Method for separating zinc, cadmium, copper, lead and silver from zinc smelting copper slag

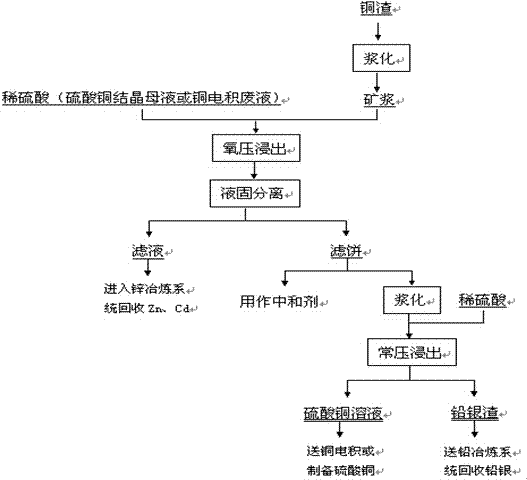

A technology for zinc smelting and copper slag, which is applied in the field of separating zinc, copper, lead, silver, and cadmium from zinc smelting copper slag, which can solve the problems of large consumption of zinc powder and achieve the effect of reducing the amount of processing and producing clean and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Slurry 20t of copper slag after mixing, the composition is: Zn 5.65%, Cd 2.51%, Cu 49.19%, directly with water.

[0036] 2) Continuously pump the pulped copper slag and dilute sulfuric acid into the autoclave respectively, and the amount of dilute sulfuric acid added is 0.8 times of the acid consumption of Zn and Cd in the copper slag.

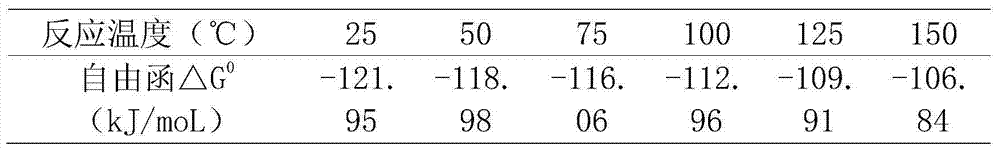

[0037] 3) Continuously feed industrial oxygen, and control the temperature in the kettle to 120°C, oxygen partial pressure to 0.6Mpa, reaction time to 2.0h, and end point pH to 5.4.

[0038] 4) After the pulp leached from the autoclave is depressurized and cooled by the flash tank and the regulating tank, it is filtered by a box-type filter press, and the filter cake is slurried and then filtered again. The filtrate obtained by the two presses enters the zinc smelting system to recover Zn and Cd .

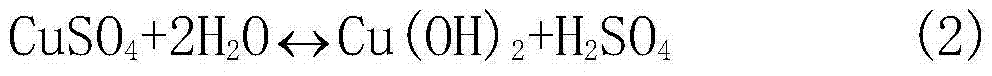

[0039] 5) After mixing the filter cake obtained by two times of pressure filtration, add dilute sulfuric acid, leaching copper at norma...

Embodiment 2

[0041] 1) Slurry 24t of mixed copper slag with the following components: Zn 7.39%, Cd 6.11%, Cu 24.33%, directly with water.

[0042]2) Continuously pump the pulped copper slag and dilute sulfuric acid into the autoclave respectively, and the amount of sulfuric acid added is 0.9 times of the acid consumption of Zn and Cd reaction in the copper slag.

[0043] 3) Oxygen is fed continuously, and the temperature in the kettle is controlled to 100°C, the oxygen partial pressure is 0.4Mpa, the reaction time is 1.5h, and the end point pH is 5.2.

[0044] 4) After the pulp leached from the autoclave is depressurized and cooled by the flash tank and the regulating tank, it is filtered by a box-type filter press, and the filter cake is slurried and then filtered again. The filtrate obtained by the two presses enters the zinc smelting system to recover Zn and Cd .

[0045] 5) After mixing the filter cake obtained by two times of pressure filtration, add dilute sulfuric acid, leaching co...

Embodiment 3

[0047] 1) The mixed copper slag 21t, whose composition is: Zn 9.67%, Cd 10.09%, Cu 10.93%, is directly slurried with water.

[0048] 2) Pour the pulped copper slag and dilute sulfuric acid into the autoclave separately and continuously, and the amount of sulfuric acid added is 1.0 times of the acid consumption of Zn and Cd reaction in the copper slag.

[0049] 3) Oxygen is fed continuously, and the temperature in the kettle is controlled at 80°C, the oxygen partial pressure is 0.2Mpa, the reaction time is 1.0h, and the final pH is 5.0.

[0050] 4) After the pulp leached from the autoclave is depressurized and cooled by the flash tank and the regulating tank, it is filtered by a box-type filter press, and the filter cake is slurried and then filtered again. The filtrate obtained by the two presses enters the zinc smelting system to recover Zn and Cd .

[0051] 5) After mixing the filter cake obtained by two times of pressure filtration, add dilute sulfuric acid, leaching coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com