Patents

Literature

117results about How to "Improve media resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

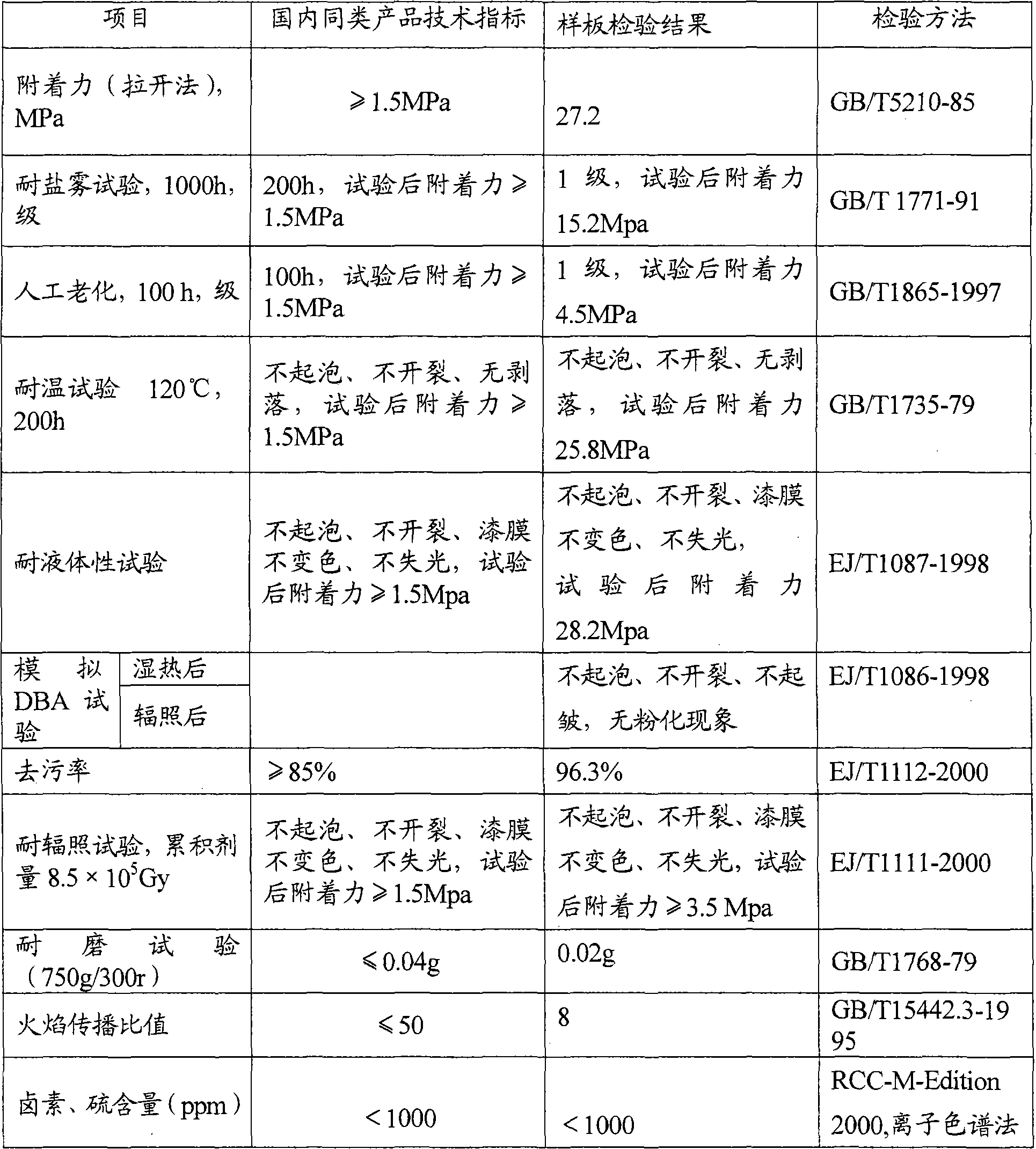

Epoxy protective coating system for high-power nuclear power station

ActiveCN101781508AImprove corrosion resistanceGood radiation protectionAnti-corrosive paintsShieldingNuclear gradeNuclear power

The invention relates to an epoxy protective coating system for a high-power nuclear power station. Priming coat comprises a component A1 and a component B with the weight ratio of 4-6, and finishing coat comprises a component A2 and the component B with the weight ratio of 3-5:1.. The component A1 comprises 20 to 50% of epoxy resin, 10 to 40% of anti-corrosion paint, 10 to 25% of radiation-resistant stuffing, 0.1 to 3% of addition agent and the balance of menstruum by weight percent. The component A2 comprises 20 to 50% of the epoxy resin, 10 to 40% of the anti-corrosion paint, 5 to 20% of the radiation-resistant stuffing, 0.1 to 3% of the addition agent and the balance of the menstruum by weight percent. The component B is a radiation-resistant epoxy-amine adduct curing agent, and is synthesized by 10 to 30% of liquid epoxy resin, 30 to 70% of polyamine with primary amine groups and 20 to 60% of the menstruum. The corrosion resistance and radiation resistance can meet the requirements of nuclear grade paint and can pass simulation DBA tests when the coating system is used for a high-power nuclear power station.

Owner:CHINA NAT OFFSHORE OIL CORP +2

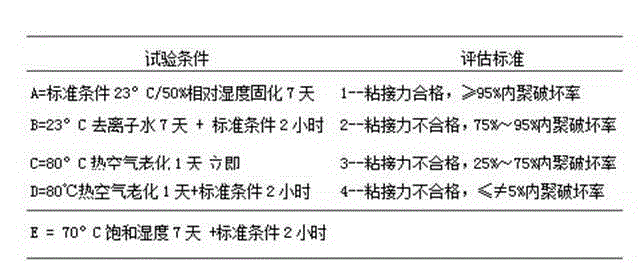

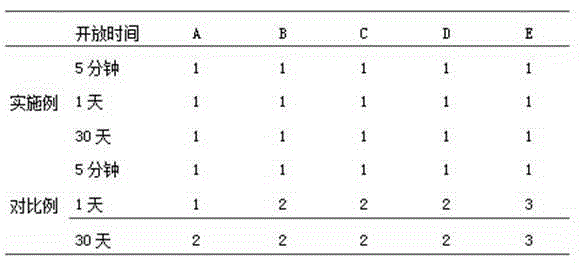

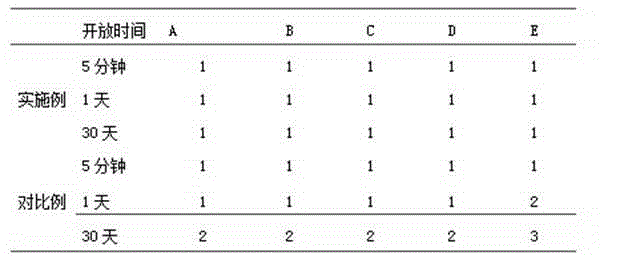

Long-opening-time primer and preparation method thereof

InactiveCN104673170ASlow reaction speedExtended opening hoursNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePolyurethane adhesive

The invention relates to a long-opening-time primer and a preparation method thereof. The primer is matched with a single-component moisture-curing polyurethane sealant. The primer comprises the following components in percentage by mass: 15-35% of silane terminated polymer, 2-10% of bonding accelerator, 0.1-2% of stabilizing agent, 1-10% of plasticizer, 3-15% of colorant, 0.3-1.5% of dispersing agent, 0.1-2.5% of antioxidant, 0.1-2.5% of ultraviolet absorbent, 0.1-2.5% of light stabilizer and 30-70% of solvent. The primer can be used for enhancing the bonding stability of the single-component polyurethane adhesive when being used for glass assembly and elastic bonding. The system is free of isocyanate, lowers the reaction speed, prolongs the opening time of the primer, has favorable adhesion with ink glass, common primers and finish coats, and enhances the medium resistance and bonding performance of the silane terminated polymer.

Owner:TONSAN ADHESIVES INC

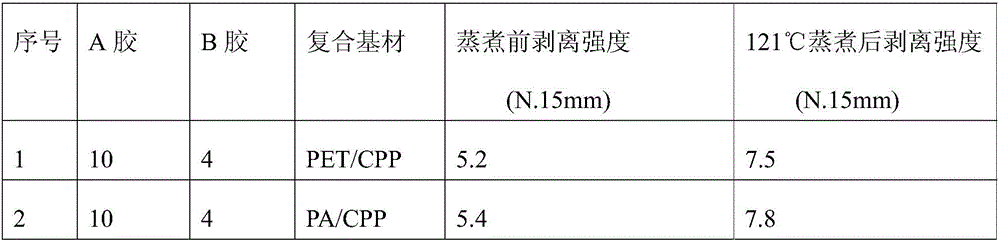

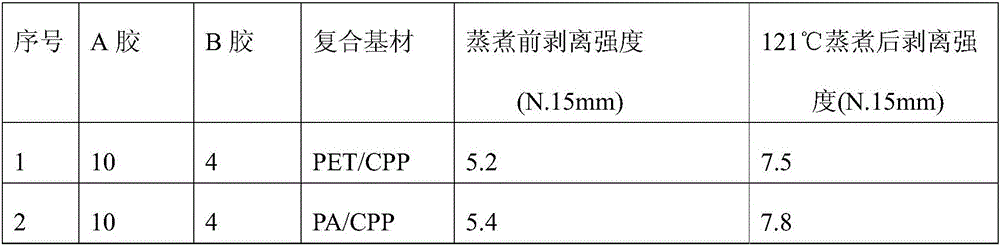

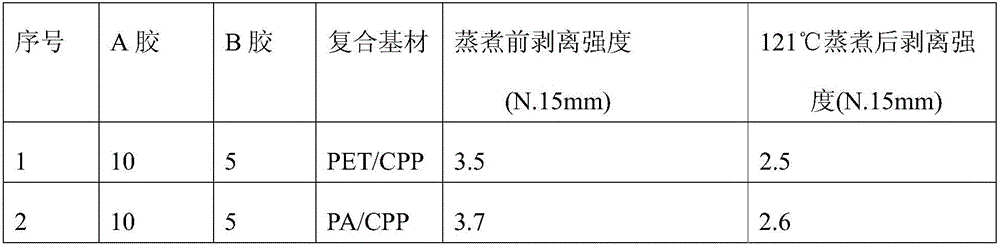

Solvent-free two-component polyurethane cooking adhesive and preparation method thereof

InactiveCN106675499AImprove temperature resistanceImprove media resistancePolyureas/polyurethane adhesivesPolyesterPolyol

The invention provides a heat-resistant solvent-free two-component polyurethane cooking adhesive. Through introducing a bisphenol A structure polyether and synthesizing appropriate polyester polyol, the temperature resistance and the medium resistance of the adhesive are improved, and the problems of low peeling strength and easiness in delaminating of a common solvent-free adhesive after cooking are solved. The heat-resistant solvent-free two-component polyurethane cooking adhesive is formed by an adhesive A and an adhesive B, wherein the adhesive A is formed by polyester polyol, liquidated-MDI and polyether polyol through an reaction; the adhesive B is formed by bisphenol A structure-contained polyether polyol, a coupling agent and castor oil; the matching ratio of the adhesive A and the adhesive B is 10 to (4 to 5).

Owner:JIANGSU LIHE ADHESIVE

High-performance silicone-acrylate-modified water-based epoxy emulsion and production method thereof

InactiveCN102336874AImprove adhesionExcellent closed shielding performanceAnti-corrosive paintsFilling pastesWater basedChemical industry

The invention discloses a high-performance silicone-acrylate-modified water-based epoxy emulsion and a production method thereof, relating to the technical field of production of coatings used in the chemical industry field. The emulsion is prepared with a core-shell mechanism process; in a core layer, a grafted polymer consists of low molecular bisphenol A epoxy resin, epoxy group siloxane and acrylic ester; a shell body consists of hydroxyl-containing siloxane and acrylic ester; and the shell body and the core layer are subjected to interpenetration graft polymerization. In the invention, epoxy resin is modified with an organic silicon acrylic acid monomer, so that a dense crosslinked netlike structure with a special interpenetration network and excellent enclosed shielding performance is obtained. Multiple series of anti-corrosive paints can be prepared on the basis of the high-performance silicone-acrylate-modified water-based epoxy emulsion provided by the invention by taking mixed modified amine as a curing agent. The emulsion has the advantages of easy and convenient production process, saving in energy, environmental friendliness, easiness for coating construction, low sensitivity to water vapor and temperature, extremely high substrate adhesion, high corrosion resistance, high chemical stability and wide formula adjusting range.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

