Patents

Literature

400results about How to "Low dissolution rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

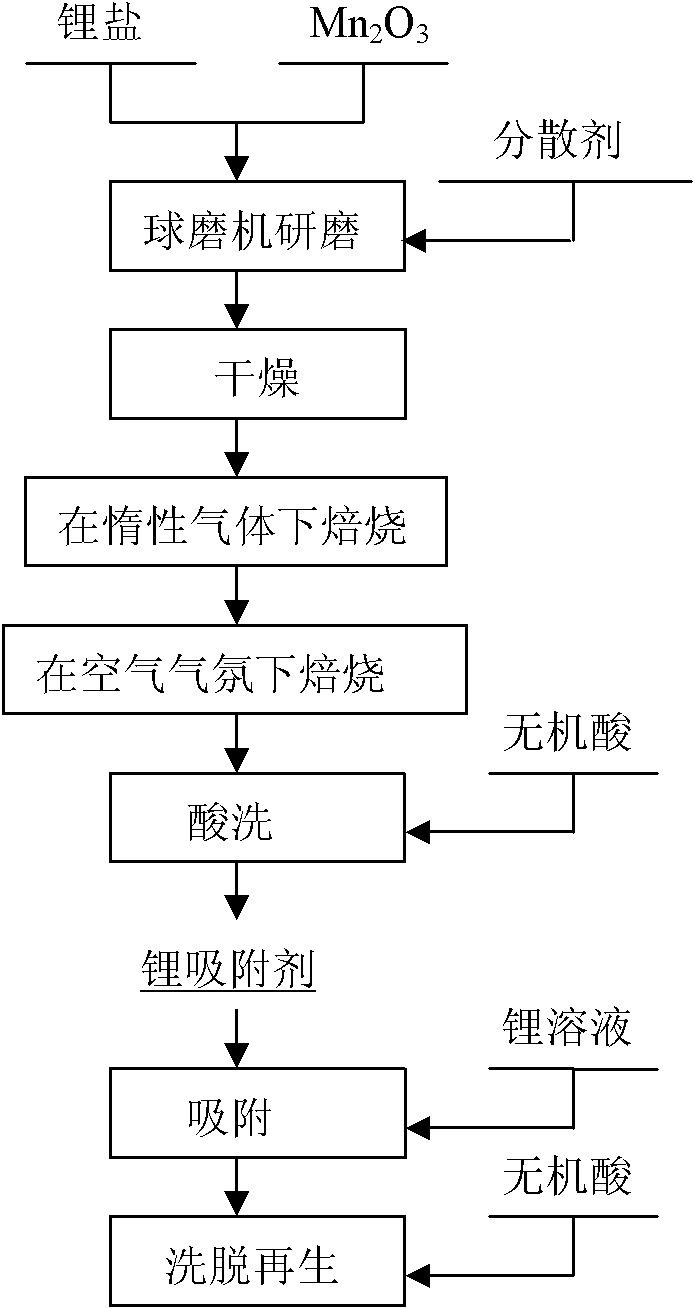

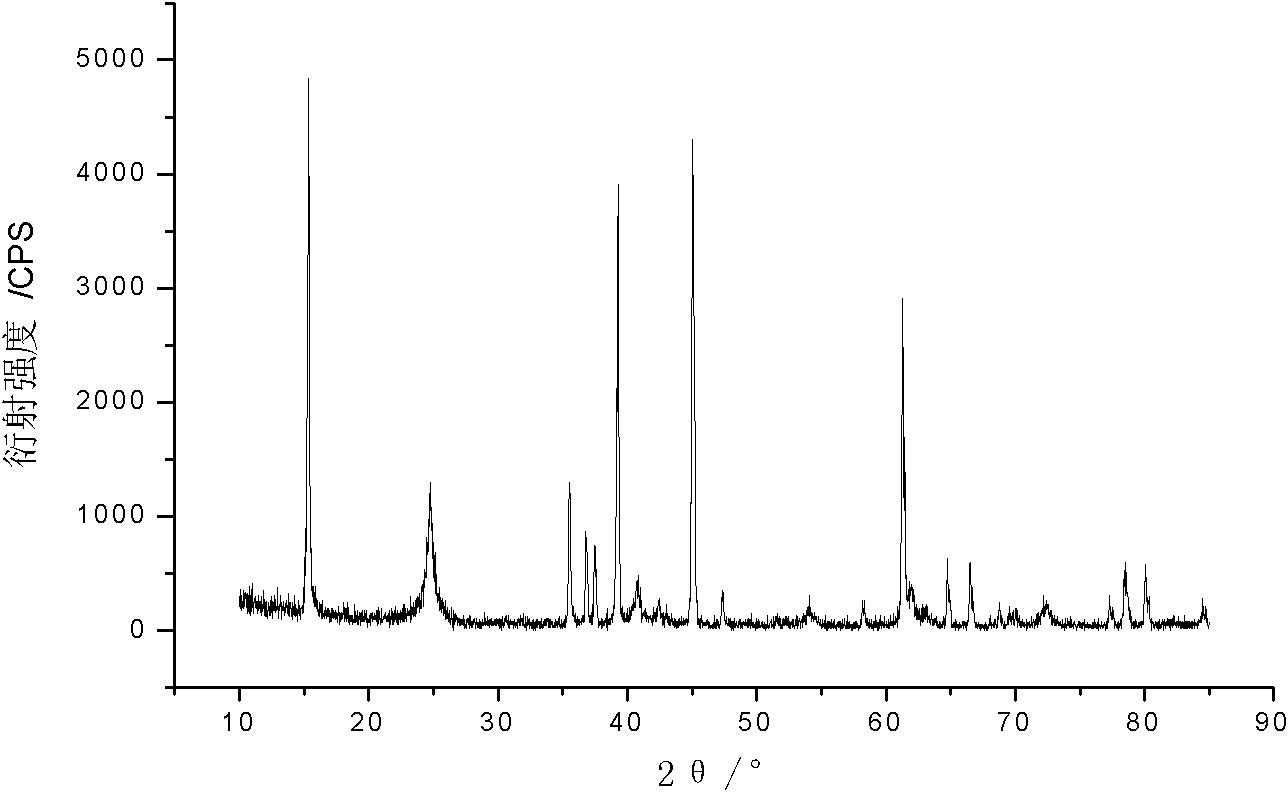

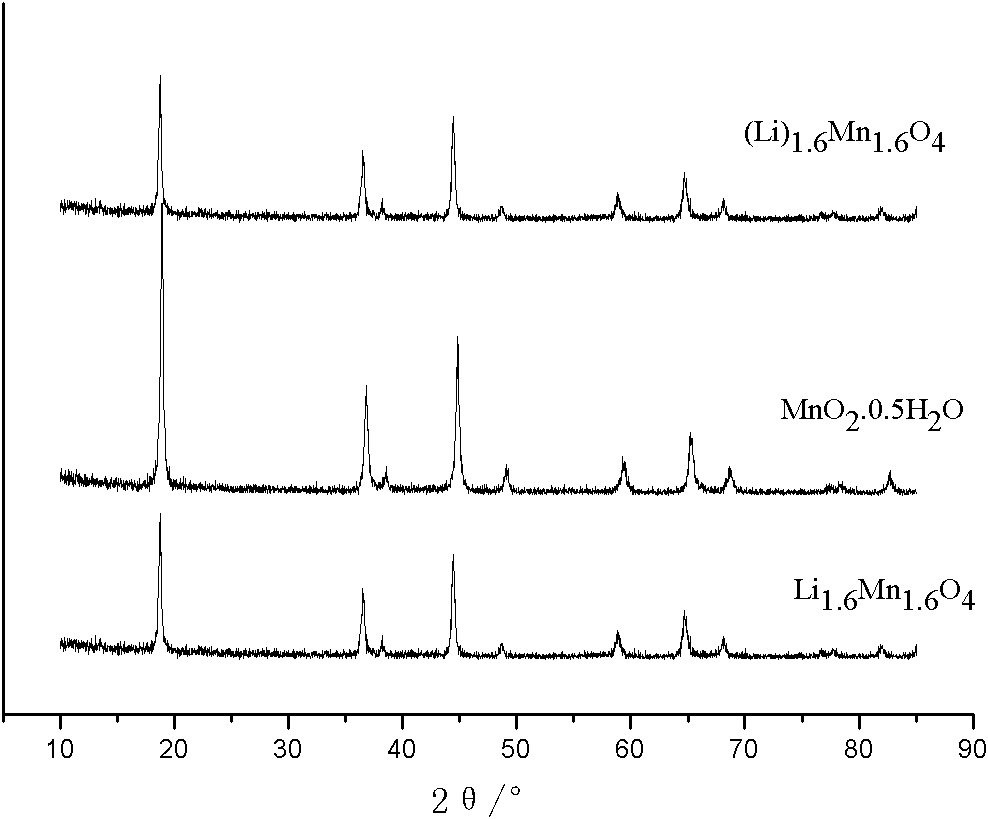

Manganese series lithium ion sieve adsorbent and preparation method of precursor thereof

ActiveCN101961634ALow priceThe ratio is easy to controlOther chemical processesManganese oxides/hydroxidesSorbentManganese

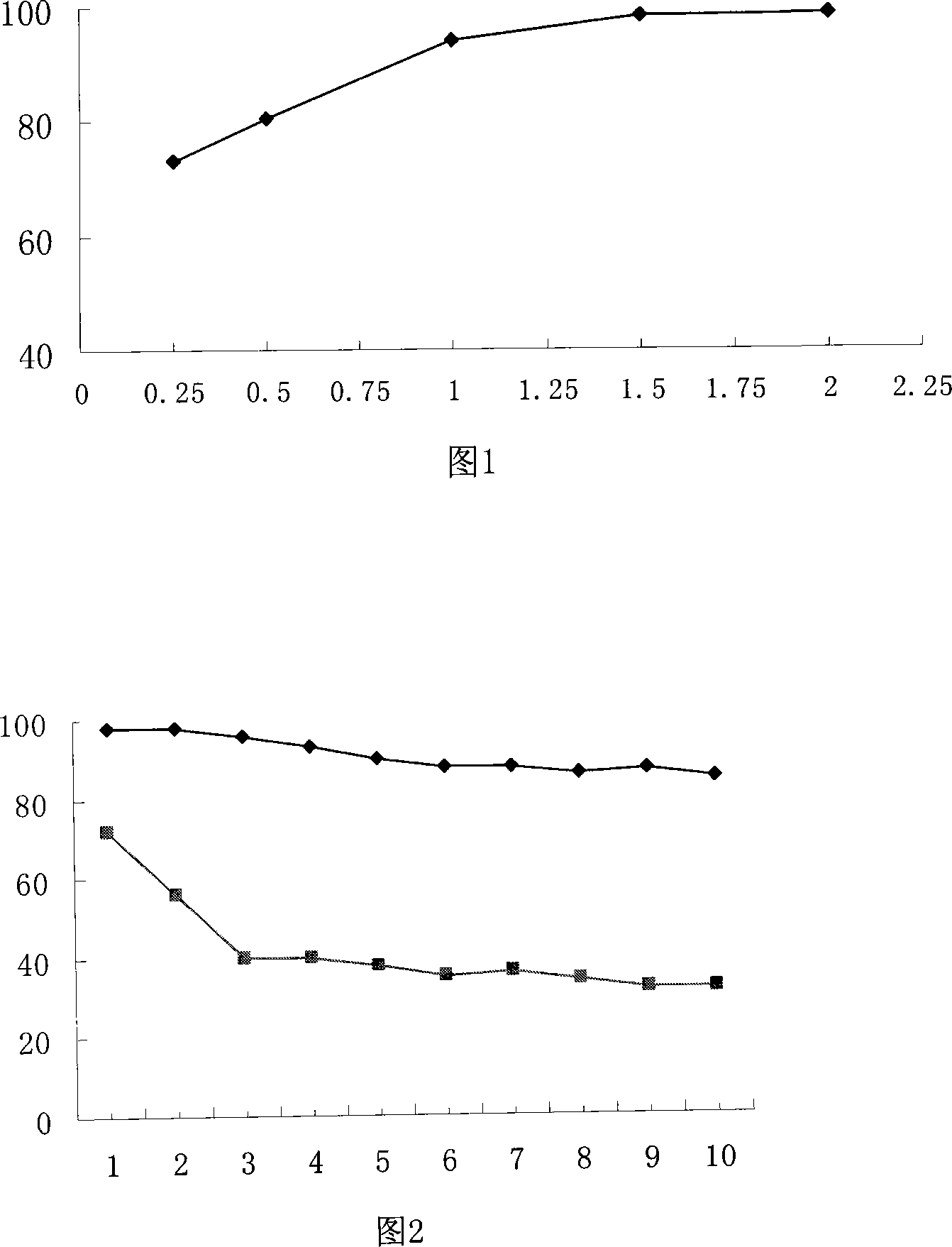

The invention discloses a method for preparing a manganese series lithium ion sieve adsorbent, and relates to a method for preparing an inorganic adsorbent for adsorbing lithium from liquid lithium resources such as brine of salt lake, seawater and the like. In the method, a cubic crystal ion sieve precursor Li1.6Mn1.6O4 is prepared from Mn2O3 and LiOH or Li2CO3 serving as raw materials by using two sections of solid-phase reactions, wherein the precursor also can be used as an anode material of a lithium ion battery. The precursor is acidized to obtain a lithium ion sieve adsorbent MnO2.0.5H2O (or expressed as H1.6Mn1.6O4), and the ion sieve is the lithium adsorbent which has high selectivity on lithium. The method has the advantages of simple and readily available raw materials, simple process, high adsorption capacity of the ion sieve, low cost, high purity of products and is easy to realize industrial production.

Owner:CENT SOUTH UNIV +1

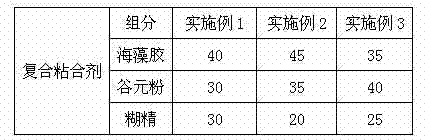

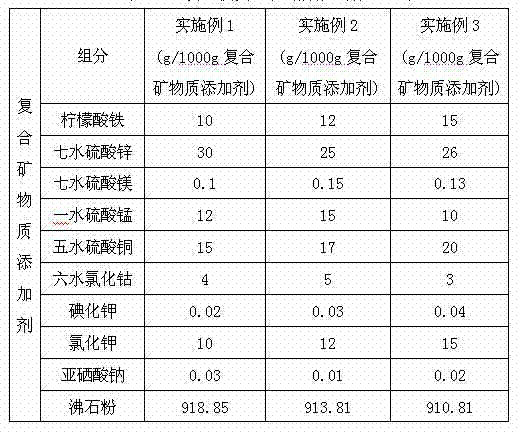

Compound feed for Scylla serrata and preparation method of same

ActiveCN102687810ALow costNutritional balanceAnimal feeding stuffBacillus licheniformisAnimal science

The invention discloses a compound feed for Scylla serrata, comprising fish meal, shrimp head powder, soybean meal, rapeseed meal, fish oil, soybean phosphatide powder, brewers yeast, choline chloride, molt hormone, bread flour, calcium dihydrogen phosphate, sodium dehydroacetate, butyl hydroxy anisole, astaxanthin, Schizochytrium limacinum, Bacillus licheniformis, a composite feeding promoting agent, a complex vitamin additive, a composite mineral matter additive and a composite adhesive. The feed has balanced nutrition, is resistant to spoilage, has a long storage life, not only reduces feed cost but also promotes the growth and improves the color of the Scylla serrate. In addition, the feed is friendly to environment, has good palatability and feed promoting effect, has high utilization efficiency and good stability in water, and can enhance the immunity and survival rate of scylla serrata. The invention also provides a preparation method for the compound feed for scylla serrata, which is simple in technology, with the function substance in raw material undestroyed in the preparation process.

Owner:ZHEJIANG MARINE DEV RES INST

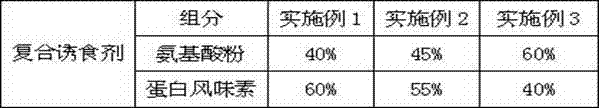

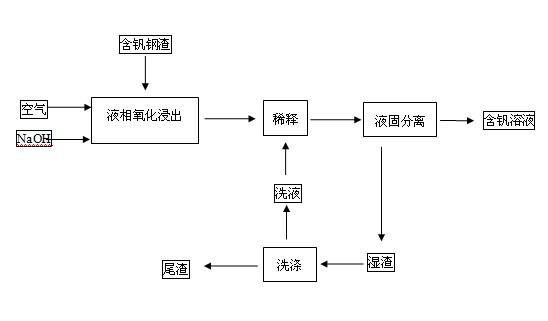

Method for extracting vanadium from vanadium-containing steel slag by using highly-alkaline sodium hydroxide medium

ActiveCN102094123AReduce productionEmission reductionProcess efficiency improvementSlagEconomic benefits

The invention relates to a method for extracting vanadium from vanadium-containing steel slag by using a highly-alkaline sodium hydroxide medium, belonging to the technical field of metallurgy. The technical scheme comprises the following steps: adding steel slag, water and NaOH into a reactor together, wherein the mass concentration of the NaOH solution is 65-90%; decomposing and leaching under atmospheric pressure, and diluting the obtained slurry with a diluter to obtain a slurry mixture; and separating the slurry mixture by filtering at constant temperature, and washing the slag with a washing solution to obtain tailings and a vanadium-containing water solution. The method provided by the invention can be implemented under atmospheric pressure at low temperature (greatly lower than the roasting temperature in the traditional pyrogenic process), and is easy to operate and safe; and the extraction rate of vanadium is greatly higher than that of the existing vanadium recovery technique based on the pyrogenic process and wet process, the one-time recovery rate of vanadium is 85-90%, and the total content of vanadium in the tailings is 0.3-0.6 wt%. The invention solves the problem that vanadium in the vanadium-containing steel slag can not be easily recovered, and has the advantages of high recovery rate of vanadium, low production cost, favorable economic benefit and environmental benefit, and the like.

Owner:承德承钢柱宇钒钛有限公司

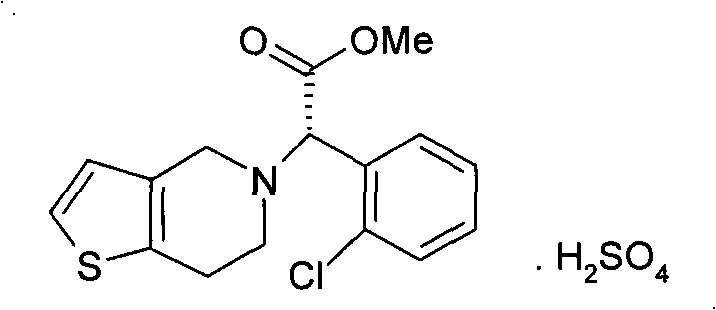

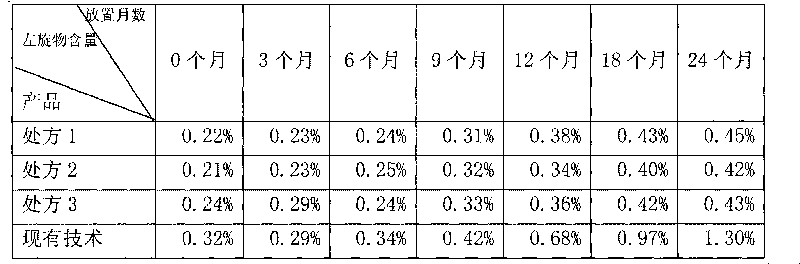

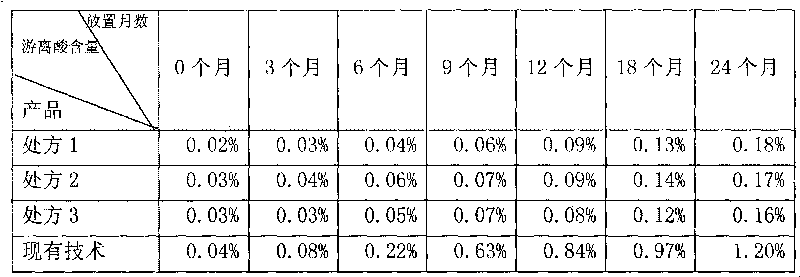

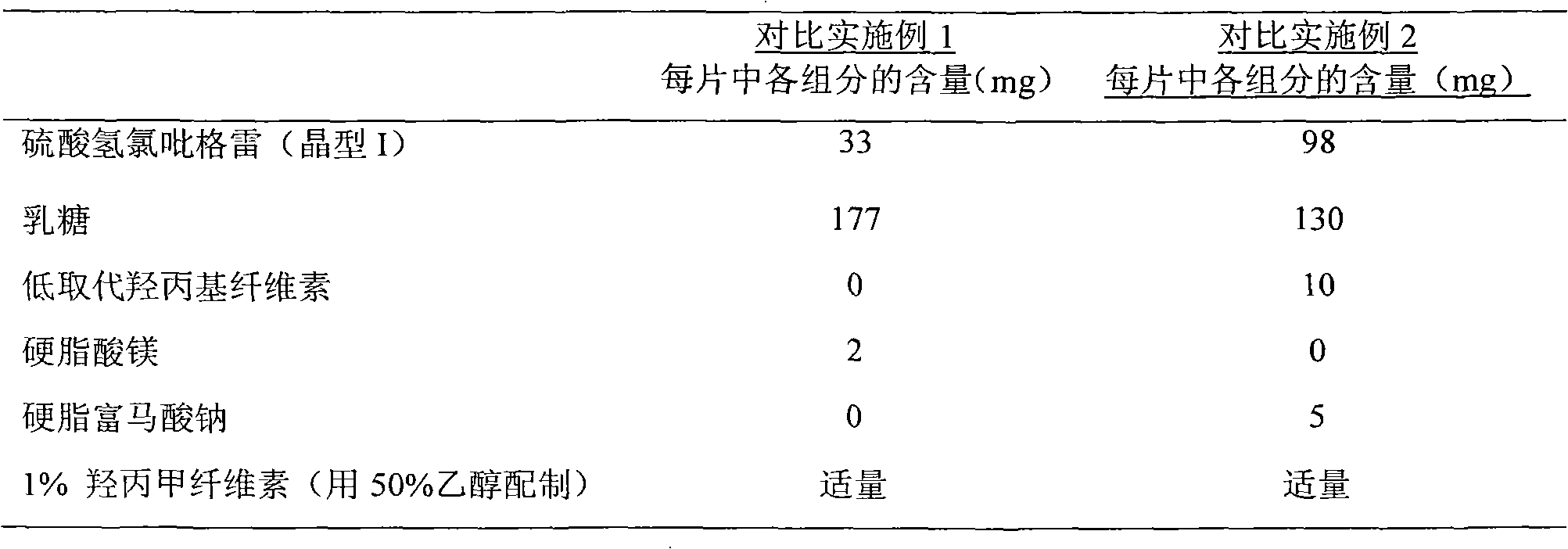

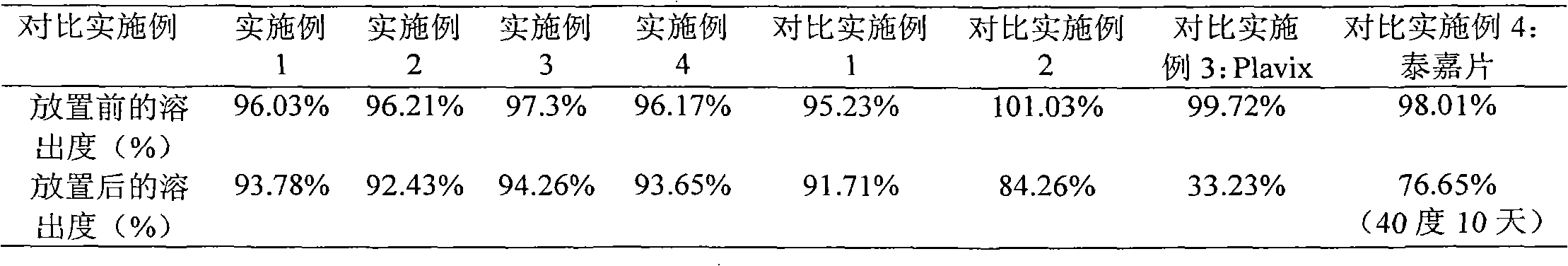

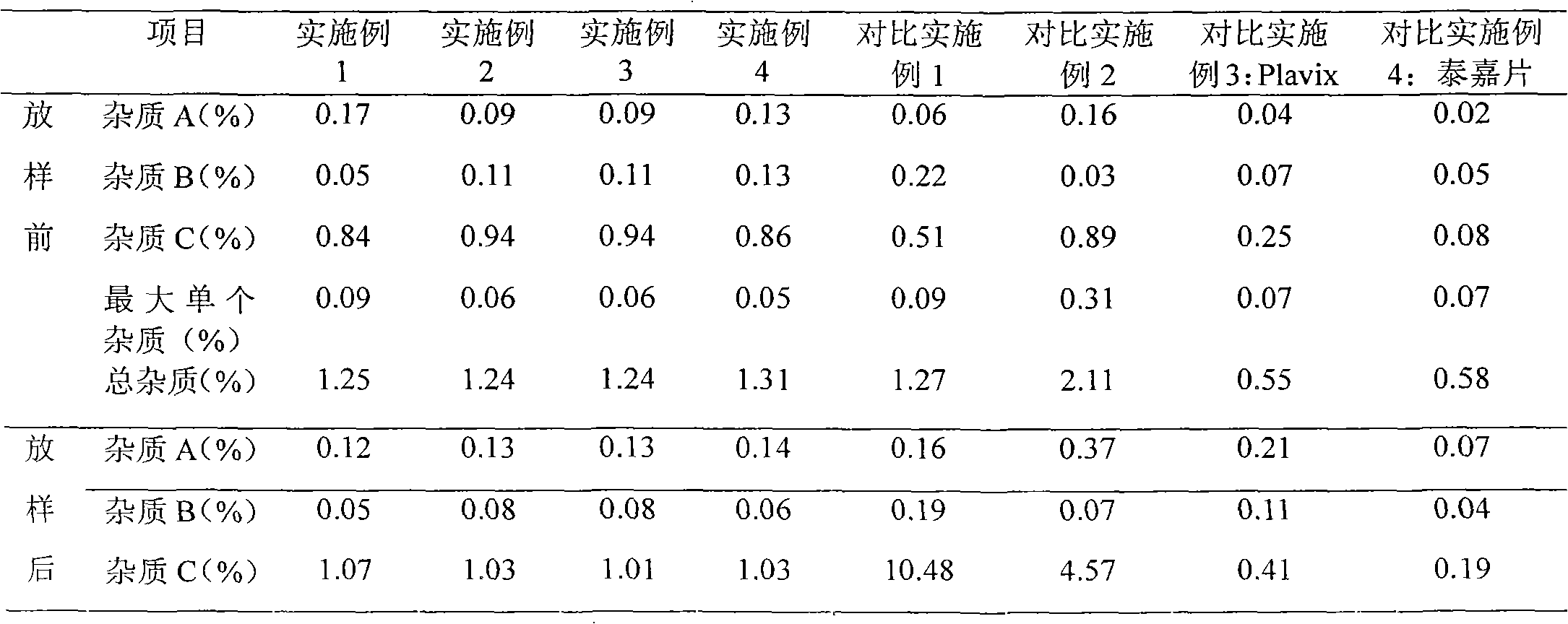

Bisulfate clopidogrel solid preparation, particles and preparation method thereof

InactiveCN101690719AGood stabilityImprove stabilityPowder deliveryOrganic active ingredientsCross-linked polyethylenePharmaceutical preservatives

The invention relates to a bisulfate clopidogrel solid preparation, particles and a preparation method thereof. Particles contained by the solid preparation are solid mixture formed from bisulfate clopidogrel, cellulose excipients and molten adhesive with the melting point between 50 and 86 DEG, and an additionally added excipient of the particles contains weak alkaline lubricants and crosslinked polyvinylpyrrolidone. The solid preparation and the particles thereof are prepared by a melting-granulating method. The solid preparation has the advantages of solving sticking-picking problems existing in the preparation process, effectively reducing the degradation of clopidogrel during storage, reducing the incidence of transforming clopidogrel dextroisomer into clopidogrel levisomer and increasing the stability and security of the solid preparation.

