Patents

Literature

36 results about "Copper(II) hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

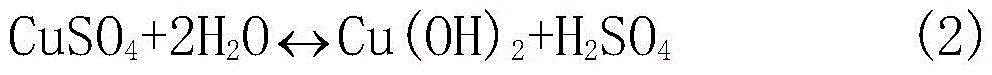

Copper(II) hydroxide is the hydroxide of copper with the chemical formula of Cu(OH)₂. It is a pale greenish blue or bluish green solid. Some forms of copper(II) hydroxide are sold as "stabilized" copper hydroxide, although they likely consist of a mixture of copper(II) carbonate and hydroxide. Copper hydroxide is a weak base.

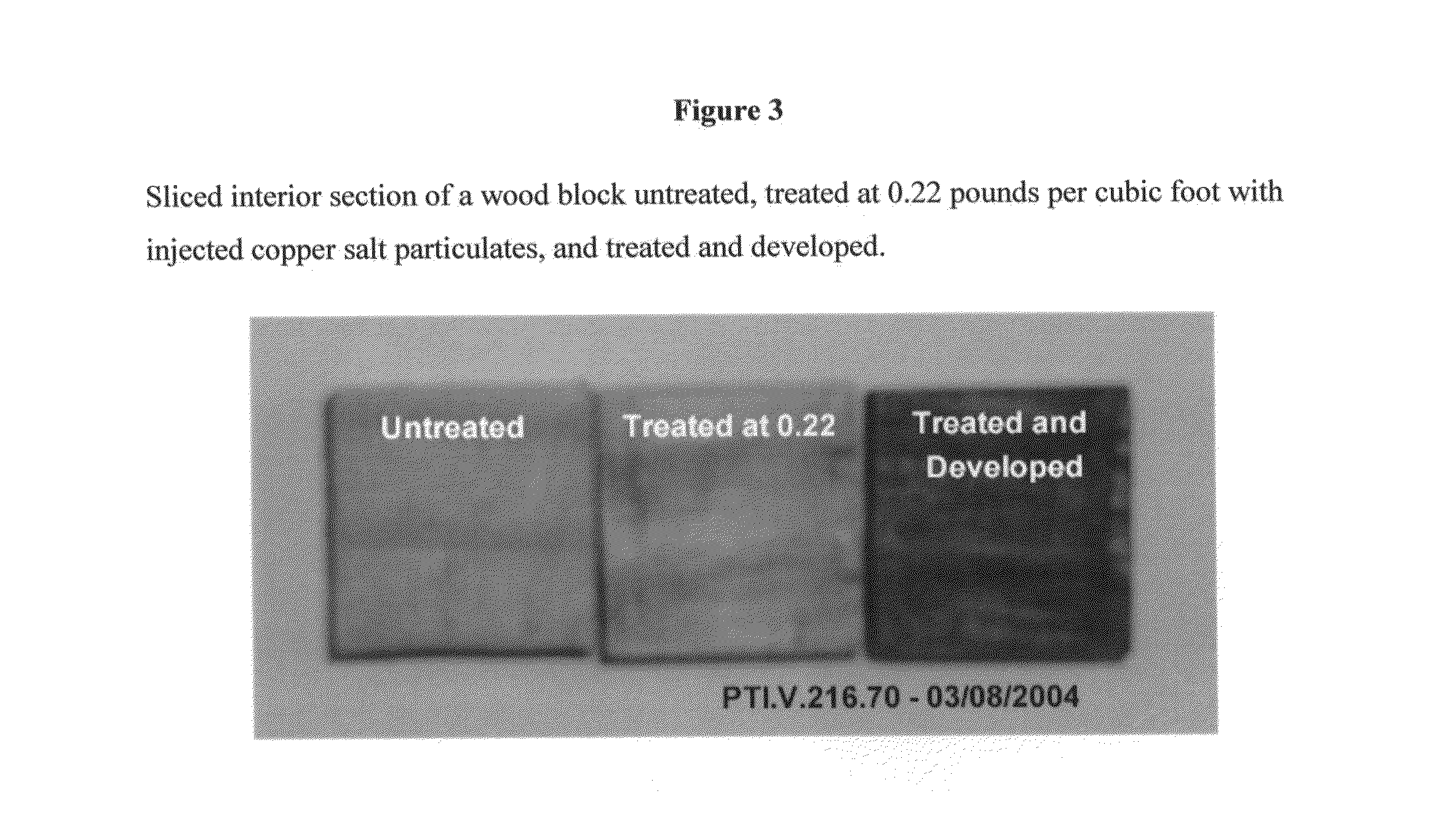

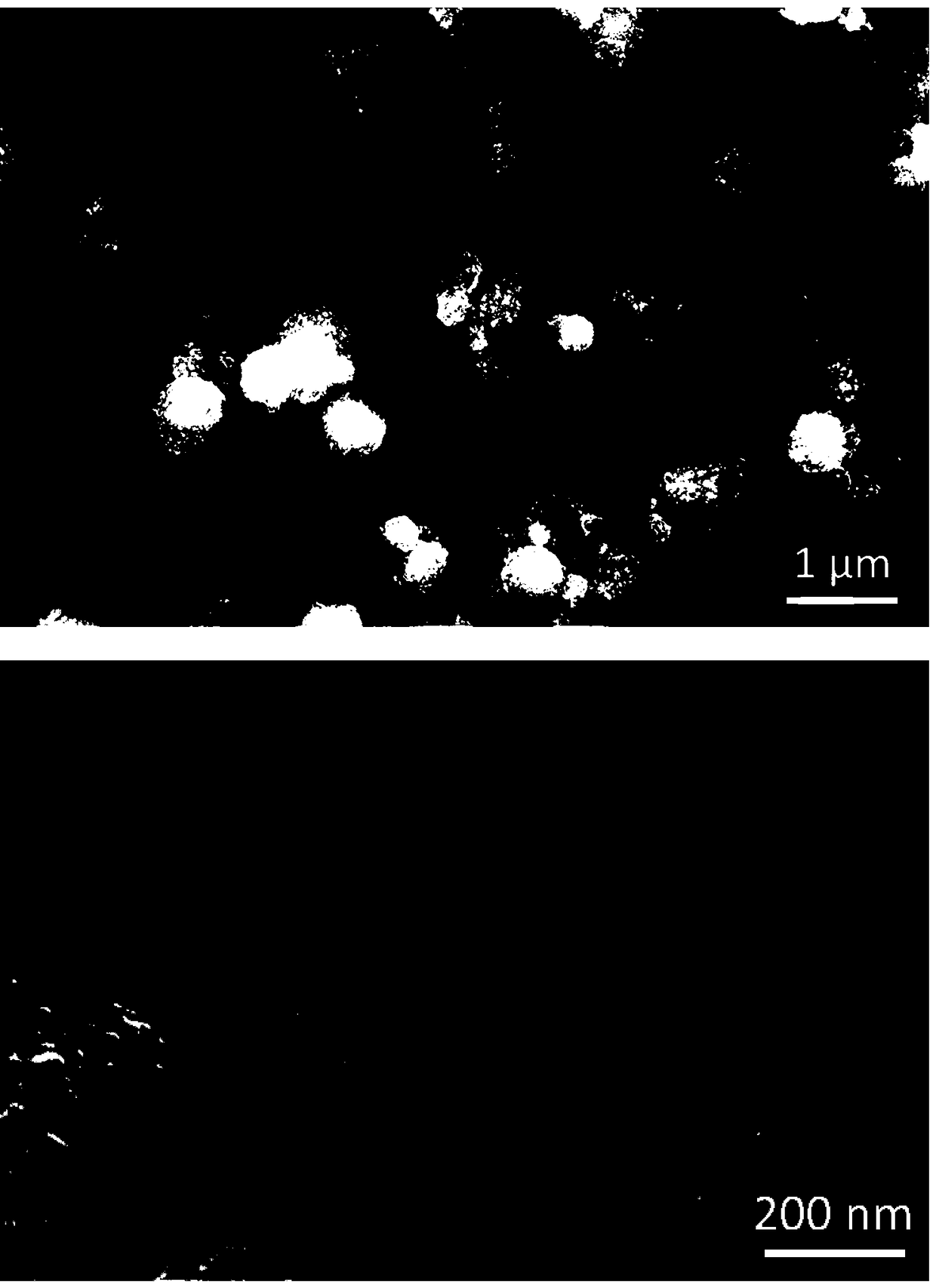

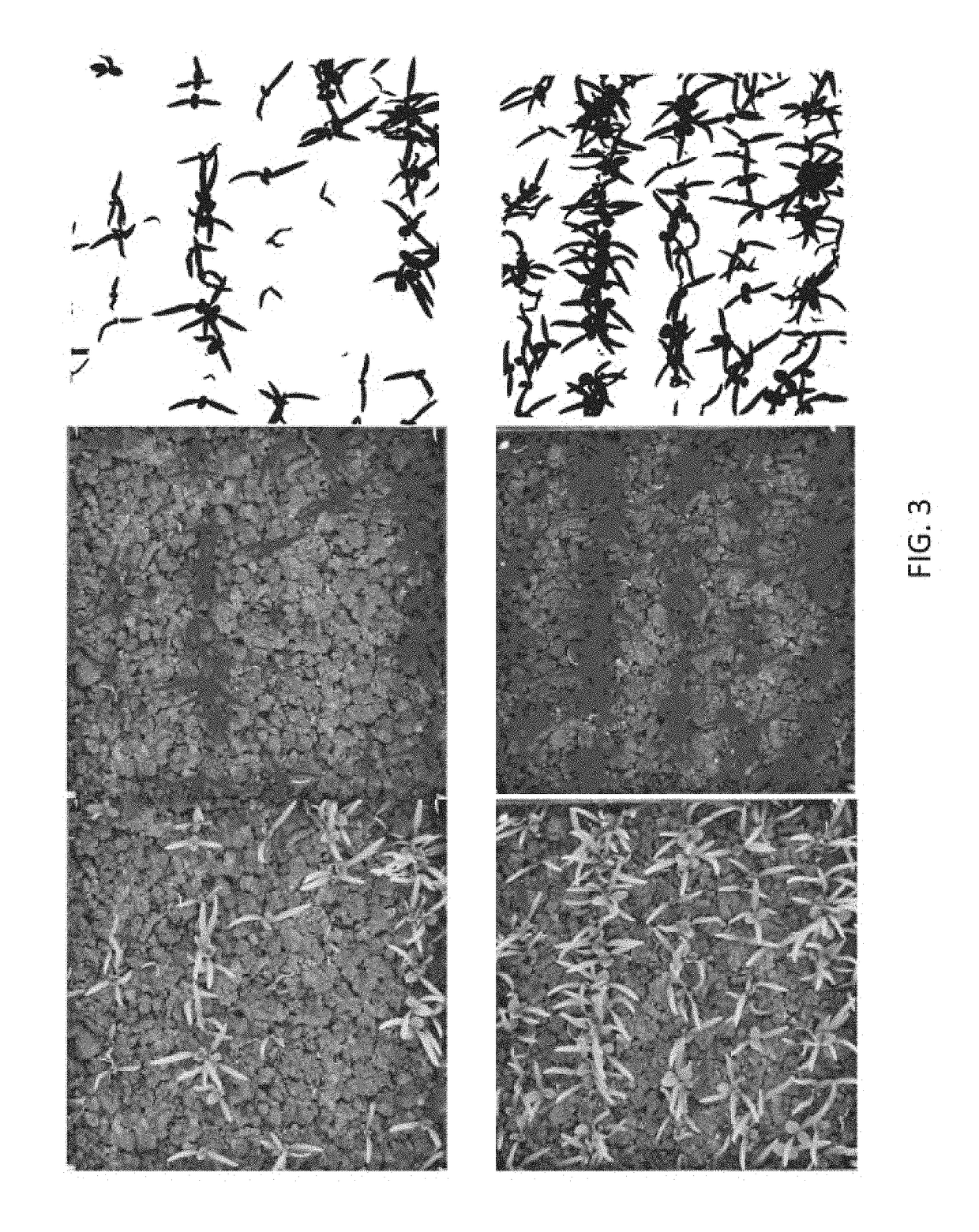

Particulate wood preservative and method for producing same

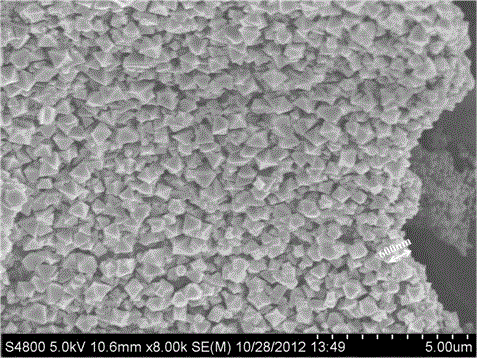

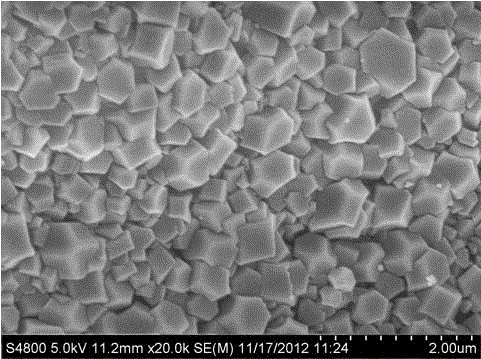

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

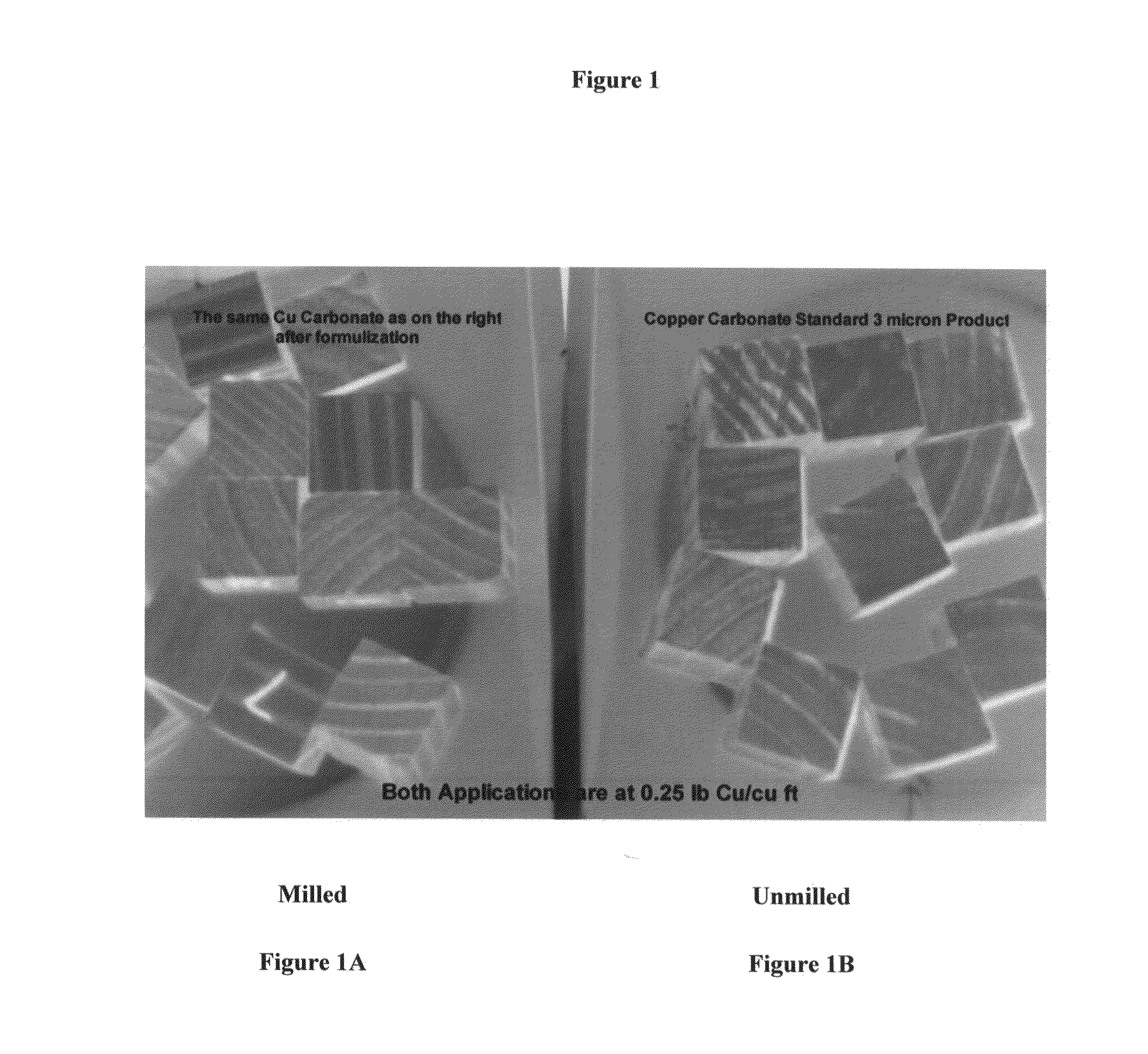

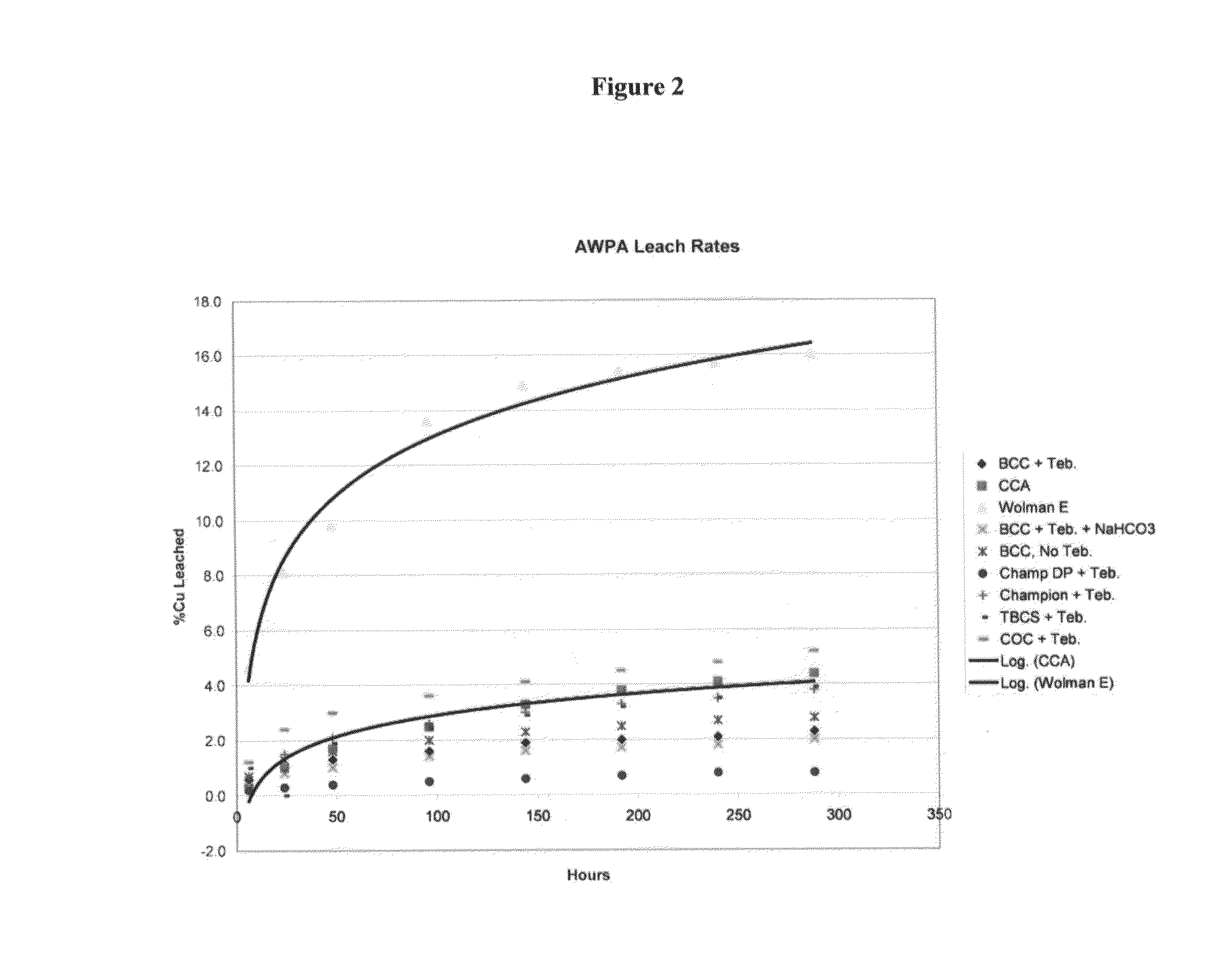

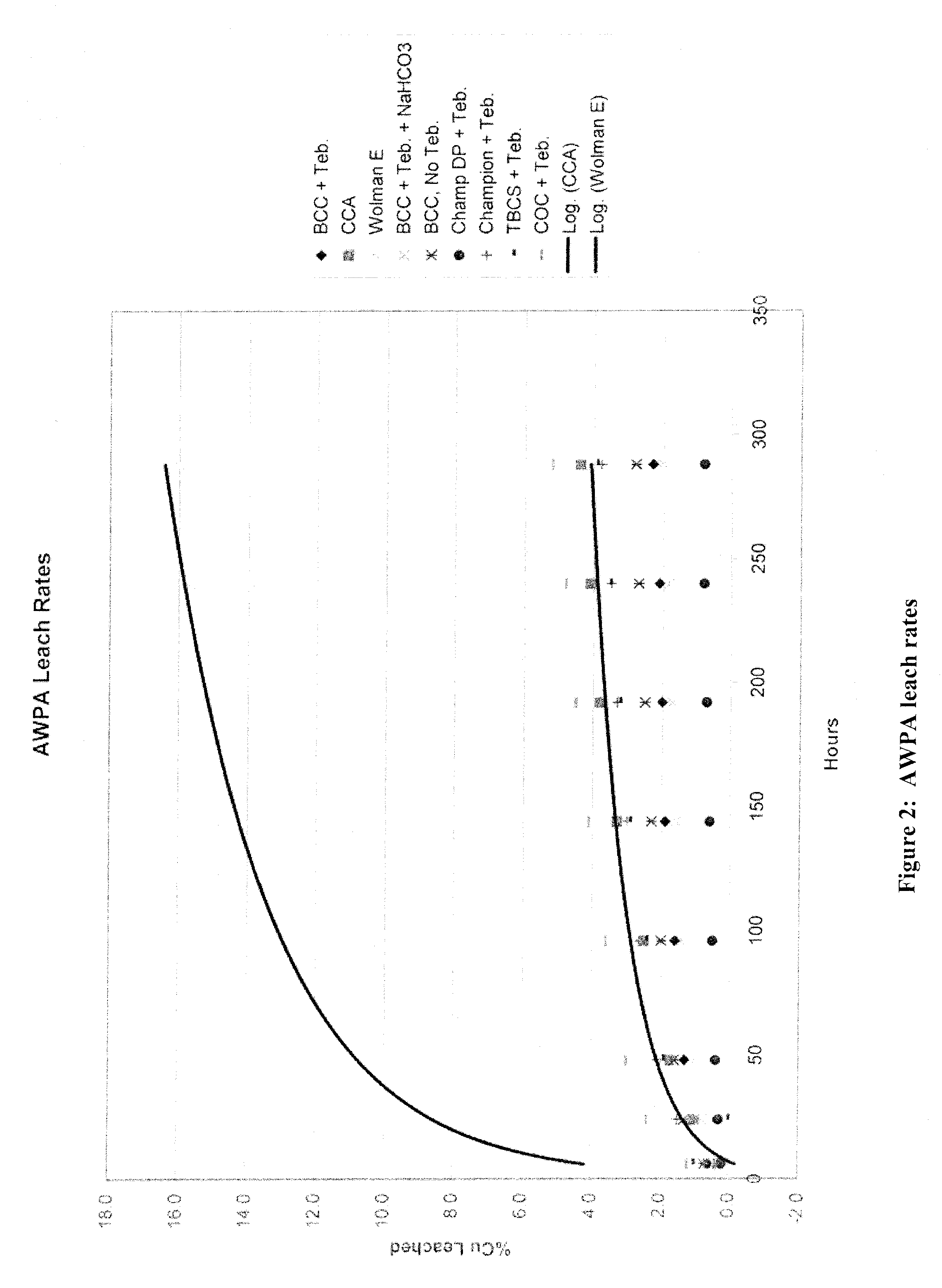

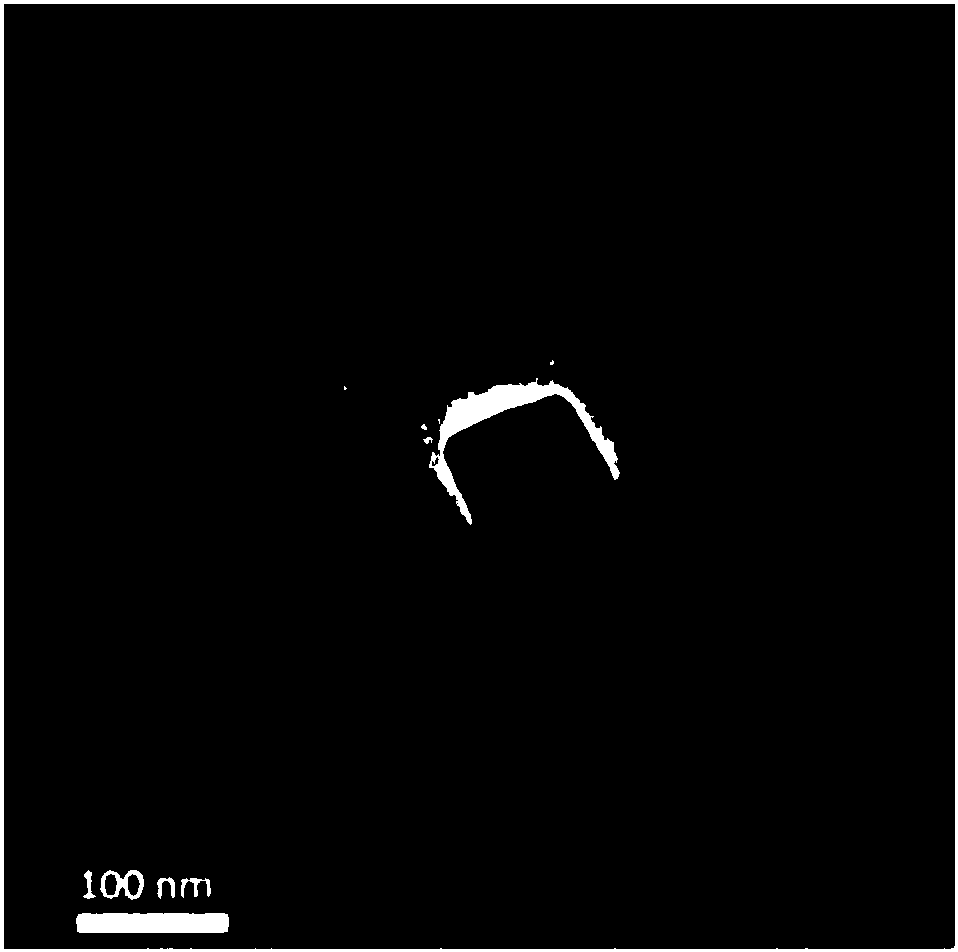

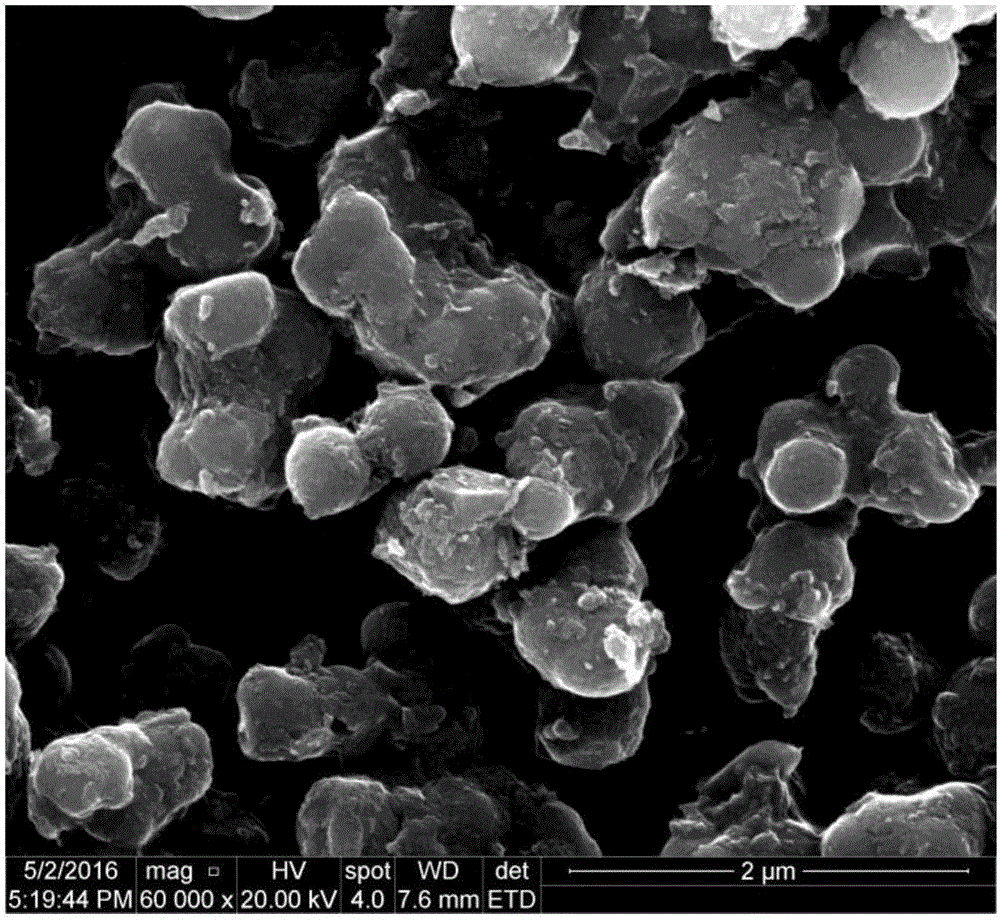

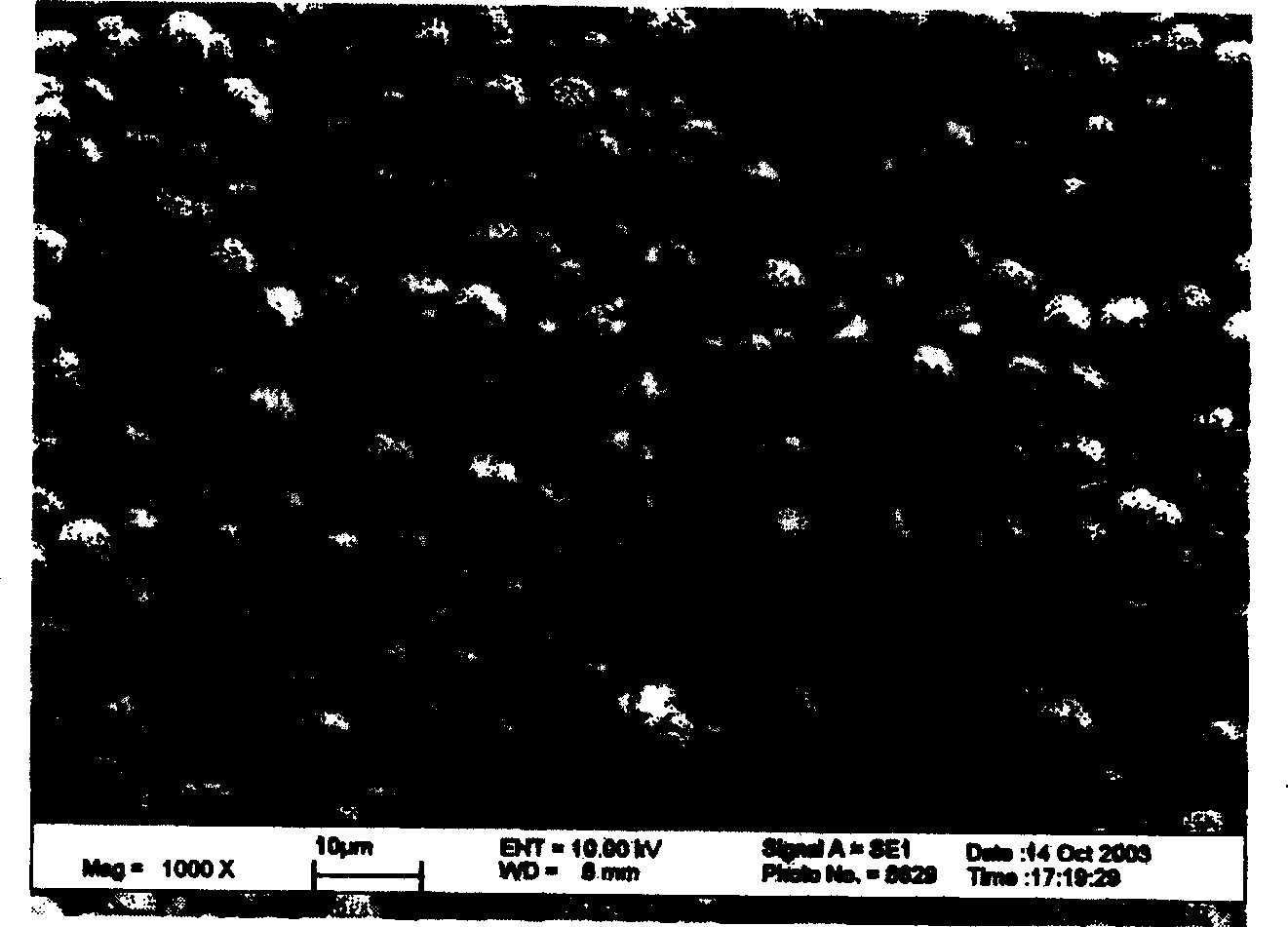

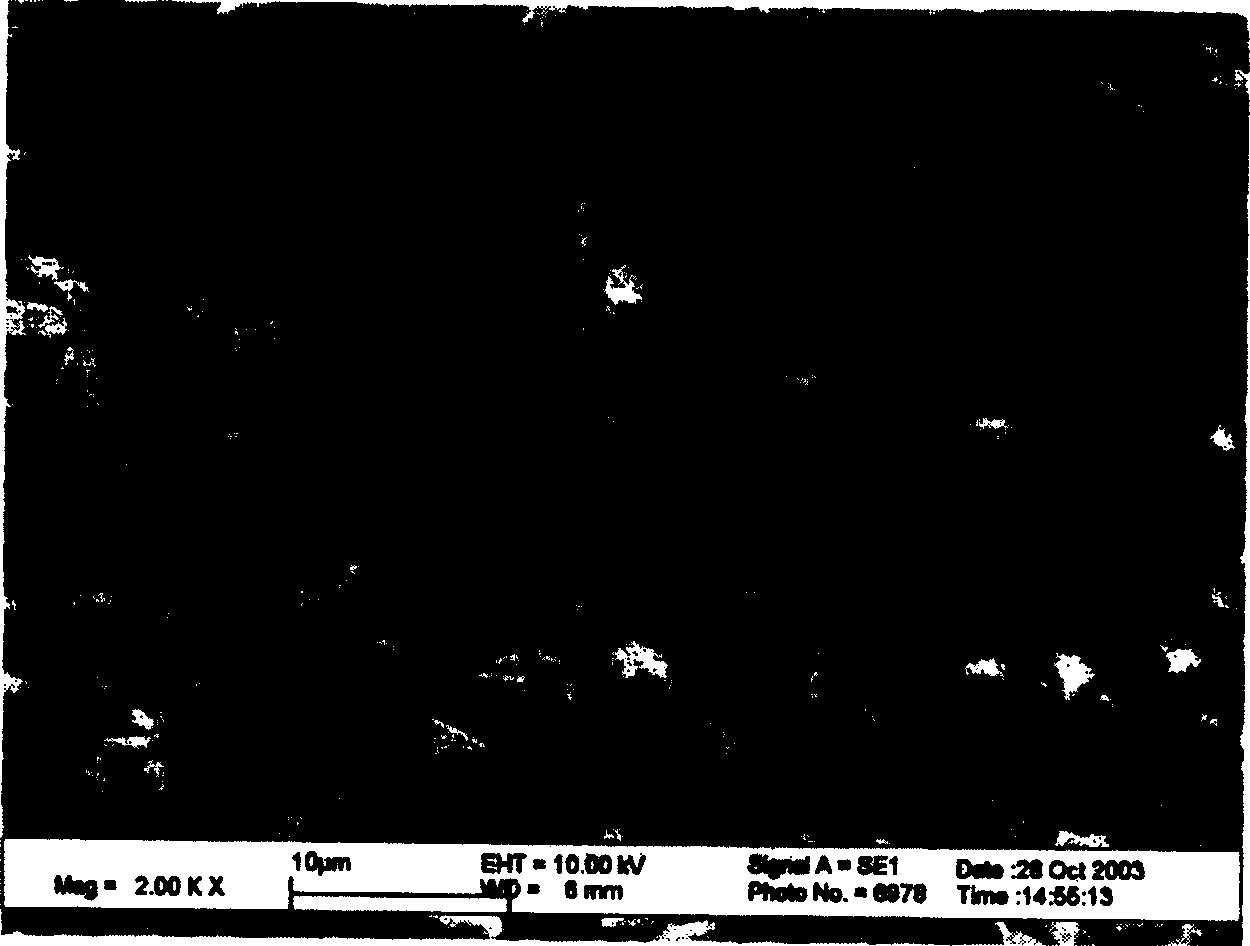

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

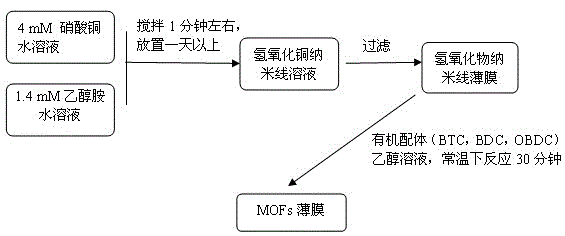

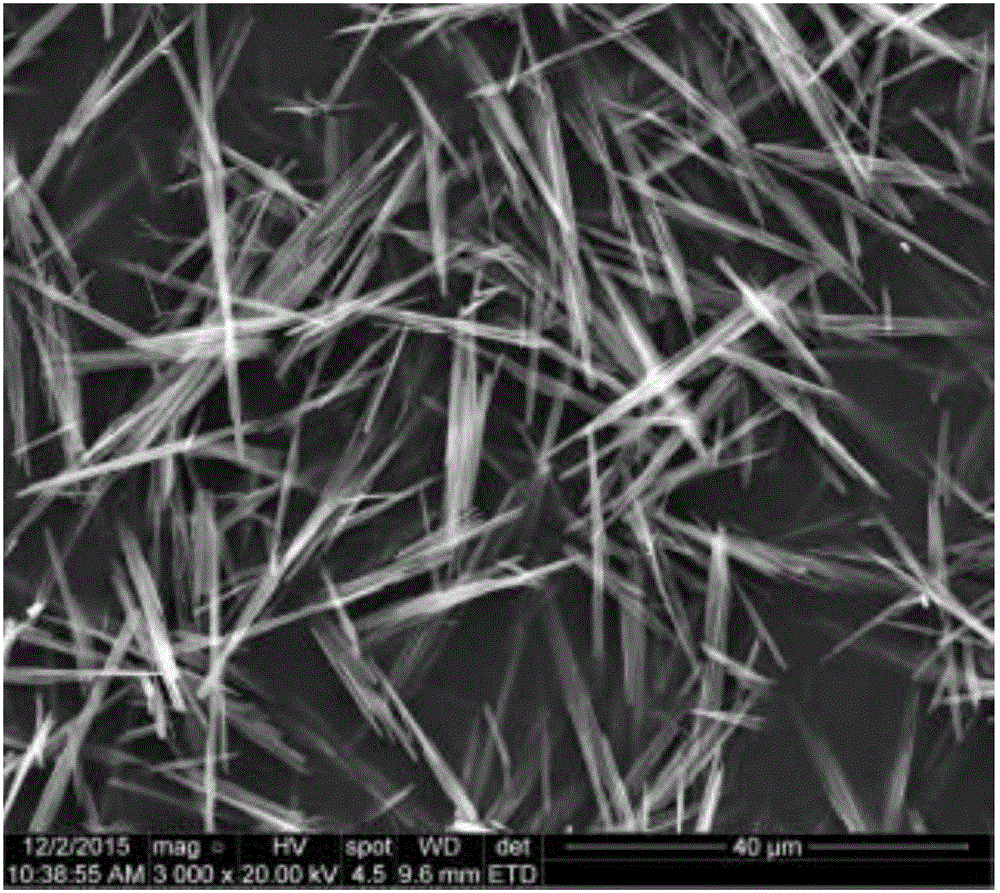

Method of rapidly preparing metal organic framework material thin-film from hydroxide nanowires and organic ligands under normal temperature

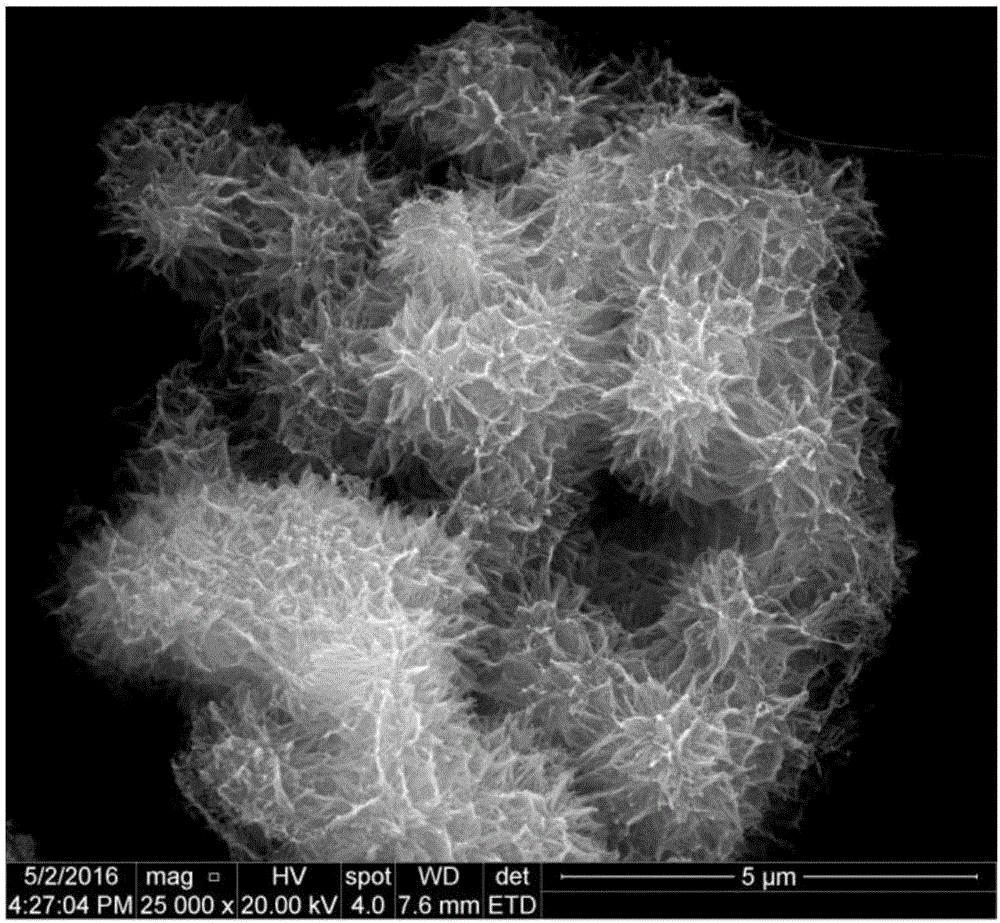

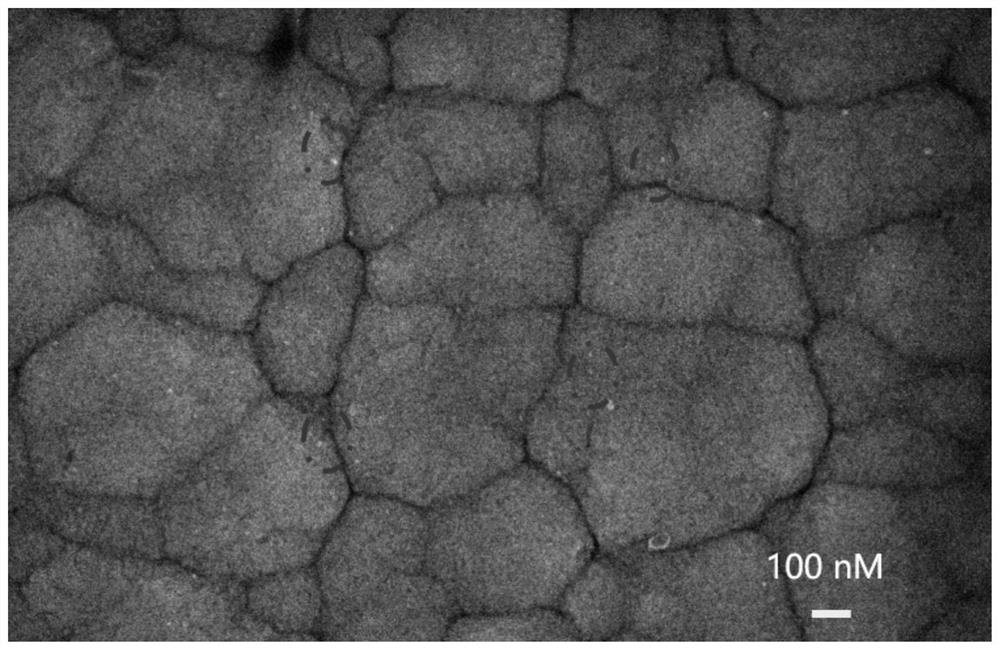