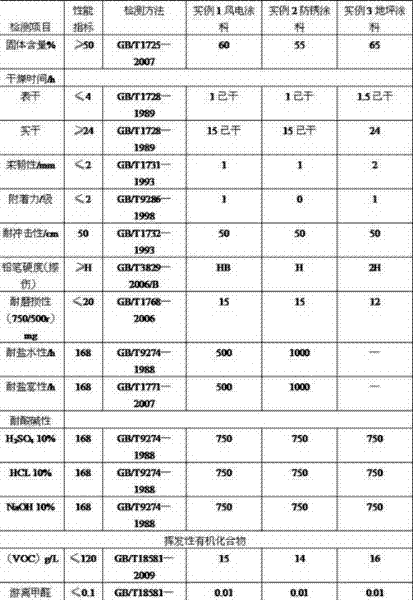

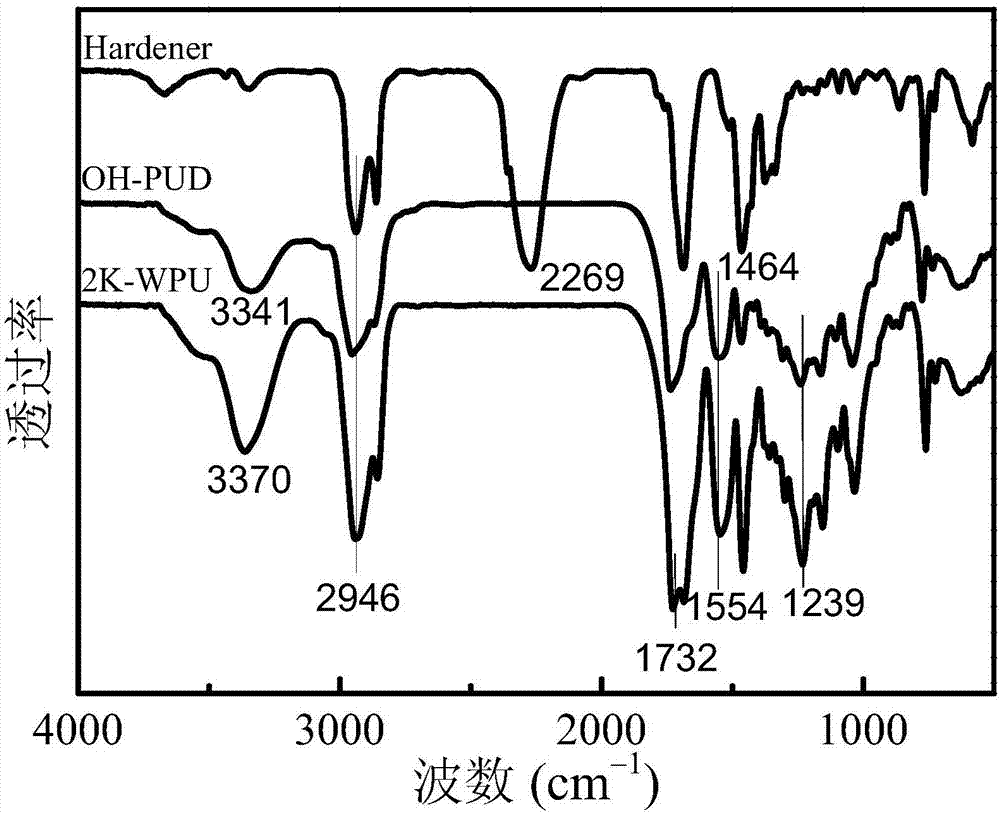

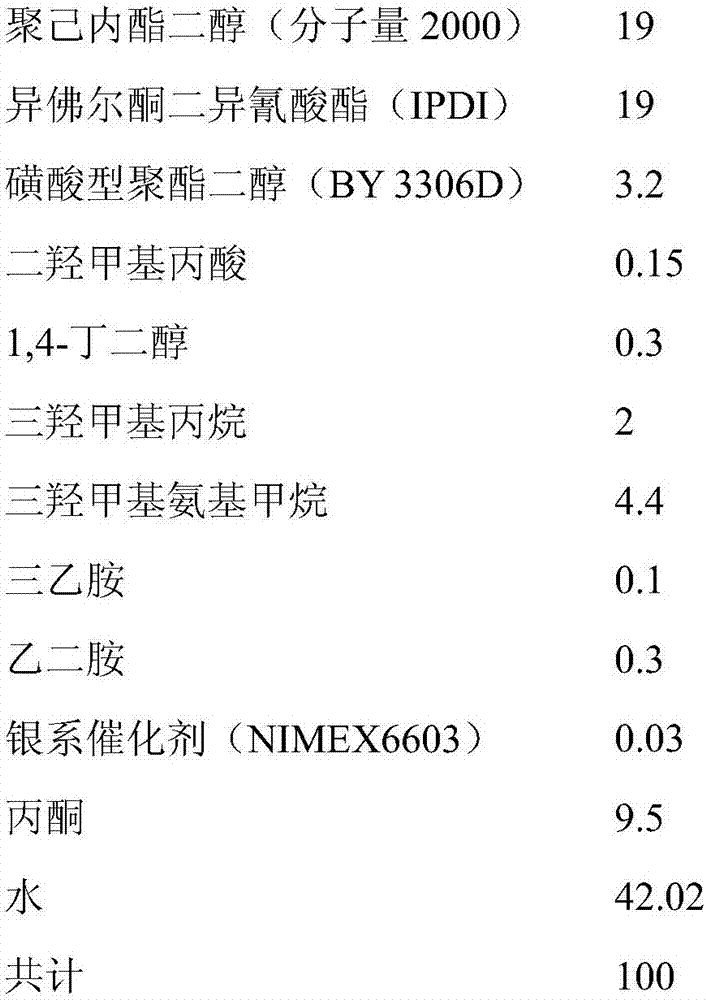

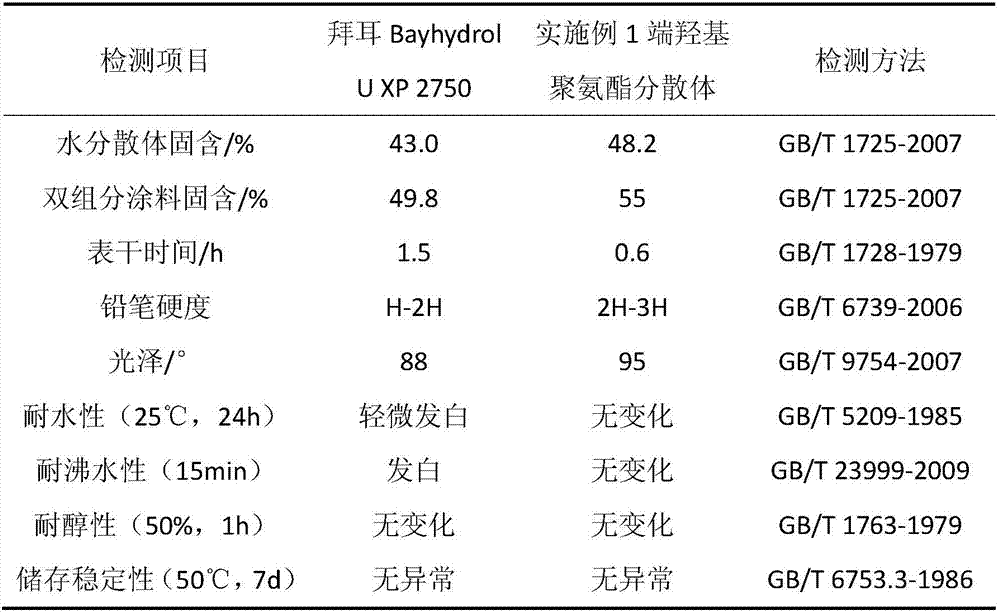

High-functionality hydroxyl-terminated polyurethane aqueous dispersion as well as preparation method and application thereof

InactiveCN106866923AIncreased average hydroxyl functionalityIncrease crosslink densityPolyurea/polyurethane coatingsEthylenediamineNitrogen gas

The invention discloses a high-functionality hydroxyl-terminated polyurethane aqueous dispersion as well as a preparation method and application thereof. The preparation method comprises the following steps: adding aliphatic diisocyanate, polyvalent alcohol, a hydrophilic chain-extending agent and a catalyst into a reaction kettle; carrying out temperature rise reaction under the protection of nitrogen gas and cooling when the NCO percent of a system reaches a theoretical value; dropwise adding an acetone solution of a dihydric alcohol chain-extending agent and a crosslinking agent, continuously reacting and diluting with acetone when the NCO percent of the system reaches the theoretical value; cooling, and adding triethylamine for neutralizing; adding water for dispersing, and adding alcamines compounds for terminating; finally, carrying out post chain extending by using ethidene diamine to obtain the hydroxyl-terminated polyurethane aqueous dispersion. According to the high-functionality hydroxyl-terminated polyurethane aqueous dispersion disclosed by the invention, an alcamines terminating agent with polyhydroxy functionality is adopted, and a polyhydroxy functional group is introduced on a polyurethane chain segment by a terminating reaction of an amine group and an NCO group; the obtained aqueous dispersion has the advantages of high solid content, small particle size and stable storage; a two-component waterborne polyurethane coating prepared by the high-functionality hydroxyl-terminated polyurethane terminating dispersion has the characteristics of high drying speed of the coating, excellent medium resistance and environment friendliness of a product.

Owner:SOUTH CHINA UNIV OF TECH

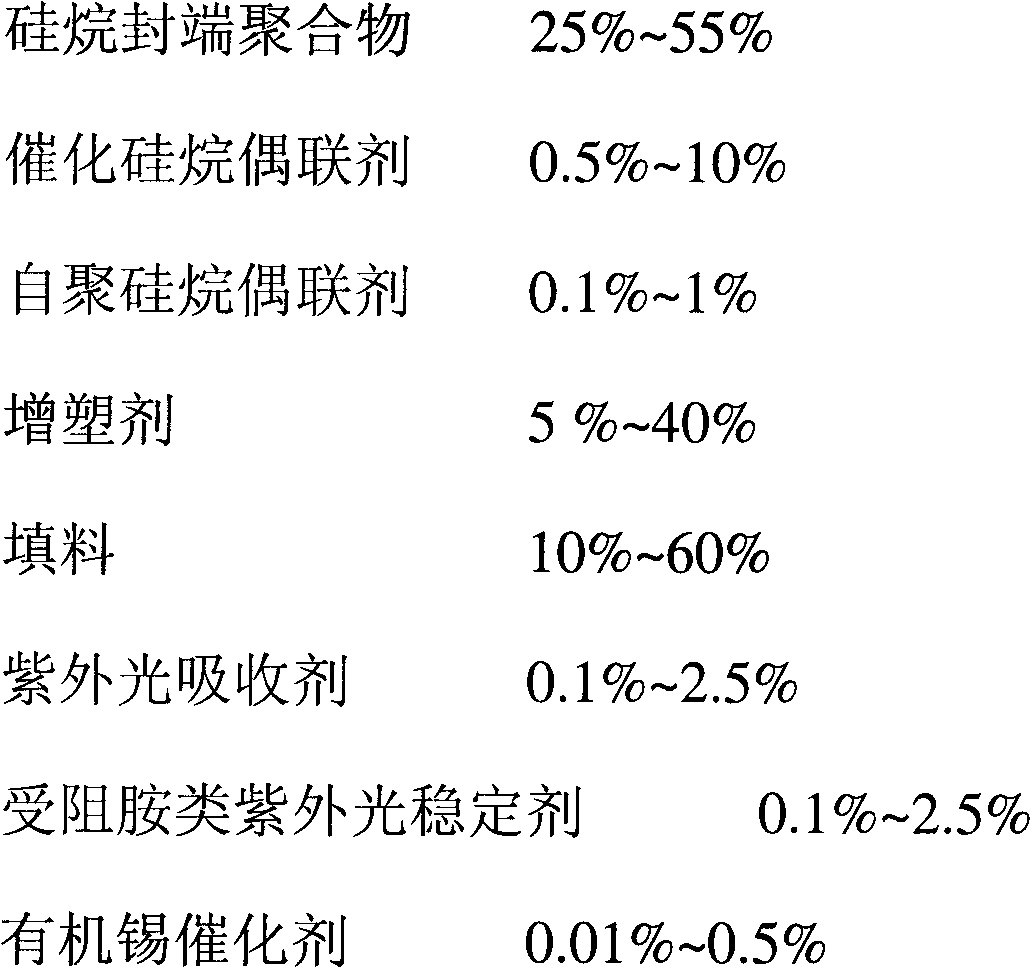

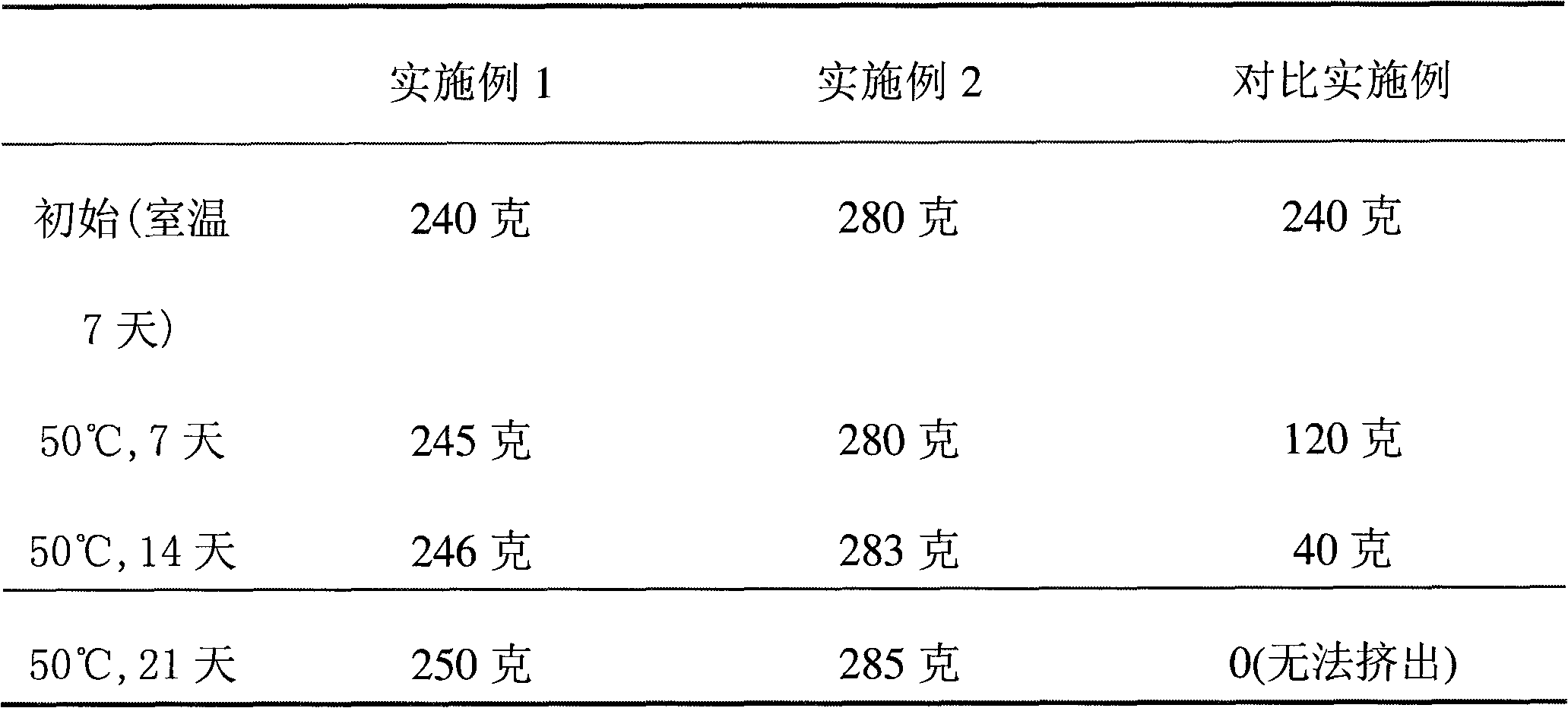

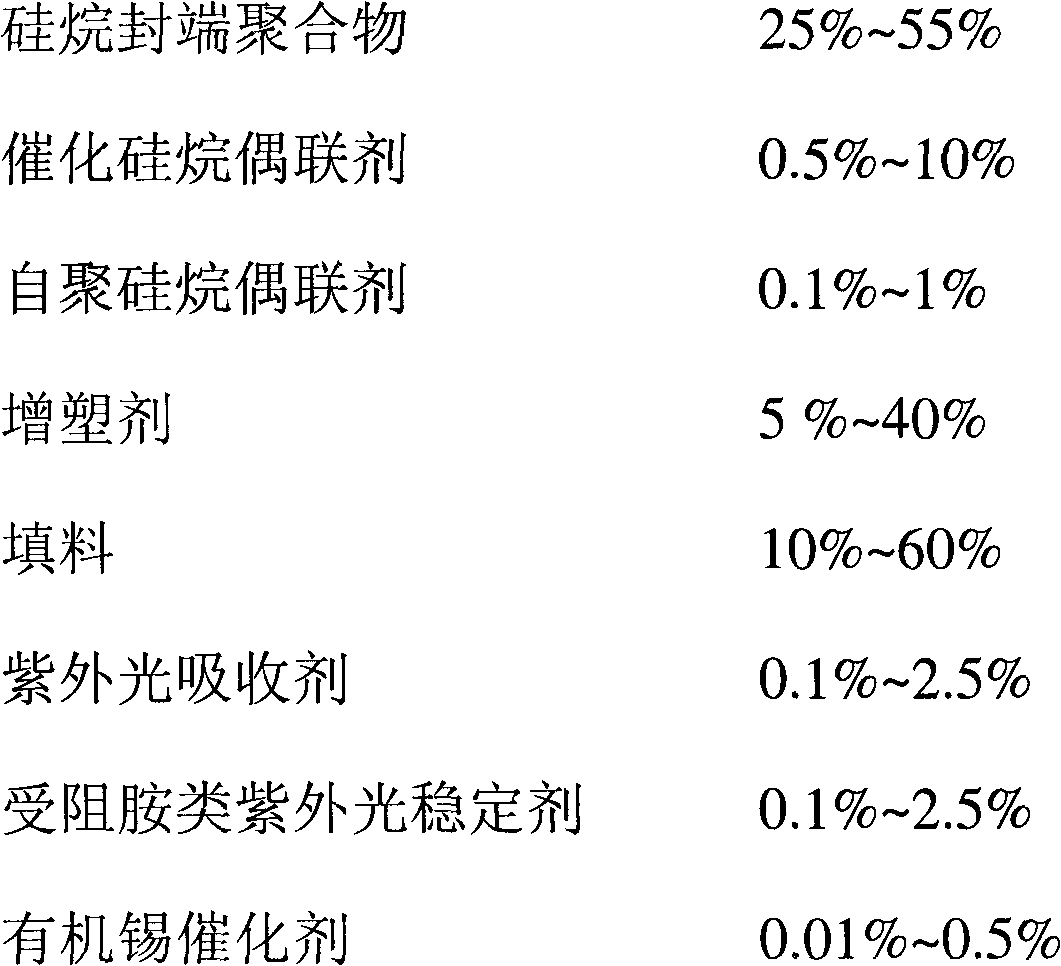

Sealant of silane-terminated polymer and preparation method thereof

ActiveCN102408870AImprove media resistanceGood adhesionOther chemical processesAdhesivesPolymer sciencePolyol

The invention discloses a sealant of a silane-terminated polymer and a preparation method thereof. The sealant comprises the following main components by mass: 25%-55% of a silane-terminated polymer, 0.5%-10% of a catalytic silane coupling agent, 0.1%-1% of a self-polymeric silane coupling agent, 5%-40% of a plasticizer, 10%-60% of a filling material, 0.1%-2.5% of an ultraviolet absorber, 0.1%-2.5% of a hindered amine ultraviolet stabilizer, and 0.01%-0.5% of an organotin catalyst. The method specifically consists of: (1) adding high molecular weight and low-unsaturation polyether polyol, an isocyanate compound, and an organotin catalyst into a stirring tank in order at room temperature, and heating the mixture to a temperature of 40DEG C-60DEG C, then conducting heat preservation till isocyanate content in the mixture stabilized; (2) then adding an active group methyldimethoxysilane as an end capping agent, continuing preserving heat for reaction till the isocyanate content becomes 0, thus obtaining a silane-terminated polymer; (3) adding the above silane-terminated polymer, the catalytic silane coupling agent, the self-polymeric silane coupling agent, the plasticizer, the filling material, the ultraviolet absorber, and the hindered amine ultraviolet stabilizer into the stirring tank, carrying out blending for 30-45min under vacuum protection, thus obtaining the sealant of a silane-terminated polymer.

