A kind of preparation method of composite modified acrylate core-shell emulsion of montmorillonite and methacrylic acid

A technology of methacrylic acid and acrylate, applied in the field of polymer emulsion, can solve the problems of unsuitability for wide application, decreased stain resistance, expensive silicone, etc., and achieves enhanced water resistance and stain resistance, better performance, The effect of improving thermal stability and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

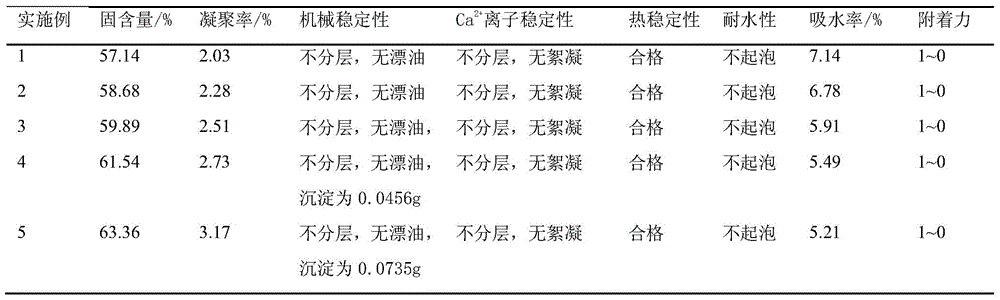

Embodiment 1

[0030] A preparation method of montmorillonite and methacrylic acid composite modified acrylate core-shell emulsion, comprising the following steps:

[0031] 1) Dissolve 0.2g OP-10 (polyethylene glycol octylphenyl ether) and 0.4g SDS (sodium dodecyl sulfate) in 18mL deionized water to prepare emulsifier aqueous solution, divide it into three For each part, add 10g of n-butyl acrylate, 2g of methyl methacrylate and 0.04g of organic montmorillonite dropwise to the first part of emulsifier aqueous solution, stir while adding, fully stir and mix at room temperature, and pre-emulsify for 1h , to obtain the core monomer pre-emulsion; 2g of n-butyl acrylate, 6g of methyl methacrylate, 0.04g of organic montmorillonite and 0.2g of cross-linking monomer methacrylic acid were added dropwise to the second part of emulsifier aqueous solution , stirred while adding dropwise, fully stirred and mixed at room temperature, and pre-emulsified for 1 hour to obtain a shell monomer pre-emulsion; di...

Embodiment 2

[0037] A preparation method of montmorillonite and methacrylic acid composite modified acrylate core-shell emulsion, comprising the following steps:

[0038] 1) Dissolve 0.3g OP-10 (polyethylene glycol octyl phenyl ether) and 0.6g SDS (sodium dodecyl sulfate) in 18mL deionized water to prepare emulsifier aqueous solution, divide it into three In one part, add 10g of n-butyl acrylate, 2g of methyl methacrylate and 0.1g of organic montmorillonite dropwise into the first part of emulsifier aqueous solution, stir while adding, fully stir and mix at room temperature, and pre-emulsify for 1h , to obtain the core monomer pre-emulsion; 2g of n-butyl acrylate, 6g of methyl methacrylate, 0.1g of organic montmorillonite and 0.8g of cross-linking monomer methacrylic acid were added dropwise to the second part of emulsifier aqueous solution , stirred while adding dropwise, fully stirred and mixed at room temperature, and pre-emulsified for 1 hour to obtain a shell monomer pre-emulsion; 0.0...

Embodiment 3

[0044] A preparation method of montmorillonite and methacrylic acid composite modified acrylate core-shell emulsion, comprising the following steps:

[0045] 1) Dissolve 0.3g OP-10 (polyethylene glycol octyl phenyl ether) and 0.6g SDS (sodium dodecyl sulfate) in 18mL deionized water to prepare emulsifier aqueous solution, divide it into three In one part, add 10g of n-butyl acrylate, 2g of methyl methacrylate and 0.2g of organic montmorillonite dropwise into the first part of emulsifier aqueous solution, stir while adding, fully stir and mix at room temperature, and pre-emulsify for 1h , to obtain the core monomer pre-emulsion; 2g of n-butyl acrylate, 6g of methyl methacrylate, 0.2g of organic montmorillonite and 1.2g of cross-linking monomer methacrylic acid were added dropwise to the second part of emulsifier aqueous solution , stirred while adding dropwise, fully stirred and mixed at room temperature, and pre-emulsified for 1 hour to obtain a shell monomer pre-emulsion; 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com