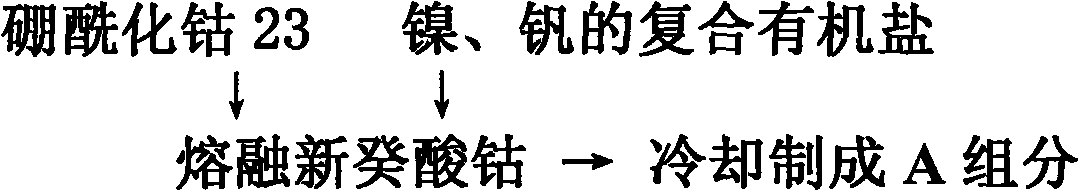

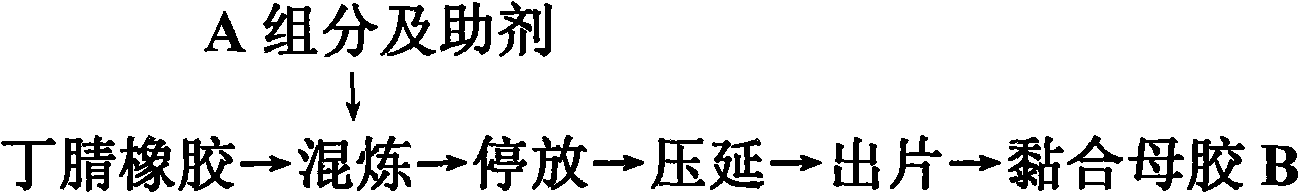

InactiveCN101560366AMeet the needs of processing and productionImprove thermal stabilityNon-macromolecular adhesive additivesConjugated diene hydrocarbon adhesivesCompound organicRubber material

