A kind of styrene, butadiene, isoprene star copolymer and preparation method thereof

A star-shaped copolymer, isoprene technology, used in tire parts, rolling resistance optimization, transportation and packaging, etc., can solve the problems of unsatisfactory rubber rolling resistance, and achieve good physical and mechanical properties and polymerization conditions. Controllable and improve the effect of comprehensive mechanical properties and dynamic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

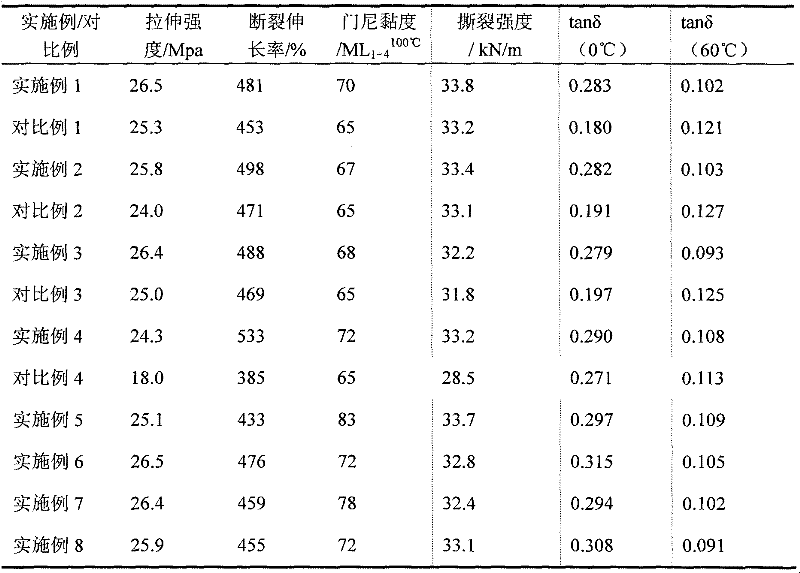

Examples

Embodiment 1

[0028] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 2241g of cyclohexane, 298g of isoprene, and 0.52g of tetrahydrofuran into the polymerization kettle, add 12.1mmol of n-butyllithium, raise the temperature to 40°C, and polymerize for 80min. Mix 4.66g of tetrahydrofuran, 3480g of cyclohexane, and 57.6g of Press the mixture of ethylene and 518.4g butadiene into the polymerization kettle, control the polymerization temperature at 40°C, continue the reaction for 80min, then press the mixture of 5.18g tetrahydrofuran, 3470g cyclohexane, 230.4g styrene and 345.6g butadiene into the polymerization kettle , the reaction time is 60 minutes, and the polymerization temperature is gradually increased from 40°C to 70°C within 60 minutes, and the temperature is increased by 0.5°C per minute. After the reaction is completed, 336g cyclohexane and 43.2g butadiene are added to the polymerization kettle to continue the reaction for 30 minutes , ...

Embodiment 2

[0032] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 3480g of cyclohexane, 576g of isoprene, and 1.02g of tetrahydrofuran into the polymerization kettle, add 24.2mmol of n-butyllithium, raise the temperature to 50°C, polymerize for 60min, and mix 9.33g of tetrahydrofuran, 3018g of cyclohexane, and 38.8g of benzene Press the mixture of ethylene and 349.2g butadiene into the polymerization kettle, control the polymerization temperature at 50°C, continue the reaction for 60min, then press the mixture of 10.37g tetrahydrofuran, 3703g cyclohexane, 105.2g styrene and 370.8g butadiene into the polymerization kettle , the reaction time is 40 minutes, within 40 minutes, the polymerization temperature is gradually increased from 50°C to 80°C, and the temperature is increased by 0.75°C per minute. After the reaction is completed, 336g cyclohexane and 43.2g butadiene are added to the polymerization kettle to continue the reaction for 20 minu...

Embodiment 3

[0036] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 3,361g of cyclohexane, 432g of isoprene, and 1.02g of tetrahydrofuran to the polymerization kettle, add 8.1mmol of n-butyllithium, raise the temperature to 60°C, and polymerize for 50min, mix 3.11g of tetrahydrofuran, 2,975g of cyclohexane, and 50.4g of The mixture of ethylene and 332g butadiene was pressed into the polymerization kettle, the polymerization temperature was controlled at 60°C, and the reaction was continued for 50 minutes, and the mixture of 3.46g tetrahydrofuran, 4867g cyclohexane, 93.6g styrene and 532g butadiene was pressed into the polymerization kettle, and the reaction The time is 40 minutes, and the polymerization temperature is controlled to gradually increase from 60°C to 90°C within 40 minutes, and the temperature is raised by 0.75°C per minute. After the reaction is completed, 224g cyclohexane and 28.8g butadiene are added to the polymerization kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com