Owner:TONSAN ADHESIVES INC

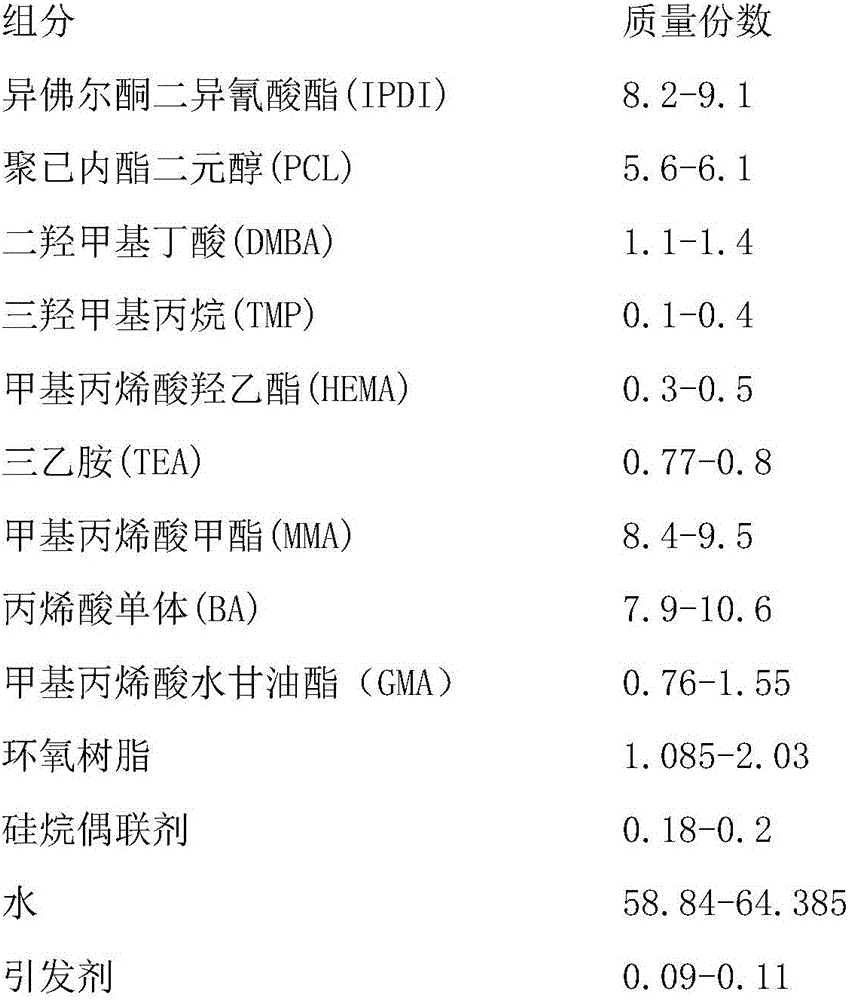

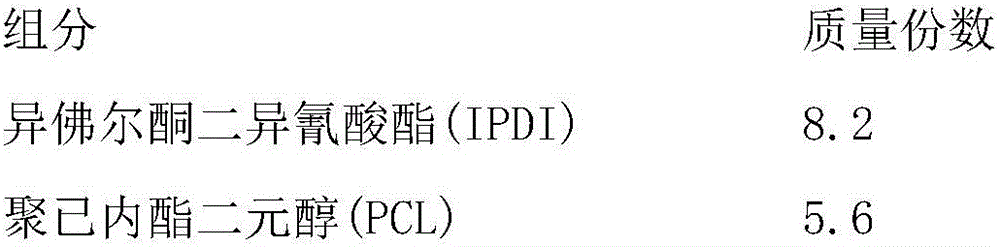

Modified polyurethane-acrylate water-based woodware emulsion and preparation method thereof

InactiveCN106118314AImprove overall performanceImprove media resistancePolyurea/polyurethane coatingsEmulsionTrimethylolpropane

The invention discloses a modified polyurethane-acrylate water-based woodware emulsion and a preparation method thereof. The modified polyurethane-acrylate water-based woodware emulsion is mainly prepared from, by mass, 8.2-9.1 parts of isophorone diisocyanate (IPDI), 5.6-6.1 parts of polycaprolactone dihydric alcohol (PCL), 1.1-1.4 parts of dihydroxymethyl butyric acid (DMBA), 0.1-0.4 part of trimethylolpropane (TMP), 0.3-0.5 part of hydroxyethyl methacrylate (HEMA), 0.77-0.8 part of triethylamine (TEA), 8.4-9.5 parts of methyl methacrylate (MMA), 7.9-10.6 parts of acrylic monomer (BA), 0.76-1.55 parts of methylacrylate water glyceride (GMA), 1.085-2.03 parts of epoxy resin, 0.18-0.2 part of silane coupling agent, 58.84-64.38 parts of water and 0.09-0.11 part of initiator. The emulsion prepared by the method is good in performance.

Owner:詹俊英

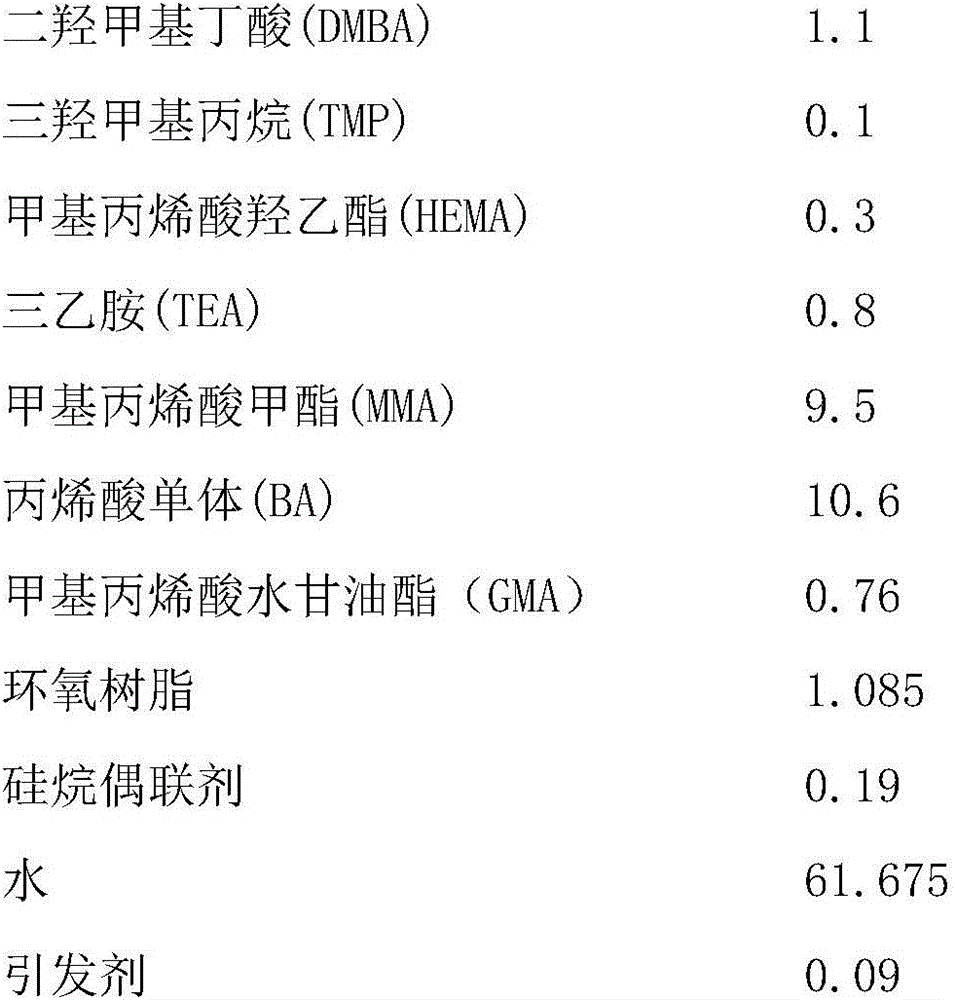

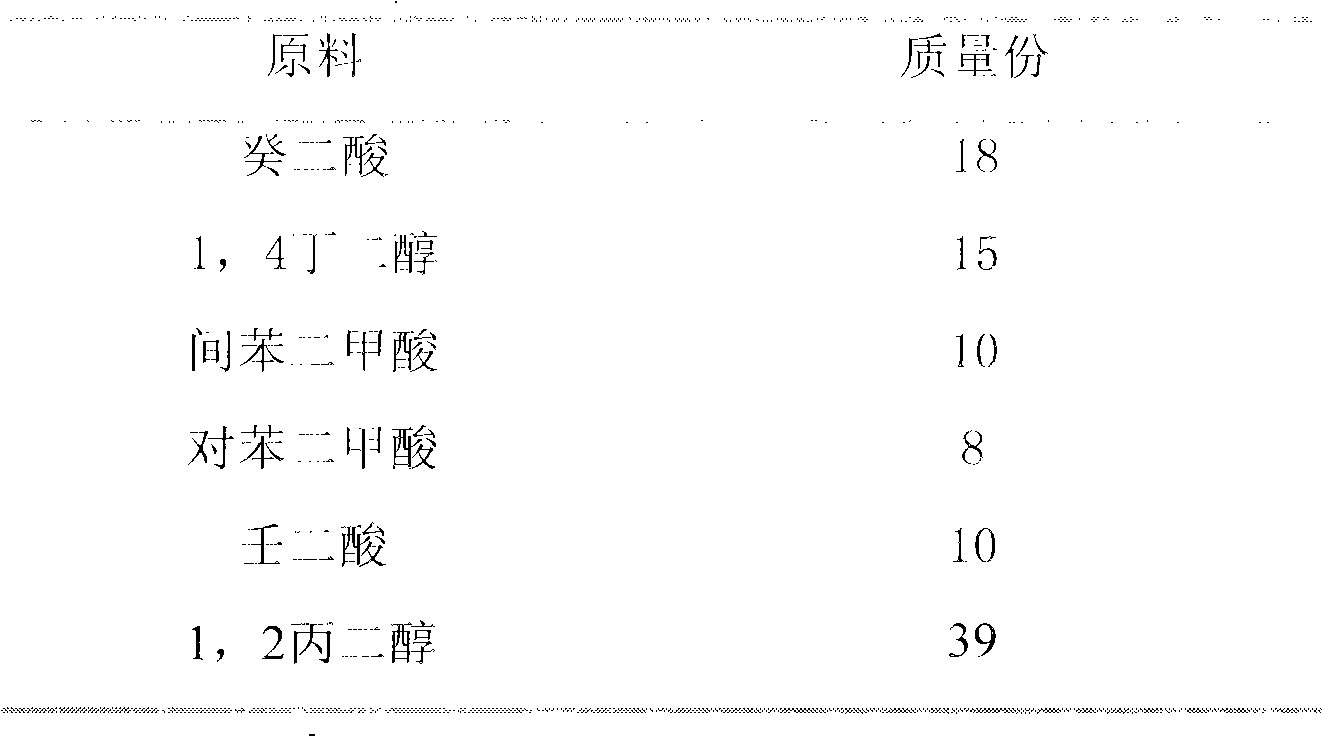

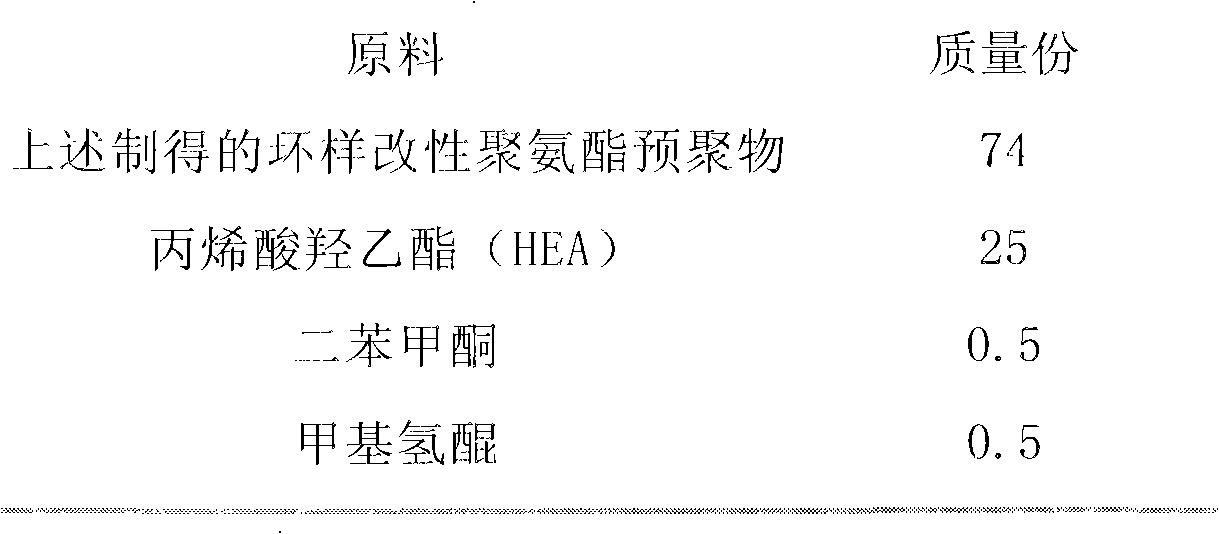

Preparation method of ultraviolet light curing composite binding agent

The invention discloses a preparation method of an ultraviolet light curing composite binding agent, belonging to the field of the binding agent. The preparation method comprises the following steps: preparing polyester polyol: preparing the polyester polyol by primary esterification, secondary esterification and condensation polymerization; preparing epoxy modified polyurethane prepolymer: reacting hydroxyl-containing epoxy resin, the prepared polyester polyol and isocyanate to prepare the epoxy modified polyurethane prepolymer; and preparing epoxy modified urethane acrylate: reacting the prepared epoxy modified polyurethane prepolymer with an ultraviolet light initiator and a polymerization inhibitor and preparing the epoxy modified urethane acrylate, namely the ultraviolet light curing composite binding agent. By designing chain segments of a polyester structure and properly matching the types and quantity of alcohol acids, the invention prepares high-performance polyester, and introduces the epoxy resin into the polyurethane prepolymer chain segments so as form the ultraviolet light curing composite binding agent at the two ends, thus improving the binding and anti-medium performances of the ultraviolet light curing composite binding agent, omitting the adding of a polyfunctional active diluent with larger toxicity and being more environment-friendly.

Owner:NANTONG GAOMENG NEW MATERIAL

Permeation resisting composite film

ActiveCN105922690AImprove penetration resistanceImprove sealingSynthetic resin layered productsDomestic containersLow-density polyethylenePolyester

The invention discloses a permeation resisting composite film. The permeation resisting composite film comprises a polyester layer, a first polyethylene layer, a polyester aluminum coated layer and a second polyethylene layer from outside to inside in sequence. The second polyethylene layer is composed of a composite layer, a middle layer and a heat sealing layer, wherein the composite layer is composed of low-density polyethylene and linear low-density polyethylene according to the weight ratio of 1:3, the middle layer is composed of low-density polyethylene, linear low-density polyethylene and high-density polyethylene according to the weight ratio of 1:1:1, and the heat sealing layer is composed of low-density polyethylene and metallocene polyethylene according to the weight ratio of 2:1. By improving the formula of the second polyethylene layer and using 2050 glue between the polyester aluminum coated layer and the second polyethylene layer, barrier property and medium resistance of the product are improved greatly while the requirement for heat sealing strength is met; meanwhile, pollution resistance is high, and the permeation resisting composite film is especially suitable for packaging oily substances such as gluten.