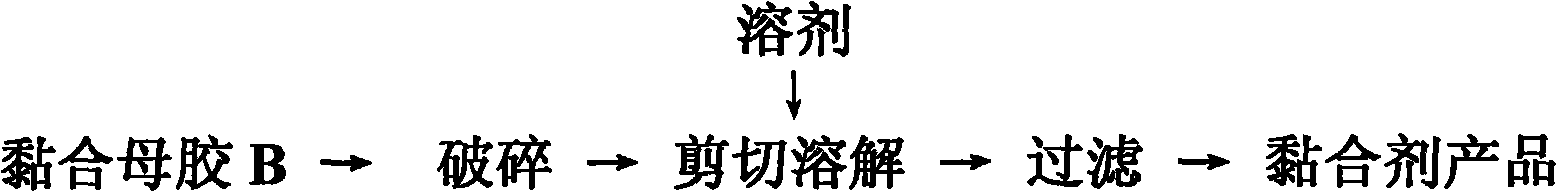

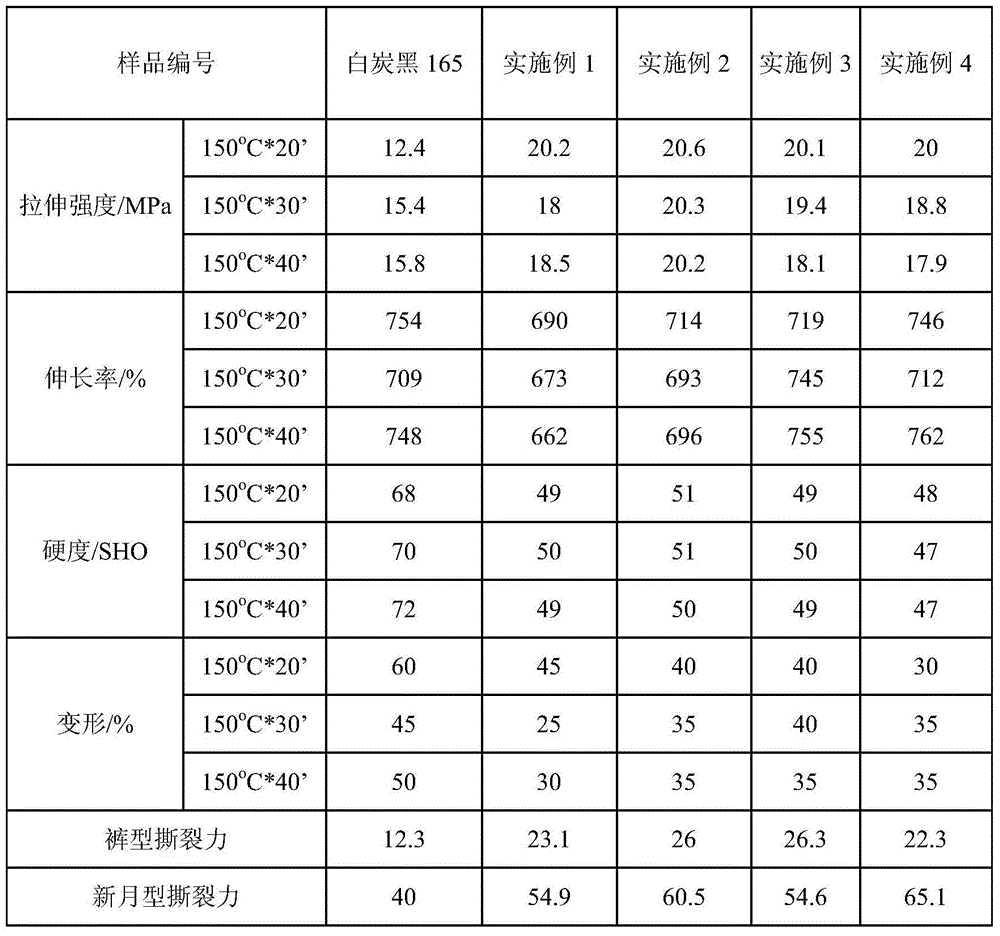

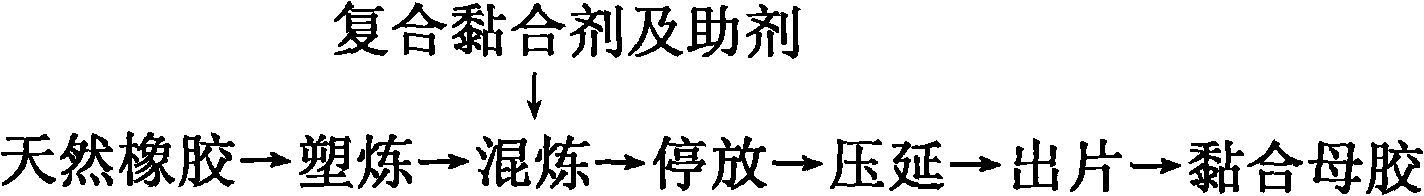

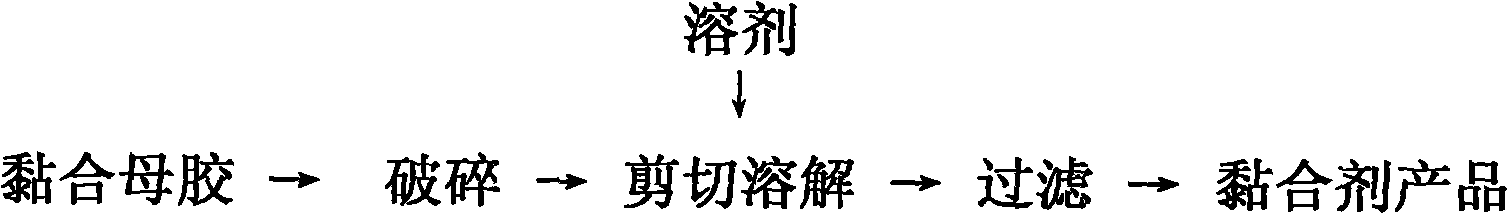

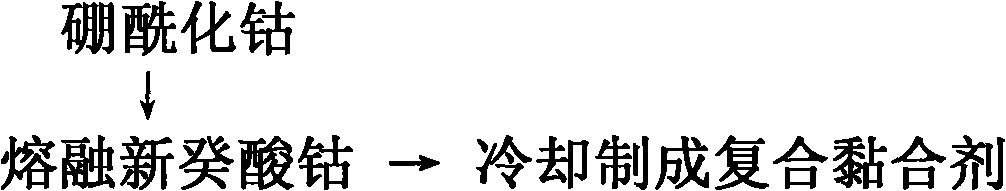

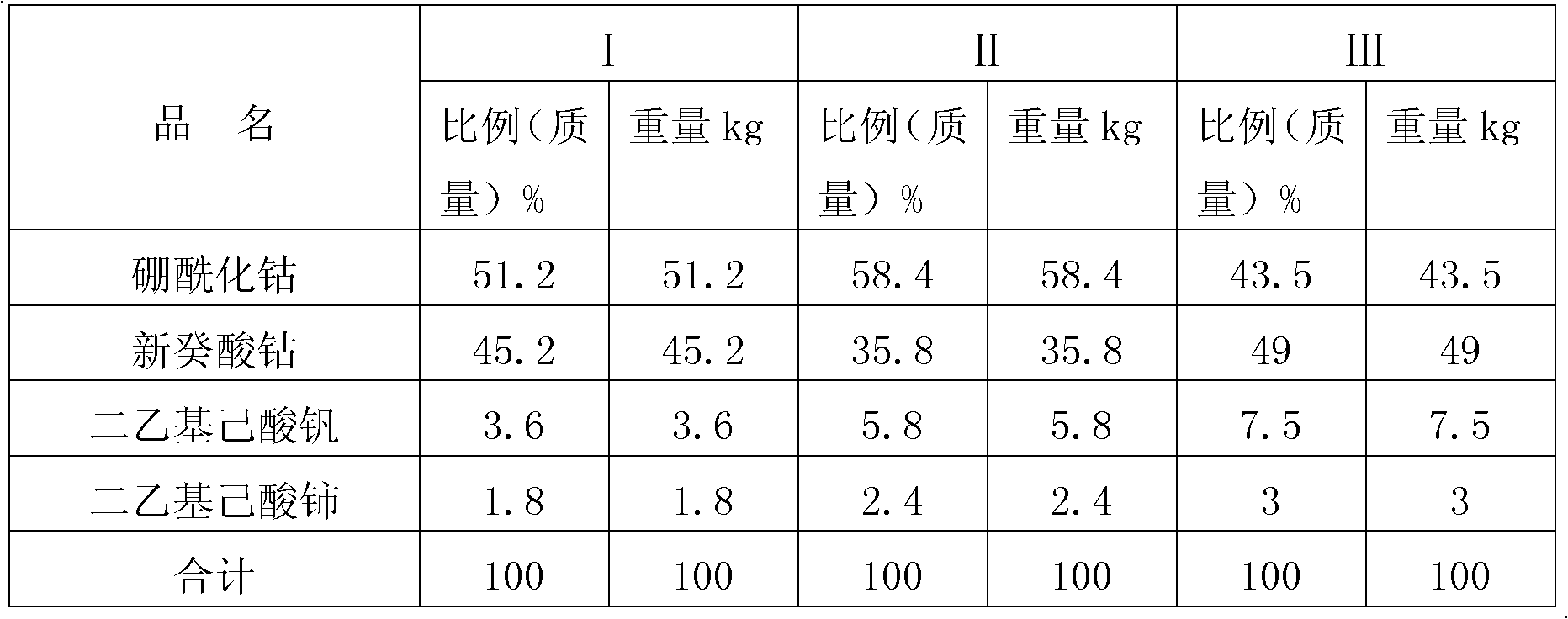

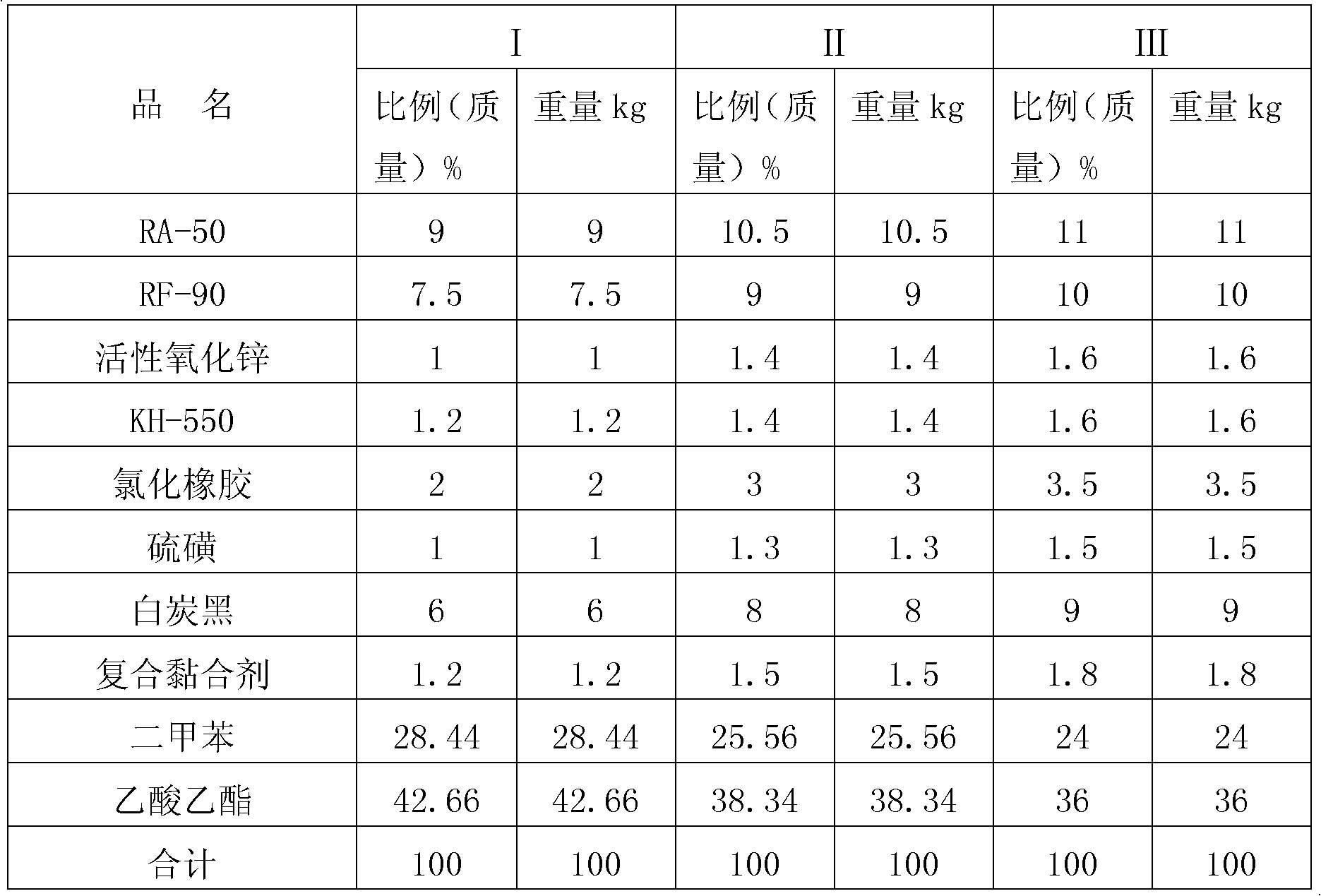

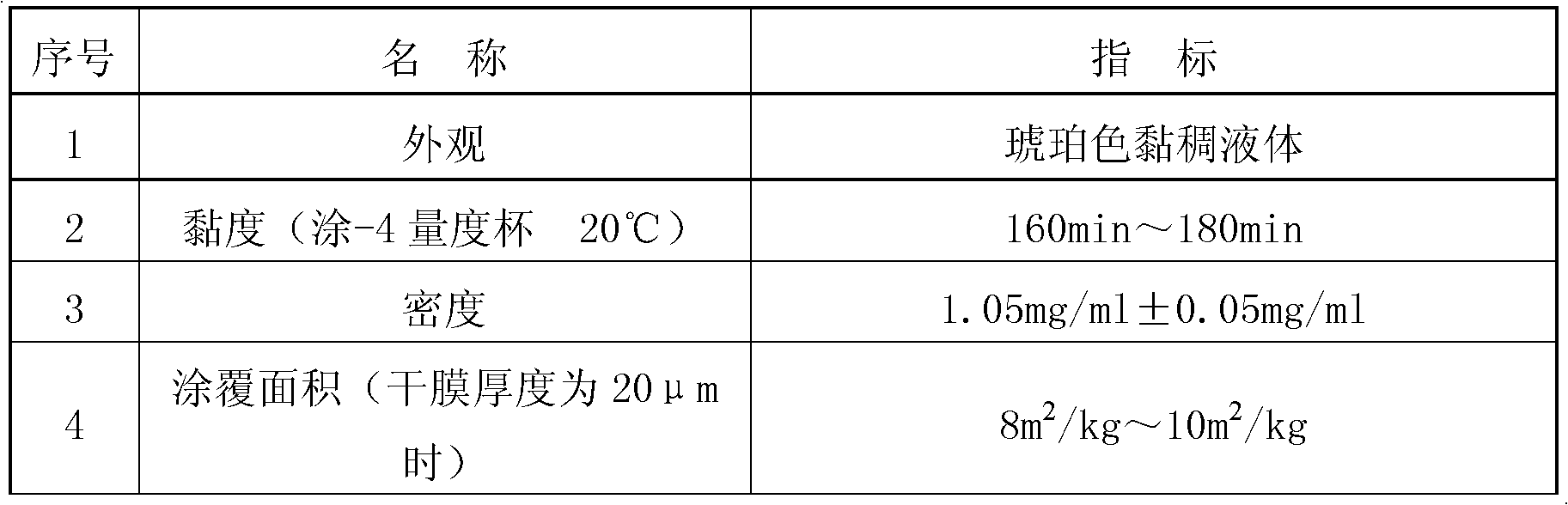

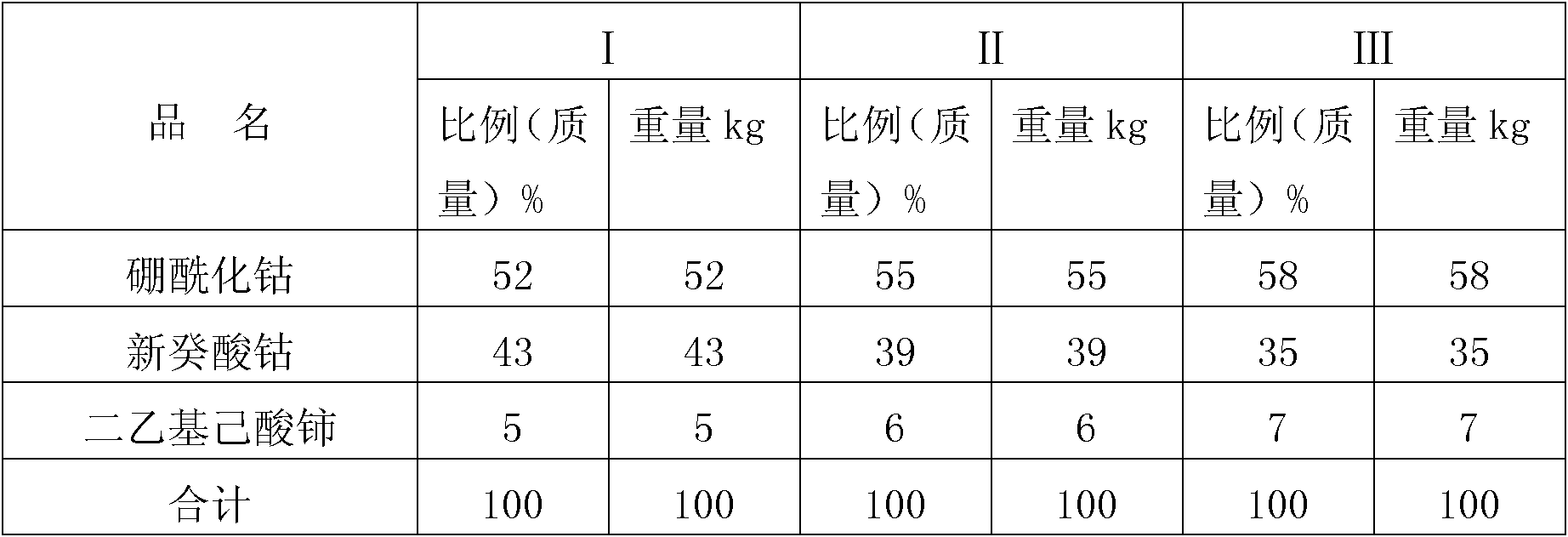

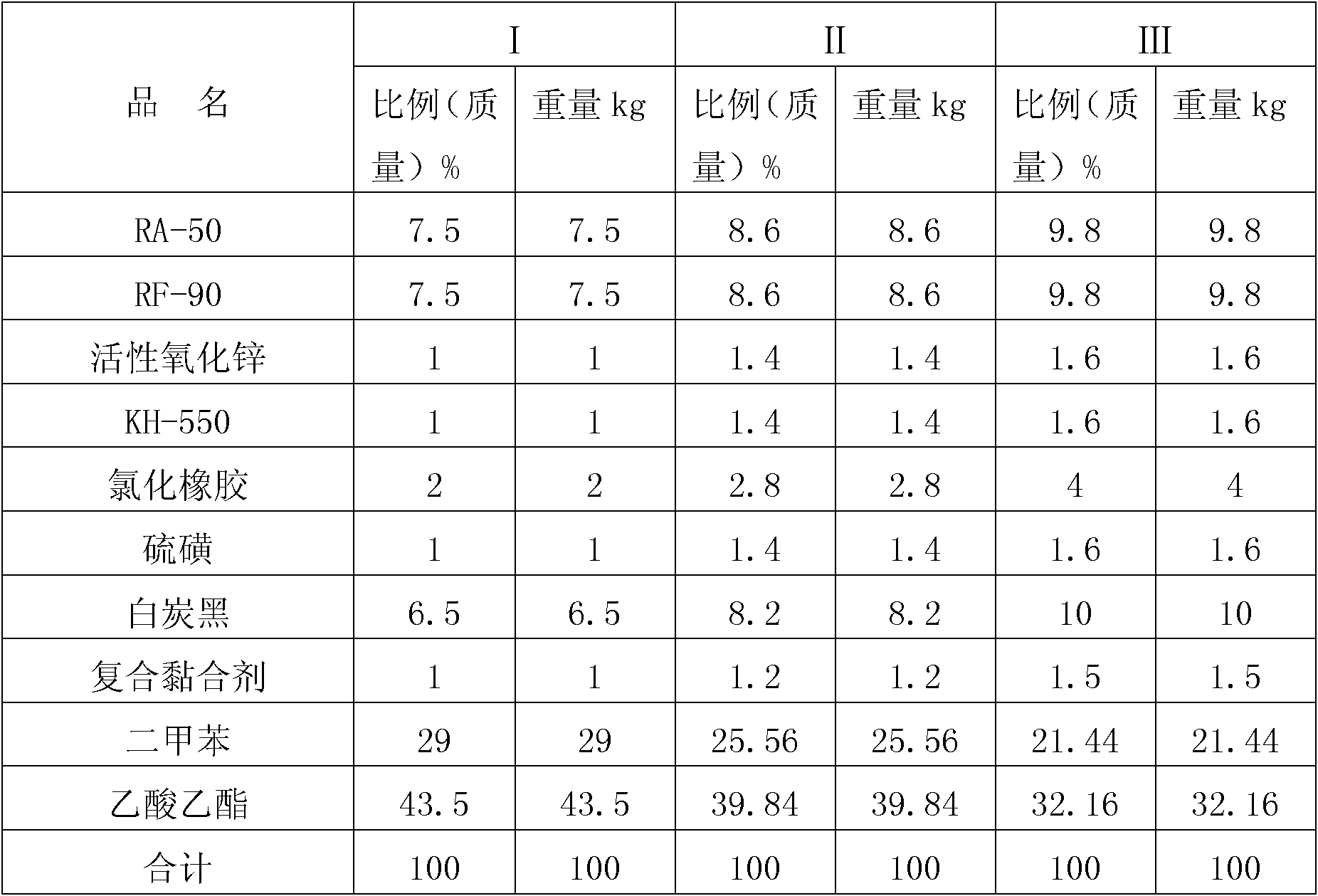

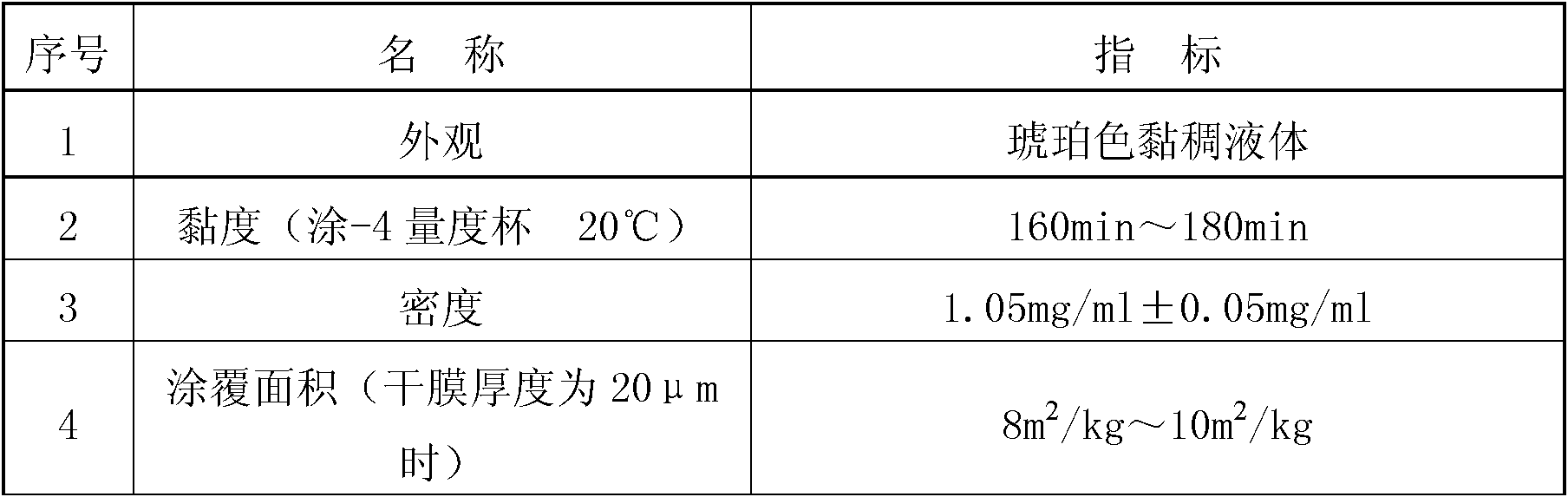

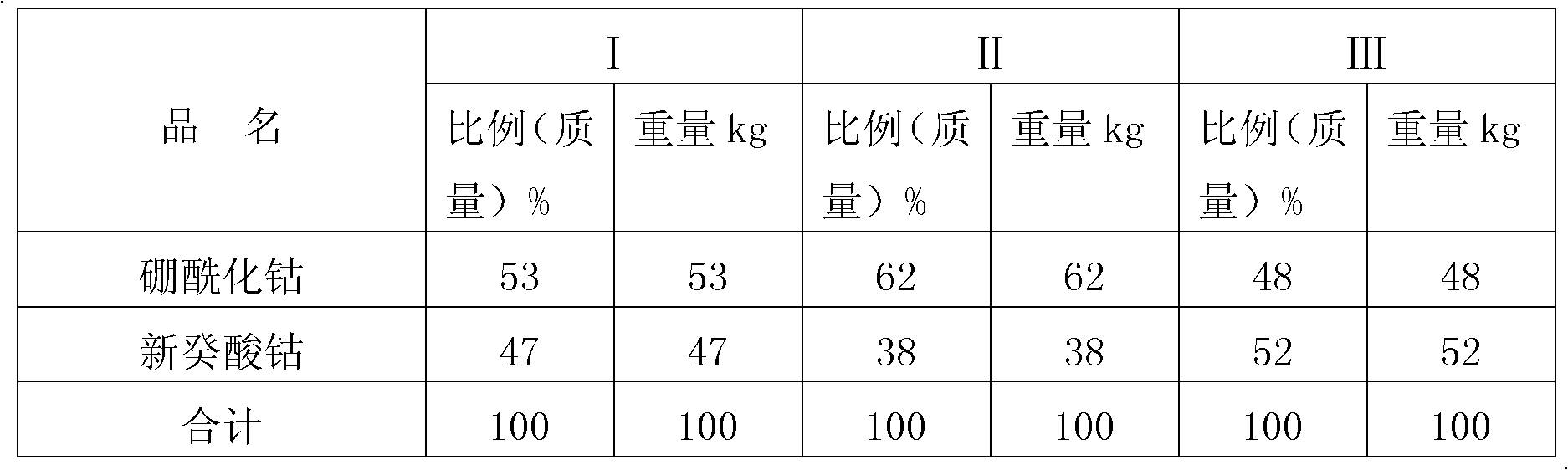

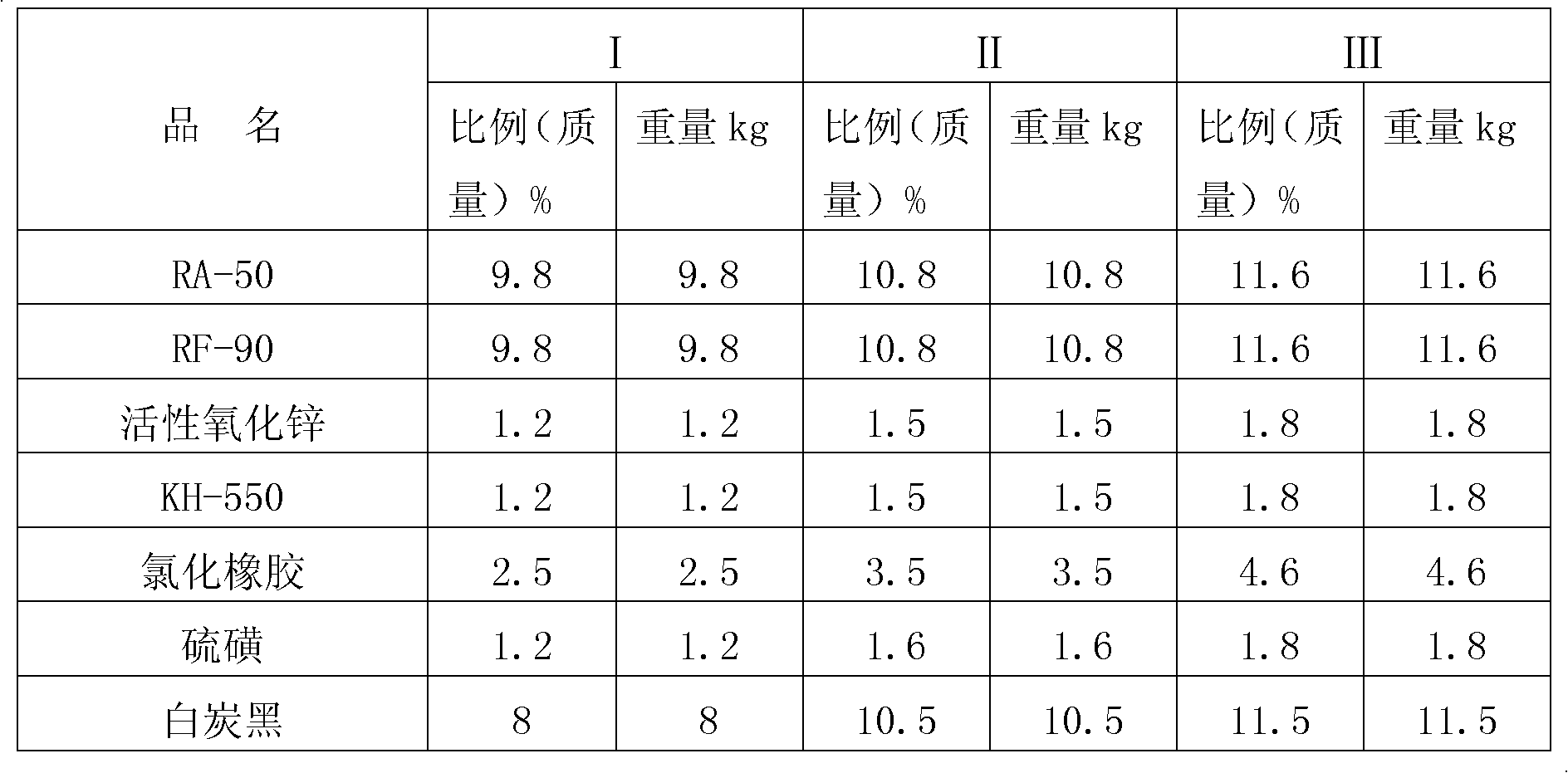

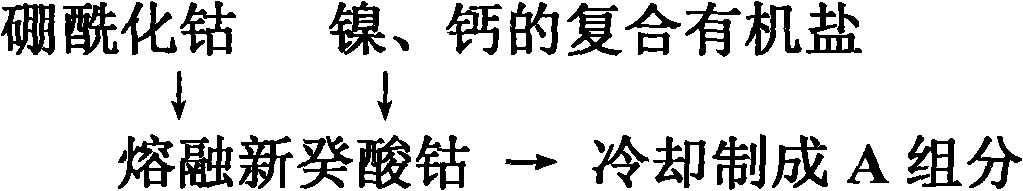

The invention provides a coating-type binder used for bounding nitrile butadiene rubber and a metal framework and a preparation method. The binder is prepared from a composite binder, rubber and an auxiliary agent; wherein the composite binder consists of a main binder and an auxiliary binder which become A component, the main binder consists of cobalt boracyl 23 and cobalt neocaprate, and the auxiliary binder is a composite organic salt containing nickel and vanadium; the rubber is nitrile butadiene rubber; the auxiliary agent consists of an age resister, a plasticizer, a strengthening agent, a loading agent, an accelerator, a activator and a vulcanizing agent which are of conventional use in rubber product production, A component is dispersed in rubber material and coordinates with the age resister, the plasticizer, the strengthening agent, the loading agent, the accelerator, the activator and the vulcanizing agent to constitute binding master batch B; the binding master batch B is dissolved by solvent of oil to prepare the coating-type binder of the invention. The coating-type binder of the invention not only maintains various excellent properties of the primary direct adding type cobalt salt binder such as high strength bonding, ageing resistance and the like, but also can be used in a coating way like imported coating binder product, thereby having obvious using effect.

Owner:镇江泛华新材料科技发展有限公司

Grafting-modified rubber and preparation method thereof

The invention discloses a grafting-modified rubber and a preparation method thereof. The grafting-modified rubber is prepared by graft polymerization of rubber latex (1) and a nano-silica / poly(conjugated diene) composite emulsion (2) in the presence of an initiator, wherein a mass ratio of the dry basis of the rubber latex to the dry basis of the nano-silica / poly(conjugated