Patents

Literature

146results about How to "Extended scorch time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire rubber composition

InactiveUS20090326109A1Improve fuel efficiencyExtended scorch timeSpecial tyresHysteresisAntioxidant

Provided is a tire rubber composition blended with an antioxidant that is derived from a raw material other than petroleum resources, the tire rubber composition being capable of achieving an oxidation resistance equal to or higher than a conventional level and of improving forming processability and a low hysteresis loss property. The tire rubber composition includes a blend of: 100 parts by weight of a diene rubber; 5 to 130 parts by weight of an inorganic filler; and 0.01 to 10 parts by weight of a tea extract containing a catechin.

Owner:THE YOKOHAMA RUBBER CO LTD

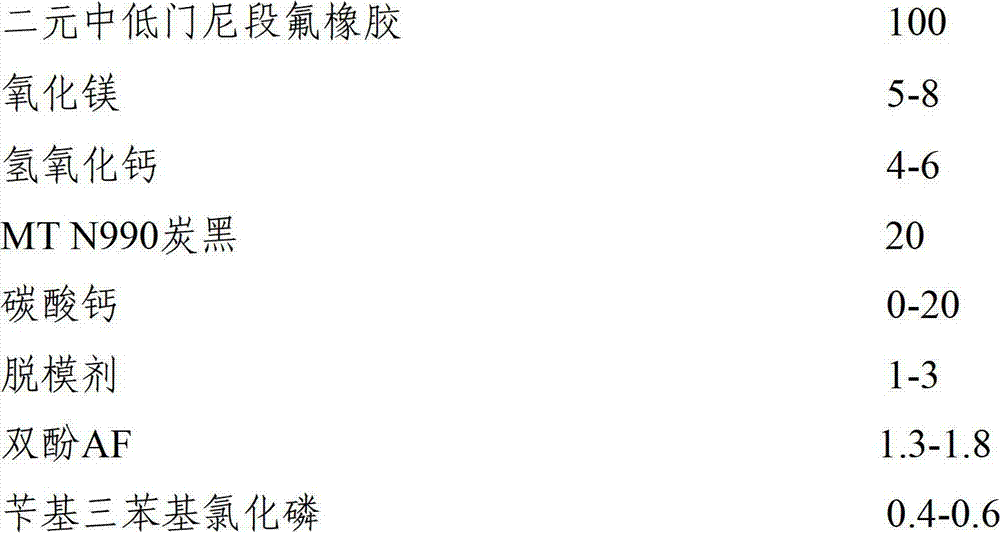

Fluororubber rubber compound and preparation method thereof

The invention provides a fluororubber rubber compound and a preparation method thereof. The fluororubber rubber compound is prepared by mixing binary intermediate-low monney sectional fluororubber rubber, reinforcing system (MT N990 carbon black and inorganic filler), acid absorbing system (active magnesium oxide and superfine calcium hydroxide), vulcanizing system (benzyl triphenyl phosphorus chloride and bisphenol AF), releasing agent (alfux and / or carnauba wax), and multifunctional bisphenol vulcanizing composite assistant vulcanizing agent L; the obtained fluororubber rubber compound has high stretching strength, and high extending rate, increases the scorching time by improving the liquidity of the rubber, therefore, high adaptability of the rubber to different manufacture technical environments and the vulcanizing environments can be ensured, the safety in vulcanizing can be improved, and as a result, the rejection rate of the products can be reduced. The fluororubber rubber compound provided by the invention is applicable to industries such as aerospace, aviation, car, metallurgy, petrochemical industry and electron and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Semi-steel wire radial tire undertread calendering sizing compound

The invention relates to calendering belt compound in a semi-steel wire radial tyre. The main points are as follows: the belt glue stuff is prepared from various materials which comprise natural rubber (code: SMR20), carbon black N326, carbon black N660, white carbon black, a silane coupling agent, zinc oxide, an antioxidant 4020, an antioxidant RD, resorcinol-80, a binding agent RA-65, an accelerator DZ, insoluble sulfur IS-7020 and a scorch retarder CTP.

Owner:SICHUAN TYRE & RUBBER CO LTD

Polysiloxane-containing rubber composition for tire

InactiveUS6103811AEasy to processLow viscosityGroup 4/14 element organic compoundsSpecial tyresSilylenePolymer science

PCT No. PCT / JP97 / 03212 Sec. 371 Date May 8, 1998 Sec. 102(e) Date May 8, 1998 PCT Filed Sep. 11, 1997 PCT Pub. No. WO98 / 11161 PCT Pub. Date Mar. 19, 1998A rubber composition for a tire comprising: 100 parts by weight of a starting rubber; 10 to 150 parts by weight of a carbon black; 0.1 to 20 parts by weight of a sulfur; and 40 parts by weight or less of a polysiloxane having the following alkoxysilyl group (I) or acyloxysilyl group (II) and having an average degree of polymerization of 3 to 10,000: 3BOND Si-OR1(I) 3BOND Si-OCOR2(II) wherein R1 is a substituted or unsubstituted monovalent hydrocarbon group or an organic group containing an ether bond and having 1 to 18 carbon atoms and R2 is hydrogen or a hydrocarbon group having 1 to 21 carbon atoms.

Owner:YOKOHAMA RUBBER CO LTD

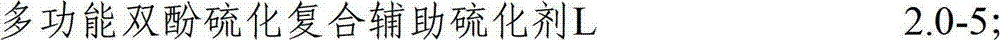

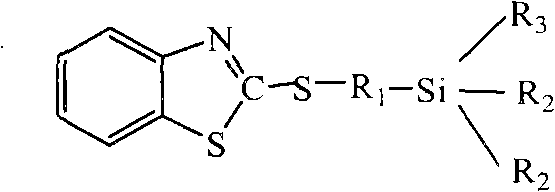

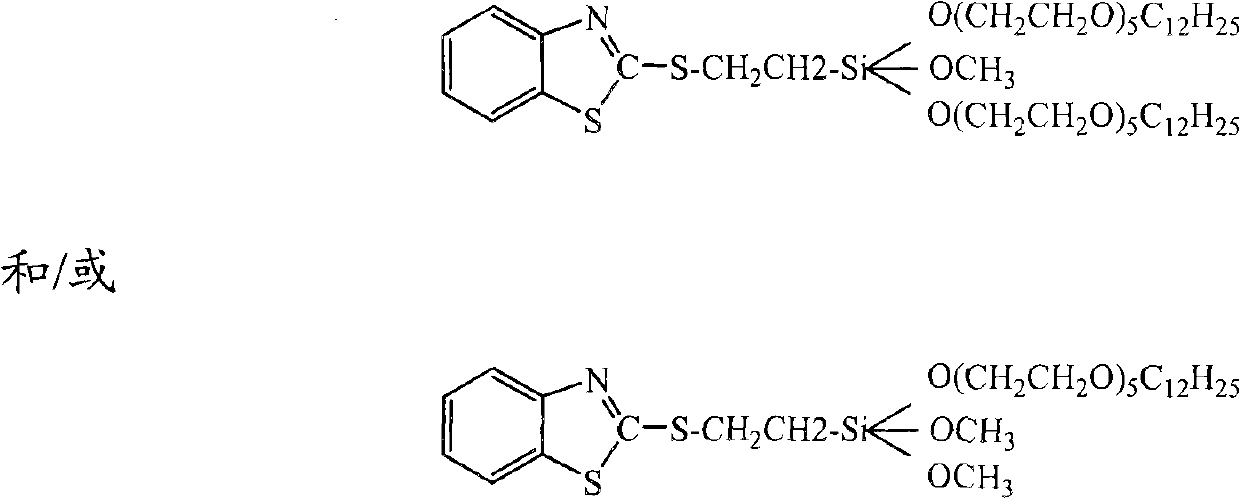

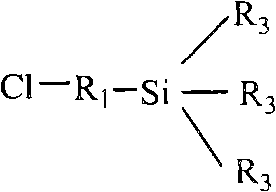

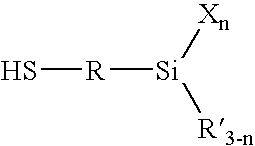

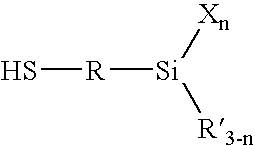

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

Low-hardness and high-drawing-fatigue-resistance flame-retardant wire rope core conveyer belt core rubber and preparation method thereof

The invention relates to low-hardness and high-drawing-fatigue-resistance flame-retardant wire rope core conveyer belt core rubber which comprises the following raw materials: 10-20 parts by weight of natural rubber, 10-20 parts by weight of cis-1,4-polybutadiene rubber, 60-80 parts by weight of chloroprene rubber CR3222, 10-30 parts by weight of reinforcing agent, 10-20 parts by weight of binding agent, 40-80 parts by weight of flame retardant, 1-5 parts by weight of anti-aging agent, 1-4 parts by weight of sulfur, 0-4 parts by weight of vulcanizing agent, 2-4 parts by weight of zinc oxide, 2-3 parts by weight of magnesium oxide, 1-2 parts by weight of accelerator and 2-3 parts by weight of activating agent. The invention also provides a preparation method of the core rubber. On the premise of not increasing the carbon black filler content in the core rubber, the invention increases the modulus of the flame-retardant wire rope core conveyer belt core rubber by adjusting the vulcanizing system in the core rubber, so that the flame-retardant wire rope core conveyer belt core rubber has favorable working property, and the drawing fatigue resistance is enhanced.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

