Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

A benzothiazole mercaptosilane and low-volatility technology, which is applied in the field of low-volatility benzothiazole-mercaptosilane and its preparation, can solve the physical damage of workers, pollute the processing workshop environment, and cannot remove methoxy and ethoxy groups and other problems, to achieve the effect of fast vulcanization speed, long scorch time, improved mechanical properties and dynamic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

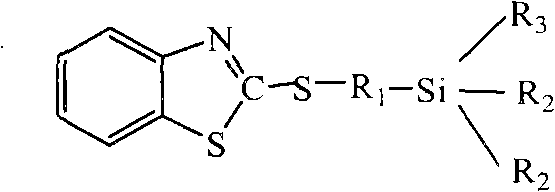

[0047] A kind of low volatility benzothiazole mercaptosilane, wherein, the molecular structural formula of silane is:

[0048]

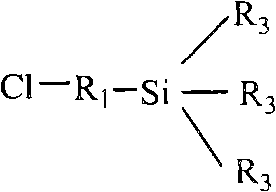

[0049] The preparation method of above-mentioned silane is:

[0050] Step a: Weigh 0.1mol (28.86g) of γ-chloropropyltriethoxysilane and 0.2mol (54.8g) of polyether HO-(C 2 h 4 -O) 2 -C 12 h 25 Place in a three-necked flask, add 0.5g of zinc naphthenate, react at 70°C for 2 hours, and remove ethanol in a vacuum for one hour to obtain polyether-modified chloropropylsilane (ie, semi-finished silane);

[0051] Step b: Weigh 0.1mol (16.7g) of 2-mercaptobenzothiazole and 250g of toluene, place them in a round-bottomed three-neck flask, add 0.1mol (5.4g) of sodium methoxide, stir well, and heat the mixture to 120°C, and from one side of the three-necked flask at a distance of 0.1m 3 Nitrogen was introduced at a speed of 1 / h, and then 75.3g of polyether modified chloropropylsilane was added to the above solution, and then reacted at 120°C for 10 hou...

Embodiment 2

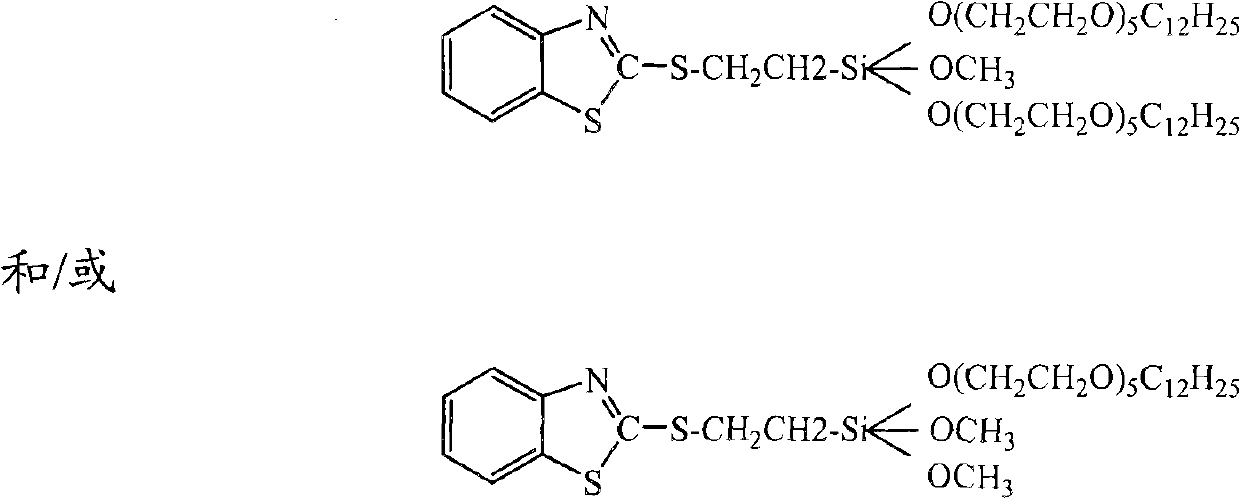

[0066] A kind of low volatility benzothiazole mercaptosilane, wherein, the molecular structural formula of silane is:

[0067]

[0068] The preparation method of above-mentioned silane is:

[0069] Step a: Weigh 0.1mol (17.1g) γ-chloromethyltrimethoxysilane and 0.2mol (81.2g) polyether HO-(C 2 h 4 -O) 5 -C 12 h 25 Place in a three-necked flask, add 0.5g of sodium ethoxide, react at 165°C for 7 hours, and remove methanol in a vacuum for one hour to obtain polyether-modified chloropropylsilane (ie semi-finished silane);

[0070] Step b: Weigh 0.1mol (16.7g) of 2-mercaptobenzothiazole and 250g of toluene, place them in a round-bottomed three-neck flask, add 0.1mol (5.4g) of sodium methoxide, stir well, and heat the mixture to 120°C, then add 81.4g of the above-mentioned polyether-modified chloropropylsilane to the above-mentioned solution, and then react at 50°C for 24 hours under the protection of nitrogen, filter the obtained product, wash, and remove the low-boiling fr...

Embodiment 3

[0085] A kind of low volatility benzothiazole mercaptosilane, wherein, the molecular structural formula of silane is:

[0086]

[0087] The preparation method of above-mentioned silane is:

[0088] Step a: Weigh 5mol (862.5) γ-chloropropyltrimethoxysilane and 10mol (508g) polyether HO-(C 2 h 4 -O) 7 -C 13 h 27 Put it in a reaction kettle, add 50g of butyl aluminate, and react under 0.09Mpa vacuum at 180°C for 10 hours to obtain polyether-modified chloropropylsilane (ie, semi-finished silane);

[0089] Step b: Weigh 5mol (835g) of 2-mercaptobenzothiazole and 10kg of acetone, place in a stainless steel container, add 7.5mol (300g) of sodium hydroxide, heat to 80°C, stir evenly, and blow in nitrogen , and then added to the above solution, and then reacted at 80°C for 6 hours under the protection of nitrogen, the obtained product, the sediment was filtered, and the low boiling point fraction was removed by vacuum distillation to obtain a brownish red liquid with a yield of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com