Patents

Literature

411 results about "Uranium ore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uranium ore deposits are economically recoverable concentrations of uranium within the Earth's crust. Uranium is one of the more common elements in the Earth's crust, being 40 times more common than silver and 500 times more common than gold. It can be found almost everywhere in rock, soil, rivers, and oceans. The challenge for commercial uranium extraction is to find those areas where the concentrations are adequate to form an economically viable deposit. The primary use for uranium obtained from mining is in fuel for nuclear reactors.

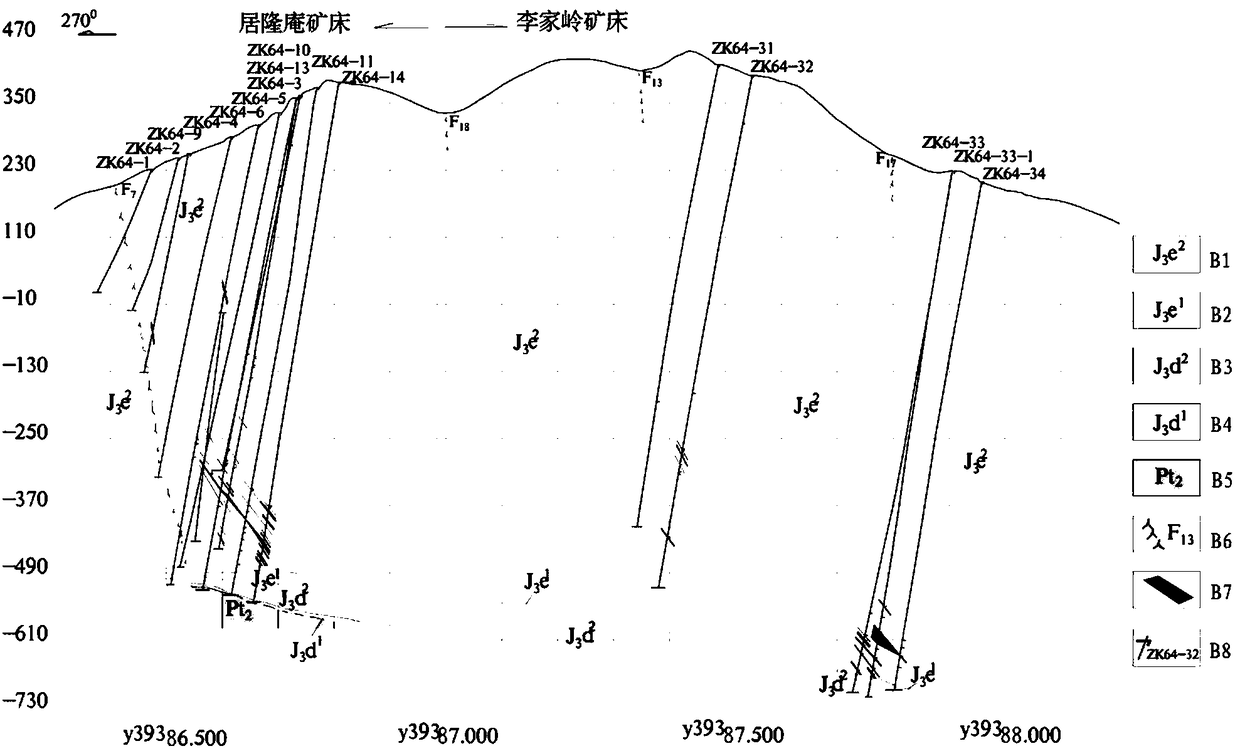

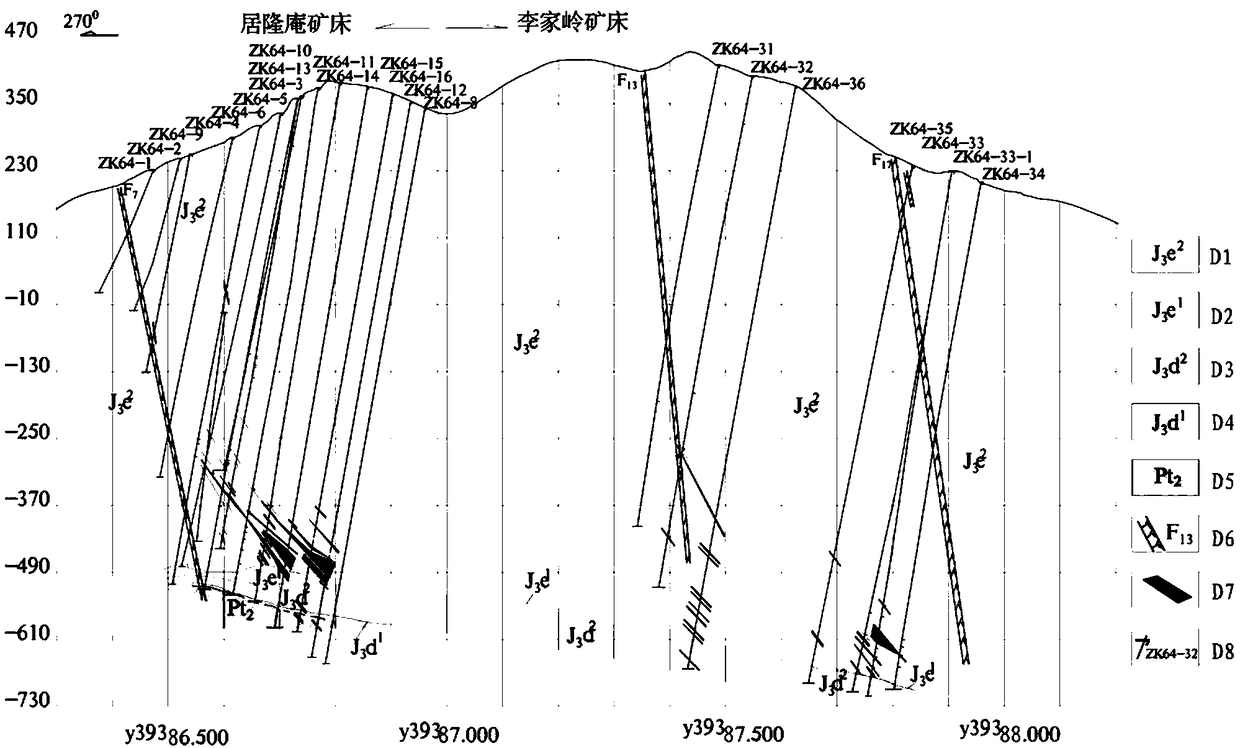

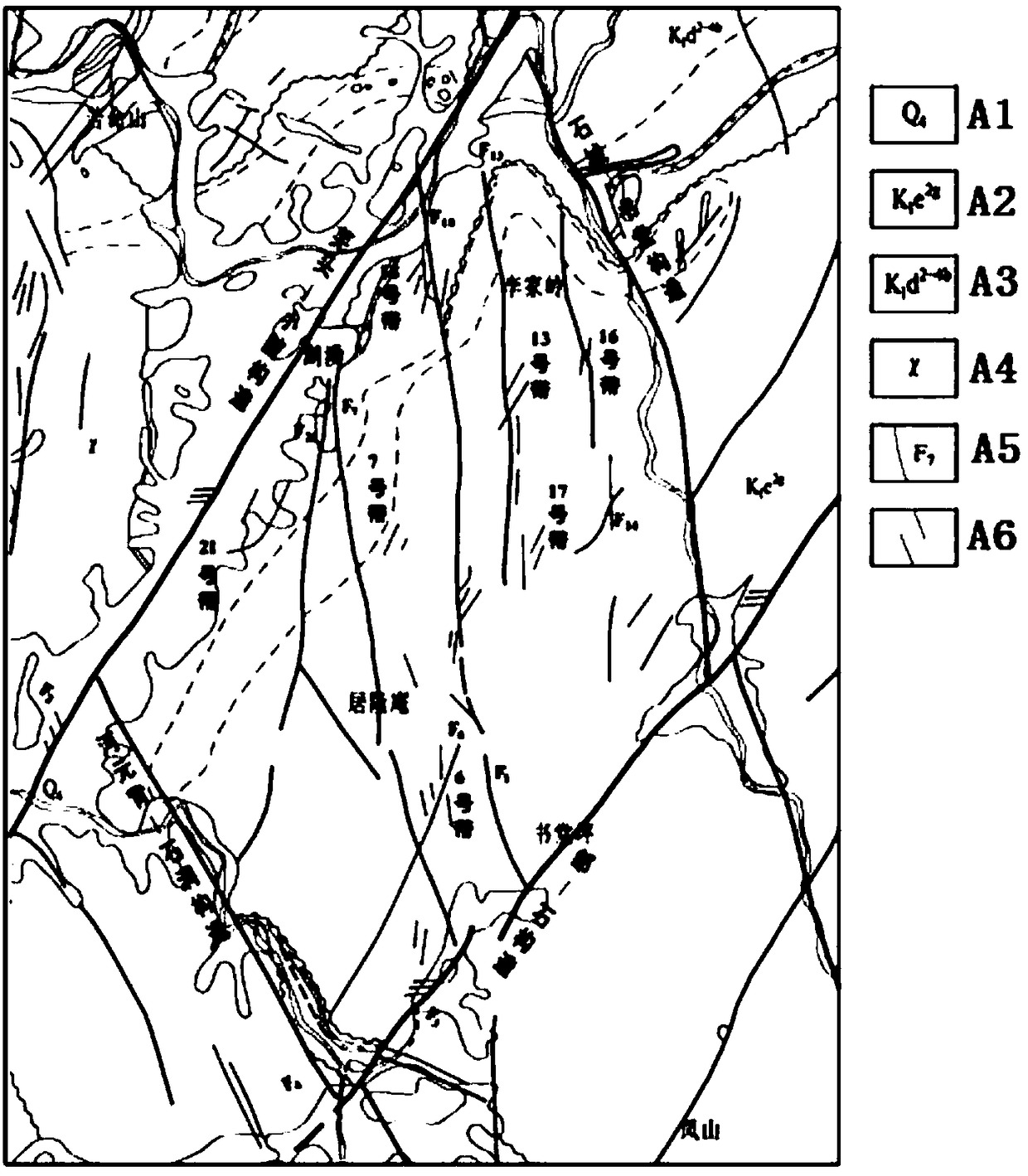

Rapid prospecting positioning method applicable to hidden sandstone-type uranium mine

