Method for recovering copper from waste version rollers used for printing to prepare copper oxide powder

A technology of copper oxide powder and copper recovery, which is applied in the direction of copper oxide/copper hydroxide, etc., to achieve the effects of easy operation, less reaction by-products, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

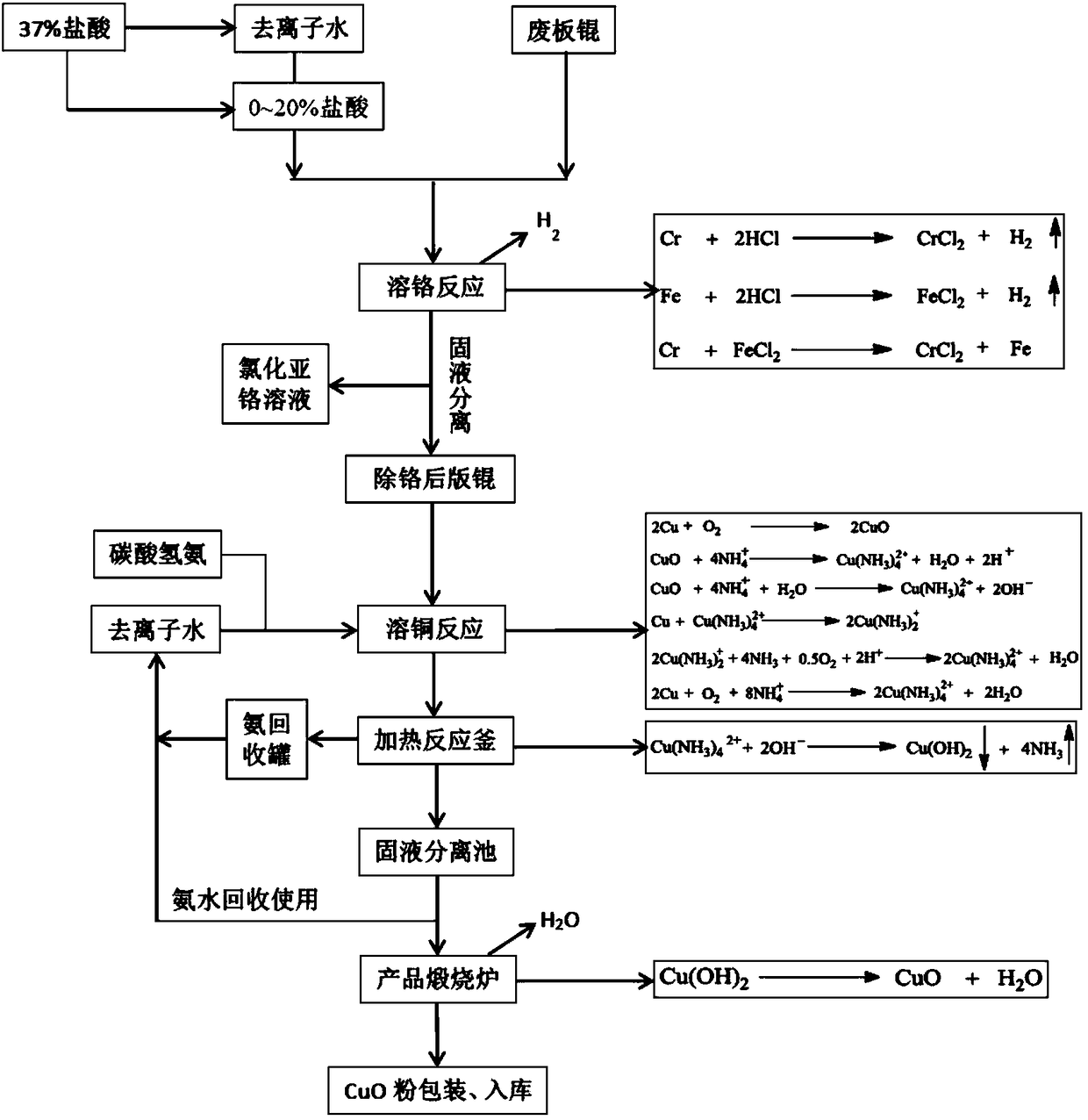

Method used

Image

Examples

Embodiment

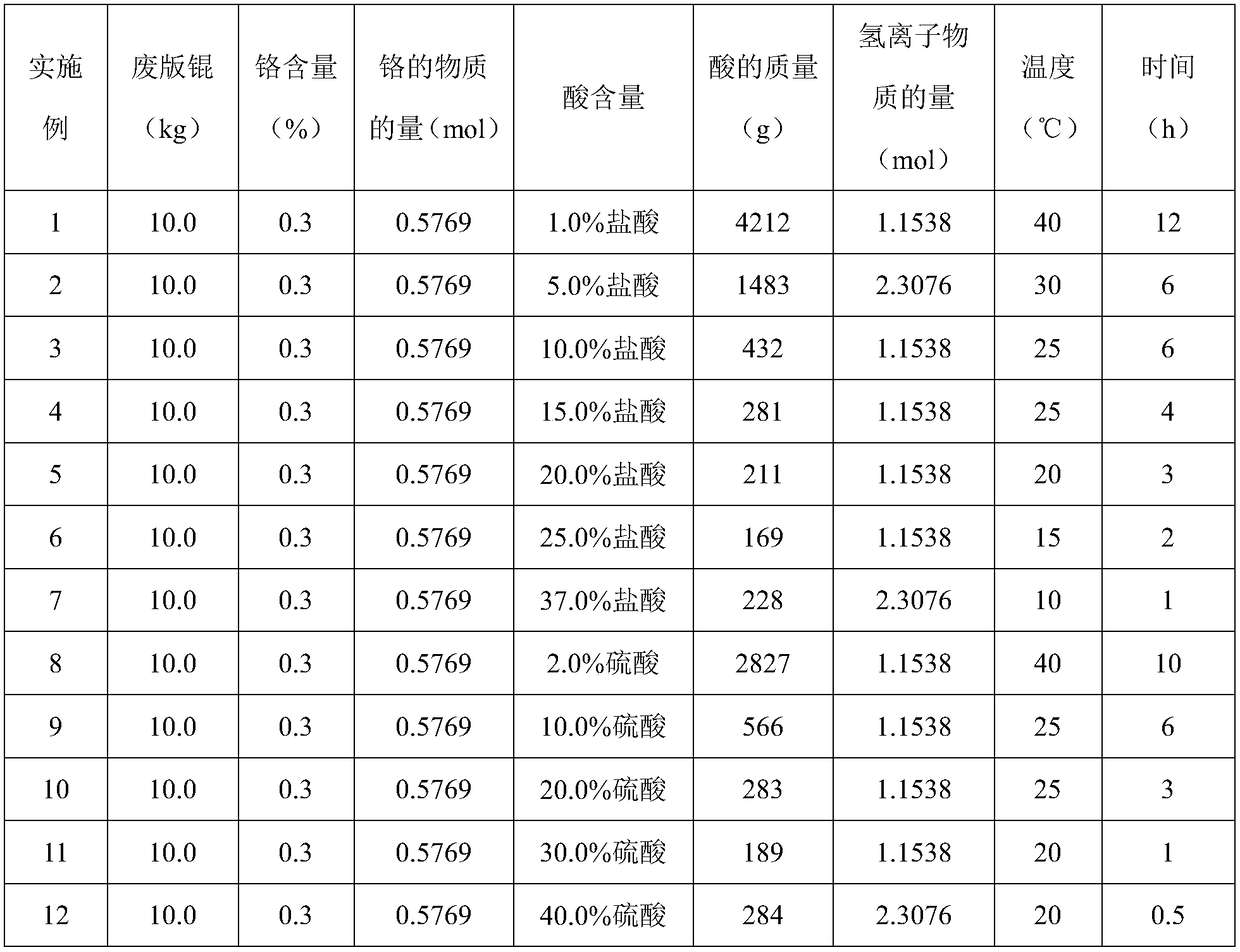

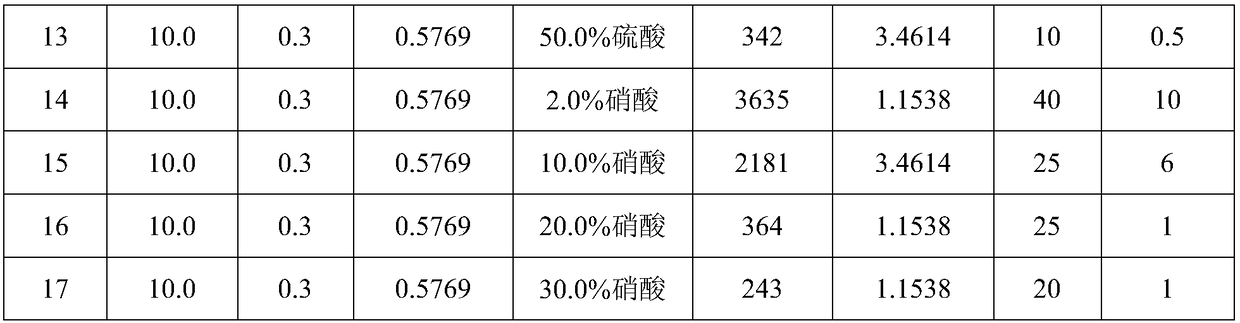

[0024] (1) Weigh 10.0kg of waste plate kun and place it in a glass 5 liter tank reactor, add the prepared acid solution, react at a certain temperature and time, and rotate the waste plate kun during the reaction. The specific results are shown in Table 1 below:

[0025] Table 1 acid treatment dissolves the chromium experimental conditions on the surface of the waste plate

[0026]

[0027]

[0028] From the experimental results given in Examples 1 to 17 in Table 1, it can be seen that all the chromium on the surface of the waste plate roller is well dissolved in the examples, and the surface of the waste plate roller is bright yellow copper color.

[0029] (2) Add ammonium bicarbonate solution to a 100L trough-type stainless steel reactor, add 10.0 kg of waste plate kun for removing chromium, heat to the set temperature, regularly feed air, and react under the set time. After the reaction is completed, remove Waste the plate, transfer the solution into a heating kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com