diene) composite emulsion is 100: (0.1 to 100); based on the dry basis of the nano-silica / poly(conjugated diene) composite emulsion, the nano-silica / poly(conjugated diene) composite emulsion comprises 0.1 to 5 parts of surface functionalization-modified nano-silica; the nano-silica / poly(conjugated diene) composite emulsion has granularity of 50 to 80nm, number-average molecular weight of 100000 to 120000 and molecular weight distribution of 2 to 3; and the rubber latex is a homopolymer or a copolymer containing a poly(conjugated diene) compound and is prepared by emulsion polymerization.

Owner:PETROCHINA CO LTD

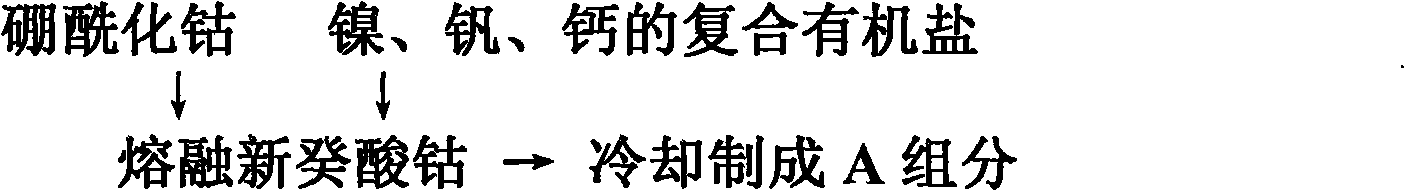

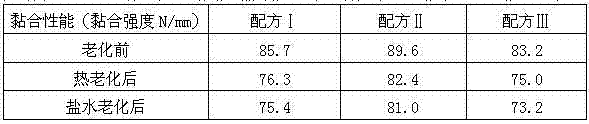

Coating-type binder used for bonding natural rubber and bare steel framework and preparation method

InactiveCN101560364AImprove thermal stabilityImprove dynamic mechanical propertiesNatural rubber adhesivesNon-macromolecular adhesive additivesCompound organicRubber material

The invention provides a coating-type binder used for bonding natural rubber and a bare steel framework and a preparation method. The coating-type binder is prepared from a composite binder, rubber and an auxiliary agent, wherein the composite binder consists of a main binder and an auxiliary binder which become A component, the main binder consists of cobalt boracyl 23 and cobalt neocaprate and the auxiliary binder is a composite organic salt containing nickel, vanadium and calcium; the rubber is the mixed rubber of natural rubber, styrene-butadiene rubber and cis-butadiene rubber; the auxiliary agent consists of an age resister, a plasticizer, a strengthening agent, an accelerator, a activator and a vulcanizing agent which are of conventional use in rubber product production, A component is dispersed in rubber material and coordinates with the age resister, the plasticizer, the strengthening agent, the accelerator, the activator and the vulcanizing agent to constitute binding master batch B; the binding master batch B is dissolved by solvent of oil to prepare the coating-type binder used for bonding natural rubber and bare steel framework. The coating-type binder of the invention can be used in middle-size and small-size rubber product industry, and can also be used on the refurbishment of radial ply tires of steel wires and the production of rubber products such as steel wire reinforcement traveling belt joint glue filling.

