Method for preparing crystalline copper powder

A technology of copper powder and crystallization, which is applied in the field of preparation of crystalline copper powder, can solve problems such as wide particle size distribution, poor dispersion performance, and easy agglomeration of copper powder, and achieve narrow particle size distribution, good dispersion, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

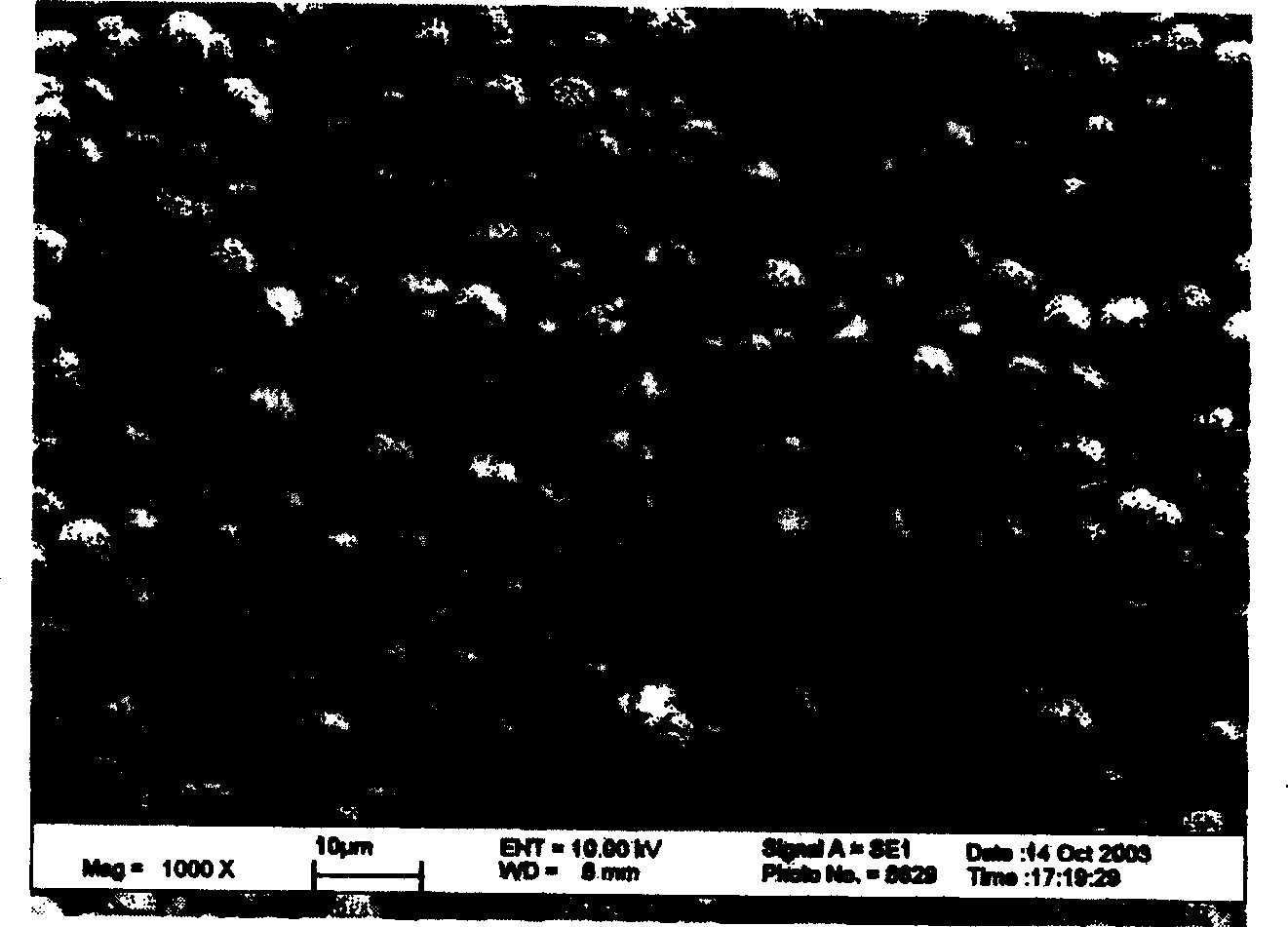

[0018] Disperse 5.47 g of cuprous oxide in 50 ml of water, add 0.78 g of cetyltrimethylammonium bromide and 0.36 g of glycine, and raise the temperature to 65°C. Add 12.5% hydrazine hydrate solution into the above reaction solution under thorough stirring. After 1.5 hours of reaction at 65°C the product was filtered, washed well and dried in vacuo. The obtained copper powder is bright pink and has obvious metallic luster. from figure 1 It can be seen in the figure that the particles are spherical and crystalline polyhedral, the particles are dispersed and not adhered to each other, and the size distribution is 3-5 μm.