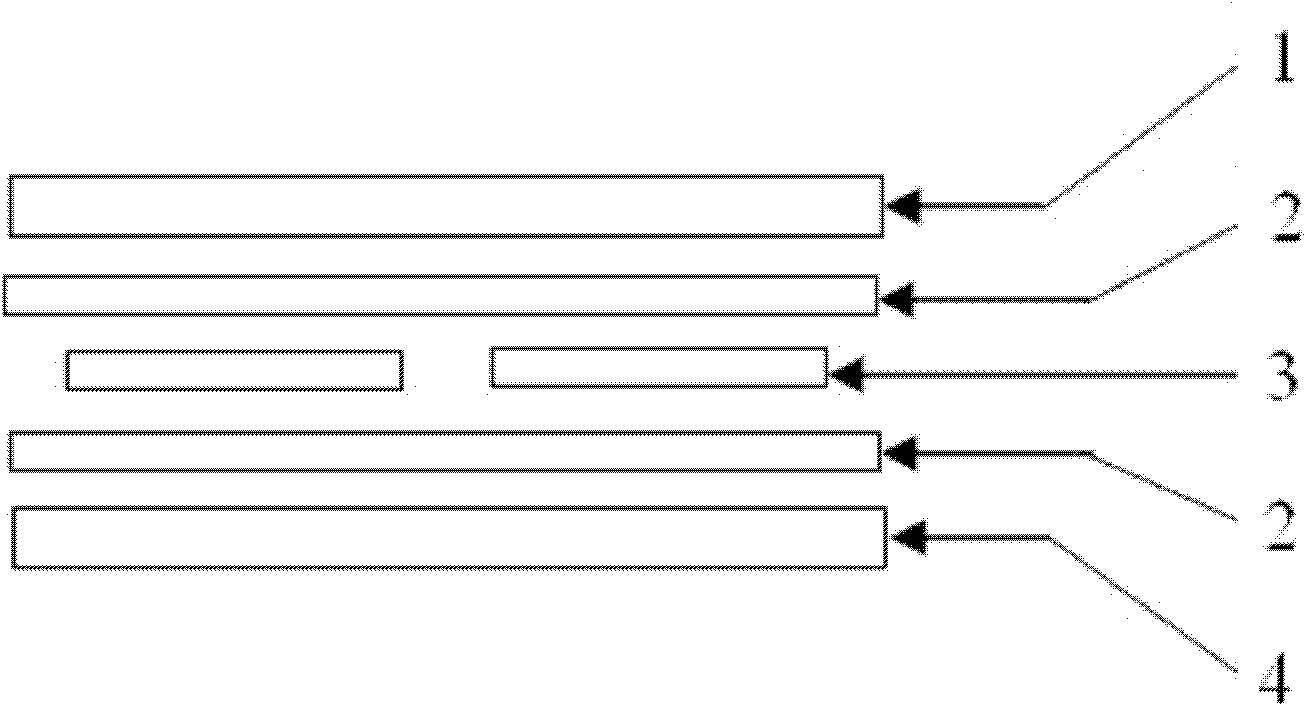

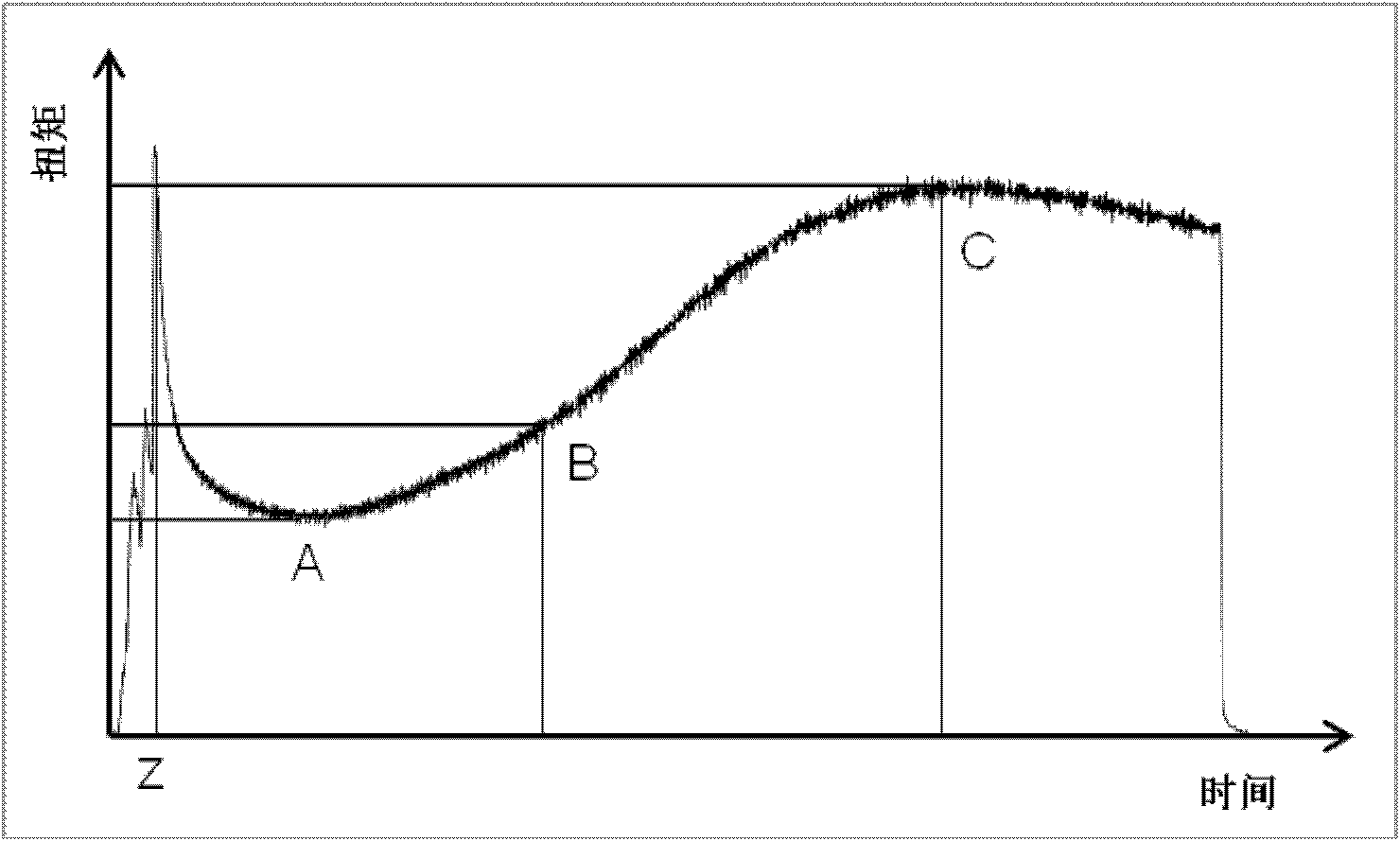

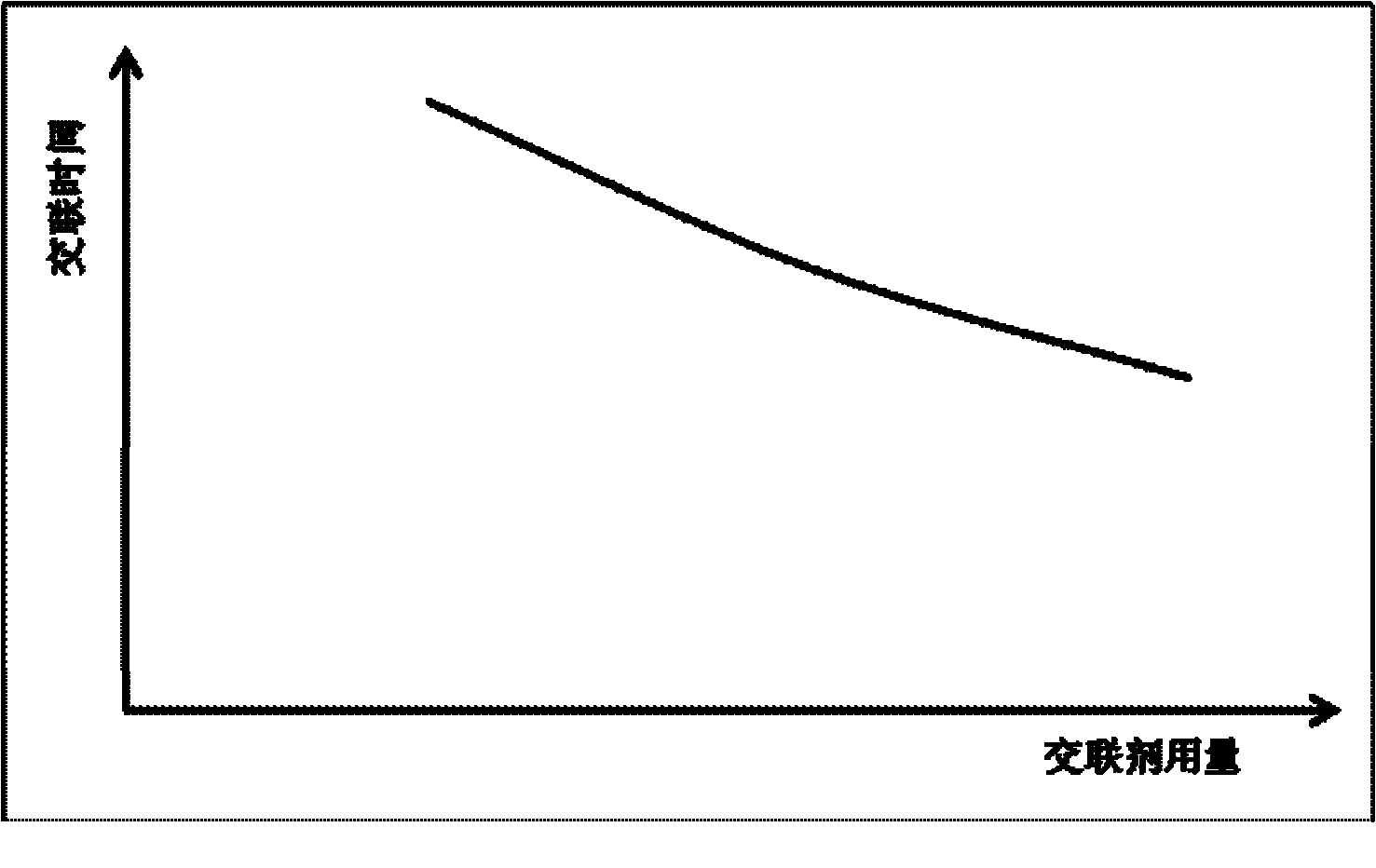

Packaging adhesive film for solar cell

InactiveCN101820001AGuaranteed production efficiencyEasy to processPhotovoltaic energy generationSemiconductor devicesCross-linkSolar cell

The invention relates to a packaging adhesive film for a solar cell, which can effectively prolong scorch time T2 and improve the processing and packaging properties of an EVA adhesive film on the basis of small change on total cross-linking time TC. The packaging adhesive film for the solar cell contains a copolymer of ethylene-vinyl acetate (EVA), a cross-linking agent, a cross-linking inhibitor and a radical trap, wherein, the masses of the cross-linking inhibitor and the radical trap are respectively 0.1-1.0% and 0-0.3% of the mass of the ethylene-vinyl acetate copolymer, and the cross-linking time of the packaging adhesive film for the solar cell is 10-30min. In the invention, the cross-linking inhibitor and the radical trap are added based on the formula of the existing packaging adhesive film for the solar cell to form a stable molecular structure with active radicals generated in the peroxide cross-linking agent, thus effectively preventing early-stage cross-linking and over cross-linking, and effectively prolonging the scorch time T2 on the basis of guaranteeing the total cross-linking time TC to meet the requirements.

Owner:南京红宝丽新材料有限公司

Rubber material for metal and rubber composite shock-absorbent product

The invention provides a rubber material for buffer composite with metal and rubber, comprising rubber, vulcanizing agent, accelerating agent, anti-aging agent, strengthening agent, active agent, elasticizer, filler and anticoking additive. The rubber material is characterized by good mechanical property, distinctive anti-aging property, strong adhesive strength between rubber and metal, permitted rubber creep range during usage, long coke burning time, and fast vulcanizing speed.