Owner:永新股份(黄山)包装有限公司

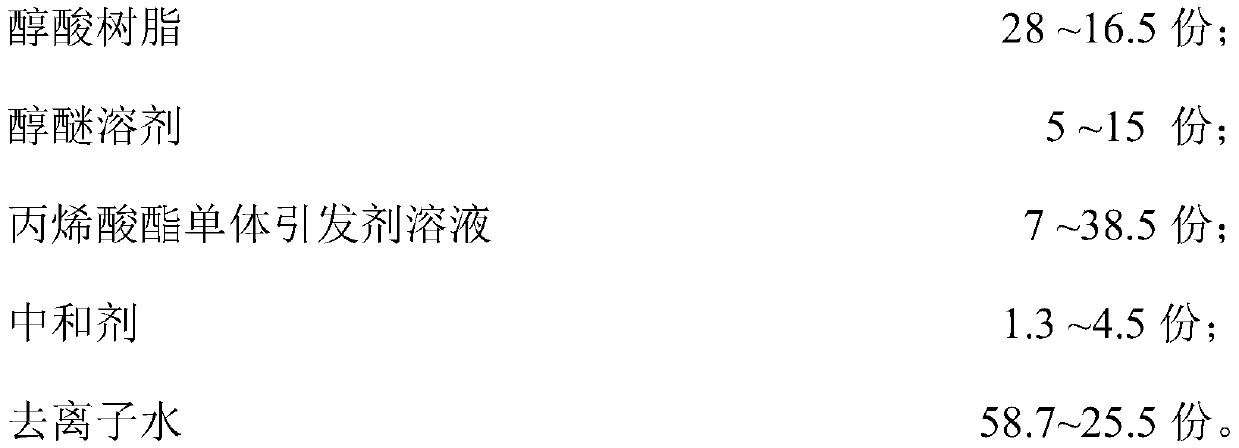

Emulsion used for quick-drying high-gloss high-weatherability waterborne alkyd paint, and preparation method thereof

The invention discloses an emulsion used for quick-drying high-gloss high-weatherability waterborne alkyd paint, and a preparation method thereof. The emulsion is composed of 28 to 16.5 parts of alkydresin; 5 to 15 parts of an alcohol ether solvent; 7 to 38.5 parts of an acrylate monomer initiator solution; 1.3 to 4.5 parts of a neutralizer; and 58.7 to 25.5 parts of deionized water. The preparation method comprises following steps: an alkyd resin with an appropriate acid value is prepared, alcohol ether is taken as a solvent, under the effect of an oil soluble initiator and a chain transferring agent, an anionic unsaturated monomer, a short chain unsaturated monomer, a long carbon chain acrylate monomer, and the alkyd resin are subjected to free radical copolymerization to prepare an acrylic acid modified alkyd resin; amine neutralizing is carried out, and water is adopted for dispersion so as to obtain the emulsion used for quick-drying high-gloss high-weatherability waterborne alkyd paint. The preparation method possesses following characteristics: monomer kind selection and composition range is wide; the raw materials are easily available; the process is convenient to control;popularization and applications in practical industrialized production are convenient; and the waterborne alkyd paint prepared from the emulsion possesses quick drying performance, high gloss, and high weatherability.

Owner:陕西宝塔山油漆股份有限公司

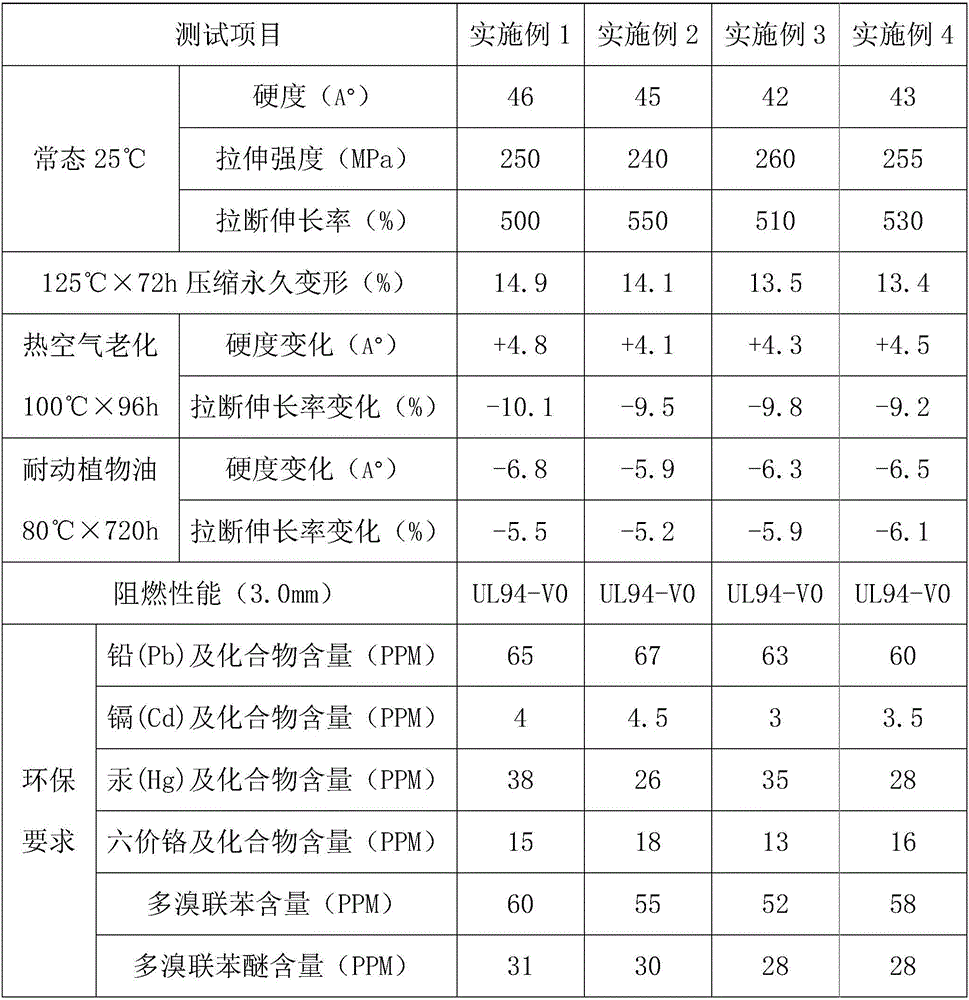

Flame-retardant sealing ring for motors of range hoods

The invention discloses a flame-retardant sealing ring for motors of range hoods. The flame-retardant sealing ring is made from raw materials including nitrile rubber, zinc oxide, stearic acid, carbon black, white carbon black, sulphur powder, an accelerant CZ, an accelerant M, an accelerant TMTD, ETU-80, light magnesium oxide, pottery clay, chloroprene rubber adhesive, aluminum hydroxide, a silane coupling agent, zinc borate, antimonous oxide, modified flame retardant, dioctyl phthalate, carnauba wax, antiager 2246, antiager BZ and a processing agent WB-16. The flame-retardant sealing ring is good in high-temperature resistance and flame retardant performance, and meanwhile has the advantages of oil resistance, no halogen, low toxicity and environment friendliness.

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

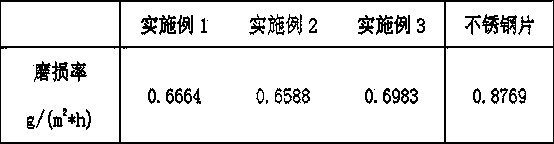

Wear-resisting epoxy paint

ActiveCN103642363AImprove wear resistanceImprove media resistanceEpoxy resin coatingsEpoxyMaterials science

The invention belongs to the technical field of macromolecules, and particularly relates to wear-resisting epoxy resin which can be used for repairing equipment and pipelines. The paint comprises a component A and a component B, and is characterized in that the component A comprises the following raw materials in parts by weight: 20 to 45 parts of mixed epoxy resin, 2 to 8 parts of diluent, 1 to 4 parts of silane coupling agent, 10 to 30 parts of iron-base alloy powder, 10 to 30 parts of aluminum oxide powder, 5 to 20 parts of silicon carbide, 10 to 20 parts of ceramic powder, 1 to 4 parts of glass flakes and 1 to 4 parts of carbon black; the component B comprises the following raw materials in parts by weight: 70 to 80 parts of high-hardness wear-resisting epoxy curing agent and 20 to 30 parts of epoxy promoter. The adhesion force of the wear-resisting epoxy resin on a base material can be improved by adopting the mixed epoxy resin; the wear resistance and the medium resistance of the epoxy paint are improved by adopting p-aminophenol glycidyl amine (ether) trifunctional epoxy resin; the wear resistance of the epoxy resin can be improved by adding the wear-resisting filler such as the iron-base alloy powder and the silicon carbide.

Owner:江西恒大高新科技有限公司

Waterproof, corrosion-resistant and fire-retardant PU (polyurethane) coating and preparation method thereof

ActiveCN104673079AHigh hardnessHigh softening temperatureFireproof paintsAnti-corrosive paintsPolymer sciencePtru catalyst

The invention discloses a waterproof, corrosion-resistant and fire-retardant PU (polyurethane) coating. The PU coating comprises a component A and a component B which are mixed in the same proportion, wherein the component A comprises components as follows: diisocyanate, polypropylene carbonate diol, a small-molecular chain extender, a catalyst, a catalyst capture agent, an organic solvent, a flame retardant and a foaming agent; the component B comprises components as follows: a curing agent and a coupling agent. The invention further designs a preparation method of the waterproof, corrosion-resistant and fire-retardant PU coating. The preparation method of the coating is simple, easy to operate and low in cost, and the prepared coating is good in corrosion resistance, excellent in electrical performance, good in decoration and protection performance and good in temperature resistance.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Nitrile-butadiene rubber sealing material and preparation method thereof

InactiveCN105061840AGood high and low temperature resistanceExcellent medium resistanceMicrocrystalline waxStearic acid

The invention discloses a nitrile-butadiene rubber sealing material which is prepared from the following raw materials in parts by weight: 40-60 parts of nitrile-butadiene rubber N241, 20-40 parts of nitrile-butadiene rubber N240S, 1-4 parts of zinc oxide, 1-3 parts of sulfur S-80, 1-2 parts of tetramethyl-thiuram disulfide, 1-2 parts of accelerator TMTD, 0.5-0.9 part of N-cyclohexyl-2-benzothiazole sulfenamide, 20-35 parts of carbon black N-774, 20-30 parts of calcined argil, 1-2 parts of stearic acid, 1-2 parts of coumarone, 1-2 parts of microcrystalline wax OK1987, 1-3 parts of anti-aging agent RD, 1-3 parts of anti-aging agent H, 1-3 parts of anti-aging agent A and 2-6 parts of plasticizer TP-90B. The invention also discloses a preparation method of the nitrile-butadiene rubber sealing material.

Owner:宋晓梅

Water-proof two-component polyurethane coating and preparation method thereof

InactiveCN104673075AHigh hardnessHigh softening temperatureFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a water-proof two-component polyurethane coating. The polyurethane coating comprises a component A and a component B mixed in the equal ratio, wherein the component A comprises components as follows: diisocyanate, poly propylene carbonate diol, a micromolecule chain extender, a catalyst, a catalyst capturing agent, an organic solvent, a flame retardant and a foaming agent; the component B comprises components as follows: a curing agent and a coupling agent. The invention further designs a preparation method of the water-proof two-component polyurethane coating. The preparation method of the coating is simple and easy to operate, the cost is low, and the prepared coating is good in corrosion resistance, excellent in electrical performance, good in decoration and protection performance and good in temperature resistance.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