Owner:SHENZHEN SALUBRIS PHARMA

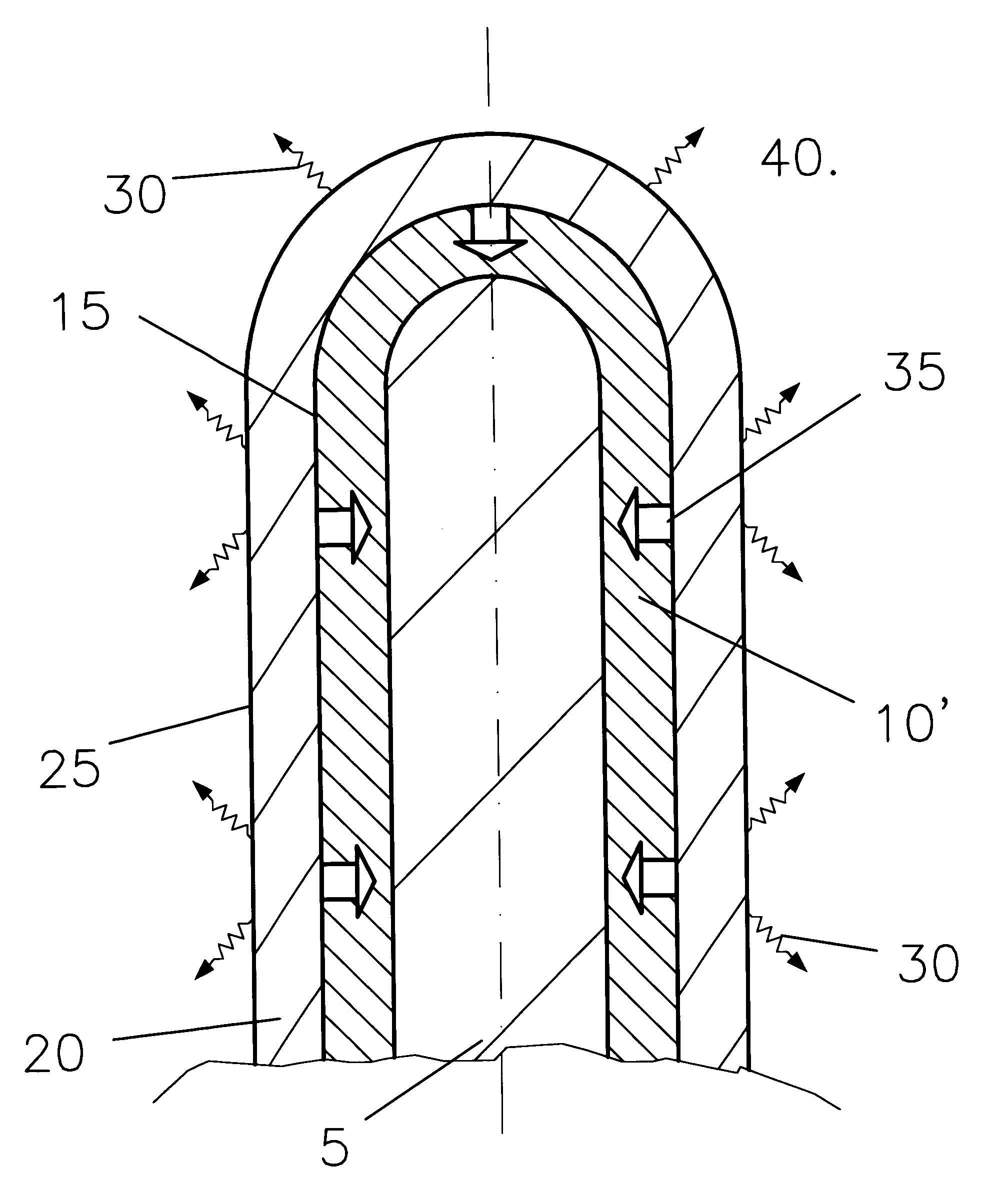

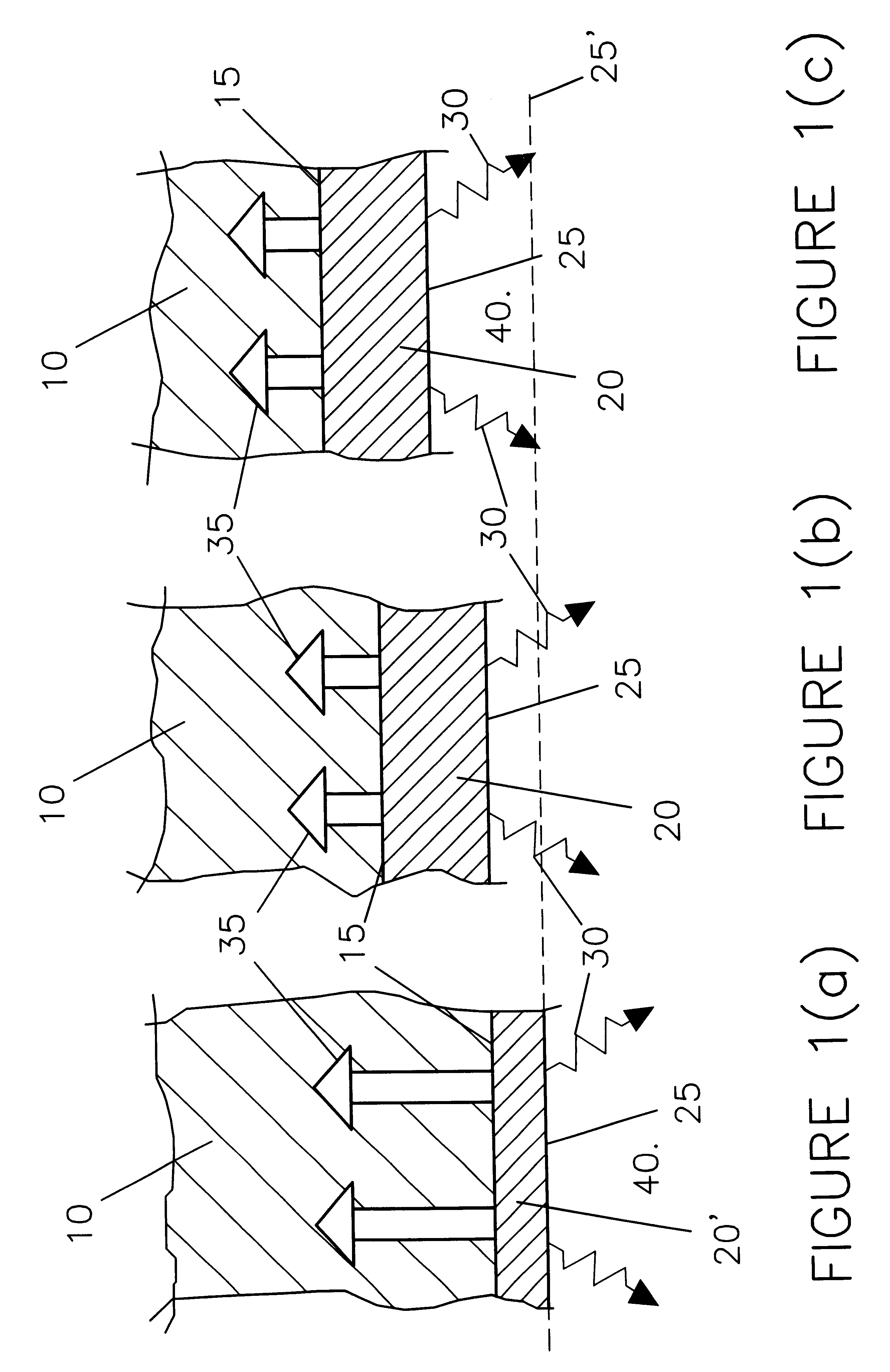

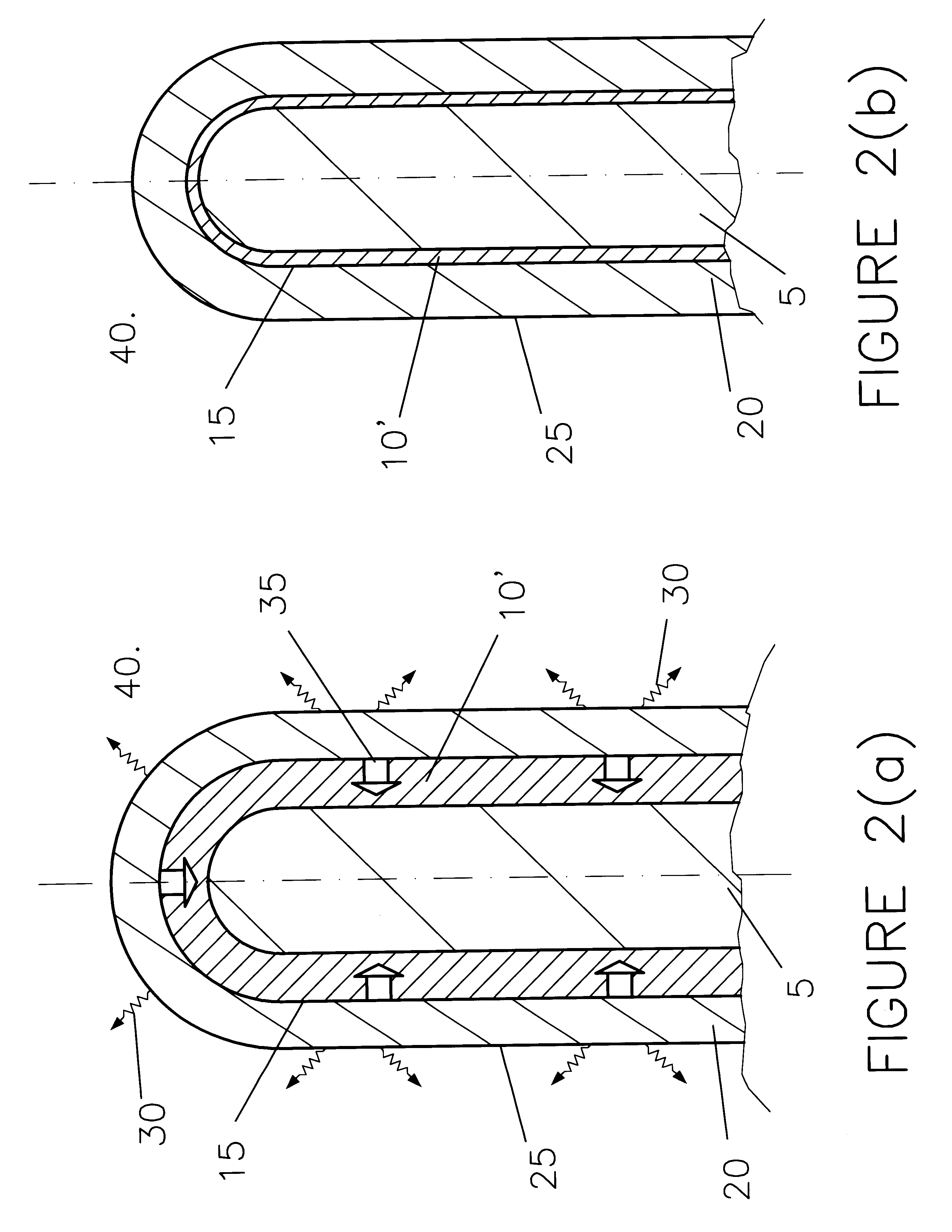

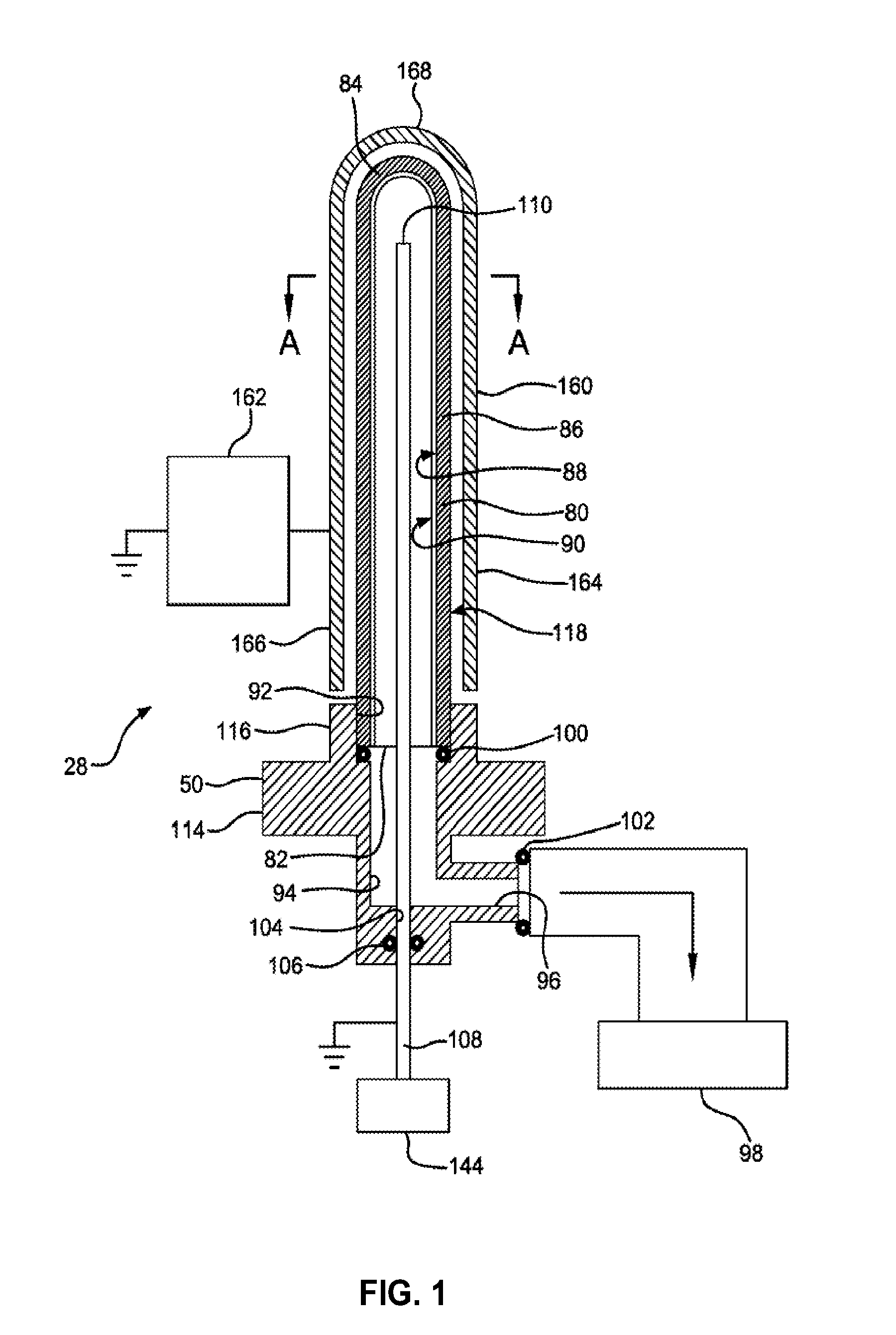

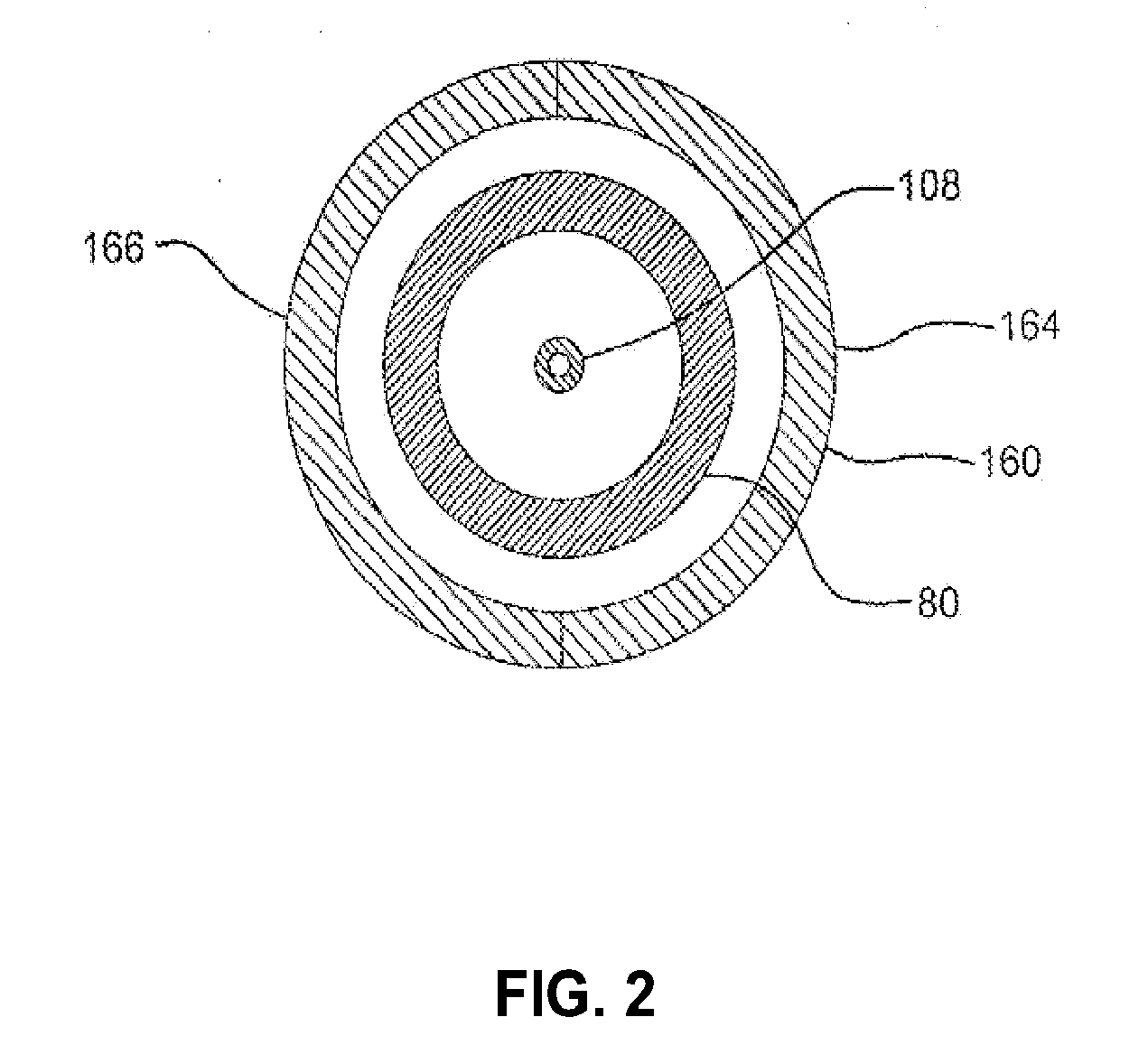

Slow consumable non-carbon metal-based anodes for aluminium production cells

InactiveUS6248227B1Eliminate carbon-generated pollutionReduce frequencyMachining electrodesIsotope separationElectrolysisAlloy

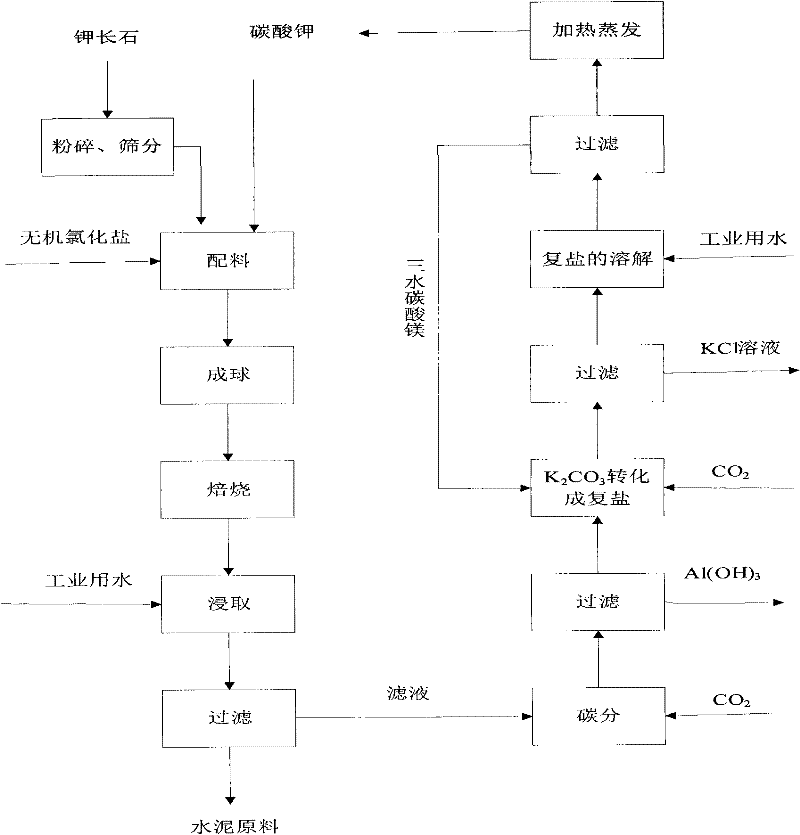

A non-carbon, metal-based slow-consumable anode of a cell for the electrowinning of aluminium self-forms during normal electrolysis an electrochemically-active oxide-based surface layer (20). The rate of formation (35) of the layer (20) is substantially equal to its rate of dissolution (30) at the surface layer / electrolyte interface (25) thereby maintaining its thickness substantially constant, forming a limited barrier controlling the oxidation rate (35). The anode (10) usually comprises an alloy of iron with at least one of nickel, copper, cobalt or zinc which during use forms an oxide surface layer (20) mainly containing ferrite.