Owner:镇江泛华新材料科技发展有限公司

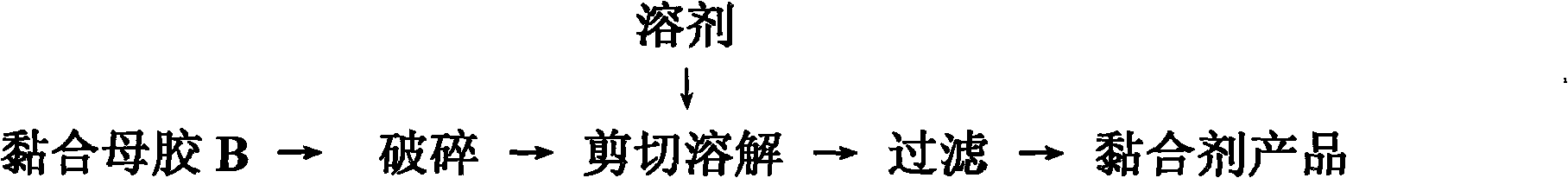

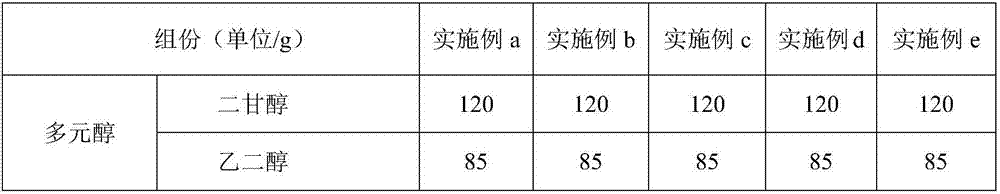

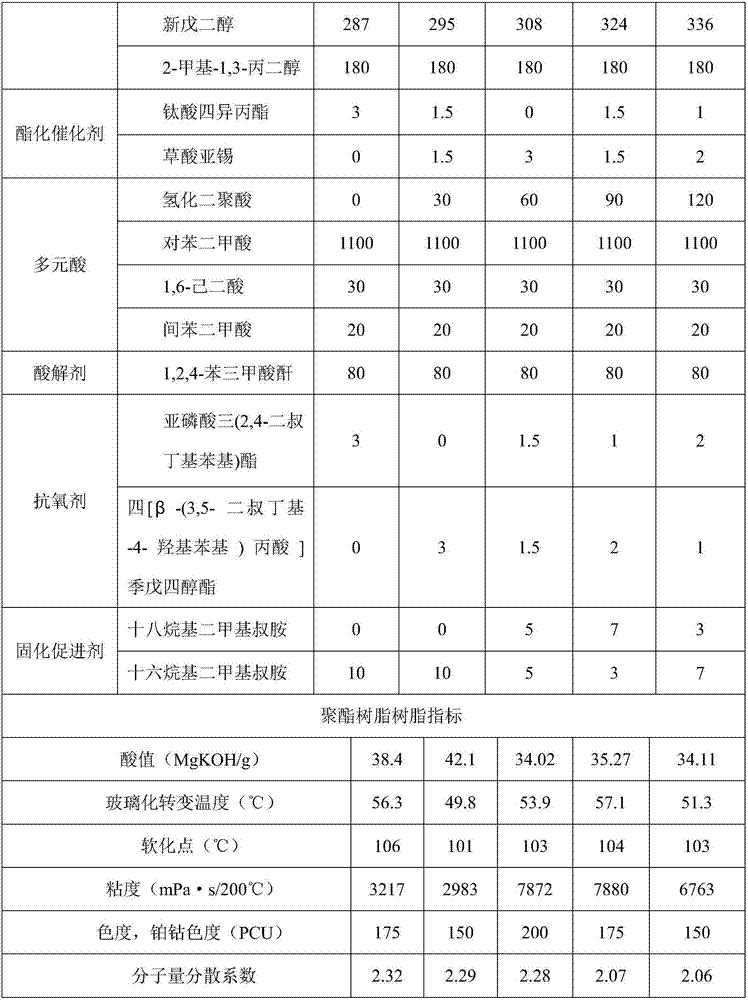

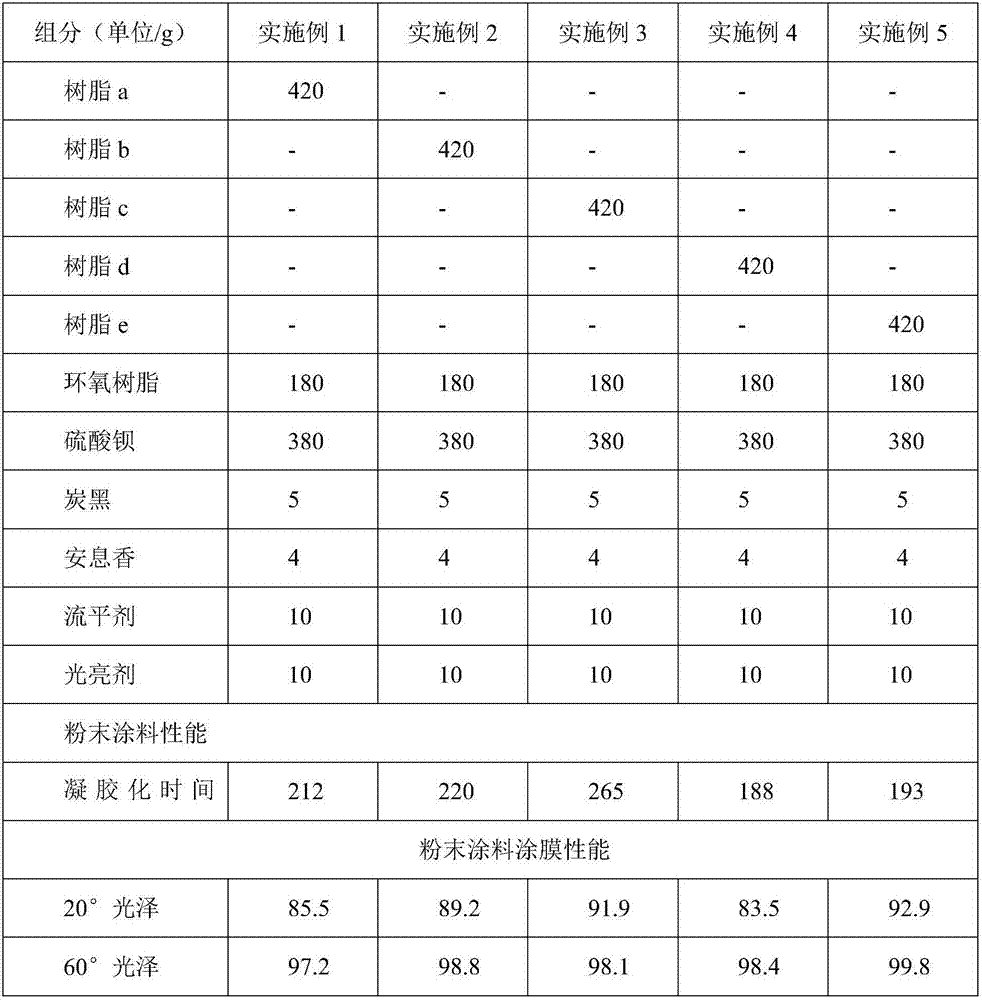

Epoxy cured polyester resin used for powdery paint having high surface decorative performance and high water resistance and preparation method thereof

ActiveCN107254240AThe temperature is 50.0~54.0℃, the rotational viscosity is highIncrease viscosityPowdery paintsPolyester coatingsEpoxyDistillation

The invention relates to epoxy cured polyester resin used for a powdery paint having high surface decorative performance and high water resistance and a preparation method thereof. The provided polyester resin has appropriate glass-transition temperature, a prepared powdery paint film has excellent dynamic mechanical properties, high surface decoration performance and high water resistance. The polyester resin is prepared by melt phase polycondensation of the raw materials of polyol, polyprotic acid, an acidulate agent, an esterification catalyst, an anti-oxidant and a curing accelerator. The method of the polyester resin comprises the following steps: 1) the polyol is delivered into a reaction kettle at a needed ratio, rapid heating esterification is carried out, water is generated, and is removed via distillation; 2) temperature is increased gradually, and an obtained material is maintained to be clear; 3) sample examination is carried out; 4) negative pressure polycondensation is carried out; and 5) cooling is carried out, the antioxidant and the curing accelerator are added, stirring dispersing is carried out, and an obtained product is cooled, and is collected.

Owner:ZHEJIANG CHUANHUA TIANSONG NEW MATERIAL CO LTD

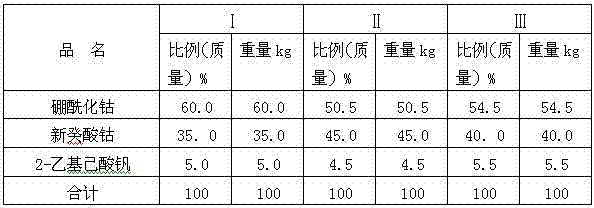

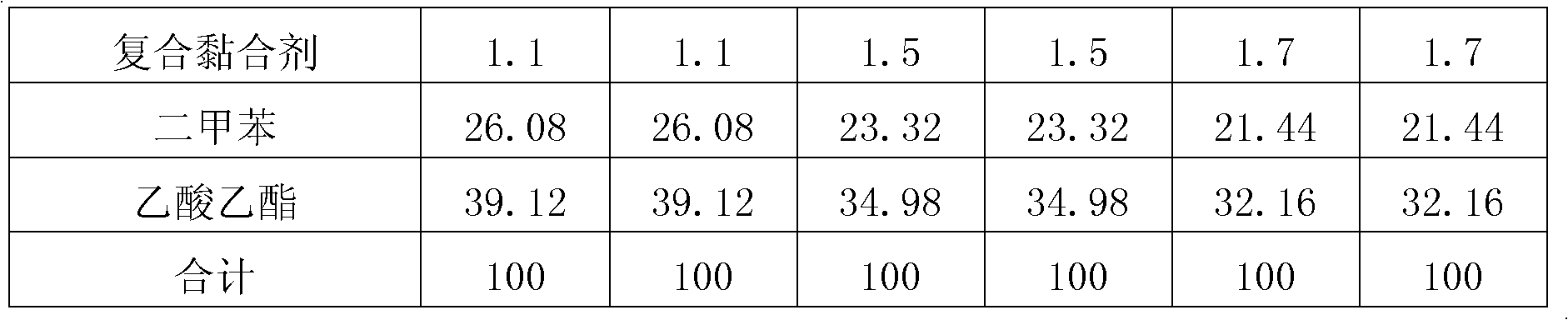

Cobalt salt adhesive for retreading radial wire cord tire and preparation method thereof

InactiveCN102504720AHigh catalytic activityEasy to useNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesive2-Ethylhexanoic acid

The invention discloses a cobalt salt adhesive for retreading a radial wire cord tire and a preparation method thereof. The adhesive comprises a composite adhesive, rubber and an addition agent, wherein the composite adhesive is mainly composed of a main adhesive and an auxiliary adhesive to form a component A; the main adhesive comprises cobalt boroacylate and cobalt neocaprate; the auxiliary adhesive is 2-vanadium ethylcaproate; the rubber comprises natural rubber and butadiene styrene rubber; the addition agent comprises an anti-ageing agent, a plasticizer, a reinforcing agent, an accelerant, an activating agent, a silane coupling agent and a vulcanizing agent. The cobalt salt adhesive for retreading the radial wire cord tire is prepared by the following steps of: dispersing the component A into a rubber carrier to be matched with the addition agent to form an adhesion master batch B; and dissolving the adhesion master batch B by a solvent gasoline to prepare adhesive slurry. The cobalt salt adhesive for retreading the radial wire cord tire provided by the invention has the advantages of good heat stability, good dynamic mechanic property, capability of being directly coated, low cost, and resource saving, and is applicable to the adhesion of new tread rubber and a previous belt compound in a retreading process of the radial wire cord tire, and the high-strength adhesion of the new tread rubber and polished belt steel wires.

Owner:镇江泛华新材料科技发展有限公司

Preparation method for high-dispersion deposition white carbon black

ActiveCN105273442AImprove hydrophobicityImprove wear resistancePigment treatment with organosilicon compoundsRolling resistanceCoupling

The invention relates to a preparation method for white carbon black, and concretely relates to a preparation method for high-dispersion deposition white carbon black. A white carbon black suspension, an umbrella-shaped siloxane dispersant and a siloxane coupling agent containing sulfydryls or carbon-carbon double bonds are mixed, the pH value is adjusted to 2-7 after mixing, the mixture is heated to 30-79 DEG C and reacted for 1-6h, and high-dispersion deposition white carbon black is obtained. The umbrella-shaped siloxane dispersant and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The siloxane coupling agent and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The prepared white carbon black has superstrong hydrophobicity, the processing performance in subsequent preparation of rubber compounds can be raised effectively, dynamic mechanical properties of vulcanized rubber as tyre tread rubber can be improved effectively, the rolling resistance of tread rubber is lowered effectively, and the wear resistant performance of tread rubber is raised.

Owner:SHENYANG RES INST OF CHEM IND

Coating-type binder used for bonding natural rubber and metallic framework and preparation method

InactiveCN101560365AMeet the needs of processing and productionImprove thermal stabilityNatural rubber adhesivesNon-macromolecular adhesive additivesRubber materialPolymer science

The invention provides a coating-type binder used for bonding natural rubber and a metallic framework and a preparation method. The coating-type binder is prepared from a composite binder, rubber and an auxiliary agent, wherein the composite binder consists of cobalt boracyl 23 and cobalt neocaprate, the rubber is natural rubber, the auxiliary agent consists of an age resister, a plasticizer, a filling agent, a strengthening agent, an accelerator, an activator, a silane coupling agent and a vulcanizing agent which are of conventional use in rubber product production. The composite binder is dispersed in rubber material and coordinates with the age resister, the plasticizer, the filling agent, the strengthening agent, the accelerator, the activator, the silane coupling agent and the vulcanizing agent to form a bonding master batch, and the bonding master batch is dissolved by solvent of oil to prepare a mucilage, thus the coating-type binder used for bonding natural rubber and metallic framework is obtained. The coating-type binder used for bonding natural rubber and metallic framework can be used in middle-size and small-size rubber product industry, and can also be used on the refurbishment of radial ply tires of steel wires and the production of rubber products such as steel wire reinforcement traveling belt joint glue filling.