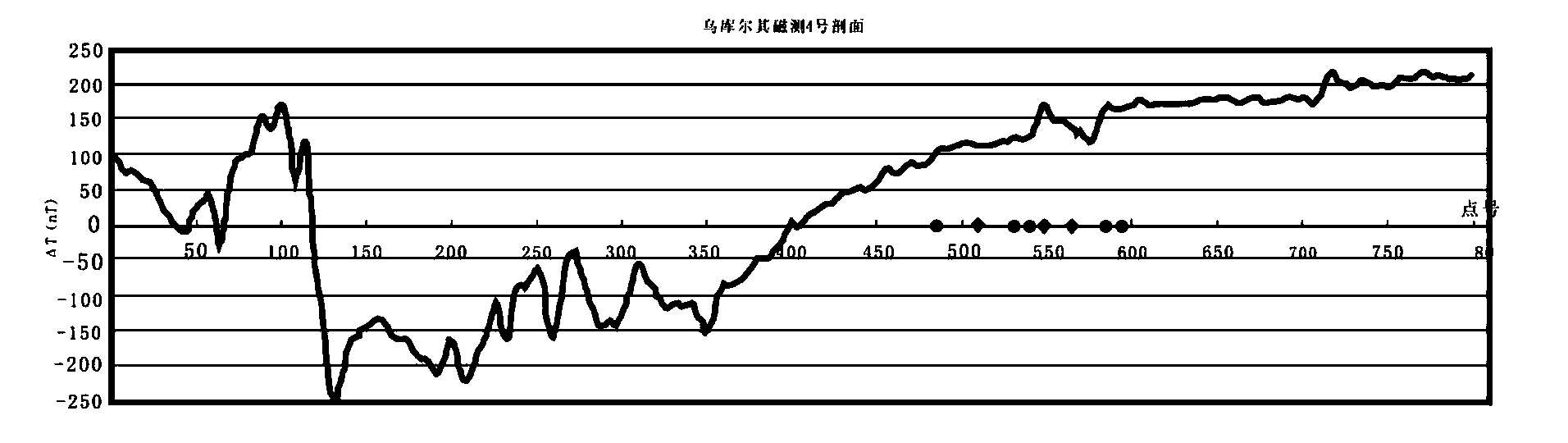

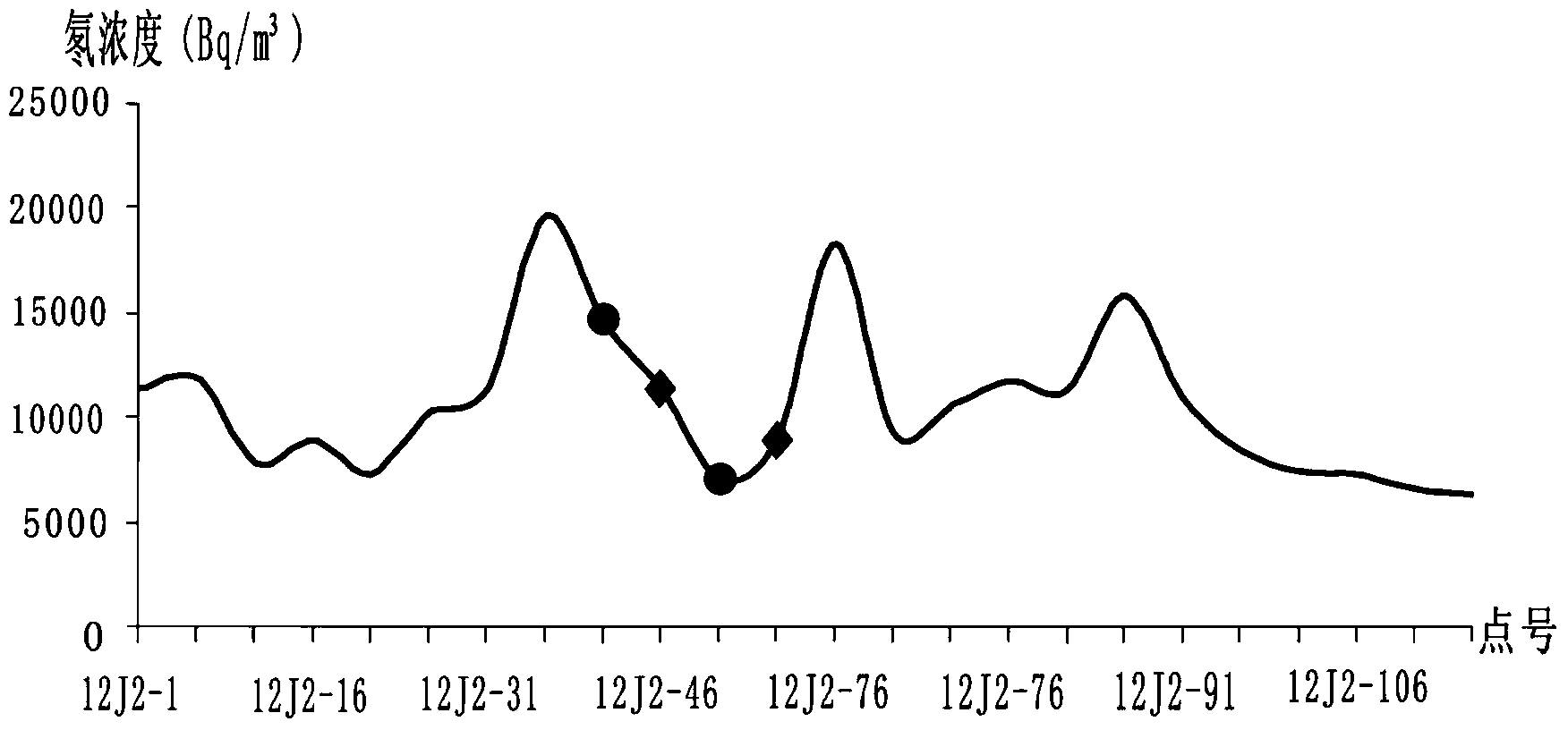

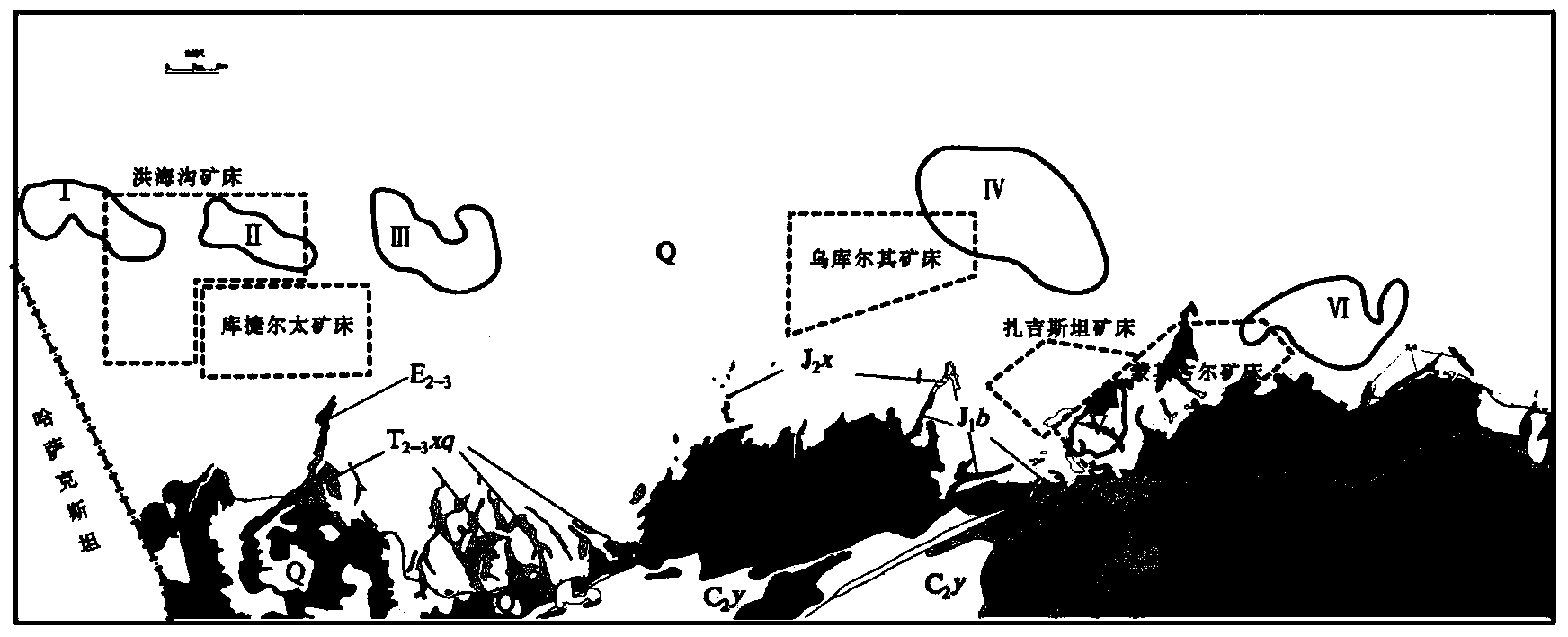

The invention belongs to the field of geological exploration and particularly relates to a rapid prospecting positioning method applicable to a hidden sandstone-type uranium mine. By means of the rapid prospecting positioning method, a minerogenic prospect of the hidden sandstone-type uranium mine can be found optimally, efficiently, rapidly and accurately. The rapid prospecting positioning method comprises the steps of finding a favorable uranium metallogenic province band preliminarily; measuring and acquiring a concentration value of radon gas, shallow earthquake data and electromagnetic data; determining a favorable target position; drawing abnormal profile maps and planar contour diagrams of radon gas data and electromagnetic data; performing mineral occurrence projection transformation; establishing a geophysical-geochemical abnormal model and finding an oxidation-reduction transitional zone predicting area; finding oxidation-reduction zone predicting areas in different positions; judging double-overlapped areas of a radon gas abnormal area and a magnetic abnormal area to be a favorable metallogenic prospect target region. The rapid prospecting positioning method based on combination of specific geological and geophysical-geochemical methods is strong in operability and high in evaluation efficiency, research results have objectivity, and therefore, the rapid prospecting positioning method has significant theoretical importance and practical meaning in deepening prospecting methods of the hidden sandstone-type uranium mine and expanding uranium resources in China.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

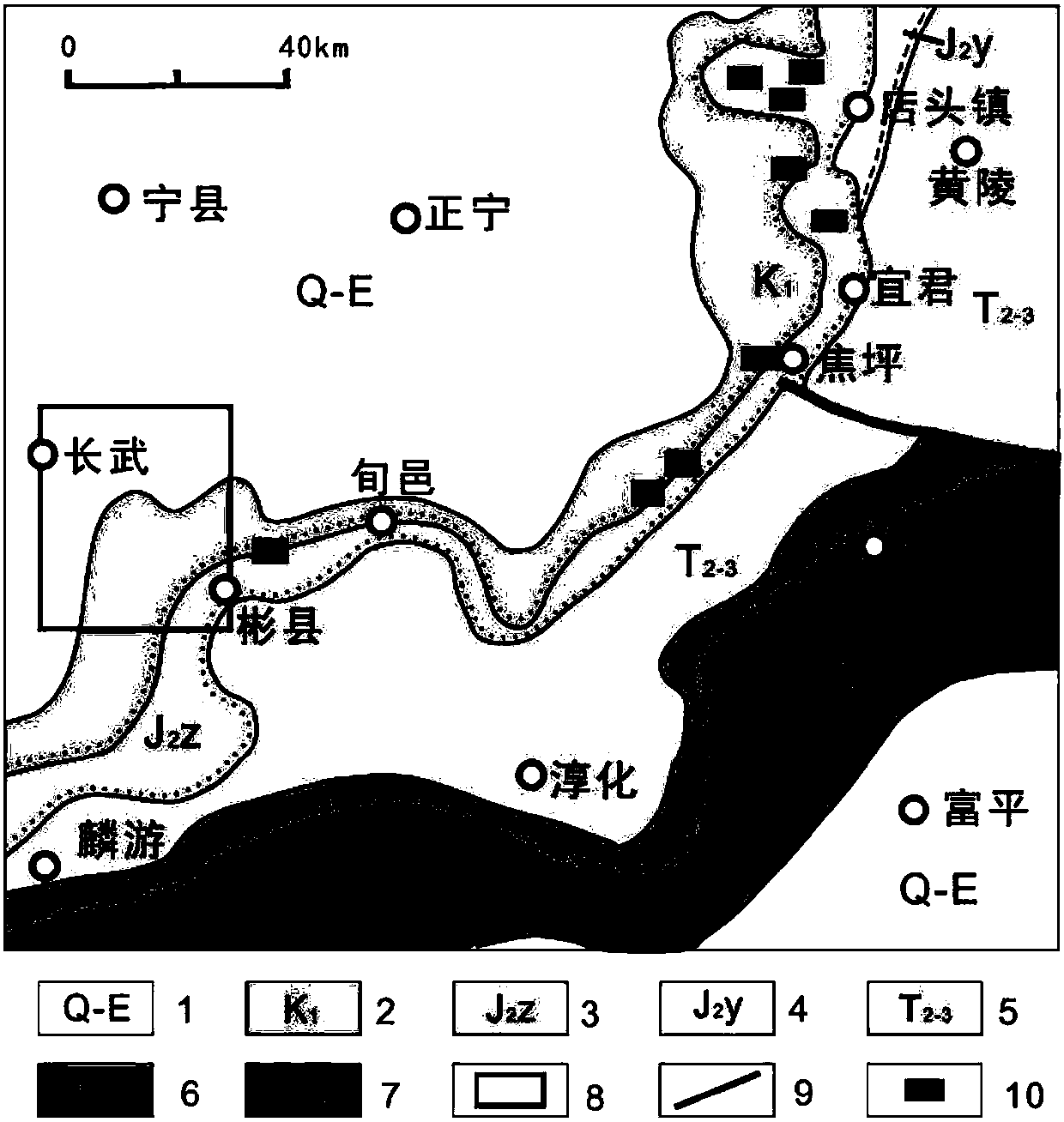

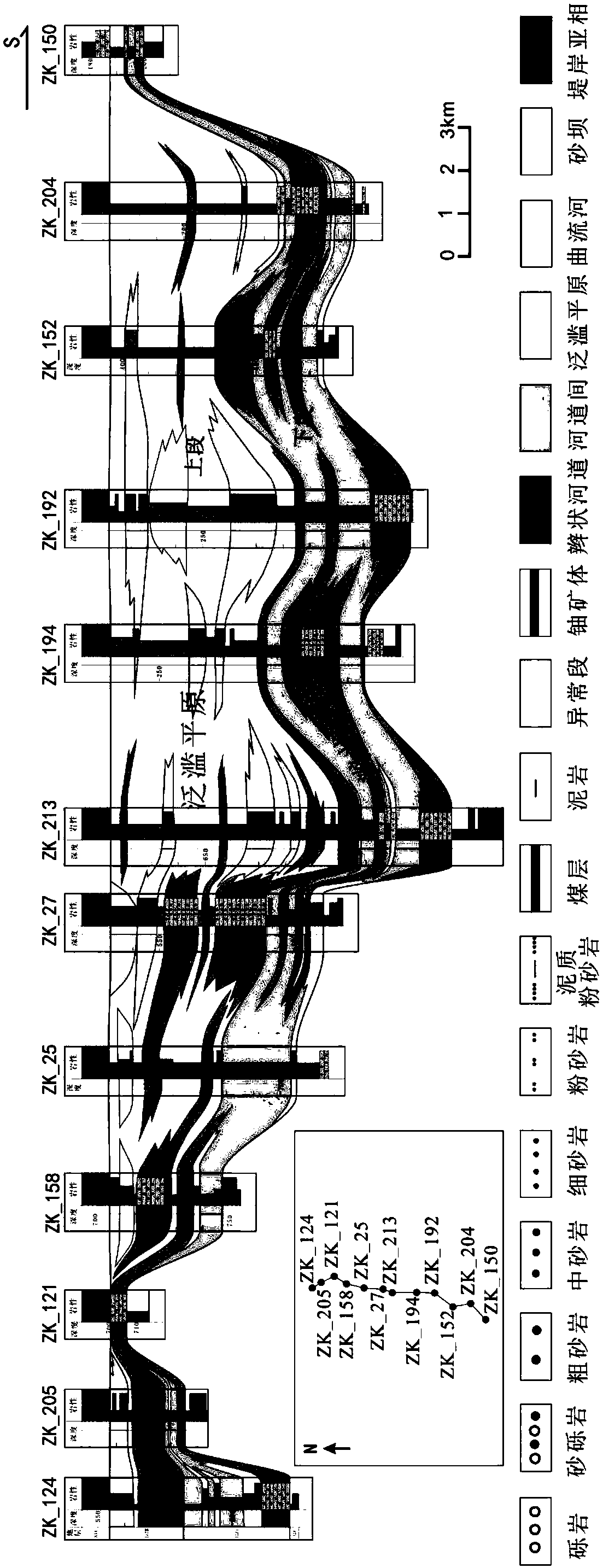

Sandstone uranium ore comprehensive evaluation technology method

The invention belongs to the technical field of uranium ore geological research, and particularly discloses a sandstone uranium ore comprehensive evaluation technology method. The method comprises thefollowing steps of 1, determining a uranium ore-forming favorable geological background and an ore-forming environment; 2, determining depositional subfacies or microfacies and spatial distribution of an ore-finding target layer; 3, identifying and locating a uranium ore-forming favorable sand body; 4, comprehensively extracting ore-forming favorable information; and 5, delineating an ore-formingfavorable region, and comprehensively evaluating ore-forming potential. According to the method, the steps are irreversibly carried out in sequence, and the uranium ore-forming potential of a regioncan be efficiently, quickly and objectively; uranium geological background and ore-forming environment analysis is a principal factor, wherein uranium source condition analysis is a top priority, andif the region does not have a uranium source condition, uranium ore does not exist no matter how good other conditions are; and by analyzing the ore-forming geological background and the ore-forming environment, favorable ore-forming geological conditions are determined.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

