Method for manufacturing iron-copper alloy from iron oxide red and copper sulfate

A technology of iron oxide red and iron-copper alloy is applied in the field of preparation of iron-copper alloy, which can solve the problems such as the inability to reflect the value of iron red well, and achieve the effects of easy promotion, simple operation process and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

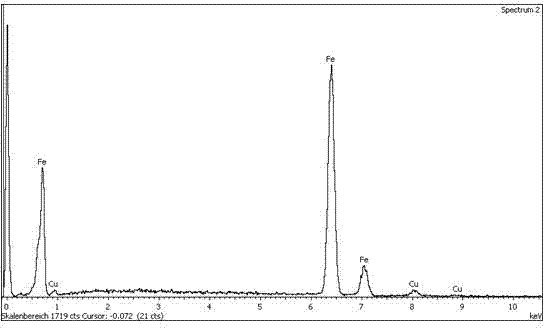

Image

Examples

Embodiment 1

[0017] Embodiment 1: The method for preparing an iron-copper alloy by using iron oxide red and copper sulfate uses cold-rolled waste acid regenerated iron oxide red and industrial-grade copper sulfate as raw materials, and the reducing gas is a mixed gas of nitrogen and hydrogen. The specific process steps for:

[0018] (1) Dissolve 500g of copper sulfate in ionized water to make a 1mol / L copper sulfate solution, and prepare a sodium hydroxide solution with sodium hydroxide in an equimolar amount to copper sulfate; slowly pour the sodium hydroxide solution into the copper sulfate solution In, stir, produce blue gel copper hydroxide.

[0019] (2) Heat the gel copper hydroxide in a constant temperature water bath at a heating temperature of 60°C for 40 minutes, filter to obtain a black precipitate - copper oxide, and dry at 105°C for 4 hours.

[0020] (3) Red iron oxide regenerated from cold rolling waste acid and precipitated copper oxide are calculated and mixed according to ...

Embodiment 2

[0023] Embodiment 2: The method for preparing an iron-copper alloy by using iron oxide red and copper sulfate uses cold-rolled waste acid regenerated iron oxide red and industrial-grade copper sulfate as raw materials, and the reducing gas is a mixed gas of nitrogen and hydrogen. The specific process steps for:

[0024] (1) Dissolve 1000g of copper sulfate in ionized water to make a 1.5mol / L copper sulfate solution, and prepare a sodium hydroxide solution with sodium hydroxide in an equimolar amount to copper sulfate; slowly pour the sodium hydroxide solution into the copper sulfate solution, stirring, to produce blue gel copper hydroxide.

[0025] (2) Heat the gel copper hydroxide in a constant temperature water bath at a heating temperature of 80°C for 50 minutes, filter to obtain a black precipitate - copper oxide, and dry at 100°C for 6 hours.

[0026] (3) Red iron oxide regenerated from cold-rolled waste acid and precipitated copper oxide are calculated and mixed accordi...

Embodiment 3

[0029] Embodiment 3: The method for preparing iron-copper alloy by using iron oxide red and copper sulfate, using cold-rolled waste acid regenerated iron oxide red and industrial-grade copper sulfate as raw materials, the reducing gas is a mixed gas of nitrogen and hydrogen, and its specific process steps for:

[0030] (1) Dissolve 1500g of copper sulfate in ionized water to make a 2mol / L copper sulfate solution, and prepare a sodium hydroxide solution with sodium hydroxide in an equimolar amount to copper sulfate; slowly pour the sodium hydroxide solution into the copper sulfate solution In, stir, produce blue gel copper hydroxide.

[0031] (2) Heat the gel copper hydroxide in a constant temperature water bath at a heating temperature of 100°C for 30 minutes, filter to obtain a black precipitate - copper oxide, and dry at 105°C for 8 hours.

[0032] (3) Red iron oxide regenerated from cold-rolled waste acid and precipitated copper oxide are calculated and mixed according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com