Owner:镇江泛华新材料科技发展有限公司

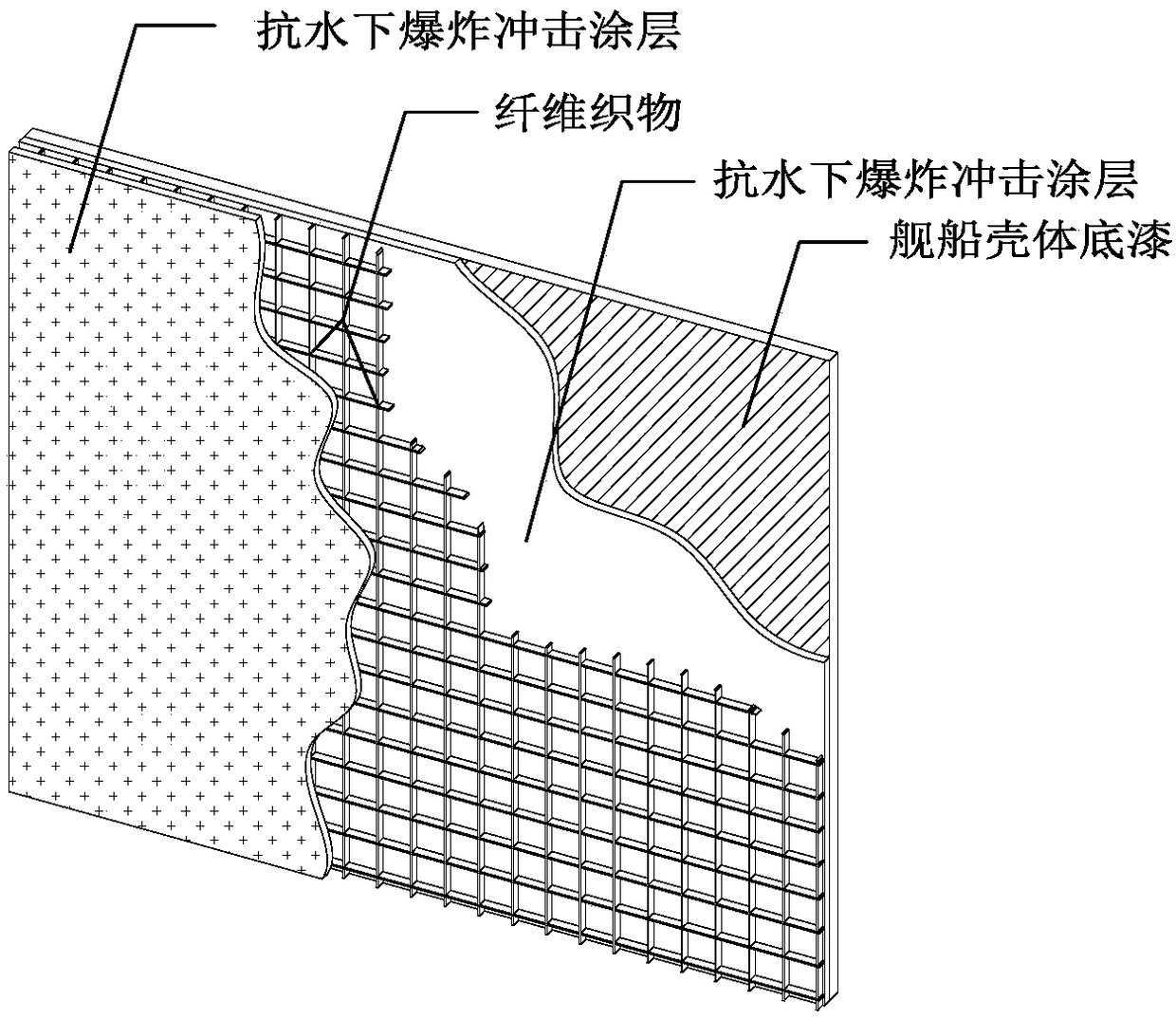

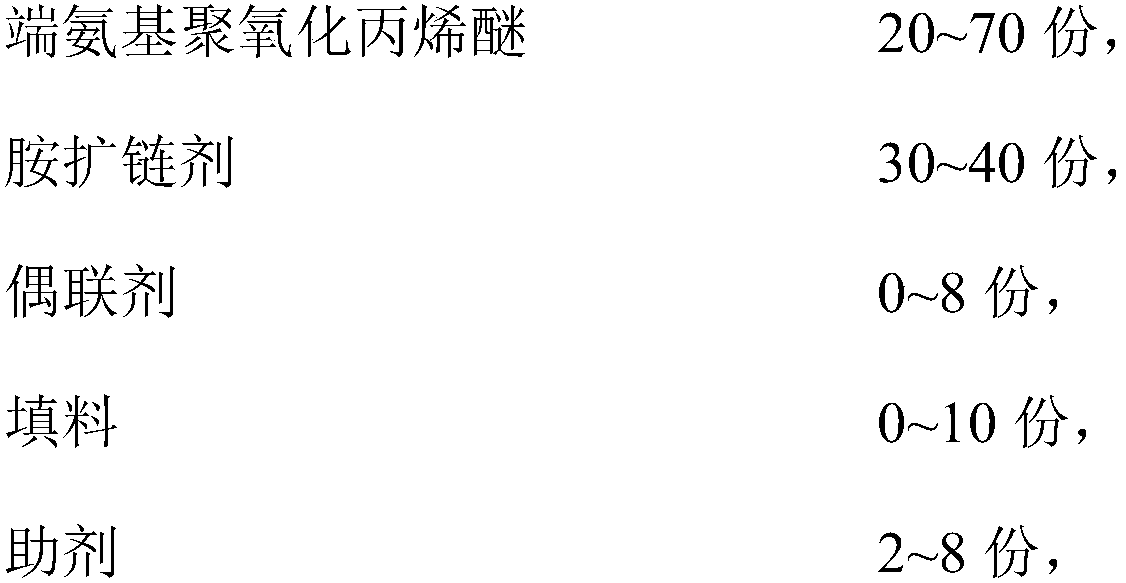

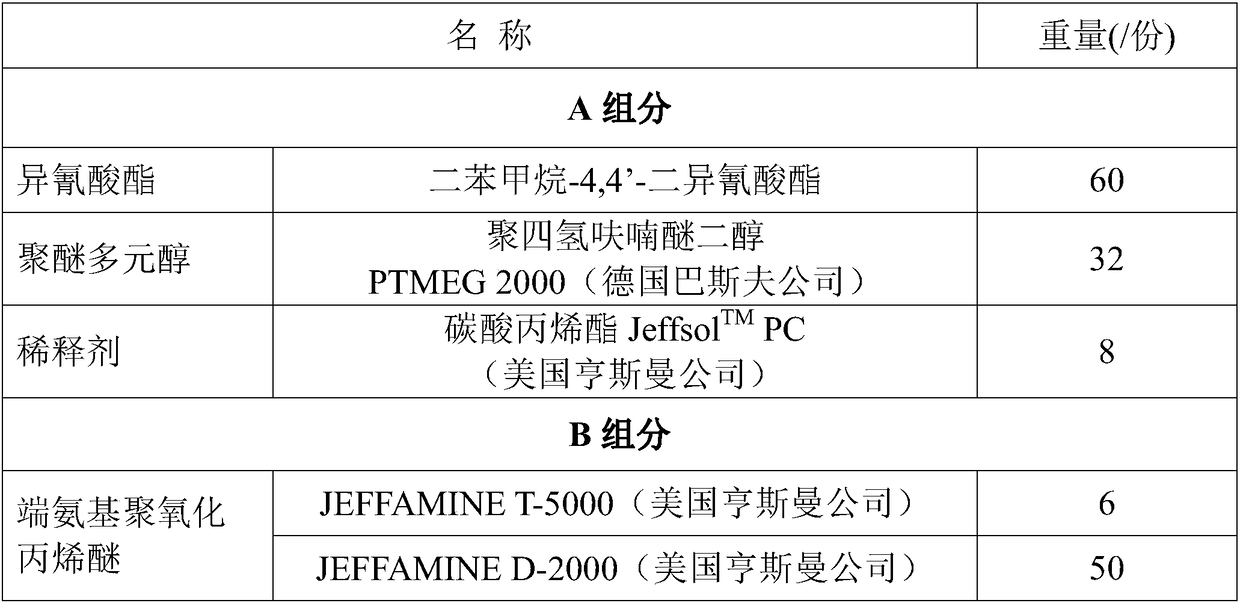

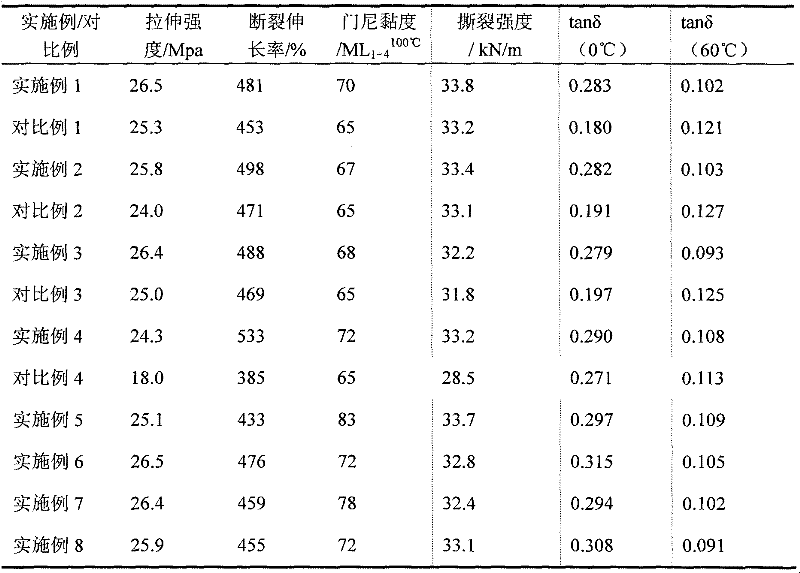

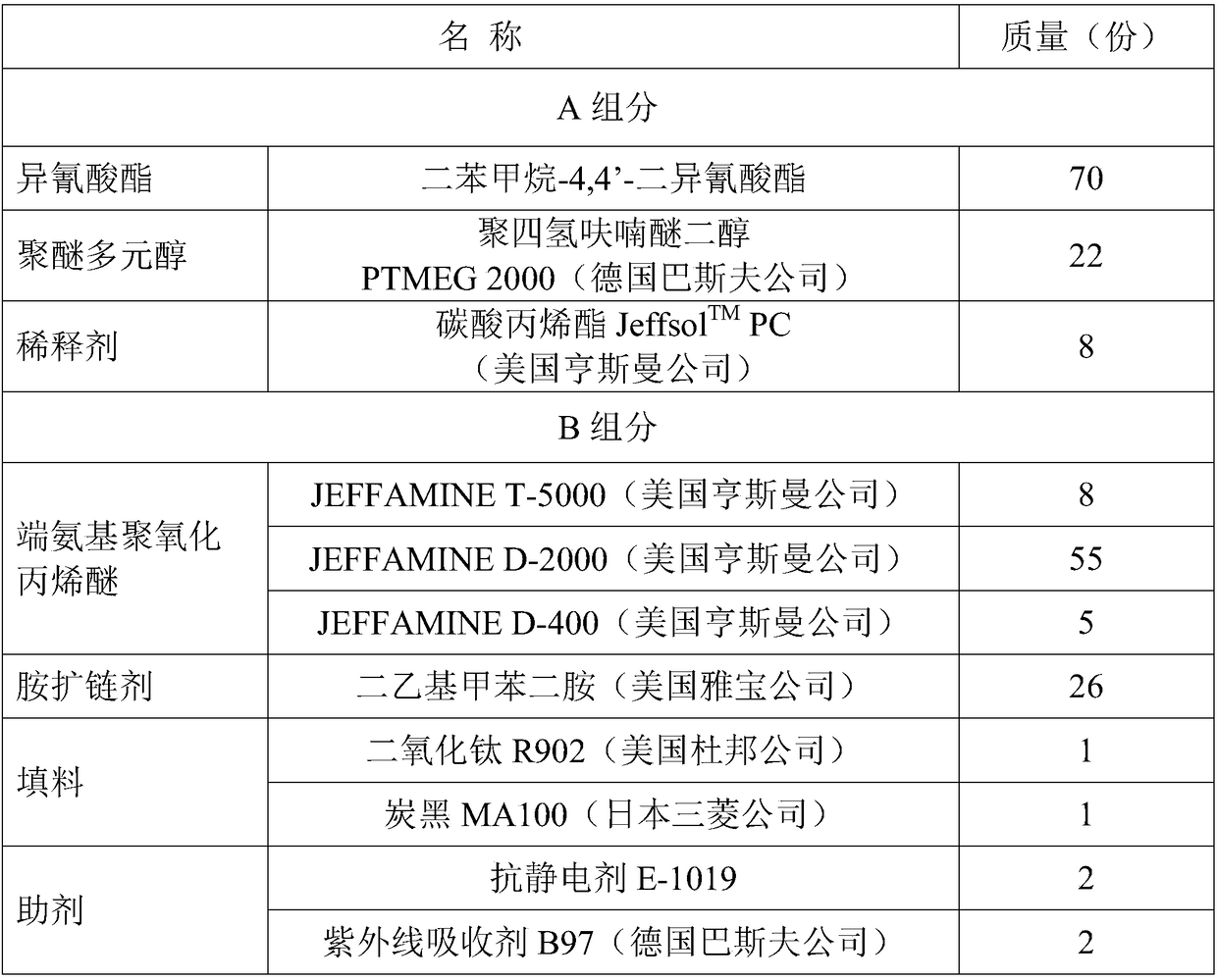

Underwater explosion shock resistant coating material, preparation method and application of material

InactiveCN108587439AImprove rigidityImprove dynamic mechanical propertiesPolyurea/polyurethane coatingsUnderwater explosionPolyol

The invention relates to an underwater explosion shock resistant coating material, a preparation method and an application of the material, and belongs to the technical field of ship protection materials. The material comprises a component A and a component B, wherein the component A comprises 30-65 parts of isocyanate, 30-40 parts of polyether polyol and 0-20 parts of diluents, and the componentB comprises 20-70 parts of amine-terminated polyether, 30-40 parts of amine chain extenders, 0-8 parts of coupling agents, 0-10 parts of fillers and 2-8 parts of auxiliaries. The volume ratio of the component A to the component B is 1:(0.97-1.03). The component A and the component B are prepared, and mixed and then sprayed onto ship shell surface primer by a bi-component high-temperature high-pressure impact mixed airless spraying device to form an underwater explosion shock resistant coating. The dynamic mechanical property of a protection structure under explosive load can be improved by thestrain rate sensitivity of the coating.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of styrene, butadiene, isoprene star copolymer and preparation method thereof

ActiveCN102295732AGood physical and mechanical propertiesGood dynamic mechanical propertiesSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention provides a star-shaped copolymer of styrene, butadiene and isoprene and a preparation method thereof. The structure of the star-shaped copolymer is described as follows: (-IR-SBR1-SBR2-B3-)nY, wherein Y is Sn or Si; IR is an isoprene homopolymer block; SBR1 is a random copolymer block of styrene and butadiene, wherein the content of styrene is 5-10%; SBR2 is the random copolymer block of styrene and butadiene, wherein the content of styrene is 20-50%; the ratio of SBR1 to SBR2 is (1:1)-(1:2); B3 is terminated butadiene, and n is between 2 and 4; and if the total weight of the monomer is 100%, in the star-shaped copolymer, the content of isoprene is 20-50%, the content of styrene is 10-30%, and the content of butadiene is 20-60%. The copolymer provided by the invention has good properties of natural rubber, cis-butadiene rubber and butadiene-styrene rubber; when the copolymer is applied to treaded rubber of a tyre, the tyre has higher slippery-resisting performance and lower rolling resistance.