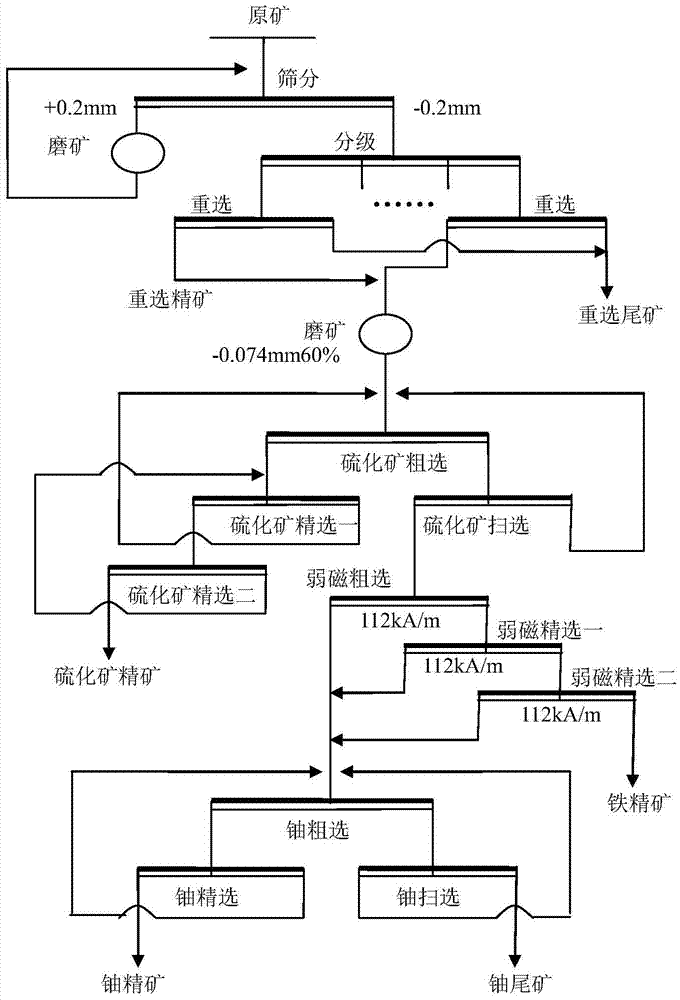

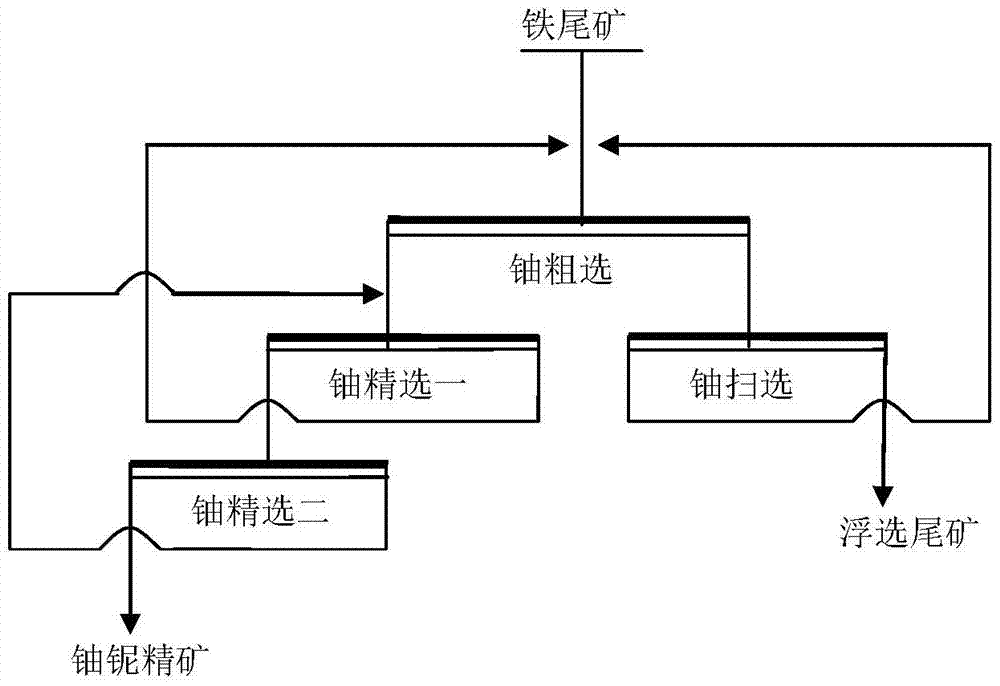

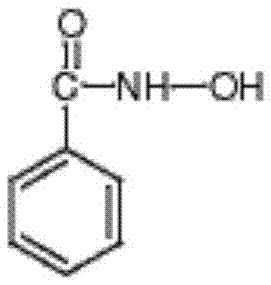

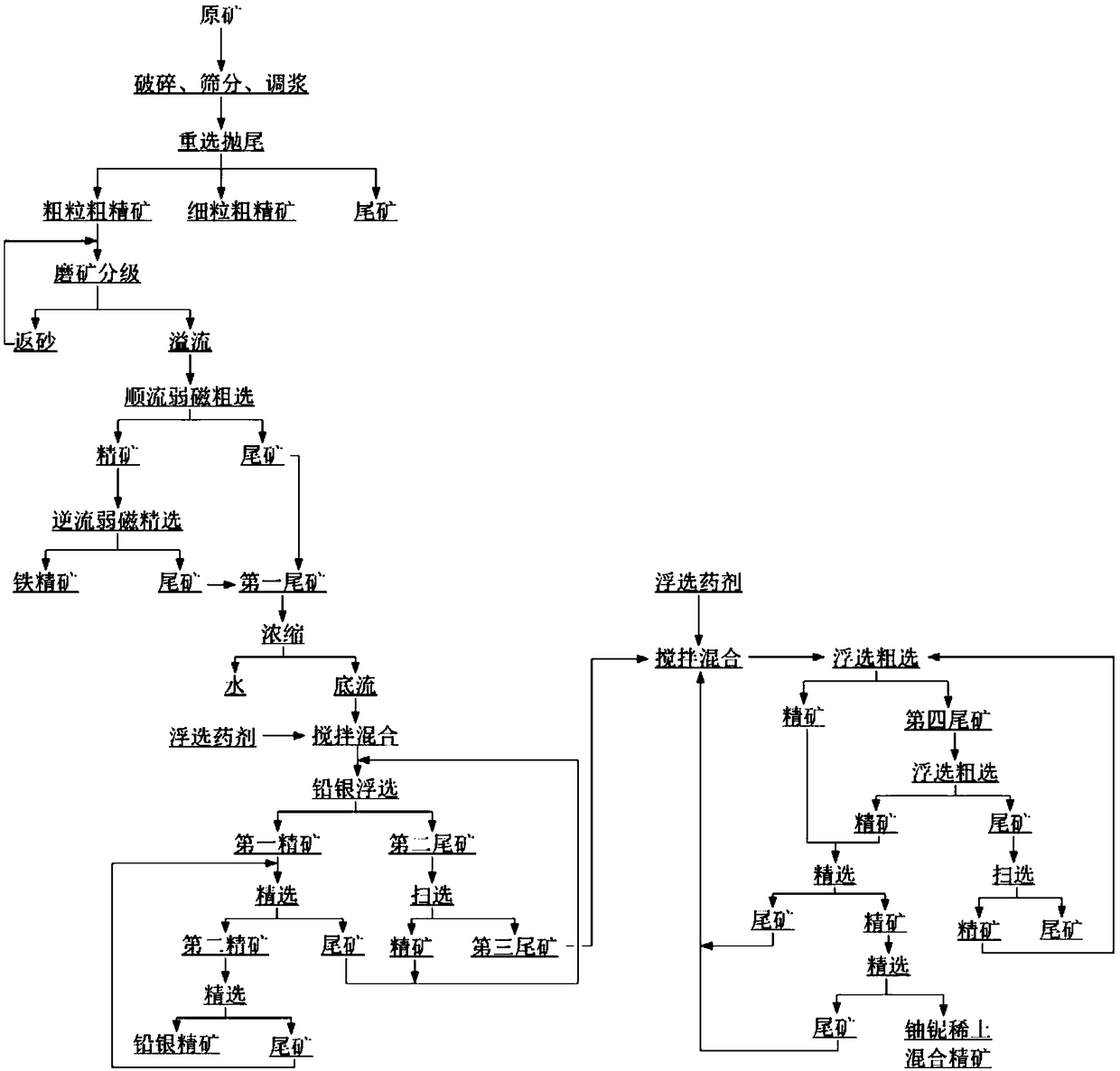

Beneficiation process of polymetallic ore containing betafite

This invention belongs to the technical field of beneficiation, is suitable for beneficiation of polymetallic ore containing betafite, and particularly relates to a beneficiation process of polymetallic ore containing betafite. According to the beneficiation process of the polymetallic ore containing the betafite, the low-grade polymetallic ore containing the betafite is economically developed and utilized, and the process relates to a combined technological process of gravity concentration, magnetic separation and flotation. Firstly, ore is subjected to gravity concentration after ore grinding and classification, after gravity concentrate is reground, sulfide ore is subjected to flotation and iron minerals are subjected to magnetic separation, and sulfide concentrate and iron concentrate can be obtained; secondly, uranium-rich ore pulp after iron removed is then subjected to flotation so that the betafite can be recycled, by adding a betafite efficient collecting agent, the direct flotation technology of the betafite is adopted, and the high-grade and high-recovery-rate uranium concentrate can be obtained; when the uranium concentrate is subjected to subsequent hydrometallurgy processing for uranium extraction, the handling capacity can be greatly reduced, the hydrometallurgy cost is substantially reduced, and the economic benefits are remarkably improved; and by means of beneficiation, the sulfide ore, the iron minerals and other associated useful components can be comprehensively recycled, and resources are fully utilized.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

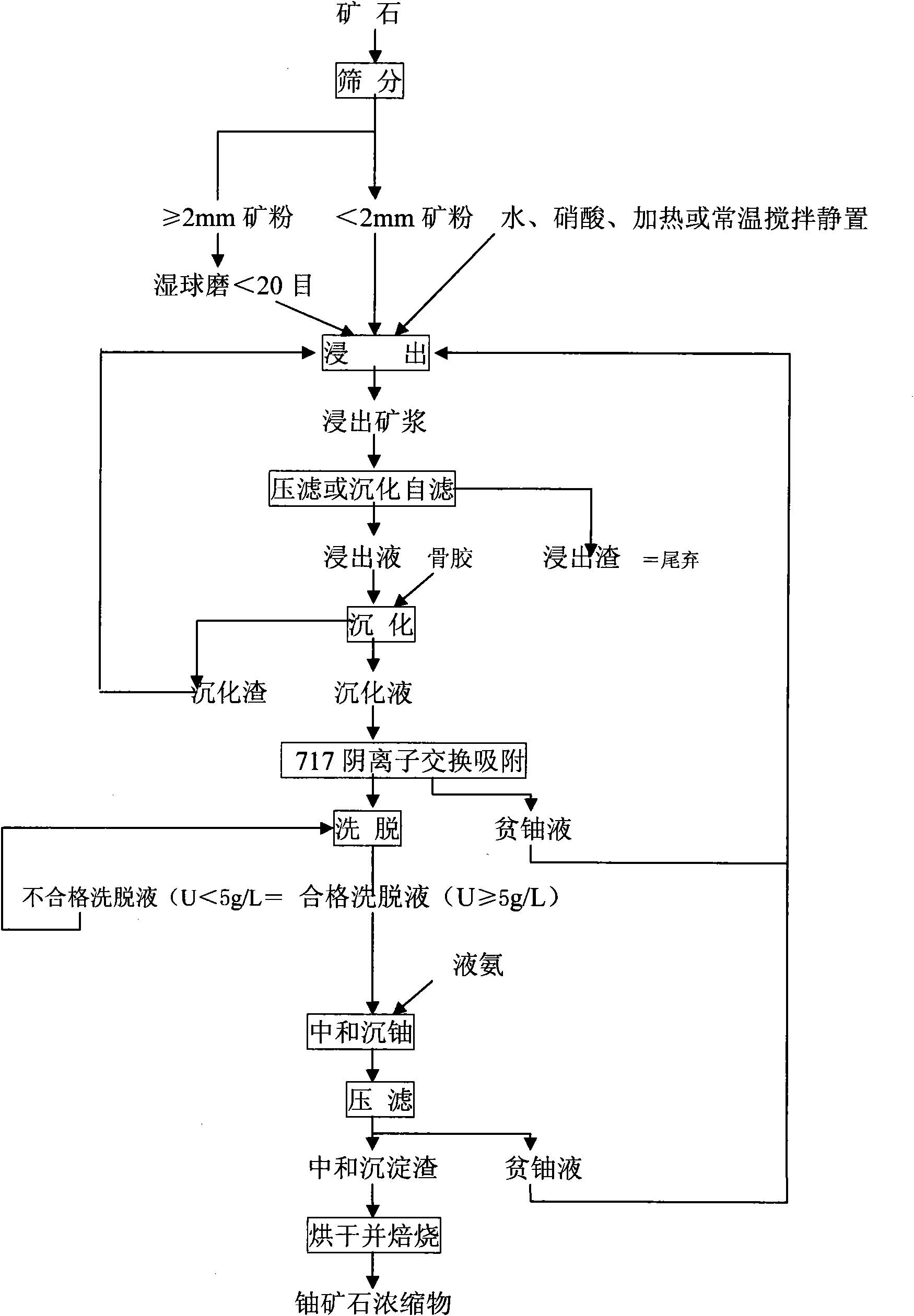

Method for recycling uranium from uranium extraction tailings

The invention discloses a method for recycling uranium from uranium extraction tailings, which comprises the following steps: crashing the tailings until the grain diameter is less than 2 mm, adding nitric acid to mix to enable the pH value of the ore pulp to reach 0.6-0.9, adding the nitric acid and water to control the volumes of the nitric acid and water to be 1.5-2 times of the mass of the tailings, heating to 65-70 DEG C, stirring and soaking for 1-1.5 hours, or after stirring and mixing uniformly at the normal temperature, soaking for 30 days, separating liquid and solid, washing the soak slag by the water until the pH value of the soaked slag is close to a neutral value (pH=5-7); adding bone glue into the nitric acid lixivium, placing and aging for 5-7 days to make supersaturated salt materials in the lixivium separate out, adjusting the pH value of the lixivium to 1.75 by using caustic soda, and then carrying out ion exchange absorption on the uranium using a 717 type anion exchange resin, eluting uranium ions by using 0.2 mol / L of nitric acid to 0.4 mol / L of ammonium nitrate solution as an eluent; and adjusting the pH value of the eluent to 7-8 to neutralize and precipitate the uranium to obtain uranium ore concentrates containing 65-75% of uranium. By adopting the method, the recycling rate of the uranium can reach over 90%.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

Gamma energy spectrum-based method for identifying clay shale reservoir and uranium ore occurrence on spot

ActiveCN102621588AQuick identificationQuick evaluationNuclear radiation detectionCounting rateUranium ore

The invention relates to a gamma energy spectrum-based method for identifying clay shale reservoir and uranium ore occurrence on the spot, which comprises the following steps that: rock debris in corresponding depth of drilling fluid is continuously sampled or a core acquired through the core drilling is sampled according to corresponding depths; the rock debris sample or the core sample is placed into a matched lead tank, and a gamma energy spectrum probe is used for measuring the rock debris sample or the core sample inside the lead tank; then counting rates and activity of uranium (U), radium (Ra), thorium (Th) and kalium (K) and a total gamma value are acquired according to the measurement result, so that the real content of U(Ra), Th and K in the rock can be calculated; and finally, a variation curve of the contents of U(Ra), Th and K is drawn according to the calculation results, and the clay shale reservoir and the uranium ore occurrence are identified according to variation characteristics of the curve. Gamma energy spectrum measurement and analysis on rock debris or the core which are acquired from the drilling are directly performed, so that the clay shale reservoir and the uranium ore occurrence can be rapidly identified and evaluated. The method is an economical and efficient method. The gamma energy spectrum measurement is performed on the drilling site, so that influence of an external environment on the rock sample can be avoided, and the accuracy of the measurement result can be guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desalination little-reagent ground-dipping uranium extraction method

