Method for removing arsenic and recovering heavy metal from copper smelting wastewater

A recovery method and technology for heavy metals, applied in chemical instruments and methods, copper oxide/copper hydroxide, inorganic chemistry, etc., can solve the problems of large arsenic hazardous waste residues, unrecovered valuable metals, etc., to achieve efficient recycling and reduce emissions , the effect of saving production costs and environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

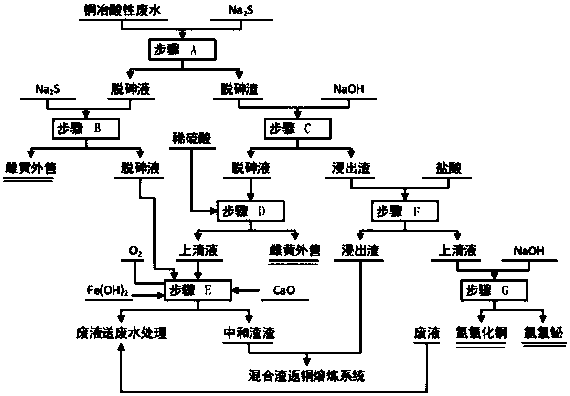

[0023] Embodiment 1. A method for removing arsenic from copper smelting wastewater and recovering heavy metals, comprising the following steps:

[0024] A. Add a sodium sulfide solution with a concentration of 50g / L to the arsenic-containing wastewater, stir and react at room temperature for 0.5 hours, the amount of sodium sulfide added is 1.2 times the theoretical amount, and the heavy metals and arsenic in the solution are initially precipitated to obtain arsenic removal Slag and initial arsenic removal solution;

[0025] B, adding excess concentration to the initial arsenic removal solution obtained in step A is 50g / L of sodium sulfide, the amount of sodium sulfide added is 2 times of the theoretical amount, and the reaction time is 2 hours to obtain orpiment and deep arsenic removal solution;

[0026] C, the arsenic-removing slag obtained by step A is dropped into a concentration of 50g / L of sodium hydroxide solution for leaching, the ratio of the volume of sodium hydroxid...

Embodiment 2

[0032] Embodiment 2. A method for removing arsenic from copper smelting wastewater and recovering heavy metals, comprising the following steps:

[0033] A. Add a sodium sulfide solution with a concentration of 80g / L to the arsenic-containing wastewater, stir and react at room temperature for 1 hour, the amount of sodium sulfide added is 1.3 times the theoretical amount, and the heavy metals and arsenic in the solution are initially precipitated to obtain arsenic removal Slag and initial arsenic removal solution;

[0034] B, adding excess concentration to the initial arsenic removal solution obtained in step A is 80g / L of sodium sulfide, the amount of sodium sulfide added is 3 times of the theoretical amount, and the reaction time is 1.5 hours to obtain orpiment and deep arsenic removal solution;

[0035] C, the arsenic-removing slag obtained in step A is put into concentration and is leached in the sodium hydroxide solution of 75g / L, and the ratio of sodium hydroxide solution ...

Embodiment 3

[0041] Embodiment 3. A method for removing arsenic from copper smelting wastewater and recovering heavy metals, comprising the following steps:

[0042]A. Add a sodium sulfide solution with a concentration of 100g / L to the arsenic-containing wastewater, stir and react at room temperature for 2 hours, the amount of sodium sulfide added is 1.5 times the theoretical amount, and the heavy metals and arsenic in the solution are initially precipitated to obtain arsenic removal Slag and initial arsenic removal solution;

[0043] B, adding excess concentration to the initial arsenic removal solution obtained in step A is 100g / L of sodium sulfide, the amount of sodium sulfide added is 4 times of the theoretical amount, and the reaction time is 1 hour to obtain orpiment and deep arsenic removal solution;

[0044] C, the arsenic-removing slag obtained in step A is put into concentration and is leached in the sodium hydroxide solution of 100g / L, and the ratio of sodium hydroxide solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com