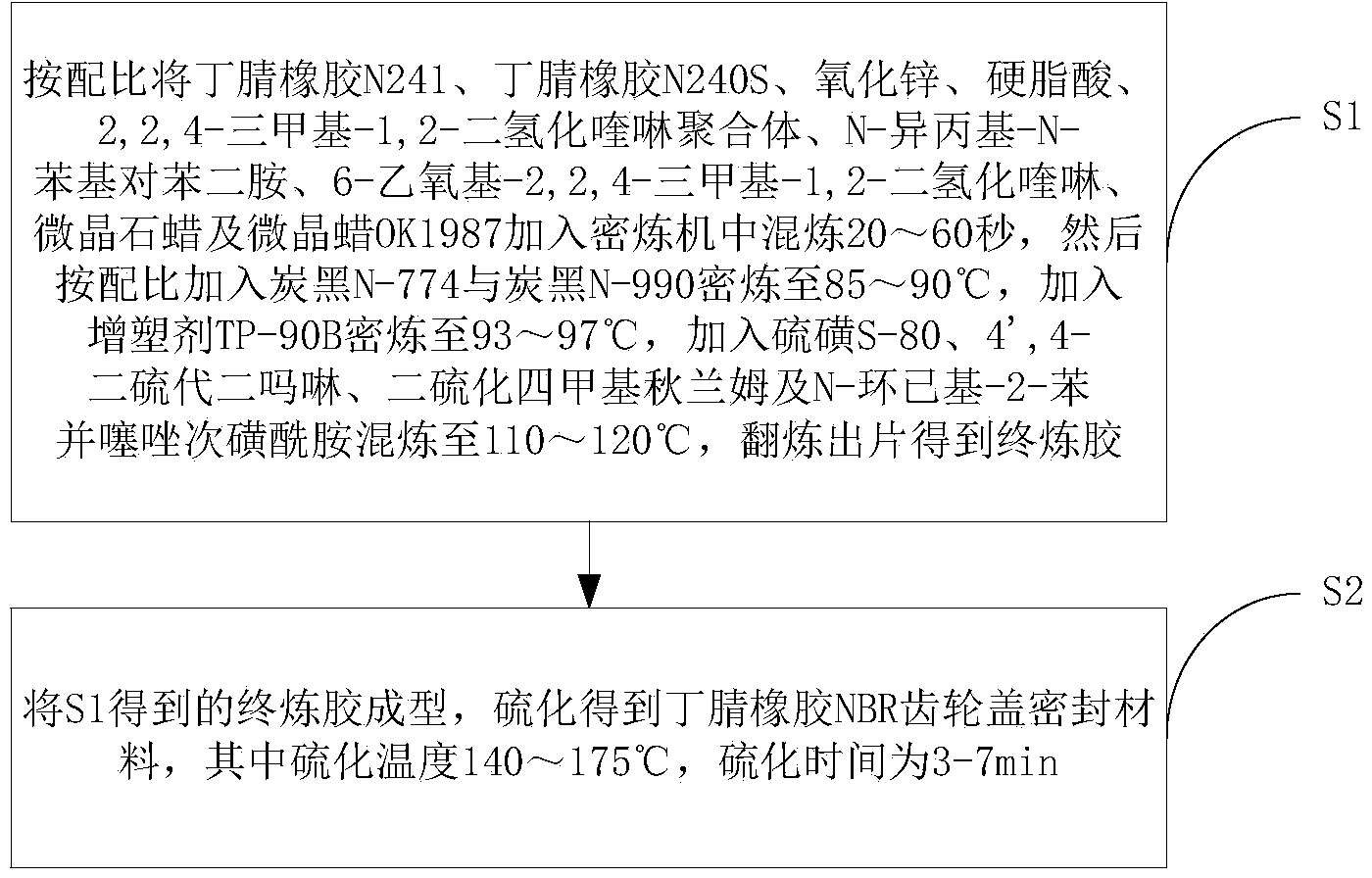

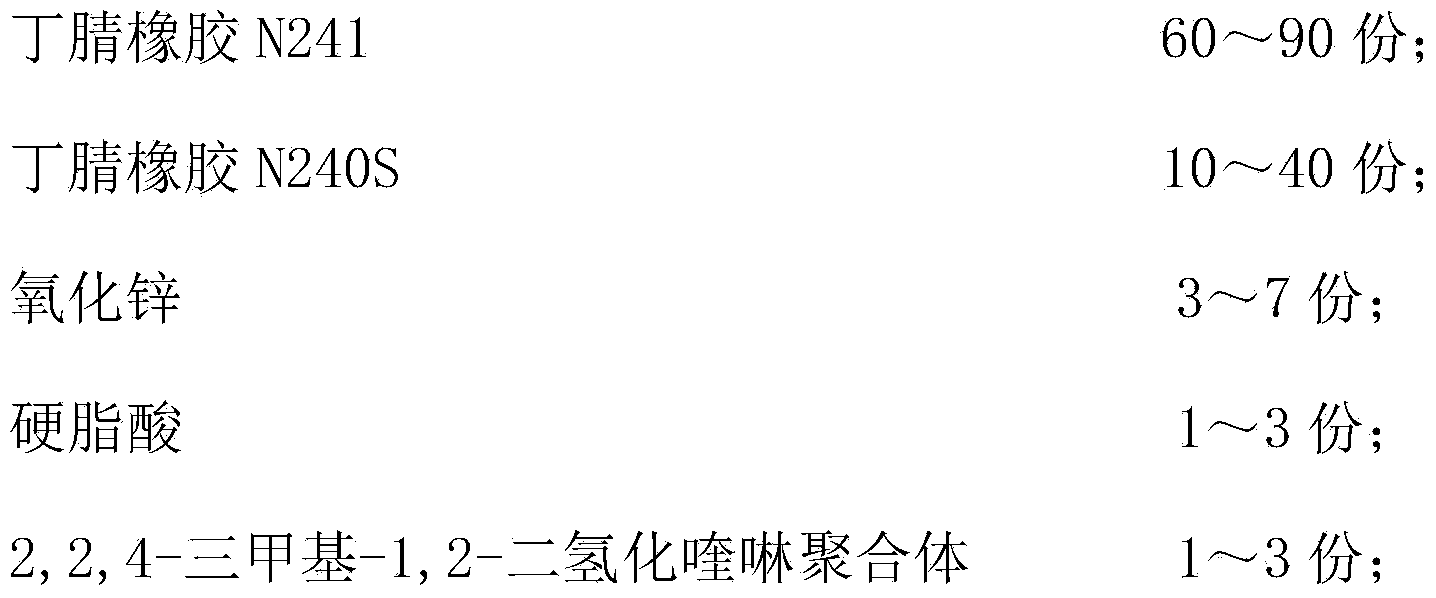

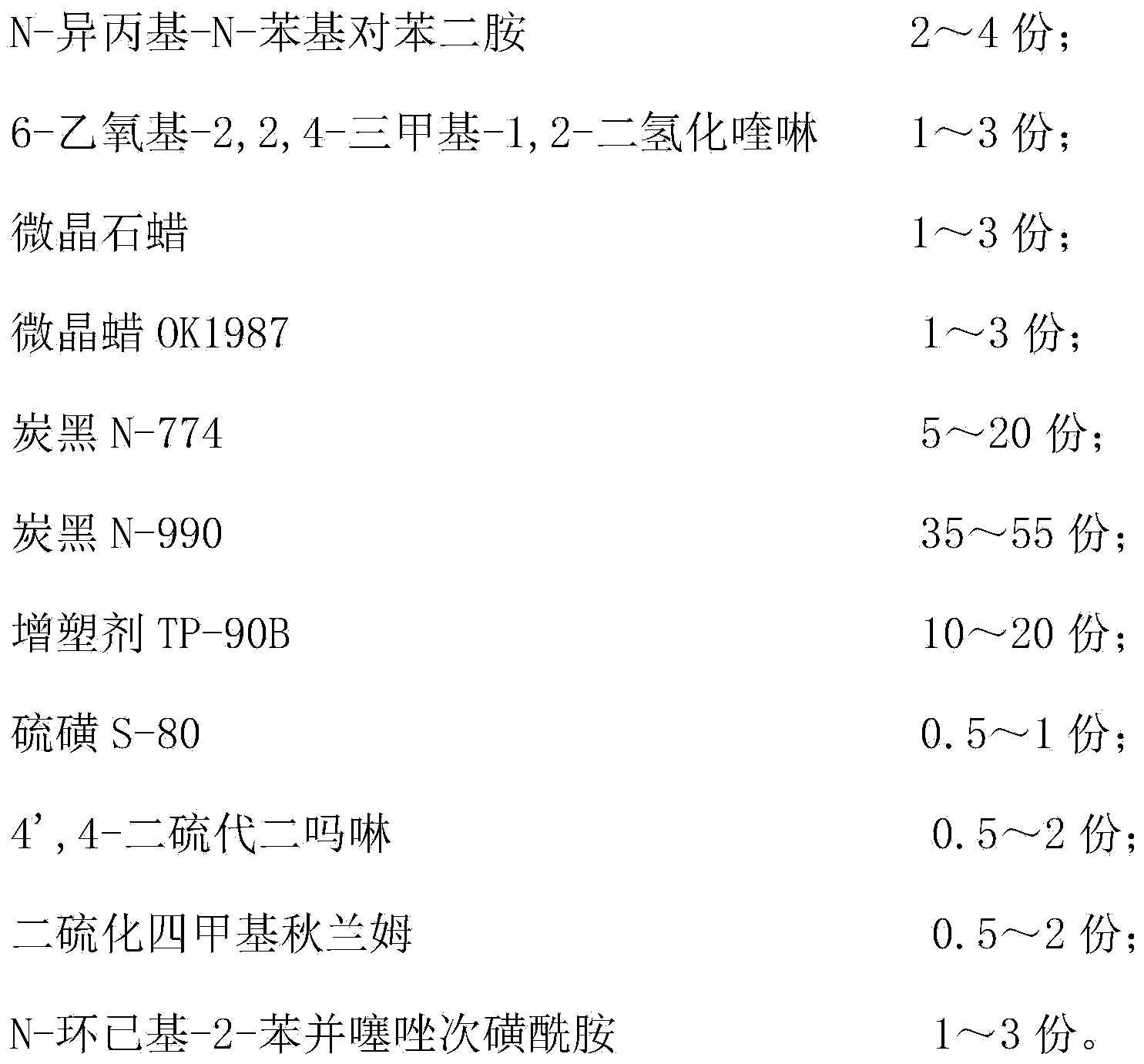

Nitrile-butadiene rubber NBR gear cover sealing material and preparation method thereof

ActiveCN103772765AImprove high and low temperature resistance and medium resistanceImprove low temperature resistanceAgricultural engineeringPlasticizer

The invention discloses a nitrile-butadiene rubber NBR gear cover sealing material which comprises the following raw materials in parts by weight: 60-90 parts of NBR N241, 10-40 parts of NBR N240S, 3-7 parts of zinc oxide, 1-3 parts of a stearic acid, 1-3 parts of RD, 2-4 parts of 4010 NA, 1-3 parts of 6-ethoxy-2-methyl-1,2,4-trimethyl-1,2-dihydroquinoline, 1-3 parts of microcrystalline wax, 1-3 parts of microcrystalline wax OK1987, 5-20 parts of carbon black N-774, 35-55 parts of carbon black N-990, 10-20 parts of a plasticizer TP-90-B, 0.5-1 part of sulfur S-80, 0.5-2 parts of 4',4-DTDM, 0.5-2 parts of tetramethyl thiuram disulfide, and 1-3 parts of N-cyclohexylbenzothiazole-2-sulphenamide. The invention also discloses a preparation method of the nitrile-butadiene rubber NBR gear cover sealing material.

Owner:ASIMCO NVH TECH CO LTD ANHUI

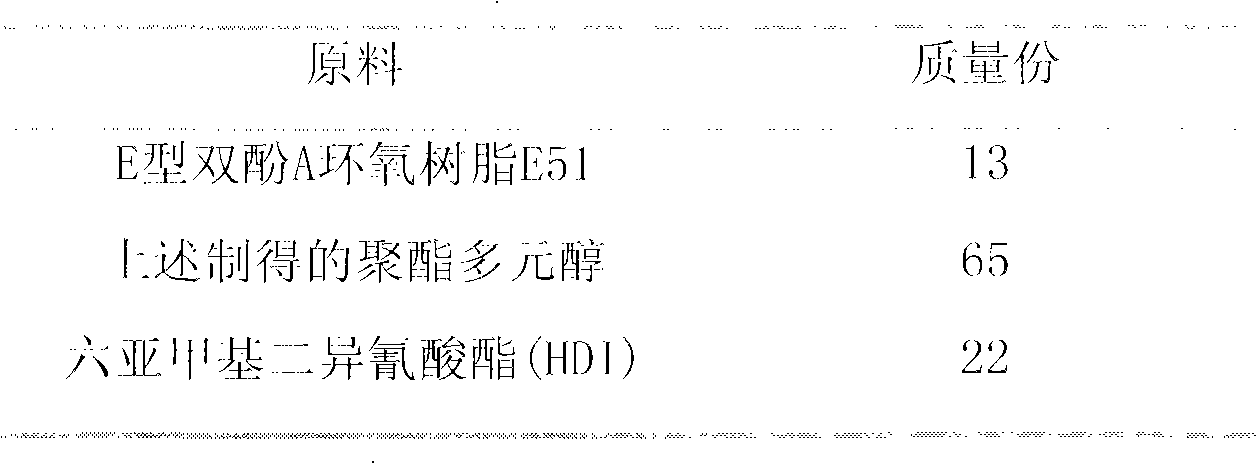

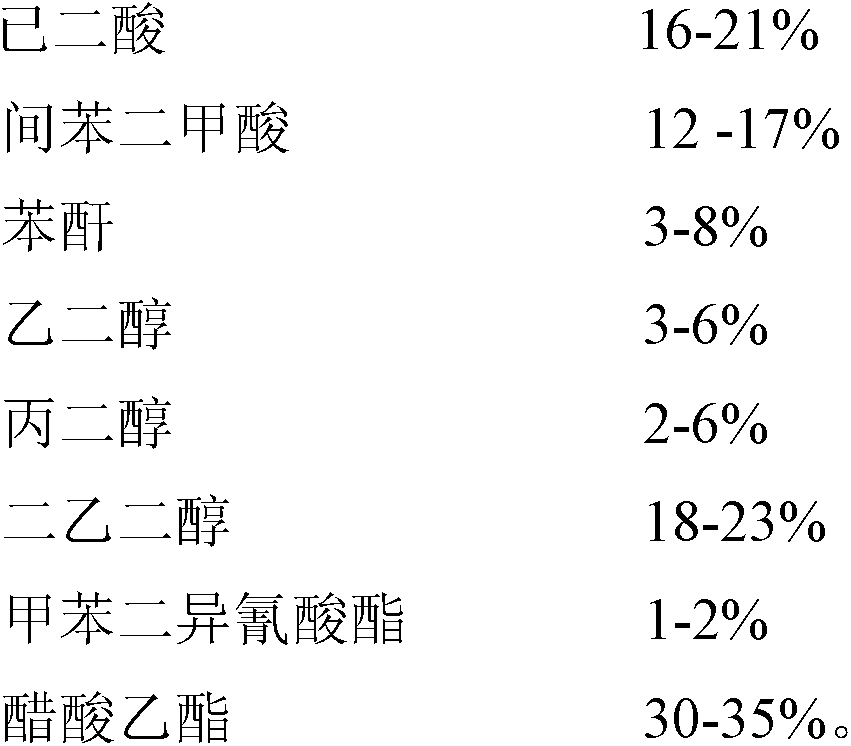

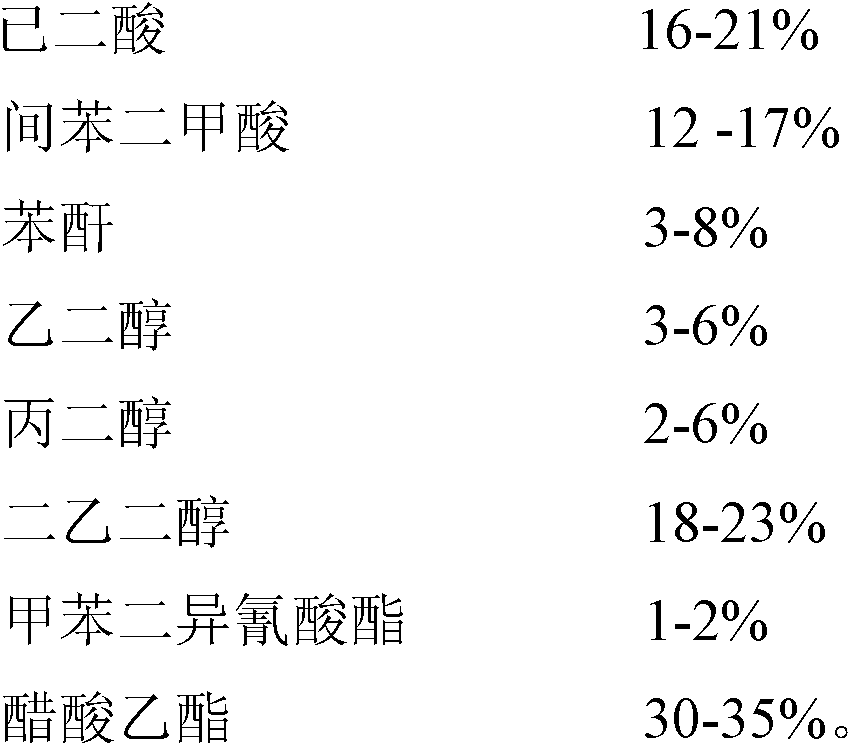

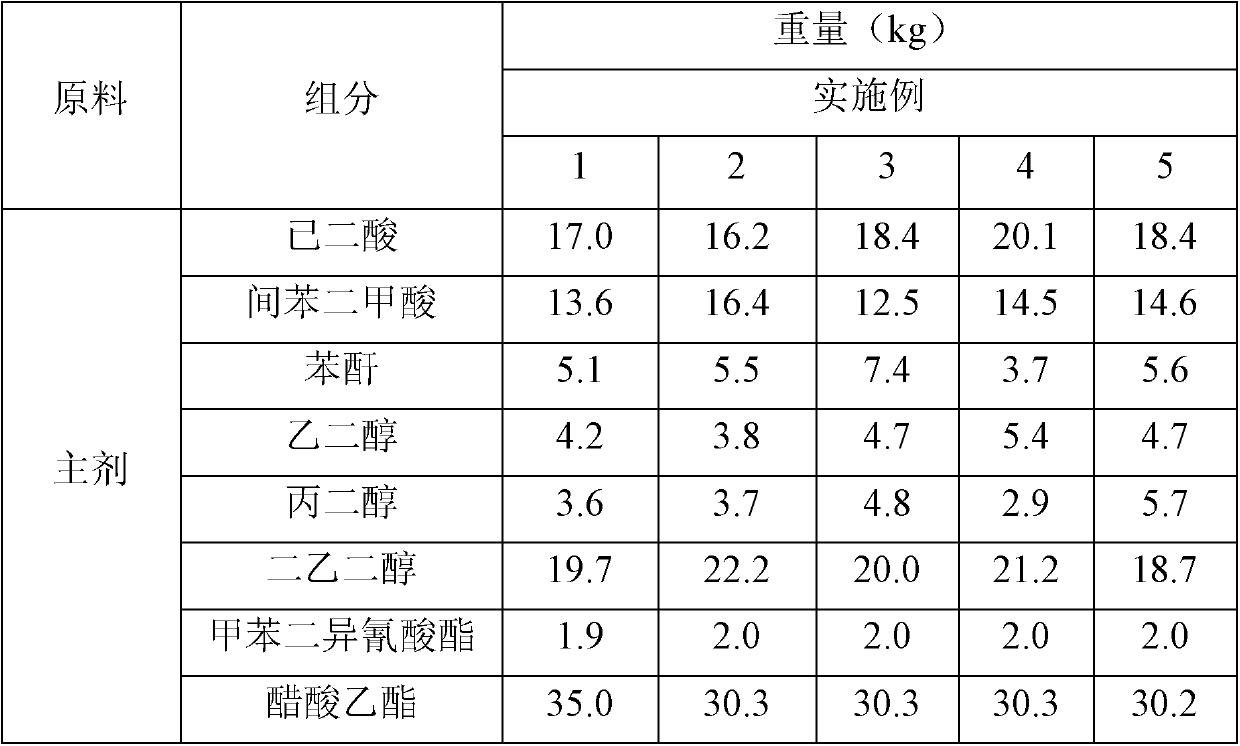

High-oil-resistance polyurethane adhesive

ActiveCN103102860AHigh peel strength and media resistanceGood oil resistancePolyureas/polyurethane adhesivesChemistryEther

The invention discloses a high-oil-resistance polyurethane adhesive. The high-oil-resistance polyurethane adhesive comprises a main agent and a curing agent; the main agent is a polyester type polyalcohol compound with hydroxyl blocked, wherein the polyester type polyalcohol compound is obtained by the reaction among adipic acid, isophthalic acid, phthalic anhydride, glycol, propylene glycol, diethylene glycol, toluene diisocynate and acetic ether; and the curing agent is an addition product obtained by the reaction among the toluene diisocynate, trimethylolpropane and acetic ether. According to the high-oil-resistance polyurethane adhesive, the aromatic acid is introduced, so that the prepared adhesive is higher in peeling strength and media resistance; and the dihydric alcohol compound is adopted, so that the compounded film is higher in oil resistance, and the requirement on manufacture of oil-resistance packaging bags can be completely met.

Owner:浙江博菲电气股份有限公司

Method for preparing fluorine-silica rubber artificial tooth soft lining material

InactiveCN101167684AImprove media resistanceLow water absorptionImpression capsDentistry preparationsPolymer scienceSilanes

The invention belongs to the technology field of biological medical high polymer materials, and concretely relates to a process for preparing soft lining material of fluorosilicone rubber false toot. The concrete steps comprise charging modified silicone oil which is made from acrylic mixing monomer to nonmonomerd hydroxyl silicone oil, and charging silane cross linking agent, ethylene glycol dimethacrylate, and white carbon black, by which modified silicone oil with a certain degree of polymerization and cross linking is made, charging the fluorosilicone rubber on the sealing end of the hydroxyl group, by which the fluorosilicone rubber is made. The silicon sulfide rubber with the room temperature is made by the mixing and reaction of the two kinds of rubber. The invention has the advantages of reasonable preparing line, easily available raw materials, relatively low cost, simple synthetic technology and has significant values of popularizing and using.