The invention discloses a method of rapidly preparing a metal organic framework material thin-film from hydroxide nanowires and organic ligands under a normal temperature. The method comprises (1) adding an ethanolamine aqueous solution into cupric nitrate, zinc nitrate or cadmium nitrate aqueous solution of a same volume under magnetic stirring, slowing down a stirring speed to obtain corresponding copper hydroxide, zinc hydroxide or cadmium hydroxide nanowire solution, and directly filtering the nanowire solution through a porous alumina film to form a nanowire layer; (2) adding the nanowire layer into an organic ligand solution with ethanol, octanol or N,N-dimethyl formamide as a solvent, and reacting for 30 minutes under the normal temperature to obtain the metal organic framework material thin-film. The method provided by the invention can directly prepare large-area compact thin-film on a porous substrate under the normal temperature, and the method is simple in operation steps, low in cost, and environmental-protective. Reaction residues can be easily recovered. The prepared thin-film can stably exist. The method expands an application range of the metal organic framework material thin-film.

Owner:ZHEJIANG UNIV

Particulate wood preservative and method for producing the same

ActiveUS8409627B2Effective, long-lasting, environmentally responsible, non-staining/coloringLow dissolution ratePowder deliveryBiocideCopper(II) hydroxideCopper nitrate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

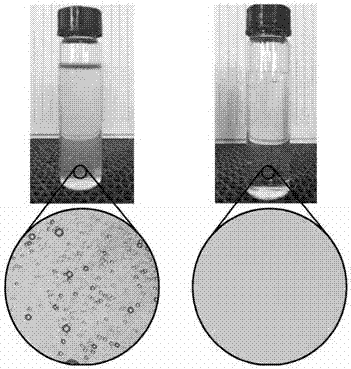

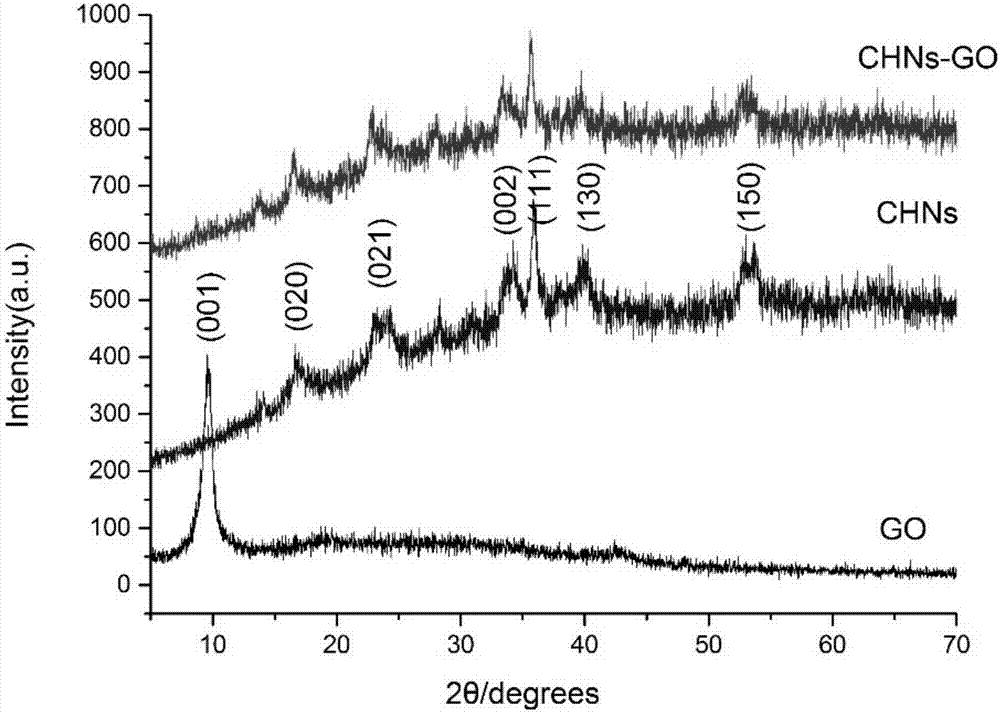

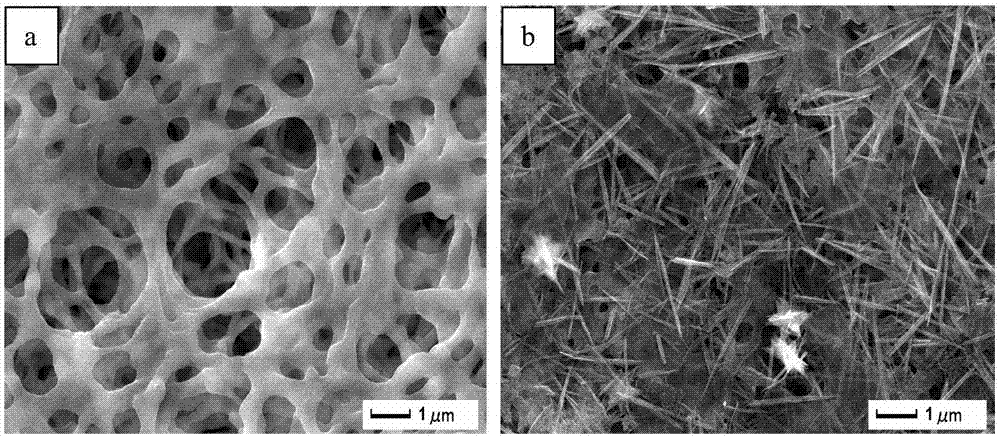