Owner:PETROCHINA CO LTD

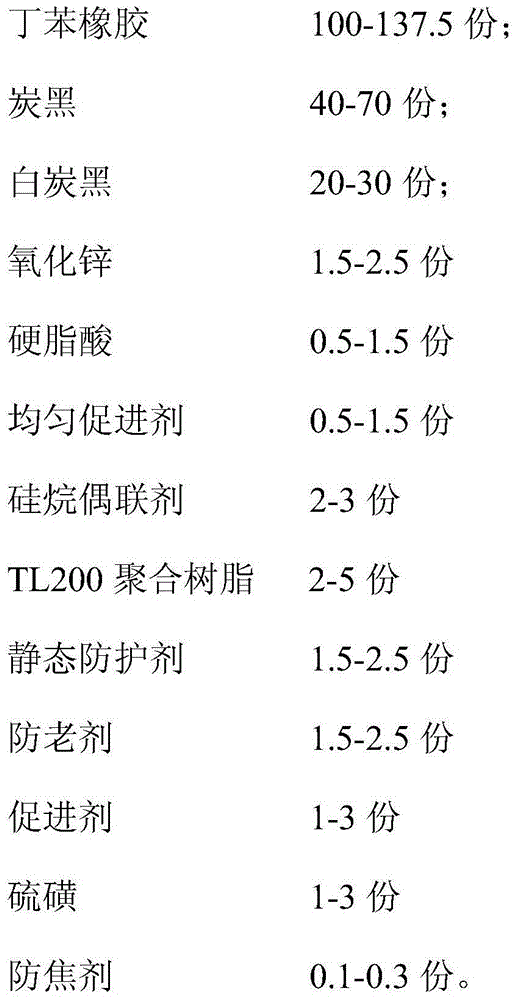

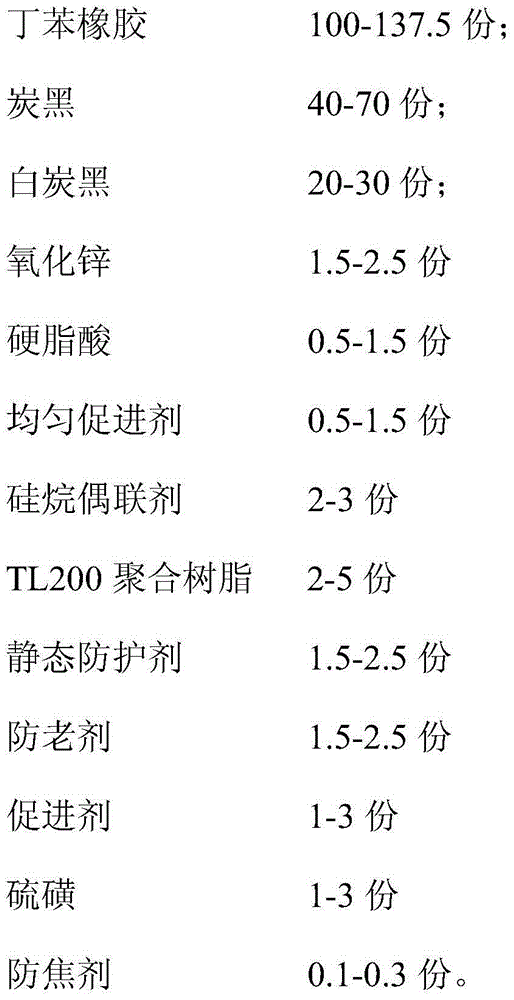

Rubber composition used for tread positions of sport tires

InactiveCN104927132AImprove balanceIncreased process safetySpecial tyresRolling resistance optimizationLanding performanceRolling resistance

The invention relates to a rubber composition used for tread positions of sport tires suitable for highways and drifting racing. The rubber composition is characterized by being composed of, by weight, 100-137.5 parts of styrene butadiene, 40-70 parts of carbon black, 20-30 parts of white carbon black, 1.5-2.5 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 0.5-1.5 parts of homogenizing agent, 2-3 parts of Si-69, 1.5-2.5 parts of static protective agent, 1.5-2.5 parts of antiager, 1-3 parts of promoter, 1-3 parts of sulfur and 0.1-0.3 part of antiscorcher. The rubber composition takes requirements on performance in two aspects into consideration, has excellent wet land performance and dry land holding power and realizes harmonization of high controlling performance and low rolling resistance.

Owner:特拓(青岛)轮胎技术有限公司

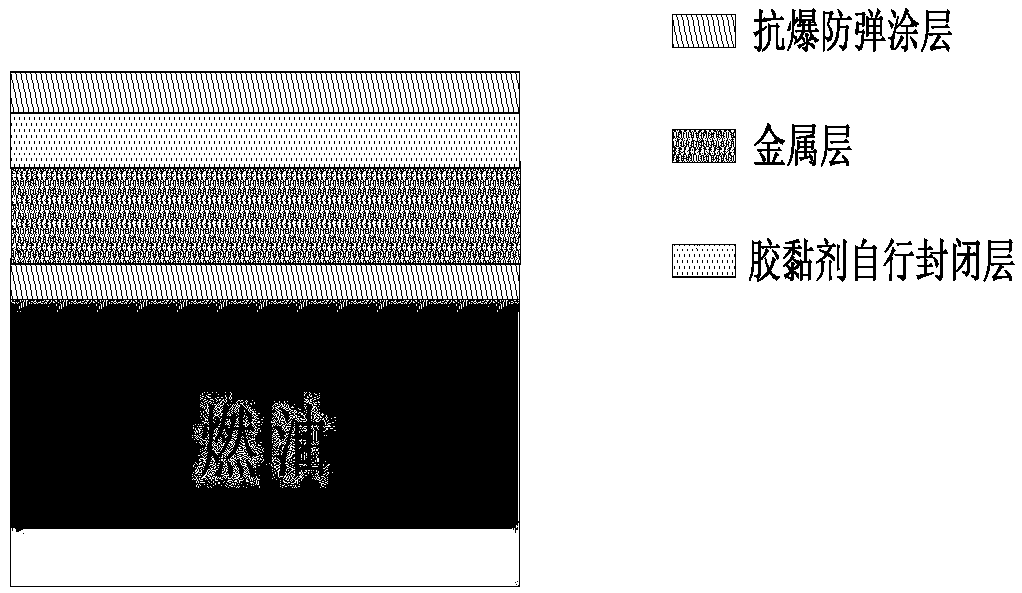

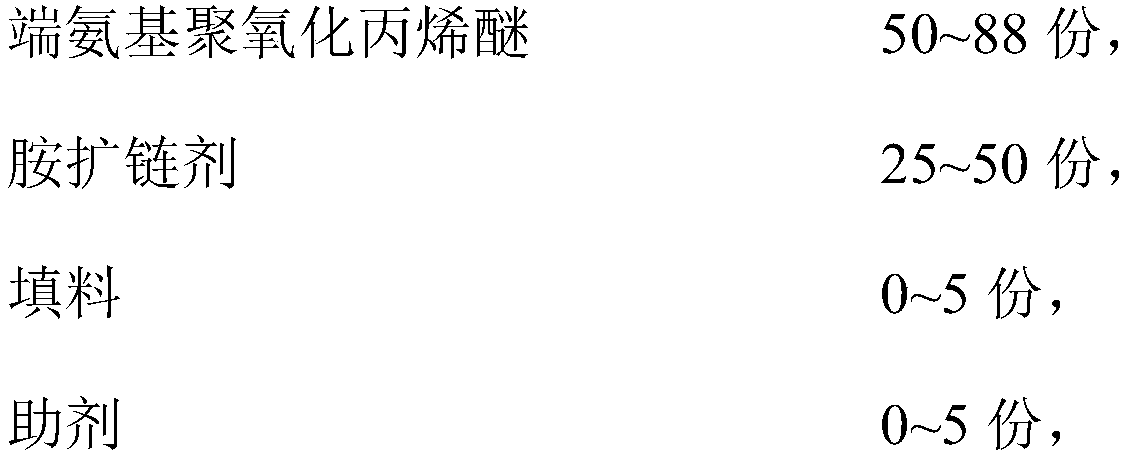

Anti-knock bulletproof coating material and preparation method and application thereof

InactiveCN108707415AImprove antiknock performanceSelf-enclosedPolyurea/polyurethane coatingsPolyolDiluent

The invention relates to an anti-knock bulletproof coating material and a preparation method and application thereof and belongs to the technical field of protective materials. The anti-knock bulletproof coating material comprises a component A and a component B; the component A comprises 40-80 parts of isocyanate, 20-55 parts of polyether polyol and 0-10 parts of diluent; the component B comprises 50-88 parts of amine-terminated polyether , 25-50 parts of amine chain extender, 0-5 parts of packing and 0-5 parts of additives. The volume ratio of the component A to the component B is 1 to 0.97-1.03. The component A and the component B are prepared respectively, and are mixed and sprayed to the surface of the base body of an oil tank or oil box by a double-component high-temperature high-pressure impact mixing airless spraying equipment so as to form the anti-knock bulletproof coating. The unique strain rate sensitivity of the anti-knock bulletproof coating can improve the dynamic mechanics performance of the oil tank / oil box under explosive load, and anti-knock anti-impact performance can be improved by reducing structural transformation of the oil tank / oil box.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

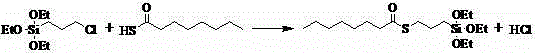

Preparation method of sulfhydryl silane coupling agent

ActiveCN102875588ALess impuritiesReduce generationGroup 4/14 element organic compoundsWastewaterMaterials science

The invention relates to a preparation method of a sulfhydryl silane coupling agent, belonging to the field of organic chemistry. According to the invention, the reaction is firstly completed partially under reduced pressure, and a small amount of acid absorbent is added to complete the reaction, thereby reducing the generation of amine hydrochloride and the generation of the byproduct. The sulfhydryl silane coupling agent product prepared by the method has the advantages of high and stable quality, high yield and fewer impurities. The invention does not discharge waste water or pollute the environment, and can easily implement industrial production. The invention solves the problems of complex after-treatment, difficulty in control of product quality, unstable product quality, high energy consumption in the synthetic process, and high waste water discharge amount in the existing complex synthesis technique. The sulfhydryl silane coupling agent prepared by the method can lower the viscosity of rubber, reduce the number of stages of milling, improve the working properties of the rubber, accelerate the dispersion of the reinforcing agent, enhances the dynamic mechanical properties of the rubber and the ageing resistance of the tread rubber, and prolong the storage time of the rubber.