Owner:长春保卓轨道交通橡塑技术有限公司

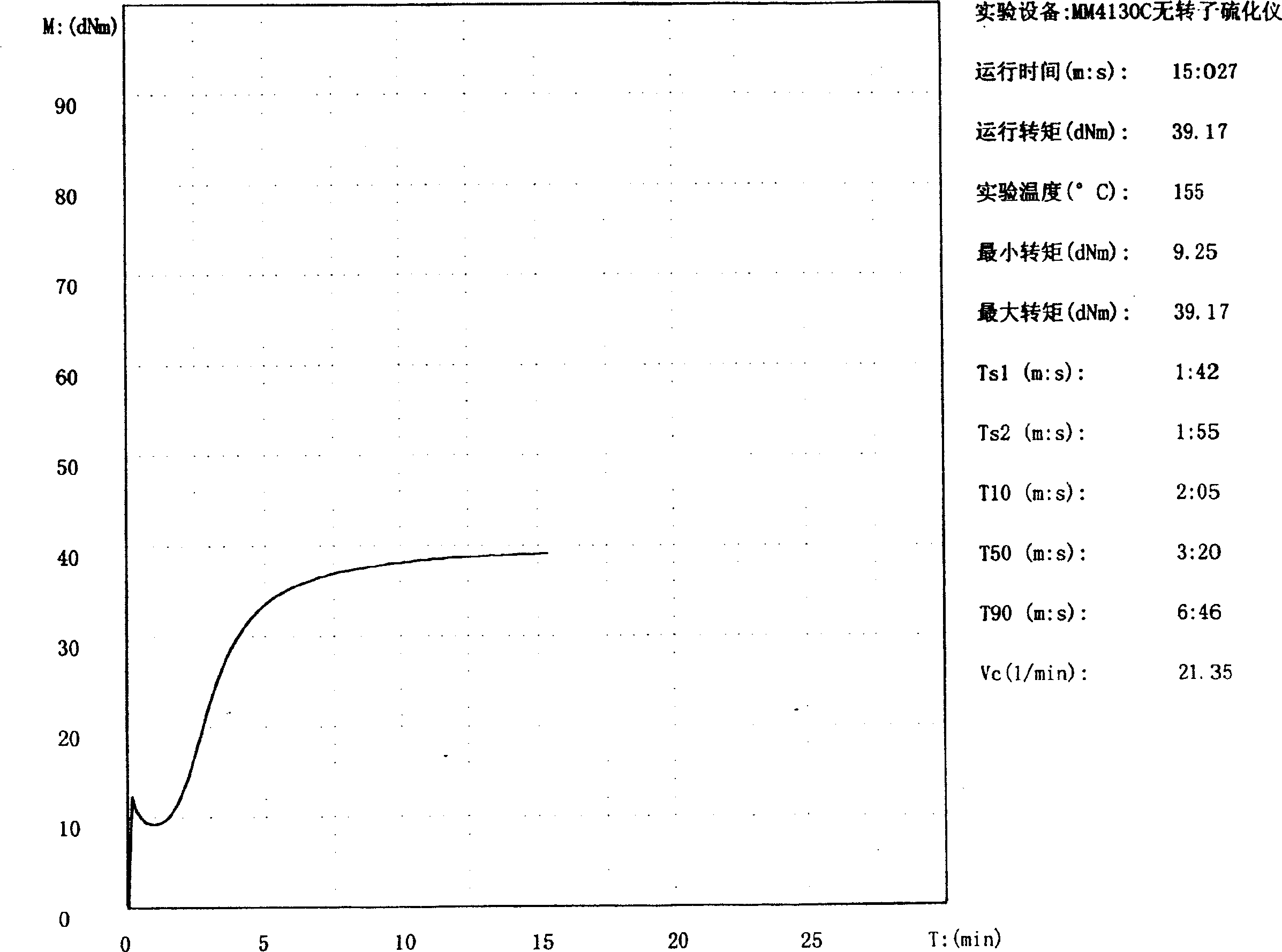

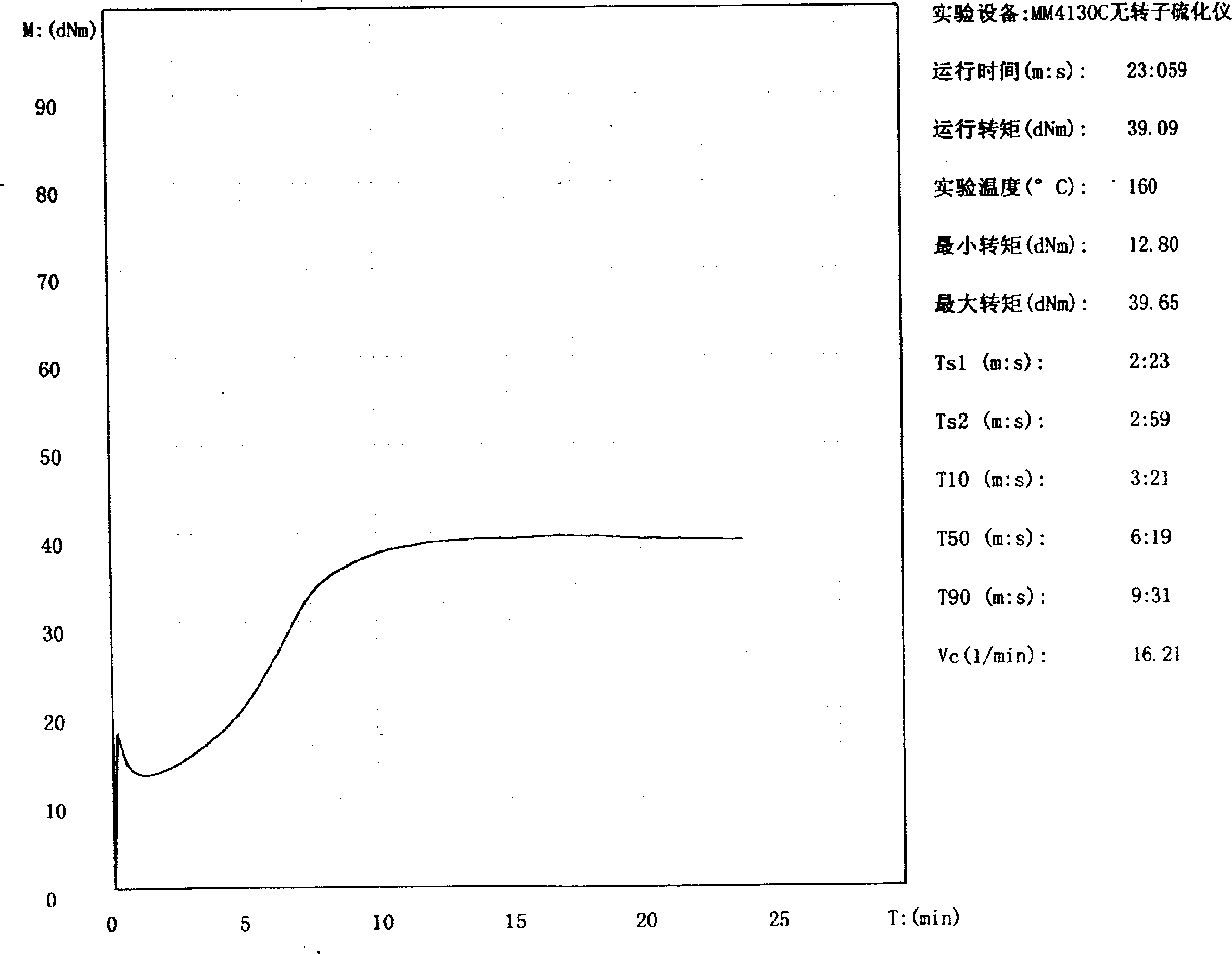

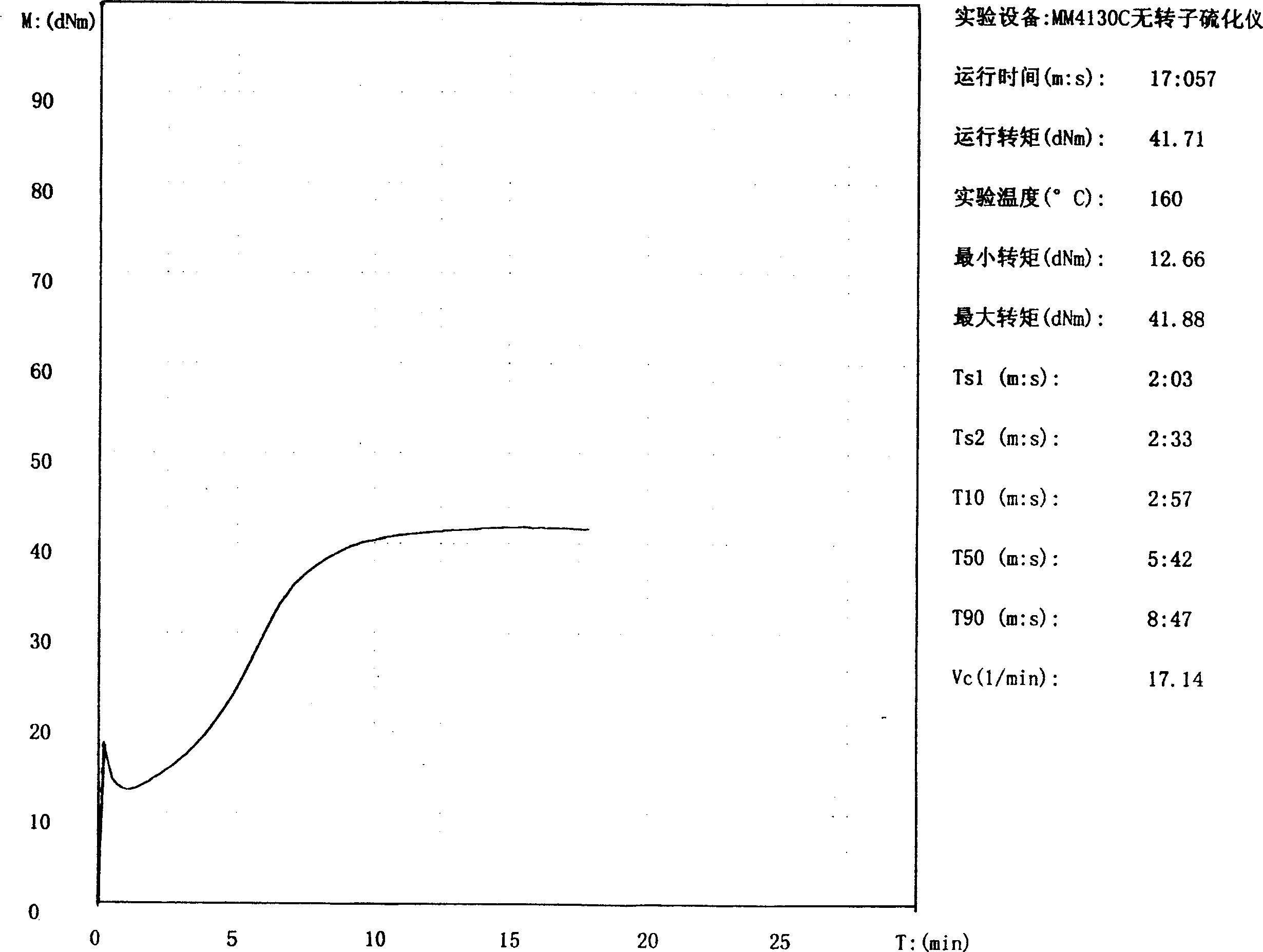

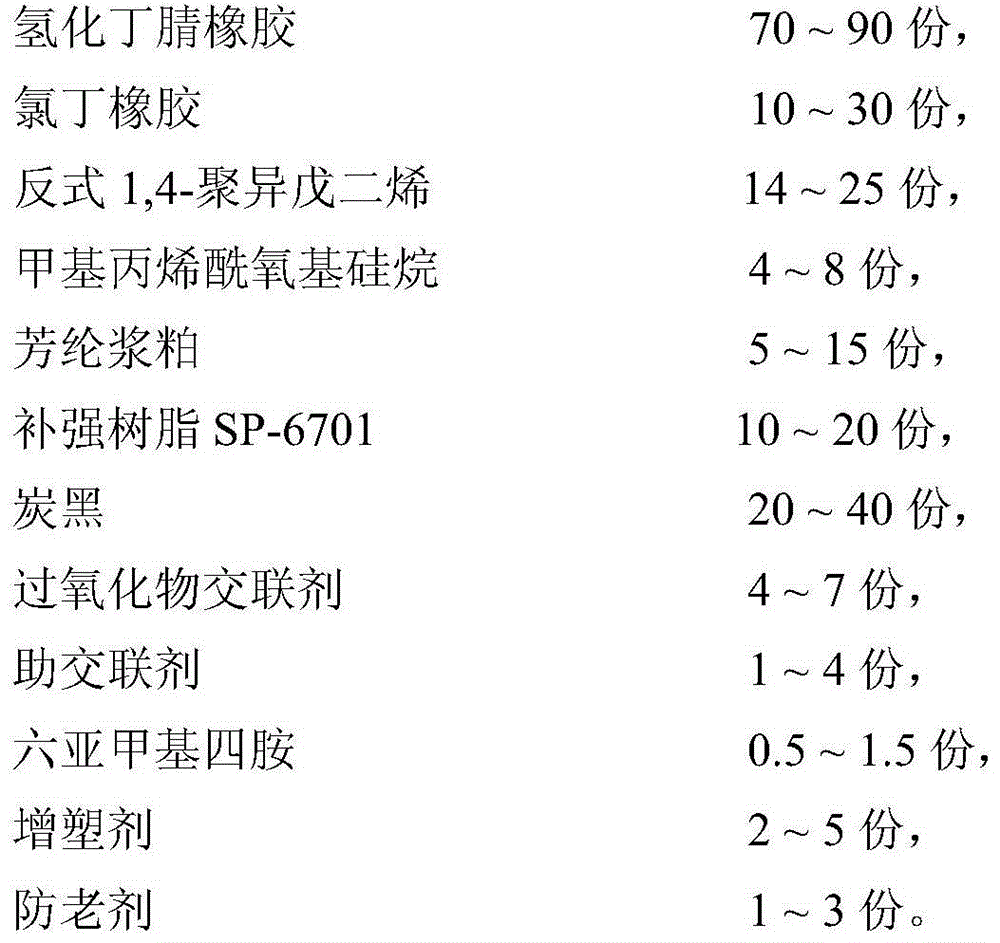

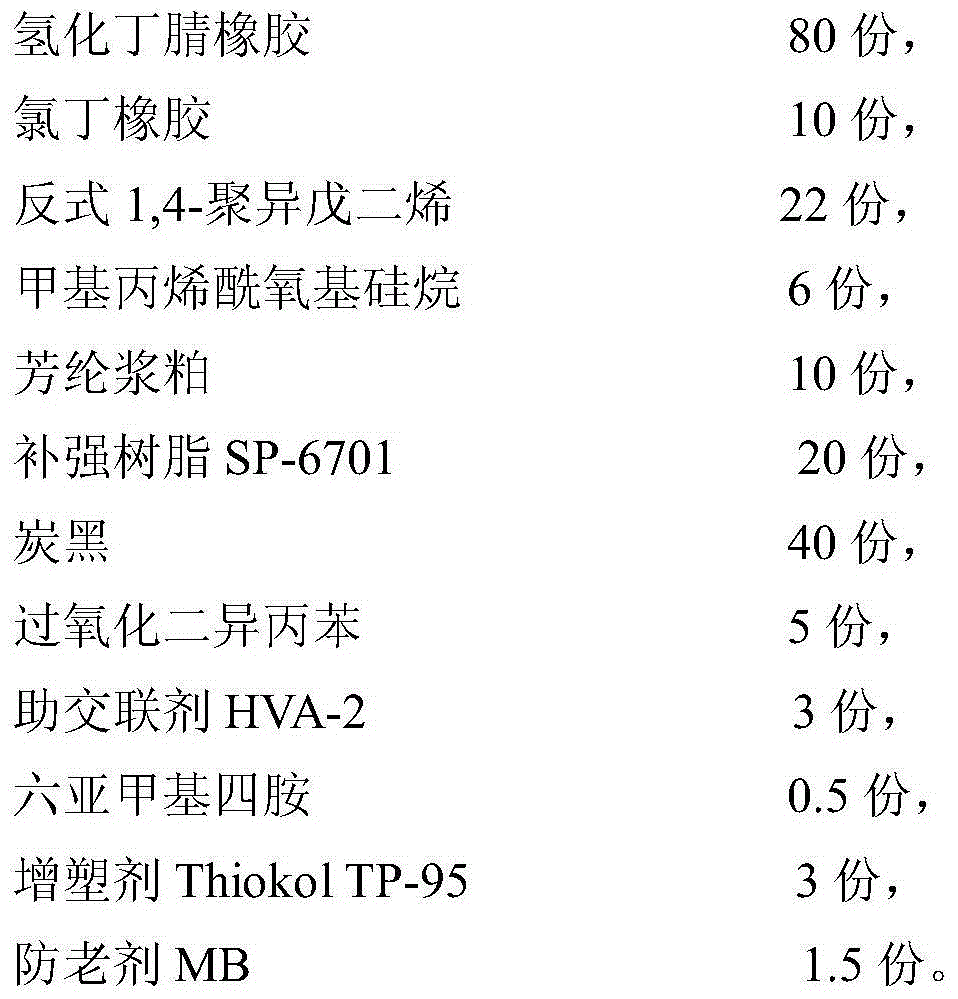

High-strength synchronous belt and manufacturing method thereof

ActiveCN104675922AGood wear resistanceImprove heat resistanceDriving beltsMonocomponent synthetic polymer artificial filamentCarbon blackPlasticizer

The invention relates to a high-strength synchronous belt. The synchronous belt comprises a synchronous belt framework and an adhesive piece attached to the outer side of the synchronous belt frame. The adhesive piece comprises the following components in parts by weight: 70-90 parts of hydrogenated butadiene-acrylonitrile rubber, 10-30 parts of chloroprene rubber, 14-25 parts of trans 1, 4-polyisoprene, 4-8 parts of methylacryloyl silane, 5-15 parts of aramid pulp, 10-20 parts of reinforced fiber SP-6701, 20-40 parts of carbon black, 4-7 parts of peroxide crosslinking agent, 1-4 parts of assistant crosslinking agent, 0.5-1.5 parts of hexamine, 2-5 parts of plasticizer and 1-3 parts of antiaging agent. The invention also relates to a manufacturing method of the synchronous belt. According to the high-strength synchronous belt and the manufacturing method thereof, the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are used together, so that the performances of the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are complementary, and thus the wear resistance and the heat resistance of the adhesive piece of the synchronous belt can be effectively improved; the shear strength and the quality stability of the synchronous belt are improved by use of the trans 1, 4-polyisoprene, the methylacryloyl silane and the aramid pulp.