Hydrophilic-underwater super-oleophobic graphene oxide-base filter membrane, preparation method and application

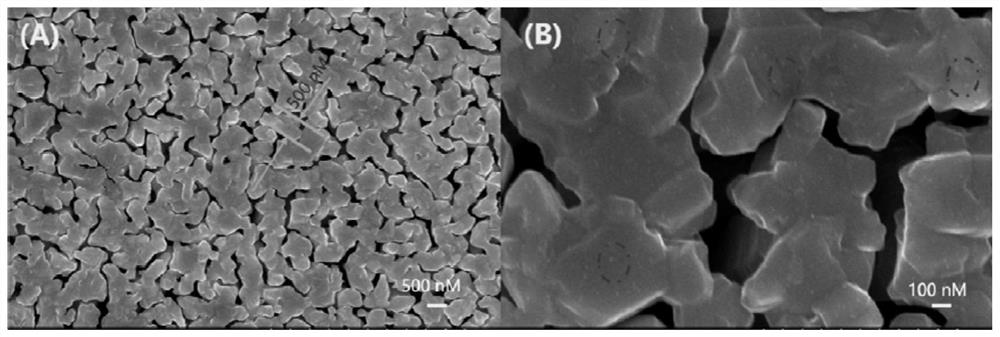

InactiveCN107376657AImprove throughputImprove stabilityMembranesSemi-permeable membranesEpoxyNanowire

The invention provides a hydrophilic-underwater super-oleophobic graphene oxide-base filter membrane, a preparation method and application. Epoxy group, hydroxyl, carbonyl and carboxyl on a graphene oxide nanosheet are used as anchoring loci for embedding a copper hydroxide nanowire, a copper hydroxide nanowire with hydroxyl on an outer surface is attached onto the graphene oxide nanosheet by virtue of hydrogen bonds, the copper hydroxide nanowire covers and is inserted into a surface and a gap of a flaky graphene oxide sheet so as to adjust the surface physical performance and a channel layering structure of the flaky graphene oxide and to form a composite material with a coarse surface structure and a nanoscale channel structure, the copper hydroxide nanowire with positive charges and the graphene oxide sheet with negative charges are closely accumulated onto a porous filter membrane by virtue of electrostatic interaction, and the hydrophilic-underwater super-oleophobic graphene oxide-base filter membrane is formed. The hydrophilic-underwater super-oleophobic graphene oxide-base filter membrane is used for separating oil and water, has the characteristics of good hydrophilic performance and mechanical performance, has good stability and improves the membrane pollution resistance.