Owner:MOLTECH INVENT

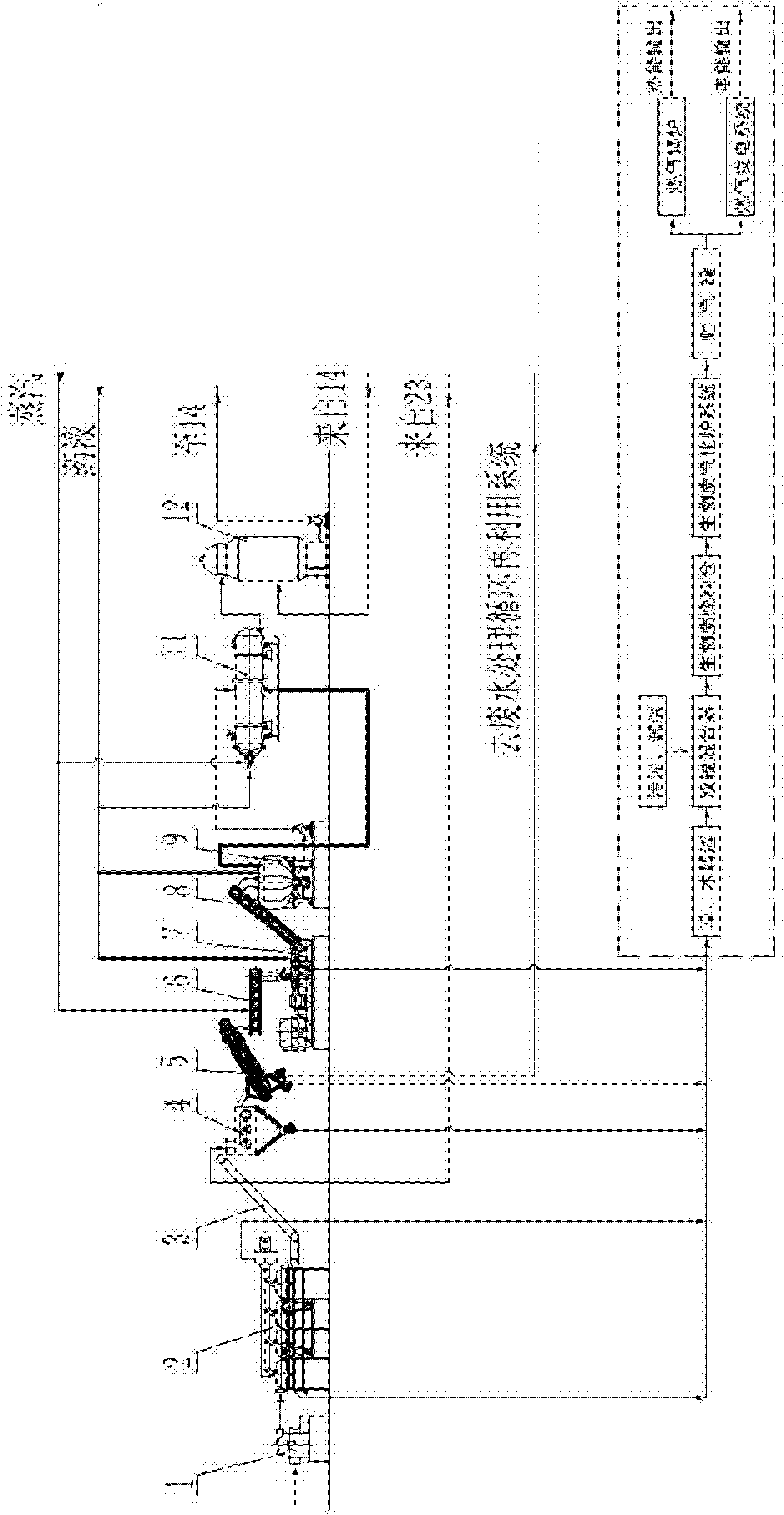

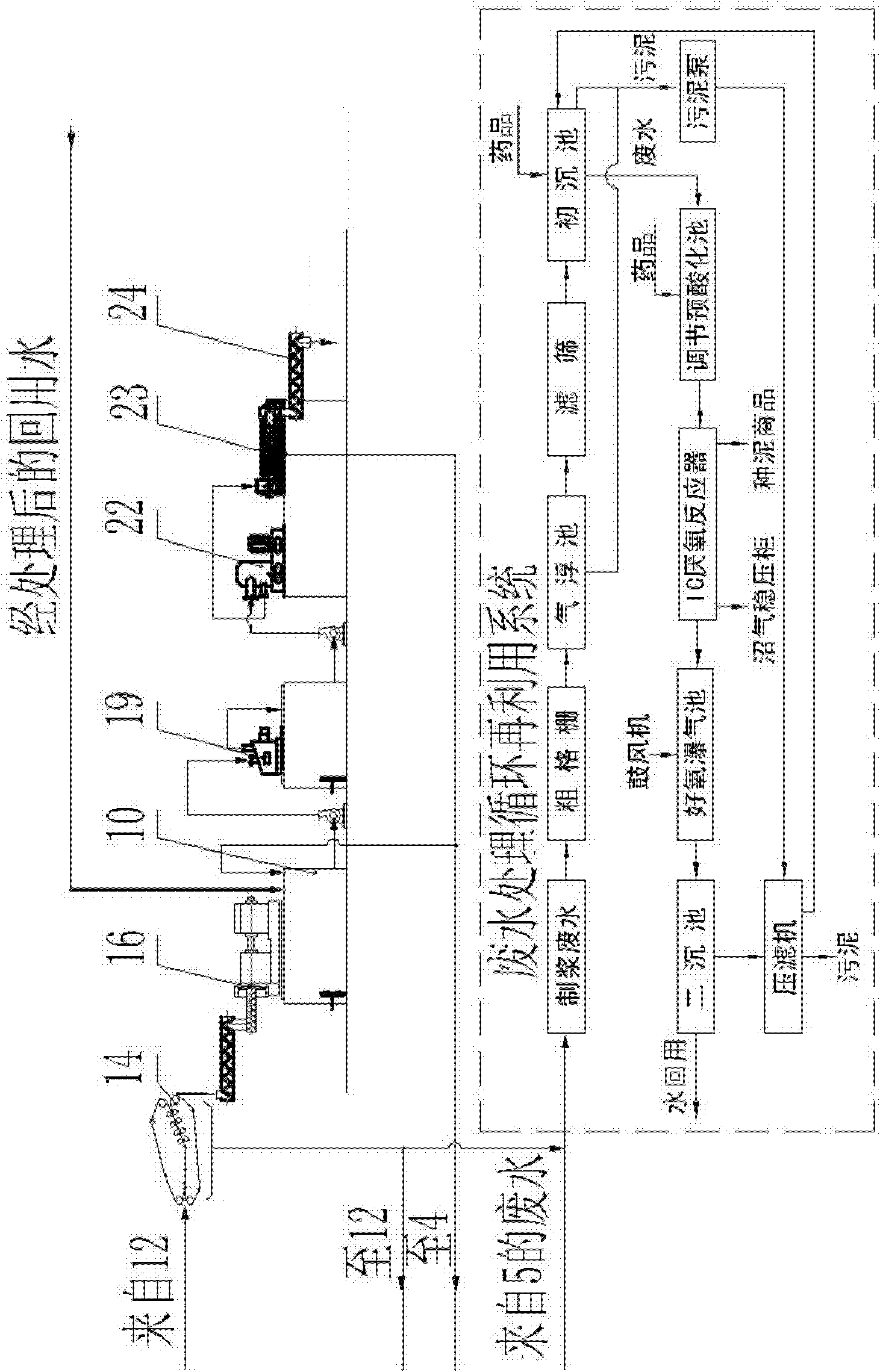

Environmentally-friendly paper making and pulping technique and system with high yield

InactiveCN102242512AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsFiberBlack liquor

The application of the invention provides an environmentally-friendly paper making and pulping technique with high yield, which comprises a raw material preprocessing stage, a physical fibrillation impregnating processing stage, an impregnating, steaming and bleaching three-section integrated pulping stage and a thickening and dewatering processing stage. An environmentally-friendly paper making and pulping system with high yield realizing the pulping technique comprises a stock cutter, a hammering and fibrillation screening dust remover, a washing dust remover, dewatering conveying equipment, a spiral steaming conveyor, a crashing, extruding and impregnating machine, a stirring and impregnating cabin, a pump pipe and a discharge pipe of a high-enriched steaming, bleaching and pulping all-in-one machine, wherein the pump pipe is connected to the high-enriched steaming bleaching pulping all-in-one machine; the discharge pipe of the high-enriched steaming, bleaching and pulping all-in-one machine is connected to a pulp cabin; the pump pipe of the pulp cabin is connected with a thickening and dewatering machine; the thickening and dewatering machine is output to the high-enriched pulping machine; the output of the high-enriched pulping machine is connected with a screening purifier and a thickening and squeezing machine in sequence. In the invention, the problems of high pollution, high energy consumption, serious shortage of paper making raw material and the like in present pulping and paper making industry can be solved fundamentally; rich plant fiber in the nature can be used, and the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption can be realized.

Owner:李刚荣 +1

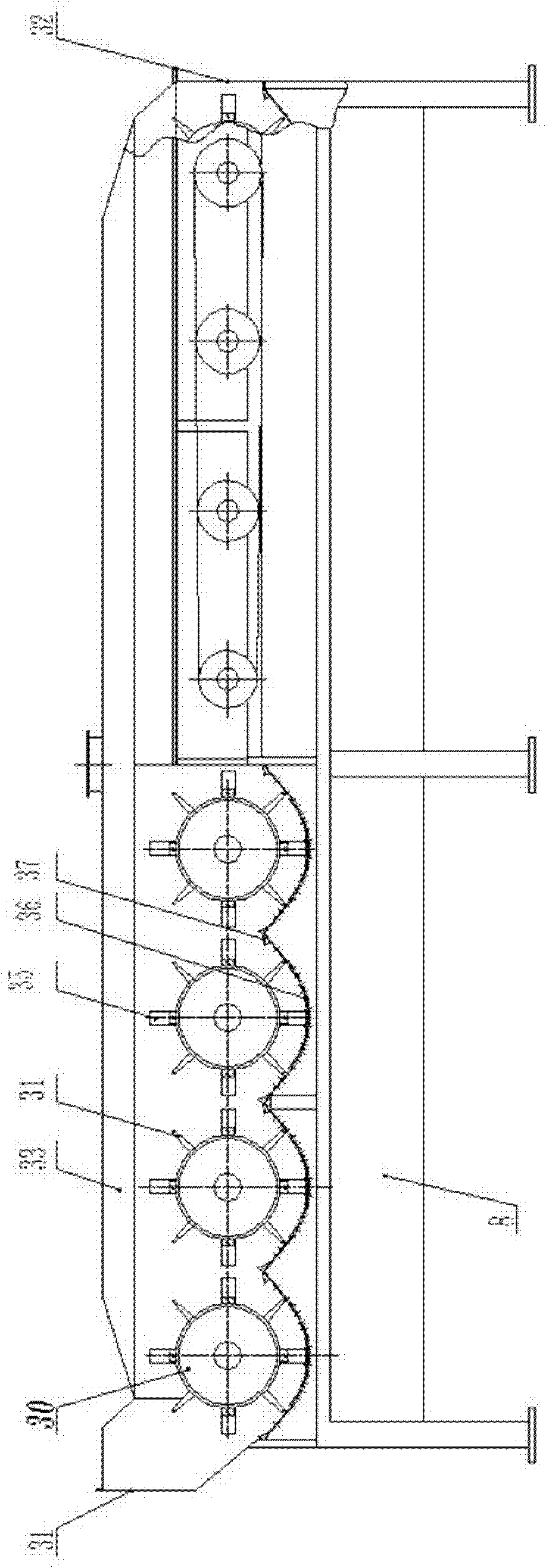

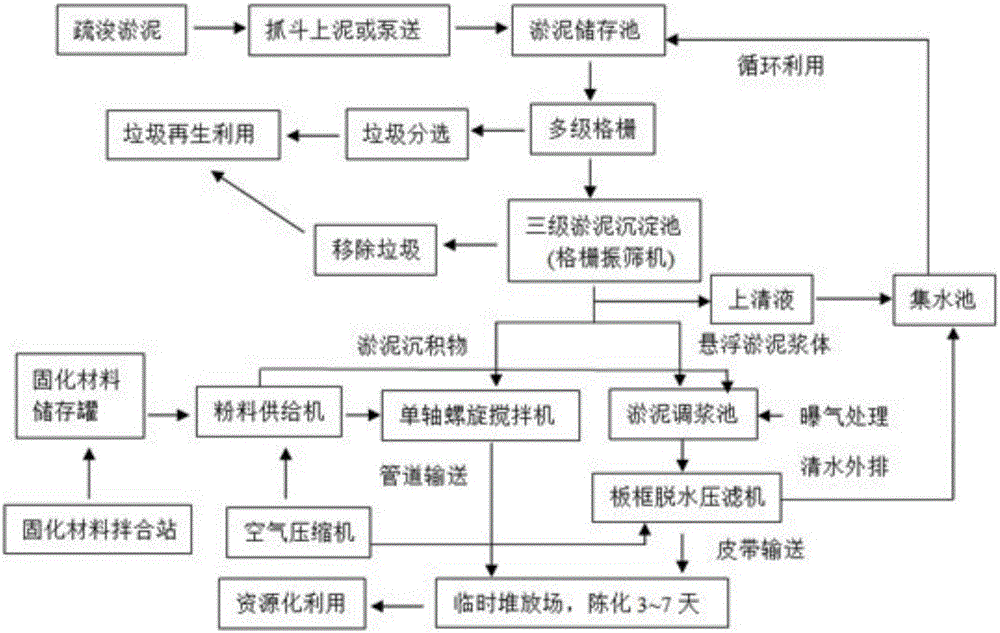

Sludge treatment process

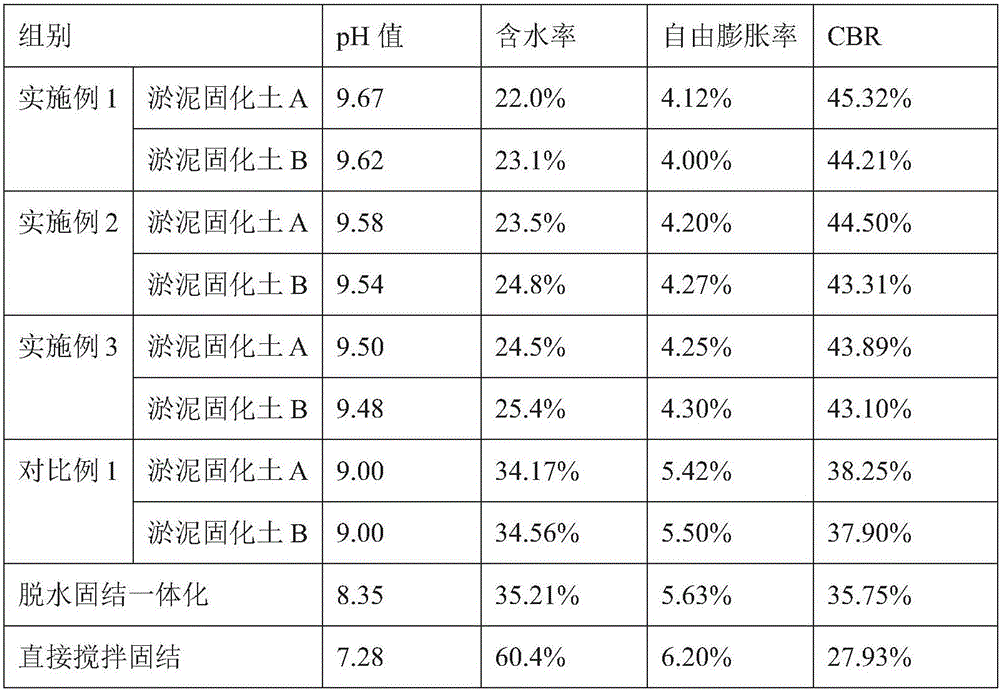

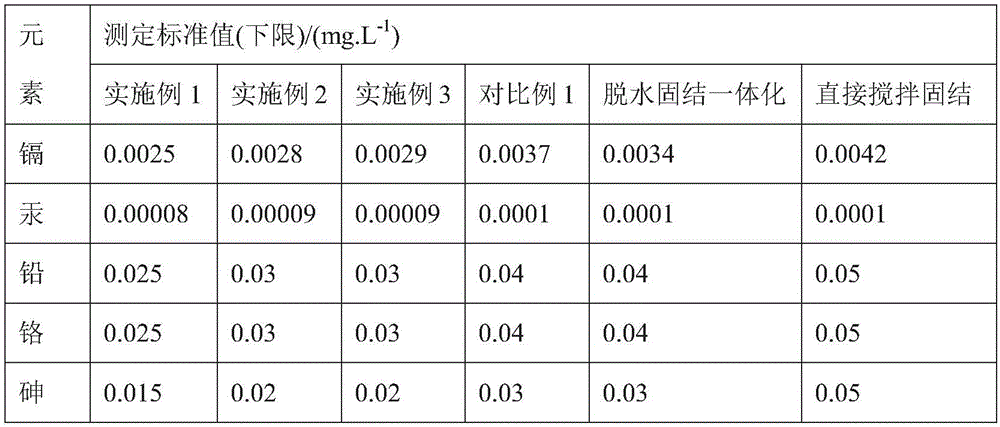

The invention belongs to the field of environmental protection, and in particular relates to a sludge treatment process. The sludge treatment process comprises the following steps: 1) impurity removal: use multi-stage grille to filter out the garbage in the sludge; 2) pretreatment: utilize the three-stage sludge settling tank to pretreat the sludge to obtain the first, second, and The sludge in the three-stage sludge settling tank, the sludge slurry and the supernatant after being settled in the three-stage sludge settling tank; 3) solidification treatment: respectively adopt mixing solidification and dehydration solidification methods for the first, second, and third-stage sludge sedimentation The silt and silt slurry in the pond are dehydrated and solidified to obtain silt-solidified soils A and B; 4) stacking and aging: transport the silt-solidified soils A and B to a temporary storage yard and age them for 3 to 7 days to complete the treatment. The sludge treatment process of the present invention can simultaneously process particles and sludge with high viscosity and low water content, as well as sludge slurry with fine particles, organic matter and high water content, and is especially suitable for river courses with complex components, wide particle distribution, and large water content differences silt.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Microparticulate systems for the oral administration of biologically active substances

InactiveUS20090053317A1Improve bioavailabilityPrevent ulcersPowder deliveryOrganic active ingredientsTolerabilityCo administration

The present invention relates to gastroresistant and enterosoluble microparticulate systems for the encapsulation of biologically active substances selected from: flavonoids, vitamins, antioxidants, immunostimulants, starchy and non-starchy polysaccharides, probiotics, prebiotics, intestinal trophism regulators, oligoelements, enzymes and bioactive peptides. Such microparticulate systems allow the administration of the aforementioned nutraceutic substances to animals such as porcines, bovines, caprines, ovines, equids, canids, felines, camelids, lagomorphs, rodents, fowl, and other mammals, including humans, fish and crustaceans, increasing the bioavailability.

Owner:UNIV DEGLI STUDI DI PARMA +1

Lead-free solder with low copper dissolution

InactiveUS20070172381A1Minimize formation of oxideAdvantageously producedWelding/cutting media/materialsSoldering mediaDissolutionImpurity

Lead-free solder compositions suitable for joining electronic devices to printed wiring boards, which comprises by weight 0.2 to 0.9% copper, 0.006 to 0.07% nickel, 0.03 to 0.08% bismuth, less than 0.5% silver, less than 0.010% phosphorus, and a balance of tin and inevitable impurities. A solder composition embodying this invention finds particular application in automated wave-soldering machines where conventional lead-free solders dissolve excessive copper from printed wiring circuitry and component terminations.

Owner:KESTER

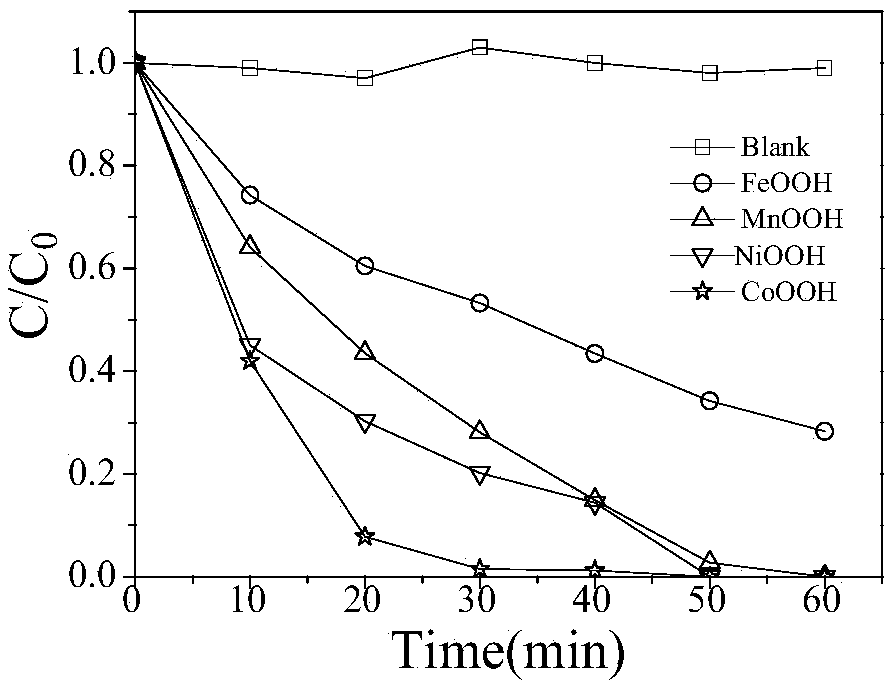

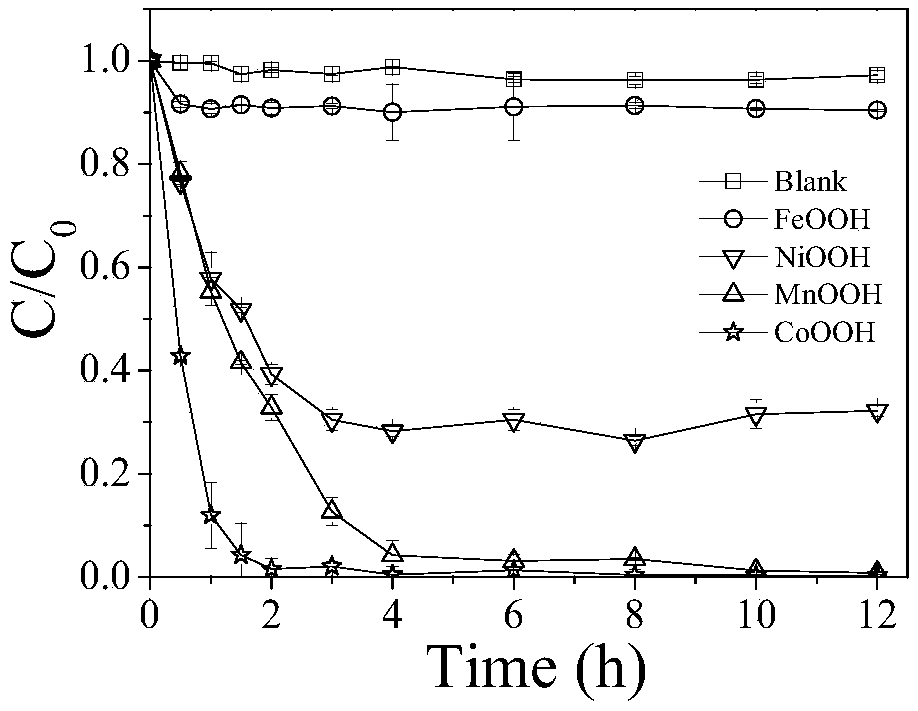

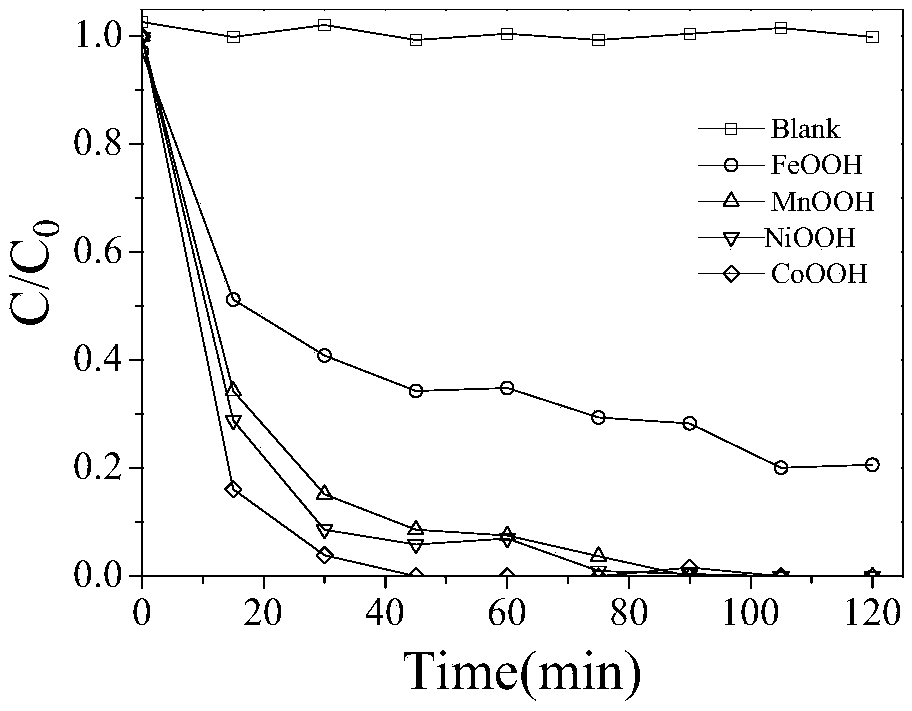

Catalytic method for generating sulfate radicals and active oxygen species as well as advanced oxidation method of organic pollutants difficult to biodegrade

ActiveCN108675430AStable structureImprove removal efficiencyWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsCatalytic methodSulfate radicals

The invention provides a catalytic method for generating sulfate radicals and active oxygen species as well as an advanced oxidation method of organic pollutants difficult to biodegrade. The problemsof low degradation efficiency of organic pollutants and high cost in the prior art are solved. According to the catalytic method for generating sulfate radicals and active oxygen species, a transitionmetal oxyhydroxide-based material serves as a catalyst, and the sulfate radicals, hydroxyl radicals, superoxide radicals and singlet oxygen non-radicals are generated, so that the organic pollutantsdifficult to biodegrade are efficiently oxidized. The transition metal oxyhydroxide-based material serves as the catalyst, the activation efficiency of perosulfate is improved and various radicals andactive oxygen species are generated, so that the oxidative degradation rate of the organic pollutants is increased; and the catalyst has a stable structure, is low in heavy metal dissolution rate inthe catalytic process, avoids secondary pollution, and can be widely applied to treatment of industrial production waste water, treatment of domestic sewage, purification treatment of polluted underground water and surface water as well as treatment of polluted soil.