Owner:NINGBO FULONG SYNCHRONOUS BELT

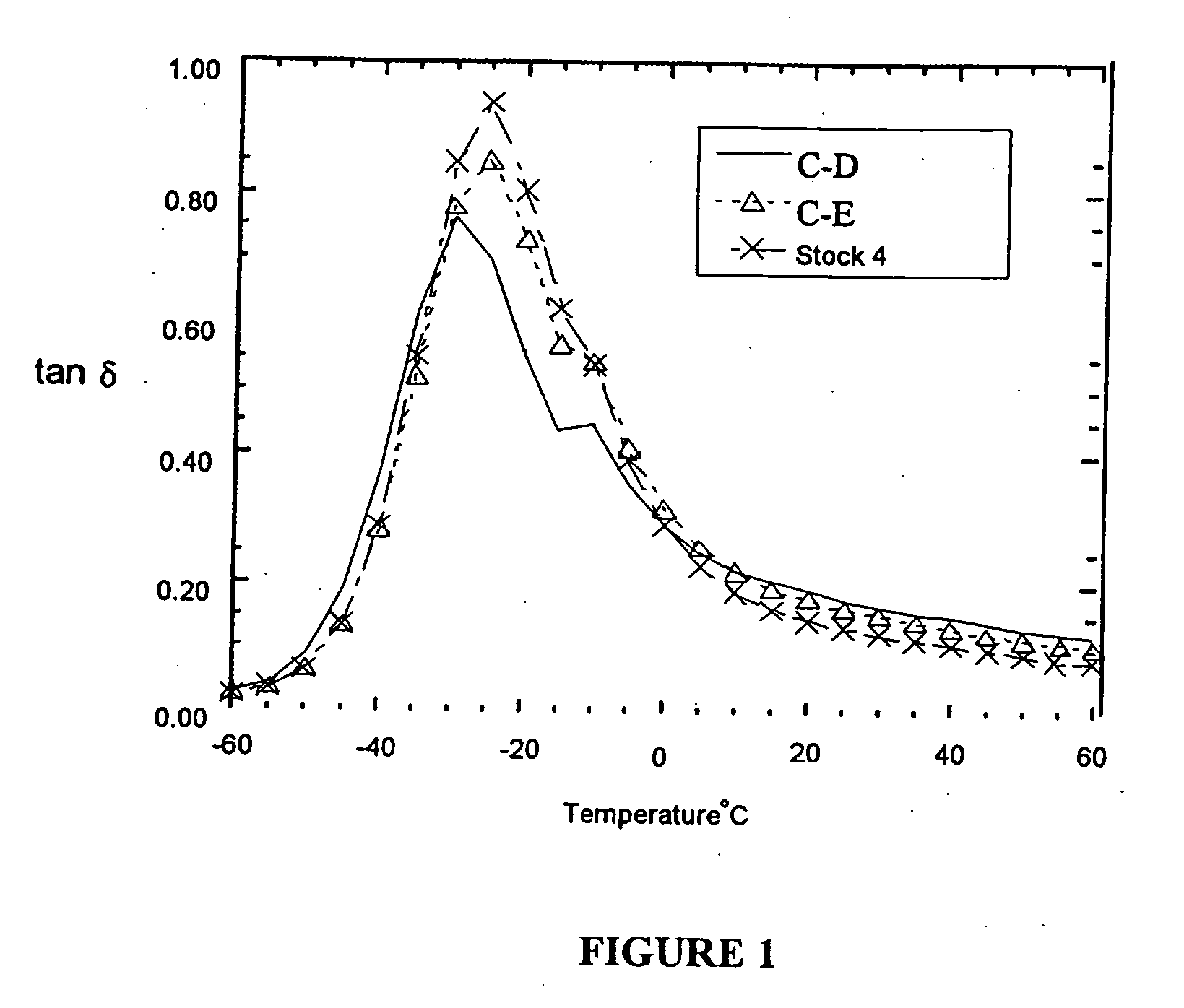

Addition of polar polymer to improve tear strength and processing of silica filled rubber

InactiveUS7041745B2Easy to processReducing compound Mooney viscositySpecial tyresInflatable tyresElastomerProduction rate

A vulcanizable rubber composition is provided that comprises an elastomer, a reinforcing filler comprising silica or a mixture thereof with carbon black, a silica dispersing aid comprising about 0.1 to about 15 phr poly(vinyl acetate) (PVA), and a cure agent. The addition of PVA to the composition improves the processability of the compound, improves the tear strength and modulus of the rubber and can reduce the number of mixing stages during compounding, resulting in lowering of the cost of operation and increasing plant productivity without compromising the processability or other physical properties of the stocks. Also provided are a vulcanizate formed from vulcanizing the rubber composition, a tire component formed from the vulcanized rubber and a process for forming the tire component.

Owner:BRIDGESTONE CORP

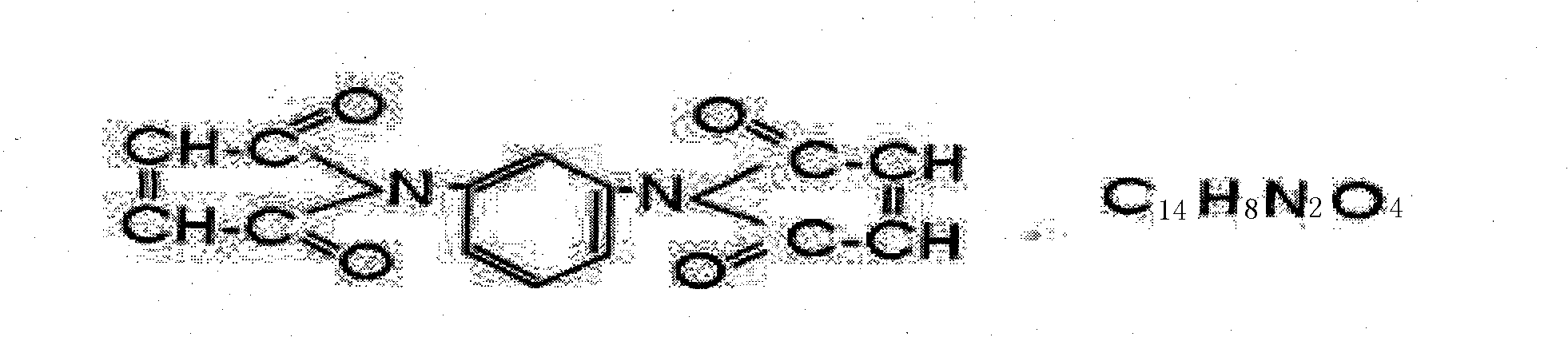

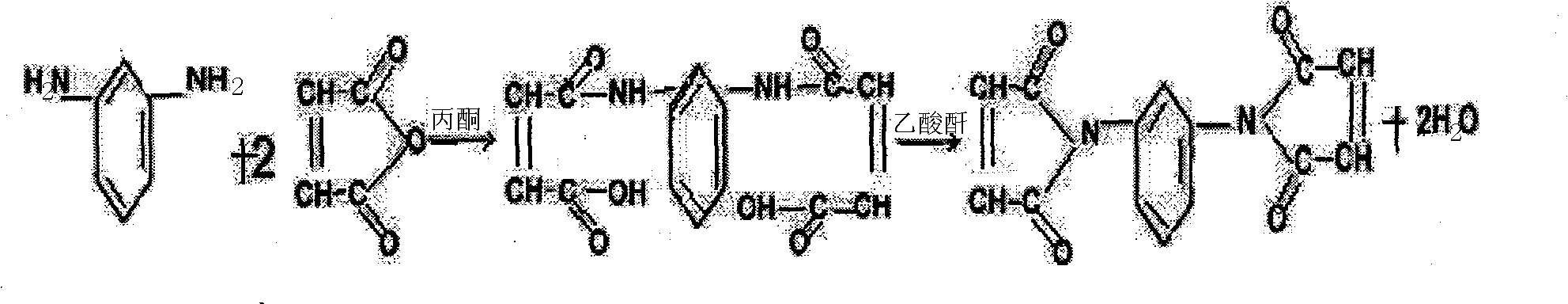

Preparation method of N,N'-m-phenylenebismaleimide

ActiveCN101805280ASolve the hardnessSolving Elasticity ProblemsOrganic chemistryPolymer scienceAcetic anhydride

The invention relates to a preparation method of N,N'-m-phenylenebismaleimide (HA-8). The preparation method is mainly technically characterized by firstly adding m-phenylenediamine in a reaction kettle equipped with a stirrer and a thermometer, then adding a solvent, stirring for fully dissolving the m-phenylenediamine, further adding maleic anhydride, keeping the temperature for 2 hours after completion, then adding acetic anhydride, completing the reaction, further evaporating, recovering the solvent of acetone, finally carrying out centrifugal washing for obtaining a crude product, drying, smashing and obtaining a finished product. The yield is calculated to be 91.5% by taking the m-phenylenediamine as a standard substance. The product is mainly used in natural rubber and various types of synthetic rubber, and can prevent reversion by being matched with sulfur, improve the heat resistance and the anti-aging property, reduce the heat production of the rubber and improve the bonding property between the rubber and metal fabric.

Owner:咸阳三精科技股份有限公司

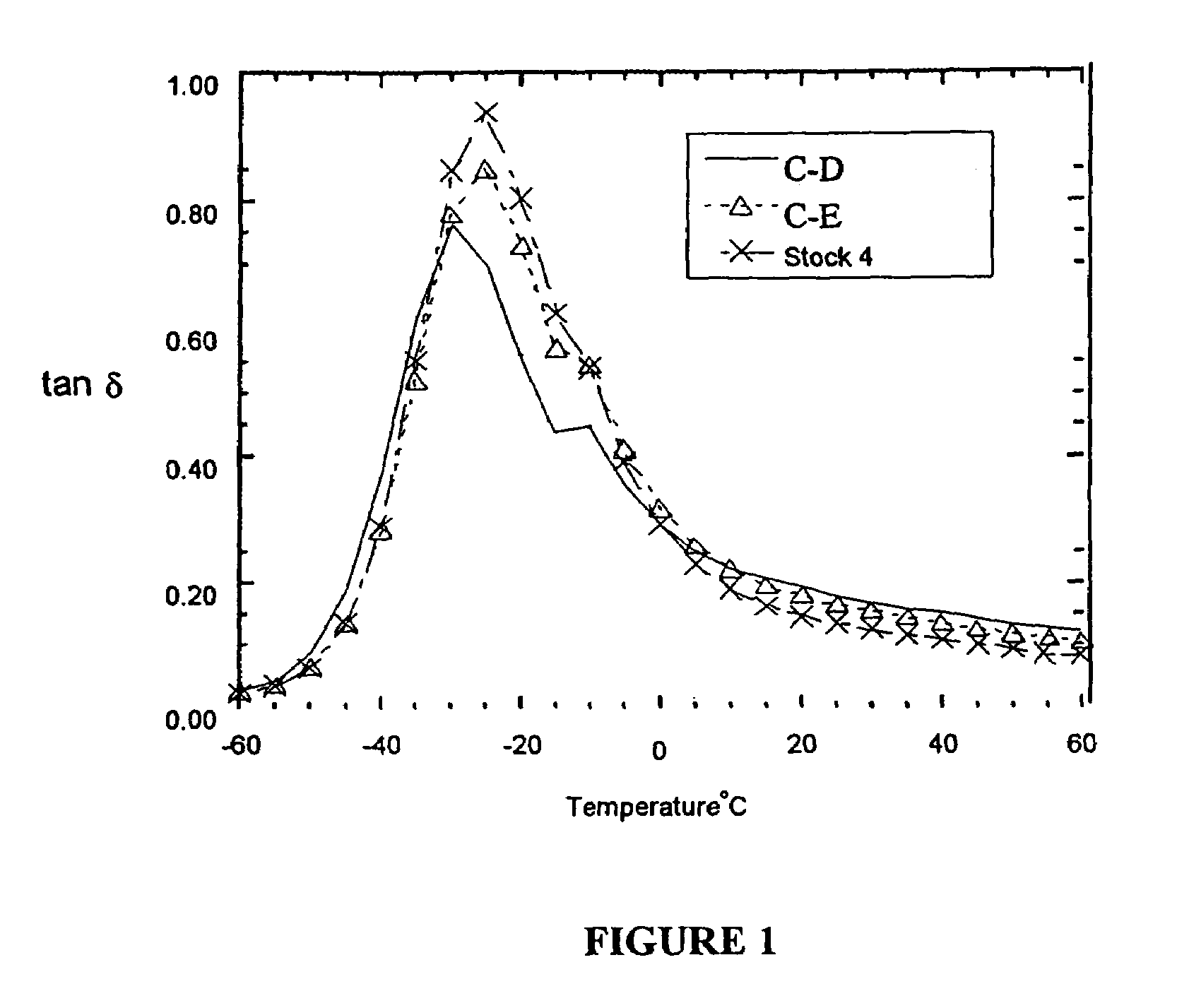

Silica-reinforced rubber compounded with an alkoxysilane and a strong organic base