Owner:JINGZHOU JIANGHAN FINE CHEM

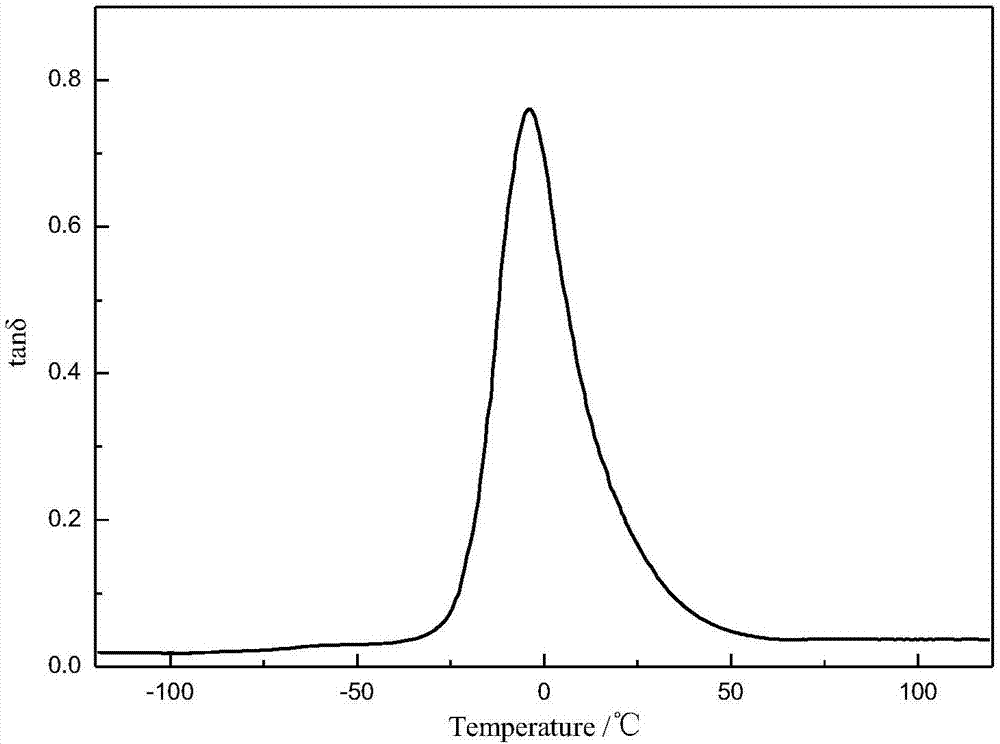

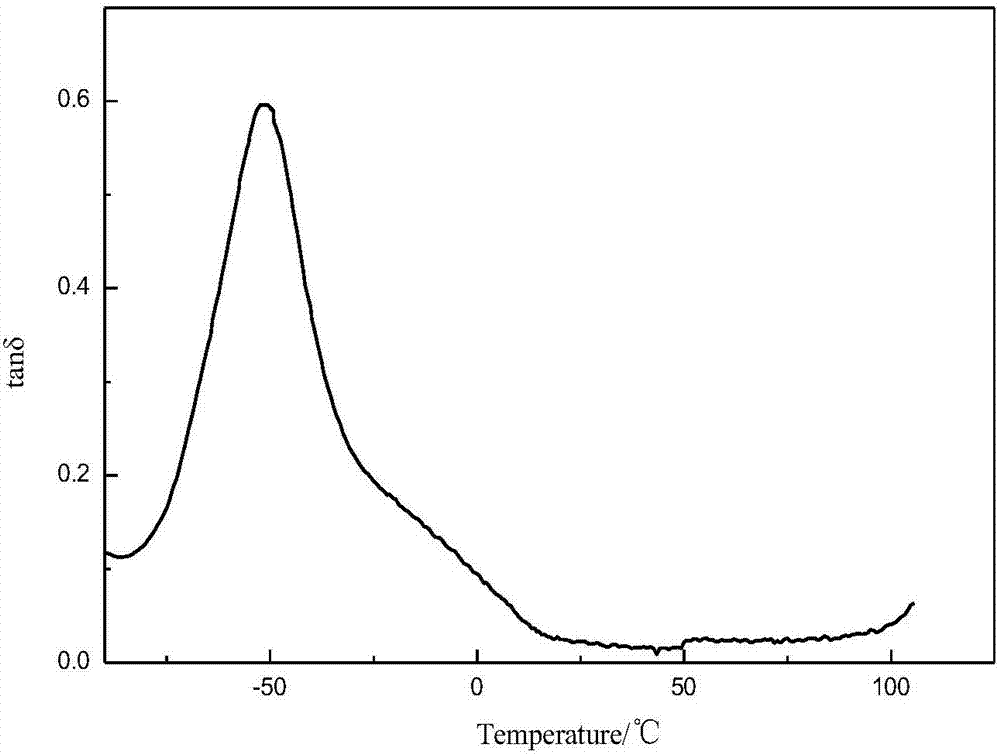

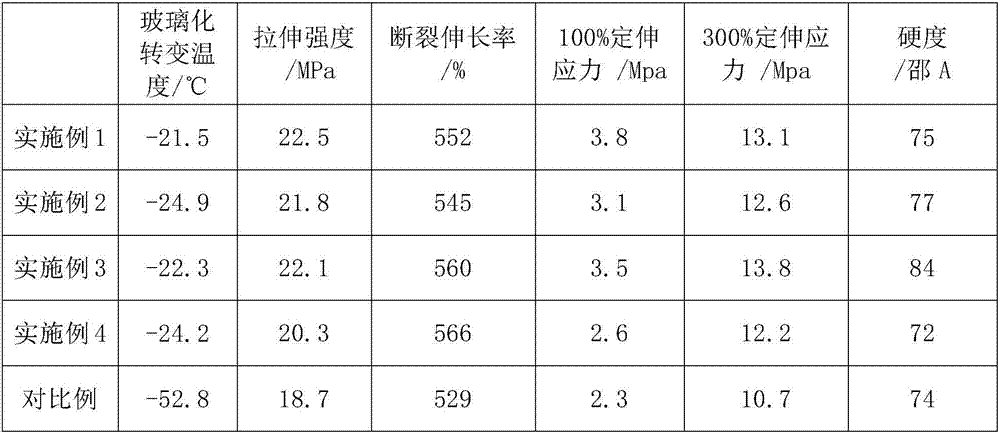

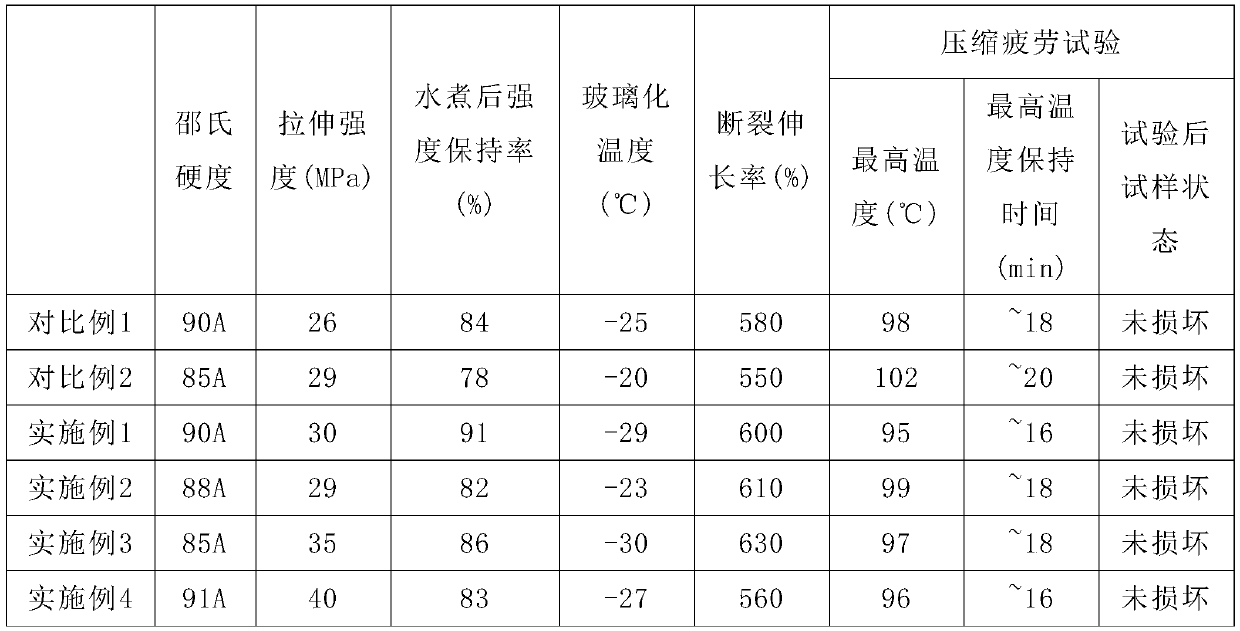

Thermoplasticity soluble polymerized styrene-butadiene rubber polyurethane elastomer material and preparation method

ActiveCN107540812AAdjust the glass transition temperatureImprove flex resistanceRolling resistancePolymer science

The invention discloses a thermoplasticity soluble polymerized styrene-butadiene rubber polyurethane elastomer material and a preparation method. The elastomer material is prepared by polymerization of the following substances: soft segment and hard segment, the mass ratio of the soft segment and the hard segment is 100: (20-90); the soft segment is hydroxyl-terminated solution polymerized styrene-butadiene rubber prepared by anionic polymerization; the hard segment includes isocyanate, and small molecular polyhydric alcohol chain extender; the mass ratio of the soft segment and the small molecular polyhydric alcohol chain extender is 100: (6-15); the mass ratio of the soft segment and isocyanate is 100: (20-70). The elastomer material introduces the hydroxyl-terminated solution polymerized styrene-butadiene rubber as the soft segment based on the synthesis of the traditional thermoplasticity soluable polyurethane elastomer, combines excellent flexural flexibility and excellent dynamicmechanical properties of the solution polymerized styrene-butadiene rubber on the basis of keeping the advantages of friendly environment, high wear resistance, oil resistance, chemical resistance and low rolling resistance of the polyurethane elastomer material, and adjusts the glass transition temperature of polyurethane elastomer; the polyurethane elastomer material is excellent in comprehensive use performance.

Owner:BEIJING UNIV OF CHEM TECH

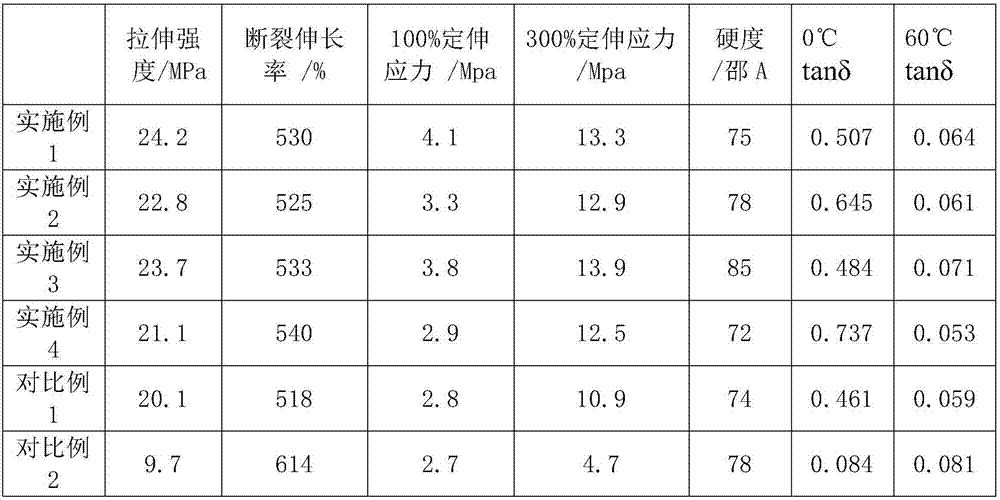

High wet-skid resistance elastomer nanocomposite for solid vehicle tire and preparation method

ActiveCN107474521AAdjust the glass transition temperatureReduce rolling resistanceRolling resistance optimizationPolyurethane elastomerVitrification

The invention discloses a high wet-skid resistance elastomer nanocomposite for a solid vehicle tire and a preparation method. The composite is prepared by mixing the following raw materials in parts by weight: 100 parts of substrate material, 5-25 parts of white carbon black and 10-30 parts of wet-skid resisting resin; the wet-skid resisting resin is styrene resin, C5C9 copolymer resin, C9 resin, coumarone resin or terpene resin; and the substrate material is selected from a solution-polymerized styrene butadiene rubber-polyurethane elastomer material. According to the invention, on the basis of maintaining the advantages of environmental protection, high abrasion resistance, oil resistance, chemical resistance and low rolling resistance of the polyurethane elastomer material, the excellent flexing resistance and excellent dynamic mechanical property of the solution-polymerized styrene butadiene rubber are combined for regulating the glass-transition temperature of the polyurethane elastomer, and meanwhile, the white carbon black is added for effectively puncturing a water film, the wet-skid resisting resin is added for further promoting the wet-skid resistance and the comprehensive use performance is excellent.

Owner:BEIJING UNIV OF CHEM TECH

Polyolefin polyol modified thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN111057208AImprove dynamic mechanical propertiesImprove low temperature resistancePolyesterPolymer science

The invention discloses a polyolefin polyol modified thermoplastic polyurethane elastomer which comprises the following components in parts by weight: 20-30 parts of polyolefin polyol, 30-40 parts ofpolyester / ether polyol, 20-40 parts of diisocyanate, and 5-20 parts of a chain extender. The invention also discloses a preparation method of the polyolefin polyol modified thermoplastic polyurethaneelastomer. The material provided by the invention has the advantages of excellent wear resistance, high hardness, rich elasticity, good mechanical strength, excellent oil resistance and excellent oxidation resistance of a thermoplastic polyurethane elastomer, and also has the characteristics of excellent low-temperature performance, excellent hydrolysis resistance and small dynamic heat generationof polyolefin rubber.

Owner:SHANGHAI HUIDE TECH CO LTD

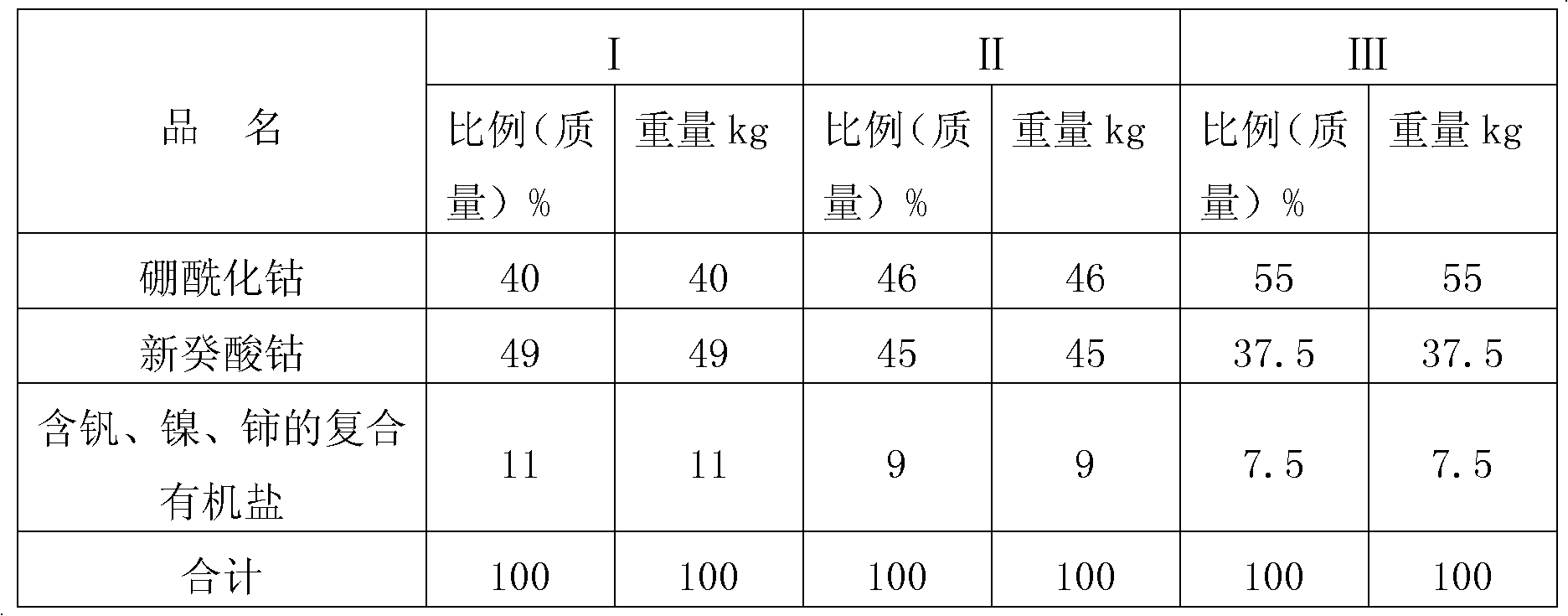

Cobalt salt adhesive for adhering ethylen e-propylene-diene mischpolymere and bare steel framework and preparation method thereof

InactiveCN101962522ATo achieve the purpose of modificationMeet the needs of processing and productionNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesive cementCerium

The invention discloses a cobalt salt adhesive for adhering ethylen e-propylene-diene mischpolymere and a bare steel framework and a preparation method thereof. The adhesive comprises a compound adhesive, phenolic resin and aids, wherein the compound adhesive consists of a main adhesive and an auxiliary adhesive; the main adhesive comprises cobalt boroacylate and cobalt neocaprate; the auxiliary adhesive is vanadium isooctanoate and cerium isooctanoate; the phenolic resin comprises a methyl donor and a methyl receptor; and the aids comprise a toughening agent, an activator, a curing activator, a silane coupling agent and a curing agent. The preparation method comprises the following steps of: dispersing the compound adhesive in the phenolic resin carrier, and matching with the aids; and adhsdissolving by using a mixed solvent to prepare adhesive cement to obtain the cobalt salt adhesive for adhering the ethylen e-propylene-diene mischpolymere and the bare steel framework. The cobalt salt adhesive has the advantages of high thermal stability, high dynamic mechanical properties, direct coating, low cost, and application to adhering ethylen e-propylene-diene mischpolymere including mixed rubber of the ethylen e-propylene-diene mischpolymere, natural rubber, reclaimed rubber or reclaimed rubber powder and the bare steel framework material.