Owner:JILIN UNIV

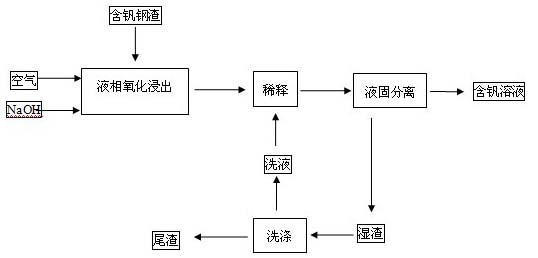

Artificial micro-particle feedstuff for pseudosciaenacrocea larvae

InactiveCN1736241AImprove stabilityLow dissolution rateClimate change adaptationAnimal feeding stuffFish oilSoya bean

Disclosed is an artificial micro-particle feedstuff for pseudosciaenacrocea larvae, which comprises white fish meal, shrimp powder, mussel powder, calamari powder, yeast powder, hydrolyzed fish meat protein, fish oil, alpha-starch, sodium alginate, mineral salts mixture, vitamins mixture, feeding promoting agent, tomatine, ethoxy quinoline, beta-gluglucosan and soya bean lecithin by the weight ratio of 35-45, 10-20, 10-15, 8-12, 3-6, 5-10, 3-6, 6-12, 1-3, 1-3, 1-3, 0.1-0.2, 0.01-0.05, 0.05-0.08, 0.1-0.3 and 5-8.

Owner:OCEAN UNIV OF CHINA

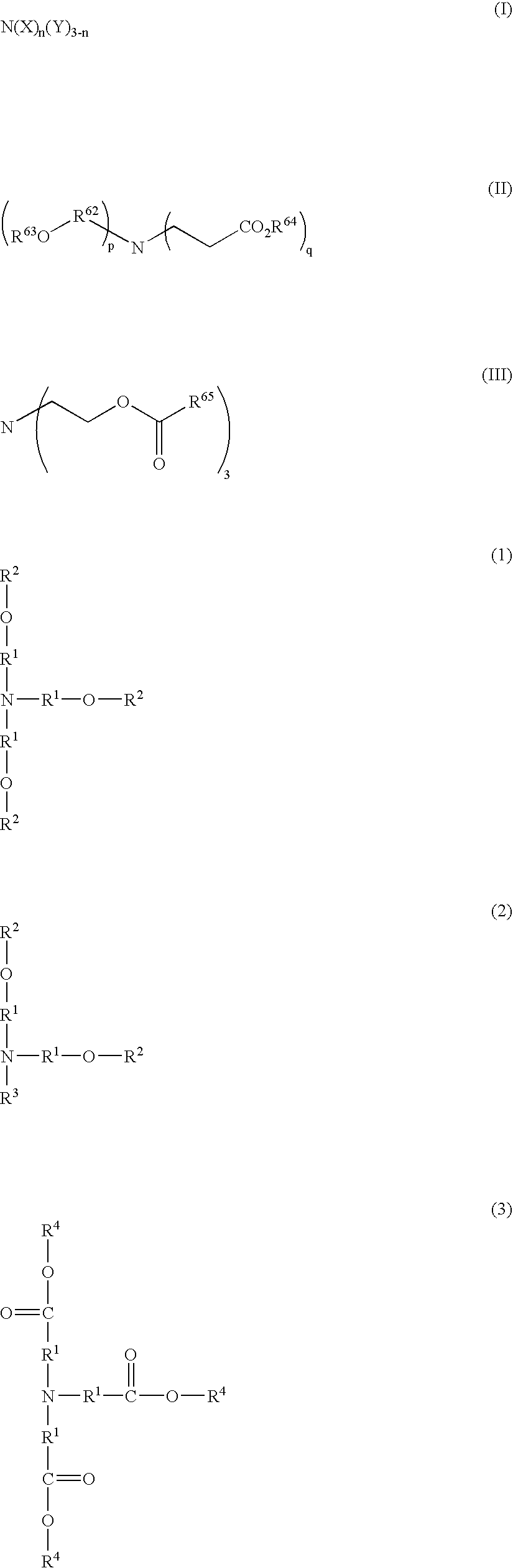

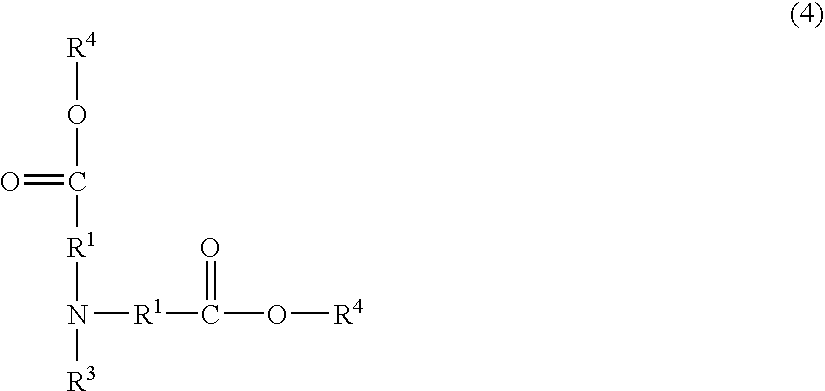

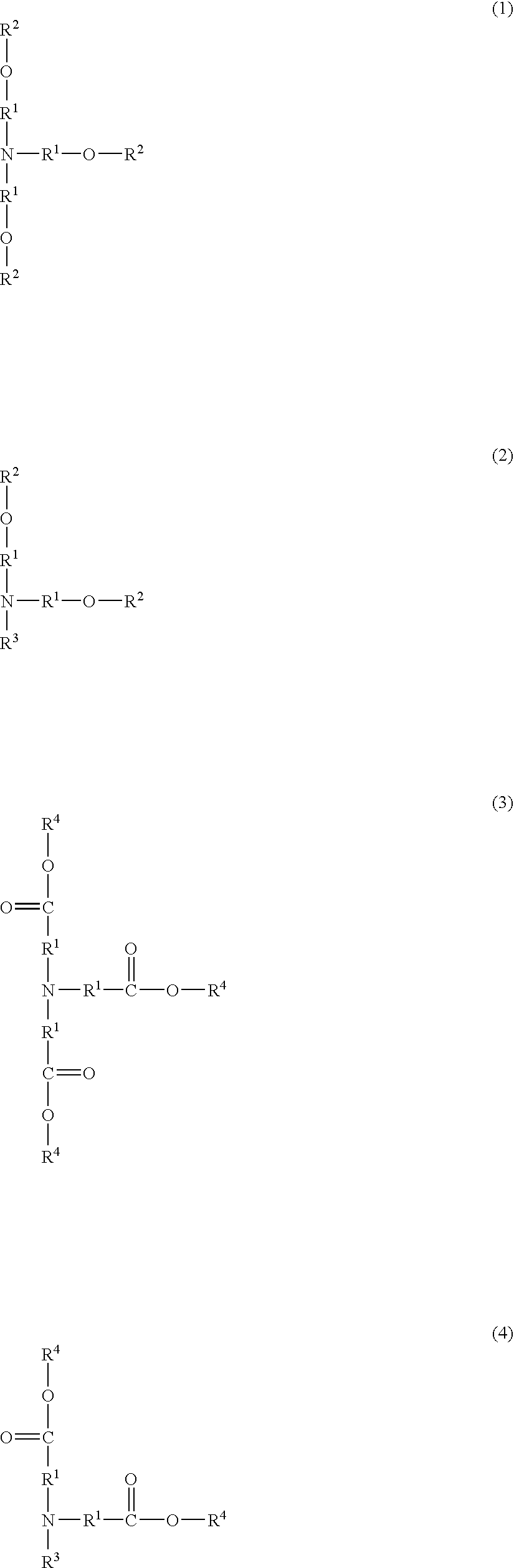

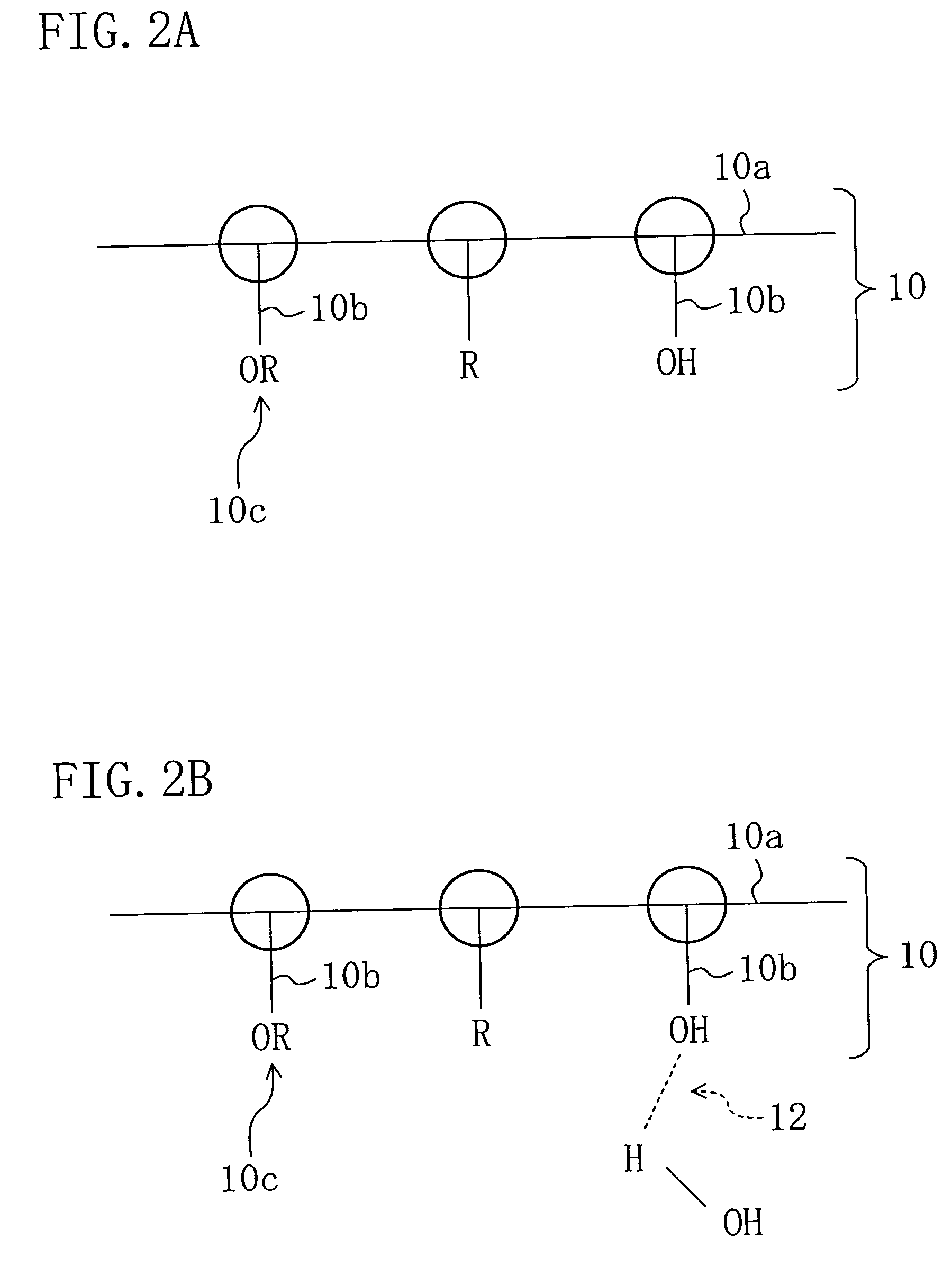

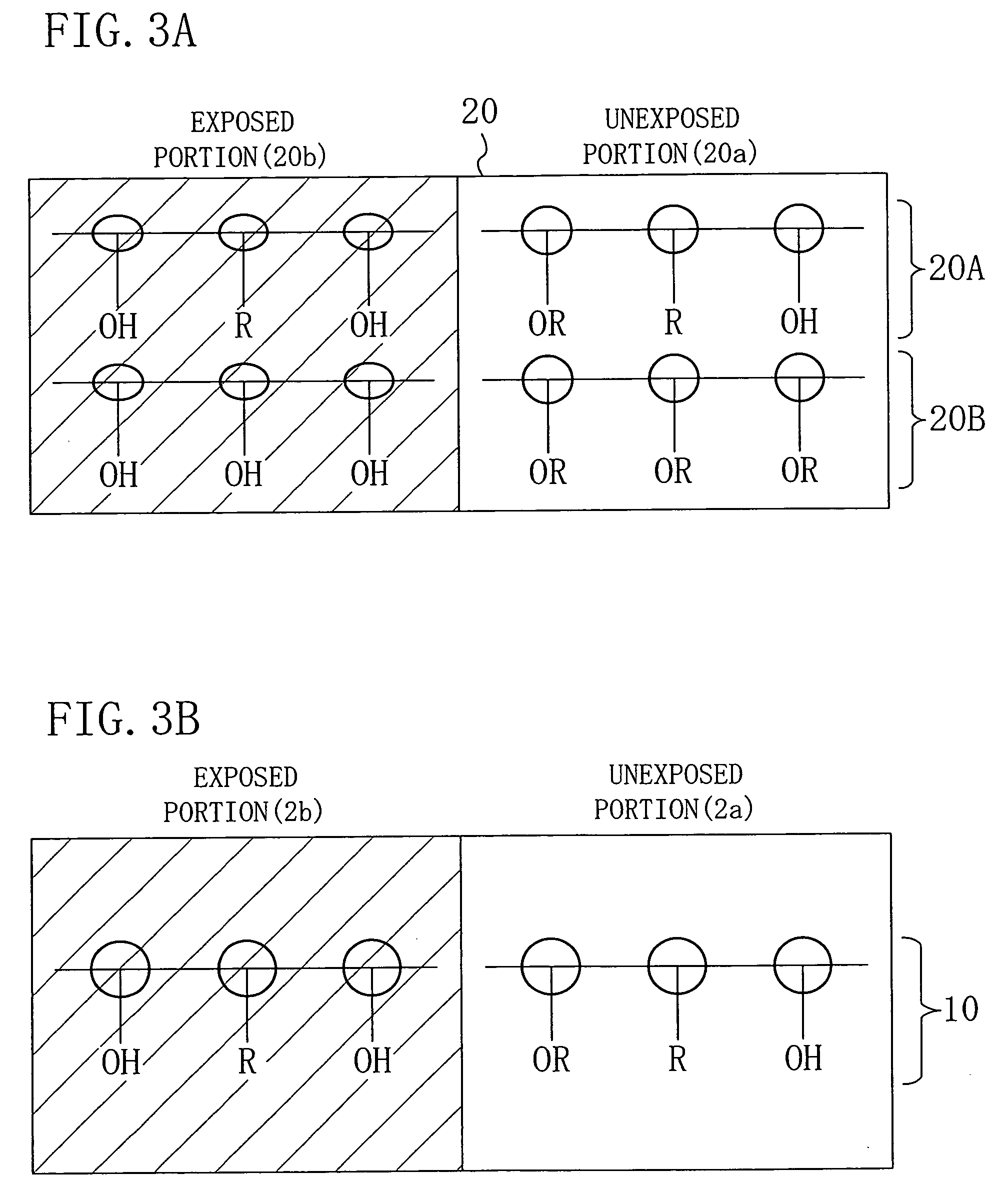

Resist composition

InactiveUS20040106063A1High rectangularityImprove reducibilityRadiation applicationsDiazo compound compositionsResistChemical compound

Although use of a nitrogen-containing compound as a basic compound component of a resist composition makes it possible to ease the T-top problem at an acid dissociation constant pKa falling within a range of 2 to 6, it is accompanied with the problem that the reaction, that is, acid diffusion upon use of a highly-reactive acid-labile group cannot be controlled. In order to overcome this problem, one or more basic compounds selected from those represented by the following formulas (I) to (III) and (1) to (4) are employed.

Owner:SHIN ETSU CHEM IND CO LTD

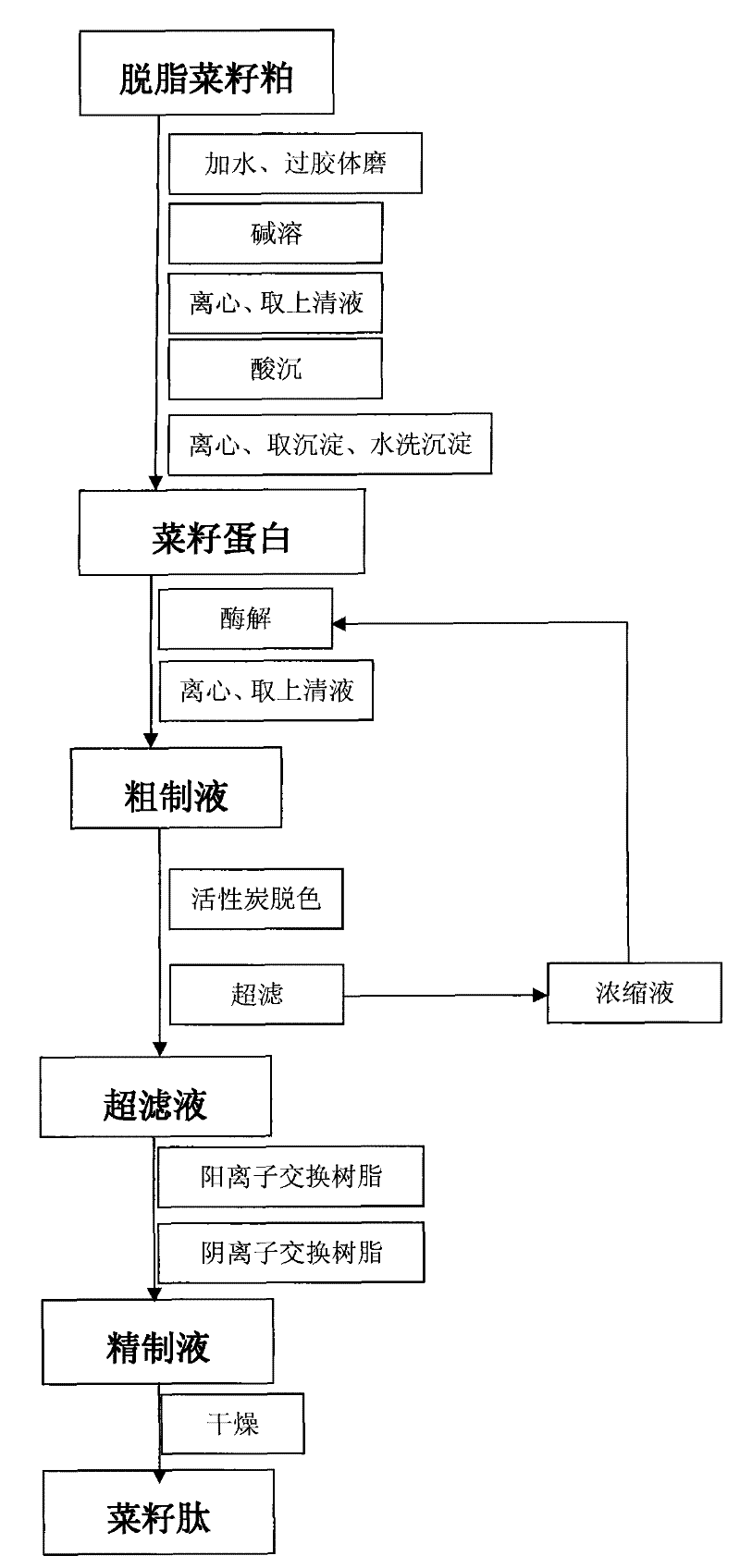

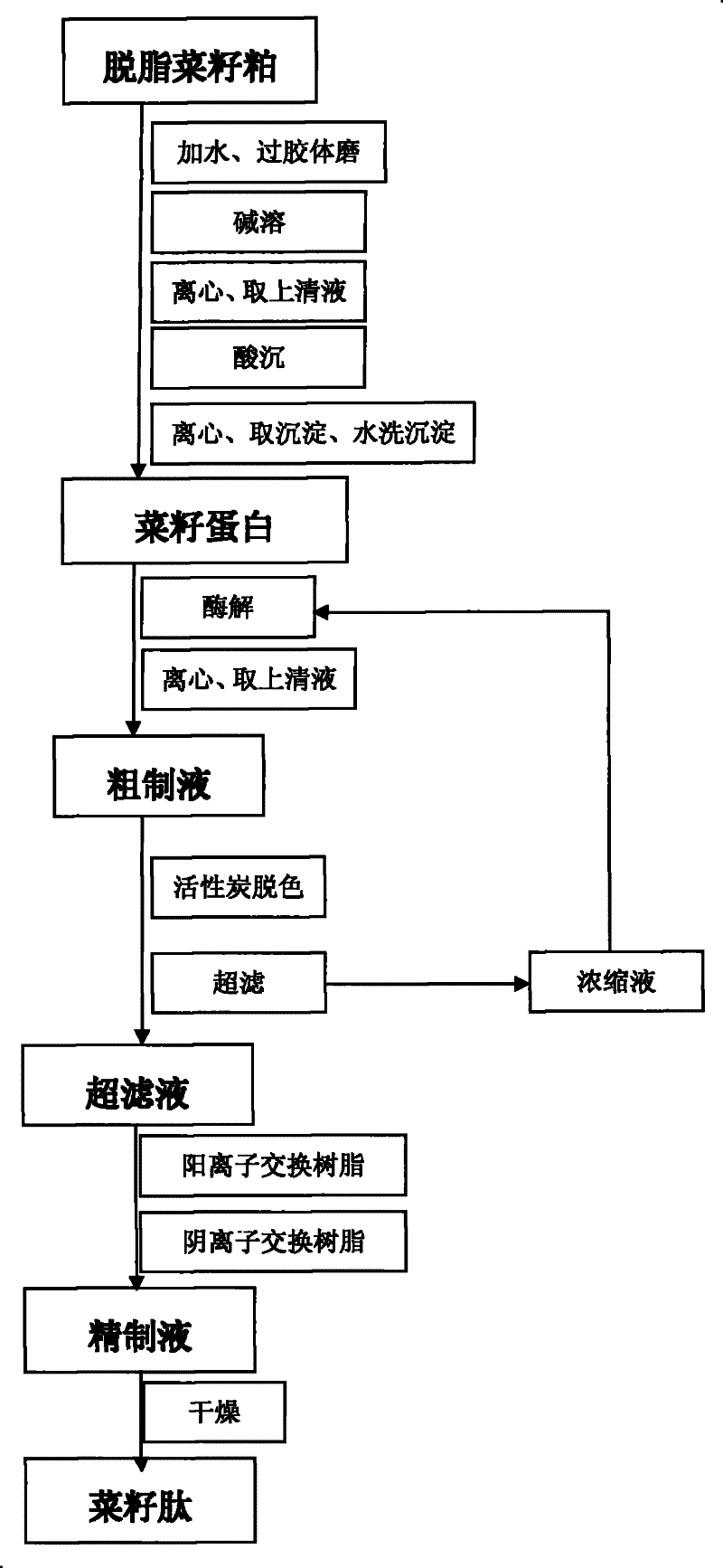

Method for preparing rapeseed bioactive peptide

ActiveCN102174627AIncrease contentLow dissolution ratePeptide preparation methodsPlant peptidesActivated carbonFreeze-drying

The invention provides a method for preparing a rapeseed bioactive peptide, comprising the following steps: taking degreased rapeseed dregs as a raw material, preparing a rapeseed protein by an alkali dissolving and acid precipitation method; adding protease hydrolyzed proteins; carrying out activated carbon decoloration, ultrafiltration grading, and cation-anion exchange resin desalination in sequence; and finally concentrating, spray drying or freeze drying to obtain the rapeseed bioactive peptide.