Owner:JIANGSU UNIV

Method for producing complexation metal salt of ethylenediamine tetra acetic acid

InactiveCN1431193AHigh purityReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationComplexonsZinc hydroxide

A process for preparing a high-purity metal salt of complexon as trace-element fertilizer includes adding complexon and alkali (sodium hydroxide, potassium hydroxide, or ammonia) to water, reaction while stirring to obtain complexon salt, adding metal salt (iron hydroxide, manganese hydroxide, etc.) at 150 deg.C for 0.5-5 hr, and filter to remove insoluble substance.

Owner:钟林 +2

Use of Sub-Micron Copper Salt Particles in Wood Preservation

InactiveUS20090223408A1Little dangerSmall particle sizeFireproof paintsBiocideCopper(II) hydroxidePhosphate

A method for preserving wood by injecting into the wood a slurry having: particles of a sparingly soluble copper salt, copper hydroxide, or both, wherein the weight average diameter d50 of the particles in the slurry is between 0.1 microns and 0.7 microns and the d98 of the particles in the slurry is less than about 1 micron; a dispersant; and water. The dispersant is anionic or a mix of anionic and non-ionic. Advantageously, less than 20% by weight of the particles have a diameter less than 20 nanometers. Useful copper salts include basic copper carbonate, tri-basic copper sulfate, copper oxychloride, basic copper nitrate, basic copper borate, copper borate, basic copper phosphate, or copper silicate. The slurry most preferably includes copper hydroxide particles. The slurry further advantageously includes at least one organic biocide, wherein at least a portion of the organic biocide is coated on the particles.

Owner:OSMOSE

Method for preparing cubic nano copper powder

ActiveCN108213456AGood dispersionNo agglomerationTransportation and packagingMetal-working apparatusDispersitySolvent

The invention belongs to the technical field of nanoscale copper powder preparation and provides a method for preparing cubic nano copper powder. The method comprises the steps that copper salt servesas a raw material, deionized water or absolute ethyl alcohol serves as a solvent, a stearic acid or oleic acid is added to a solution to serve as a protective agent and a dispersing agent, then a high-concentration alkali solution is added, the high-concentration alkali solution and the copper slat are made to generate copper hydroxide colloid, the pH of the solution is adjusted through the alkali solution, and the solution is made to be alkaline; and then, hydrazine hydrate serves as a reducing agent to be added to the prepared copper hydroxide colloid drop by drop, the mixture is heated atthe constant temperature of 20-90 DEG C, a reaction is performed for 10-300 minutes, and the cubic nano copper powder can be obtained. The copper powder in the prepared nano copper powder is in a cubeshape, particle size distribution is uniform, the average edge length is 100 nm, the yield is 90% or above, the dispersity is extremely high, the phenomenon of particle aggregation does not exist, and the cubic nano copper powder can be dispersed in water as well as in a weak solvent; and the method is simple in process, low in heating temperature, low in energy consumption and suitable for large-batch production.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

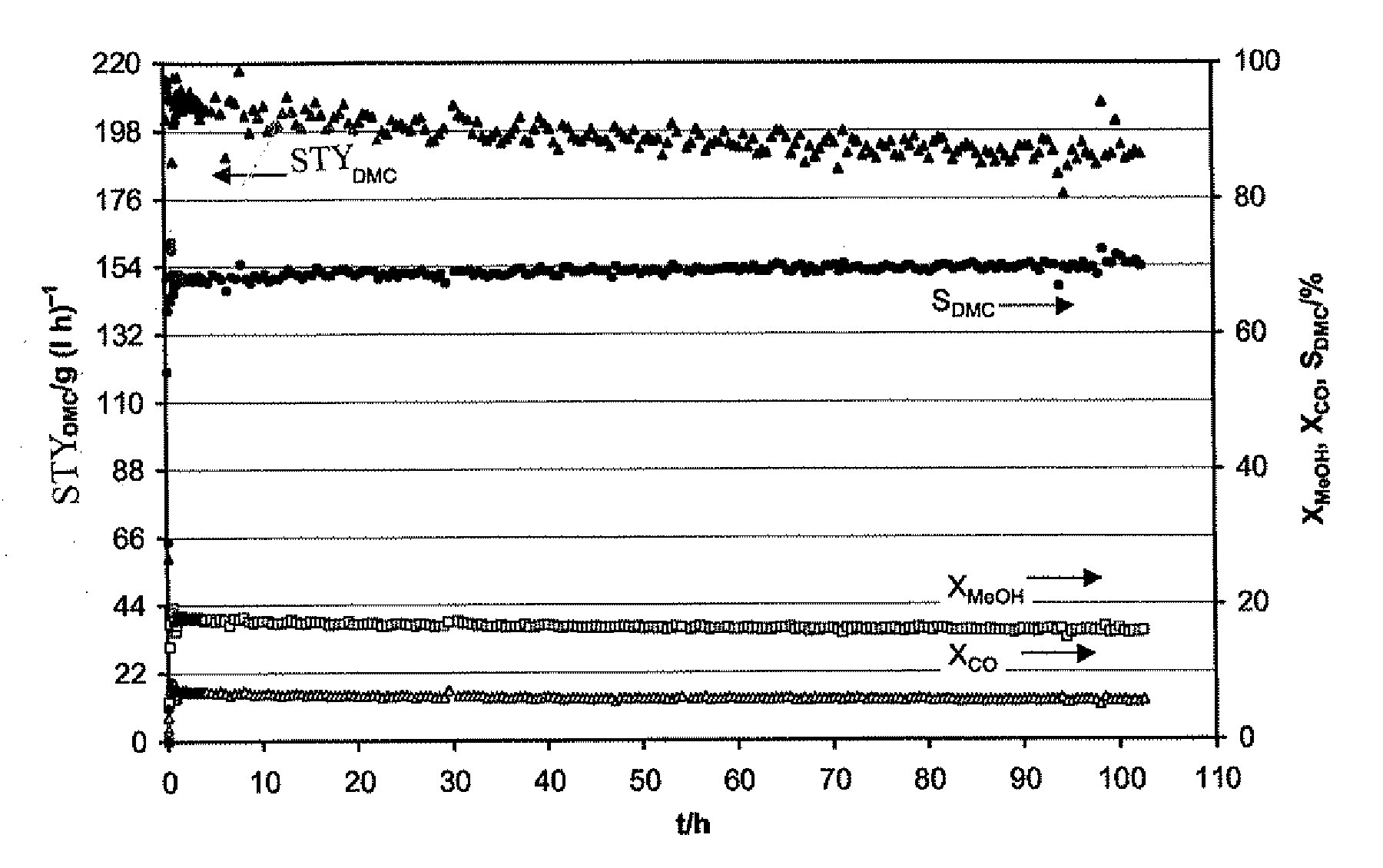

Catalyst for the Synthesis of Dimethyl Carbonate in the Gas Phase

InactiveUS20080249327A1Increased space-time yieldConstant operationAluminium compoundsMolecular sieve catalystsPtru catalystLiquid medium

The invention relates to an improved catalyst for the synthesis of dimethyl carbonate by reacting methanol, carbon monoxide and oxygen in the gas phase and to the use thereof. The catalyst consists of a copper-containing zeolite produced by admixing one or more halide-free copper(II) compounds to a zeolite in a liquid medium, drying the zeolite modified by the admixture, and tempering at 400-900° C. under inert conditions, essentially retaining the crystallinity of the zeolite, said admixing being effected by means of a method selected from the group consisting of impregnation of the zeolite, ion exchange, precipitation of copper(II) hydroxide in the presence of the zeolite, and a combination of these methods. The catalyst shows high space-time yields, is constant over the period of operation and has no corrosive action.

Owner:SUD CHEM AG

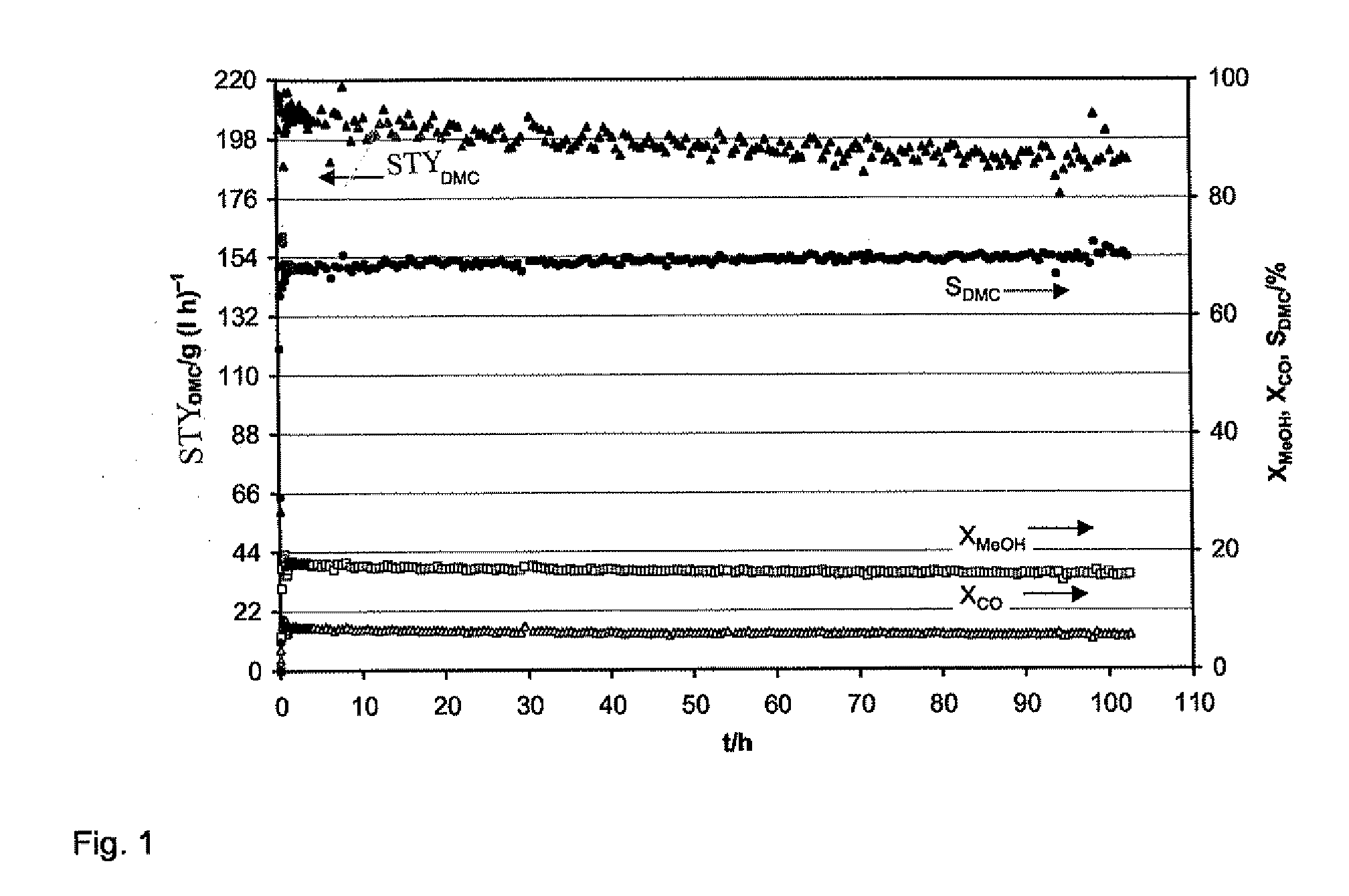

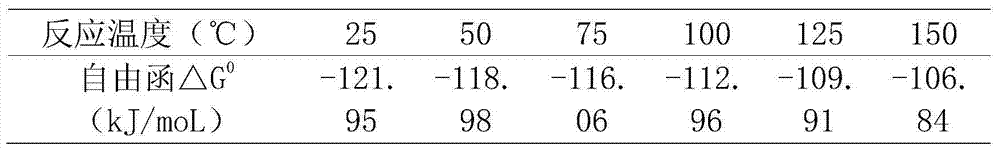

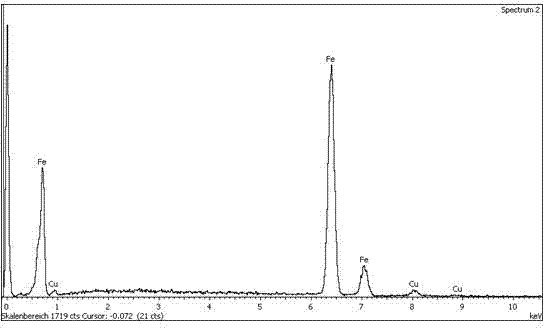

Method for removing iron and arsenic in copper sulfate solution

InactiveCN104846199ALow costAchieve the purpose of removalProcess efficiency improvementLead smeltingCopper(II) hydroxide

The invention relates to a method for removing iron and arsenic in a copper sulfate solution and belongs to the field of nonferrous metal hydrometallurgy. The method comprises the following steps: under a stirring condition, adding copper hydroxide slag to a copper sulfate solution containing a certain amount of iron and arsenic, controlling the pH of the solution to the range of 1.0-2.0, adding industrial-grade hydrogen peroxide in a certain molar ratio according to the content of iron and arsenic in the solution to oxidize the low-valence state iron and arsenic in the solution, and then adding the copper hydroxide slag again, controlling the final pH to the range of 2.0-3.5, and after liquid-solid separation, crystalizing the solution removed from iron and arsenic to prepare a copper sulfate product or an electro-deposited cathode copper product, and treating the filter cake in a lead smelting system. The method is capable of efficiently removing the iron and arsenic in the copper sulfate solution; the iron removal rate is within the range of 99.20-99.80% and the arsenic removal rate is within the range of 95.86-99.22%; and no impurity ion is introduced in the whole process, and the whole process is clean and efficient in production.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

