Method for preparing rapeseed bioactive peptide

A bioactive peptide and rapeseed technology, which is applied in the field of protease hydrolysis technology, can solve the problems of uneven molecular weight distribution of products, affecting the physiological activity of products, and high salt content in finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

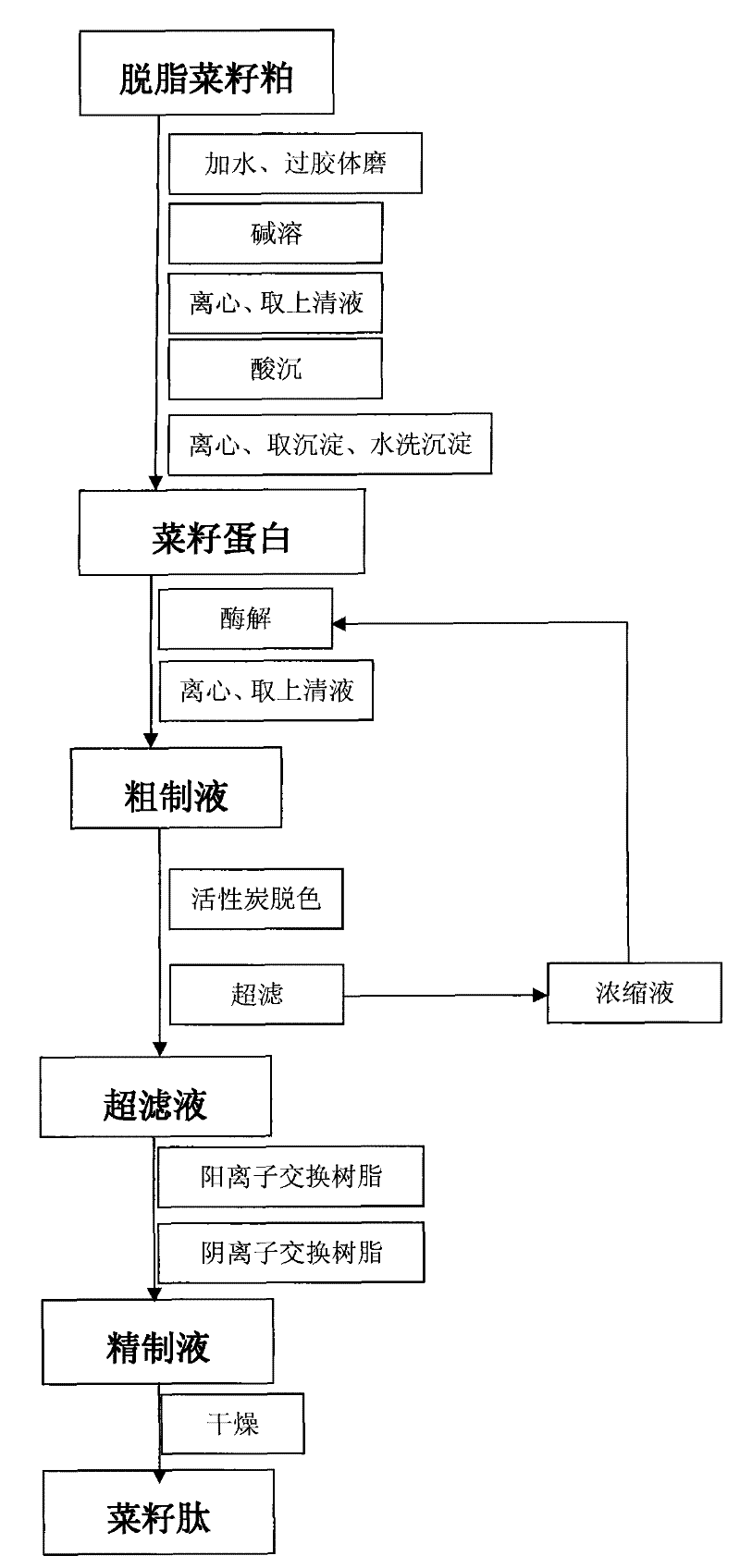

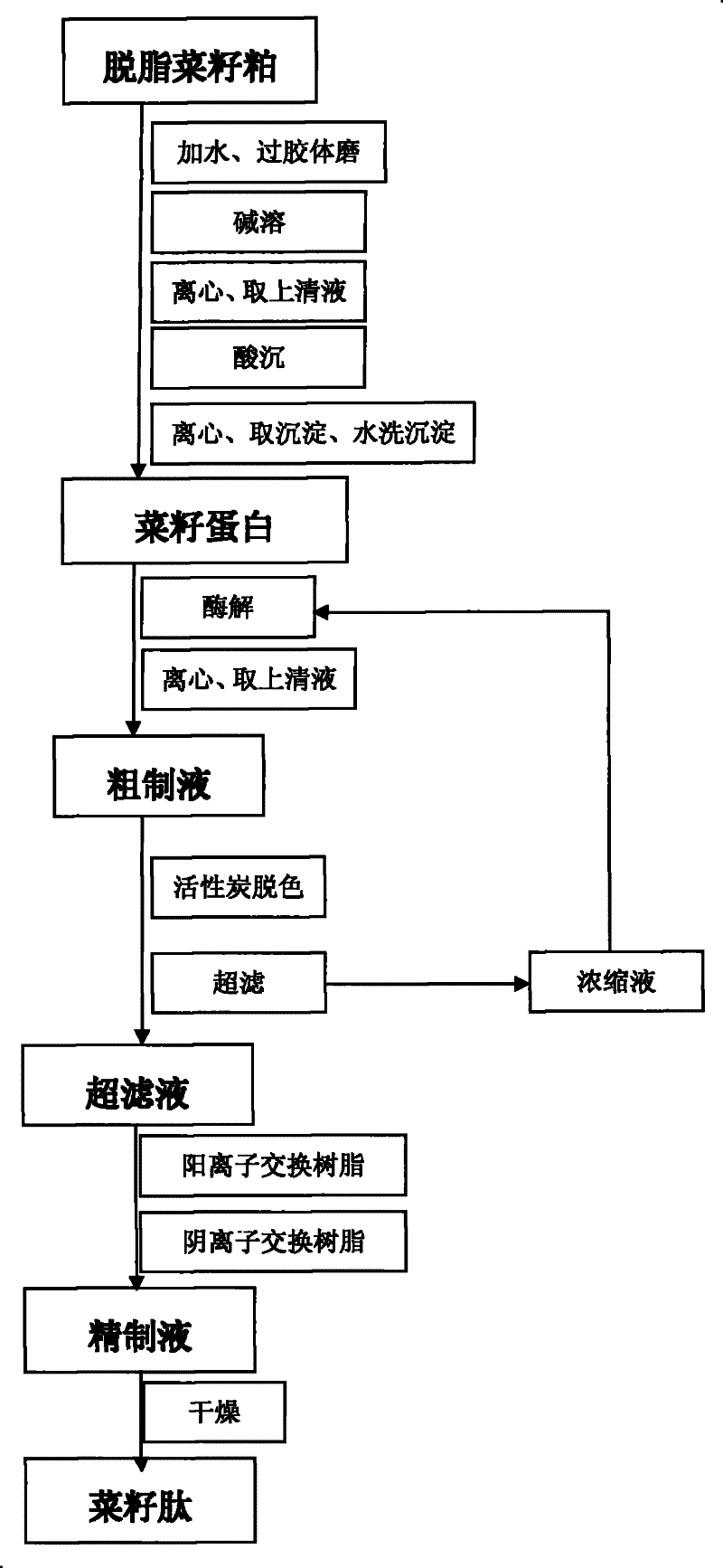

Method used

Image

Examples

Embodiment 1

[0039] (1) Dissolve 100 g of defatted rapeseed meal into 800 mL of water, pulverize it with a colloid mill, adjust the pH to 10.0 with NaOH reagent, stir continuously for 15 min, 3000 rpm, 15 min, and centrifuge to take the supernatant;

[0040] (2) Heat the supernatant from step 1 to 90°C, adjust the pH value to 3.5 with citric acid, set the temperature at 45°C, and stir at a speed of 45r / min to precipitate the protein for 30min, then centrifuge at 3000r / min for 10min, and remove the supernatant liquid, collect the solid phase, add water and mix again according to the above steps, adjust the pH value to 3.5 with citric acid, and precipitate the protein, repeat three times, and finally wash twice with water, centrifuge to obtain the solid phase, which is rapeseed protein, and weigh as 58g;

[0041] (3) Pour the precipitate in step 2 into 600mL of water, heat to 90°C, keep for 30min, then cool to 50°C, add 2.32g of neutral protease As1.398 (enzyme activity is 130000U / g), adjust...

Embodiment 2

[0051] (1) Dissolve 500 g of rapeseed meal into 5 L of water, pulverize it with a colloid mill, adjust the pH to 12.0 with NaOH reagent, stir continuously for 15 min, 3000 rpm, 15 min, and centrifuge to get the supernatant;