Owner:武汉百信正源生物技术工程有限公司

Catalyst for inducing catalytic oxidation technique and preparation method thereof

ActiveCN101185888AEvenly distributedIncrease contactMetal/metal-oxides/metal-hydroxide catalystsExternal energyMass ratio

The invention relates to a catalyst used for inducing catalysis and oxidation and a preparation method. The invention uses one or a plurality of salt solution of transition metals with certain concentration to immerse the Al2O3 which is activated, activated clay or diatomite, puts the Al2O3 which is activated, activated clay or diatomite into a muffle furnace to be roasted after being dried to dissolve the transition metal salt and reduce the oxide on the surface of the vector into metal substance after being reduced and activated to prepare the catalyst. The mass ratio between the vector of the catalyst prepared by the invention and the loading transition metal is (70-99):(1-30). The catalyst is mainly used for the catalysis and oxidation under the existence of an external energy field and has the advantages of the large adsorption capacity, the better effect of catalysis and oxidation, the fast reaction, the stable treatment effect, the wide scope of application, the long service life and so on. The invention can quickly dissolve the micromolecular substances into small molecule substances, facilitate the quick degradation of featured pollutants and reduce the biological toxicity of organic wastewater, so as to improve the biodegradability of the wastewater.

Owner:NANJING UNIV OF TECH

Adherent polyol troche

ActiveUS20070274927A1Low dissolution rateReduce solubilityAntibacterial agentsSenses disorderPacifierBi layered

A slow-dissolving troche with polyol molecules is disclosed. It may be an adherent troche, preferably adhered to teeth or gums or cheek with acacia gum, or a lollipop or child's pacifier. Consumers are instructed to use the troches at the end of each day and after each meal, at least four times per day to benefit oral health, particularly caries, gingivitis, periodontitis, ear infections, sinus infections, halitosis and risk of Streptococcus mutans infecting their blood from their mouths. The polyol molecules are preferably xylitol. The troches may be made with a bi-layer tablet press rounded on one side and flat on the other, preferably using acacia gum in the flat side layer for adhesion.

Owner:ORAHEALTH LLC

Method for producing potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar

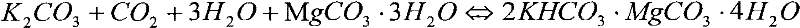

InactiveCN102531710ARealize comprehensive utilizationImprove utilizationAluminium compoundsPotassium fertilisersAluminium hydroxideChloride

The invention relates to a method for producing a potassium fertilizer and aluminum oxide by comprehensively using potassium feldspar. The method comprises the following steps of: (1) smashing potassium feldspar and inorganic chlorate, and burdening potassium feldspar, inorganic chlorate and potassium carbonate in the mass ratio of 1:(1-2):(1-10); (2) pelletizing the prepared material, and sintering at the temperature of 500-1,200 DEG C for 1-5 hours to obtain a sintered material and generate CO2 gas simultaneously; (3) soaking the material obtained in the step (2) into water and filtering; (4) introducing a filtrate obtained in the step (3) into the CO2 gas obtained in the step (2) to obtain an aluminum hydroxide precipitate, and filtering; (5) adding a filtrate obtained in the step (4) into nesquehonite, introducing CO2 gas to obtain a complex salt precipitate, filtering and crystalizing a filtrate to obtain a potassium chloride chemical fertilizer; and (6) adding water for dissolving a complex salt obtained in the step (5) to obtain a solid of nesquehonite, circularly using, heating a potassium bicarbonate solution for decomposing to obtain a potassium carbonate solution for circularly using, and repeating the step (1) to the step (6).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

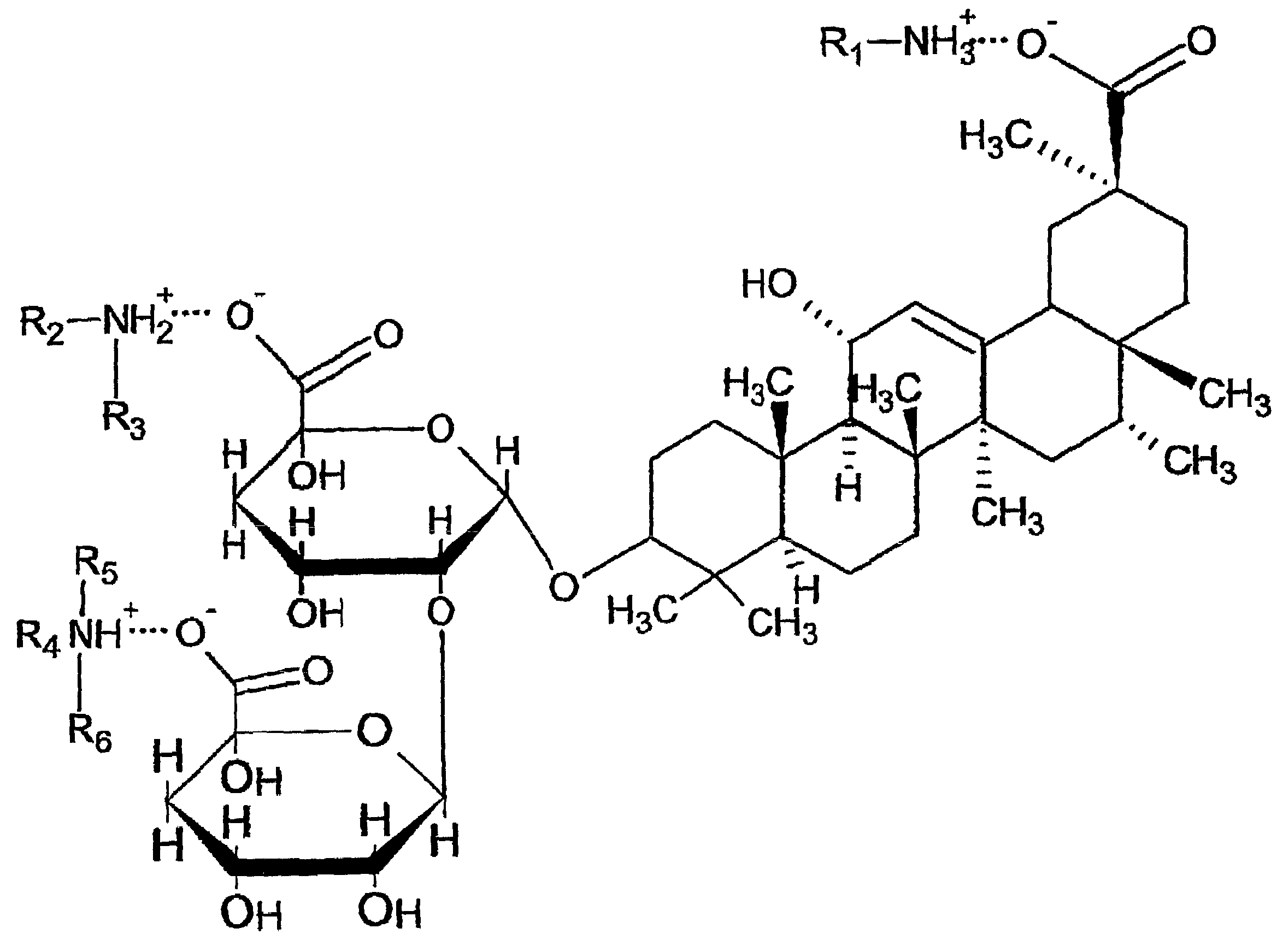

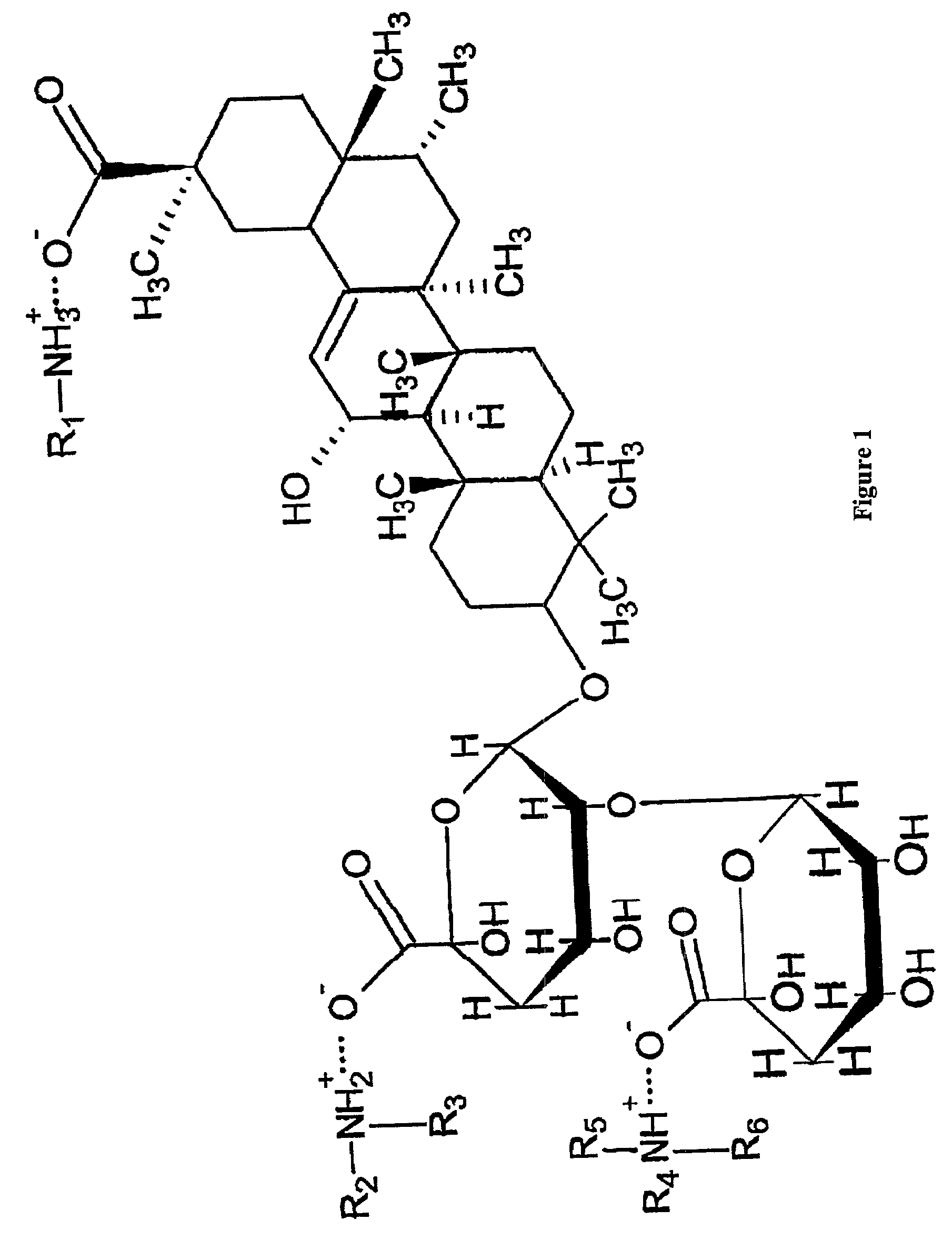

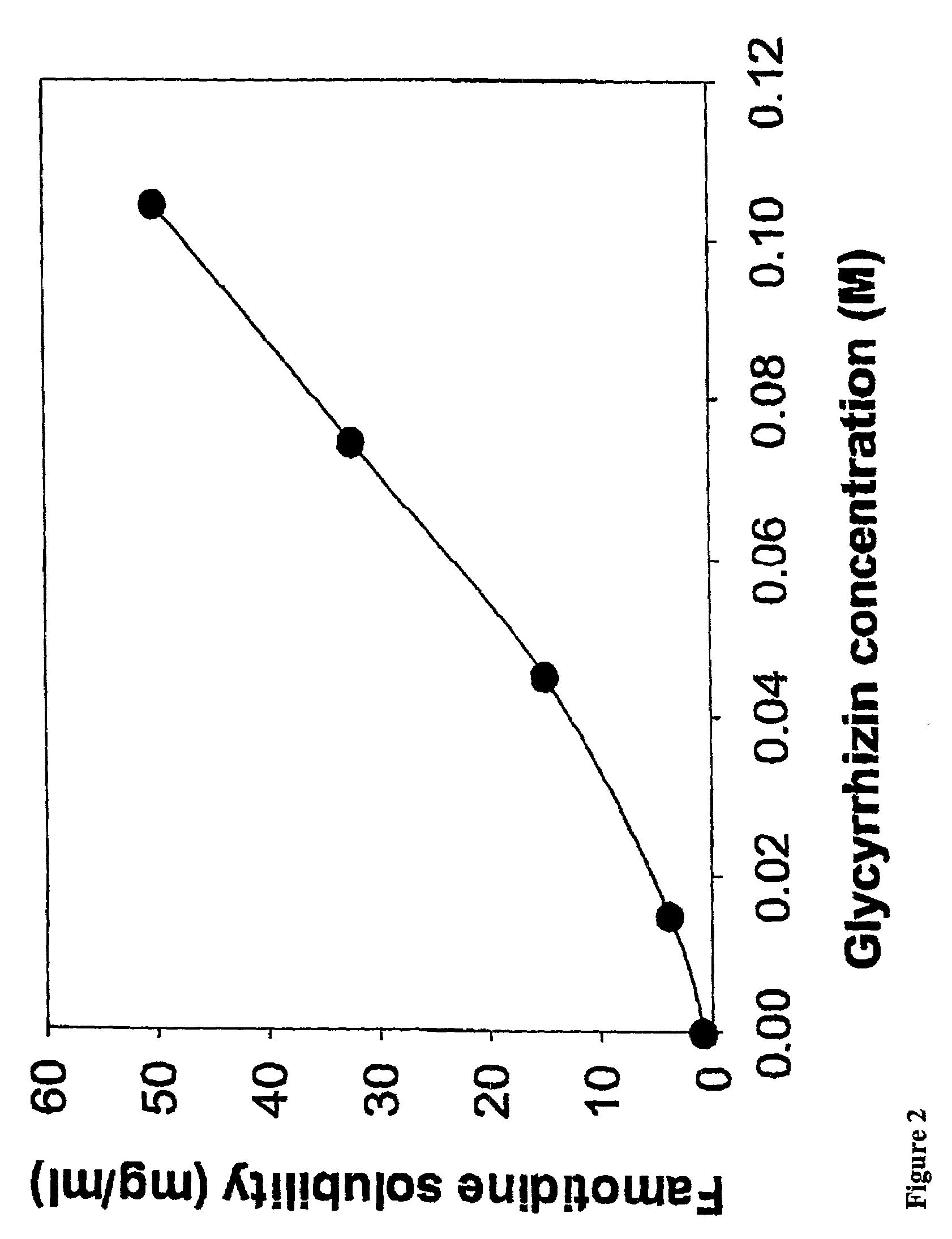

Water soluble and palatable complexes

InactiveUS7125564B2BioavailabilityBioavailability is incompleteBiocidePowder deliverySolubilityActive agent

The products and methods of the present invention provide a means for increasing the solubility and bioavailability of active agents. More particularly the invention provides compositions containing active agents as water-soluble complexes with glycyrrhizin, and methods of preparing such complexes. The invention further provides methods for the preparation of highly water soluble complex dosage forms.

Owner:THALLIUM HLDG CO LLC

Leaching method capable of reducing leached acid consumption of uranium ores

The invention provides a leaching method capable of reducing leached acid consumption of uranium ores, which comprises the following steps: leaching uranium ores by using the mixed solution of sulfuric acid and polyferric sulfate aluminium as the leaching agent, wherein if adopting an agitation leaching mode, the amount of the sulfuric acid in the mixed solution is 6-12% by mass of uranium ores, the amount of the polyferric sulfate aluminium is 0.3-0.7% by mass of uranium ores, and the mass proportion (liquid to solid ratio) of the leaching agent to the uranium ores is (1-2):1; and if adopting a heap leaching mode, the concentration of the sulfuric acid in the mixed solution is 5-10 g / L, and the amount of the polyferric sulfate aluminium is controlled, so that the concentration of Fe<3+> in the mixed solution is 3.0-8.0 g / L, and the concentration of Al<3+> is 0.2-0.8 g / L. On the premise of not affecting the leaching of uranium ores, the polyferric sulfate aluminium selectively inhibits the principal acid-consuming elements and the reaction of sulfuric acid, lowers the leaching rate and reduces the leached acid consumption of ores, thereby lowering the processing cost for uranium ore heap leaching.

Owner:BEIJING RES INST OF CHEM ENG & METALLURGY

Resist material and pattern formation method

ActiveUS20060051702A1Improve solubilityIncrease contrastPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistMedicinal chemistry

A resist material includes a first polymer in which part of alkali-soluble groups are protected by an acid labile group labilized by an acid; a second polymer in which substantially all alkali-soluble groups are protected by an acid labile group labilized by an acid; and an acid generator.

Owner:RPX CORP

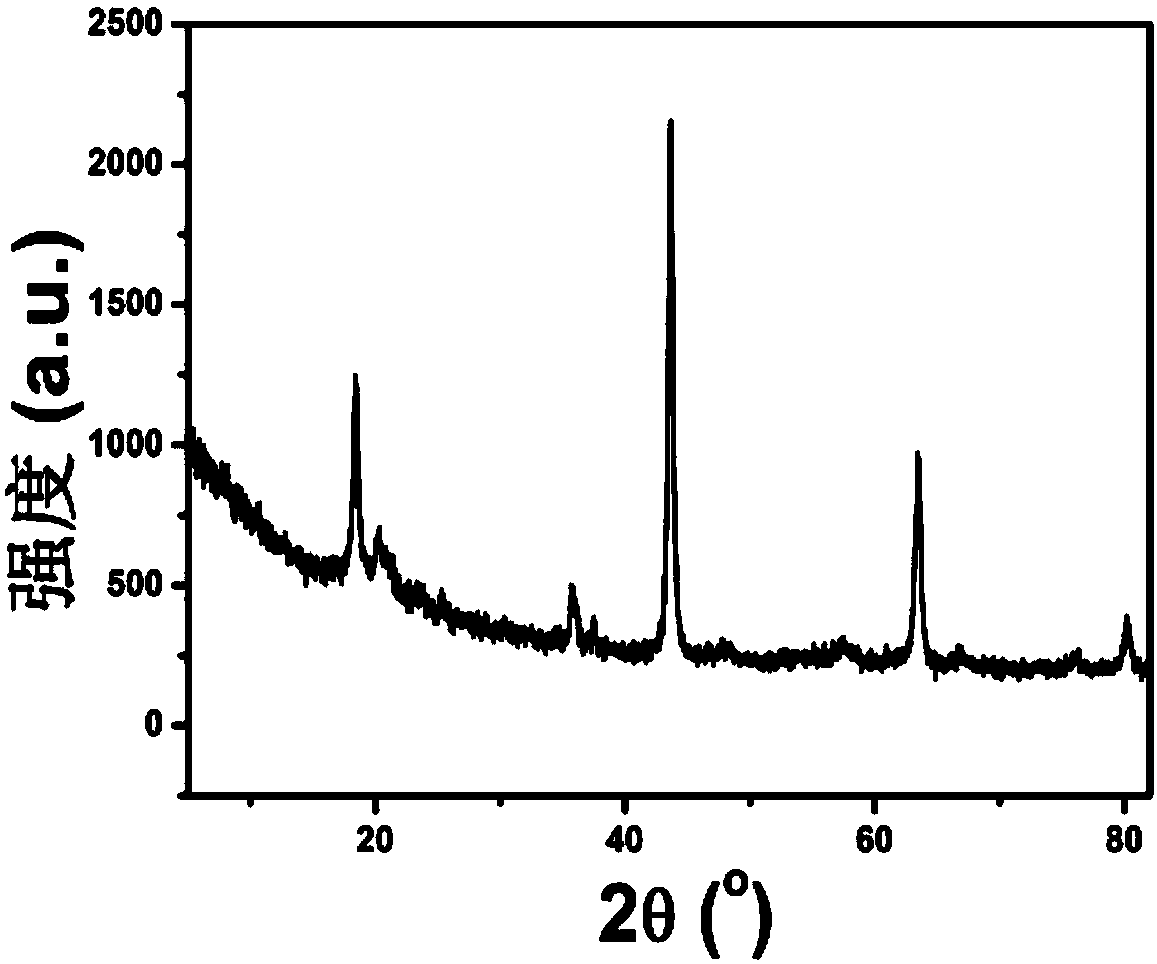

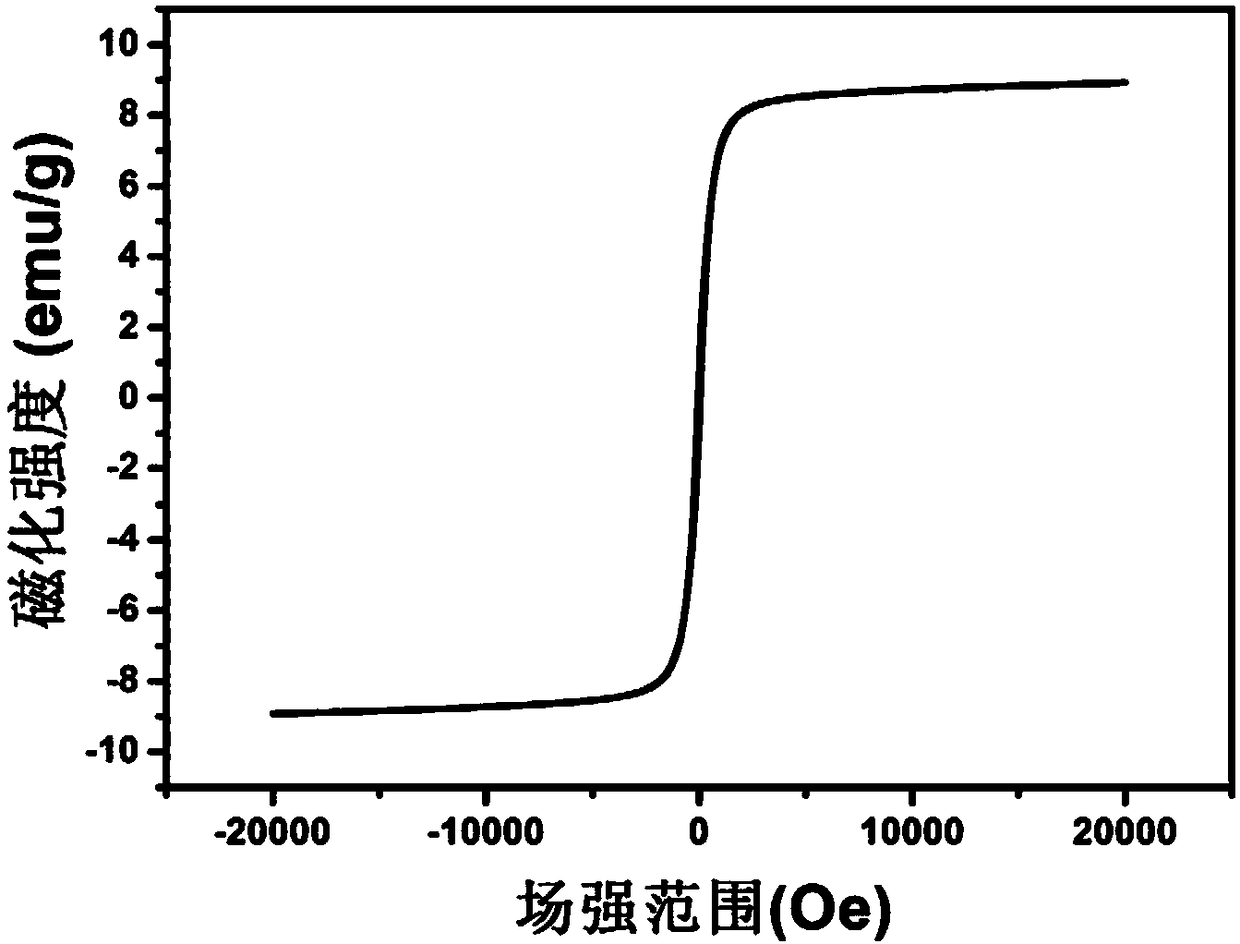

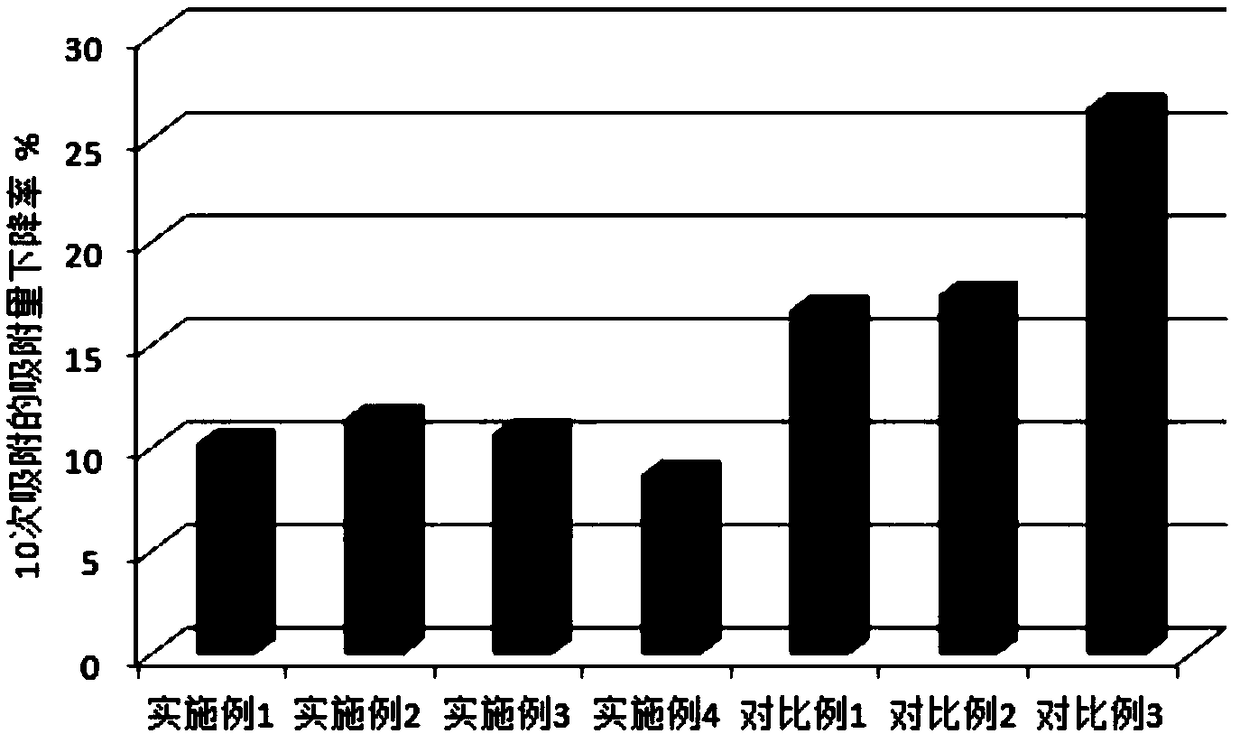

Magnetic separable metatitanic acid lithium ion sieve, preparation method and application of lithium ion sieve

