Method for preparing polyurethane hybridization material for hydroxyl-containing filler

A hybrid material, polyurethane technology, applied in the field of material science and technology, can solve the problems of material mechanical properties decline, weaken the intermolecular force, etc., and achieve the effect of low cost, excellent strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

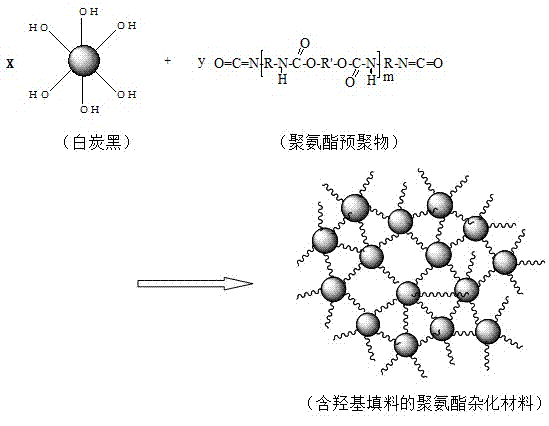

Method used

Image

Examples

Embodiment 1

[0029] mass ratio n NCO / n OH = 2.2: 1, PU prepolymer: halloysite nanotube (a kind of clay-like natural nanomaterial, referred to as HNTs) = 100: 10 (mass ratio) to calculate the consumption of each raw material. After the measured polyoxypropylene glycol (PPG) with a molecular weight of 2000 is vacuum-dried at 110°C and fully dehydrated, the temperature is lowered to 80°C and a certain amount of toluene diisocyanate (TDI) is added. After reacting for 2 hours, a certain amount of HNTs is added and mixed evenly After solidification and molding at 120°C for 0.5 hours, take it out of the mold and put it in an oven at 120°C for 4 hours to cure, and test the performance after cooling.

Embodiment 2

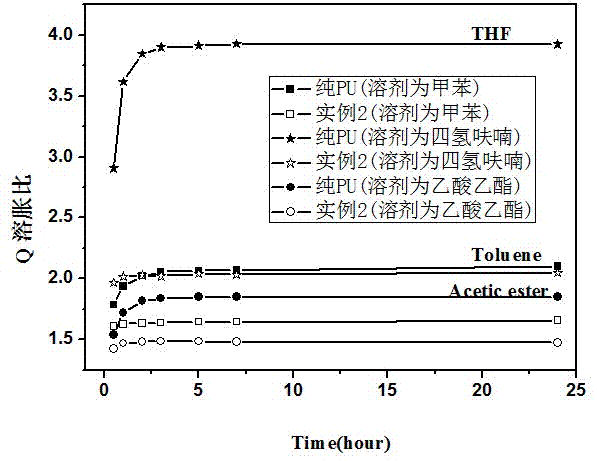

[0031] mass ratio n NCO / n OH =2.5:1, PU prepolymer: precipitated silica (SiO 2 )=100:30 (mass ratio) to calculate the consumption of each raw material. After the polytetrahydrofuran diol (PTMG) with a molecular weight of 1500 was vacuum-dried at 130°C and fully dehydrated, the temperature was lowered to 90°C and a quantitative molar ratio of 3:1 TDI and hexamethylene diisocyanate (HDI) was added. Mixture, after reacting for 60min, add quantitative SiO 2 , after mixing evenly, solidify at 110°C for 2 hours, take it out of the mold and put it in an oven at 110°C for 8 hours, and test the performance after cooling.

Embodiment 3

[0033] mass ratio n NCO / n OH= 5.0: 1, PU prepolymer: montmorillonite (a kind of clay material, MMT for short): aluminum hydroxide = 100: 30: 10 (mass ratio) to calculate the consumption of each raw material. After the hydroxyl-terminated polybutadiene (HTPB) with a measured molecular weight of 2000 is vacuum-dried at 120°C and fully dehydrated, the temperature is lowered to 20°C and a quantitative amount of diphenylmethane diisocyanate (MDI) is added. After reacting for 24 hours, a quantitative amount of MMT and aluminum hydroxide were added dropwise with 0.1% stannous octoate of the mass of MDI, mixed evenly, cured and molded at 20°C for 7 days, and tested for performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com