Method for extracting vanadium from vanadium-containing steel slag by using highly-alkaline sodium hydroxide medium

A sodium hydroxide and high alkalinity technology, applied in the field of vanadium extraction, can solve the problems of insufficient processing capacity of vanadium-containing steel slag, increased energy consumption in the iron-making process, low content of effective calcium oxide, etc., and achieves low production cost and economical efficiency. The effect of good economic and environmental benefits and high dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

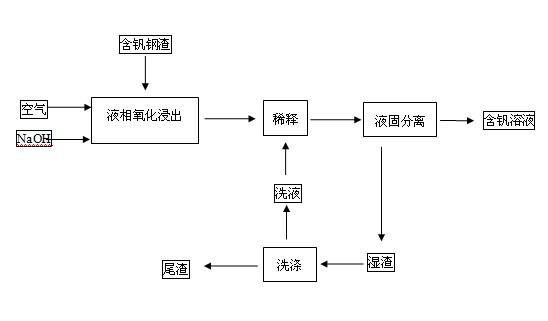

Image

Examples

Embodiment 1

[0017] A method for extracting vanadium from vanadium-containing steel slag with high-alkalinity sodium hydroxide medium: Weigh 200g of solid industrial NaOH into a reaction kettle, add 50mL of deionized water to an initial concentration of 60%, start stirring, and the stirring speed is 600rpm , heated up to 200°C, weighed 50g of vanadium-containing steel slag and put it in the reactor, and the reaction time was 6h; at the end of the reaction, 400mL of water was added to the reactor to dilute, filtered by suction, the alkalinity of the liquid phase was 345g / L, and the slag was Washing three times; using chemical and instrumental analysis to analyze the content of vanadium in the slag phase and liquid phase, the total vanadium content in the tailings is 0.435wt% (calculated as vanadium pentoxide), and the leaching rate of the obtained vanadium is 87.5%.

Embodiment 2

[0019] A method for extracting vanadium from vanadium-containing steel slag with a high-alkalinity sodium hydroxide medium: Weigh 200g of solid analytical pure NaOH in a reaction kettle, add 50mL of deionized water to an initial concentration of 80%, turn on the stirring, and the stirring speed 600rpm, heat up to 240°C, weigh 50g of vanadium-containing steel slag and put it in the reaction kettle, and the reaction time is 4h. At the end of the reaction, add 400mL of water to the reaction kettle to dilute, filter with suction, the alkalinity of the liquid phase is 356.5g / L, wash the slag three times; use chemistry and instruments to analyze the content of vanadium in the slag phase and liquid phase. The total amount of vanadium is 0.338wt% (calculated as vanadium pentoxide), and the leaching rate of the obtained vanadium is 90.3%.

Embodiment 3

[0021] A method for extracting vanadium from vanadium-containing steel slag with a high-alkalinity sodium hydroxide medium: Weigh 175g of solid analytically pure NaOH and 25g of NaNO3 in a reaction kettle, add 50mL of deionized water to an initial alkali concentration of 70%, nitric acid The initial concentration of sodium is 10%; turn on the stirring, the stirring speed is 600rpm, heat up to 220°C, weigh 50g of vanadium-containing steel slag and put it in the reaction kettle, and the reaction time is 5h; The basicity of the phase is 346.40g / L, and the slag is washed three times; the content of vanadium in the slag phase and liquid phase is analyzed by chemical and instrumental analysis. The total amount of vanadium in the tailings is 0.452wt% (calculated as vanadium pentoxide), and the leaching rate of vanadium obtained is 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com