ActiveCN108212074AImprove adsorption capacityImprove leaching rateOther chemical processesLithium compoundsLithiumPhysical chemistry

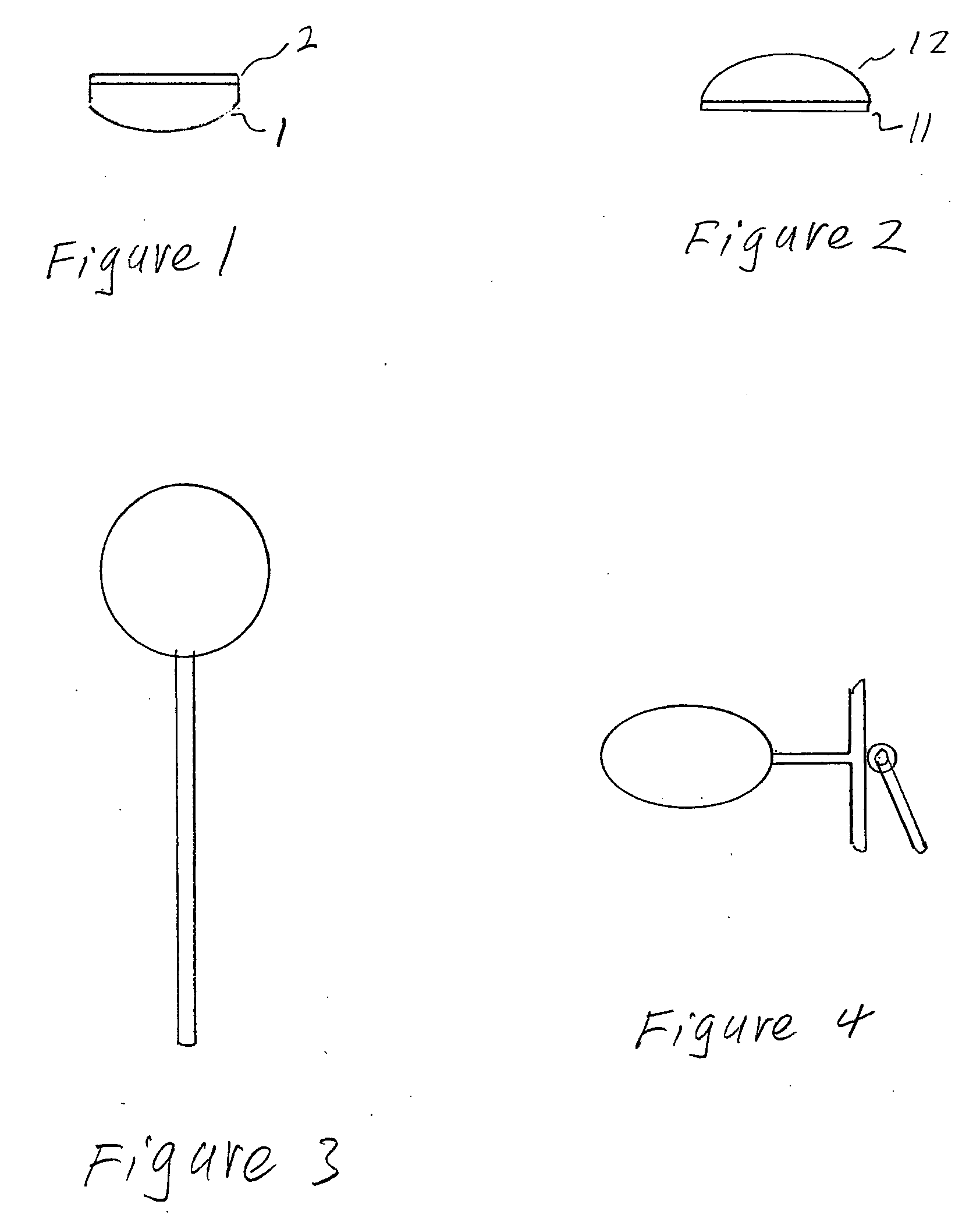

The invention provides a metatitanic acid lithium ion sieve and a preparation method of the lithium ion sieve. A molecular formula of the lithium ion sieve is H2RxTi1xO3; R is a magnetic element; x isbetween 0.01 and 0.2; and the lithium ion sieve is formed by doping the magnetic element into an Li2TiO3 lattice, substituting part of titanium positions and removing lithium by pickling. A lithium ion sieve precursor is prepared by calcining a lithium source, a titanium source and a superparamagnetic substance and subjected to pickling and liquid-solid separation to form the magnetic separable metatitanic acid lithium ion sieve. The prepared metatitanic acid lithium ion sieve has the advantages of high adsorption capacity and leaching rate, low solution loss rate, stable structure and the like; the adsorption capacity of the lithium ion sieve is above 50mg / g; the leaching rate is greater than 99%; the solution loss rate is less than 0.1%; and the lithium ion sieve can be repeatedly usedfor many times. After adsorption, the lithium ion sieve can be separated from a lithium containing solution quickly by the action of an externally applied magnetic field, and the separation time is 1-10min.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

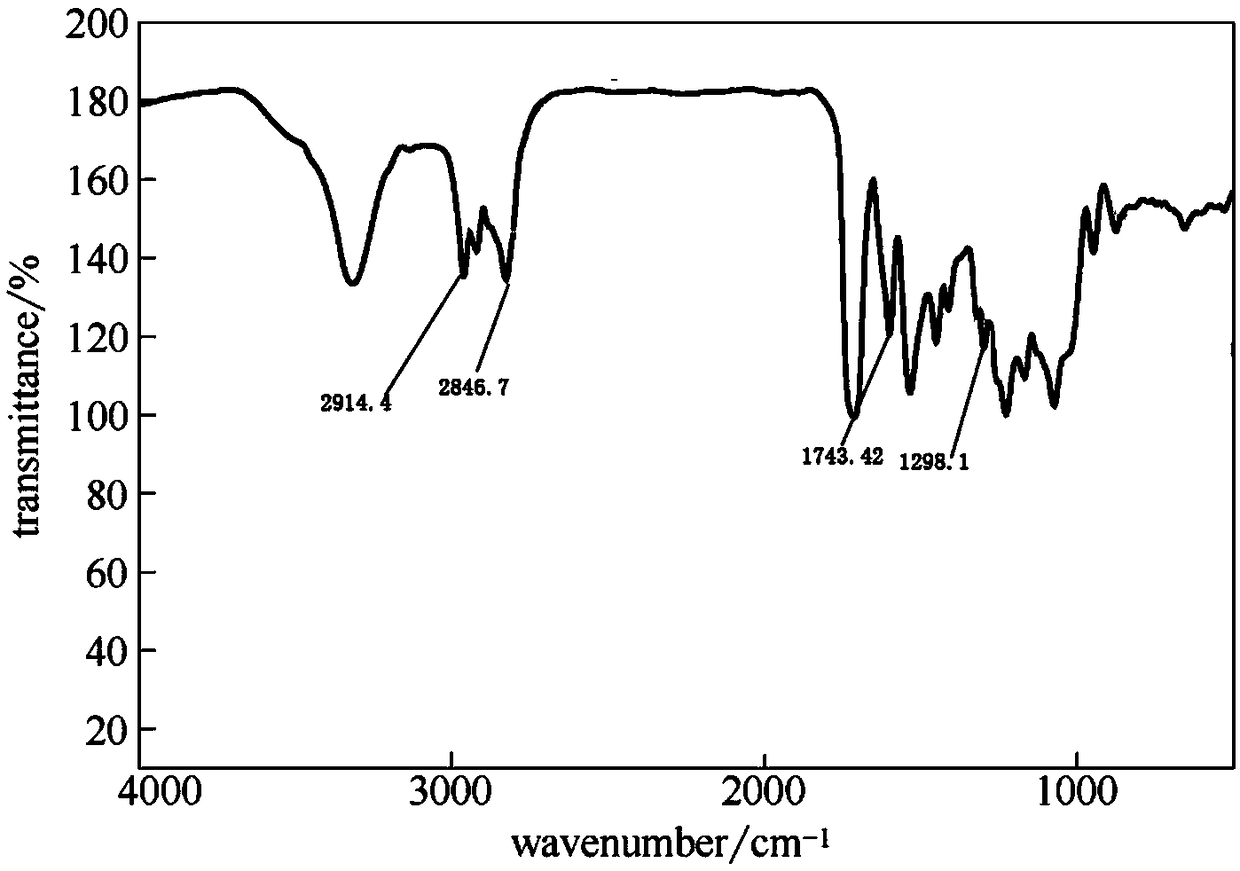

Aluminum salt adsorbent and application thereof in extraction of lithium in salt lake brine

InactiveCN108854996AImprove multiple service lifeSmall particle sizeOther chemical processesProcess efficiency improvementLoss rateSalt lake brine

The invention relates to an aluminum salt adsorbent and application thereof in extraction of lithium in salt lake brine, and belongs to the technical field of extraction of lithium resources. According to the aluminum salt adsorbent and the application thereof, aluminum hydroxide is adopted as the adsorbent, and meanwhile, macroporous resin subjected to modification treatment is adopted as a carrier. The adsorbent is suitable for adsorption separation of the lithium in the salt lake brine, and a catalyst has the advantages of being high in adsorption capacity and low in dissolution loss rate.

Owner:JIANGSU JIUWU HITECH

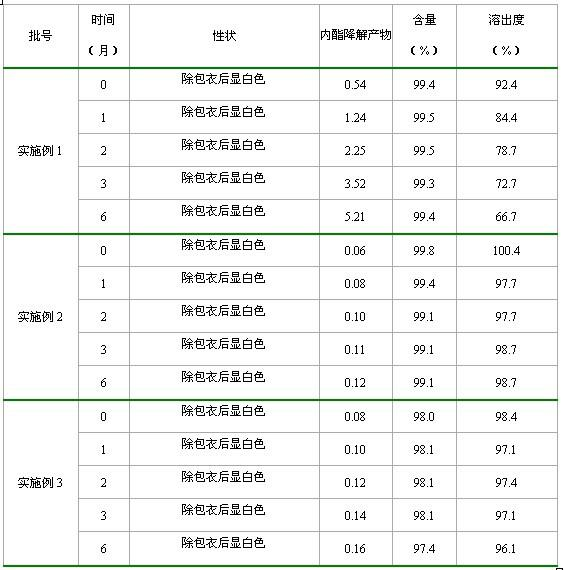

Oral solid preparation containing clopidogrel hydrogen sulfate

ActiveCN101791309ARealize industrial productionAvoid elevationOrganic active ingredientsInorganic non-active ingredientsParaffin waxOral medication

The invention relates to an oral administration, in particular to a solid composite containing clopidogrel hydrogen sulfate; the solid composite containing clopidogrel hydrogen sulfate comprises the following ingredients by weight part: 100 parts of clopidogrel hydrogen sulfate and 5-100 parts of mixture of liquid paraffin and talcum powder; the composite can realize industrial production of the clopidogrel hydrogen sulfate and solve the problems that related substances of the tablets rises and the dissolution is reduced.

Owner:CHINA PHARM UNIV +1

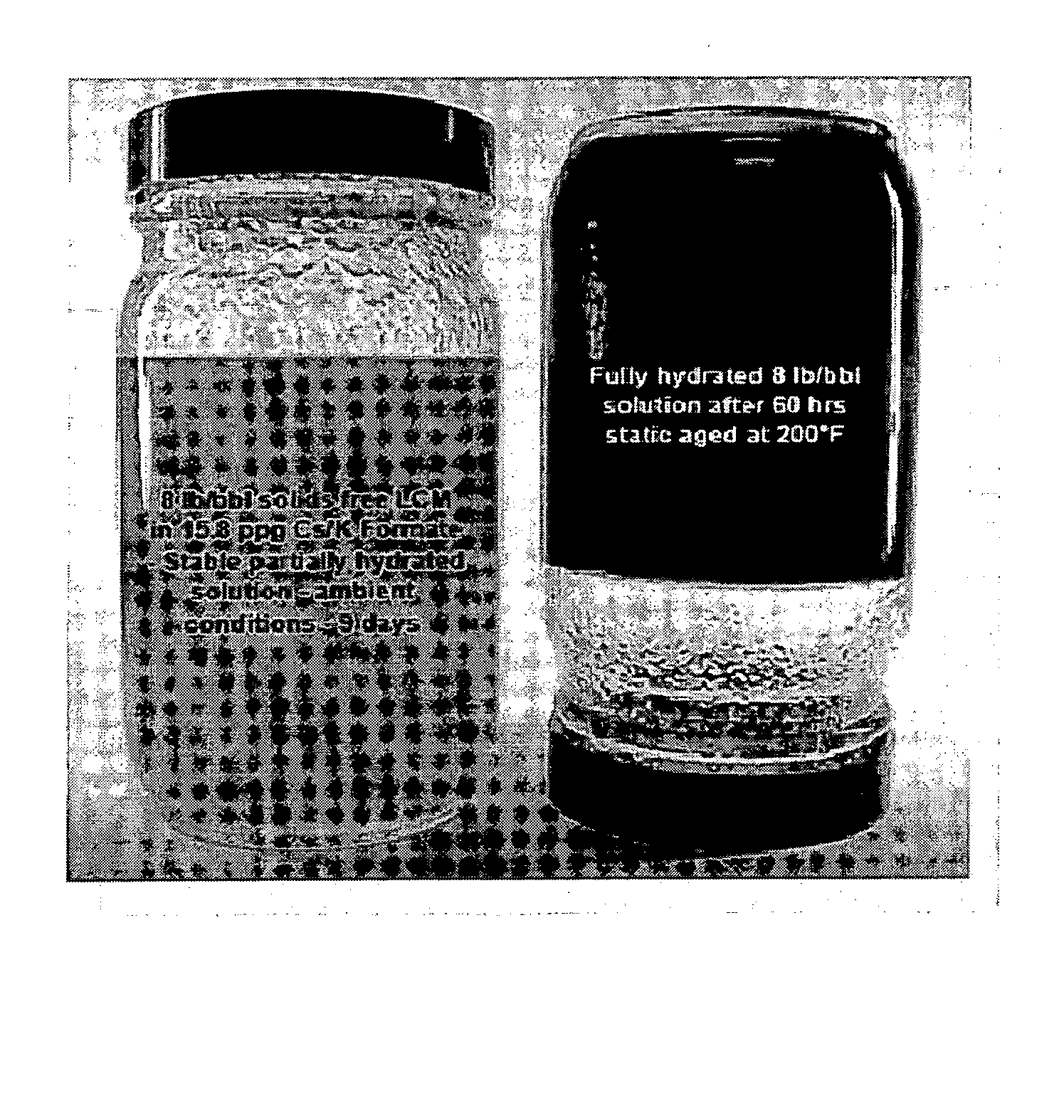

Weighted zero solids loss circulation, fluid loss and insulating annular space fluid systems

InactiveUS20070261848A1Easy to separateLow dissolution rateInsulationLiquid/gas jet drillingMedicineFluid system

Loss circulation fluids are described, as well as methods to reduce the loss of circulation fluids into flow passages of a subterranean formation. In addition, packer fluids are further described. The various compositions of the present invention are preferably aqueous-based compositions which contain a thermally activated self-crosslinkable gel forming material.

Owner:CABOT SPECIALTY FLUIDS

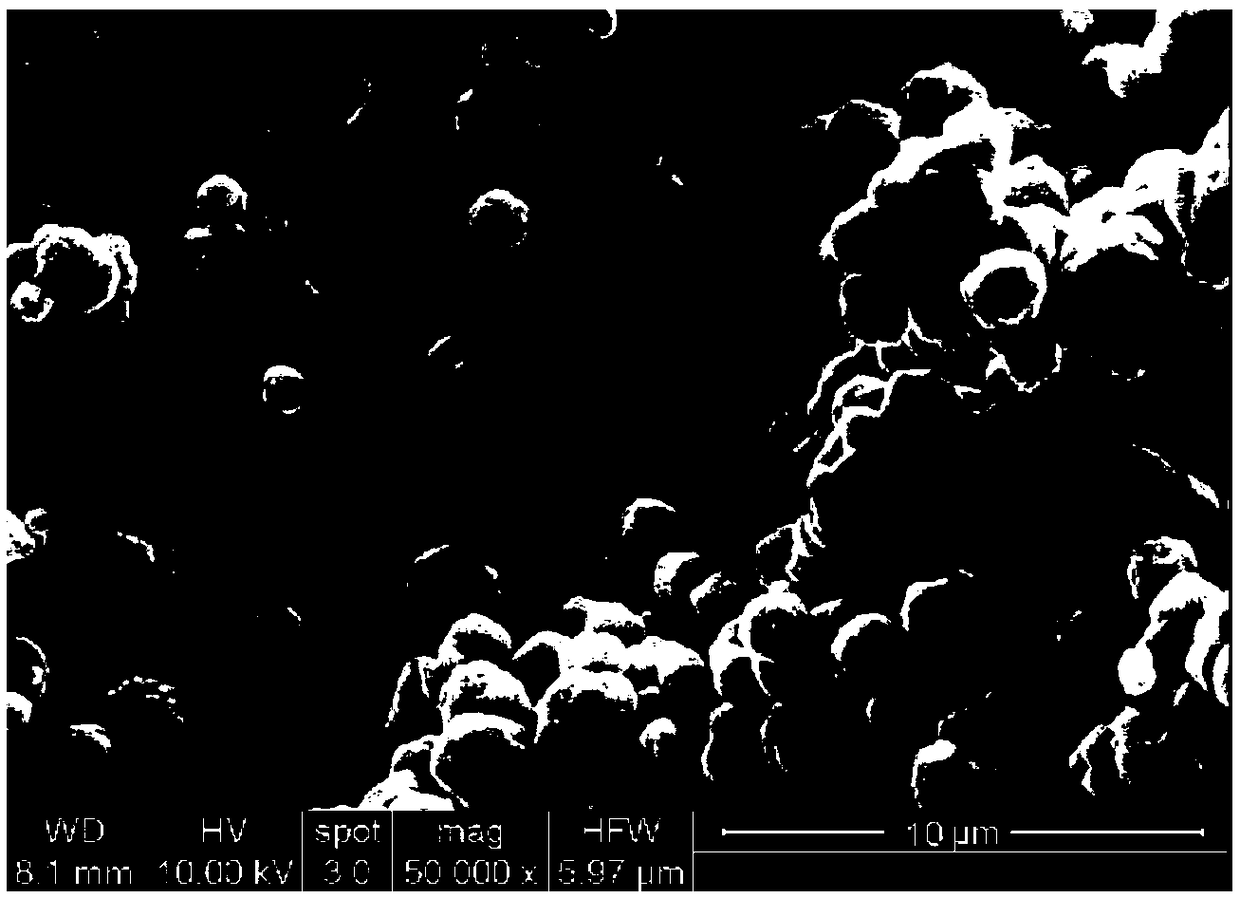

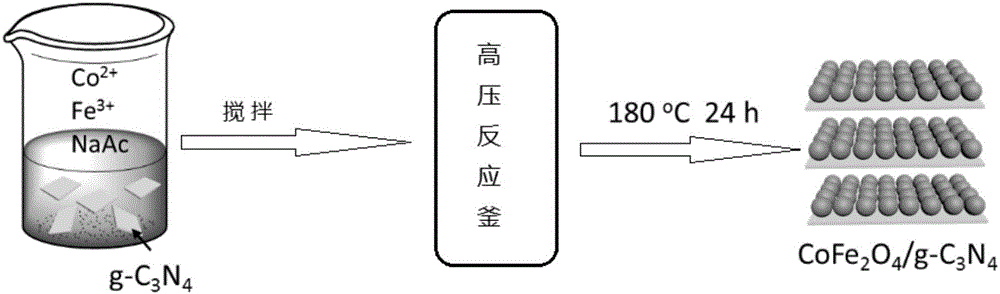

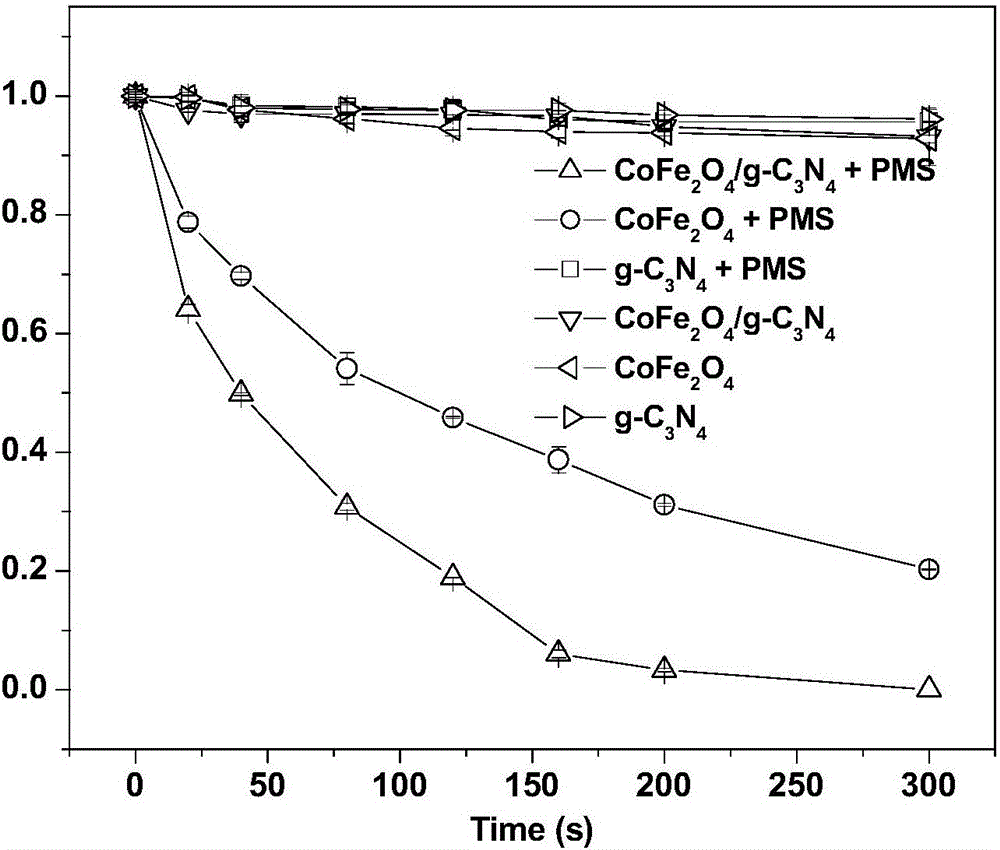

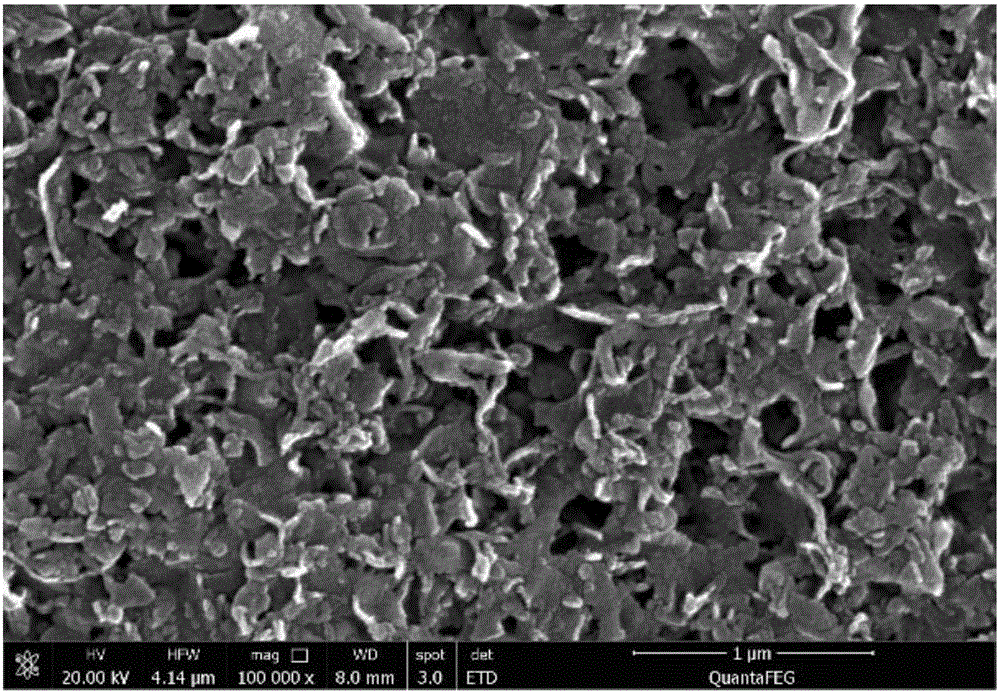

CoFe<2>O<4>/g-C<3>N<4> magnetic nanomaterial and preparation method therefor

ActiveCN106582772ASolve reunionEasy to recyclePhysical/chemical process catalystsDispersed particle separationSodium acetateNanoparticle