Owner:TONGJI UNIV

High density polyethylene plastic container

InactiveCN104861267AIncrease resistanceImprove high temperature resistanceLow-density polyethyleneTetrafluoroborate

The invention discloses a high density polyethylene plastic container, which comprises components with parts by weight: high density polyethylene 82-90, aminocyclopropane carboxylic acid 0.1-0.2, tetraethylammonium tetrafluoroborate 0.4-1, ethylparaben 2-3, expanded perlite 6-10, 2-ethylhexyl acrylate 3-4, triallyl isocyanurate 0.1-0.3, manganese oxide 1-2, ricinoleic acid 0.3-0.7, polyethyleneimine 0.8-2, cyclohexanhexol 0.2-0.4 and fluorinated rubber 10-13. The high density polyethylene plastic container uses the high density polyethylene as main materials, has excellent insulativity, impact resistance and low temperature resistance, can be suitable to store goods in cold regions, is not easy to damage, and is long in service life.

Owner:ANHUI YIJIA COMMODITY

Adhesive containing modified PVC (polyvinyl chloride) resin for packaging materials

InactiveCN103045106AStrong water resistanceImprove water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesion forceAfter treatment

The invention discloses an adhesive containing modified PVC (polyvinyl chloride) resin for packaging materials. The adhesive comprises an A component and a B component. The adhesive disclosed by the invention has the advantages of reasonable formula design, easily avaliable raw materials, simple production process, easiness in matching with equipment, stable product quality and strong adhesion force, and can be used for improving the physical properties, medium resistance, storage stability and the like in comparison with a traditional adhesive; by adding plant ash after treatment, the damages of water molecules to the adhesive are effectively reduced, the water resistance of the adhesive is greatly improved, and the adhesive has great quick-drying property because the hydrophilicity of the adhesive is reduced; and by adding the modified PVC resin, the viscosity of the adhesive is increased, the flowability of colloid is improved and the adhesion performance of a product is further enhanced.

Owner:滁州市鑫彩印务有限公司

Normal-temperature self-crosslinking type core-shell structure acrylate emulsion as well as preparation and application thereof

ActiveCN113292682AImprove water resistanceGood weather resistanceInksEmulsion paintsMethacrylatePolymer science

The invention belongs to the technical field of film printing materials, and discloses a normal-temperature self-crosslinking type core-shell structure acrylate emulsion as well as preparation and application thereof. The preparation method comprises the steps: carrying out dehydrogenation condensation reaction on a vinyl polyether monomer and a hydrogen-containing silane coupling agent to obtain a modified macromonomer; heating a core-layer monomer emulsion composed of styrene, methacrylate and acrylate to 55-85 DEG C, and then adding an initiator solution to carry out polymerization reaction to obtain a core-layer emulsion; and dropwise adding a shell monomer emulsion composed of methacrylate, acrylic acid and a modified macromonomer and an initiator solution, and continuously carrying out a polymerization reaction to obtain the normal-temperature self-crosslinking type core-shell structure acrylate emulsion. According to the invention, the modified macromonomer with the specific structure is used as a shell polymerization monomer, so that the product can be endowed with a normal-temperature cross-linking characteristic, the adhesive force is enhanced, the wettability is improved, and the water resistance is good. The emulsioncan be used for preparing water-based ink and water-based latex paint.

Owner:李星明

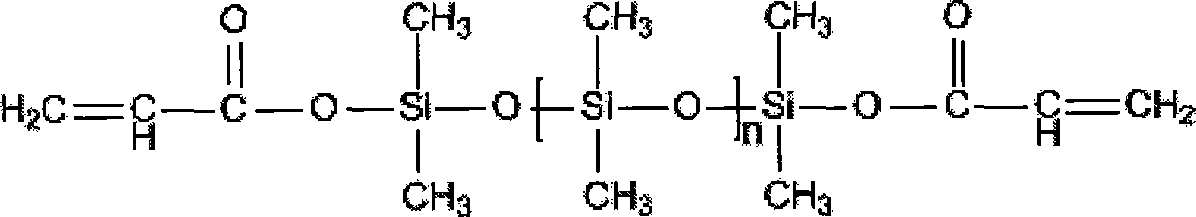

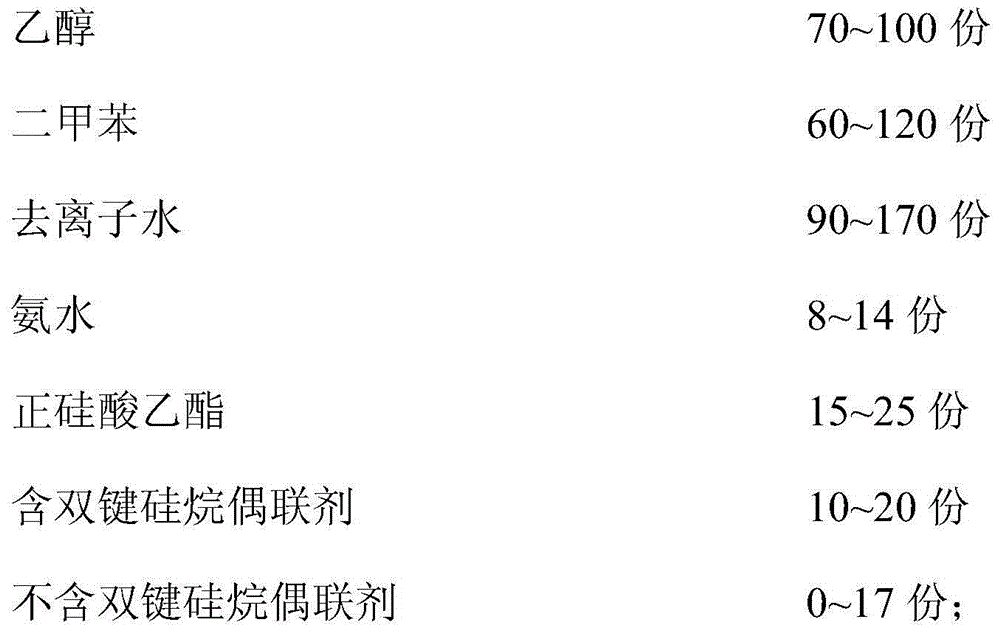

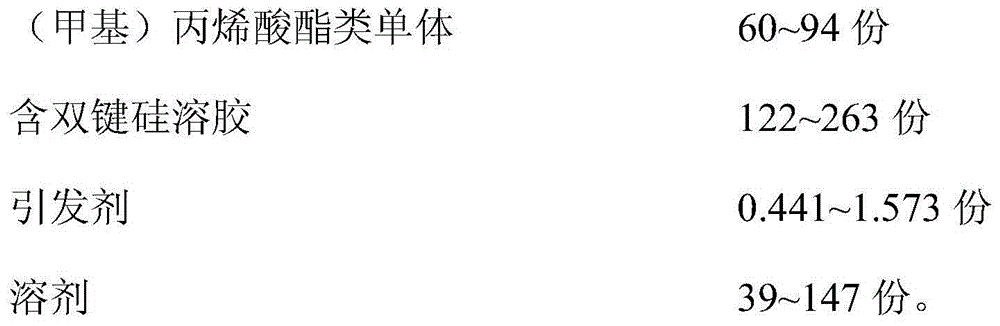

Method for preparing self-extinction resin

ActiveCN104530328AWide variety of sourcesThe synthesis method is simplePolyurea/polyurethane coatingsExtinctionSynthesis methods

The invention relates to a method for preparing self-extinction resin. The method comprises the following steps: A, preparing double bond-containing silica sol, namely adding ethanol and deionized water into a reaction flask, adjusting the pH to be 9-11 with ammonia water, under the protection of inert gas, at 40 DEG C-65 DEG C, dropwise adding a mixture of a double bond-containing silane coupling agent, a double bond-free silane coupling agent, tetraethylortho silicate and xylene, wherein the addition is completed within 0.5-6 hours, and carrying out heat preservation and reaction for 1-3 hours to obtain the double bond-containing silica sol; and B, preparing the self-extinction resin, namely uniformly mixing the double bond-containing silica sol obtained in the step A and a solvent in the reaction flask, under the protection of the inert gas, refluxing to remove the mixture of the ethanol and water in the step A, and at 70 DEG C-130 DEG C, dropwise adding a mixture of a (meth)acrylate monomer and an initiator, and carrying out radical polymerization reaction to finally obtain the hydroxyl group-containing self-extinction resin. The synthesis method is simple, convenient, good in controllability and low in production cost.

Owner:中昊北方涂料工业研究设计院有限公司

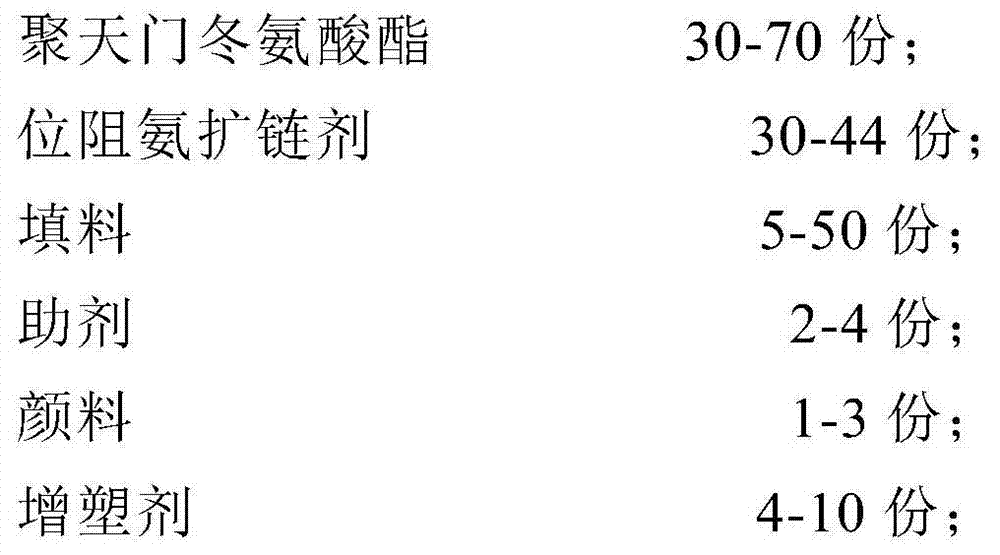

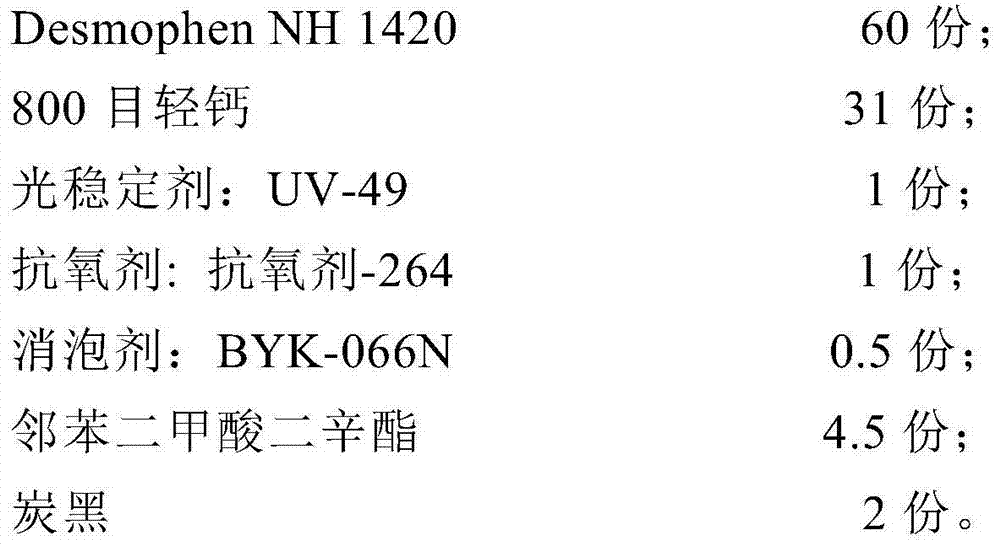

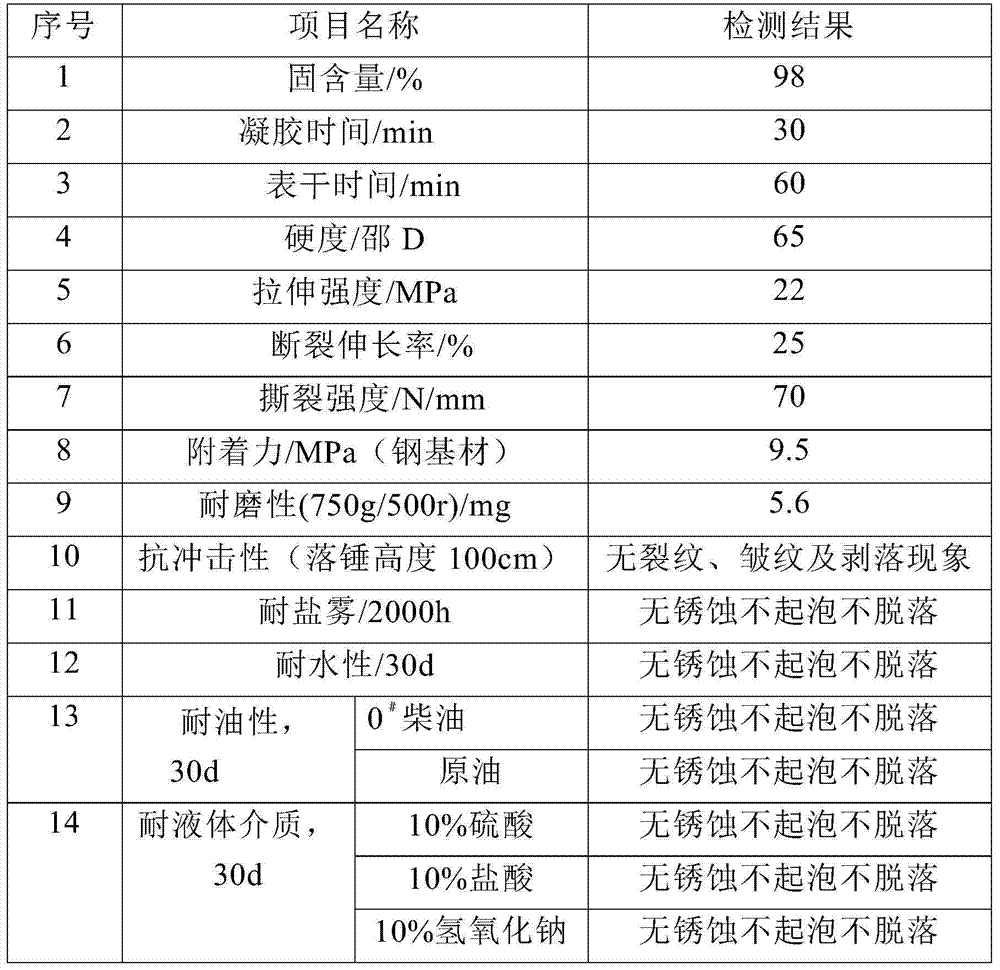

Polyaspartic acid ester type sealant for oil pipeline head and preparation method thereof

InactiveCN103788913BGood effectImprove work efficiencyPolyureas/polyurethane adhesivesLiquid mediumSealant

The invention provides a polyaspartic acid ester sealant for a petroleum pipeline end socket and a preparation method of the polyaspartic acid ester sealant. The polyaspartic acid ester sealant for the petroleum pipeline end socket comprises, by weight ratio, including a constituent A and a constituent B, wherein the constituent A includes 20-70 parts of aliphatic isocyanate and 20-65 parts of polyether polyol; the constituent B includes 30-70 parts of asparaginic acid resin, 30-44 parts of a steric hindrance chain extender, 5-50 parts of padding, 2-4 parts of an addition agent, 1-3 parts of a pigment and 4-10 parts of a plasticizing agent; the mass ratio of the constituent A to the constituent B is 1:1-1.3:1. The polyaspartic acid ester sealant for the petroleum pipeline end socket has the advantages that the formula is scientific and reasonable; the oil resistance, the liquid medium resistance, the weather resistance and the ageing resistance of the polyaspartic acid ester sealant are excellent; the mechanical property of the polyaspartic acid ester sealant is approximately the same as that of anti-corrosion polyurea of a pipeline, so that the adhesive force of the polyaspartic acid ester sealant is excellent.