Improved tensile mechanical and dynamic viscoelastic properties of silica-reinforced sulfur vulcanized rubbers can be achieved by compounding elastomers with silica in the presence of an alkoxysilane and a catalytic amount of a strong organic base. The strong organic base acts as a catalyst to accelerate the alkoxysilane-silica reaction, especially at high compounding temperatures, resulting in rubber compounds that exhibit reduced compound viscosity, improved dispersion of silica, and reduced filler flocculation after compounding, and reduced hysteresis and improved abrasion resistance in the vulcanized product, compared to similar compounds prepared at the temperature without the strong organic base catalyst.

Owner:BRIDGESTONE CORP

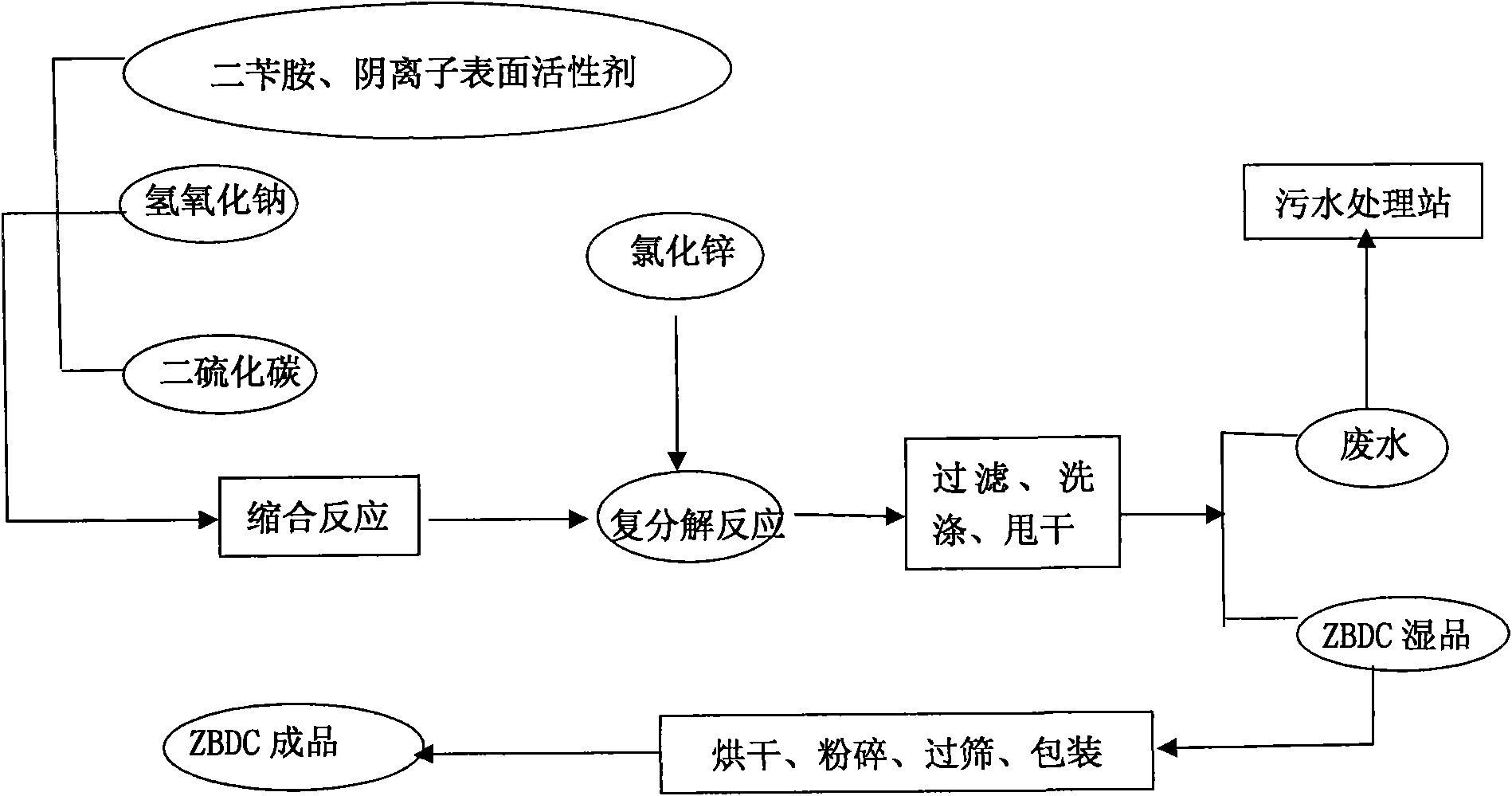

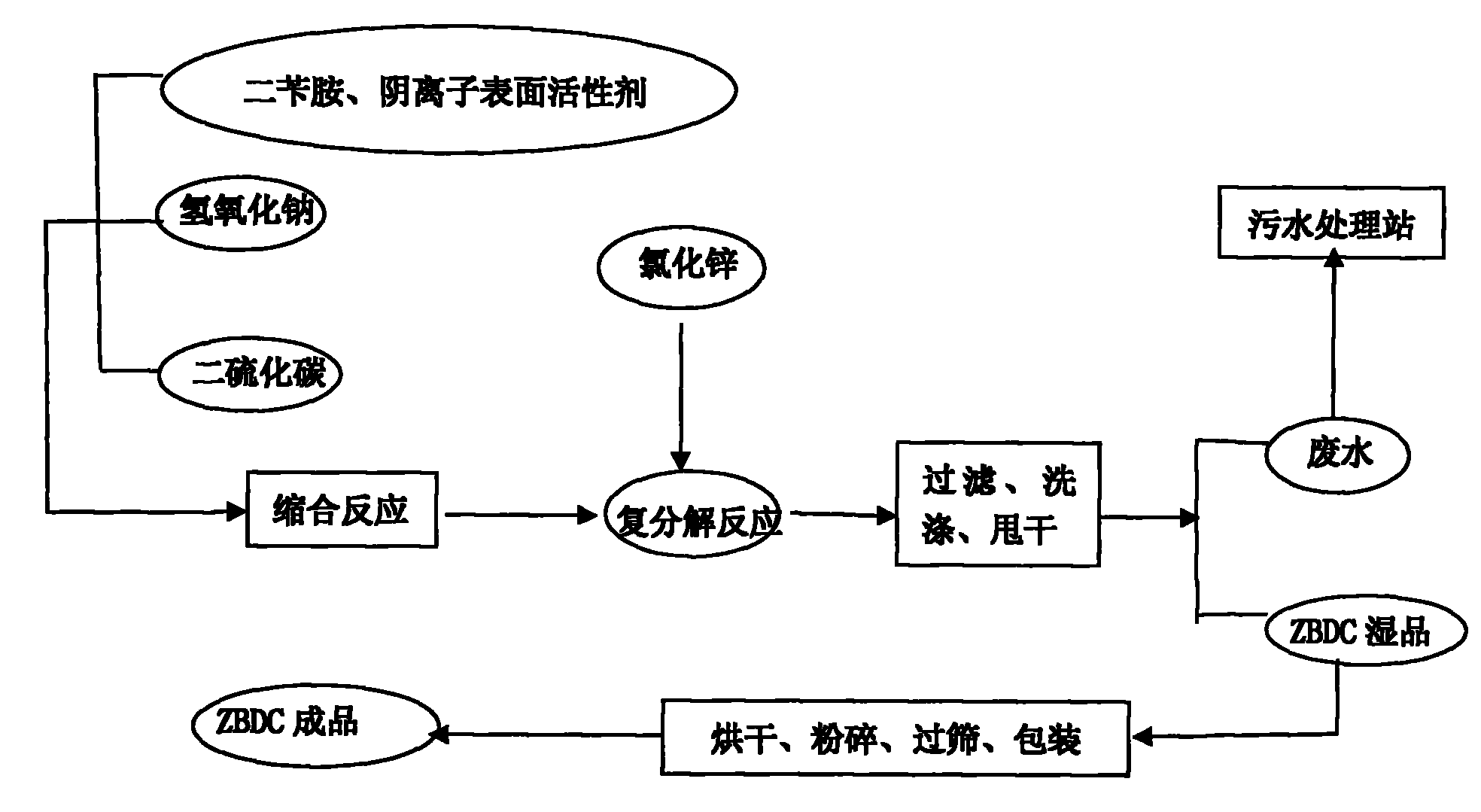

Method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide

ActiveCN101955452AReduce pollutionLess waste waterOrganic chemistryZinc dibenzyldithiocarbamateDodecylsulfonic acid

The invention provides a method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide, which comprises that: the raw materials used are dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant, wherein the stoichiometric molar ratio of dibenzylamine to carbon disulfide to sodium hydroxide and anionic surfactant to zinc chloride to sulfuric acid is 1:1.05-1.2:1.05-1.2:0.020-0.025:0.53-0.58:0.005-0.015; and the process comprises: adding dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant in a given amount into a reaction kettle holding purified water with stirring in turn, lower the temperature by 10 to 20 DEG C totally, dripping carbon disulfide liquid in a given amount within 6 to 7 hours, stirring for 0.5 to 1 hours after the dripping is finished, keeping the temperature at 30 to 38 DEG C constantly, dripping solution of zinc chloride, performing replacement reaction, regulating the pH value of the reaction liquid to 7 to 9 with sulfuric acid after the replacement reaction is finished, finishing the reaction, stirring for 1 to 2 hours, performing solid-liquid separation, discarding liquid and drying, crushing, sieving and packaging the solid. The anionic surfactant is sodium dodecyl sulfate.

Owner:WILLING NEW MATERIALS TECH CO LTD

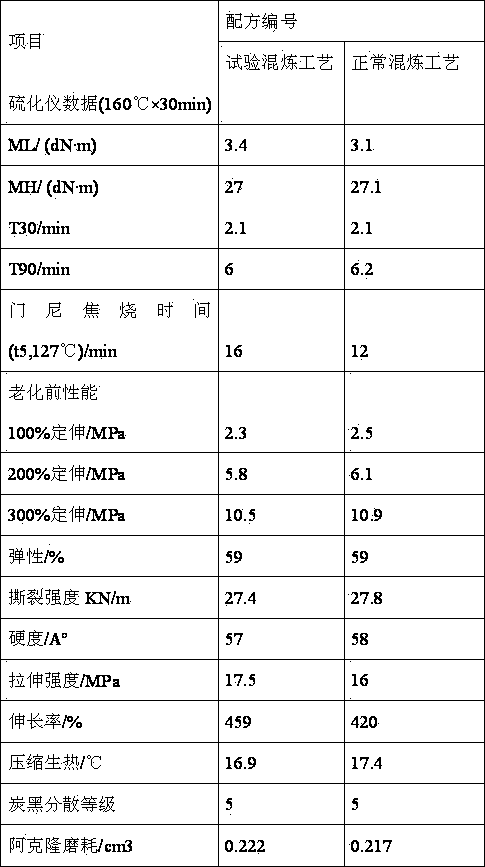

High-temperature-resistant strong-resilience high-safety mixed rubber

The invention discloses high-temperature-resistant strong-resilience high-safety mixed rubber, and is characterized in that the mixed rubber comprises the following components by the weight percentage: 10-30% of natural rubber, 5-10% of chloroprene rubber, 5-10% of polyisoprene, 4-6% of polybutadiene, 5-15% of white carbon black, 8-12% of a silicon alkyl coupling agent, 10-20% of methyl vinyl silicone rubber, 3-4% of tetravinyltetramethylcyclotetrasiloxane, 1-2% of a catalyst, 1-3% of dimethyl hydroxyl silicone oil, 8-10% of dihydroxydiphenylsilane, 2-3% of a heat stabilizer, 2-3% of a surface modification agent, 5-8% of zinc oxide, 1-2% of stearic acid, 2-6% of sulfur, 1-2% of an accelerator, and 1-3% of other auxiliary agents. The wear resistance is improved, the life problem is overcome, introduction of butyl rubber is known to be capable of improving a wet-skid resistance ability of the mixed rubber, and the obtained mixed rubber has excellent mechanical properties, resilience and high-temperature resistance; and through innovating a rubber mixing technology and changing a feeding sequence, a portion of parts of the sulfur is put in masterbatch rubber to prolong the rubber scorching time, and the rubber processing safety performance is ensured.

