Coating-type binder used for bonding ethylene propylene diene rubber and metal framework and preparation method

A technology of EPDM rubber and metal skeleton, which is applied in the direction of natural rubber adhesives, adhesive additives, adhesives, etc., and can solve the problems of adhesive solvent pollution, high cost of use, thermal aging, and poor dynamic mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

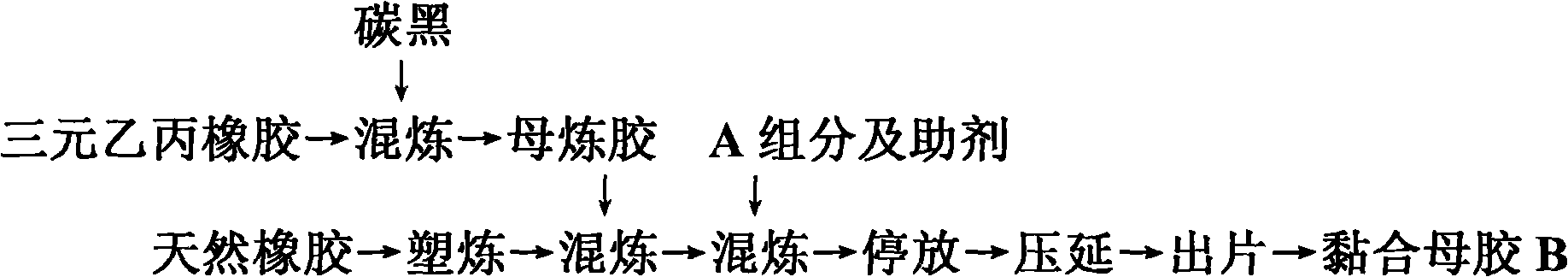

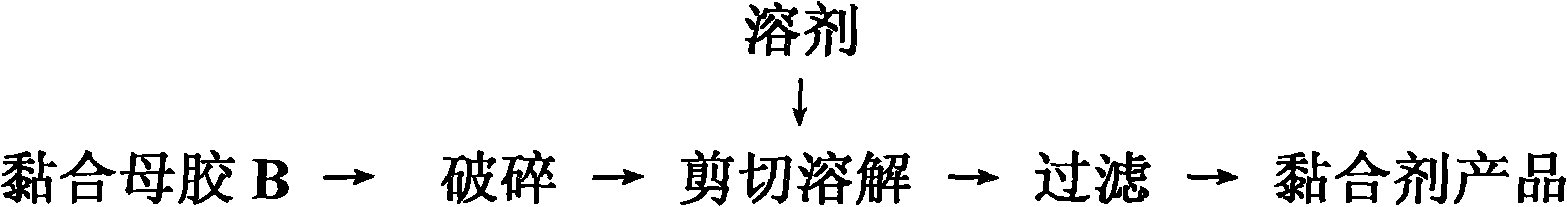

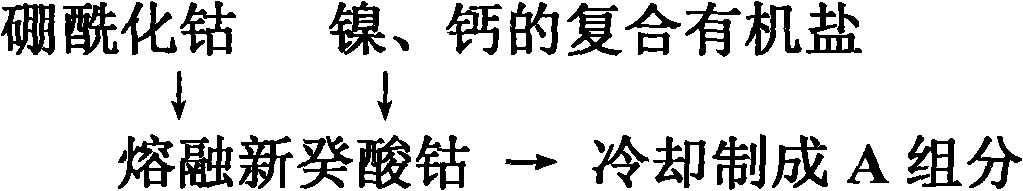

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, EPDM rubber and metal frame bonding coating adhesive and preparation method

[0041] (1) Raw materials

[0042] Raw material name

Specification index, grade

Cobalt boroacylate

Cobalt content 22.5±0.5%; heptane insoluble matter ≤0.5%

Zhenjiang Matt

cobalt neodecanoate

Cobalt content 20.5±0.5%; softening point 80-100℃

Zhenjiang Matt

Total metal content 12±0.5%; softening point 80-100℃

self made

Composite cobalt salt A component

Total metal content 21±0.5%; softening point 80-100℃

self made

natural rubber

1# cigarette film

Yunnan

EPDM

4045

Lanzhou

Complies with HG-2-465-75

Changzhou Changjia Chemical

white ointment

Comply with Q / XKHJ02-2007 superior product

Xinji Keda Chemical

Antiaging agent 4040NA

Conform to GB-8828-88 standard

Nanjing Chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com