A ceria-modified copper hydroxide composite electrode and its application in glucose sensor

A technology of ceria and composite electrodes, which is applied in the field of biochemical sensors, can solve the problems of insufficient sensitivity of electrodes and poor conductivity, and achieve the effects of improving electrode performance, high sensitivity, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] nano-CeO 2 -Cu(OH) 2 Preparation of composite electrodes:

[0039] S1. Preparation of ceria-copper-tin alloy: degreasing the brass sheet by ultrasonic vibration in acetone for 30 min, cleaning the degreasing substrate with deionized water, soaking in 0.4M Na 2 S 2 o 8 and 0.4M H 2 SO 4 The oxide film on the surface layer was removed in the mixed solution, and then washed with deionized water and dried.

[0040] Electrodeposit a copper layer on the area to be plated on the brass sheet, then use the brass sheet as the working electrode, and the platinum sheet as the counter electrode, in 1g / L CeO 2 , 19g / L Cu 2 P 2 o 7 ·3H 2 O, 15.6g / L Sn 2 P 2 o 7 、280g / L K 4 P 2 o 7 ·3H 2 O, 80g / L K 2 HPO 4 ·3H 2 O and 3.95g / L H 3 PO 4 In the ceria-copper-tin plating solution, the ceria-copper-tin alloy was electroplated with a current density of 1ASD and a time of 15min.

[0041]S2. Preparation of cerium dioxide-nanoporous copper: the copper-tin alloy obtained in...

Embodiment 2

[0045] nano-CeO 2 -Cu(OH) 2 The preparation of composite electrode, its raw material and method are with embodiment 1;

[0046] The difference is:

[0047] In step S1, ceria-copper tin bath composition is 0.8g / L CeO 2 , 18g / L Cu 2 P 2 o 7 ·3H 2 O, 15g / LSn 2 P 2 o 7 、260g / L K 4 P 2 o 7 ·3H 2 O, 70g / LK 2 HPO 4 ·3H 2 O and 3g / L H 3 PO 4 ;

[0048] In step S3, the scan rate is 1mV s -1 .

Embodiment 3

[0050] nano-CeO 2 -Cu(OH) 2 The preparation of composite electrode, its raw material and method are with embodiment 1;

[0051] The difference is:

[0052] In step S1, ceria-copper tin bath composition is 0.9g / L CeO 2 , 20g / L Cu 2 P 2 o 7 ·3H 2 O, 17g / LSn 2 P 2 o 7 、290g / L K 4 P 2 o 7 ·3H 2 O, 90g / LK 2 HPO 4 ·3H 2 O and 5g / L H 3 PO 4 ;

[0053] In step S3, the scan rate is 5mV s -1 .

[0054] Adopt SEM scanning electron microscope to observe the nanometer CeO that the present invention prepares 2 -Cu(OH) 2 composite electrode.