[0052] (2) Heat the supernatant from step 1 to 90°C, adjust the pH value to 4.2 with citric acid, set the temperature at 50°C, and stir at a speed of 30r / min to precipitate the protein for 45min, then centrifuge at 3000r / min for 5min, and remove the supernatant liquid, collect the solid phase, add water and mix again according to the above steps, adjust the pH value to 4.2 with citric acid, and precipitate the protein, repeat three times, and finally wash twice with water, centrifuge to obtain the solid phase, which is rapeseed protein, and weigh as 326g;

[0053] (3) Pour the precipitate in step 2 into 4L water, heat to 95°C, keep for 30min, then cool to 45°C, add 14.67g of neutral protease As1.398 (enzyme activity is 130000U / g), adjust with NaOH reagent...

Embodiment 3

[0063] (1) Take 1000g of rapeseed meal and dissolve it in 12L of water, pulverize it with a colloid mill, adjust the pH to 9.0 with NaOH reagent, stir continuously for 15min, 3000rpm, 15min, and centrifuge to get the supernatant;

[0064] (2) Heat the supernatant from step 1 to 90°C, adjust the pH value to 4.5 with citric acid, set the temperature at 40°C, and stir at a speed of 40r / min to precipitate the protein for 20min, then centrifuge at 3000r / min for 10min, and remove the supernatant Liquid, collect the solid phase, add water and mix according to the above steps again, so that the protein precipitates at the isoelectric point, repeat three times, finally wash twice with water, and centrifuge to obtain the solid phase, which is rapeseed protein, weighing 589g;

[0065] (3) Pour the precipitate in step 2 into 6L water, heat to 90°C, keep for 30min, then cool to 50°C, add 29.45g of neutral protease As1.398 (enzyme activity is 130000U / g), adjust with NaOH reagent and Keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com