High-performance water-based acrylic polyurethane coating and preparation method thereof

An acrylic polyurethane and water-based polyurethane technology, applied in the field of coatings, can solve the problems of single application scenario, unstable product performance, complex preparation process, etc., achieve excellent adhesion performance, improve crosslinking density and coating film drying speed, stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

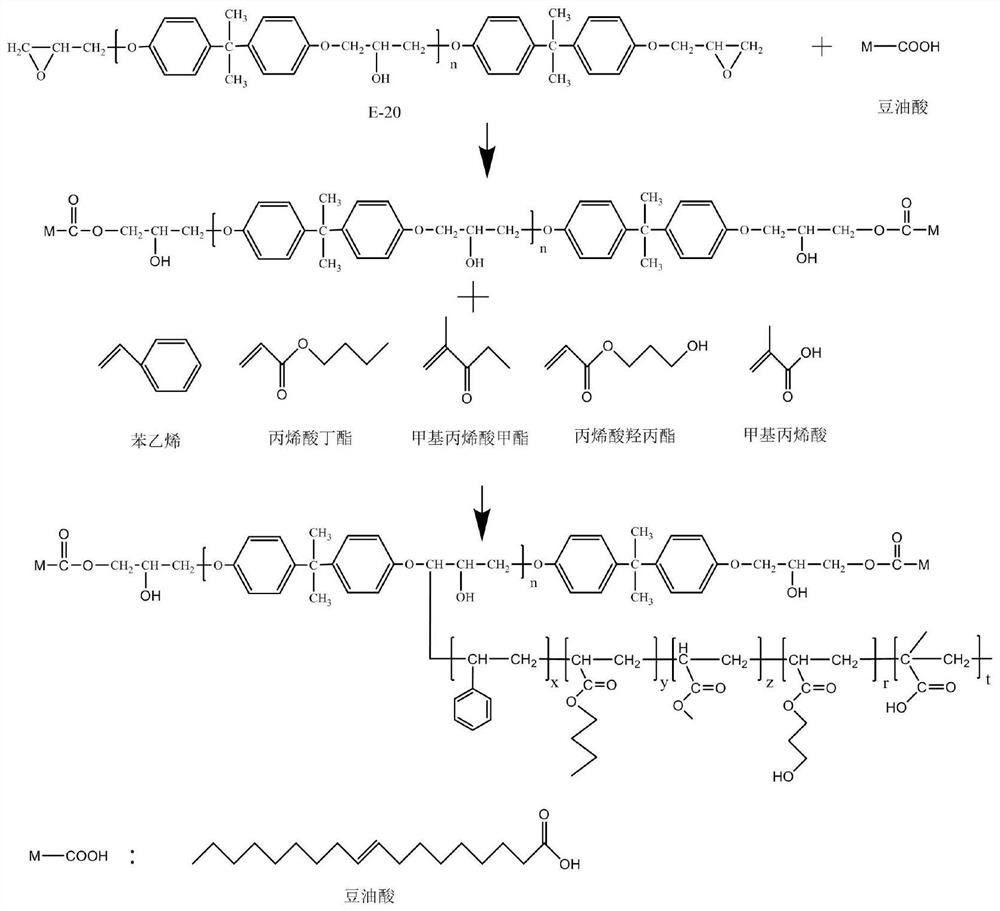

[0032] (1) Add soybean oil acid, epoxy resin E-20, and tetrabutylammonium bromide to the reaction kettle, and feed N 2 , start stirring at 150r / min, raise the temperature to 130°C and react for 3h, until the acid value in the system is lower than 5 to obtain epoxy ester; then slowly cool down to 120°C, add propylene glycol methyl ether and n-butanol, and then add styrene, methacrylic acid Mix methyl ester, butyl acrylate, acrylic acid and benzoyl peroxide evenly, and pump them into the reaction kettle at a constant speed with a peristaltic pump. After about 3 hours of pumping, react at 120°C for a further 2 hours: then cool down to 80°C and add triethylamine to neutralize After 30 minutes, deionized water was added under high-speed stirring at 3000 r / min to prepare soy-oleic acid-modified epoxy-acrylic resin.

[0033] Wherein the amount of each raw material used in the step (1) is:

[0034] soybean oil 29 copies Epoxy resin E-20 60 copies tetrabutylamm...

Embodiment 2

[0042] (1) Add soybean oil acid, epoxy resin E-12, and tetrabutylammonium bromide to the reaction kettle, and feed N 2 , start stirring at 150r / min, raise the temperature to 130°C and react for 3h, until the acid value in the system is lower than 5 to obtain epoxy ester; then slowly cool down to 120°C, add propylene glycol methyl ether and n-butanol, and then add styrene, methacrylic acid Mix methyl ester, butyl acrylate, acrylamide, acrylic acid and benzoyl peroxide evenly, and pump them into the reaction kettle at a constant speed with a peristaltic pump for about 3 hours, then react at 120°C for 2 hours; then cool down to 80°C and add triethyl ether The amine was neutralized for 30 minutes, and deionized water was added under high-speed stirring at 3000 r / min to prepare soy-oleic acid-modified epoxy-acrylic resin.

[0043] Wherein the amount of each raw material used in the step (1) is:

[0044] soybean oil 29 copies Epoxy resin E-12 96 copies tetra...

Embodiment 3

[0052] (1) Dehydrated ricinoleic acid, epoxy resin E-20, and tetrabutylammonium bromide are added to the reactor, and N 2 , start stirring at 150r / min, raise the temperature to 130°C and react for 3h, until the acid value in the system is lower than 5 to obtain epoxy ester; then slowly cool down to 120°C, add propylene glycol methyl ether and n-butanol, and then add styrene, methacrylic acid Mix methyl ester, butyl acrylate, hydroxyethyl acrylate, acrylic acid and benzoyl peroxide evenly, and pump them into the reaction kettle at a constant speed with a peristaltic pump for about 3 hours, then react at 120°C for 2 hours; then cool down to 80°C and add Triethylamine was neutralized for 30 minutes, and deionized water was added under high-speed stirring at 3000 r / min to prepare dehydrated ricinoleic acid modified epoxy-acrylic resin.

[0053] Wherein the amount of each raw material used in the step (1) is:

[0054] dehydrated ricinoleic acid 28 copies Epoxy res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com