Embodiment 2

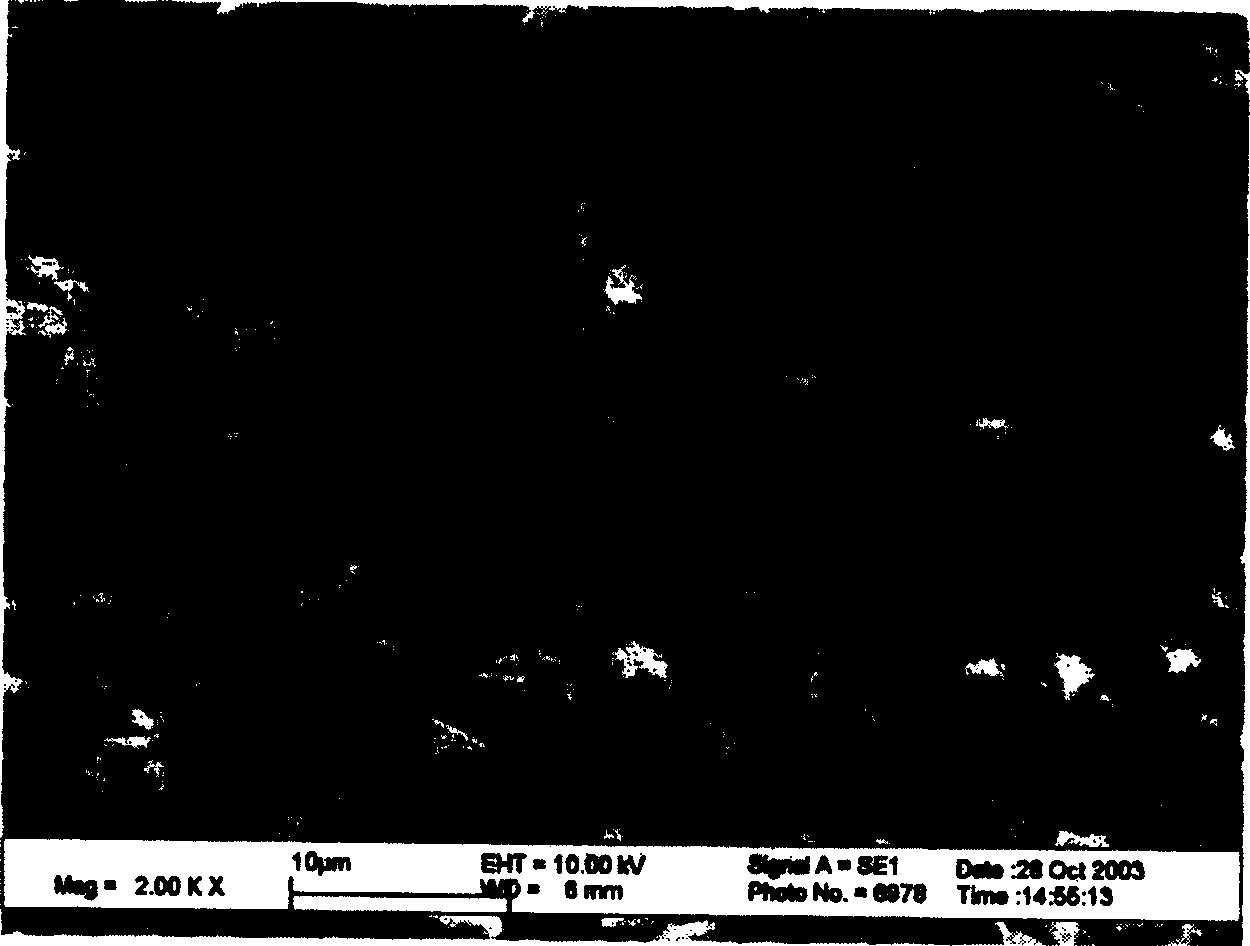

[0020] Disperse 3.60 g of cuprous oxide in 50 ml of water, add 1.82 g of cetyltrimethylammonium bromide and 1.90 g of glycine, and raise the temperature to 65°C. Add 12.5% hydrazine hydrate solution into the above reaction solution under thorough stirring. After 0.5 hour reaction at 65°C the product was filtered, washed well and dried in vacuo. The scanning electron microscope picture of the product shows that the shape of the copper powder particles is spherical, and the size distribution is 0.8-1.2 μm.

Embodiment 3

[0022] Disperse 3.55 g of cuprous oxide in 50 ml of water, add 1.54 g of dodecyltrimethylammonium bromide and 0.37 g of glycine, and raise the temperature to 65°C. Add 12.5% hydrazine hydrate solution into the above reaction solution under thorough stirring. After reacting at 65°C for 1.0 hour the product was filtered, washed well and dried under vacuum. The scanning electron microscope picture of the product shows that the shape of the copper powder particles is spherical, and the size distribution is 1.5-2.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com