Magnetic separable metatitanic acid lithium ion sieve, preparation method and application of lithium ion sieve

A technology for magnetic separation and lithium ions, which is applied in chemical instruments and methods, lithium compounds, and other chemical processes, and can solve problems such as high ratio, complexity, and large amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

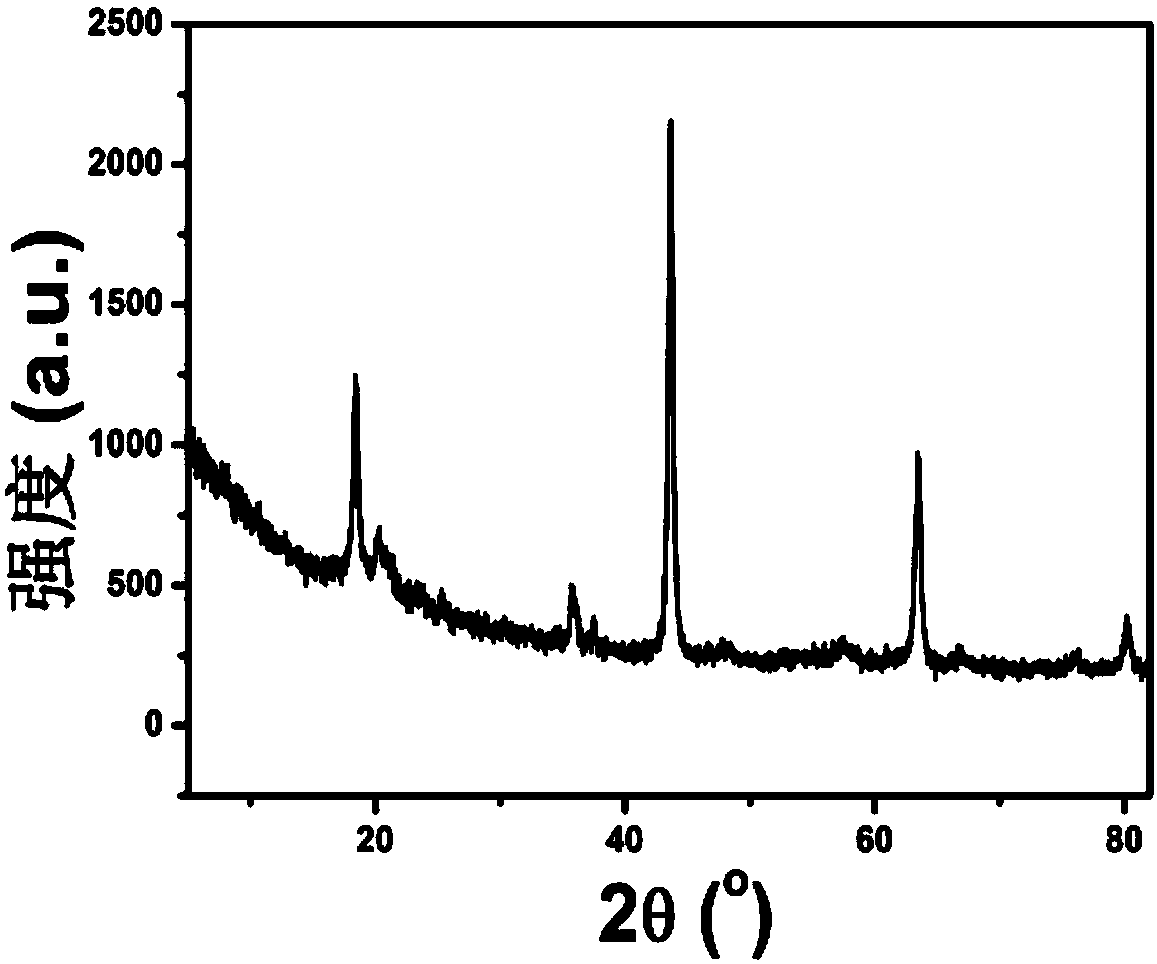

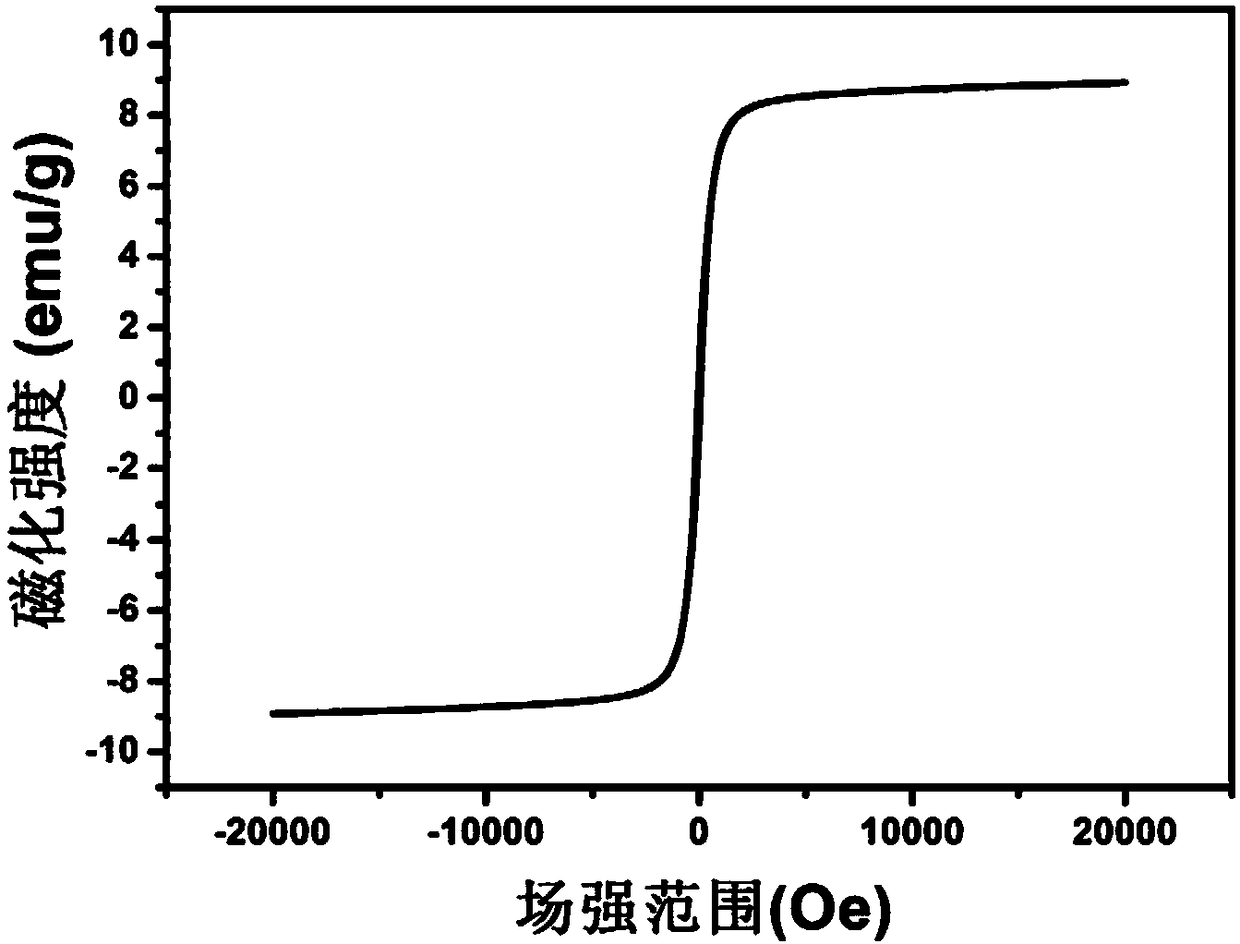

[0069] A magnetically separable metatitanic acid lithium ion sieve with a molecular formula of H 2 Fe 0.074 Ti 0.926 o 3 , the particle size distribution of the lithium ion sieve is between 100-200nm, and the BET specific surface area is 58.42m 2 / g.

[0070] Prepare as follows:

[0071] According to the molar ratio of Li, Ti and Fe 2.2:1:0.08, lithium hydroxide, titanium dioxide and ferric oxide are mixed, fully ground until the mixture is uniform, and then the ground sample is placed in a crucible for compaction, and the lid is closed. The crucible was placed in a muffle furnace, heated to 600°C at a heating rate of 8°C / min, calcined at 600°C for 3 hours, and then cooled to room temperature. The cooled samples were washed with water and dried in an oven at 90°C. The dried sample was delithiated by acid leaching in 0.5 mol / L hydrochloric acid solution, and the acid leaching time was 24 hours. Then the solution after acid leaching was filtered, washed with distilled wat...

Embodiment 2

[0078] A magnetically separable metatitanic acid lithium ion sieve with a molecular formula of H 2 Fe 0.01 Ti 0.99 o 3 , the particle size distribution of the lithium ion sieve is between 60-170nm, and the BET specific surface area is 43.20m 2 / g.

[0079] Prepare as follows:

[0080] According to the molar ratio of Li, Ti and Fe 2:1:0.01, lithium carbonate, titanium dioxide and iron are mixed, fully ground until the mixture is uniform, and then the ground sample is placed in a crucible for compaction, and the covered crucible is placed In a muffle furnace, the temperature was raised to 350° C. at a heating rate of 0.1° C. / min, calcined at 350° C. for 0.5 hour, and then cooled to room temperature. The cooled samples were washed with water and dried in an oven at 90°C. The dried sample was delithiated by acid leaching in 0.01 mol / L sulfuric acid solution, and the acid leaching time was 48 hours. Then the solution after acid leaching was filtered, washed with distilled wa...

Embodiment 3

[0082] A magnetically separable metatitanic acid lithium ion sieve with a molecular formula of H 2 Fe 0.15 Ti 0.85 o 3 , the particle size distribution of the lithium ion sieve is between 110-200nm, and the BET specific surface area is 38.94m 2 / g.

[0083] Prepare as follows:

[0084] According to the molar ratio of Li, Ti and Fe 2.8:1:0.3, lithium acetate, tetrabutyl titanate and ferric sulfate were mixed, fully ground until the mixture was uniform, and then the ground sample was placed in a crucible for compaction, and the lid A good crucible is placed in a muffle furnace, heated to 1050°C at a heating rate of 10°C / min, calcined at 1050°C for 8 hours, and then cooled to room temperature. The cooled samples were washed with water and dried in an oven at 90°C. The dried sample was delithiated by acid leaching in 0.8 mol / L nitric acid solution, and the acid leaching time was 0.5 hours. Then the solution after acid leaching was filtered, washed with distilled water until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com