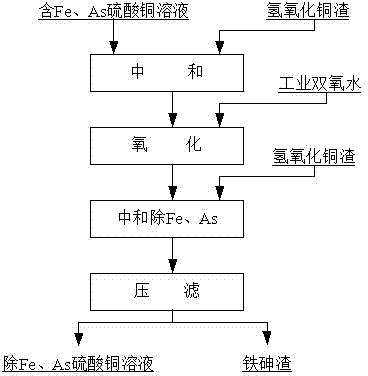

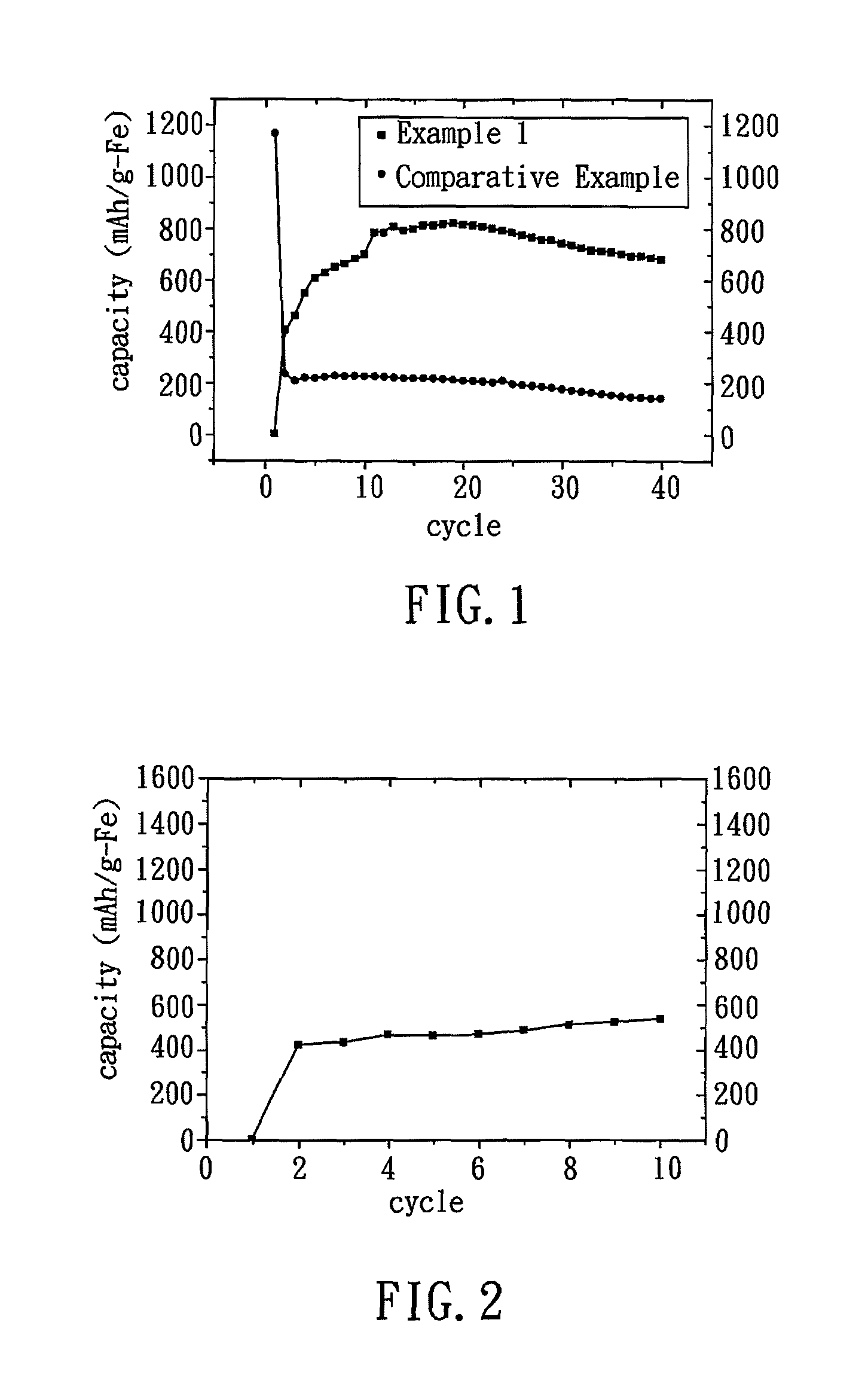

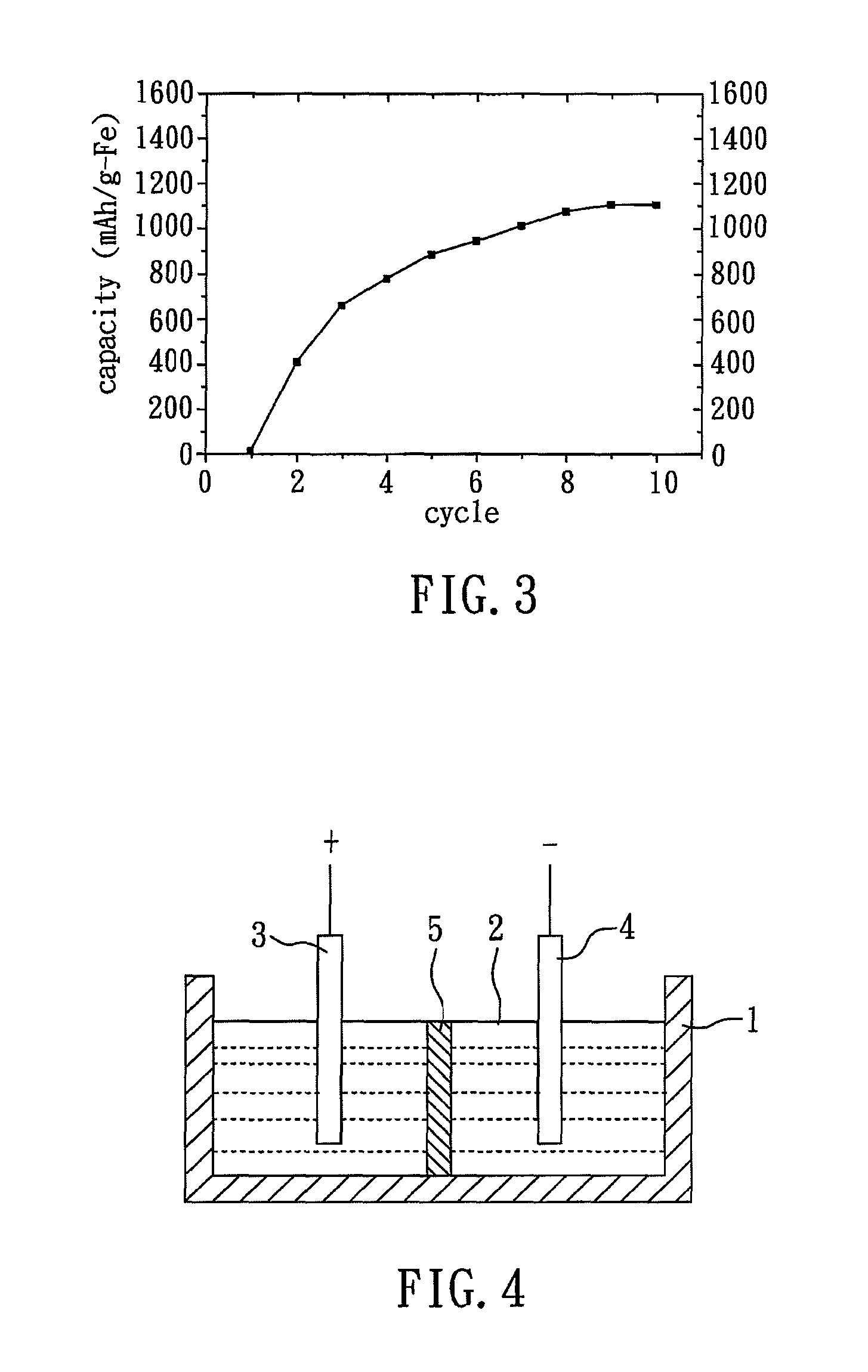

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS8486563B2Large capacityLarge scaleSilver accumulatorsNon-metal conductorsGold(III) hydroxideIndium

Owner:NATIONAL TSING HUA UNIVERSITY

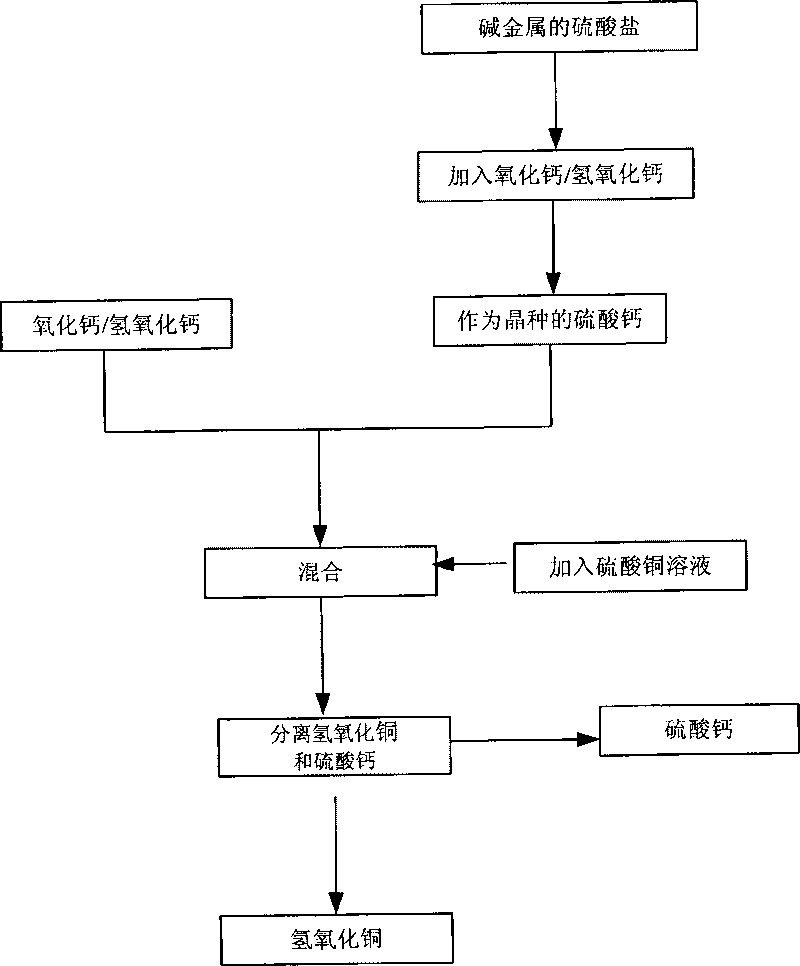

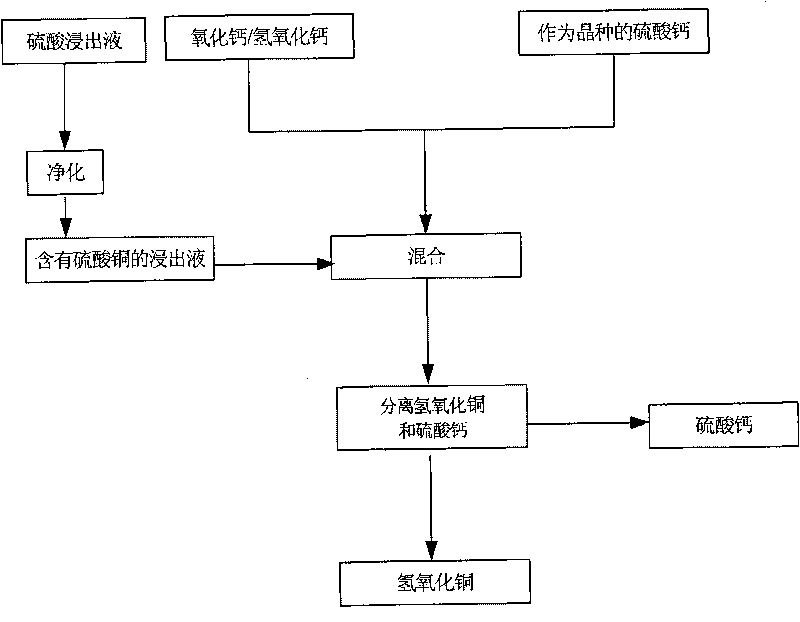

Method for recovering copper from copper sulfate solution

InactiveCN101760630ALarge granularityPollution reachesProcess efficiency improvementCalcium hydroxideHydrogen

The invention provides a method for recovering copper from a copper sulfate solution, comprising the following steps of: A) mixing calcium oxide and / or calcium hydrogen carbonate with calcium sulfate as a seed crystal; B) mixing the mixture of the calcium oxide and / or the calcium hydrogen carbonate and the calcium sulfate with the copper sulfate solution to generate a calcium sulfate sediment and a copper hydrogen carbonate sediment; and C) separating the calcium sulfate and copper hydrogen carbonate sediment. The method for recovering the copper from the copper sulfate solution can recover the copper from the copper sulfate solution in the mode of low cost and pollution to recycle resources and also can produce the calcium sulfate (plaster), thereby reducing the production cost and relieving the environmental pollution.

Owner:CHINA ENFI ENGINEERING CORPORATION

Preparation method of nano-copper-coated aluminum composite fuel

ActiveCN108687359AFast preparationSimple production equipmentTransportation and packagingMetal-working apparatusAluminum IonCopper(II) hydroxide

The invention discloses a preparation method of a nano-copper-coated aluminum composite fuel. The preparation method comprises the steps of adding trace copper ion complexing agent trisodium citrate and aluminum ion complexing agent ammonium fluoride into mixed water-phase turbid liquid of copper hydroxide and aluminite powder; centrifugally separating a purple red product obtained through reaction; and obtaining the nano-copper-coated aluminum composite fuel. The process provided by the invention is carried out at normal temperature and normal pressure, no any surface active agent is introduced, and the obtained nano-copper is uniformly distributed on the surface of nano-aluminum and uniform in grain size; and the concentration of the trace copper ion complexing agent is regulated, and the granularity of the obtained nano-copper particles can be further adjusted.

Owner:合肥净龙环保科技有限公司

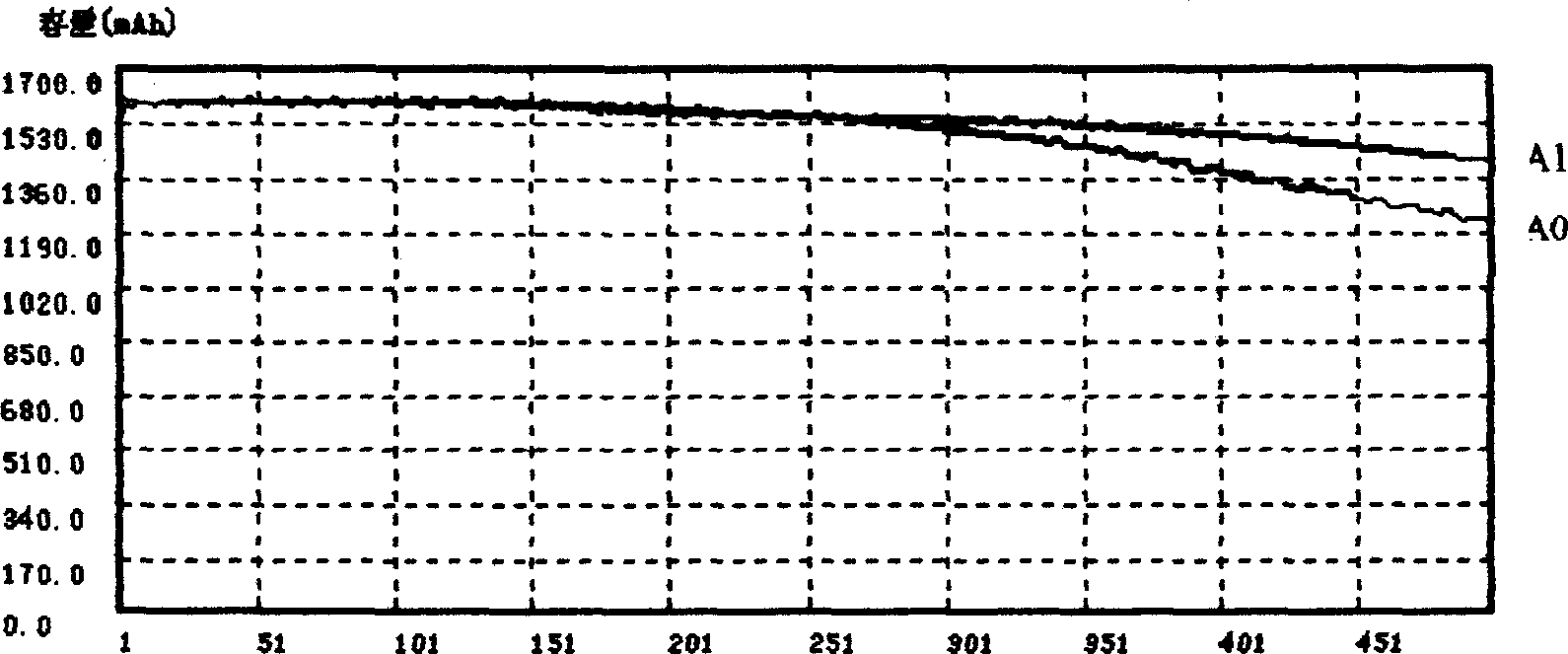

Nickel-cadmium accumulator

InactiveCN1487616ALow costImprove performanceAlkaline accumulator electrodesNickel accumulatorsCopper(II) hydroxideInternal resistance

The nickel-cadmiunm accumulator includes negative pole of cadmium oxide and positive pole of nickel hydroxide. The negative pole of cadmium oxide is adhered one and dry powder for the negative pole consists of active cadmium oxide, conducting agent and other additives, and the conducting agent is copper hydroxide in the added amount of 1-5 % of the dry powder weight. The positive pole has spherical granular nickel hydroxide as its active matter. Using copper hydroxide as the conductive additive for the cadmium negative pole can improve the performance of Ni-Cd accumulator, lower its internal resistance, reduce capacity attenuation and raise great current discharge performance.