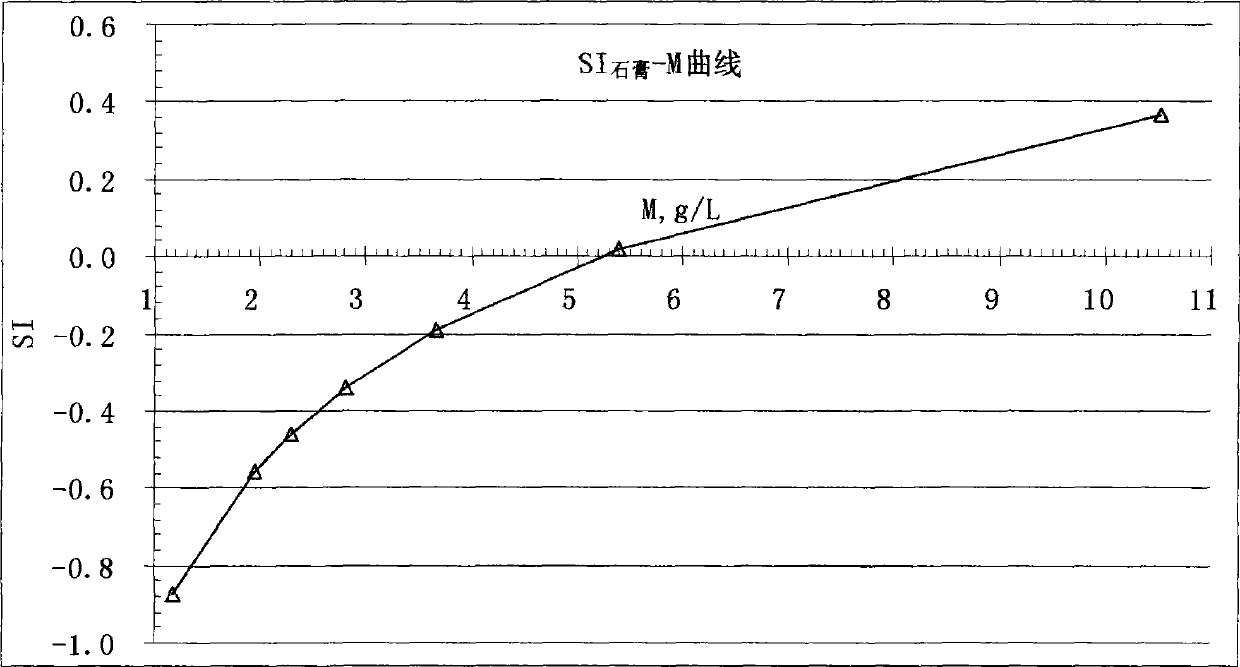

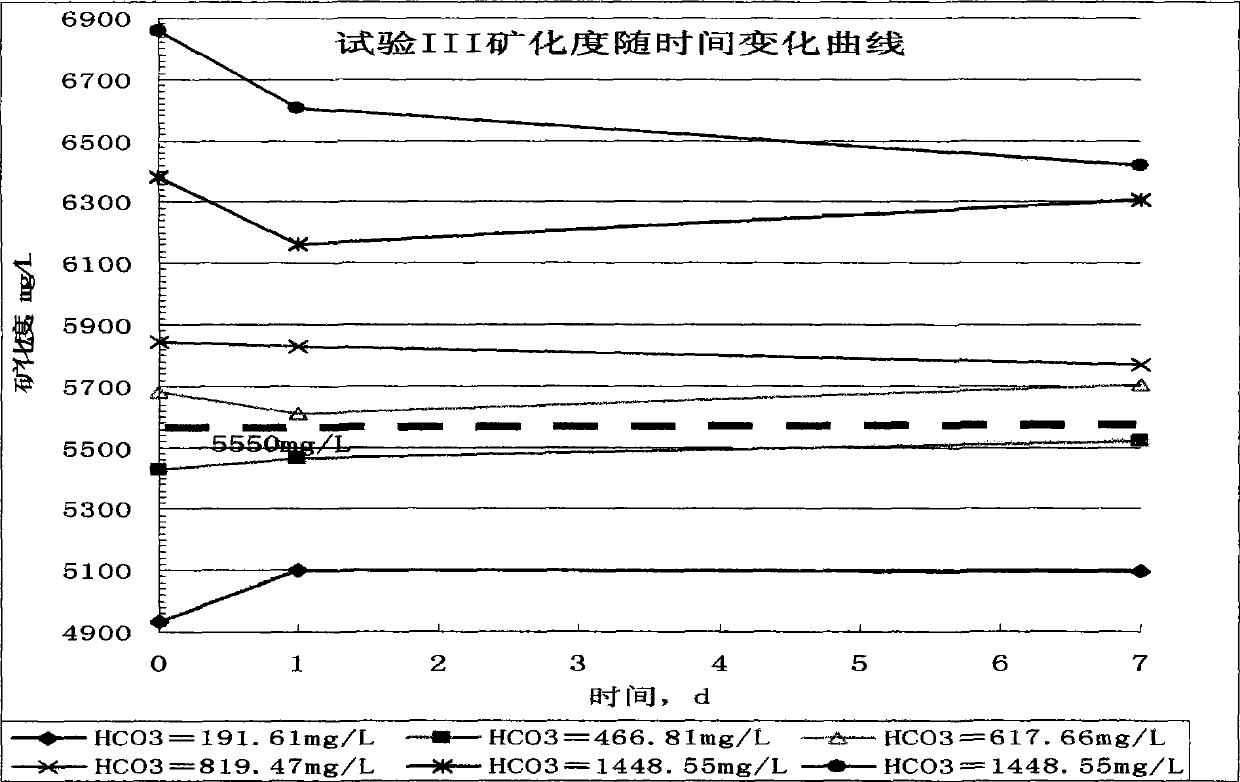

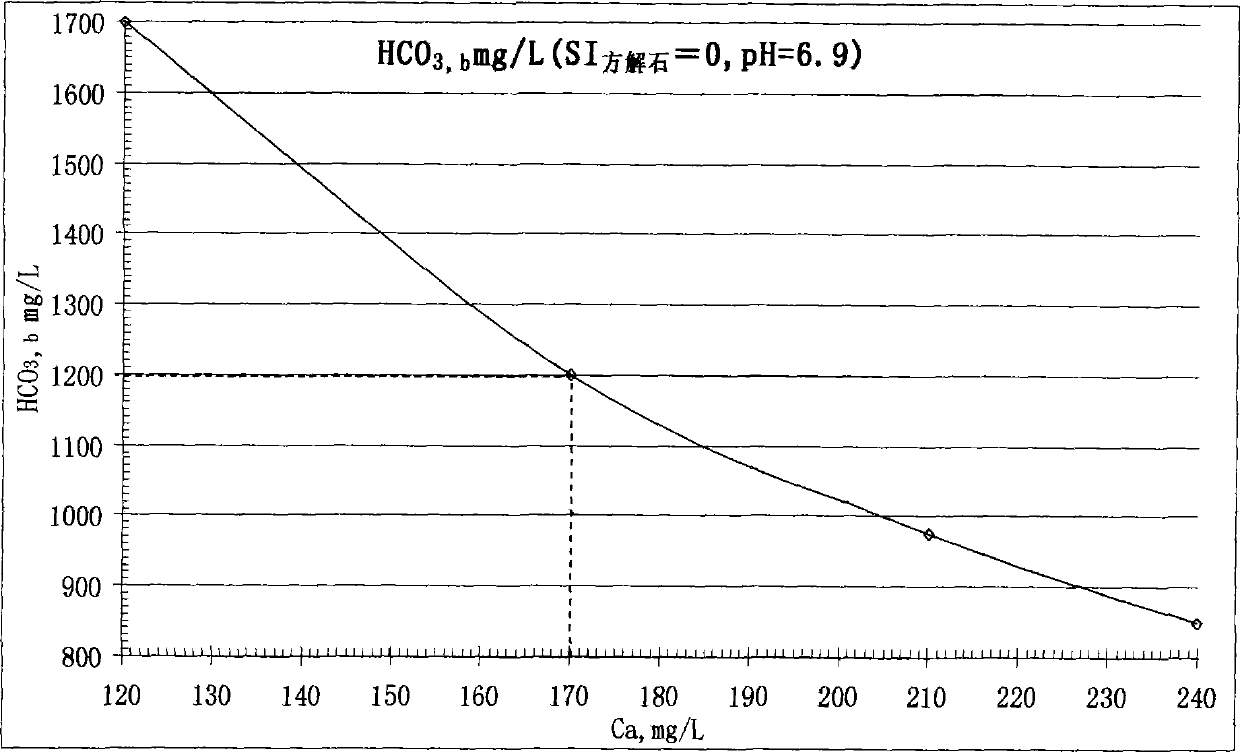

The invention relates to a method for extracting uranium by desalting and on-site leaching with less agent, in particular to a technique for extracting uranium from uranium ores with high degree of mineralization of underground water in an ore bed. The technique adopts a desalting plus less agent step, and the concrete steps of the technique include: 1. desalting underground water and reducing the degree of mineralization of the underground water; and 2 extracting uranium by a leaching agent containing a latent solvent HCO3<->, oxygen and a pH adjustment agent. The invention solves problems of blockage caused by calcium sulphate and calcium carbonate in area with underground water of high degree of mineralization during on-site leaching, ensures smooth uranium extraction by on-site leaching and improves the uranium leaching efficiency.

Owner:EAST CHINA UNIV OF TECH

Preparation method of biomass charcoal-based magnetic activated sludge and application of biomass charcoal-based magnetic activated sludge to uranium-bearing wastewater treatment

ActiveCN105597698AAchieve recyclingImplement resourcesOther chemical processesAlkali metal oxides/hydroxidesPorosityActivated sludge

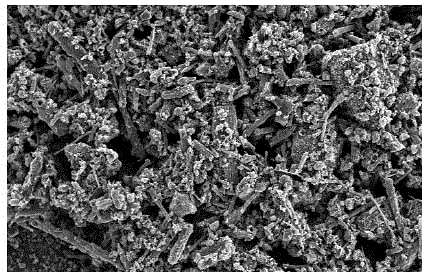

The invention relates to a preparation method of biomass charcoal-based magnetic activated sludge and application of the biomass charcoal-based magnetic activated sludge to uranium-bearing wastewater treatment. The preparation method of the biomass charcoal-based magnetic activated sludge and application of the biomass charcoal-based magnetic activated sludge to uranium-bearing wastewater treatment have the advantages that the biomass charcoal-based magnetic activated sludge high in porosity, large in specific surface area, few in macroscopic defects and stable in structure is mainly prepared from cheap natural resource biomass, waste beer yeast mycelia, activated sludge of sewage treatment plants and starch and is applied to remove uranium from low-concentration uranium-bearing wastewater; the biomass charcoal-based magnetic activated sludge is free from toxicity and pollution to the environment, so that natural resource recycling is achieved; the preparation method is simple and mild in reaction condition, and the biomass charcoal-based magnetic activated sludge can enable the concentration of the uranium of the low-concentration uranium-bearing wastewater to be decreased from 0.45-0.50mg / L to be below the national discharge standard of 0.05mg / L, thereby being suitable for environmental modification of various low-concentration uranium-polluted water bodies such as the uranium-bearing wastewater produced by uranium mines and uranium hydrometallurgy plants as well as uranium ore and uranium tailing pond lixivia.

Owner:NANHUA UNIV

Uranium mine exploration residual facility management and vegetation recovery method in high-cold high-altitude regions

ActiveCN101725353AGuarantee early stabilityUnderground miningSurface miningRecovery methodRevegetation

The invention discloses a uranium mine exploration residual facility management and vegetation recovery method in high-cold high-altitude regions. The method comprises the following steps: 1) covering the land needing to be managed by soil; determining the thickness of a covering layer according to radon exhalation rate and penetrating radiation dose rate; and then covering the land needing to be managed; 2) carrying out slope protection and insulation on the covered managing land; 3) planting indigenous plants which do not adsorb radioactive nuclide on the covering layer, comprising locally collected wild weed seeds, plateau Tamarix chinensis and at least two of annual ryegrass, Elymus sibiricus cv. Chuancao No.1, dahusian wildrye, Poa pratensis, chewings fescue and white clover. The invention not only can meet the radiation protective requirements of inhibiting the radon exhalation rate and shielding the penetrating radiation dose rate, but also can ensure earlier stage stability of the covering layer and continue survival optimum succession of vegetation, thus ensuring that the management of the waste (ore) piles and the exploratory trenches in high altitude regions can achieve long-term stability and optimum ecological environment efficiency and economical efficiency.

