Method for preparing cubic nano copper powder

A technology of nano-copper powder and cubes, which is applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of uneven powder particle size, cumbersome operation steps, high heating temperature, etc., and achieve good oxidation resistance, simple process, The effect of low heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

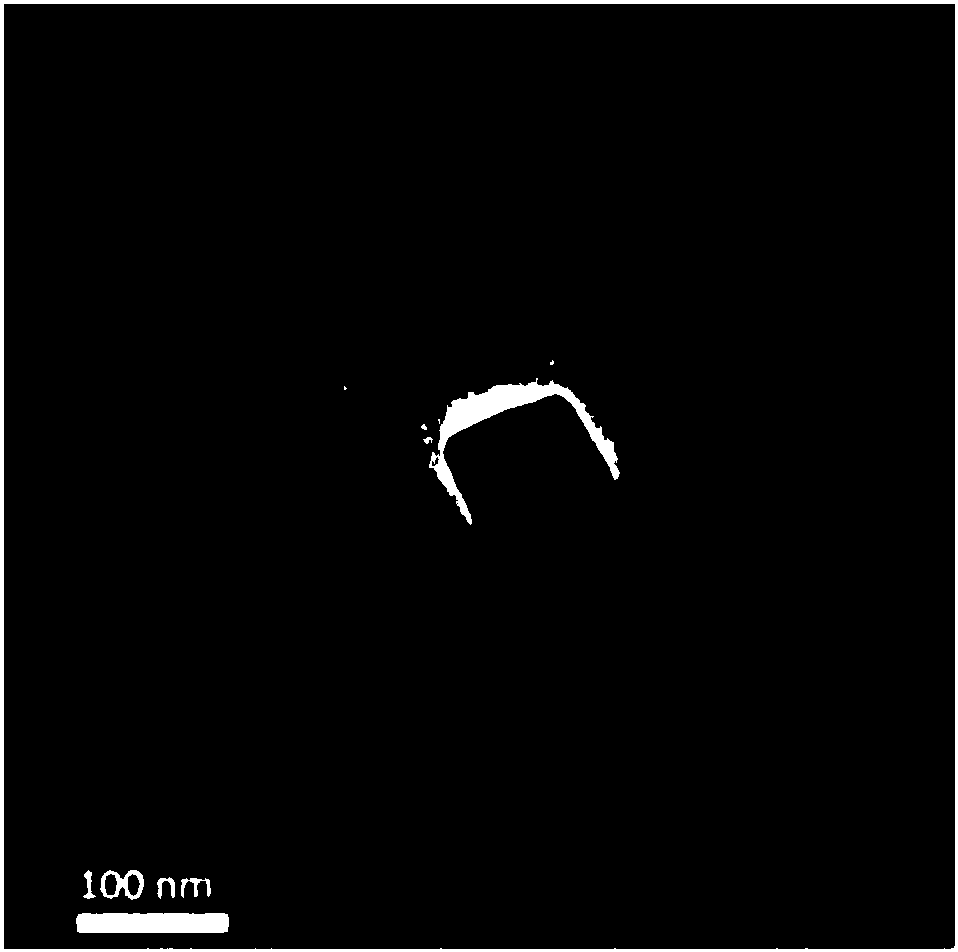

Image

Examples

Embodiment 1

[0029] (1) At 50°C, add 5g of stearic acid to 250mL, 0.04mol / L CuCl 2 In the ethanol solution, stir evenly with magnetic force to obtain CuCl 2 and a mixed solution of stearic acid;

[0030] (2) Configure the NaOH ethanol solution of 2mol / L, under the condition of 800r / min magnetic stirring, add the NaOH ethanol solution to the solution obtained in step (1) quickly at a speed of 0.7L / min, and adjust the pH of the solution to 12 , making Cu(OH )2 colloid;

[0031] (3) the colloidal solution gained in step (2) is poured in the three-necked flask, and normal pressure is logical N 2 Protect the gas, heat the colloidal solution while stirring, and heat it to an external temperature of 75°C, then add 6.4g of hydrazine hydrate dropwise into the three-necked flask, and stir at a constant temperature for 120min. After the reaction, a cubic nano-copper dispersion is obtained;

[0032] (4) Centrifuge the cubic copper powder dispersion obtained in step (3) to obtain the copper colloid...

Embodiment 2

[0034] (1) At room temperature, add 3 g of oleic acid to 100 mL of 0.1 mol / L CuCl 2 In deionized aqueous solution, stir evenly with magnetic force to obtain CuCl 2 Mixed solution with oleic acid;

[0035] (2) configuration concentration is the NaOH aqueous solution of 4mol / L, under the condition of 700r / min magnetic stirring, quickly add NaOH aqueous solution to step (1) gained solution with the speed of 1.2L / min, makes Cu(OH) 2 colloid;

[0036] (3) Pour the colloidal solution obtained in step (2) into a three-necked flask, pass argon as a protective gas, and stir the colloidal solution while heating until the external temperature is 80° C., then add 4 g dropwise to the three-necked flask Hydrazine hydrate, stirred at a constant temperature for 180min, and obtained a nano-copper dispersion after the reaction;

[0037] (4) Centrifuge the copper powder dispersion obtained in step (3) to obtain the copper colloid, wash it three times with deionized water, and vacuum dry to ob...

Embodiment 3

[0039] (1) At 50°C, add 3g of stearic acid to 200mL of 0.05mol / L CuSO 4 In ethanol solution, CuSO 4 and a mixed solution of stearic acid;

[0040] (2) configuration concentration is the KOH ethanol solution of 1.5mol / L, under the condition of 1000r / min magnetic stirring, with the speed of 1.9L / min, KOH ethanol solution is added in step (1) gained solution fast, the solution pH The value was adjusted to 12 to obtain Cu(OH) 2 colloid;

[0041] (3) Pour the colloidal solution obtained in step (2) into a three-necked flask, pass argon as a protective gas, heat the colloidal solution while stirring, and at the same time heat it to an external temperature of 75°C, and then add it dropwise to the three-necked flask 5g of hydrazine hydrate, stirred at a constant temperature for 300min, and obtained a nano-copper dispersion after the reaction;

[0042] (4) Centrifuge the copper powder dispersion obtained in step (3) to obtain the copper colloid, wash it three times with absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com