Owner:佛山市华勇有机硅有限公司

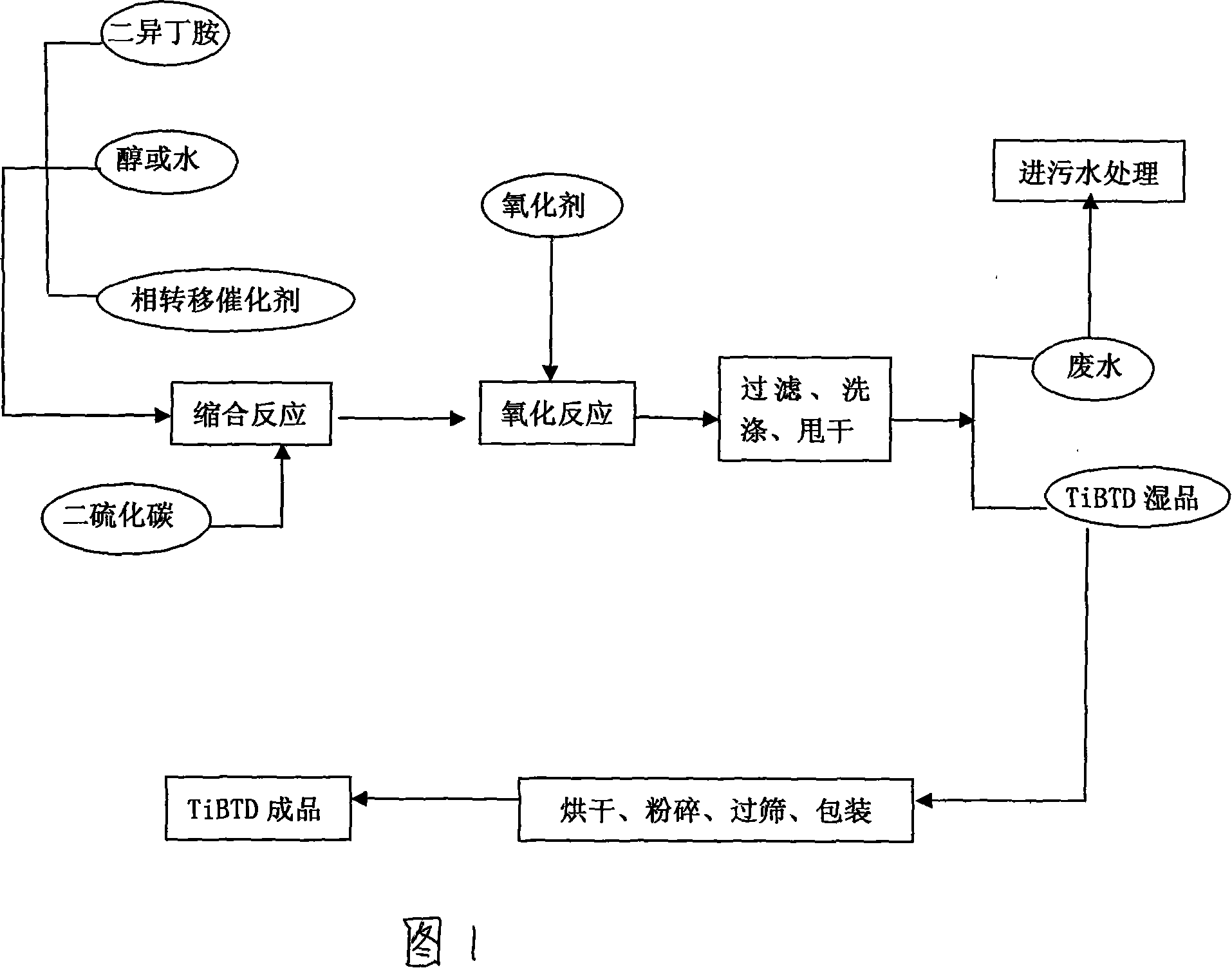

Process for producing vulcanization of rubber accelerant disulfide diisobutyl thiuram

A production method of the diisobutylthiuram disulfide-accelerant of the vulcanization of rubber is provided, which is the production method of the accelerant of the vulcanization of rubber. The method overcomes the defects existing when others produce the product. The raw materials and the mixture ratio of the invention are diisobutylamine : carbon disulfide : oxidant equals to 1 : 1-1.3 : 0.35-0.55; the production method is that enamel reaction axe with volume of 2000L is added with the diisobutylamine, alcohols or water and phase transfer catalyst with specified amount in turns; the cooling water is turned on with temperature reduced to the preferential temperature and is added with carbon disulfide liquid measured accurately by drops, and the time is controlled; after added by drops, the pH value of the reaction liquid is measured to the specialized range; after the pH value is stable, the preferential temperature is controlled and the oxidant is added by drops to carry out oxidation reaction. After the oxidation reaction, the insulation temperature is kept for 1h and solid-liquid separation is conducted to abandon the liquid and dry, crush, sieve and pack the solid.

Owner:WILLING NEW MATERIALS TECH CO LTD

Vibration damping rubber composition

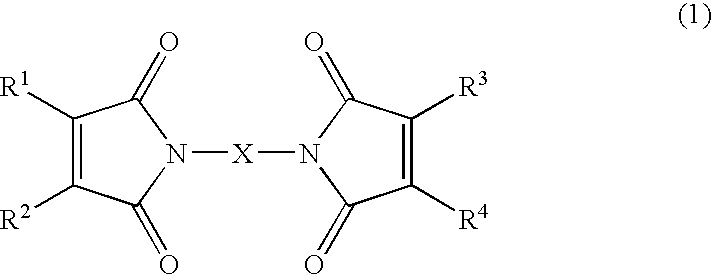

InactiveUS20060217493A1Good vibration reduction effectCross-linking reactivity can be improvedVulcanizationHydrogen atom

A vibration damping rubber composition having an excellent vibration damping performance includes the following (A) to (C) as essential components: (A) a diene-based rubber; (B) a vulcanizing agent of a bismaleimide compound represented by the following formula (1): [wherein X denotes a substituted or unsubstituted aliphatic saturated hydrocarbon group; and R1 to R4 may be the same or different and each denote a hydrogen atom, an alkyl group, —NH2, or —NO2, provided that the bismaleimide compound represented by formula (1) excludes a compound in which X is —(CH2)n- (n is an integer of 4 to 12) and all R1 to R4 are hydrogen atoms], wherein the vulcanizing agent is sulfur-free; and (C) a vulcanization accelerator.

Owner:SUMITOMO RIKO CO LTD

High-strength corrosion resistance distribution box used for electric power

The invention relates to a distribution box, which includes a box body, a box cover, and a fastening mechanism for movably connecting the box body and the box cover. The raw material components of the box body and the box cover are as follows, all in parts by weight: polyethylene resin 40-60 20-30 parts of phenolic resin, 2-10 parts of elastomer, 0.1-15 parts of graphene, 3-7 parts of silicon carbide, 1-10 parts of silane coupling agent, 12-15 parts of semi-reinforced furnace black, calcined 10-12 parts of pottery clay, 6-12 parts of surface-treated Kevlar chopped fibers, 5-7 parts of nanomolybdenum disulfide (MoS2), 0.5-3 parts of aluminum oxide, 3 parts of polydimethylsiloxane ‑5 parts, 0.5‑2.5 parts of flame retardant, 1‑3 parts of dispersant. In the preparation process of the distribution box body and the box cover of the present invention, the raw materials and the proportions, together with the processing technology, make the distribution box box and the box cover of the present invention have excellent flexibility, mechanical properties and corrosion resistance, and at the same time It has good thermal conductivity, improves the performance of the distribution box as a whole, is not easy to age, has sufficient rigidity, and has a long service life, reducing maintenance costs.

