Flame-retardant sealing ring for motors of range hoods

A range hood and sealing ring technology, which is applied in the field of rubber materials, can solve the problems of poor high-temperature flame retardancy, poor sealing, and easy aging, so as to achieve good high-temperature resistance, ensure sealing, and improve high-temperature resistance and medium resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

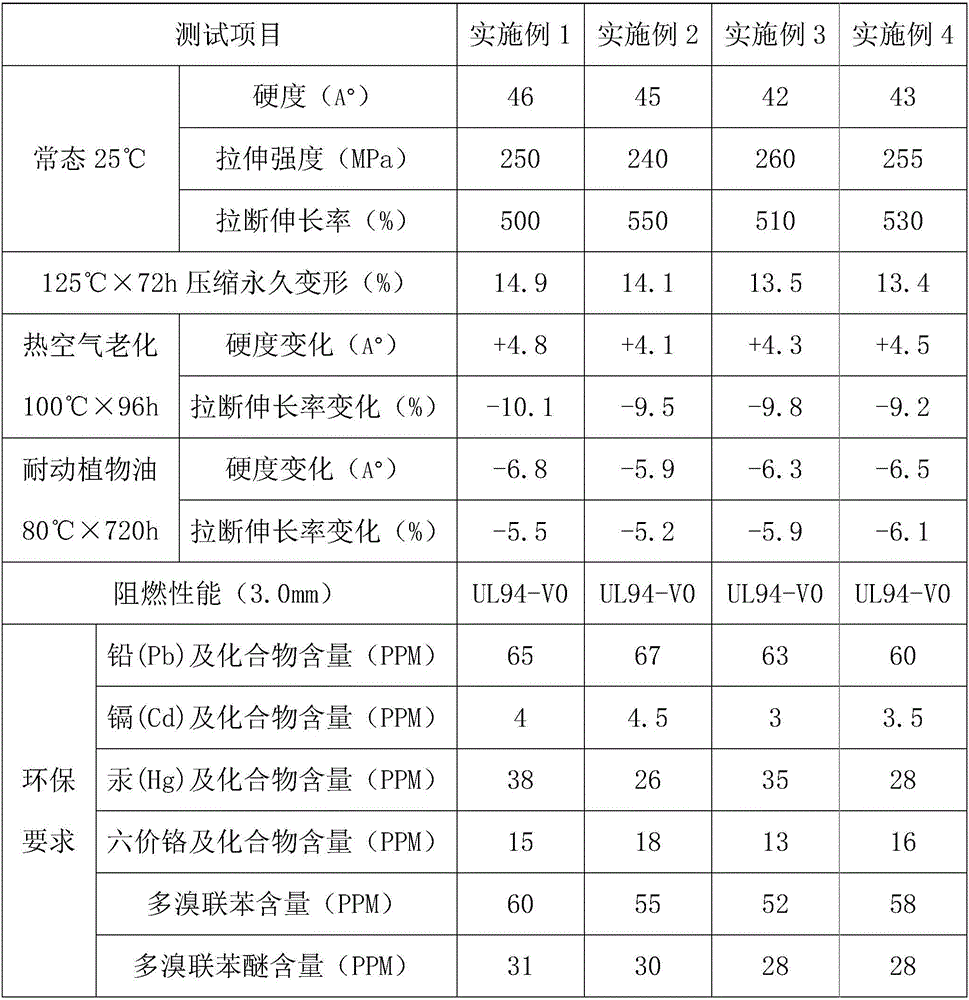

Examples

Embodiment 1

[0017] A flame retardant sealing ring for a range hood motor proposed by the present invention, its raw materials include by weight: 60 parts of nitrile rubber, 12 parts of zinc oxide, 0.8 part of stearic acid, 20 parts of carbon black N990, 10 parts of white carbon black 2.5 parts of sulfur powder, 1.0 parts of accelerator CZ, 2.0 parts of accelerator M, 0.8 parts of accelerator TMTD, 1.2 parts of ETU-80, 2.0 parts of light magnesium oxide, 30 parts of clay, 15 parts of neoprene, hydroxide 150 parts of aluminum, 1.0 parts of silane coupling agent Si-69, 50 parts of zinc borate, 3 parts of antimony trioxide, 20 parts of modified flame retardant, 20 parts of environmentally friendly DOA, 0.6 parts of carnauba wax, and 1.0 part of antioxidant 2246 , 3.5 parts of anti-aging agent BZ, 4 parts of processing aid WB-16.

Embodiment 2

[0019]A flame retardant sealing ring for a range hood motor proposed by the present invention, its raw materials include by weight: 150 parts of nitrile rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 5 parts of carbon black, and 30 parts of white carbon black , 1.5 parts of sulfur powder, 2.0 parts of accelerator CZ, 1.0 parts of accelerator M, 1.2 parts of accelerator TMTD, 0.8 parts of ETU-80, 3.5 parts of light magnesium oxide, 10 parts of clay, 45 parts of neoprene, aluminum hydroxide 30 parts, 2.0 parts of silane coupling agent Si-69, 10 parts of zinc borate, 8 parts of antimony trioxide, 10 parts of modified flame retardant, 50 parts of environmental protection DOA, 0.4 parts of carnauba wax, 2.0 parts of anti-aging agent 2246, anti-aging Agent BZ 2.5 parts, processing aid WB-166 parts;

[0020] Wherein, the nitrile rubber is composed of nitrile rubber N230S and nitrile rubber N240S, and the weight ratio of nitrile rubber N230S and nitrile rubber N240S is 1:8;...

Embodiment 3

[0025] A flame retardant sealing ring for a range hood motor proposed by the present invention, its raw materials include by weight: 80 parts of nitrile rubber, 10 parts of zinc oxide, 1 part of stearic acid, 15 parts of carbon black, and 15 parts of white carbon black , 2.2 parts of sulfur powder, 1.3 parts of accelerator CZ, 1.8 parts of accelerator M, 0.9 parts of accelerator TMTD, 1.1 parts of ETU-80, 2.2 parts of light magnesium oxide, 25 parts of clay, 20 parts of neoprene, aluminum hydroxide 120 parts, 1.2 parts of silane coupling agent Si-69, 40 parts of zinc borate, 5 parts of antimony trioxide, 18 parts of modified flame retardant, 30 parts of environmental protection DOA, 0.5 parts of carnauba wax, 1.3 parts of antioxidant 2246, Antiaging agent BZ 3.1 parts, processing aid WB-164.5 parts;

[0026] Wherein, the nitrile rubber is composed of nitrile rubber N230S and nitrile rubber N240S, and the weight ratio of nitrile rubber N230S and nitrile rubber N240S is 1:10; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com