Owner:大连怿文新材料科技发展有限公司

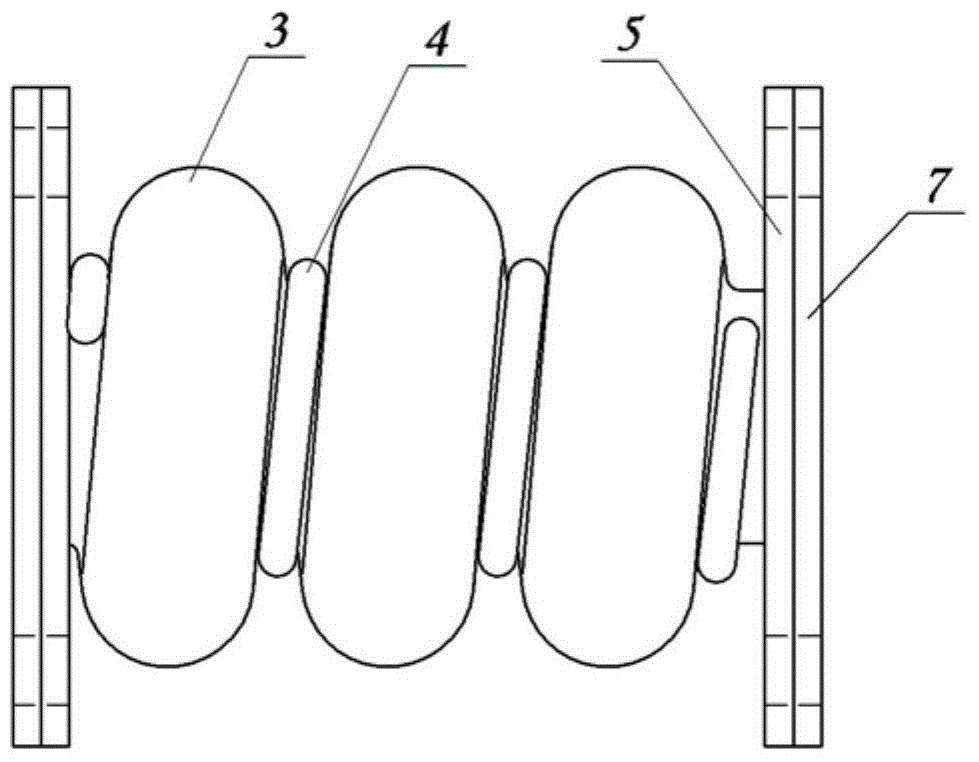

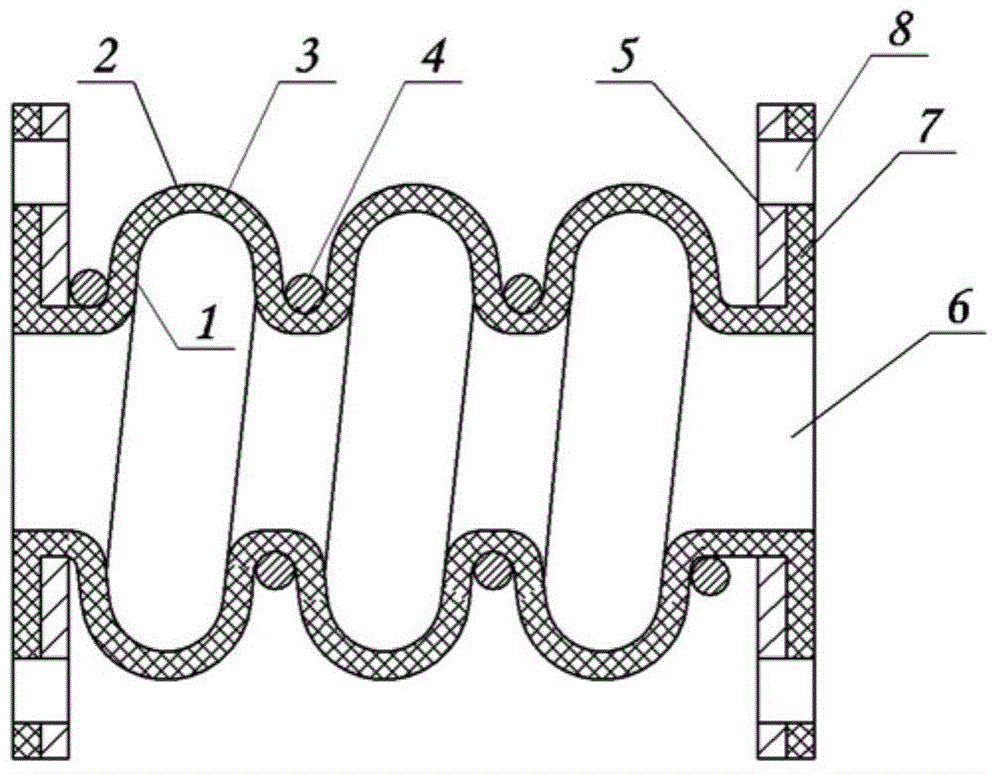

Joint with spirally-reinforcing rubber pipe

InactiveCN104373720AConstrained radial expansionImprove affordabilityPipeline expansion-compensationAdjustable jointsCompensation effectCoil spring

The invention discloses a joint with a spirally-reinforcing rubber pipe. Spiral grooves are formed in the middle of the rubber pipe, and a spiral spring is mounted in each spiral groove in a matched and sleeved manner. The joint has the advantages of simple structure and high strength; through the spiral springs, radial expansion amplitude of the rubber joint can be constrained, and traction and compression resisting effects on the axial direction of the rubber joint can be realized to achieve good axial compensation effect, so that pressure bearing capacity can be improved, and service life can be prolonged; the rubber joint and flanges are fully fitted and fixed together, so that sealing strength when the rubber joint is connected with a pipeline can be improved, and end structure of the rubber pipe is simplified.

Owner:张实

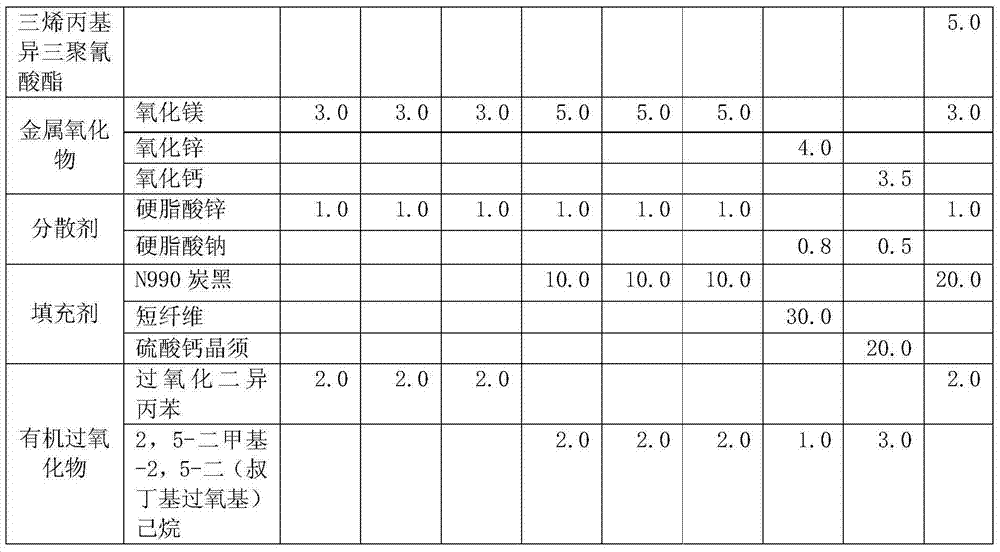

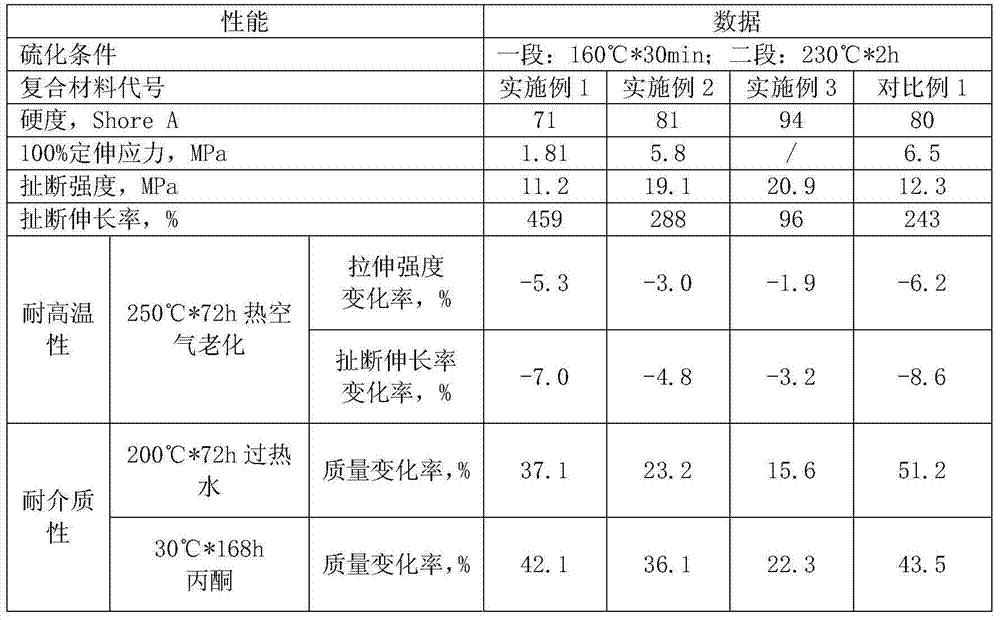

Fluororubber/ N,N'-m-phenylene bismaleimide composite

InactiveCN103497460AImprove high temperature resistance and medium resistanceRestricted movementTemperature resistancePolymer chemistry

The invention discloses a fluororubber / N,N'-m-phenylene bismaleimide composite. The N,N'-m-phenylene bismaleimide composite comprises the following components mainly including, by weight, 100 parts of fluororubber capable of being cross-linked through peroxides, 5-30 parts of N,N'-m-phenylene bismaleimide, 3-5 parts of metallic oxide and 1-3 parts of oxganic peroxides. In the composite material, chemical connection is established between a dispersion phase of N,N'-m-phenylene bismaleimide resin and fluorine rubber molecules serving as matrix, so that the composite material is enabled to be endowed with better high-temperature resistance and medium resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Water-based epoxy putty

InactiveCN102337050AHigh bond energyLower surface energyFilling pastesWater basedMechanical property

The invention discloses water-based epoxy putty, relating to the technical field of coating production in the chemical industrial field. The water-based epoxy putty is prepared by mixing a component A, a component B and a component C, wherein the component A is a high-performance modified water-based epoxy emulsion; the component B is a mixed modified amine curing agent; the component C is mixed dry powder consisting of cement and quartz powder; and the weight ratio of the component A to the component B to the component C is (15-18):1:(15-18). The aging resistance, heat resistance, oil resistance, water resistance, precipitation resistance, medium resistance and electrical performance of the putty are enhanced; and the water-based epoxy putty has high physical and mechanical properties and high chemical resistance, and can be applied to the protection of a cement concrete fundamental plane.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

Material for ring-pull can body

The invention discloses a material of a ring-pull can body. The material comprises an aluminum alloy board and a protection coating coated on the surface of the aluminum alloy board. The aluminum alloy board is made of the material prepared from chemical components including, by weight, 1.0-1.5% of Mg, 0.8-1.2% of Mn, 0.20-0.30% of Cu, 0.25-0.60% of Fe, 0.20-0.40% of Si, 0.01-0.03% of Ni, 0.03-0.05% of Zn, 0.01-0.03% of Re, and the balance Al and inevitable impurities. The aluminum alloy board is obtained by conducting homogenization, hot rough rolling and hot finish rolling on an aluminum alloy cast ingot. The protection coating is formed by smearing epoxy resin paint onto the surface of the aluminum alloy board uniformly. The thickness of the coating is 3-5 micrometers.

Owner:天津国科医疗科技发展有限公司

High-performance strong glue

InactiveCN106634638AGood storage stabilityHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPropolisPolyvinyl alcohol

The invention discloses high-performance strong glue. The high-performance strong glue is prepared from the following components: modified cassava starch, polyvinyl alcohol, vinyl acetate, nano-diatomite, a yam and wolfberry mixed extracting solution, lauryl methacrylate, sodium lignosulfonate, butyl acrylate, propolis and lanolin. The high-performance strong glue is environment-friendly and has excellent comprehensive performance; the high-performance strong glue can generate very low stress to a contact object during cold-hot impact cycle at -12 to 180 DEG C after being cured, and can still resist destructive power above 60N after being subjected to 200 cold-hot impact cycles at -12 to 180 DEG C; and water resistance and heat resistance are excellent, fast bonding is realized, the falling is avoided, and the cementing strength is high.