Owner:DONGA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

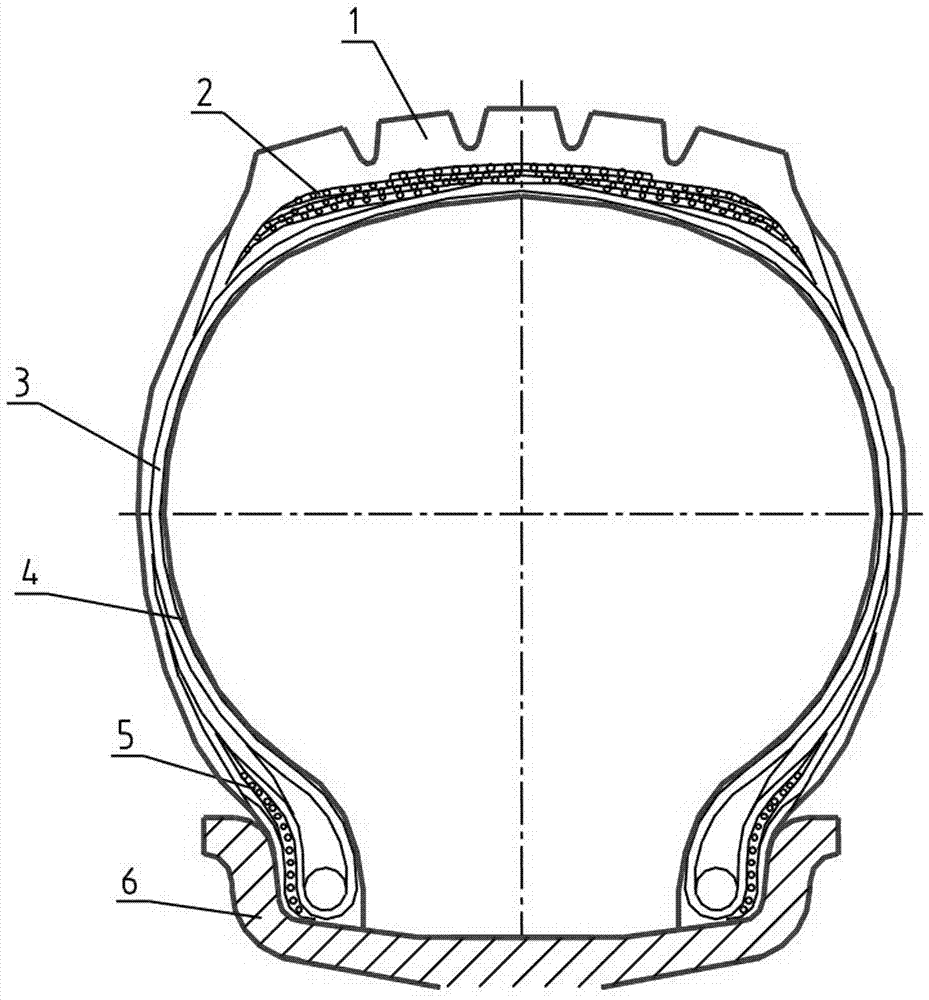

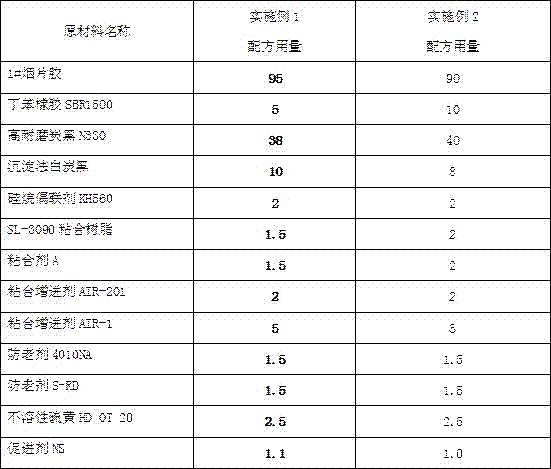

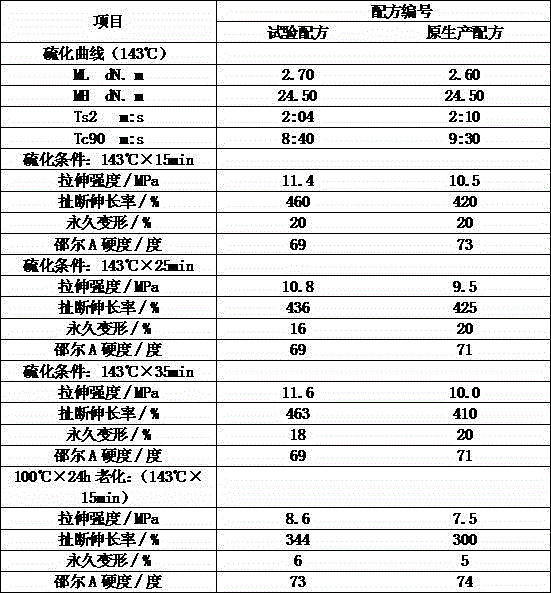

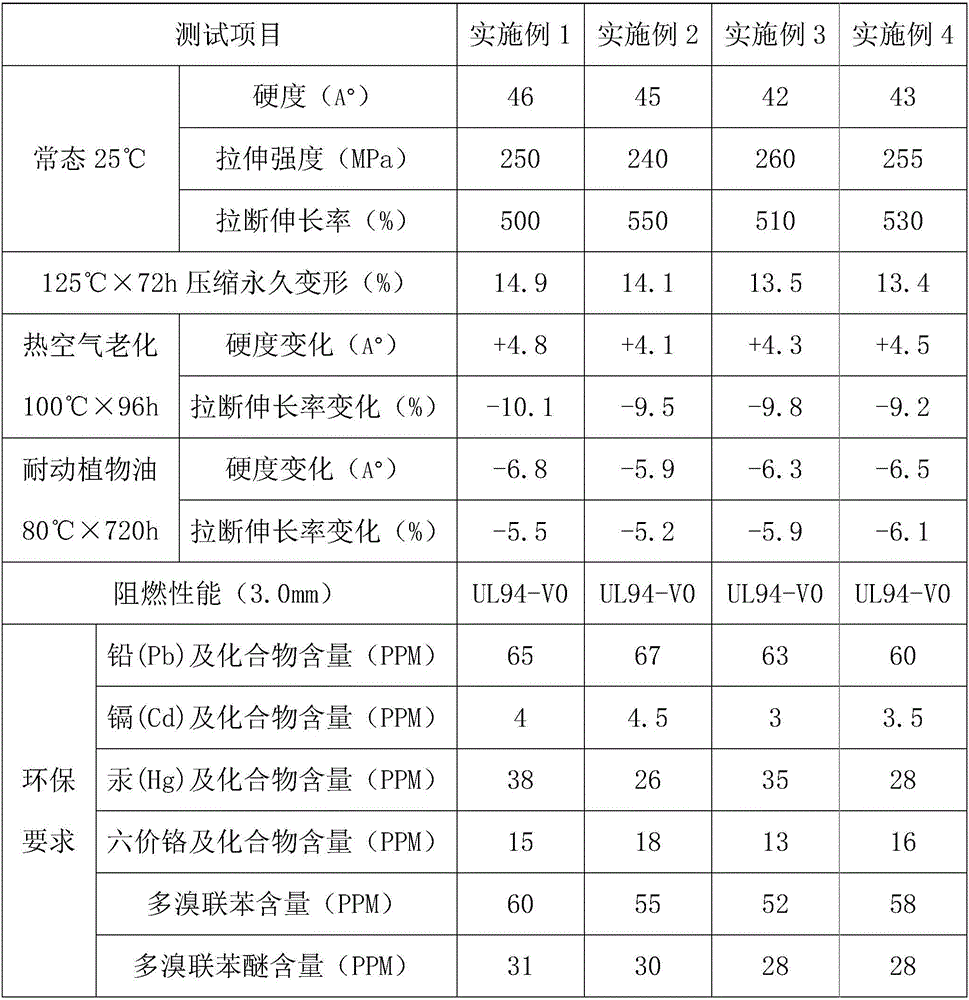

Tread rubber materials for making meridian aircraft tire belt layer cord threads with aramid fiber threads

Disclosed are tread rubber materials for making meridian aircraft tire belt layer cord threads with aramid fiber threads. The rubber materials are prepared according to a certain ratio with 1# smoke sheet rubber as main rubber materials and butadiene styrene rubber, resorcinol bonding resin, formaldehyde bonding resin, a bonding promoter AIR-201 special for the aramid fiber threads, a bonding promoter AIR-1, highly-abrasion-resistant carbon black, precipitated silica, a novel silane coupling agent, insoluble sulfur and a sulfenamide accelerator as main auxiliary materials. The rubber materials have the performance advantages that the bonding strength of the rubber materials and the aramid fiber threads is high, and the bonding retention rate after thermal ageing is high and have the performance characteristics of being high in tensile strength and tearing strength, low in compression fatigue heat generation and high in definite elongation stress. The rubber materials are used as aircraft meridian tire belt layer tread rubber, thus under the high-load and high-speed severe usage conditions, the quality problems of rubber thread loosening or delaminating of layers do not occur to the belt layer position of the aircraft tire, the rubber threads are bonded firmly, and the tire is safe to use.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Aircraft tire flap rubber

InactiveCN102977438AHigh hardnessHigh strengthBuilding insulationsCyclohexylthiophthalimideEngineering

The invention discloses an aircraft tire flap rubber which is prepared by using a banbury mixer according to a conventional technology from the following raw materials in parts by weight: 30-50 parts of 20# standard glue, 30-50 parts of butadiene-styrene rubber, 50-70 parts of reclaimed rubber, 1-6 parts of zinc oxide, 1-6 parts of stearic acid, 0-2 parts of anti-aging agent A, 0-2 parts of anti-aging agent D, 0-2 parts of paraffin, 2-6 parts of asphalt, 40-60 parts of N660 carbon black, 5-10 parts of aromatic oil, 1-3 parts of sulfur, 0-2 parts of accelerant TMTD (teramethyl-thiuram disulfide), 0-2 parts of accelerant MBTS (mercaptobenzthiazole disulfide) and 0.1-2 parts of scorch retarder CTP (cyclohexylthiophthalimide). The aircraft tire flap rubber has the advantages of improving hardness and strength of a sizing material by adopting the carbon black N660 as a reinforcing agent; prolonging scorch time without reducing the curing speed in a curing stage and improving processing and storing stabilities of the sizing material by adding the scorch retarder CTP in the formula; and improving plasticity and uniformity of the sizing material, improving technological operation properties of the sizing material and effectively solving various problems in a production process by adopting the aromatic oil as a softening agent.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Rubber mixtures containing trimethylopropane distillation residues

InactiveUS6251976B1Improve liquidityExtended scorch timeFireproof paintsSpecial tyresPolymer scienceRolling resistance

The present invention relates to rubber mixtures consisting of at least one rubber and a specific proportion of a distillation residue from industrial trimethylolpropane production and the use of the rubber mixtures for the production of vulcanisates, especially for the production of highly reinforced, abrasion-resistant mouldings, particularly preferably for the production of tyres exhibiting low rolling resistance and high abrasion resistance.

Owner:BAYER AG

Novel medical powder injection rubber plug and manufacturing method thereof

ActiveCN101851377AGood chemical resistanceImprove cleanlinessPharmaceutical containersMedical packagingEngineeringPack material

The invention discloses a novel medical powder injection rubber plug and a manufacturing method thereof, which belong to the technical field of medical packaging materials. The invention is characterized in that the rubber plug is manufactured by using the following raw materials in part by weight: halogenated butyl rubber 50-60, argil 30-40, carbon black 0.5-1.0, magnesium oxide 2.0-3.0, vulcanizing agent 0.1-0.3, titanium white 0.5-2.5, and carbon black master batch 0.2-1.0. The halogenated butyl rubber may be chlorinated butyl rubber or brominated butyl rubber. The rubber plug of the invention has high chemical resistance, high chemical compatibility, high biological safety and good chemical properties.

Owner:SHANDONG PHARMA GLASS

Flame-retardant sealing ring for motors of range hoods

The invention discloses a flame-retardant sealing ring for motors of range hoods. The flame-retardant sealing ring is made from raw materials including nitrile rubber, zinc oxide, stearic acid, carbon black, white carbon black, sulphur powder, an accelerant CZ, an accelerant M, an accelerant TMTD, ETU-80, light magnesium oxide, pottery clay, chloroprene rubber adhesive, aluminum hydroxide, a silane coupling agent, zinc borate, antimonous oxide, modified flame retardant, dioctyl phthalate, carnauba wax, antiager 2246, antiager BZ and a processing agent WB-16. The flame-retardant sealing ring is good in high-temperature resistance and flame retardant performance, and meanwhile has the advantages of oil resistance, no halogen, low toxicity and environment friendliness.

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

Tall oil modified phenolic resin and preparation method thereof

The invention discloses tall oil modified phenolic resin including the following components by weight: 50-100 parts of phenol, 1-50 parts of alkylphenol, 50-100 parts of a 37% formaldehyde aqueous solution, 0.1-5 parts of a catalyst, 1-100 parts of tall oil and 0.1-5 parts of a terminating agent. The invention also discloses a two-step preparation method of the tall oil modified phenolic resin. The tall oil modified phenolic resin is suitable for rubber reinforcement, and is particularly suitable for the production of tires.

Owner:SINO LEGEND CHINA CHEM

Silica-reinforced rubber compounded with an alkoxysilane and a strong organic base

Improved tensile mechanical and dynamic viscoelastic properties of silica-reinforced sulfur vulcanized rubbers can be achieved by compounding elastomers with silica in the presence of an alkoxysilane and a catalytic amount of a strong organic base. The strong organic base acts as a catalyst to accelerate the alkoxysilane-silica reaction, especially at high compounding temperatures, resulting in rubber compounds that exhibit reduced compound viscosity, improved dispersion of silica, and reduced filler flocculation after compounding, and reduced hysteresis and improved abrasion resistance in the vulcanized product, compared to similar compounds prepared at the temperature without the strong organic base catalyst.

Owner:BRIDGESTONE CORP

Generator damping pad for electric power and preparing method of generator damping pad

The invention relates to a generator damping pad for electric power. The damping pad is prepared from, by weight, 40-60 parts of butadiene styrene rubber, 20-40 parts of chloroprene rubber, 23-26 parts of fluoroether rubber, 0.1-15 parts of graphene, 13-15 parts of phenolic resin, 1-10 parts of a silane coupling agent, 12-15 parts of semi-reinforcing furnace black, 10-12 parts of roasted pottery clay, 6-12 parts of Kevlar chopped fibers subjected to surface treatment, 1-10 parts of carbon black, 5-7 parts of nanometer molybdenum disulfide (MoS2), 1-10 parts of an anti-aging agent, 4-8 parts of zinc oxide and 1-5 parts of an accelerator. Butadiene styrene rubber, chloroprene rubber and fluoroether rubber serve as the main materials of the generator damping pad, and thus the prepared generator damping pad is resistant to abrasion and high temperatures and low in noise and has excellent impact resistance and abrasion resistance.

Owner:郭秀珍

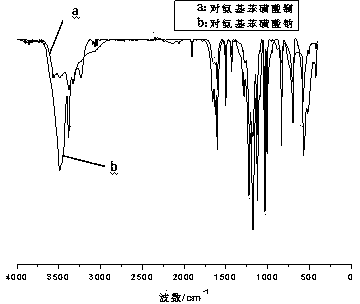

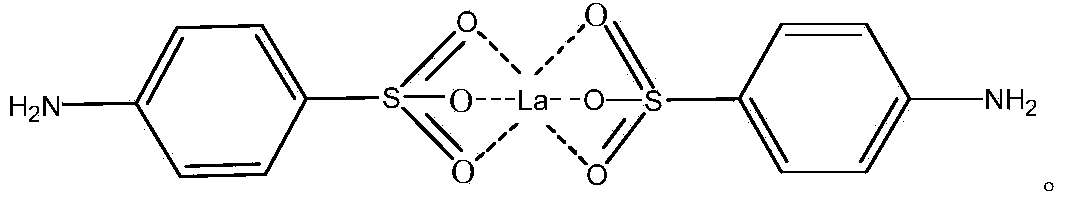

Rare-earth complex rubber anti-aging agent, and preparation method and application thereof

InactiveCN104004224AThe synthesis method is simpleGood oxidation protection performanceSulfonic acid preparationRubber materialPolymer science

The invention discloses a rare-earth complex rubber anti-aging agent, and a preparation method and application thereof. The preparation method of the rare-earth complex comprises the following steps: dissolving sodium sulfanilate in water to prepare a solution having a concentration of 5-60%; adding rare-earth salts of which the mole number is equivalent to 10-100% of the mole number of the sodium sulfanilate, and then performing stirring reaction at 40-95 DEG C for 2-24 hours; and filtering the obtained product, washing, and drying to obtain a powdered target product lanthanum sulfanilate. The rare-earth complex rubber anti-aging agent is applied in rubber preparation. According to the invention, the preparation method of the rare-earth complex rubber anti-aging agent is simple and easy to implement; and the rare-earth complex rubber anti-aging agent can obviously decelerate aging of rubber, can be singly used or compounded with other anti-aging agents for use, and has the advantages of causing no pollution to a rubber product, prolonging the scorching time of a rubber material, lowering the viscosity of the rubber material and the like.