Owner:四川省核工业地质局分析测试中心

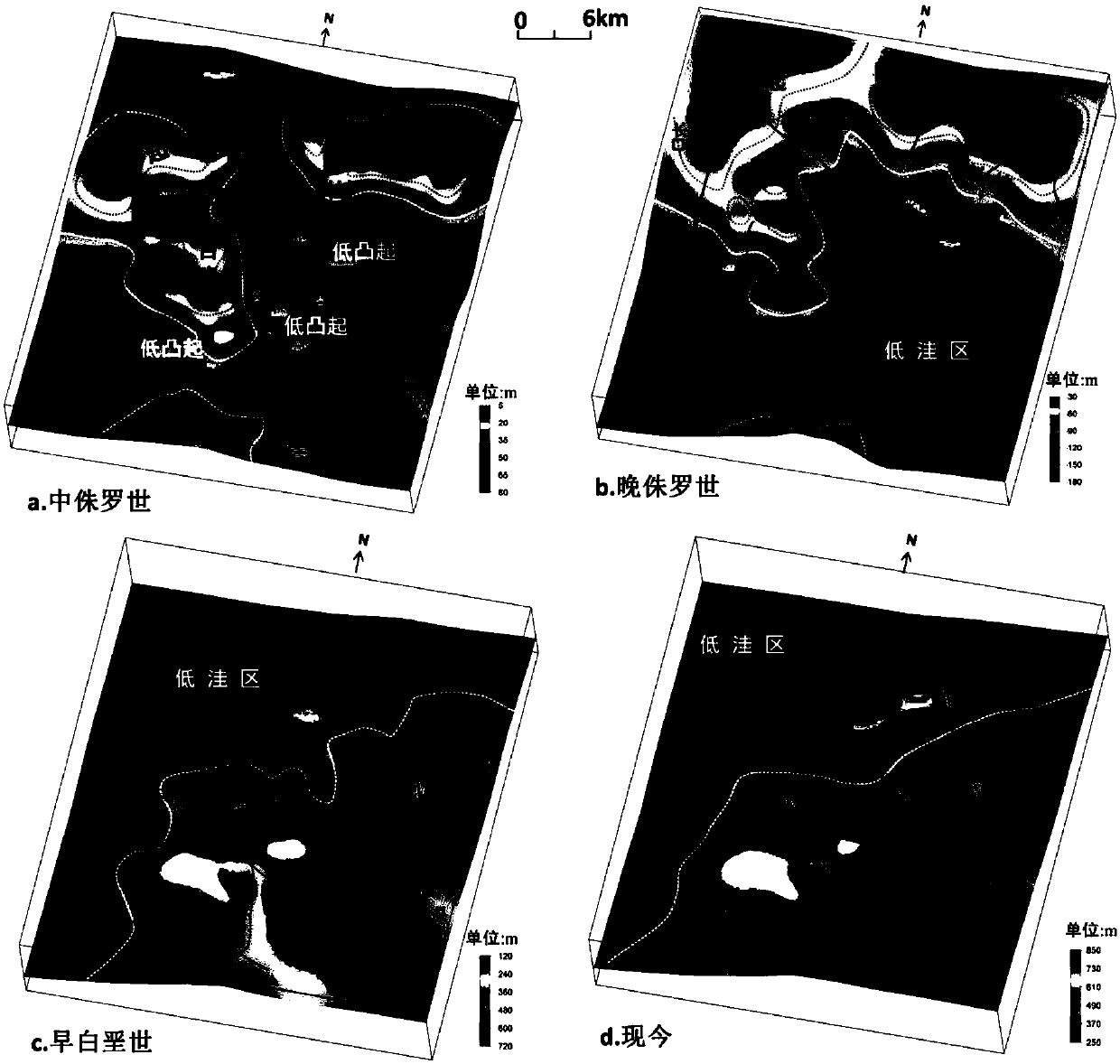

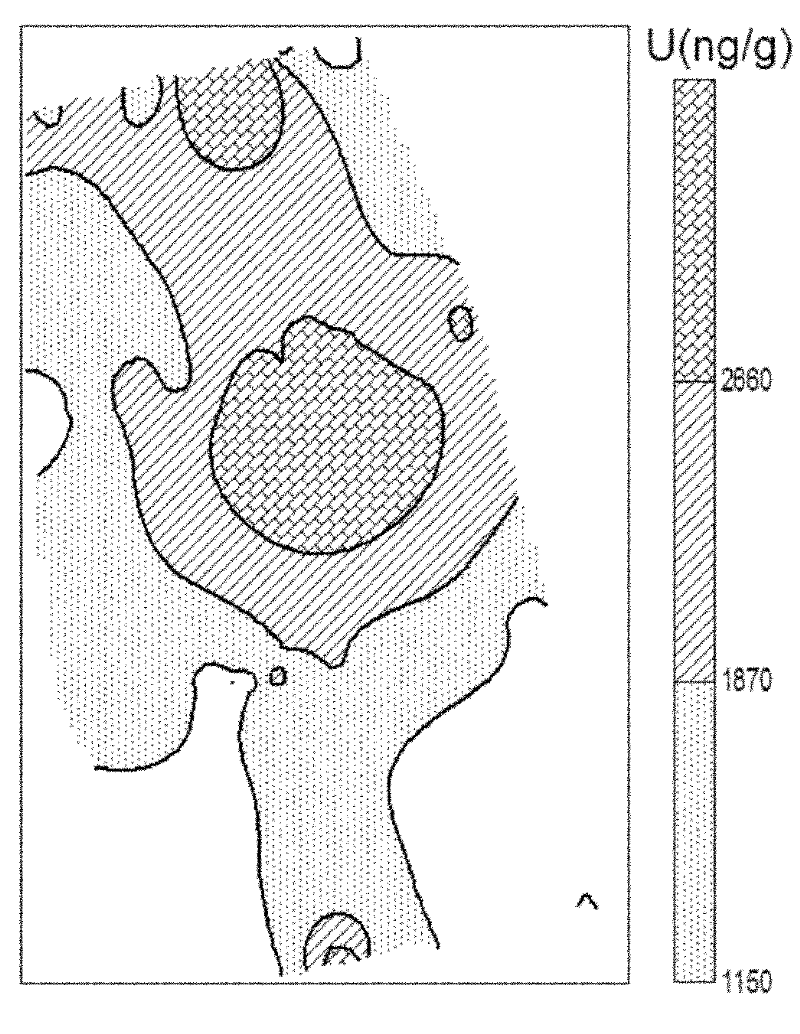

Prediction method of favorable sand body and favorable zone of sandstone type uranium ore

ActiveCN107664772ARevealing the evolution of time and spaceClear featuresSeismic signal processingUranium oreLandform

The invention, which belongs to the technical field of uranium ore geological research, specifically discloses a prediction method of a favorable sand body and a favorable zone of sandstone type uranium ore. The method comprises the following steps: step 1, carrying out ancient landform restoration; step 2, carrying out ancient landform division; and step 3, predicting a favorable sand body and afavorable zone of uranium ore. With the method provided by the invention, the favorable zone of the sandstone type uranium ore is determined by restoring an ancient landform of the ore target stratumdepositional stage and the uranium ore formation key period.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

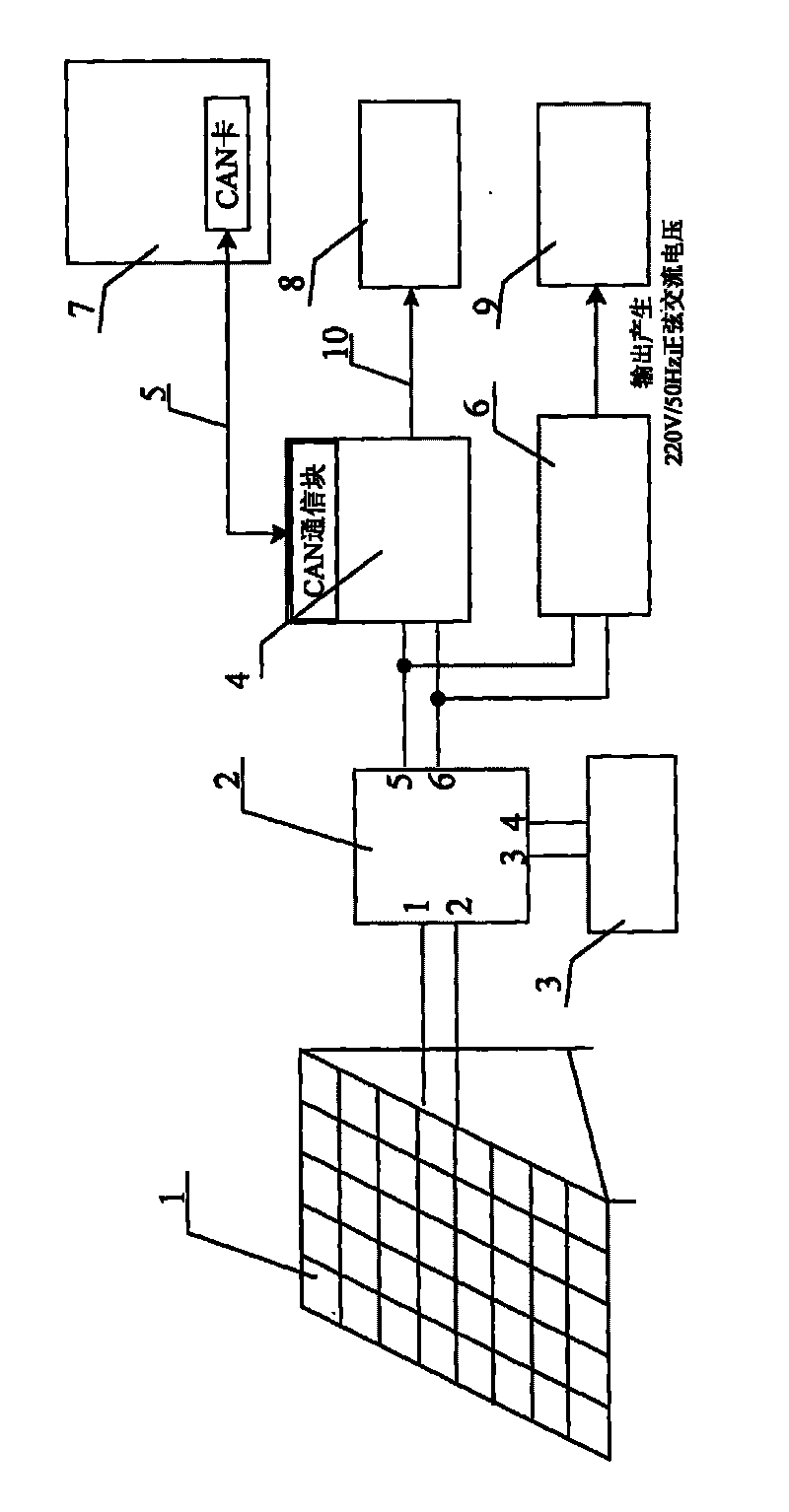

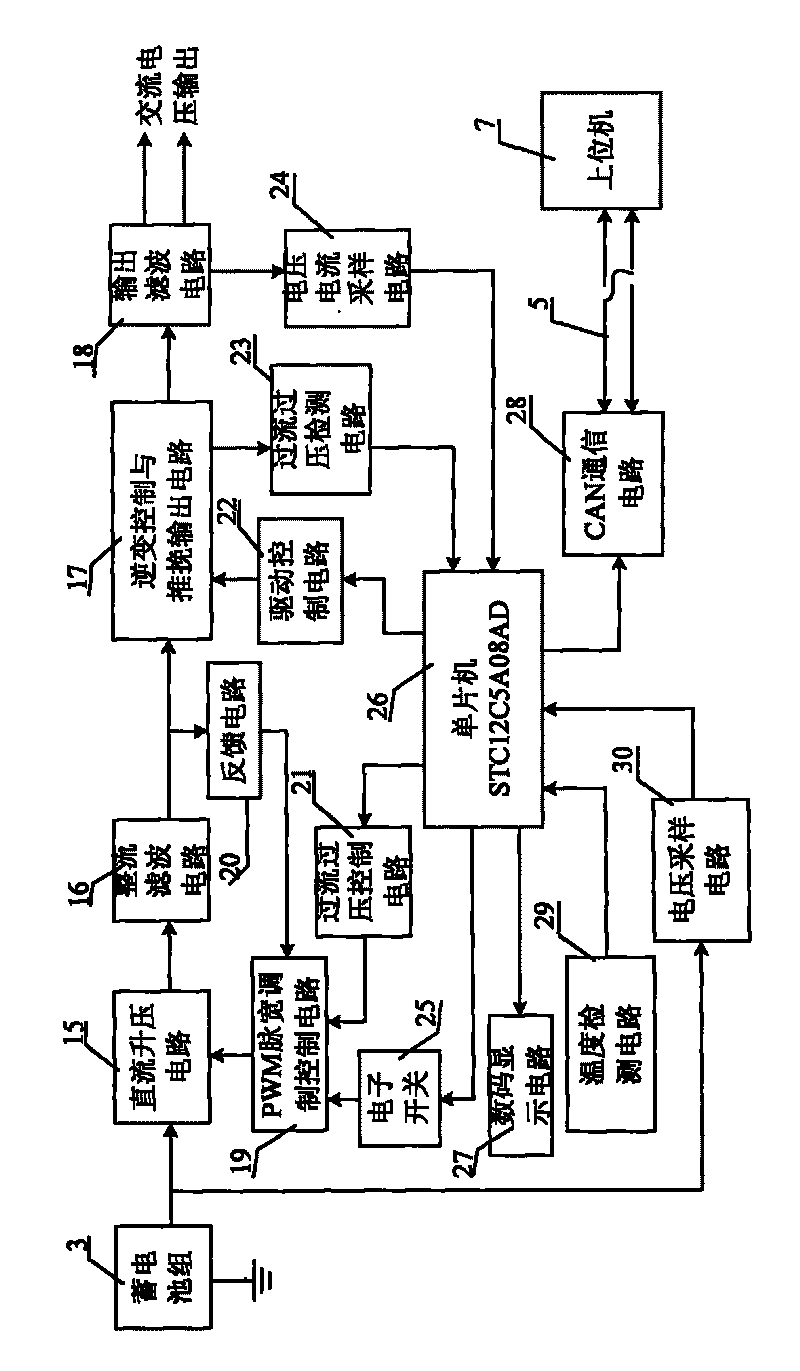

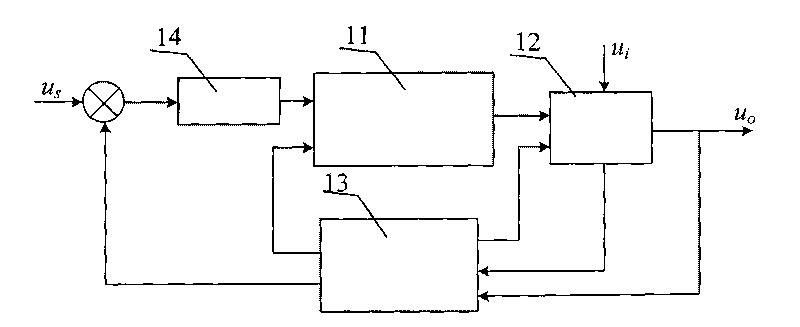

Intelligent power supply control device for uranium ore resource exploration

InactiveCN101702526ARealize intelligenceNetworkingBatteries circuit arrangementsAc-dc conversionHigh pressureSolar battery

The invention belongs to the technical field of power and electronics control, and relates to a power supply device in the direct current electric exploration technology applied to the field of uranium ore resources and environment exploration. The power supply device comprises an accumulator, a solar battery component, an inversion controller and the like, wherein the inversion controller uses an STC single chip as a core and converts the electrical energy of the accumulator into alternating current staircase voltage to be output and supplied to the high-voltage electrode on a mind field, the frequency of the output voltage can be switched and changed in five levels, and the single side value of the output voltage can be switched and regulated in ten levels. The invention uses the solar photovoltaic generating technology to provide power supply, uses the single chip and a CAN communication module to realize the intellectualization and networking of the power supply control device, uses the inversion technology and the frequency conversion technology, uses the PID algorithm, carries out remote switching through an upper computer and a CAN bus network, has multi-frequency and multi-voltage optional output, has the characteristics of safety, high speed, high efficiency, stability and reliability, and provides much convenience for the workers conducting electric exploration of field uranium ore resources and other mineral resources.