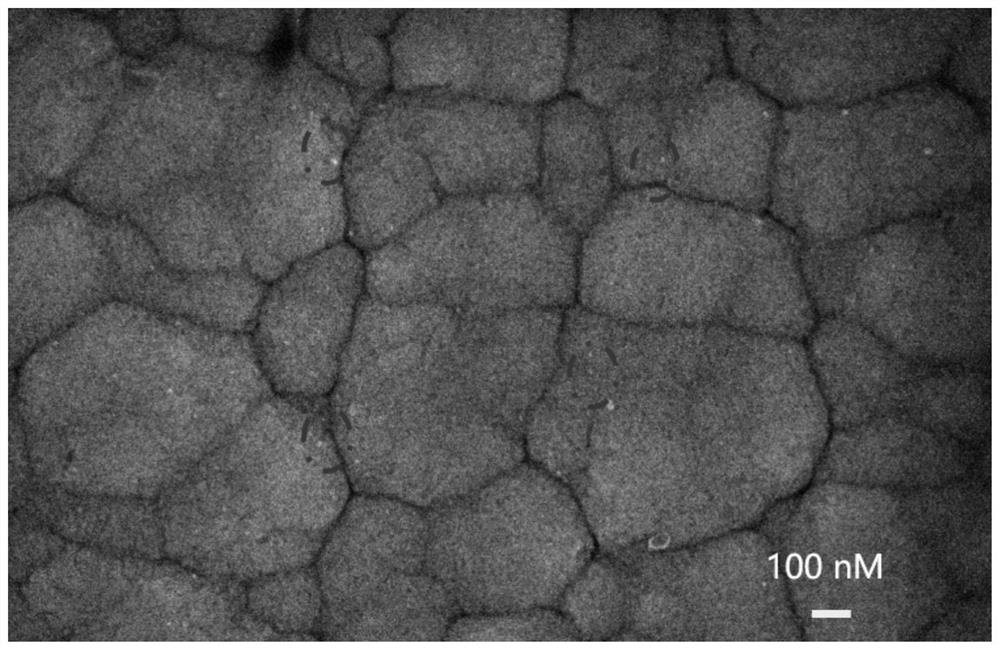

[0055] Such as figure 1 As shown, the scanning electron micrograph is obtained after SEM detection of the ceria-copper-tin alloy prepared in Example 2 of the present invention. It can be observed that the surface of the alloy is compact and orderly, containing clear ceria nanoparticles with a diameter of about 20-50nm.

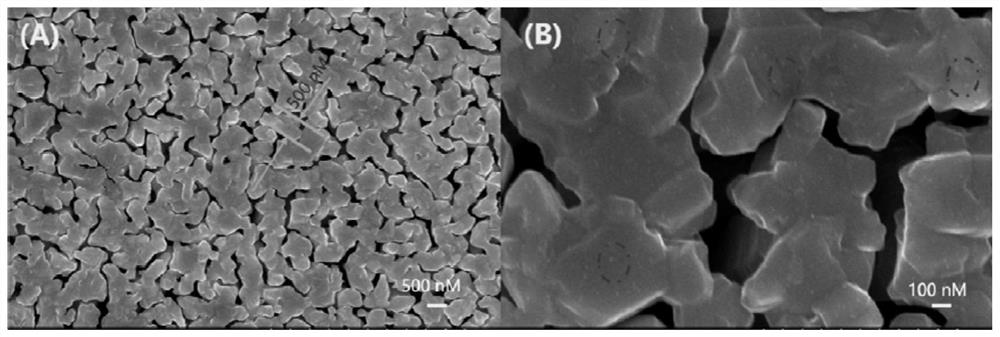

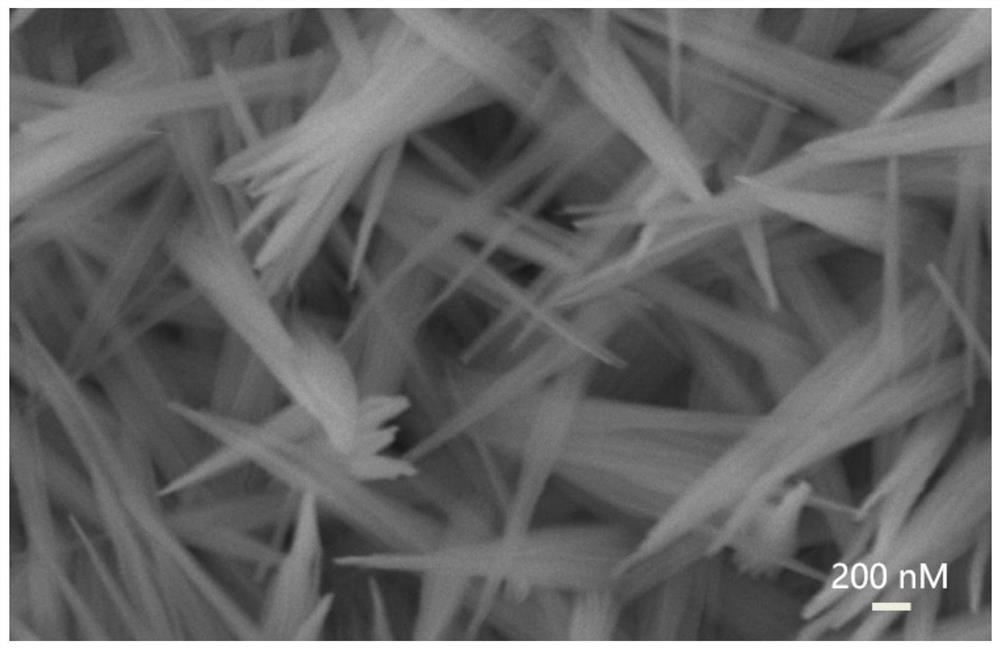

[0056] Such as figure 2 Shown are the scanning electron micrographs of different magnifications of the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com