Owner:SOUTH CHINA UNIV OF TECH

Tire rubber composition

Owner:THE YOKOHAMA RUBBER CO LTD

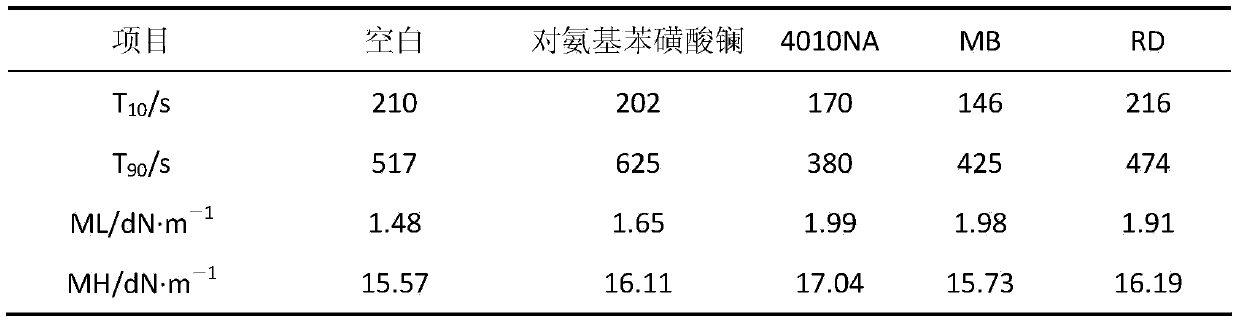

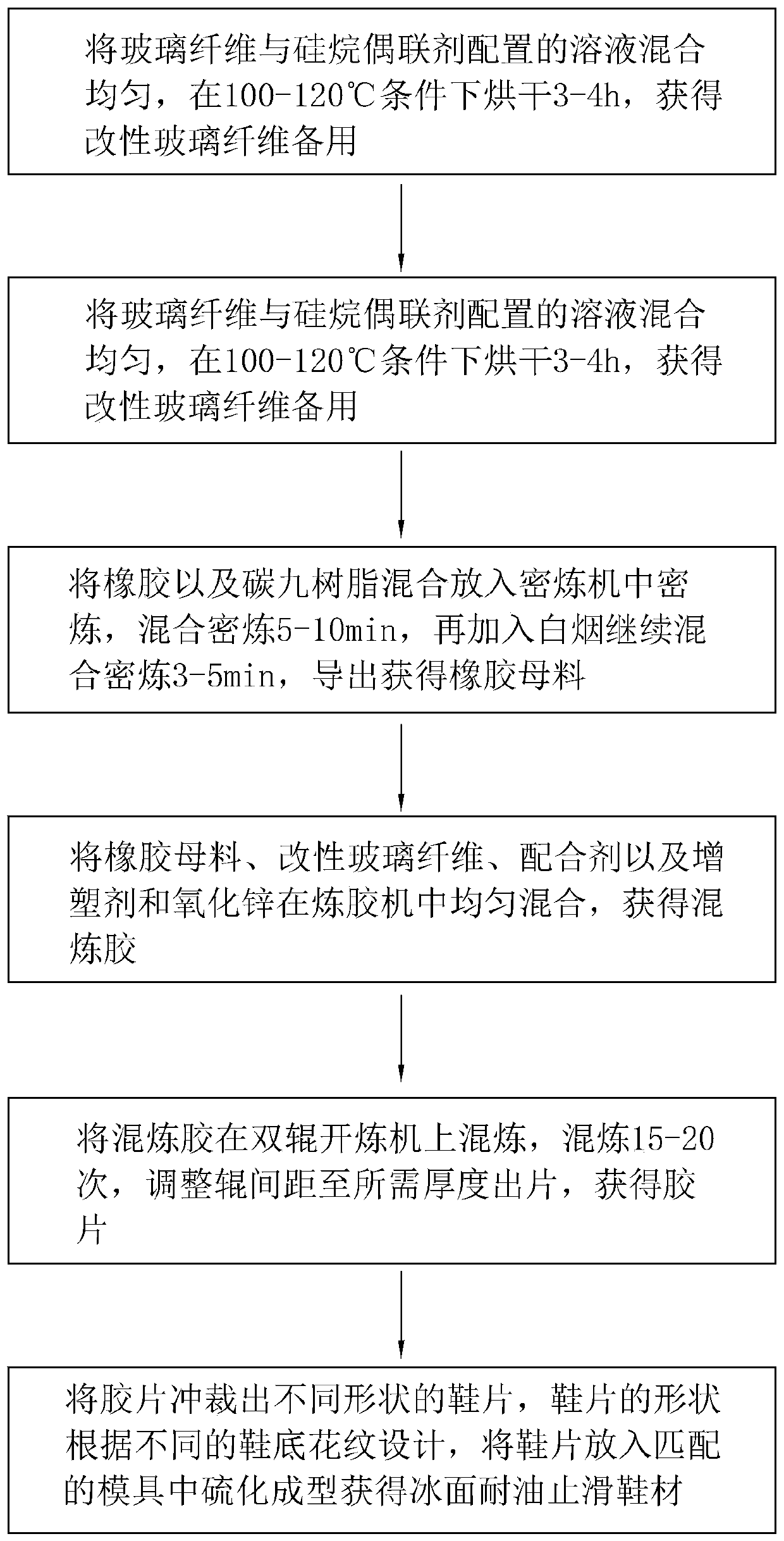

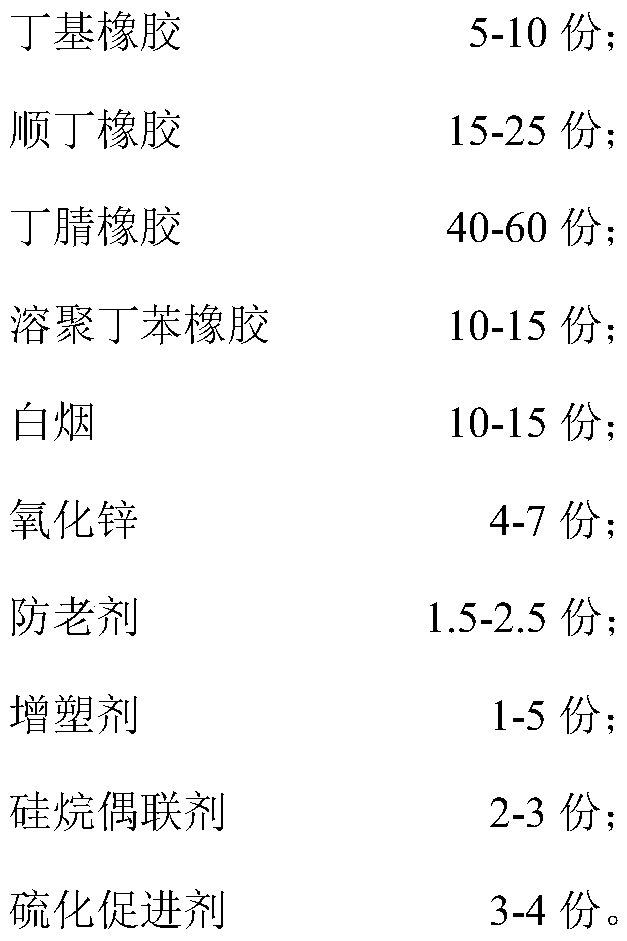

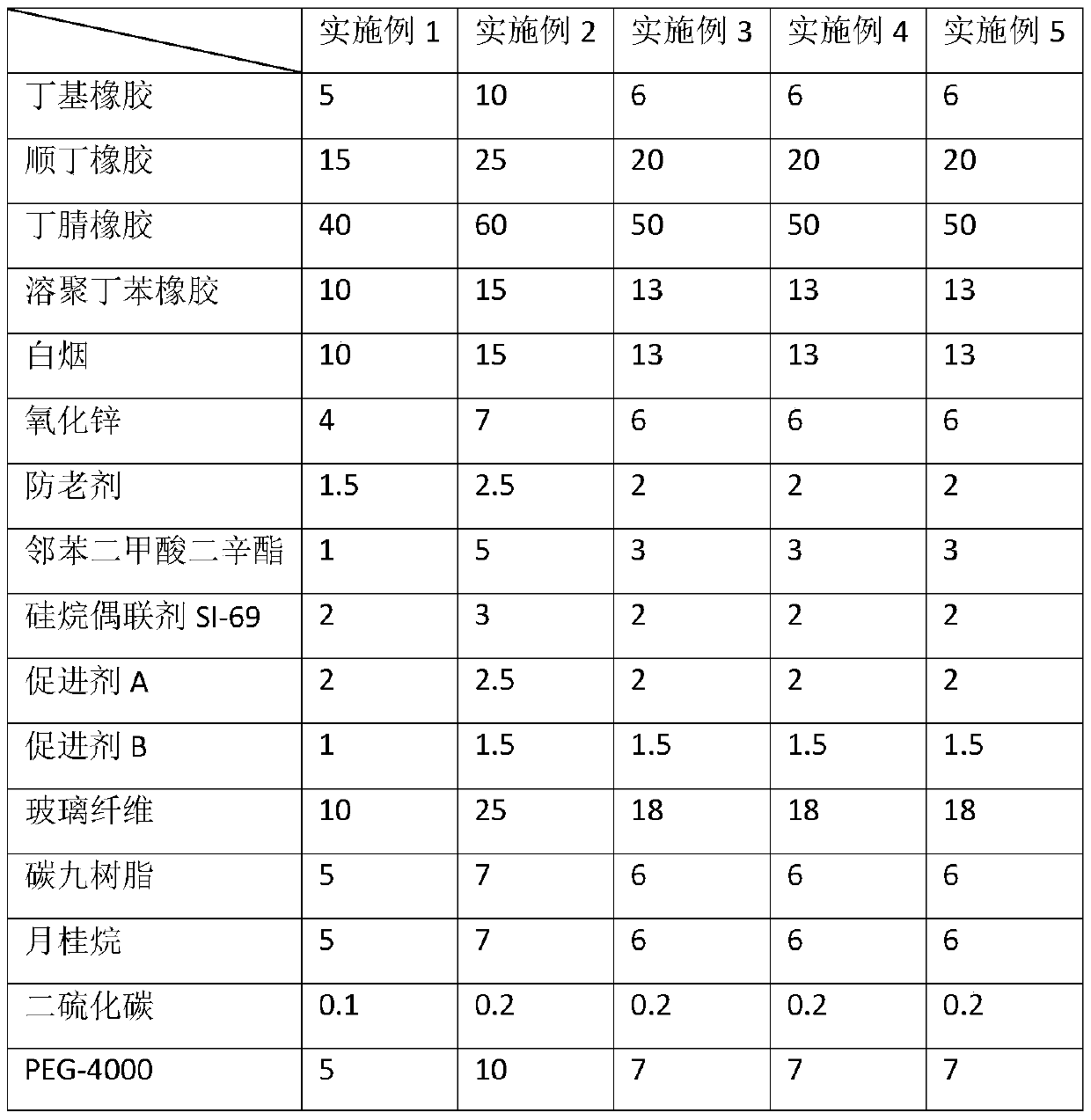

Ice-surface oil-resistant non-slip shoe material and preparation method thereof

The invention discloses an ice-surface oil-resistant non-slip shoe material and a preparation method thereof, and relates to the technical field of shoe materials. The shoe material is prepared from butyl rubber, butadiene rubber, nitrile rubber, solution polymerized styrene-butadiene rubber, white smoke, zinc oxide, an anti-ageing agent, a plasticizer, a silane coupling agent and a vulcanizationaccelerator. The shoe material prepared through the formula is combined with the specific pattern of an outsole and integrally formed or adhered to the outsole, and the obtained sole has the advantages of being resistant to oil and slip, good in mechanical performance, free of fog return and the like. The anti-slip performance is excellent, and the shoe material is suitable for being used on the ice and snow ground.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

High-performance modified styrene-butadiene rubber material

The invention discloses a high-performance modified styrene-butadiene rubber material, wherein the raw materials comprise a styrene-butadiene rubber, a natural rubber, a copolymerized epichlorohydrin rubber, amide ester, carbon nano-tubes, modified white carbon black, modified Kaolin, zinc oxide, stearic acid, an accelerator CZ, an accelerator DM, an accelerator TDEC, sulphur, an antioxidant DFC-34, an anti-aging agent MB, a vulcanizing agent PDM, an anti-scorching agent CTP, 2-mercapto benzimidazole, a coupling agent, and dibutyl phthalate. The high-performance modified styrene-butadiene rubber material of the present invention has characteristics of high strength, high elasticity, good heat resistance, good cold resistance, aging resistance, and long service life.

Owner:ANHUI RUIXIN AUTOMATION INSTR

High-performance natural rubber/butadiene styrene rubber composite material

The invention discloses a high-performance natural rubber / styrene-butadiene rubber composite material. The raw materials include: natural rubber, styrene-butadiene rubber, rare-earth isoprene rubber, zinc oxide, stearic acid, sulfur, benzoyl peroxide, and an accelerator CZ, accelerator DM, accelerator NOBS, antioxidant, light calcium carbonate, magnesium oxide, calcium hydroxide, graphene oxide, bamboo charcoal powder, aluminum silicate, diatomaceous earth, sodium montmorillonite, benzyl triphenyl Phosphorous chloride, polyethylene glycol. The high-performance natural rubber / styrene-butadiene rubber composite material proposed by the invention has high strength, good heat resistance and wear resistance, can meet the use requirements of various fields, and has a long service life.

Owner:合肥市再德高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com