Thermoplasticity soluble polymerized styrene-butadiene rubber polyurethane elastomer material and preparation method

A technology of solution-polymerizing styrene-butadiene rubber and polyurethane elastomer, which is applied in the field of polymer synthesis, can solve problems such as poor wet skid resistance, achieve low rolling resistance, and improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Preparation of naphthalene lithium initiator: prepared by referring to the literature "Research on Negative Dilithium Initiator System" (Han Bingyong et al., Synthetic Rubber Industry, 1999-01-15, 22(1): 5-8). The polymerization bottle is vacuumized, flame-baked and filled with argon for 3 times, then naphthalene, lithium, polar additives, and benzene are added, reacted at room temperature, and finally butadiene or isoprene is added, and naphthalene lithium short-term can be obtained after filtration. chain initiator. The initiator concentration was calibrated by double titration method, and the initiator concentration was 1mol / L.

[0053] 2) Distillation of ethylene oxide: Grind 100 g of calcium hydride into powder, add 1 L of ethylene oxide and soak for 24 hours, and distill the ethylene oxide at room temperature under nitrogen atmosphere.

[0054] 3) Preparation of hydroxyl-terminated solution-polymerized styrene-butadiene rubber: the temperature of the reaction ...

Embodiment 2

[0058] 1) Preparation of naphthalene lithium initiator: prepare with reference to the literature "Research on Anion Dilithium Initiator System" (Han Bingyong et al., Synthetic Rubber Industry, 1999-01-15, 22(1): 5-8), and the polymerization bottle was pumped Vacuum, flame baking and filling with argon are repeated 3 times, then add naphthalene, lithium, polar additives, benzene, react at room temperature, finally add butadiene or isoprene, and filter to get naphthalene lithium short chain initiator. The initiator concentration was calibrated by double titration method, and the initiator concentration was 1mol / L.

[0059] 2) Distillation of ethylene oxide: Grind 100 g of calcium hydride into powder, add 1 L of ethylene oxide and soak for 24 hours, and distill the ethylene oxide at room temperature under nitrogen atmosphere.

[0060] 3) Preparation of hydroxyl-terminated solution-polymerized styrene-butadiene rubber: the temperature of the reaction kettle was raised to 50° C., a...

Embodiment 3

[0064] 1) Preparation of naphthalene lithium initiator: prepare with reference to the literature "Research on Anion Dilithium Initiator System" (Han Bingyong et al., Synthetic Rubber Industry, 1999-01-15, 22(1): 5-8), and the polymerization bottle was pumped Vacuum, flame baking and filling with argon are repeated 3 times, then add naphthalene, lithium, polar additives, benzene, react at room temperature, finally add butadiene or isoprene, and filter to get naphthalene lithium short chain initiator. The initiator concentration was calibrated by double titration method, and the initiator concentration was 0.8mol / L.

[0065] 2) Distillation of ethylene oxide: Grind 100 g of calcium hydride into powder, add 1 L of ethylene oxide and soak for 24 hours, and distill the ethylene oxide at room temperature under nitrogen atmosphere.

[0066] 3) Preparation of hydroxyl-terminated solution-polymerized styrene-butadiene rubber: the temperature of the reaction kettle was raised to 45° C.,...

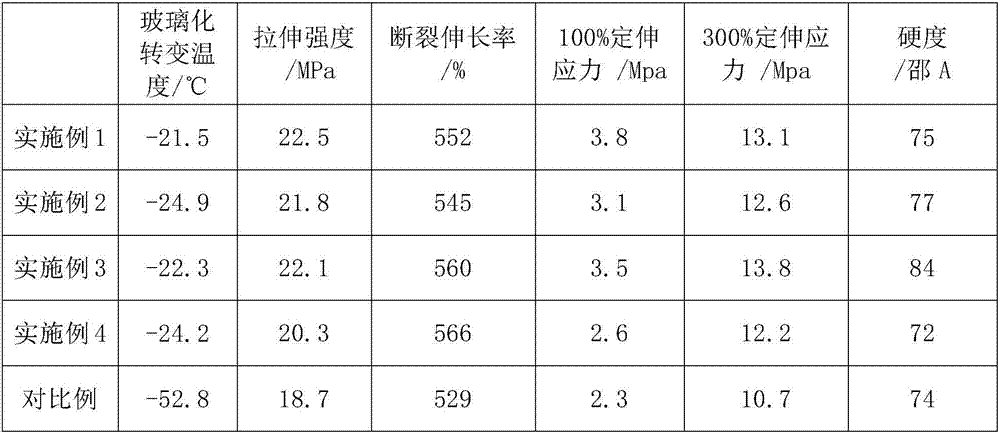

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com