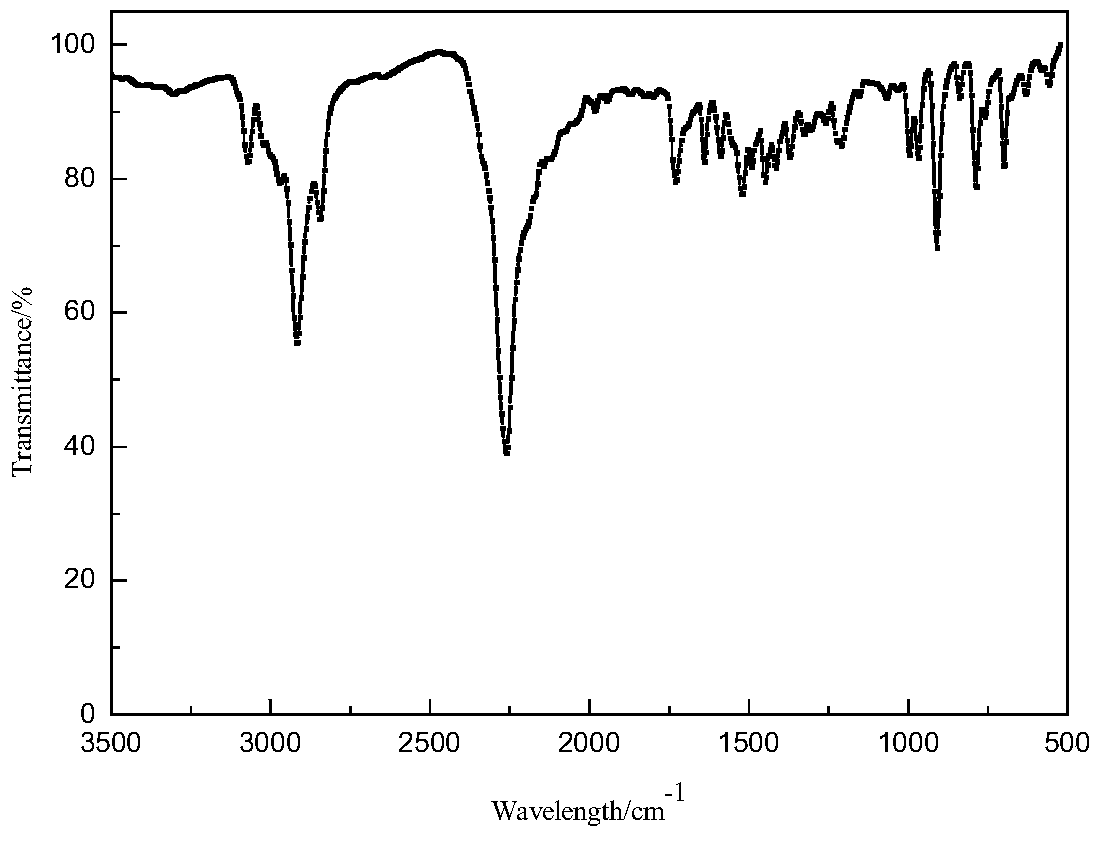

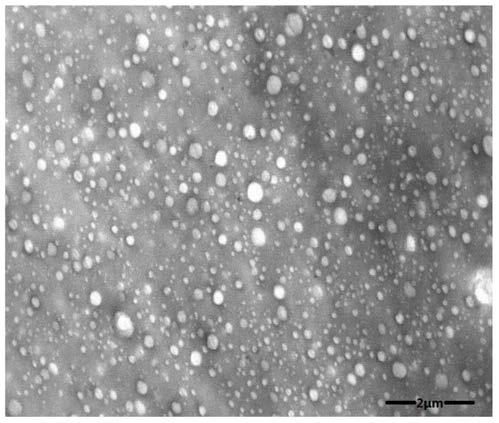

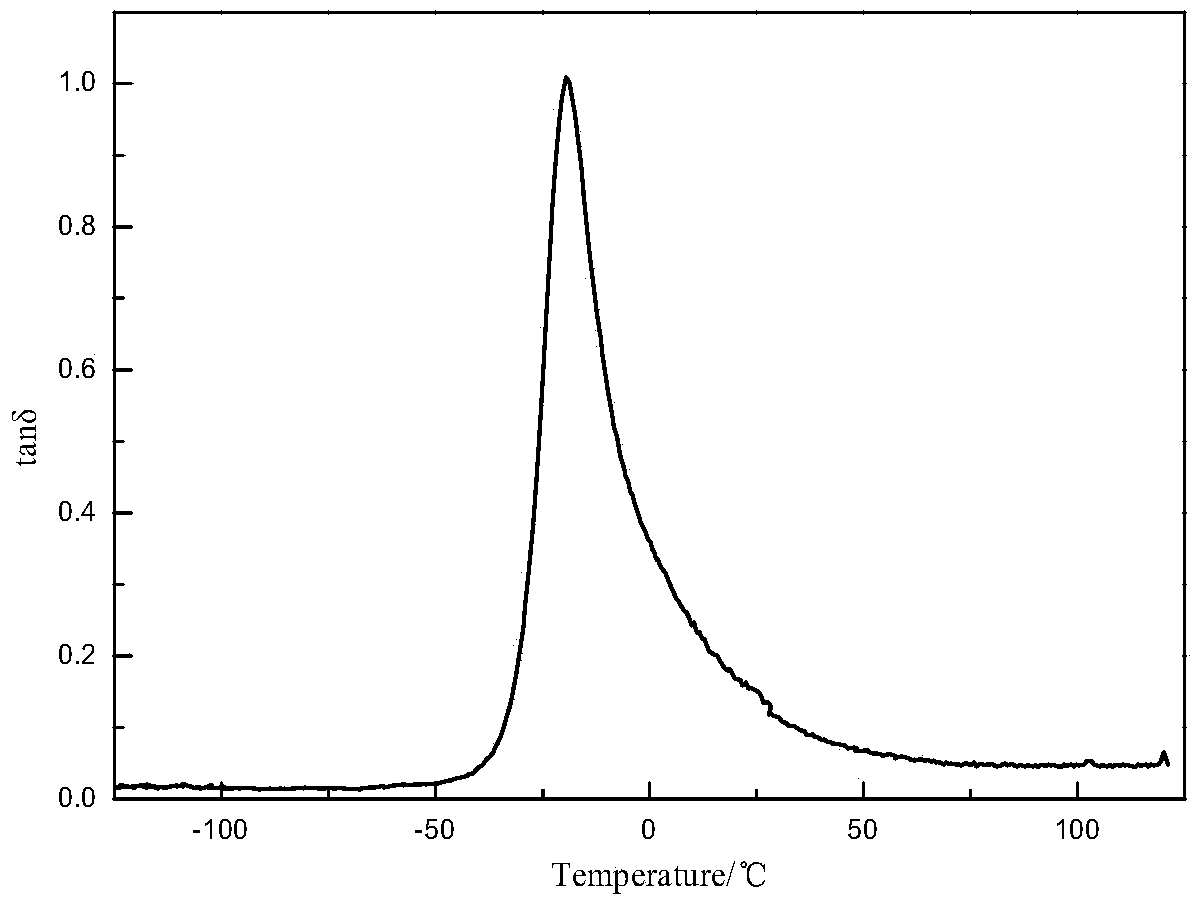

A solution-polymerized styrene-butadiene rubber-polyurethane elastomer material for high-performance tires and its preparation method

A technology for solution-polymerizing styrene-butadiene rubber and polyurethane elastomers, which is applied in the field of polymer synthesis, can solve the problems of unsatisfactory high temperature resistance, wet slip gripping ability, etc., achieve excellent dynamic mechanical properties, overcome poor high temperature resistance, The effect of excellent flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation process of the present embodiment polyurethane elastomer is as follows:

[0059] 1) Preparation of dilithium initiator: select cyclohexane and tetrahydrofuran as a solvent, and react with isoprene and metal lithium in an ice-water bath to form a dilithium initiator. Take 70g of lithium flakes with the oxide layer stripped off and 500ml of tetrahydrofuran into a three-necked flask, protect with argon, and place in an ice-water bath to ensure that the temperature is stable at about 0°C. Mix 200ml of isoprene and 500ml of cyclohexane evenly, add it to a constant pressure titration funnel, slowly add it dropwise to a three-necked flask, and fully react with lithium metal. After the dropwise addition was completed, stirring was continued at 0° C. for 6 h. After the reaction was completed, it was left to stand at low temperature for 24 hours. Filter the upper clarified reaction solution with a G4 sand core funnel to obtain a brown-red transparent initiator s...

Embodiment 2

[0065] The preparation process of the present embodiment polyurethane elastomer is as follows:

[0066] 1) Preparation of dilithium initiator: select cyclohexane and tetrahydrofuran as a solvent, and react with isoprene and metal lithium in an ice-water bath to form a dilithium initiator. Take 60g of lithium flakes stripped of the oxide layer and 500ml of tetrahydrofuran into a three-necked flask, protect with argon, and place in an ice-water bath to ensure that the temperature is stable at about 0°C. Mix 200ml of isoprene and 500ml of cyclohexane evenly, add it to a constant pressure titration funnel, slowly add it dropwise to a three-necked flask, and fully react with lithium metal. After the dropwise addition was completed, stirring was continued at 0° C. for 6 h. After the reaction was completed, it was left to stand at low temperature for 24 hours. Filter the upper clarified reaction solution with a G4 sand core funnel to obtain a brown-red transparent initiator solutio...

Embodiment 3

[0072] The preparation process of the present embodiment polyurethane elastomer is as follows:

[0073] 1) Preparation of dilithium initiator: select cyclohexane and tetrahydrofuran as a solvent, and react with isoprene and metal lithium in an ice-water bath to form a dilithium initiator. Take 90g of lithium flakes stripped of the oxide layer and 500ml of tetrahydrofuran into a three-necked flask, protect it with argon, and place it in an ice-water bath to ensure that the temperature is stable at about 0°C. Mix 200ml of isoprene and 500ml of cyclohexane evenly, add it to a constant pressure titration funnel, slowly add it dropwise to a three-necked flask, and fully react with lithium metal. After the dropwise addition was completed, stirring was continued at 0° C. for 6 h. After the reaction was completed, it was left to stand at low temperature for 24 hours. Filter the upper clarified reaction solution with a G4 sand core funnel to obtain a brown-red transparent initiator s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com