Owner:镇江泛华新材料科技发展有限公司

Modified rubber and preparation method thereof

Owner:PETROCHINA CO LTD

Polyurethane self-sealing rubber core for well drilling and production process

InactiveCN101481452AGood physical and mechanical propertiesIncrease elasticityFlushingMass ratioPhosphoric acid

The invention discloses a well-drilling polyurethane self-sealing rubber core and a production process thereof, relating to a formulation design of a well-drilling polyurethane self-sealing rubber core and a preparation process thereof. The invention is characterized in that the formulation contains a component 1 and a component 2, and the ratio of component 1 to component 2 is 100:6 to 100:600 by mass ratio; the component 1 contains 0-76.4% of component A and 23.6-100% of component B in terms of mass percentage, while the component 2 contains 0-90% of component A and 10-100% of component C terms of mass percentage; and the component A contains polyalcohol, benzoyl chloride, phosphoric acid or hydrochloric acid, the component B is polyisocyanate, and the component C contains trimethylolpropane, glycol or ethylene glycol, inorganic filler, energy auxiliary agent and anti-foaming agent, benzoyl chloride, phosphoric acid or hydrochloric acid, and catalyst. The production process decreases the operation temperature in the production process, and reduces chemical gas emission, the power consumption and the harm to operators.

Owner:ZIBO SAITONG POLYURETHANE

Cobalt salt bonding agent for bonding nitrile butadiene rubber with bare steel framework and preparation method thereof

InactiveCN101985545AMeet the needs of processing and productionRetain heat and humidity resistanceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCompound organicPolymer science

The invention discloses a cobalt salt bonding agent for bonding nitrile butadiene rubber with a bare steel framework and a preparation method thereof, the bonding agent consists of a composite bonding agent, phenolic resin and auxiliaries, the composite bonding agent comprises a main bonding agent and an auxiliary bonding agent, wherein the main bonding agent comprises cobalt boroacylate and cobalt neocaprate, the auxiliary bonding agent is a composite organic salt containing vanadium, nickel and cerium, the phenolic resin comprises a methylene donor and a methylene acceptor, and the auxiliaries comprise a toughener, an activating agent, a vulcanizing activator, a silane coupling agent and a vulcanizing agent; and the cobalt salt bonding agent for bonding the nitrile butadiene rubber with the bare steel framework is obtained by dispersing the composite bonding agent in a phenolic resin carrier, using the auxiliaries for matching and dissolving in mixed solvent for preparing rubber slurry. The cobalt salt bonding agent has the advantages of good thermal stability, good dynamic mechanical properties, capability of being directly coated for use and low cost, and is applicable to high-strength bonding mixed rubber of the nitrile butadiene rubber and regenerated rubber or regenerated rubber powder with material of the bare steel framework.

Owner:镇江泛华新材料科技发展有限公司

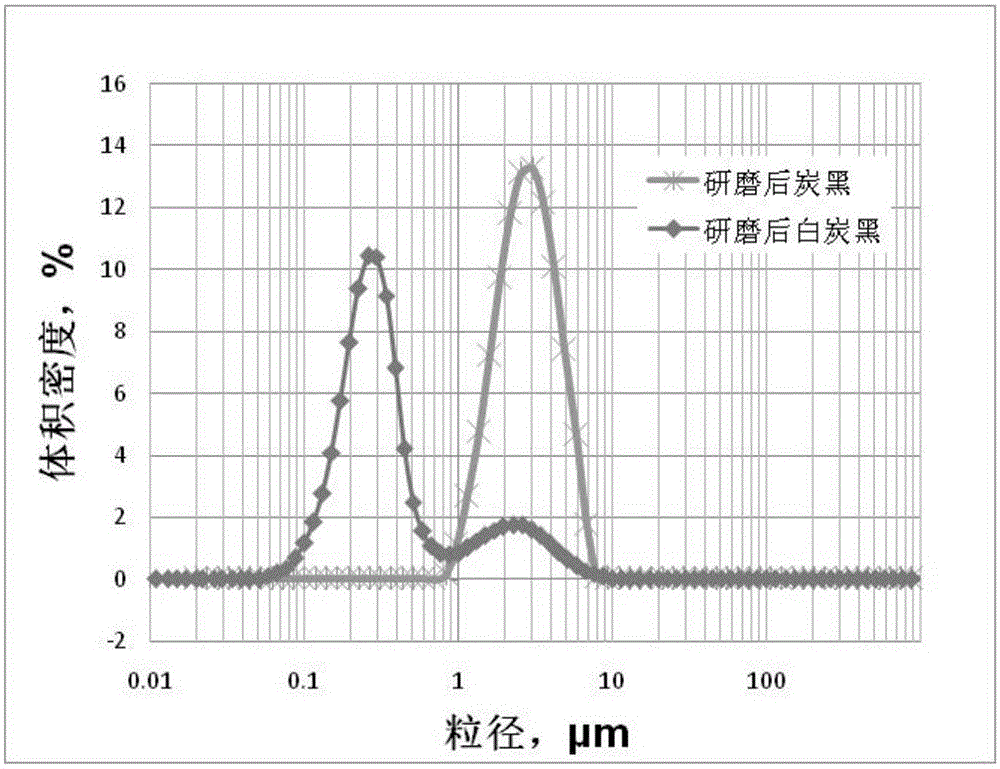

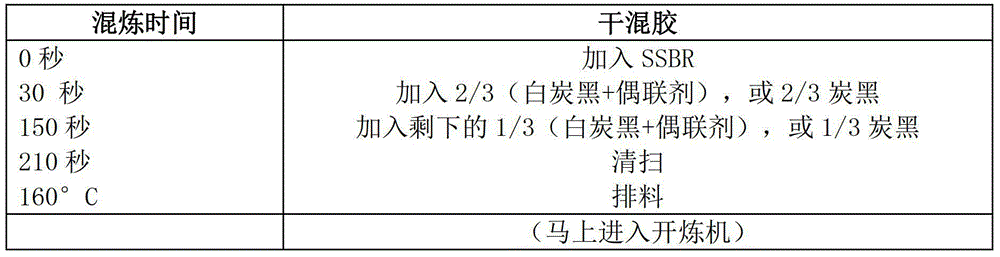

Elastomeric composite body

The invention relates to an elastomeric composite body, which comprises a solution polymerization synthesis rubber and a filler, wherein the filler is modified white carbon black or carbon black, a ration of the rubber to the filler is 100:30-110, and the filler aggregate particle size is 100 nm-10 [mu]m. The preparation method comprises: (1) in a non-polar organic solvent, preparing a modified white carbon black grinding slurry or carbon black grinding slurry, wherein the modified white carbon black grinding slurry or carbon black grinding slurry is recorded as the filler slurry, and the modified white carbon black or carbon black is recorded as the filler; (2) carrying out dispersed mixing on the filler slurry or filler and the rubber slurry according to a certain ratio under high energy shearing to form a composite body slurry rubber liquid; (3) dynamically removing the solvent from the uniformly dispersed and mixed composite body slurry rubber liquid through a dry method; and (4) carrying out shearing kneading drying on the solvent-removed composite body to obtain the product.

Owner:PETROCHINA CO LTD

Cobalt salt bonding agent for bonding ethylene propylene diene monomer with copper or zinc framework and preparation method thereof

InactiveCN101967360AGood effectGood thermal stabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSolventAdhesive

The invention discloses a cobalt salt bonding agent for bonding ethylene propylene diene monomer with a copper or zinc framework and a preparation method thereof, the bonding agent consists of a composite bonding agent, phenolic resin and auxiliaries, the composite bonding agent comprises a main bonding agent and an auxiliary bonding agent, wherein the main bonding agent comprises cobalt boroacylate and cobalt neocaprate, the auxiliary bonding agent is cerium 2-ethylhexanoate, the phenolic resin comprises a methyl donor and a methyl acceptor, and the auxiliaries comprise a toughener, an activating agent, a vulcanizing activator, a silane coupling agent and a vulcanizing agent; and the cobalt salt bonding agent for bonding the ethylene propylene diene monomer with the copper or zinc framework is obtained by dispersing the composite bonding agent in a phenolic resin carrier, using the auxiliaries for matching and dissolving in mixed solvent for preparing into glue slurry. The cobalt salt bonding agent has the advantages of good thermal stability, good dynamic mechanical properties, direct coating for use and low cost, and is applicable to high-strength bonding the ethylene propylene diene monomer including mixed rubber of the ethylene propylene diene monomer, natural rubber and reclaimed rubber or reclaimed rubber powder with the copper, zinc, copper alloy, zinc alloy, zinc-plated and brass-plated frameworks.

Owner:镇江泛华新材料科技发展有限公司

Cobalt salt adhesive for adhering natural rubber and copper and zinc frameworks and preparation method thereof

InactiveCN101962523AMeet the needs of processing and productionEasy to useNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

The invention discloses a cobalt salt adhesive for adhering natural rubber and copper and zinc frameworks and a preparation method thereof. The adhesive comprises a compound adhesive, phenolic resin and aids, wherein the compound adhesive comprises cobalt boroacylate and cobalt neocaprate; the phenolic resin comprises a methyl donor and a methyl acceptor; and the aids comprise a toughening agent,an activating agent, a curing activator, a silane coupling agent and a vulcanizer. The preparation method comprises the following steps of: dispersing the compound adhesive in the phenolic resin carrier, matching with the aids, dissolving by using a mixed solvent to prepare adhesive cement so as to obtain the cobalt salt adhesive for adhering the natural rubber and the copper and zinc frameworks.The cobalt salt adhesive has the advantages of high thermal stability, good dynamic mechanical performance, direct coating, and low cost, and is suitable for high-strength adhesion between the reclaimed rubber or reclaimed rubber granule-containing natural rubber, including the natural rubber and mixed rubber of the natural rubber and general-purposed synthetic rubber, and copper, zinc, copper alloy, zinc alloy, zinc-plated and brass-plated frameworks.

Owner:镇江泛华新材料科技发展有限公司

Cobalt salt bonding agent for bonding natural rubber and naked steel framework and preparation method thereof

InactiveCN102417803AMeet the needs of processing and productionPreserve anti-agingNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

The invention discloses a cobalt salt bonding agent for bonding natural rubber and a naked steel framework and a preparation method thereof. The bonding agent comprises a compound bonding agent, a phenolic resin and an aid, wherein the compound bonding agent consists of a main bonding agent and an auxiliary bonding agent; the main bonding agent comprises cobalt boroacylate and cobalt neodecanoate; the auxiliary bonding is 2- ethyl vanadium caproate; the phenolic resin comprises a methyl donor and a methyl acceptor; and the aid comprises a toughening agent, an activating agent, a vulcanizing activator, a silane coupling agent and a vulcanizing agent. The cobalt salt bonding agent for bonding natural rubber and the naked steel framework is obtained by dispersing the compound bonding agent into a phenolic resin carrier, adding the aid, and dissolving into adhesive cement by using a mixed solvent. The cobalt salt bonding agent has the advantages of high thermal stability, high dynamic property, direct coating and low cost, an is suitable for high-strength bonding of natural rubber containing reclaimed rubber or reclaimed rubber powder such as natural rubber and mixed rubber consisting of the natural rubber and general synthetic rubber with a naked steel framework material.

Owner:镇江泛华新材料科技发展有限公司

Coating-type binder used for bonding ethylene propylene diene rubber and metal framework and preparation method

InactiveCN101560368AImprove thermal stabilityImprove dynamic mechanical propertiesNatural rubber adhesivesNon-macromolecular adhesive additivesSolventPlasticizer

The invention discloses a coating-type binder used for bonding ethylene propylene diene rubber and a metal framework and a preparation method. The coating-type binder is prepared from a composite binder, rubber and an auxiliary agent, wherein the composite binder consists of a main binder and an auxiliary binder which become A component, the main binder consists of cobalt boracyl 23 and cobalt neocaprate and the auxiliary binder is a composite organic salt containing nickel and calcium; the rubber is ethylene propylene diene rubber and natural rubber; the auxiliary agent consists of an age resister, a plasticizer, a strengthening agent, an accelerator, a activator and a vulcanizing agent which are of conventional use in rubber product production, A component is dispersed in rubber material and coordinates with the age resister, the plasticizer, the strengthening agent, the accelerator, the activator and the vulcanizing agent to constitute binding master batch B; the binding master batch B is dissolved by solvent of oil to prepare the coating-type binder used for bonding ethylene propylene diene rubber and metal framework. The coating-type binder of the invention is suitable for the high tenacity bonding between the mixed rubber of ethylene propylene diene rubber and natural rubber and copper, zinc, copper alloy, zinc alloy and aluminum alloy framework.

Owner:镇江泛华新材料科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com