Catalyzer slurry for producing fuel cell membrane electrode and process for production thereof

A fuel cell membrane and catalyst slurry technology, which is applied to fuel cell parts, battery electrodes, solid electrolyte fuel cells, etc., can solve problems such as troublesome, high operating environment requirements, and affecting battery electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

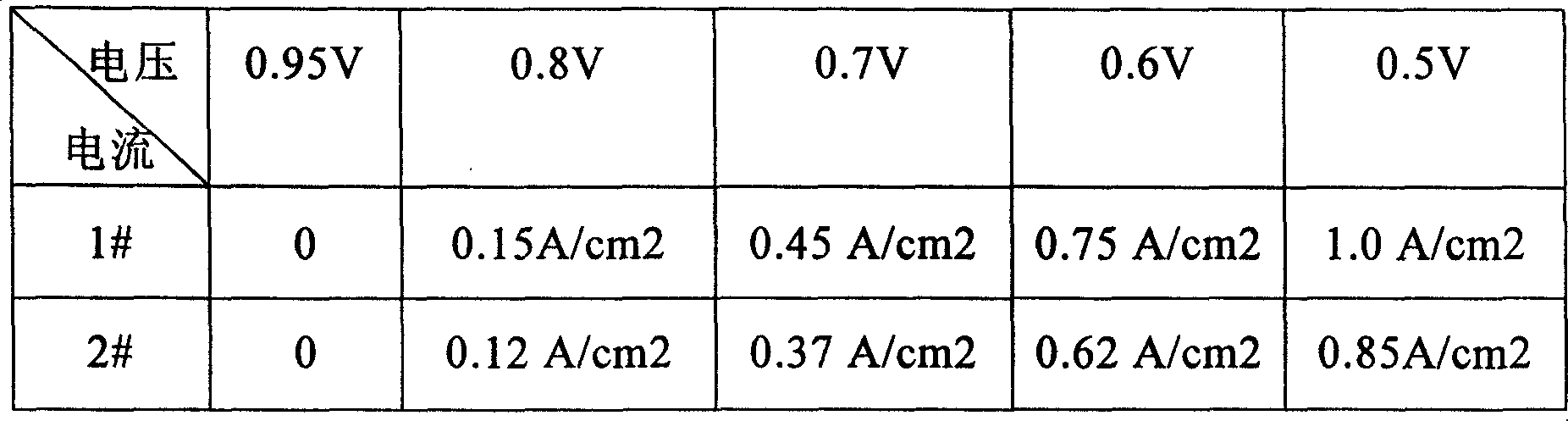

Examples

Embodiment 1

[0025] Get the HP40%Pt / C catalyst that 0.1g E-TEK company produces, add 2g acetic acid, ultrasonic vibration 5min, add the Nafion DE 520 dispersion liquid that Dupont company produces (wherein the concentration of perfluorosulfonic acid resin in the dispersion liquid is 5.4%, The solvent contains 45-48% of water, 45-48% of 1-propanol, less than 4% of ethylene glycol, and less than 1% of mixed ethers) 0.8g, ultrasonically oscillated for 5 minutes, and kept stirring. That is, a catalyst slurry of the present invention is obtained.

Embodiment 2

[0027] Mix 1g of perfluorosulfonic acid resin, 4g of water and 5g of ethanol, put it into an autoclave, seal it, heat it to 250 degrees Celsius, and keep stirring for 3 hours. After cooling, the dispersion liquid of the high molecular polymer proton conductor is obtained;

[0028] Take 0.1g of HP40%Pt / C produced by E-TEK Company, add 1g of oxalic acid, ultrasonically shake for 5min, add 0.5g of the above dispersion, ultrasonically shake for 5min, and keep stirring. That is, a catalyst slurry of the present invention is obtained.

Embodiment 3

[0030] Mix 1 g of sulfonated trifluorostyrene resin, 3 g of water and 6 g of 1-propanol, put into an autoclave, seal, heat, and keep stirring for 3 hours, and after cooling, the dispersion liquid of the high molecular polymer proton conductor is obtained;

[0031] Take 0.1g of HP40%Pt / C produced by E-TEK Company, add 3g of oxalic acid, ultrasonically shake for 5min, add 0.6g of the above dispersion, ultrasonically shake for 5min, and keep stirring. That is, a catalyst slurry of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com