Owner:EAST CHINA UNIV OF TECH

Hydrothermal type uranium ore deep detection method

InactiveCN108279444ARealize indirect prospectingImprove accuracyGeological measurementsContinuous measurementMeasuring instrument

The invention belongs to the technical field of ore deposit exploration, and particularly relates to a hydrothermal type uranium ore deep detection method. The method comprises the following steps: according to the ore-forming rule of a hydrothermal type uranium ore, determining the ore-forming perspective area; carrying out electromagnetic sounding through an audio earth electromagnetic instrument in a tensor or scalar measurement mode; carrying out total magnetic field intensity measurement and gradient measurement in the section continuous measurement working mode by means of a high-precision magnetometer; carrying out radon measurement in the air-exhaust measuring mode by means of a radon measuring instrument; according to above measurement results, obtaining the ore-forming environment information and the direct ore-forming information in combination with known geological data; and predicting the beneficial part of the uranium ore-forming process. According to the invention, the geological structure information of the uranium ore forming environment can be obtained, and the indirect ore exploration can be realized. Meanwhile, the direct information of the uranium ore forming can be obtained, and the direct ore exploration can be achieved. Compared with a traditional radioactivity measurement and ore exploration method, the accuracy and the efficiency of ore exploration areremarkably improved. Especially, the method has a good ore exploration effect for deep ore exploration.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore

The invention provides a comprehensive recovery and beneficiation method for low-grade uranium-containing polymetallic ore. The comprehensive recovery and beneficiation method comprises the followingsteps that (1) overflow products obtained by grinding the uranium-containing polymetallic ore are subjected to direct flow magnetic separation roughing operation and reverse flow magnetic separation concentration operation in sequence, and iron concentrate and first tailings are obtained; (2) the tailings are subjected to condensation and flotation to obtain first concentrate and second tailings,the first concentrate is subjected to concentration to obtain lead silver concentrate, and the second tailings are subjected to scavenging to obtain third tailings; and (3) the third tailings are subjected to flotation roughing and condensation, and then uranium, niobium and rare earth mixed concentrate is obtained. The beneficiation index is good, the purpose of fully recovering all useful components in coarse-grain coarse concentrate subjected to tailing discarding through gravity concentration under the coarse grinding condition is achieved, an efficient beneficiation separation and enrichment technology is provided for large-scale development and utilization of the low-grade complex polymetallic hard rock uranium ore in China, and the subsequent cost of extracting uranium, niobium andrare earth in the uranium ore through hydrometallurgy is greatly lowered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Method for in-situ leaching of uranium by low concentration sulfuric acid and oxygen

ActiveCN104726725ANo chemical cloggingNo obvious chemical blockageChemical compositionGroundwater chemistry

The invention relates to a method for in-situ leaching of uranium by low concentration sulfuric acid and oxygen. In-situ leaching of metal uranium from ore beds relates to a process of recovering uranium from uranium ore deposits with non-uniformly distributed carbonate content. The method includes groundwater chemical composition analysis, oxygen injection and oxidation of ore bed, preparation of leaching solution, leaching of metal uranium by leaching solution, leaching maintaining, resin adsorption and other steps. The method can be applied to uranium ore deposits with non-uniformly distributed carbonate content to effectively control chemical clogging and improve the leaching efficiency of in-situ uranium mining. Compared with conventional acidic in-situ leaching of uranium, the method alleviates pollution to mining area groundwater environment. Effects of the leaching process by low concentration sulfuric acid and oxygen show that the method is an effective process for in-situ leaching of uranium.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

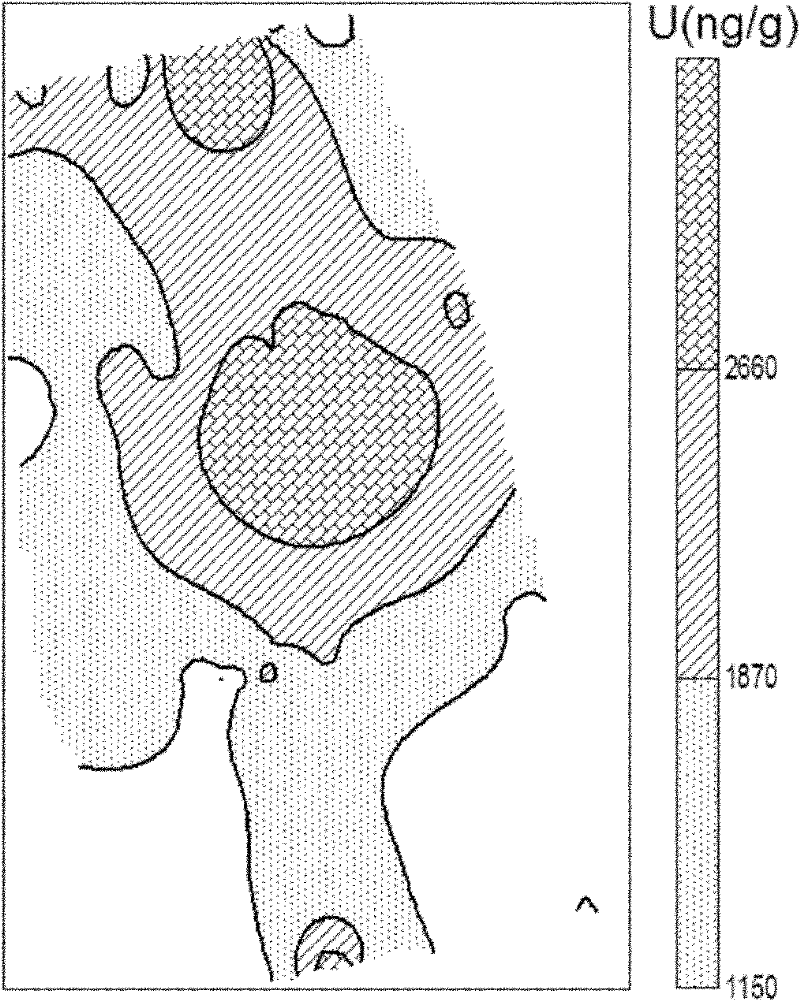

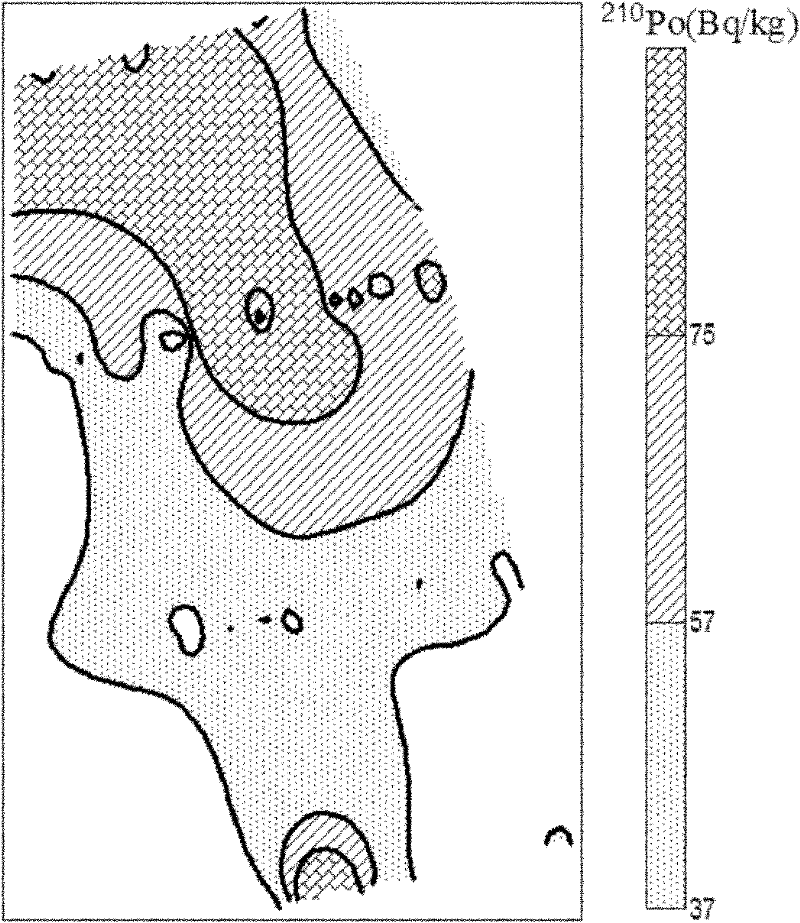

Method for combined tracing exploration on hydrothermal uranium ore through geochemical elements

ActiveCN102478674ASimple methodLow costMaterial analysis using wave/particle radiationPreparing sample for investigationUranium oreComputer science

The invention belongs to a uranium ore exploration method and particularly discloses a method for combined tracing exploration on a hydrothermal uranium ore through geochemical elements. The method comprises the following steps of: measuring a uranium component in soil in an exploration area; measuring 210Po; drawing a plane isoline graph of the uranium component and the 210Po element; judging whether an ore-induced uranium component is abnormal or not according to the ratio between the uranium component and uranium total amount; if the ore-induced uranium component is abnormal, further judging (1) whether the uranium component has an abnormal concentration center or not according to a uranium component isoline graph, judging (2) whether the uranium component and the 210Po are abnormally combined or not according to a 210Po isoline graph, and judging (3) whether a uranium component abnormal area and a beneficial ore-forming fracture structure alteration zone correspondingly compound asection; and if at least two results of the steps (1) to (3) are positive, judging that the hydrothermal uranium ore exists. The hydrothermal uranium ore of which the covering layer is 10 meters to several hundred meters can be detected by extracting and measuring the uranium component and the 210Po in a surface soil sample.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

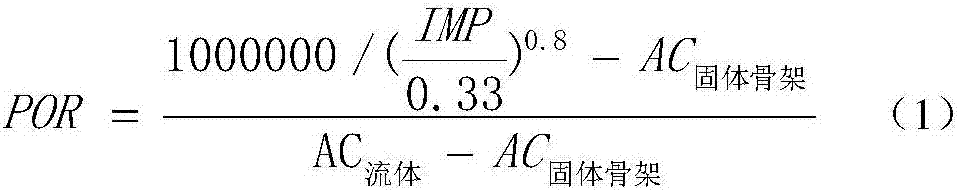

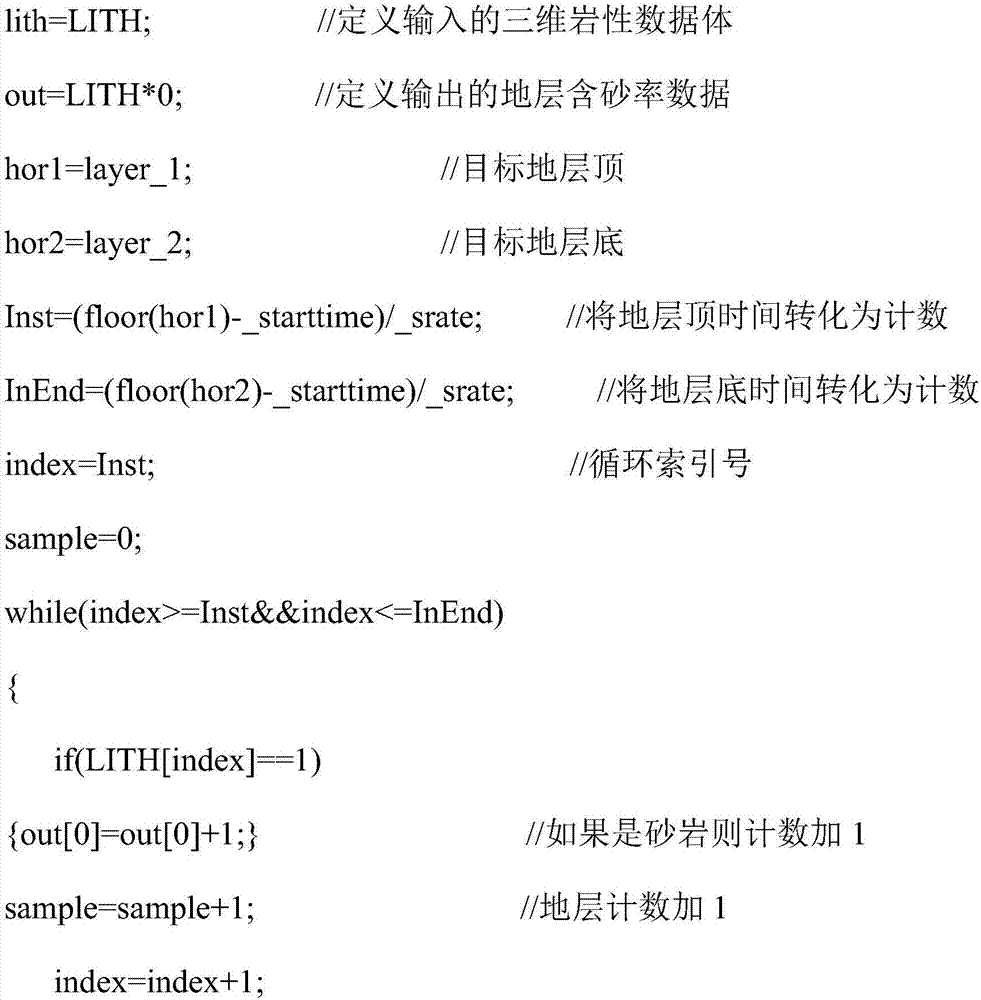

Method for comprehensively predicting earthquake in sandstone uranium ore

The invention belongs to the technical field of comprehensive prediction methods of earthquake in uranium ore, in particular to a method for comprehensively predicting earthquake in sandstone uraniumore. A seismic wave impedance inversion method is used to reversely calculate distribution of sand to obtain sand content information of a target formation directly related to uranium ore formation; wave impedance information of the target formation is converted into porosity information related to ore forming action via the conversion relation or experiential conversion relation of drilling datastatistics; a three-dimensional seismic data body is finally used to extract sensitive seismic attribute information related to a uranium ore forming environment; by comprehensively analyzing and studying and predicating the uranium ore forming potential of a work area via the three types of information, it is possible to quickly and effectively predict the development range of a sandstone uraniumore target reservoir.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