The invention relates to the technical field of a material, and discloses a CoFe<2>O<4> / g-C<3>N<4> magnetic nanomaterial and a preparation method therefor. The preparation method comprises the steps of preparing g-C<3>N<4> nanosheets, and dispersing the g-C<3>N<4> nanosheets into ethylene glycol; then adding FeCl<3>.6H<2>O and CoCl<2>.4H<2>O and fully dissolving; and finally adding sodium acetate, stirring and calcining in a drying oven, and finally obtaining black sediments CoFe<2>O<4> / g-C<3>N<4>. According to the CoFe<2>O<4> / g-C<3>N<4> magnetic nanomaterial disclosed by the invention, the CoFe<2>O<4> nanoparticles are uniformly distributed on the g-C<3>N<4> nanosheets, so that CoFe<2>O<4> nanoparticle agglomeration can be prevented, and more active sites are provided to improve catalytic activity; in addition, the CoFe<2>O<4> nanoparticles are magnetic, so that the particles are distributed on the g-C<3>N<4> nanosheets sequentially to form bigger planar nanomaterials; and the planar nanomaterials can be separated more quickly under a magnetic field compared with independent CoFe<2>O<4> nanomaterials.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

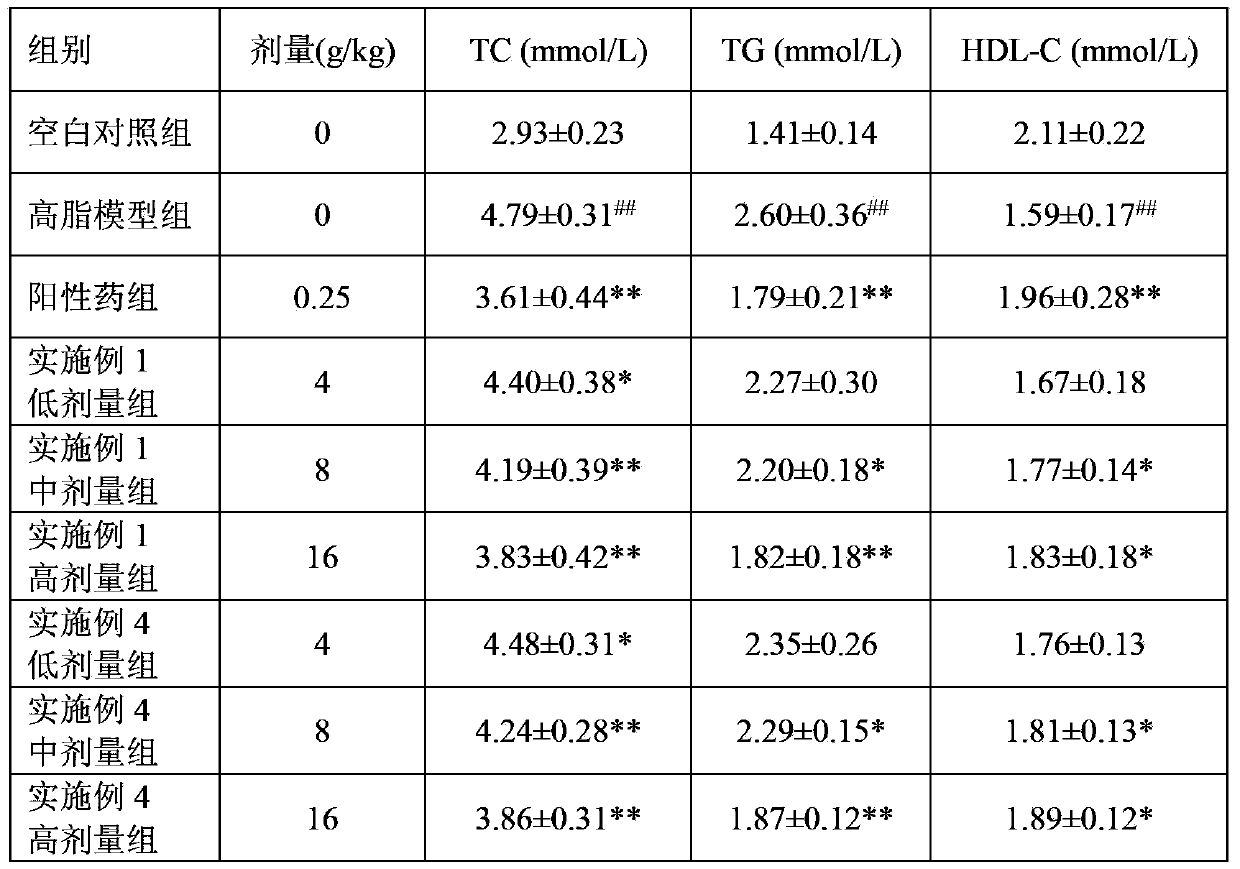

Vegetable oil composition with hypolipidemic effect as well as preparation method and application thereof

The invention discloses a vegetable oil composition with hypolipidemic effect and a preparation method thereof. The vegetable oil composition is prepared from the following raw materials in parts by weight: 5-50 parts of jujube seed oil, 10-80 parts of artemisia seed oil, 5-50 parts of perilla seed oil, 10-80 parts of flax seed oil and 5-50 parts of grape seed oil. The vegetable oil composition with hypolipidemic effect provided by the invention is prepared and screened by a large number of experiments and is prepared by adopting natural and traditional medicine and food dual-purpose vegetable oil with multiple healthcare functions, thereby being free of toxic side effect, healthy and safe; as shown in the experimental results, the vegetable oil composition can safely and effectively regulate the blood fat of human body, prevent arteriosclerosis and soften blood vessels, and is capable of being widely used by hyperlipidemia population resulting from high cholesterol or high triglycerides.

Owner:南京百草和康医药科技有限公司

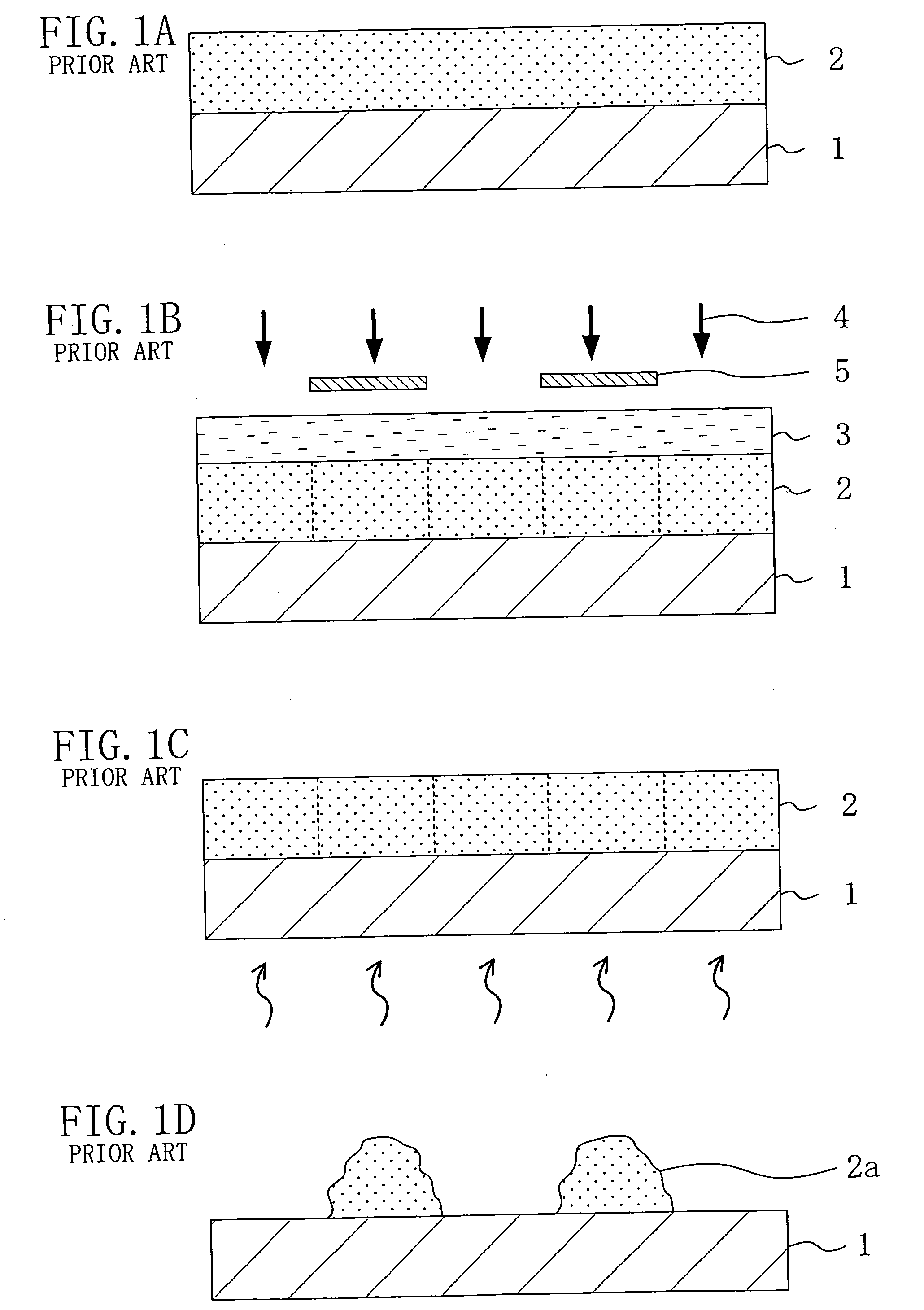

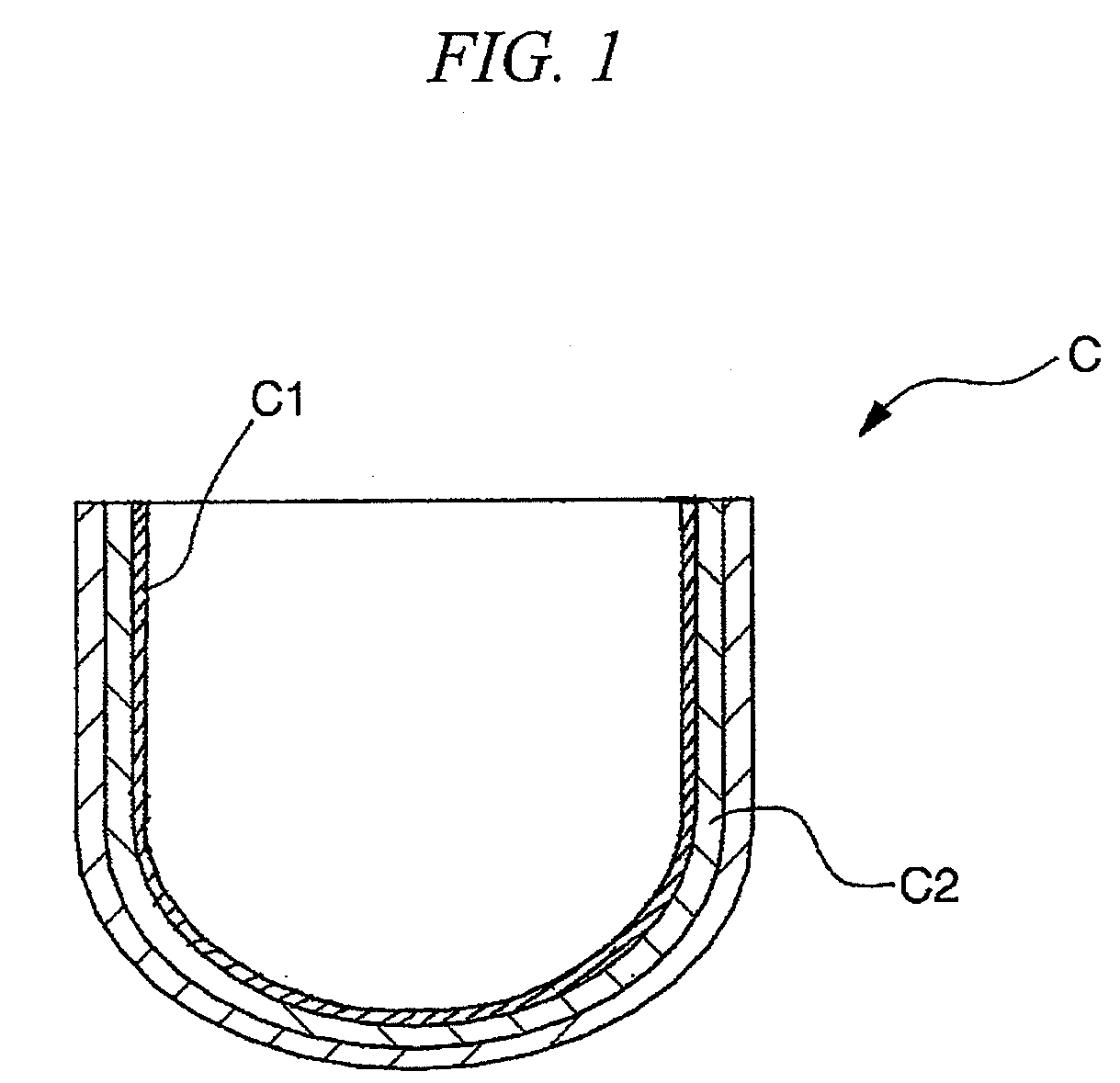

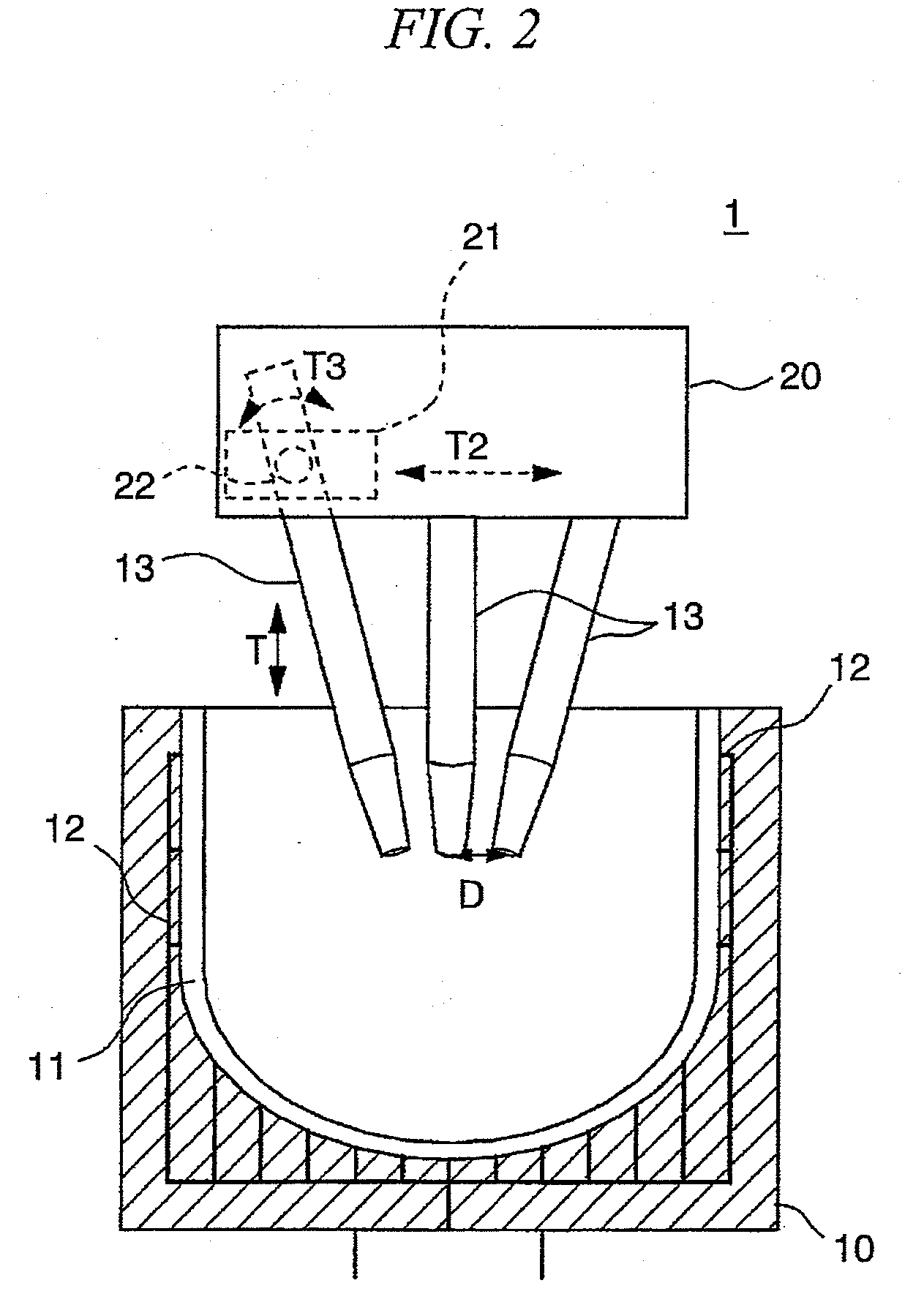

Inner crystallization crucible and pulling method using the crucible

InactiveUS20090165700A1Low dissolution ratePromote growthPolycrystalline material growthBy pulling from meltCrucibleSingle crystal silicon

A vitreous silica crucible for pulling single-crystal silicon, comprising a surface glass layer having a thickness of 100 μm from an inner surface of the crucible, and a glass layer provided below the surface glass layer in a thickness direction of the crucible and extending to a depth of 1 mm from the inner surface of the crucible. The concentration of OH groups in the surface glass layer is 90 ppm or less, and the concentration of OH groups in the glass layer is equal to or more than 90 ppm and equal to or less than 200 ppm. The bubble content in the glass layer is 0.1% or less.

