Preparation method of nano-copper-coated aluminum composite fuel

A composite fuel and coated aluminum technology, which is applied in nanotechnology, transportation and packaging, metal processing equipment, etc., can solve the problem of low combustion calorific value, achieve uniform distribution, simple production equipment, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

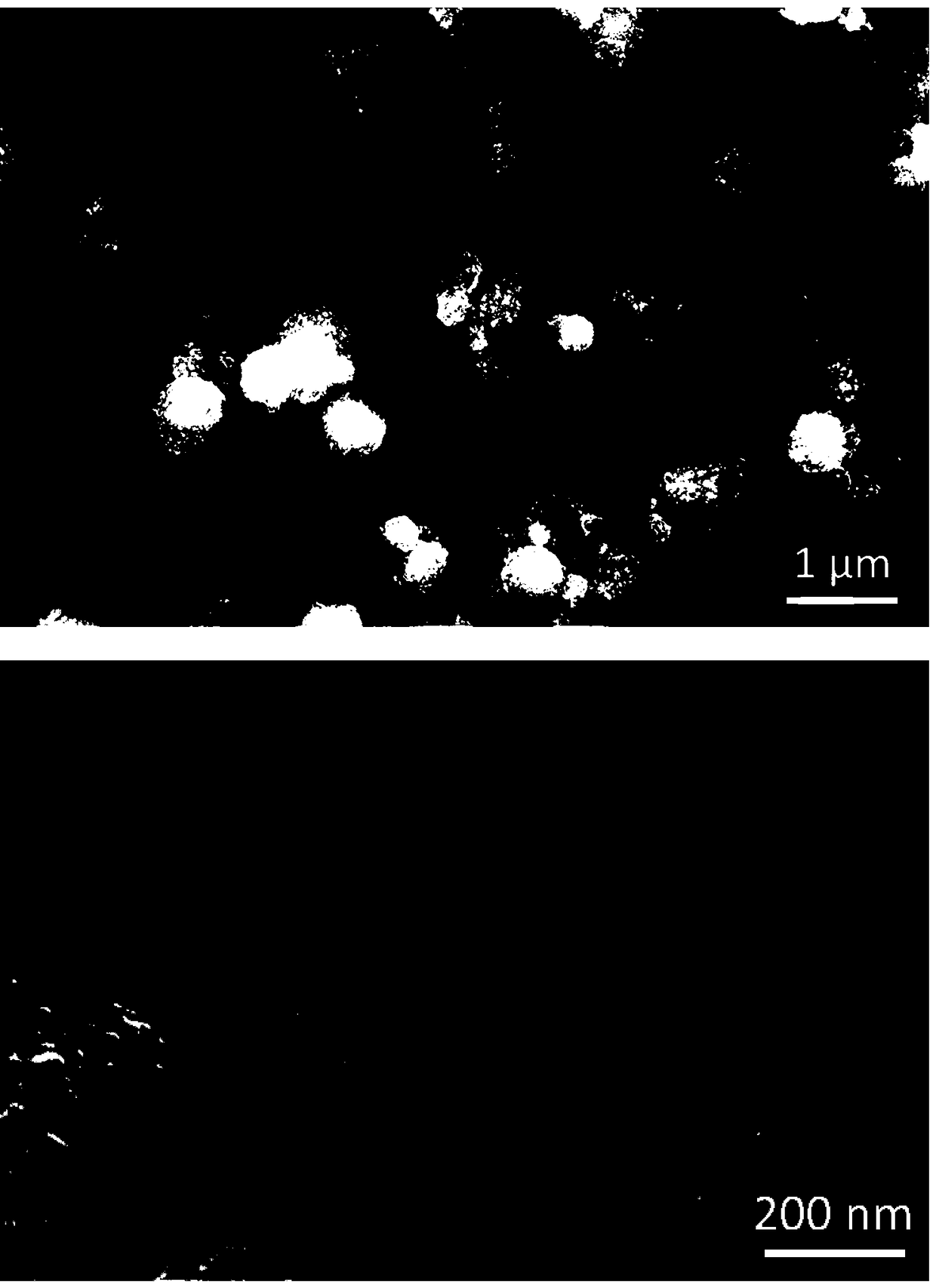

Image

Examples

Embodiment 1

[0024] Embodiment 1: The steps of preparing nano-copper-coated aluminum composite fuel are as follows:

[0025] (1) Under normal temperature and pressure, prepare a certain concentration of copper sulfate aqueous solution and sodium hydroxide aqueous solution, and mix the copper sulfate aqueous solution and sodium hydroxide aqueous solution at a volume ratio of 1:1 to form a copper hydroxide suspension; The copper oxide suspension is centrifuged, washed with deionized water until the pH is neutral, and copper hydroxide is obtained; wherein, the concentration of the copper sulfate aqueous solution is 0.01mol / L, and the concentration of the sodium hydroxide aqueous solution is 2.1 times the concentration of the copper sulfate water;

[0026] (2) Add the copper hydroxide and aluminum powder obtained in step (1) into water for ultrasonic dispersion with a power of 60 watts to obtain a mixed aqueous phase suspension of copper hydroxide and aluminum powder; wherein, the particle size...

Embodiment 2

[0028] Embodiment 2: The steps of preparing nano-copper-coated aluminum composite fuel are as follows:

[0029] (1) Under normal temperature and pressure, prepare a certain concentration of copper sulfate aqueous solution and sodium hydroxide aqueous solution, and mix the copper sulfate aqueous solution and sodium hydroxide aqueous solution at a volume ratio of 1:1 to form a copper hydroxide suspension; The copper oxide suspension is centrifuged, washed with deionized water until the pH is neutral to obtain copper hydroxide; wherein, the concentration of the copper sulfate aqueous solution is 0.055mol / L, and the concentration of the sodium hydroxide aqueous solution is 2.1 times the concentration of the copper sulfate water;

[0030] (2) Add the copper hydroxide and aluminum powder obtained in step (1) into water for ultrasonic dispersion with a power of 210 watts to obtain a mixed aqueous phase suspension of copper hydroxide and aluminum powder; wherein, the particle size of t...

Embodiment 3

[0032] Embodiment 3: The steps of preparing nano-copper-coated aluminum composite fuel are as follows:

[0033] (1) Under normal temperature and pressure, prepare a certain concentration of copper sulfate aqueous solution and sodium hydroxide aqueous solution, and mix the copper sulfate aqueous solution and sodium hydroxide aqueous solution at a volume ratio of 1:1 to form a copper hydroxide suspension; The copper oxide suspension is centrifuged, washed with deionized water until the pH is neutral, and copper hydroxide is obtained; wherein, the concentration of the copper sulfate aqueous solution is 0.1 mol / L, and the concentration of the sodium hydroxide aqueous solution is 2.1 times the concentration of the copper sulfate water;

[0034](2) Add the copper hydroxide and aluminum powder obtained in step (1) into water for ultrasonic dispersion with a power of 360 watts to obtain a mixed aqueous phase suspension of copper hydroxide and aluminum powder; wherein, the particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com