Owner:BYD CO LTD

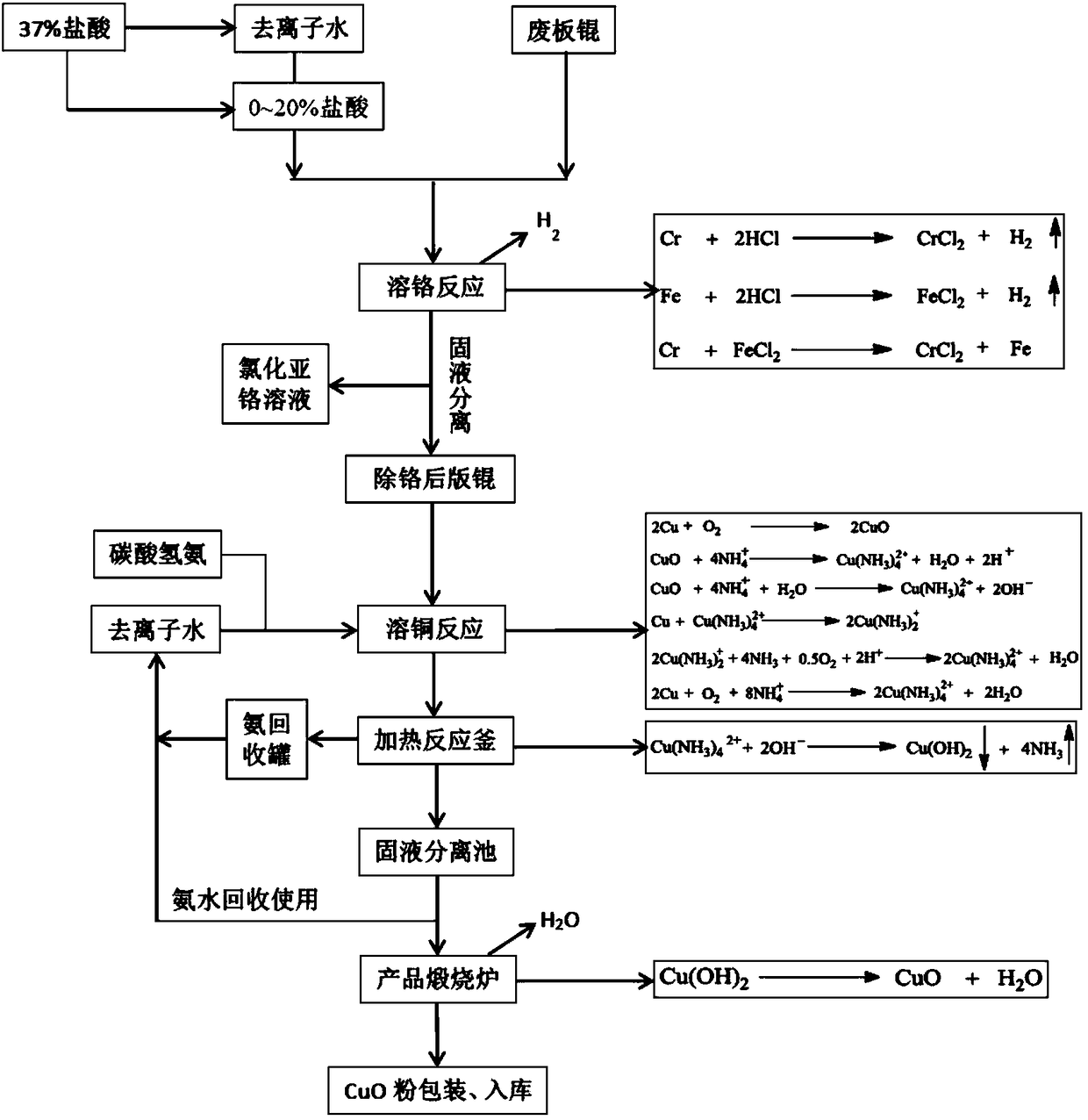

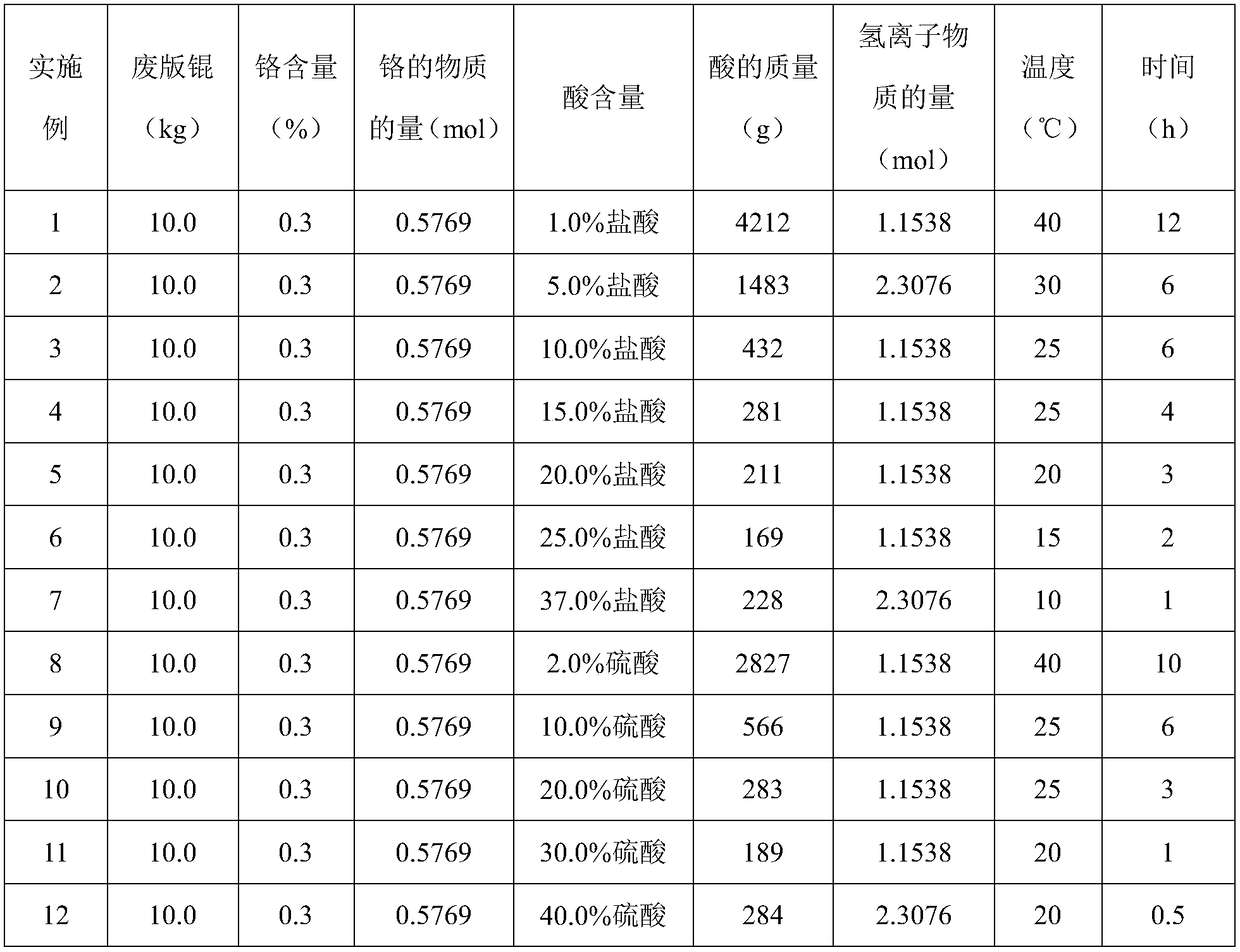

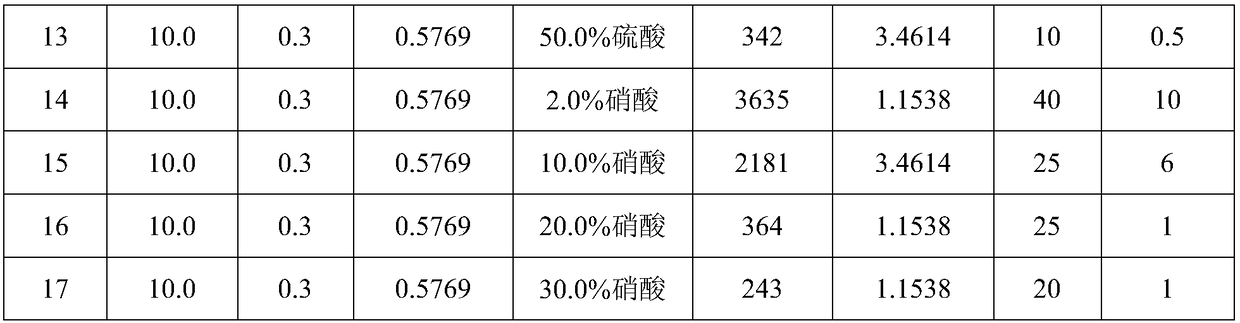

Method for recovering copper from waste version rollers used for printing to prepare copper oxide powder

PendingCN109354054ASimple methodEasy to operateCopper oxides/halidesCopper(II) hydroxideCopper oxide

The invention discloses a method for recovering copper from waste version rollers used for printing to prepare copper oxide powder. The waste version rollers used for printing are treated by acid to dissolve chrome on the surfaces of the waste version rollers, and waste version rollers without chrome on the surfaces are prepared; the waste version rollers without chrome on the surfaces are placedin an ammonia solution, copper on the surfaces of the waste version rollers is dissolved by introduced air, and an ammonia copper carbonate solution is obtained; the ammonia copper carbonate solutionis transferred into a heating kettle and slowly heated to 100 DEG C within 1-2 h, the temperature is preserved for 1 h, after ammonia gas is completely released, copper hydroxide is prepared, and thereleased ammonia gas is absorbed by an absorbing device for recycling; copper hydroxide mixed liquid is transferred into a sedimentation pond and separated from water through sedimentation, and solidsare aired to obtain copper hydroxide powder; the copper hydroxide is subjected to calcining at the high temperature to prepare the copper oxide powder. The method is simple in method, the operation is easy, there are fewer reaction by-products, the productive rate of the copper oxide powder reaches 95%, and the purity reaches 98% or above.

Owner:文水县鑫垚再生资源有限公司 +1

Preparation method of copper benzoate hydroxide-SiO2 composite material with photocatalysis

InactiveCN106391110AImprove degradation efficiencyComplete shapeWater/sewage treatment by irradiationWater treatment compoundsCopper benzoateBenzoic acid

The invention discloses a preparation method of a copper benzoate hydroxide-SiO2 composite material with photocatalysis. The preparation method comprises preparing copper hydroxide by a precipitation method, preparing laminated copper benzoate hydroxide from the copper hydroxide and benzoic acid as main raw materials, and carrying out a hydro-thermal synthesis reaction process on the laminated copper benzoate hydroxide and SiO2 microspheres to obtain a copper benzoate hydroxide-SiO2 compound. Through a self-assembly method, an LDH-Cu@SiO2 composite material with a core-shell structure is obtained and LDH-Cu fibers uniformly coat the silicon dioxide microspheres so that the whole morphology is complete. Compared with the conventional layered nano-compounds, the copper benzoate hydroxide-SiO2 composite material has better dispersibility and better photocatalytic activity in the reaction system. LDH-Cu in the LDH-Cu@SiO2 composite material can synergistically degrade organic matters in dye waste water through ion exchange and electrostatic interaction and improve the degradation efficiency of dye wastewater. The preparation method is simple and effective, does not need special equipment, and provides a simple and feasible method for compounding different functional materials.

Owner:BAOJI UNIV OF ARTS & SCI

Preparation of Stable Copper(II) Hydroxide

InactiveUS20190152796A1Eliminate needImprove stabilityBiocideWater/sewage treatmentAcetic acidCopper(II) hydroxide

A method for producing stable copper(II) hydroxide. The method comprises the treatment of a copper metal powder in an acidic aqueous solution containing acetic acid in the pH range less than 3.0 and at temperature below 30 ° C. under stirring conditions. To this acidic solution an alkali metal hydroxide solution is added to raise the pH above 7.0 to form copper(II) hydroxide. The method also comprises preparation of copper(II) hydroxide by treating the copper salts water solution with an alkali metal hydroxide solution in the pH range 7.0 to 12. To improve the stability of the copper(II) hydroxide prepared according to all the said method, a small amount of alkali or alkaline metal gluconate can be added to the suspension before or after the reaction. Also disclosed is a composition comprising stabilized copper(II) hydroxide prepared according to the method and at least one of a plant derived extract demonstrated to have antifungal, antibacterial or antiviral activity as a solid or a liquid or as a surfactant or as a coating.

Owner:NANO THERANOSTICS INC

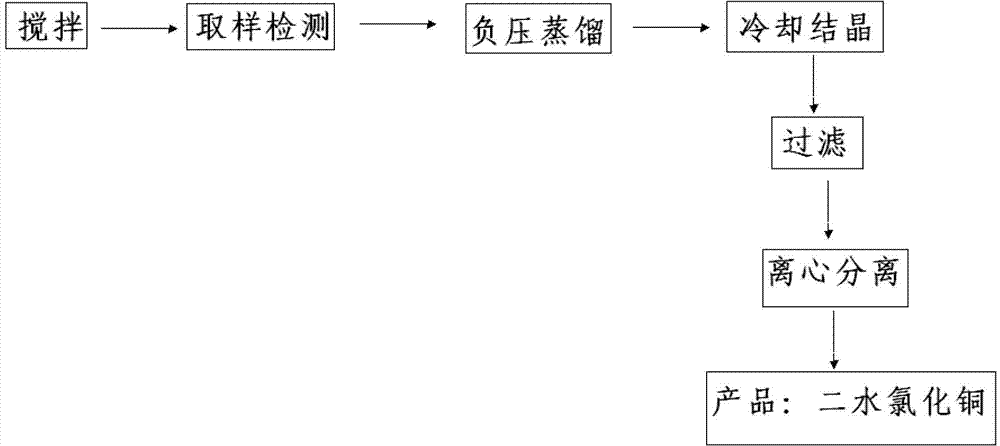

Method for preparing copper chloride dihydrate by alkaline type copper chloride

ActiveCN103241762AImprove responseReduce consumptionCopper chloridesCopper chlorideCopper(II) hydroxide

The invention provides a method for preparing copper chloride dihydrate by alkaline type copper chloride. The method comprises the steps of: (1) stirring hydrochloric acid, adding alkaline type copper chloride into the hydrochloric acid, controlling the concentration of free hydrogen chloride at 0.8-8% for 20-40min, and completely dissolving the added material till no sediment exists; and (2) carrying out negative pressure distillation to the material completely dissolved in the step (1) for 8-10 hours, and cooling and crystallizing after finishing evaporation, filtering, centrifuging and separating to obtain copper chloride dihydrate. The alkaline type copper chloride is adopted as an initial raw material, not only can the production efficiency be improved, but also the production cost can be lowered; copper hydroxide contained in the alkaline type copper chloride more easily reacts with hydrochloric acid, and the consumption of the hydrochloric acid can be more effectively reduced through the copper chloride component; and the preparation method is simple, low in cost, higher in efficiency by 20-30% compared with the existing method, thus being suitable for industrialized production.

