Nickel-cadmium accumulator

A storage battery and electrode technology, which is applied in the direction of nickel storage battery, alkaline storage battery, alkaline storage battery electrode, etc., can solve the problems of poor conductivity of cadmium negative electrode, coarsening of active material crystal grains, and poor conductivity of carbon powder, etc. The effect of battery cost, internal resistance and other performance improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

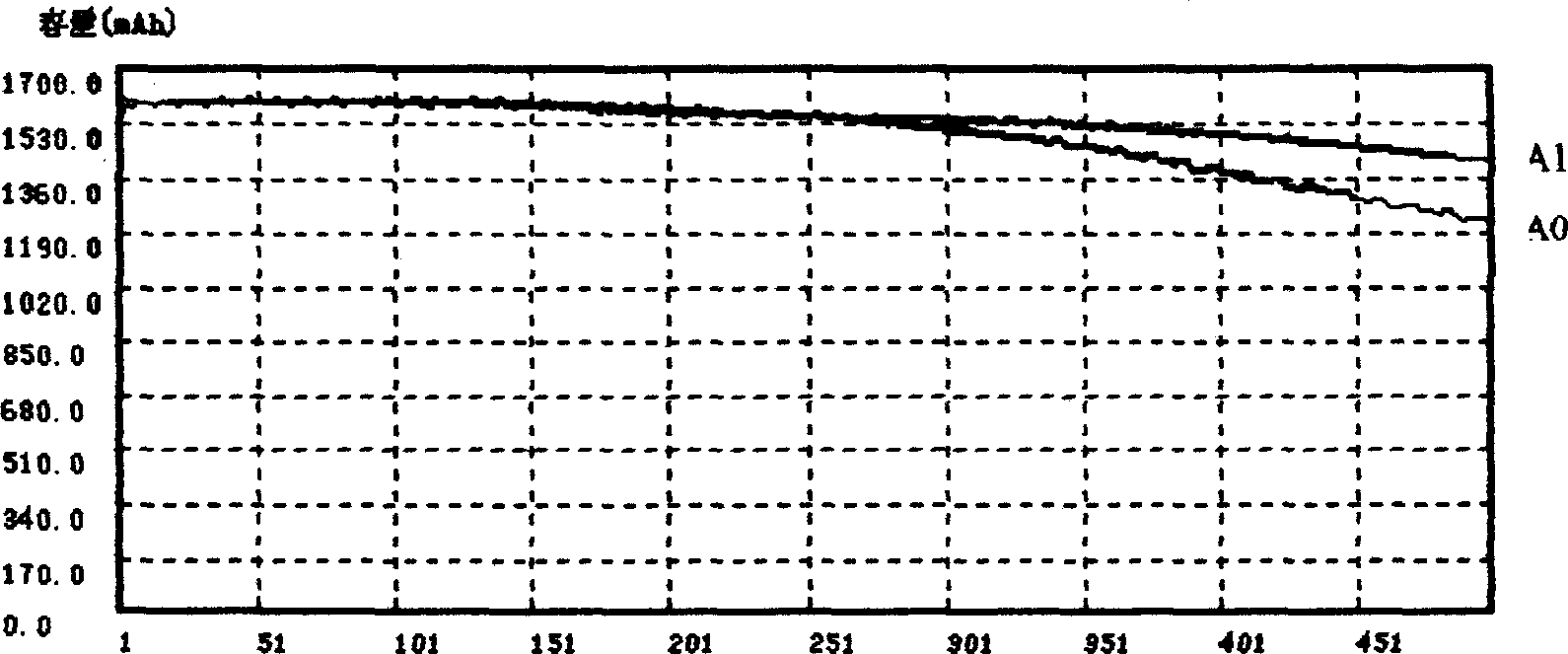

Embodiment 1

[0017] The production of cadmium negative electrode: mix cadmium oxide, copper hydroxide and other additives in a certain proportion, wherein copper hydroxide powder accounts for 1% of the total weight of the dry material; add water, 2% CMC aqueous solution, 60% PTFE emulsion, stir Mix evenly to obtain a mixed slurry, which is coated on both sides of a perforated nickel-plated steel strip, dried and sliced into negative electrode sheets with a size of 250×33.6×0.5mm.

[0018] Production of nickel positive electrode: Mix nickel hydroxide, cadmium oxide, and other additives in a certain proportion, add water, 2% CMC aqueous solution, and 60% PTFE emulsion, stir and mix evenly, and obtain a mixed slurry. Fill this slurry into foamed nickel, and make a positive electrode sheet with a size matching the negative electrode and a rated capacity of 1700mAh through steps such as drying, scraping, pressing, and cutting.

[0019] Battery production: Combine the above-mentioned nickel po...

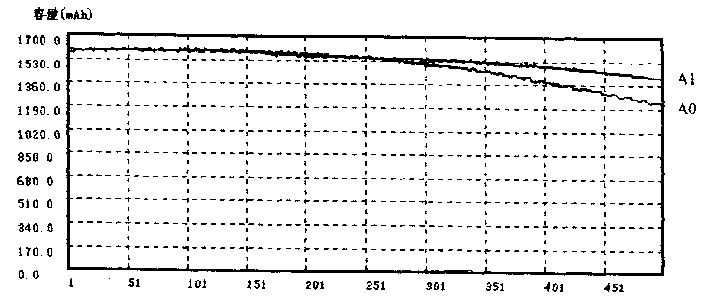

Embodiment 2~3

[0021] Production of cadmium negative electrode: copper hydroxide accounts for 3.5% and 4.5% of the total weight of active material dry powder respectively, and the others are the same as in Example 1.

[0022] Production of nickel positive electrode: same as in Example 1.

[0023] Battery production: The above-mentioned cadmium negative electrodes and nickel positive electrodes are respectively made into Sc-type batteries, which are respectively recorded as: A 2 、A 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com