Owner:JAPAN SUPER QUARTZ CORP

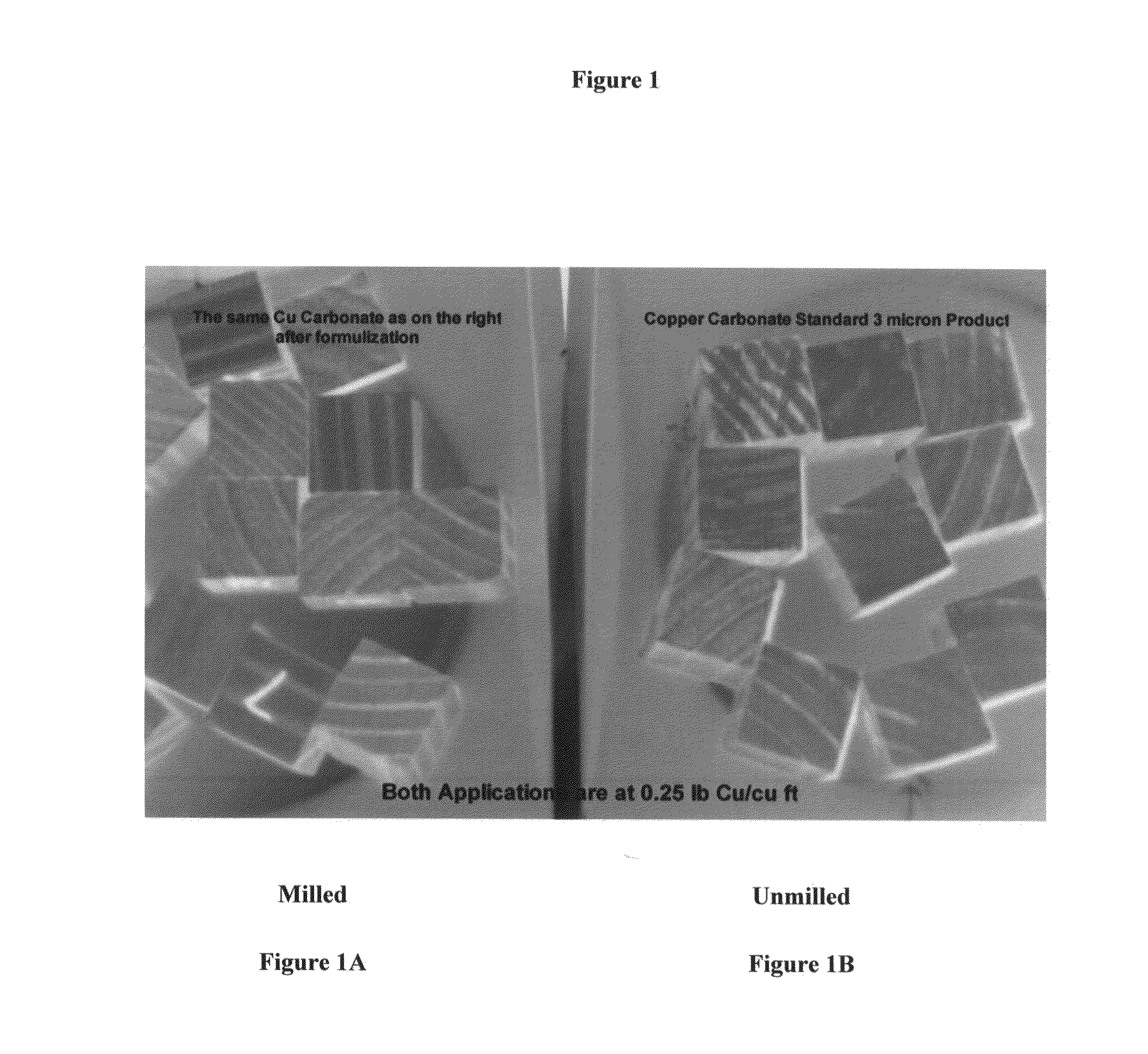

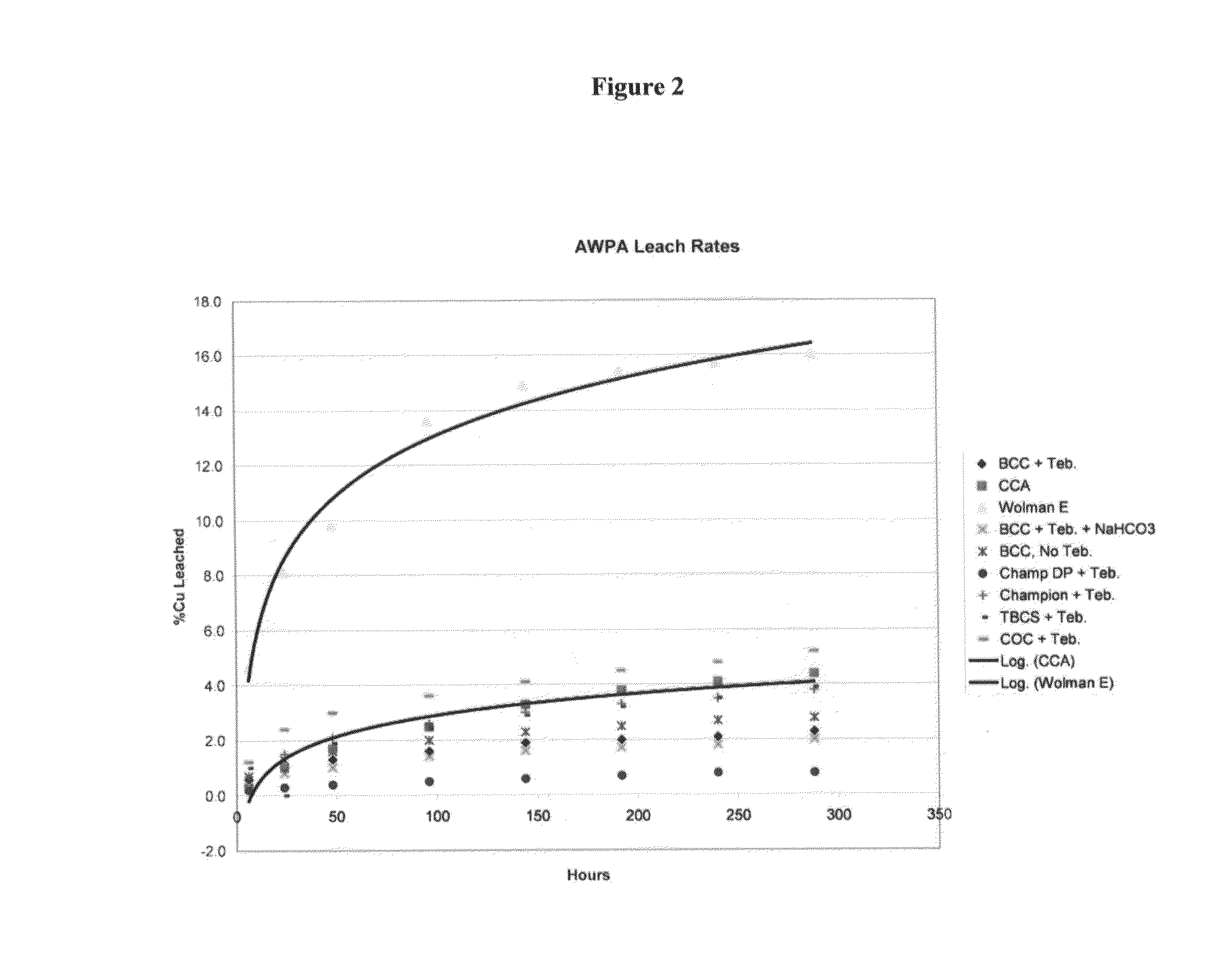

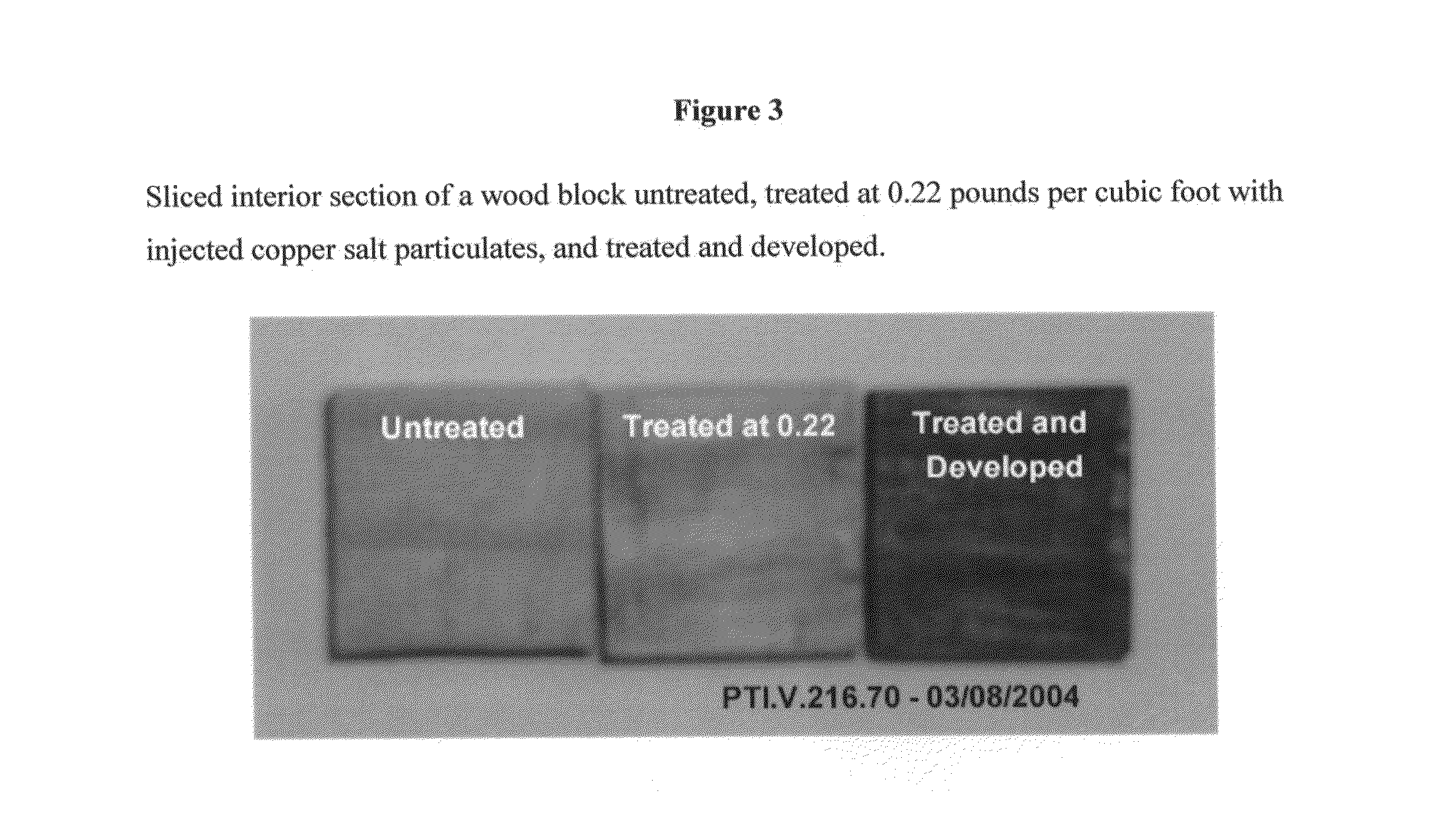

Particulate wood preservative and method for producing the same

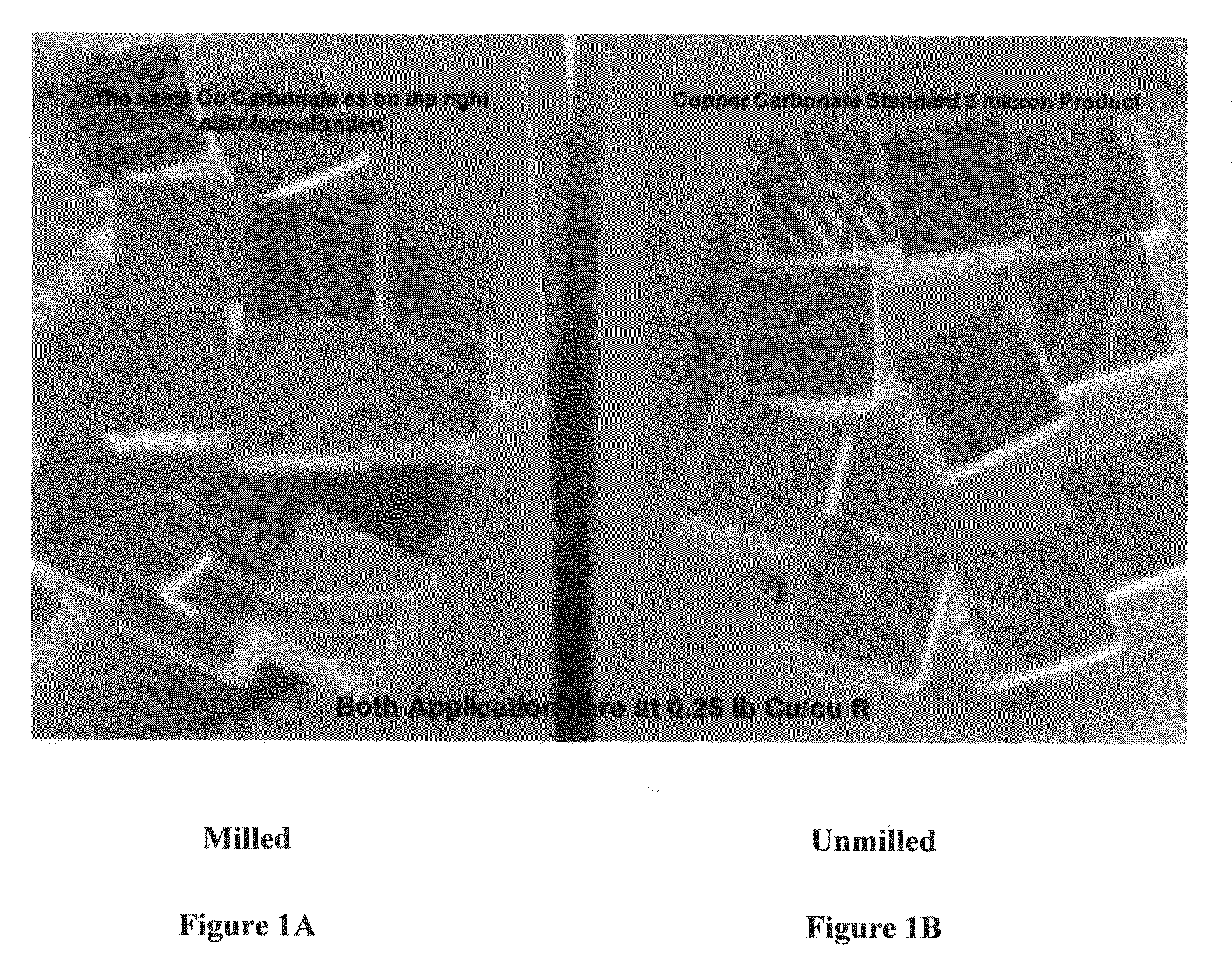

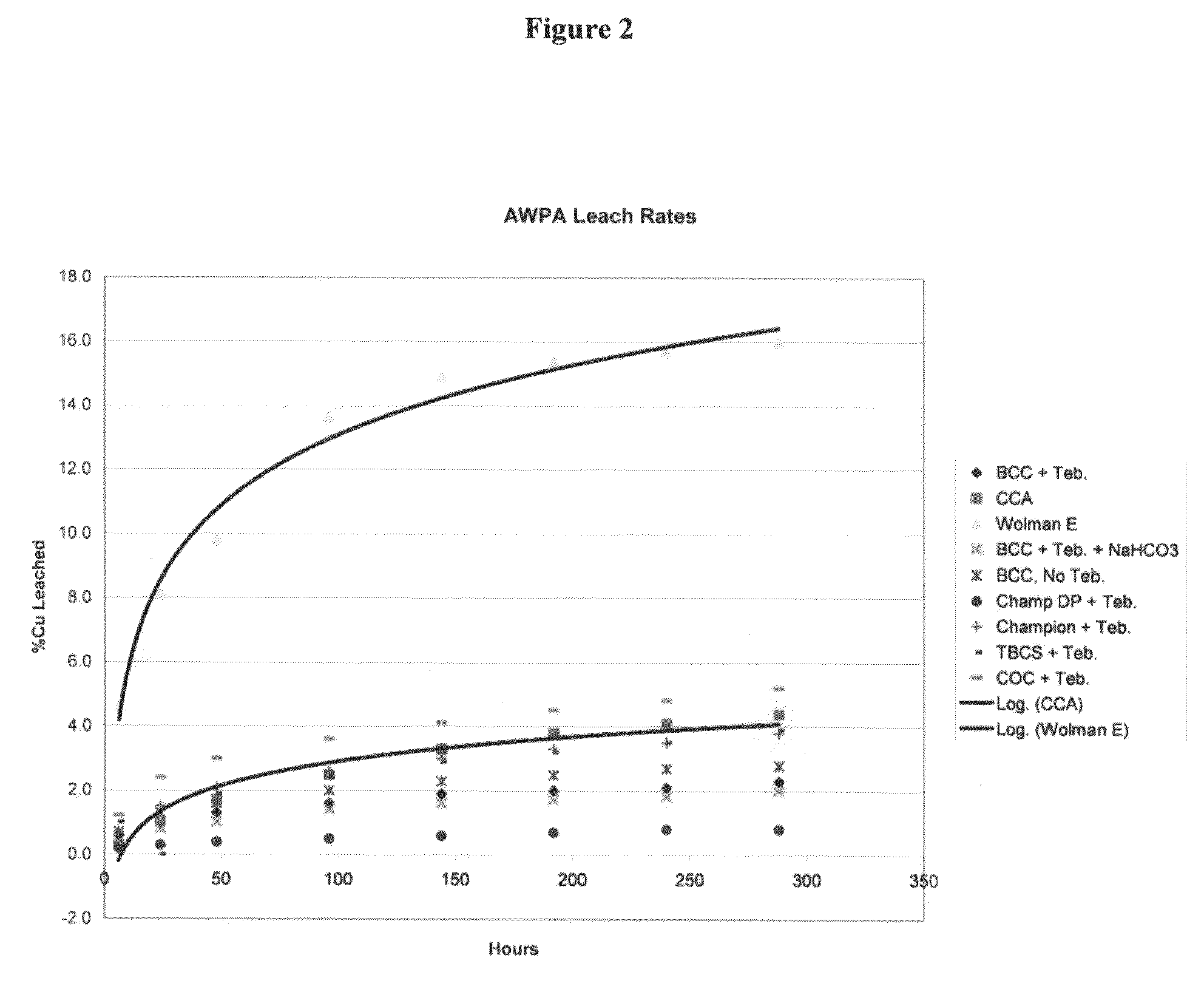

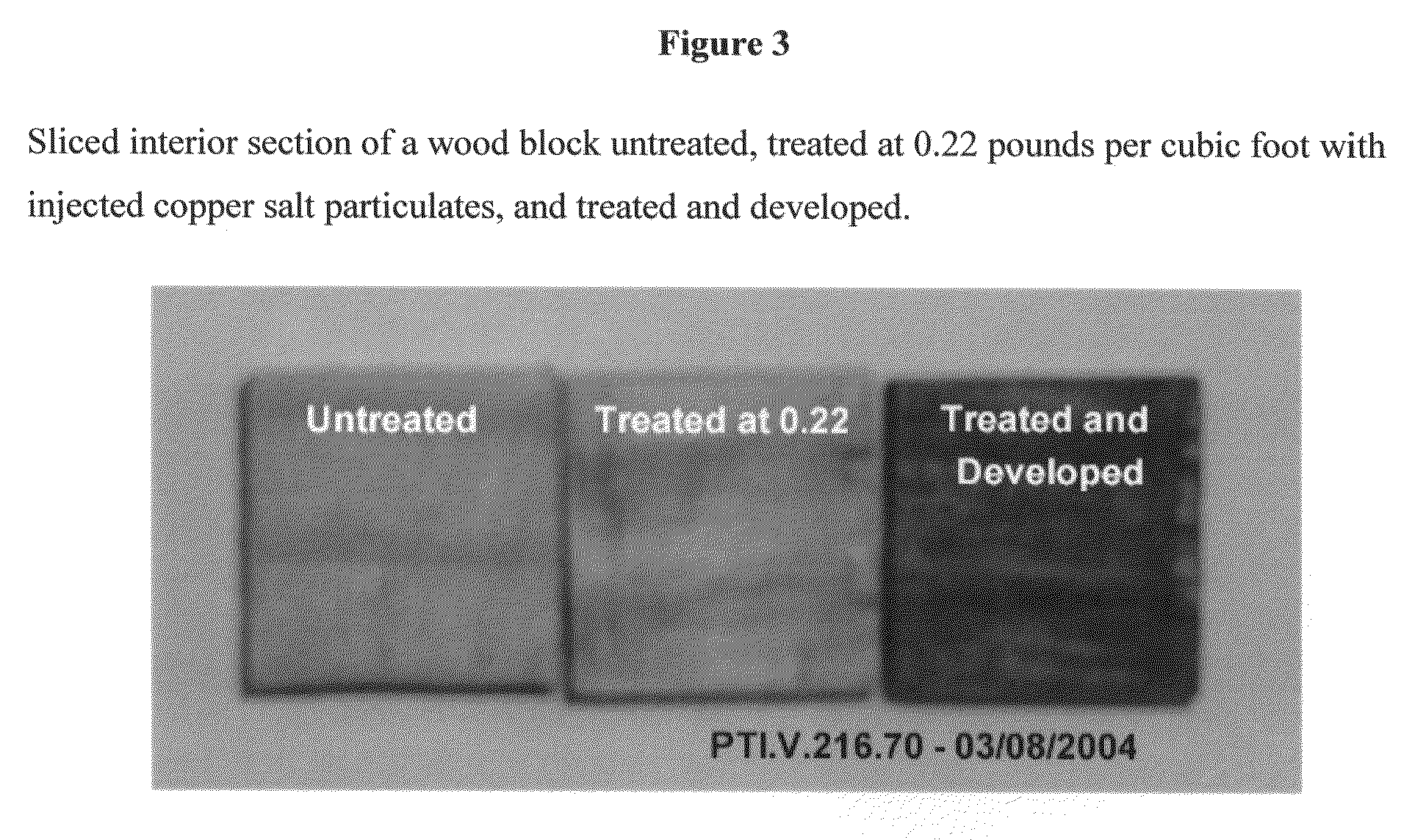

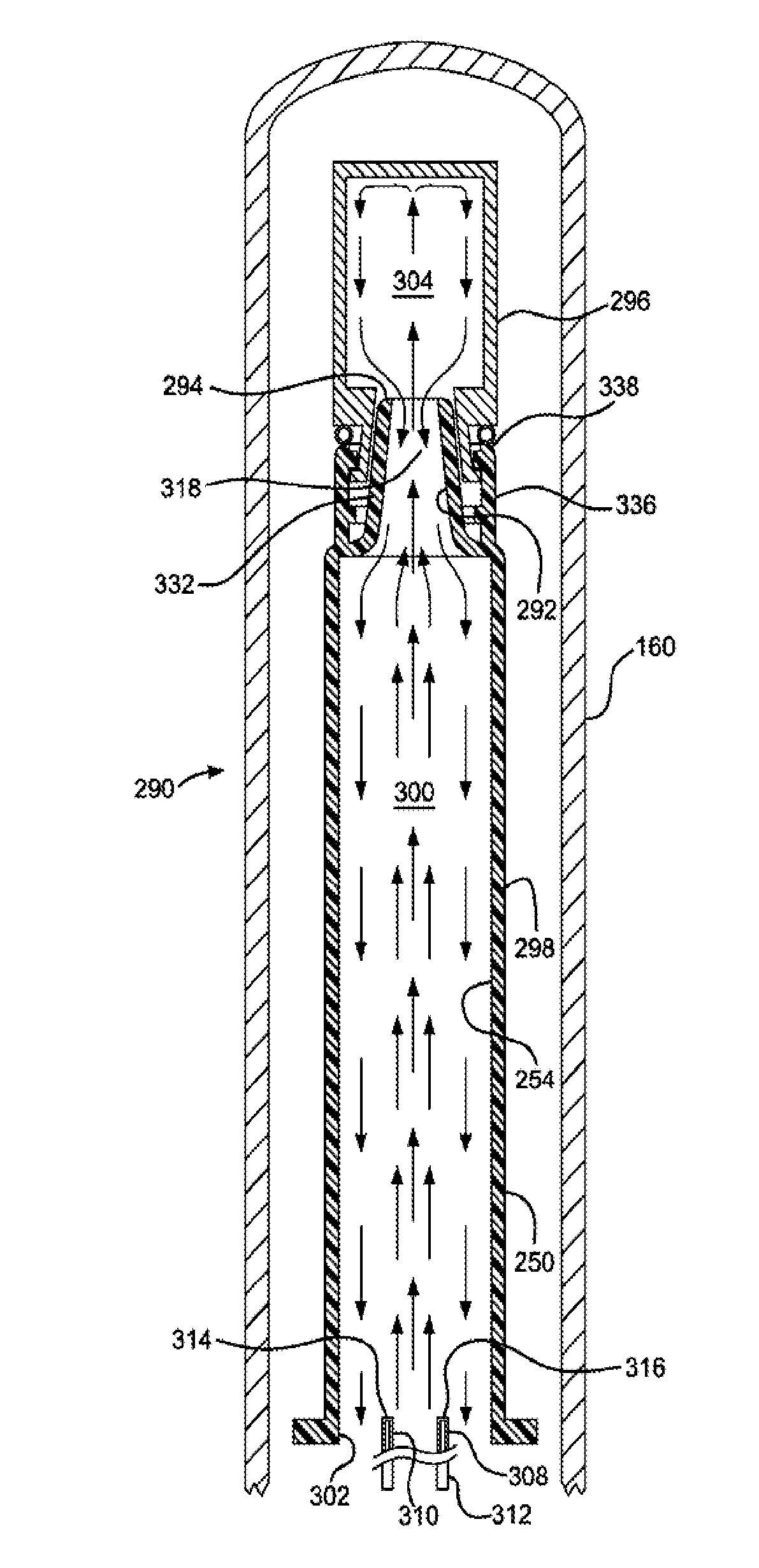

ActiveUS8409627B2Effective, long-lasting, environmentally responsible, non-staining/coloringLow dissolution ratePowder deliveryBiocideCopper(II) hydroxideCopper nitrate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

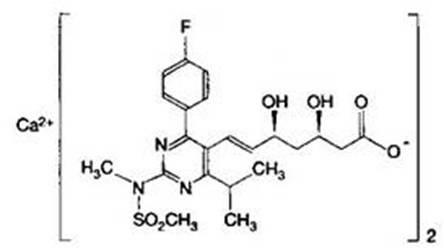

Method for preparing tablet drug composition containing Rosuvastatin calcium

InactiveCN102008477AThe monitoring indicators are qualifiedLow dissolution rateOrganic active ingredientsMetabolism disorderCyclodextrinRosuvastatin Calcium

The invention relates to a method for preparing a tablet drug composition containing Rosuvastatin calcium. The preparation forms of the drug composition can be administered to the patients safely and the stability of Rosuvastatin calcium and the absorbability in gastrointestinal tract can be improved. Specifically, the invention relates to a method for preparing the drug composition containing amorphous Rosuvastatin calcium and beta-cyclodextrin. The method is characterized by grinding Rosuvastatin calcium and beta-cyclodextrin under alkaline condition, drying and crashing to obtain (80-100)-mesh fine powder, mixing the fine powder with appropriate auxiliary materials, preparing granules, carrying out tabletting and carrying out coating, thus preparing the drug composition. The in vitro release of the composition is improved to a greater degree, thus improving the bioavailability; and the composition can effectively treat hyperlipidemia, is convenient to take orally, covers the bad taste and is fast to disintegrate and absorb and convenient to carry.

Owner:TIANJIN HANRUI PHARMA

Particulate wood preservative and method for producing the same

ActiveUS20090280185A1Low dissolution rateEasy to characterizePowder deliveryBiocideCopper nitrateTribasic copper sulfate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

Saccharide protective coating for pharmaceutical package

ActiveUS20150126941A1Stay efficientReduce decreaseDiagnosticsSurgeryChemical effectsBiomedical engineering

A method for providing a saccharide based lubricating or protective coating or layer on a substrate surface is provided. In particular, a lubricity and / or protective coating or layer made by said method is provided. Pharmaceutical packages or other vessels coated by said method and the use of such pharmaceutical packages or other vessels protecting a compound or composition contained or received in said vessel with a protective coating against mechanical and / or chemical effects of the surface of the vessel without a protective coating material are also provided.

Owner:SI02 MEDICAL PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com