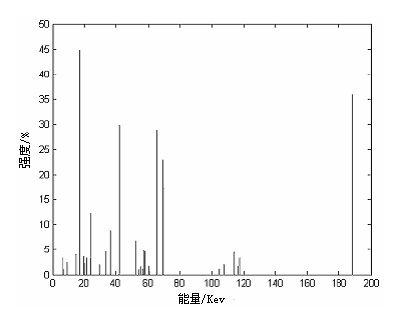

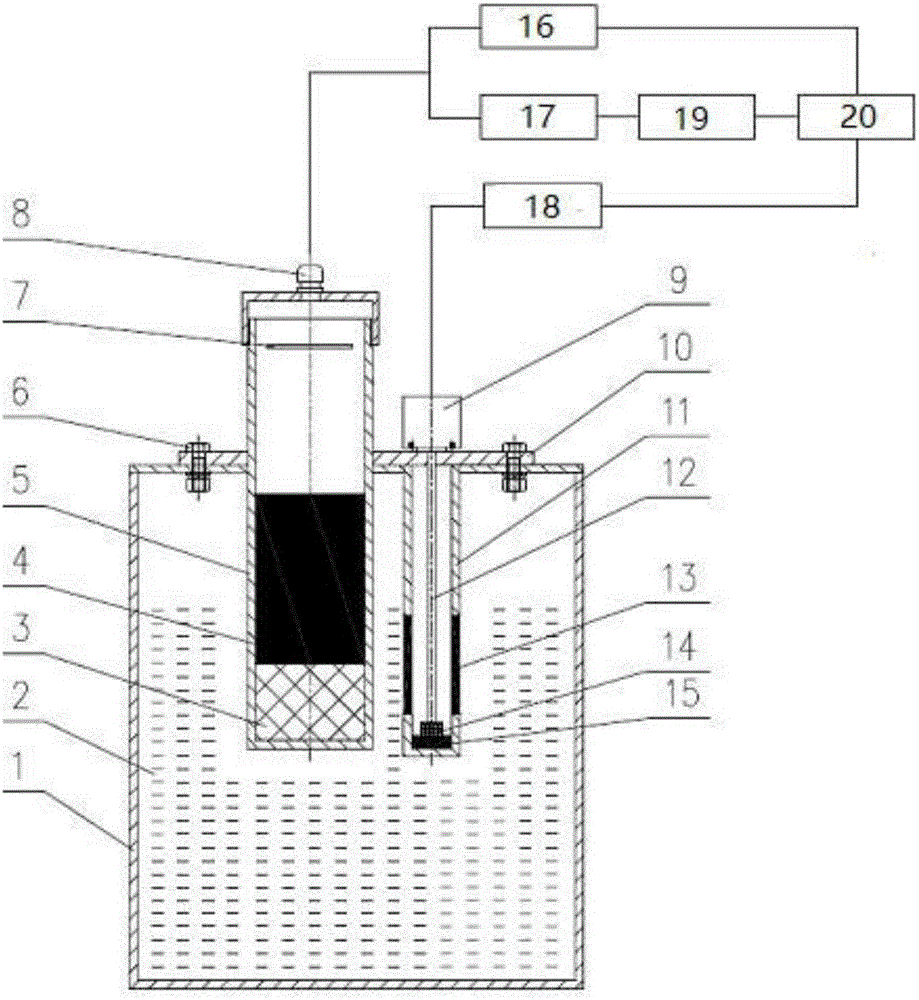

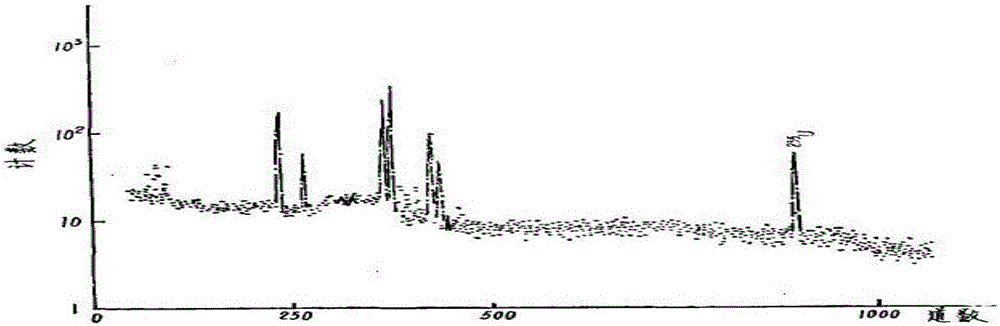

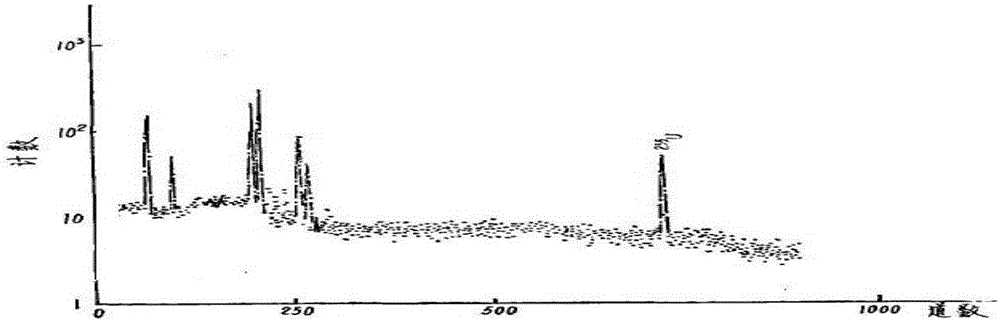

Device for online measurement of uranium concentration of leach slurry of uranium ore, and application method

ActiveCN106569250ALittle influence on measurement resultsWith anti-scaling functionX-ray spectral distribution measurementNegative feedbackUranium ore

The invention belongs to the technical field of online analysis and measurement of the uranium concentration of leach slurry of a uranium ore hydrometallurgical mill, and specifically relates to a device for the online measurement of the uranium concentration of leach slurry of a uranium ore, and an application method. The device determines the area of a uranium peak through dynamically capturing the position of the gamma peak 185.7keV of 235U in a spectrum and determining an ROI value, solves a problem of impacts on a measurement result from temperature changes, high-voltage source changes, the gain changes of a photomultiplier and the drift of an electronic circuit, and improves the measurement stability and reliability of an instrument. The device does not employ a complex negative feedback temperature compensation method, and employs a computer to track the gamma feature peak of 235U, and determines the measurement position. Figure 2 and Figure 3 describe the change conditions of the gamma feature peak of 235U along with the temperature. Only if the gamma feature peak of 235U is determined, can the uranium concentration be accurately determined.

Owner:北京博瑞赛科技有限责任公司

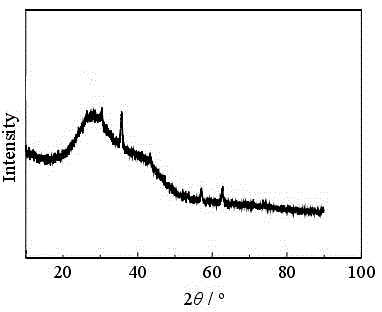

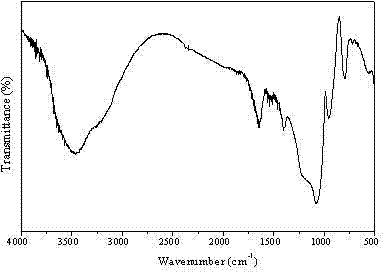

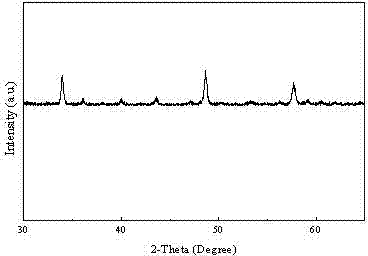

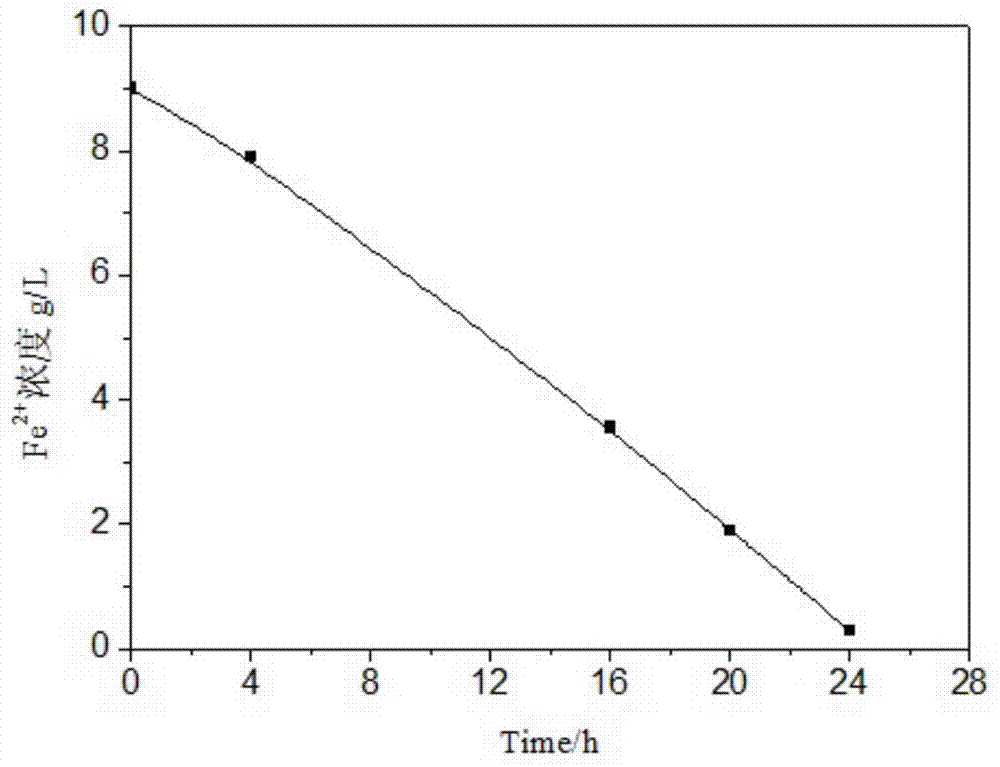

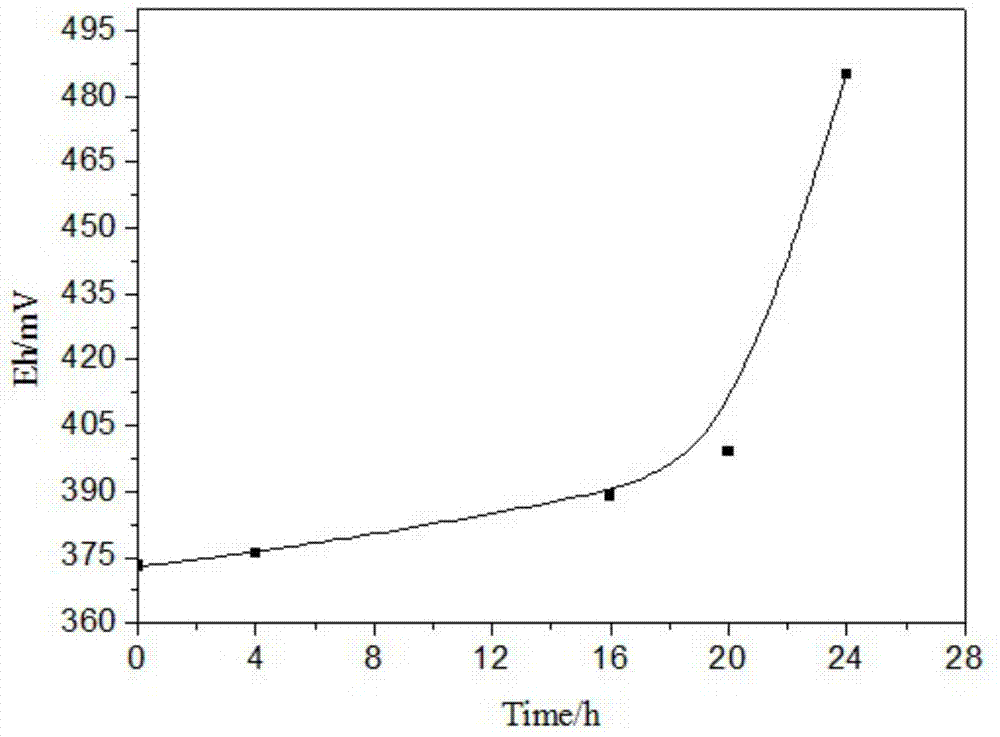

Preparation method of magnetic nano Fe3O4 particles by biological catalysis and application of particles to treatment of uranium-containing wastewater

InactiveCN103877927AImprove adsorption capacityThe synthesis process is simpleOther chemical processesAlkali metal oxides/hydroxidesThiobacillus ferrooxidansIron(II) oxide

The invention provides an ecological and environment-friendly new method for preparing magnetic nano Fe3O4 particles by biological catalysis, and application of the particles to treatment of uranium-containing wastewater. The method comprises the following concrete steps: (1) culturing and domesticating thiobacillus ferrooxidans; (2) preparing bio-polymeric ferric sulfate; (3) synthesizing the magnetic nano Fe3O4 particles; (4) performing a test of adsorbing uranium in the uranium-containing wastewater by the magnetic nano Fe3O4 particles. The obtained magnetic nano Fe3O4 particles are simple in preparation synthesis route, mild in reaction condition and easy to operate; a biological catalysis oxidant is used for replacing a conventional chemical oxidant (nitrite), so that cancerogenic substances are prevented from being discharged to the environment and the environment-friendly effect is really achieved. Meanwhile, the obtained magnetic nano Fe3O4 particles can reduce the content of uranium in the low-concentration uranium-containing wastewater with the concentration of 0.45-0.50mg / L by more than 90% and have very important practical meaning in aspects of uranium-containing wastewater treatment, uranium recovery and the like in uranium mining and metallurgy.