Owner:嘉兴德达资源循环利用有限公司

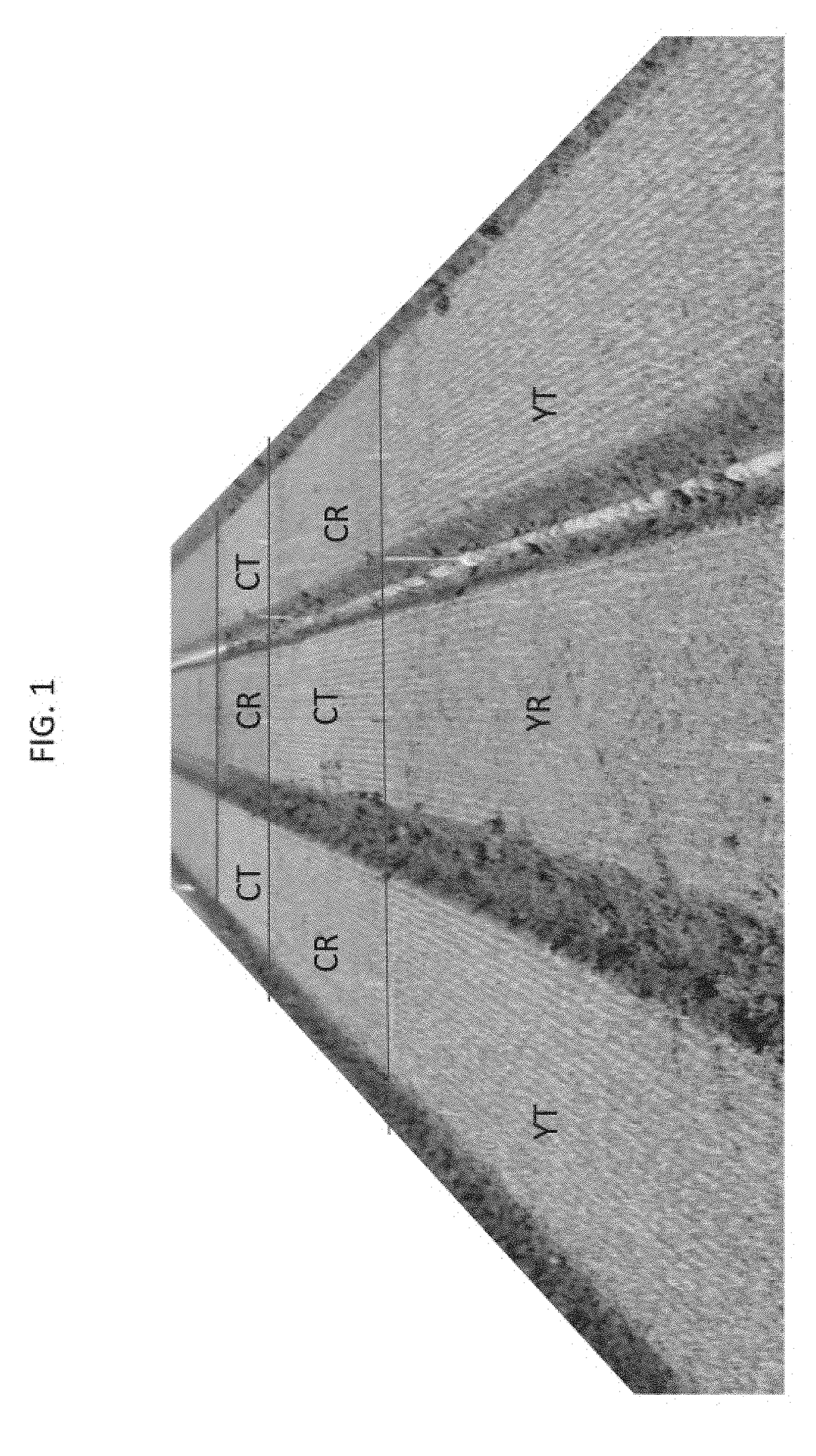

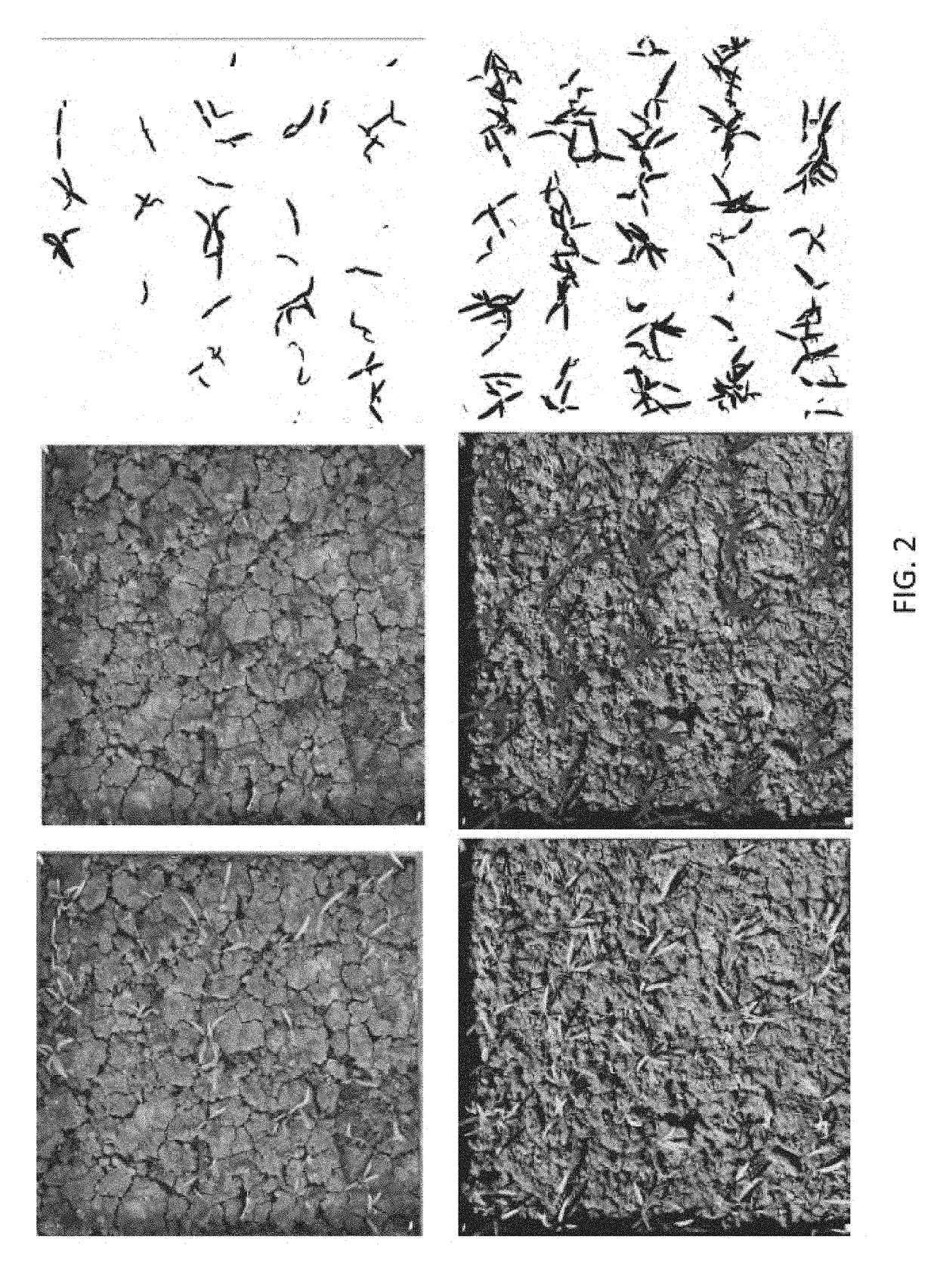

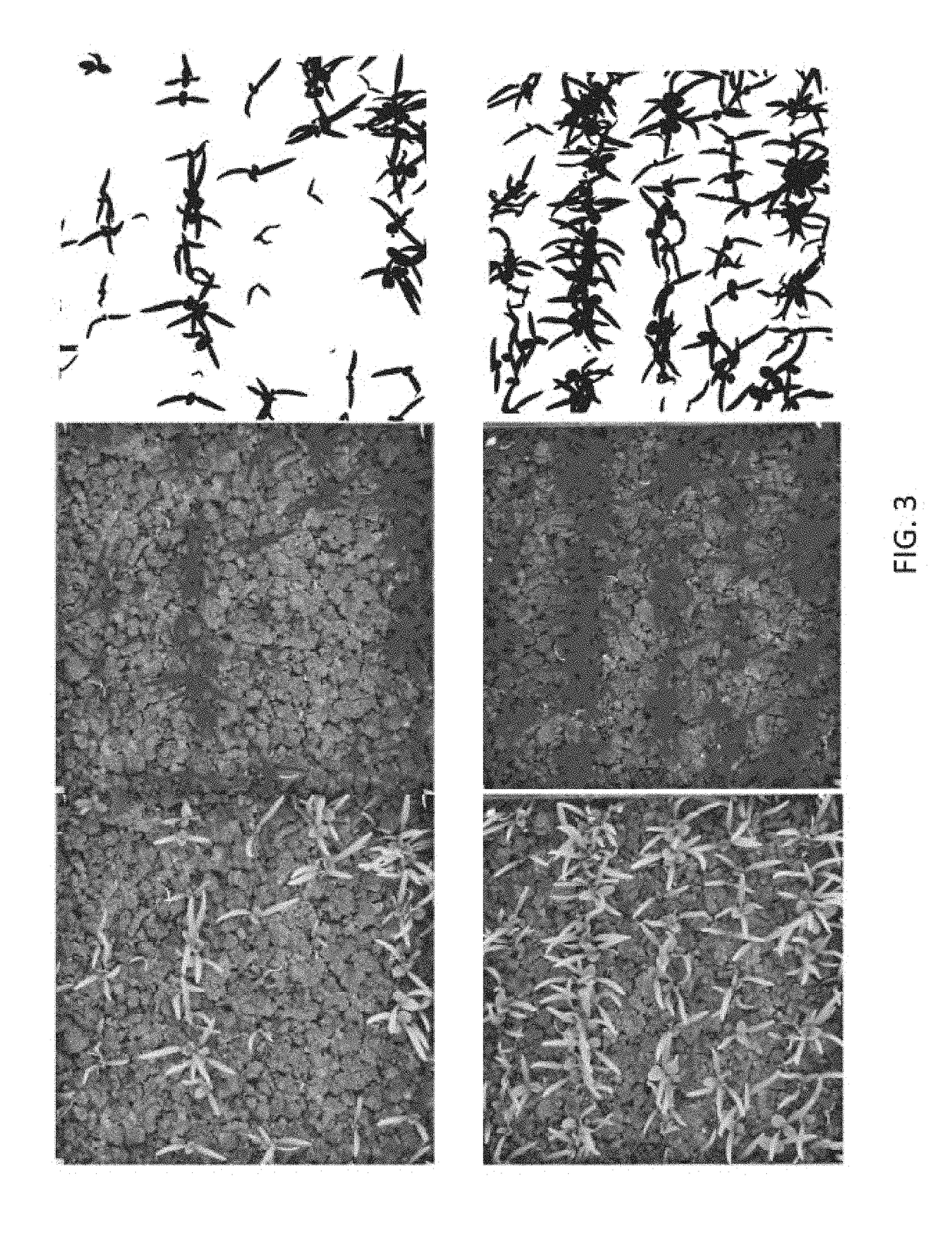

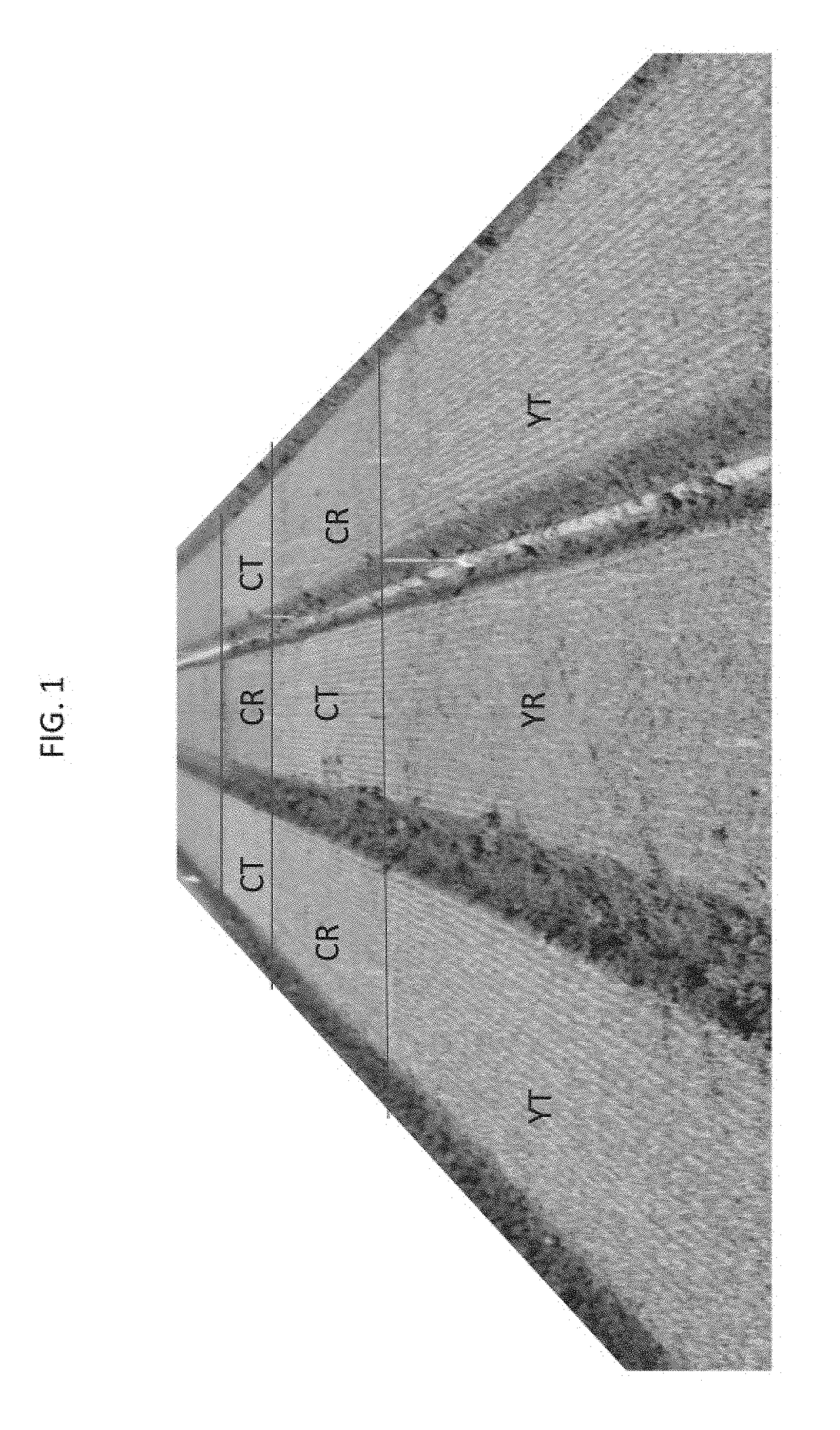

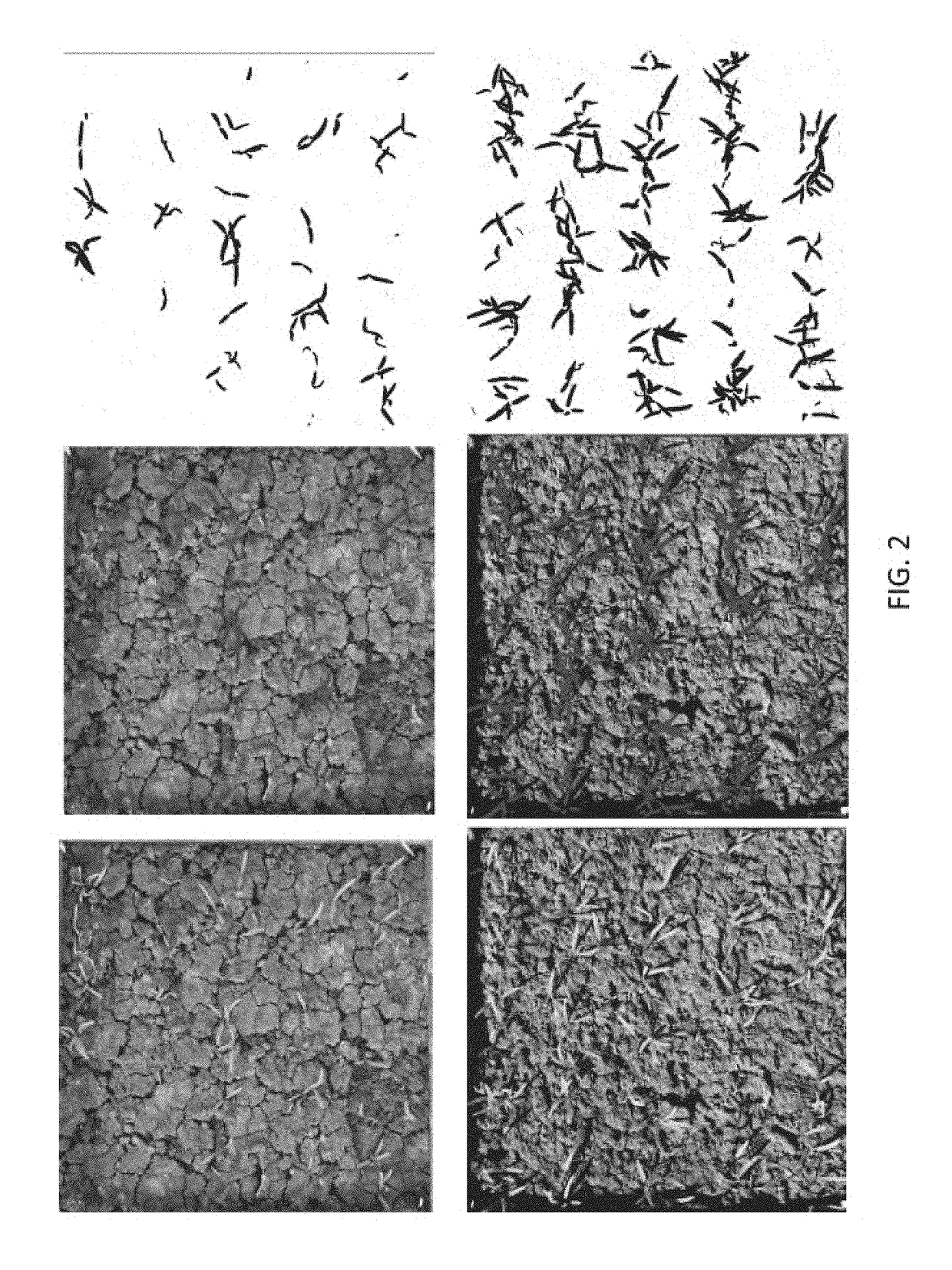

Anti-fungal seed treatment formulations, treated seeds, and methods

A coated seed comprises a seed and a coating at least partially surrounding the seed. The coating comprises a fungicide, a micronutrient metal, and a chelating agent, the fungicide comprising copper (II) hydroxide, wherein the amount of copper (II) hydroxide is from about 0.05 mg / seed to about 0.21 mg / seed.A method for applying a seed treatment to a seed or a population of seeds comprises distributing on the surface of the seed or the population of seeds a seed treatment formulation comprising a fungicide, a micronutrient metal, and a chelating agent. The fungicide comprises copper (II) hydroxide in an amount ranging from about 2 wt. % to about 20 wt. % of the total seed treatment formulation.

Owner:GERMAINS SEED TECH INC

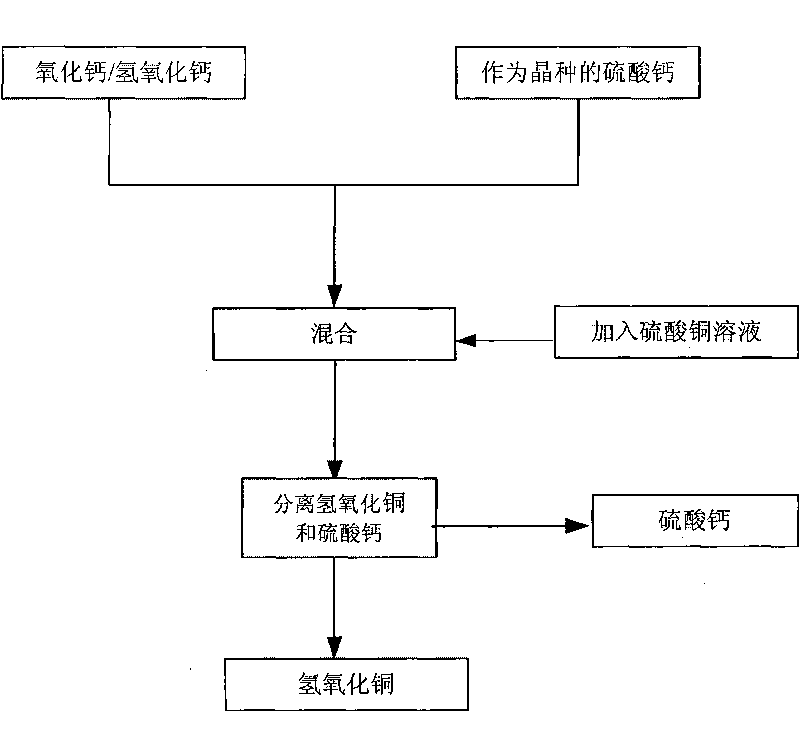

A method for continuously preparing copper hydroxide by electrolysis

ActiveCN108754524BRealize continuous productionElectrolysis componentsFlotationElectrolysisCopper(II) hydroxide

Owner:KUNMING UNIV OF SCI & TECH

Anti-fungal seed treatment formulations, treated seeds, and methods

A coated seed comprises a seed and a coating at least partially surrounding the seed. The coating comprises a fungicide, a micronutrient metal, and a chelating agent, the fungicide comprising copper (II) hydroxide, wherein the amount of copper (II) hydroxide is from about 0.05 mg / seed to about 0.21 mg / seed.A method for applying a seed treatment to a seed or a population of seeds comprises distributing on the surface of the seed or the population of seeds a seed treatment formulation comprising a fungicide, a micronutrient metal, and a chelating agent. The fungicide comprises copper (II) hydroxide in an amount ranging from about 2 wt. % to about 20 wt. % of the total seed treatment formulation.