Owner:QUANJIAO XIANGRUI PLASTIC

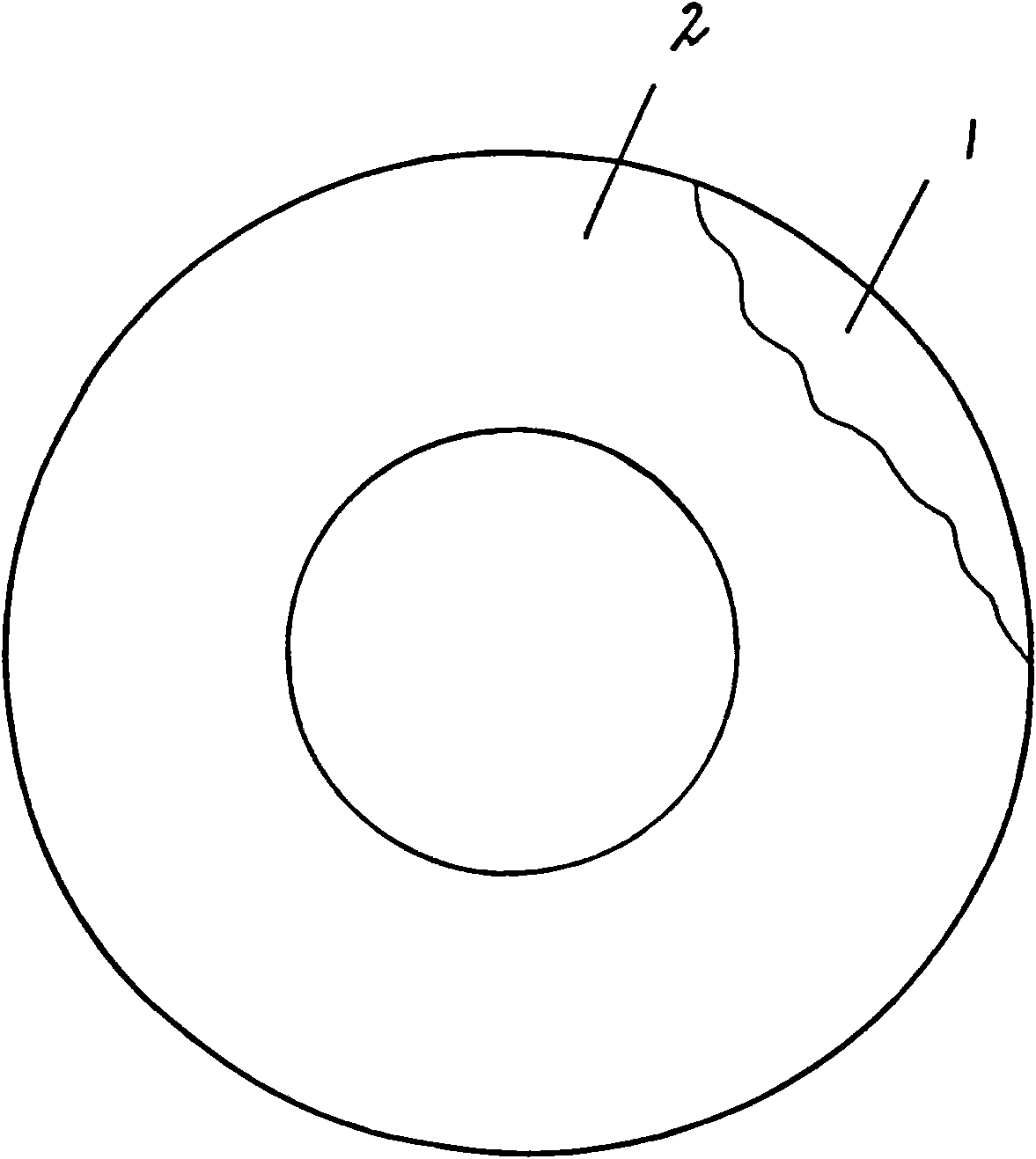

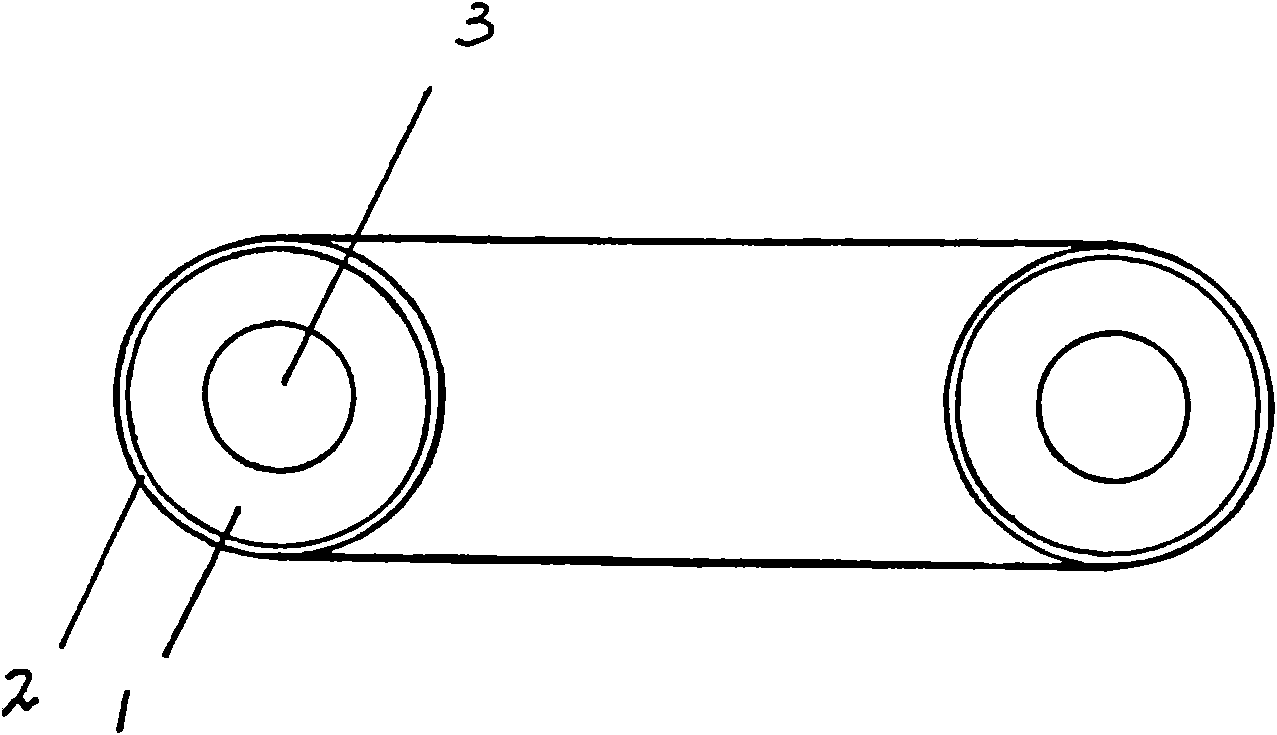

Rubber-polytetrafluoroethylene compounded sealing ring

The invention relates to a rubber-polytetrafluoroethylene compounded sealing ring which comprises a ring-shaped body, wherein the ring-shaped body is a silicon rubber ring-shaped body or a fluororubber ring-shaped body. The sealing ring is characterized in that a polytetrafluoroethylene felt pad is wrapped outside the ring-shaped body. The compounded sealing ring can be used for comprehensively improving the mechanical property and the chemical stability of a rubber sealing ring as well as the wear resistance and the medium corrosion resistance of a compounded sealing ring, enhancing the corrosion resistance, the adhesion resistance and the sealing rebound resilience of rubber, increasing the oil resistivity on the surface of the rubber, obviously improving the high-temperature and low-temperature resistance of the surface of the rubber, obviously reducing the friction consumption, keeping the physical mechanical property of the rubber unchanged and also improving the strength and the hardness of the rubber. In addition, the invention also ensures that the using range of the rubber sealing ring is further expanded, and moreover, the service life of the rubber sealing ring coated with the polytetrafluoroethylene felt pad is obviously prolonged by 5-6 times. The rubber-polytetrafluoroethylene compounded sealing ring is suitable for equipment of pipeline systems in the chemical industry, and the like.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

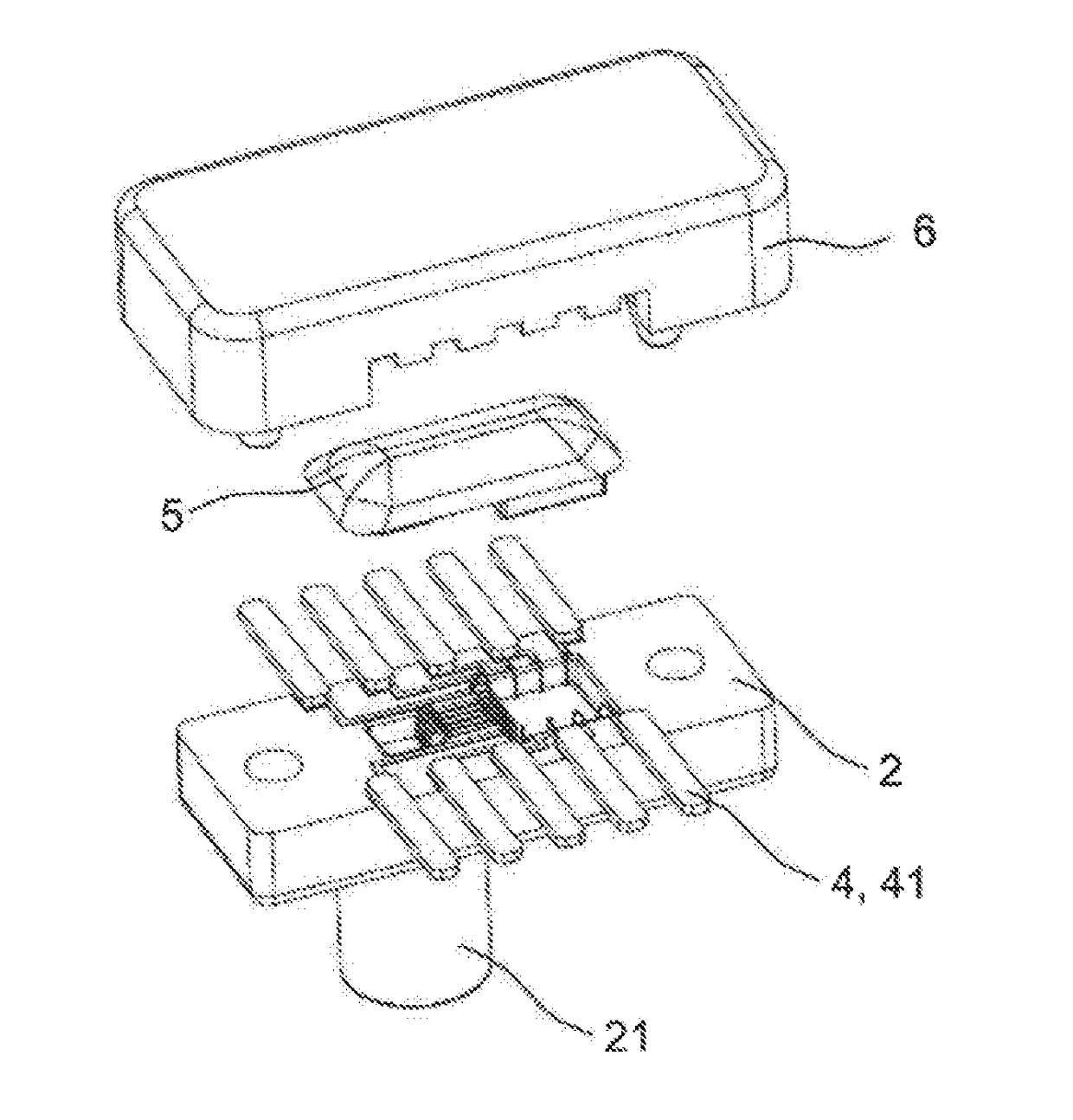

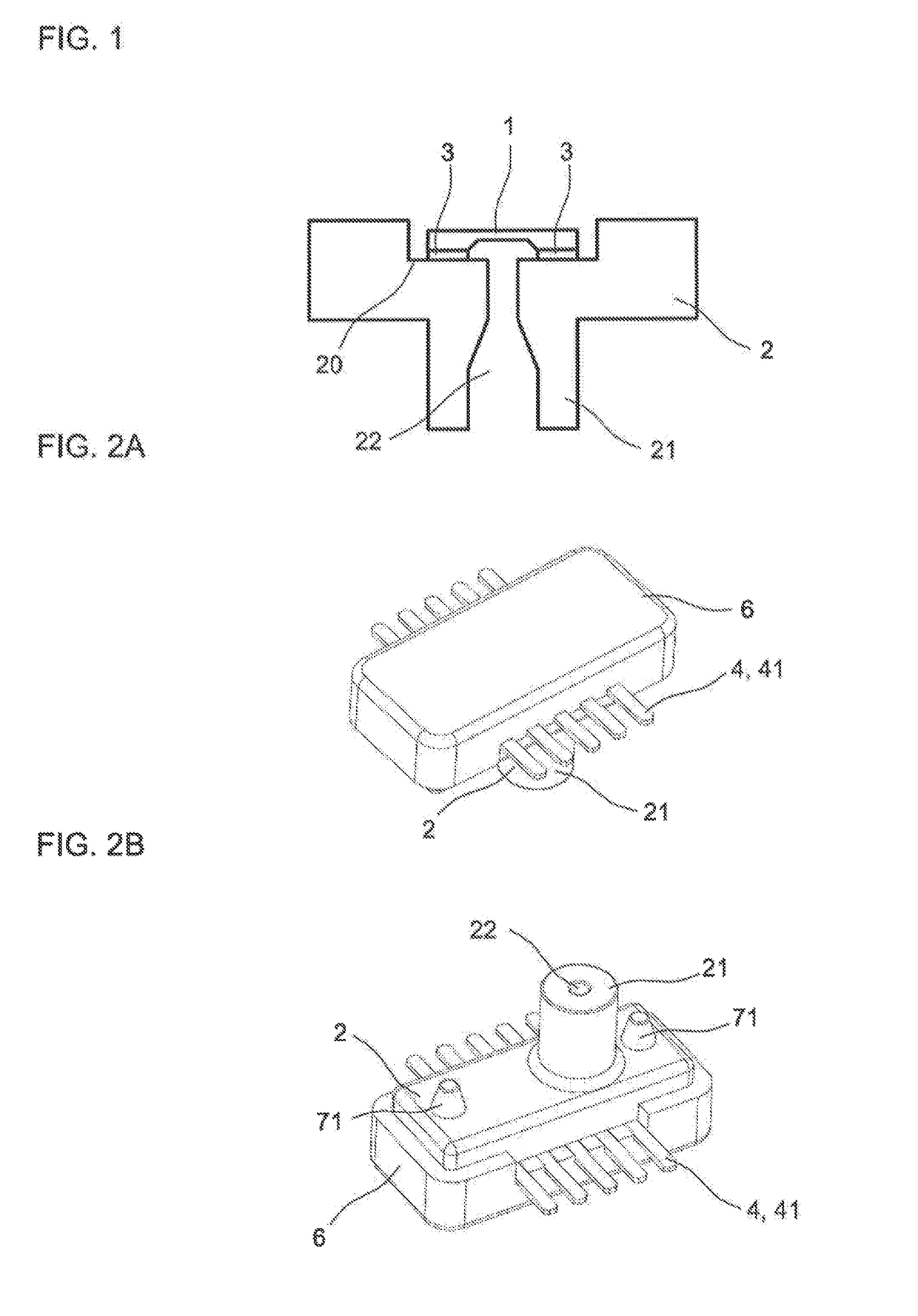

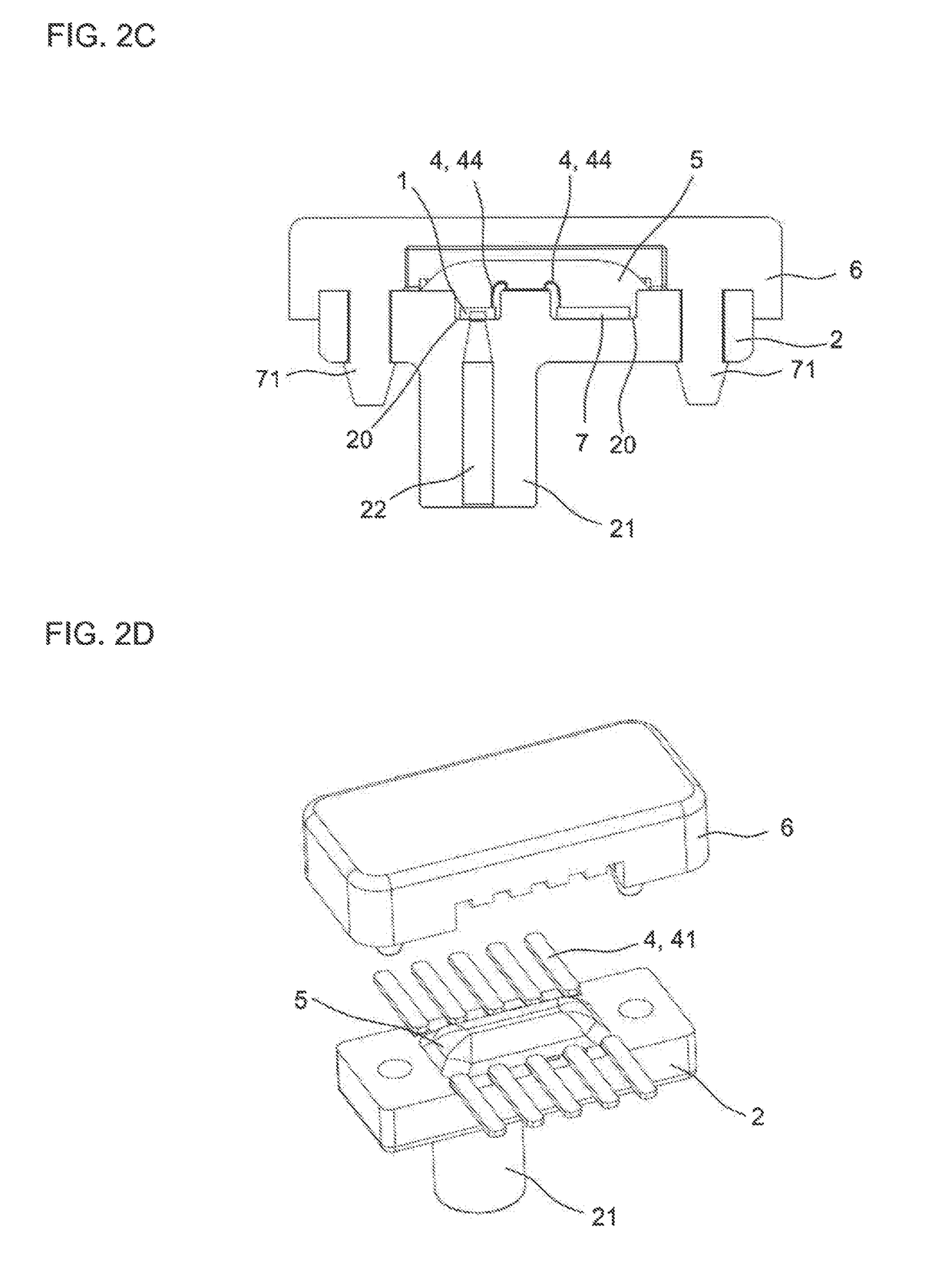

Pressure Sensor System

ActiveUS20170089796A1Improve media resistanceHigh mechanical strengthSolid-state devicesFluid pressure measurementThermal expansionEngineering

A pressure sensor system having a pressure sensor chip is specified. The pressure sensor chip is mounted on a mounting receptacle of a ceramic housing body having a pressure feed guided to the pressure sensor chip. The housing body is three-dimensionally shaped and monolithically formed and is formed by a ceramic material having a coefficient of thermal expansion which deviates by less than 30% from the coefficient of thermal expansion of the pressure sensor chip in a temperature range of greater than or equal to −40° C. and less than or equal to 150° C.

Owner:EPCOS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com