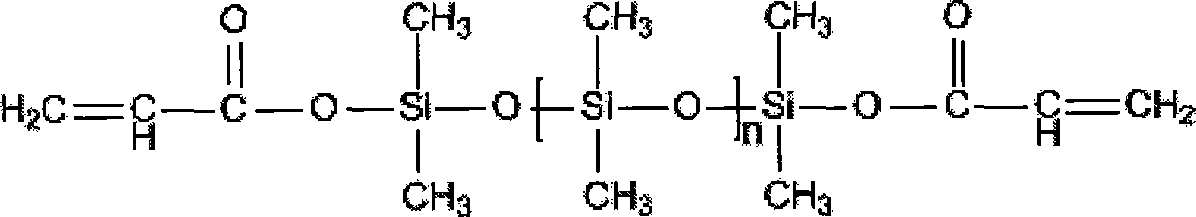

Method for preparing fluorine-silica rubber artificial tooth soft lining material

A technology of fluorosilicone rubber and soft lining, applied in dental preparations, pharmaceutical formulas, dental prostheses, etc., can solve the problems of lagging development of soft lining materials, products with excellent comprehensive performance, etc., achieve easy availability of raw materials and low price, and reduce water absorption , Reasonable effect of preparation line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Acrylic mixed monomer modified silicone rubber:

[0036] Mix 100ml of toluene and vinyl acetate 1:1 mixed solvent with 100ml of hydroxy silicone oil, then put 28ml of butyl acrylate, 8ml of methyl methacrylate, 2ml of methacrylic acid, and 2ml of β-hydroxypropyl acrylate into the dropping funnel Mix evenly in the medium, and put it on a three-neck flask equipped with an electric stirrer, a condenser, and a thermometer, heat it in a water bath, and feed it with N 2 Protection; when the temperature of the mixed solution reaches 70°C, add 1g of refined azobisisobutyronitrile and 1g of p-toluenesulfonic acid, start to add acrylic mixed monomers dropwise, and the polymerization reaction is carried out at about 70°C; acrylic mixed monomers After the dropwise addition is complete, add 100ml of toluene and vinyl acetate 1:1 mixed solvent, add dropwise and react for 3 hours to obtain the modified silicone oil.

[0037] 2. Co-vulcanization of fluorosilicone rubber and modifie...

Embodiment 2

[0043] 1. Acrylic mixed monomer modified silicone rubber:

[0044]Mix 150ml of xylene and butyl acetate 1:1 mixed solvent with 100ml of hydroxy silicone oil, then put 28ml of butyl acrylate, 8ml of methyl methacrylate, 2ml of methacrylic acid, and 2ml of β-hydroxypropyl acrylate into the drop Mix evenly in the funnel, and put it on the three-necked flask equipped with electric stirrer, condenser, and thermometer, heat it in a water bath, and feed it with N 2 protection; when the temperature of the mixed solution reaches 50°C, add 2g of refined azobisisobutyronitrile, start to add the acrylic mixed monomer dropwise, and the polymerization reaction is carried out at about 50°C; Add 150ml of toluene and vinyl acetate 1:1 mixed solvent, add dropwise and react for 5h to obtain modified silicone oil.

[0045] 2. Co-vulcanization of fluorosilicone rubber and modified silicone rubber:

[0046] Add 5ml of modified silicone oil to 100ml of unmodified hydroxysilicone oil, add 10ml of m...

Embodiment 3

[0051] 1. Acrylic mixed monomer modified silicone rubber:

[0052] Mix 100ml of toluene and butyl acetate 1:1 mixed solvent with 100ml of hydroxy silicone oil, then put 20ml of butyl acrylate, 6ml of methyl methacrylate, 4ml of methacrylic acid, and 4ml of β-hydroxypropyl acrylate into the dropping funnel Mix evenly in the medium, and put it on a three-neck flask equipped with an electric stirrer, a condenser, and a thermometer, heat it in a water bath, and feed it with N 2 Protection; when the temperature of the mixed solution reaches 60°C, add 1g of refined azobisisobutyronitrile and 1g of p-toluenesulfonic acid, start to add dropwise acrylic mixed monomer, and the polymerization reaction is carried out at about 60°C; acrylic mixed monomer After the dropwise addition is complete, add 100ml of toluene and butyl acetate 1:1 mixed solvent, add dropwise and react for 2 hours to obtain the modified silicone oil.

[0053] 2. Co-vulcanization of fluorosilicone rubber and modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com