Owner:GERMAINS SEED TECH INC

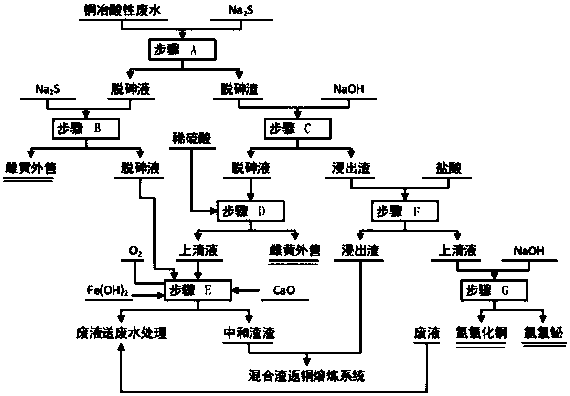

Method for removing arsenic and recovering heavy metal from copper smelting wastewater

InactiveCN110923440ARealize harmless treatmentPrevent overflowCopper oxides/halidesProcess efficiency improvementSlagCopper(II) hydroxide

The invention discloses a method for removing arsenic and recovering heavy metal from copper smelting wastewater, and belongs to the field of environmental protection engineering. The problems that inan existing method, valuable metal is not recovered, and a large amount of arsenic-containing hazardous waste slag is generated are solved. The method comprises the following steps that sodium sulfide is added into arsenic-containing wastewater to obtain arsenic removal slag and initial arsenic removal liquid; excessive sodium sulfide is added into the initial arsenic removal liquid to obtain orpiment and deep arsenic removal liquid; the arsenic removal slag is put into a sodium hydroxide solution to be leached to obtain an arsenic-containing solution I and metal slag; pH of the arsenic-containing solution I is adjusted through sulfuric acid to obtain orpiment and an arsenic-containing solution II; the deep arsenic removal liquid and the arsenic-containing solution II are mixed, ferrous hydroxide and calcium oxide are added for neutralization, oxygen is blown, and thus wastewater and neutralization slag are obtained; the metal slag is leached through hydrochloric acid to obtain leachate and leaching residue; the leachate is neutralized through a sodium hydroxide solution to obtain bismuth oxychloride; and sodium hydroxide continues to be added into filtrate to obtain copper hydroxide. According to the method, arsenic and valuable metal in the wastewater are efficiently recycled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

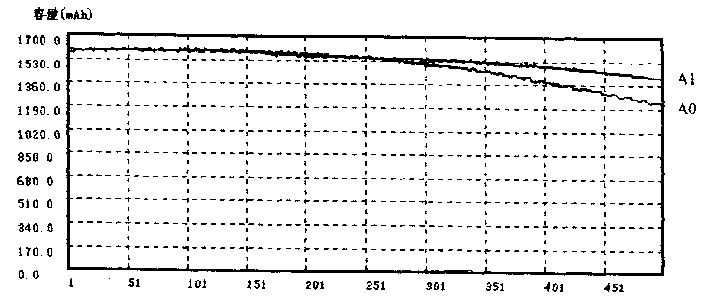

Gel polymer electrolyte of blended ceramic as well as preparation method and application of gel polymer electrolyte

InactiveCN107768718AImprove wettabilityImprove conductivitySecondary cellsPolymer scienceCopper(II) hydroxide

The invention discloses gel polymer electrolyte of blended ceramic as well as a preparation method and application of the gel polymer electrolyte. The preparation method particularly comprises the following steps: (1) preparing a blended polymer solution; (2) sequentially dropwise adding zirconium nitrate and acetylacetone which account for 5% of the total content of the blended polymer solution into the blended polymer solution A, continuously stirring for 15-30 minutes, and dropwise adding a copper hydroxide solution which accounts for 2% of the total content of the blended polymer solution,so as to obtain a mixed solution B; and (3) spraying the obtained mixed solution B to an electrode membrane or a carrier, and naturally drying, so as to obtain the gel polymer electrolyte mixed withceramic (a ceramic skeleton structure consisting of zirconium, hafnium and copper). The prepared ceramic skeleton structure consisting of zirconium, hafnium and copper has relatively strong mechanicalproperties, and the compound oxide can generate free metal ions due to the running of current in a working process of a lithium battery, so that the electrical conductivity can be improved, and meanwhile, an attenuation phenomenon caused due to the aging of the electrolyte can be remedied; and the electrolyte has relatively good infiltration effect to an electrolyte solution and further has goodelectrochemical stability, so that the conductivity, mechanical strength and safety performance of a polymer film can be improved.

Owner:孙健春

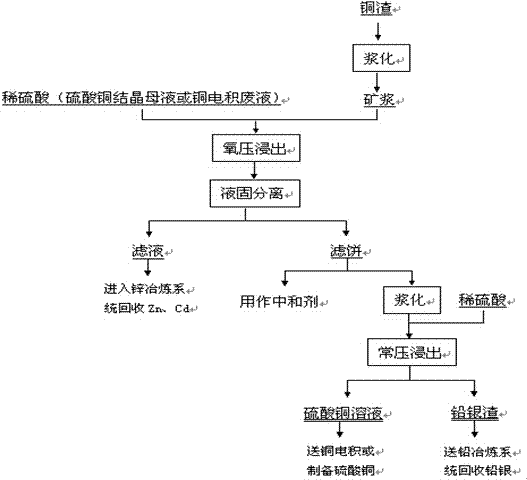

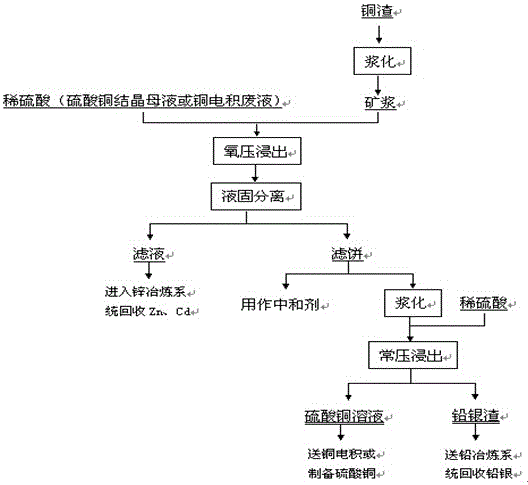

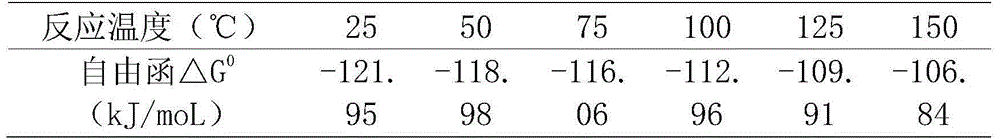

Method for separating zinc, cadmium, copper, lead and silver from zinc smelting copper slag

ActiveCN104846211AReduce processingEasy to separateProcess efficiency improvementLead smeltingCopper(II) hydroxide

The invention relates to a method for separating zinc, cadmium, copper, lead and silver from zinc smelting copper slag and belongs to the field of wet-process metallurgy of nonferrous metals. The method comprises the following steps: directly slurrying mixed copper slag without ore grinding; leaching by adopting a pressure reactor; controlling the technical parameters of acid volume, temperature, oxygen partial pressure, reaction time, terminal pH value and the like; dissolving out zinc and cadmium from the copper slag into a solution; dissolving out copper, and hydrolyzing the copper into copper hydroxide which is added into the slag again; performing liquid-solid separation and washing on a leached ore pulp, and then adding the filtrate containing zinc and cadmium and a washing solution into a zinc smelting system to recover zinc and cadmium; adding sulfuric acid to a filter cake, and controlling the leaching terminal pH value at a normal temperature and a normal pressure to ensure that copper is leached out; and performing liquid-solid separation on a copper leaching ore pulp, and then adding the obtained lead and silver slag into a lead smelting system to recover lead and silver. By adopting the technical scheme of the invention, zinc, cadmium and copper can be completely separated, copper is completely separated from lead and silver, the valuable metals of Cu, Zn, Cd, Pb, Ag and the like in the copper slag can be completely recycled, the whole process avoids the generation of 'three wastes', and the production is clean and efficient.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

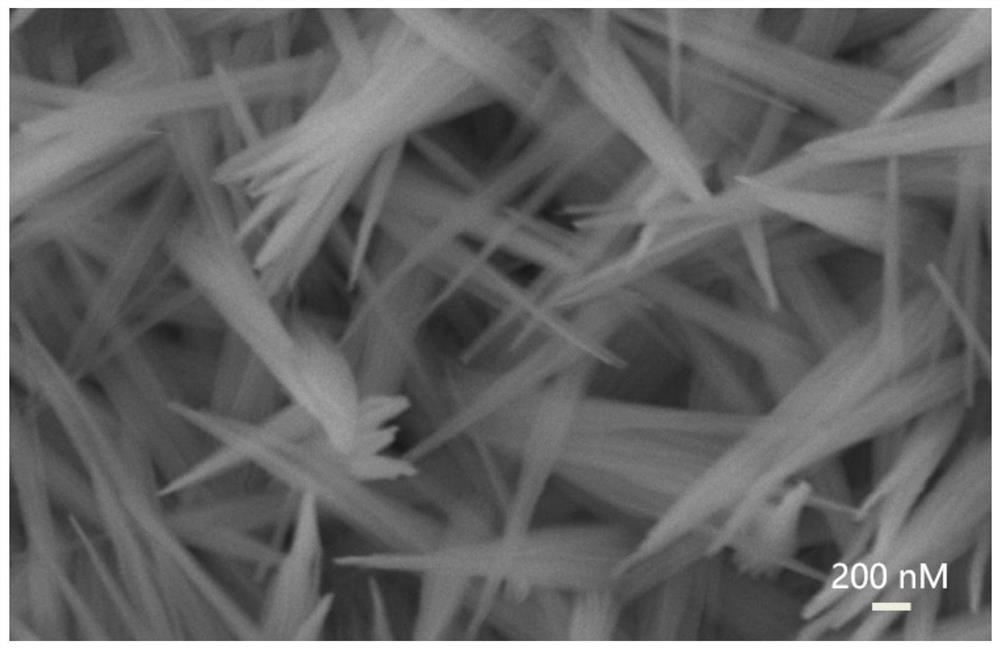

Preparation and application of nano copper hydroxide controlled release system

InactiveCN105724375AHarm reductionHas a double effectBiocideDead animal preservationControlled releaseGranularity

The invention discloses preparation and an application of a nano copper hydroxide controlled release system. The preparation of the nano copper hydroxide controlled release system comprises preparation of a copper-glycerin solution and dilution of the copper-glycerin solution, wherein the pH value of the copper-glycerin solution is 13.30-13.40. The copper-glycerin solution is prepared and water is added into the copper-glycerin solution to dilute and slowly release nano copper hydroxide; and compared with a traditional coordinate precipitation method, the preparation has the advantages of relatively low requirements on equipment, relatively low production cost, easiness of controlling granularity, environmental friendliness, simplicity and easiness of operation. The copper-glycerin solution is modified by adopting SDBS (Sodium Dodecyl Benzene Sulfonate) so that the nano copper hydroxide can be slowly released in relatively short time without stirring after the dilution, and furthermore, the solution can be directly applied to plants and is used for preventing and treating plant diseases.

Owner:周子杰

A ceria-modified copper hydroxide composite electrode and its application in glucose sensor

ActiveCN111796014BImprove electrode performanceReduce manufacturing costElectrolytic coatingsMaterial electrochemical variablesGlucose sensorsComposite electrode

The invention discloses a ceria-modified copper hydroxide composite electrode and its application in a glucose sensor. The composite electrode includes an electrode base, a protective layer, and nano-CeO in sequence from the inside to the outside. 2 ‑Cu(OH) 2 Composite modification layer; the nano-CeO 2 ‑Cu(OH) 2 The composite has a three-dimensional nanograss array structure. The present invention adopts simple and feasible electrochemical deposition and oxidation method to prepare nano-CeO 2 ‑Cu(OH) 2 The nanograss array structure greatly improves the electrode performance, the preparation cost is low, and no special environment and large instruments are required. When the electrode of the invention is used for glucose, it has lower detection limit, higher sensitivity and good anti-interference performance.

Owner:SOUTH CHINA UNIV OF TECH +1

A kind of preparation method of the Zong leaf that removes free copper

The invention discloses a piece of steamed rice dumpling leaf capable of removing free copper and a preparation method thereof. The steamed rice dumpling leaf is put into quick lime filtration liquid for soaking treatment after being blanched in boiling water containing copper sulfate. The quick lime filtration liquid has the processing steps of putting 5 to 15 parts of humidified and dissolved quick lime into 85 to 95 parts of clear water to be uniformly stirred, and obtaining lime milk; adopting a 100-mesh gauze screen to filter the lime milk, and obtaining the quick lime filtration liquid. The steamed rice dumpling leaf has the processing steps of putting the steamed rice dumpling leaf into clear water to clean and soak for one hour; putting the soaked steamed rice dumpling leaf into boiling water to blanch for 5 to 10 minutes; cutting off leaf stalks of the blanched steamed rice dumpling leaf, and then putting the steamed rice dumpling leaf into the quick lime filtration liquid to soak for two hours; cleaning for five minutes by clear water; drying under low temperature; packaging. Since the blanched steamed rice dumpling leaf can be subjected to the soaking treatment by the quick lime filtration liquid, the free copper in the steamed rice dumpling leaf reacts with calcium hydroxide to form copper hydroxide precipitate, and thus the situations of emesis, diarrhea and heavy metal poisoning caused by excess copper ion intake by a human body can be avoided.

Owner:嘉兴联飨科技有限公司

Method for manufacturing iron-copper alloy from iron oxide red and copper sulfate

InactiveCN103203457AIncrease added valueWide range of applications and high priceCopper(II) hydroxideAdditional values

The invention discloses a method for manufacturing iron-copper alloy from iron oxide red and copper sulfate. The method includes technological steps of (1), adding sodium hydroxide solution into copper sulfate solution, and stirring a mixture of the sodium hydroxide solution and the copper sulfate solution to generate blue copper hydroxide gel; (2), heating, filtering and drying the copper hydroxide gel to obtain copper oxide;(3), mixing a certain amount of copper oxide with the iron oxide red, and grinding and uniformly mixing the copper oxide and the iron oxide red to obtain a mixture; and (4), heating and pretreating the mixture in inert atmosphere, and then enabling the mixture to carry out reduction reaction to obtain the iron-copper alloy. The certain amount of the copper oxide is calculated according to the proportion of iron to copper of the manufactured iron-copper alloy. The method has the advantages that the regenerated iron oxide red of cold-rolling waste acid and the copper sulfate are used as raw materials, iron-copper alloy powder is manufactured by means of reduction reaction, as the iron-copper alloy powder is widely applied and is high in selling price, the additional value of the iron oxide red is greatly increased, and a novel utilization channel of the iron oxide red is provided; and the superiority of an iron and steel enterprise is sufficiently utilized, an operation process is simple, and the cost is low.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Method for preparing a stable isothiazolone formulation

A method for producing a stable microbicidal composition. The method comprises steps of: (a) combining a glycol solvent of formula R(OCH2CHR1)nH, wherein R is C1-C6 alkyl and n has a number average value from 2 to 5 and R1 is hydrogen or methyl; dodecylbenzenesulfonic acid in an amount from 0.3 to 1.8 wt % based on the entire microbicidal composition; and a copper (II) salt selected from the group consisting of copper (II) hydroxide, copper (II) carbonate and mixtures thereof to form an initial mixture; wherein a mole ratio of copper:dodecylbenzenesulfonic acid is from 1:0.25 to 1:1.95; (b) maintaining the initial mixture at 40 to 80° C. until an amount of copper ion in solution is stable; and (c) adding 4,5-dichloro-2-n-octyl-4-isothiazolin-3-one to produce a final mixture.

Owner:DOW GLOBAL TECH LLC

Method for preparing crystalline copper powder

InactiveCN1238144CGood dispersionNarrow particle size distributionHydrazine compoundCopper(II) hydroxide

The preparation process of crystallized copper powder includes the following steps: dissolving amino acid or its salt as reaction promoter and alkyl quarternary ammonium salt surfactant as dispersant inside polar liquid phase reaction medium; adding copper oxide or hydroxide as reaction initiator and hydrazine or its compound as reductant; and reaction at 40-100 deg.c to synthesize copper powder. The prepared copper powder is in spherical or polyhedral shape, and has good dispersivity, average size of 0.5-5 micron and homogeneous size distribution.

Owner:SOUTH CHINA UNIV OF TECH

A method for separating zinc, cadmium, copper and lead and silver from zinc smelting copper slag

ActiveCN104846211BReduce processingEasy to separateProcess efficiency improvementLead smeltingCopper(II) hydroxide

The invention relates to a method for separating zinc, cadmium, copper, lead and silver from zinc smelting copper slag and belongs to the field of wet-process metallurgy of nonferrous metals. The method comprises the following steps: directly slurrying mixed copper slag without ore grinding; leaching by adopting a pressure reactor; controlling the technical parameters of acid volume, temperature, oxygen partial pressure, reaction time, terminal pH value and the like; dissolving out zinc and cadmium from the copper slag into a solution; dissolving out copper, and hydrolyzing the copper into copper hydroxide which is added into the slag again; performing liquid-solid separation and washing on a leached ore pulp, and then adding the filtrate containing zinc and cadmium and a washing solution into a zinc smelting system to recover zinc and cadmium; adding sulfuric acid to a filter cake, and controlling the leaching terminal pH value at a normal temperature and a normal pressure to ensure that copper is leached out; and performing liquid-solid separation on a copper leaching ore pulp, and then adding the obtained lead and silver slag into a lead smelting system to recover lead and silver. By adopting the technical scheme of the invention, zinc, cadmium and copper can be completely separated, copper is completely separated from lead and silver, the valuable metals of Cu, Zn, Cd, Pb, Ag and the like in the copper slag can be completely recycled, the whole process avoids the generation of 'three wastes', and the production is clean and efficient.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com