Preparation method of sulfhydryl silane coupling agent

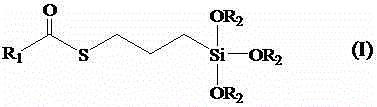

A technology of mercaptosilane coupling agent and chloropropylalkoxysilane, which is applied in the field of preparation of mercaptosilane coupling agent, can solve problems such as agglomeration and increase in rubber viscosity, difficult control of product quality, and high energy consumption in the synthesis process. , to achieve the effect of reducing the viscosity of the rubber, stable quality, and reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

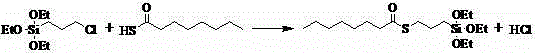

Method used

Image

Examples

Embodiment 1

[0027] Add thiooctanoic acid 647.6g and xylene 1000g in a 5000ml four-necked reaction flask with mechanical stirring, constant pressure dropping funnel and condenser, and drop 3-chloropropyltriethoxy in the constant pressure dropping funnel simultaneously Silane 972.9g. The molar ratio of thiooctanoic acid to 3-chloropropyltriethoxysilane is 1:1, and the amount of xylene added is 50%-100% of the total mass of thiooctanoic acid and 3-chloropropyltriethoxysilane 。 Then start the circulating water vacuum pump, and start the dropwise reaction under mechanical stirring at 400 rpm. The temperature of the reaction system is 80° C., and the dropwise time of 3-chloropropyltriethoxysilane is 4 hours. After the dropwise addition is completed, continue After reacting for 0.5 hours, the hydrogen chloride gas generated by the reaction was absorbed by water, and most of the system reaction had been completed at this time.

[0028] After 0.5 hours, the system was cooled to 40° C., and then 1...

Embodiment 2

[0031] Add thiooctanoic acid 647.6g and xylene 1150g in the 5000ml four-necked reaction flask with mechanical stirring, constant pressure dropping funnel and condenser, drop into 3-chloropropyltriethoxy in the constant pressure dropping funnel simultaneously Silane 972.9g. The molar ratio of thiooctanoic acid to 3-chloropropyltriethoxysilane is 1:1, and the amount of xylene added is 50%-100% of the total mass of thiooctanoic acid and 3-chloropropyltriethoxysilane . Then start the circulating water vacuum pump, and start the dropwise addition reaction under mechanical stirring at 450 rpm. The temperature of the reaction system is 100°C, and the dropwise addition time of 3-chloropropyltriethoxysilane is 3.5 hours. After the dropwise addition is completed, The reaction was continued for 0.5 hour, and the hydrogen chloride gas generated by the reaction was absorbed by water. At this time, the reaction had completed nearly a large part.

[0032] Then the reaction system was coole...

Embodiment 3

[0035] Add thiooctanoic acid 647.6g and xylene 1300g in the 5000ml four-necked reaction flask with mechanical stirring, constant pressure dropping funnel and condenser, drop into 3-chloropropyltriethoxy in the constant pressure dropping funnel simultaneously Silane 972.9g, the molar ratio of thiooctanoic acid to 3-chloropropyltriethoxysilane is 1:1, the amount of xylene added is 50% of the total mass of thioctanoic acid and 3-chloropropyltriethoxysilane %—100%. Then start the circulating water vacuum pump, and start the dropwise addition reaction under mechanical stirring at 400 rpm. The temperature of the reaction system is 135° C., and the dropwise addition time of 3-chloropropyltriethoxysilane is 3 hours. After the dropwise addition is completed, The reaction was continued for 0.5 hour, and the hydrogen chloride gas generated by the reaction was absorbed by water. At this time, the reaction had completed almost a large part.

[0036] Then the reaction system was cooled dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com