Owner:NANHUA UNIV

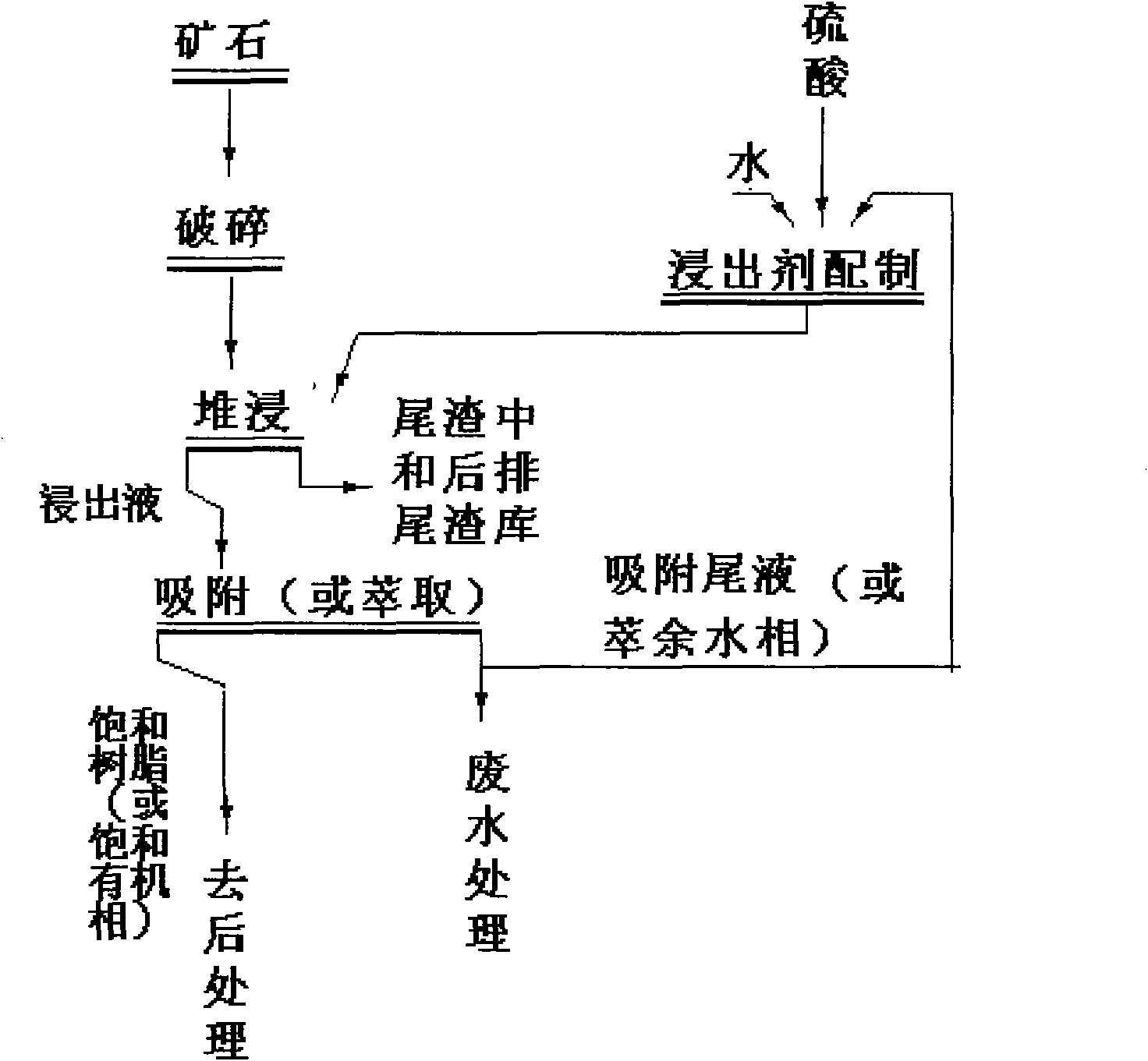

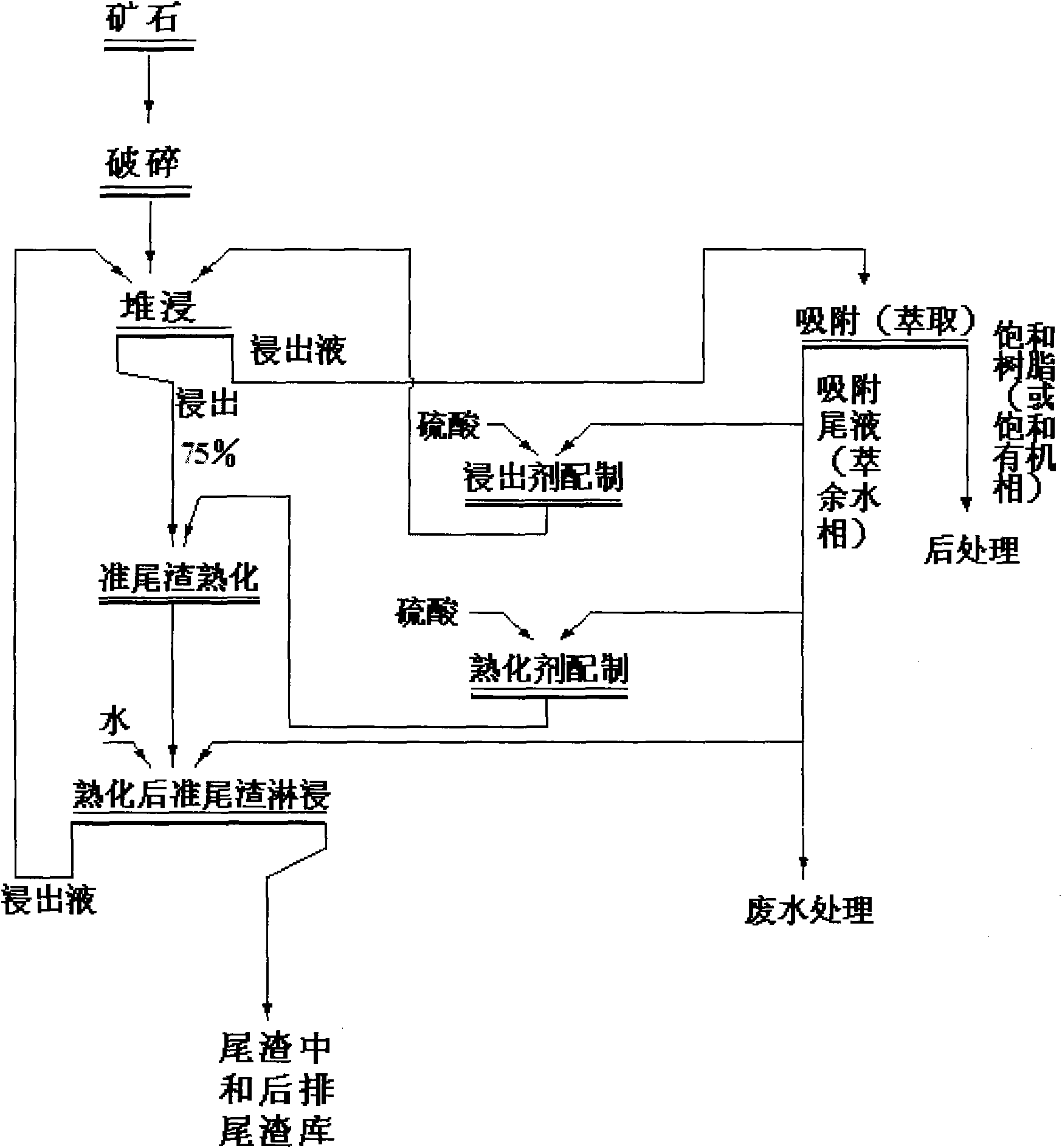

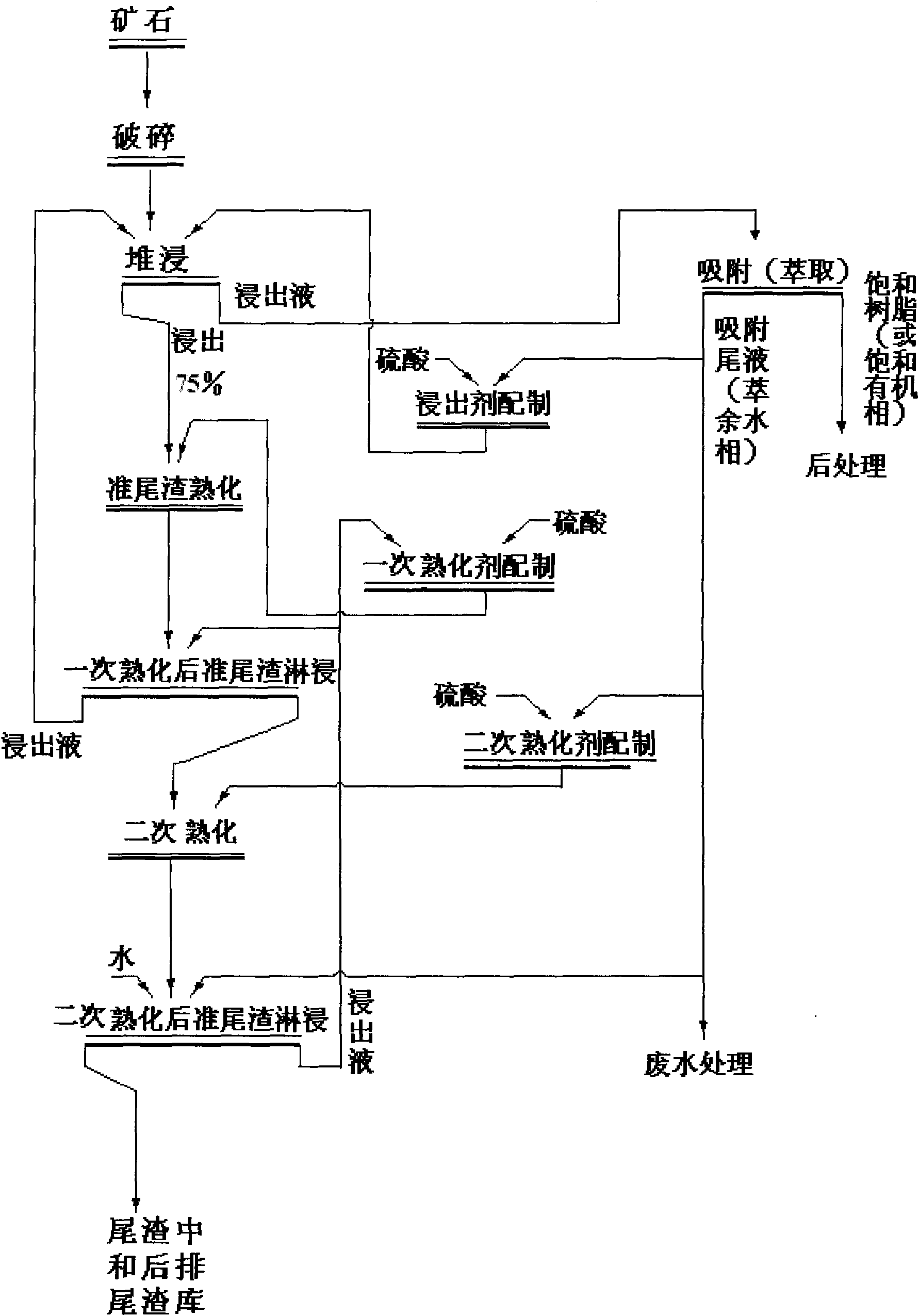

Intensified uranium ore heap leaching method

ActiveCN101560613AShorten the leaching timeDowngradeProcess efficiency improvementPregnant leach solutionUranium ore

The invention provides an intensified uranium ore heap leaching method, which comprises the following steps: (1) uranium ores are crushed firstly and then transported to a heap leaching field for heaping; (2) a leaching agent is sprayed on stock heap for leaching; (3) leachate obtained from step (2) is absorbed or extracted. Saturated resin containing metallic uranium or saturated organic phase goes through a post treatment process, and absorption tailing solution or raffinate water phase is added with acid and then returned for being used as a leaching agent for the next heap; when the leaching agent is sprayed in step (2), the leaching agent spraying is called off if the leaching ratio of the metallic uranium reaches 70 percent to 80 percent. After prospective tailings are dried and heaped for a plurality of days, a curing agent with a weight of 0.08 to 0.12 time of that of the prospective tailings is used for curing and the prospective tailings are cured for a plurality of days and then leached in a sprayed manner. The leachate obtained from sprayed leaching can return and be used as the leaching agent for the next heap. After the neutralization, the tailings are discharged into a tailing tank. The uranium ores are heap leached by the method so that the grade of the tailings can be reduced and leaching time can be shortened.

Owner:中核赣州金瑞铀业有限公司

Diluted acid in-situ leaching uranium mining technology

ActiveCN104533376AIncrease injection volumeIncrease concentrationFluid removalPregnant leach solutionUranium ore

The invention provides a diluted acid in-situ leaching uranium mining technology according to the characteristics of a carbonate cement low-permeability sandstone type uranium ore deposit. Diluted hydrochloric acid serves as a leaching agent and is injected into an ore bed in an online acid adding mode, the PH value of a leaching solution is kept between 3 and 6 so that carbonate in the ore bed can be quickly dissolved, HCO3- is generated on site, and leaching is promoted. The diluted acid in-situ leaching uranium mining technology has been used in in-situ leaching uranium mining experiments and production of the Shashagetai uranium ore deposit and the Nalinggou uranium ore deposit in Ordos, the liquid injection amount is remarkably increased, and the concentration of the HCO3- and the concentration of leaching liquid uranium are obviously increased.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Bioleaching method-uranium leaching from fungus

The invention relates to a bioleaching method-uranium leaching from fungus. The method comprises the following steps of: using chemical reagents or fermenting low-price carbon source straws to generate fungus of organic acids of citric acid, oxalic acid, malic acid and lactic acid; and leaching uranium out from uranium tailings, tailing residues, uranium barren rocks or uranium ores by utilizing the fungus (1),or fermentation liquor (2) of the fungus, or a fungus mixed fermentation liquor (3), or by adding chemical reagents, such as sulfuric acid and hydrochloric acid to the fungus (1), or the fermentation liquor (2) of the fungus, or the fungus-mixed fermentation liquor (3). The invention has the advantages of convenient material obtainment, low cost, simple and convenient processing steps environmentally-friendly performance, energy saving and the like.

Owner:NANHUA UNIV +1

Fluoride-resistant ore leaching bacterium and application thereof in efficient leaching process of high-fluoride uranium ore

ActiveCN104745498AStrong fluorine resistanceAchieve protectionBacteriaMicroorganism based processesHigh fluorideUranium ore

The invention relates to a fluoride-resistant ore leaching bacterium and application thereof in an efficient leaching process of high-fluoride uranium ore. The fluoride-resistant acidophilus Acidithiobacillus ferrooxidans is collected at China General Microbiological Culture Collection Center (CGMCC for short) on July 1, 2013 and has a collection number of CGMCC NO.7836. The strain can grow in a fluorine-containing solution under an acidic condition, has fluorine resistance of 3.0g / L or above and also has a relatively good capability of oxidizing Fe<2+> into Fe<3+>. When the fluoride-resistant strain (CGMCC NO.7836) is applied to simulated biological dump leaching process of fluorine-containing uranium ore, 55-day uranium leaching rate is improved by 3.70% as compared with that in an acid leaching method; the uranium leaching rate is improved obviously and production cost is reduced; moreover, since adsorption tail liquid during uranium leaching can be recycled, environment pollution can be reduced. Therefore, the strain can be widely applied to biological leaching.

Owner:有研资源环境技术研究院(北京)有限公司

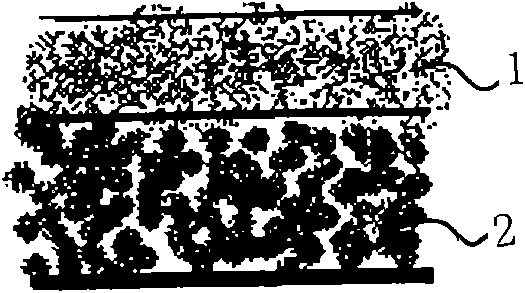

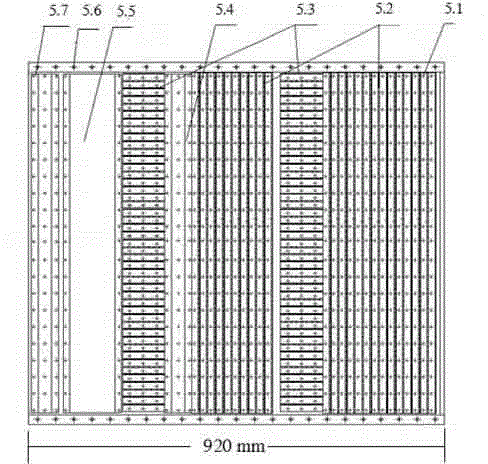

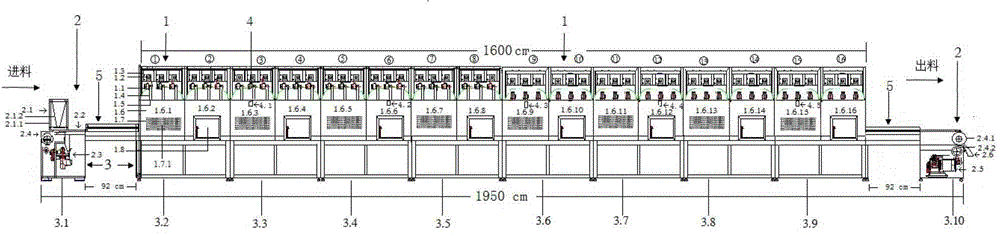

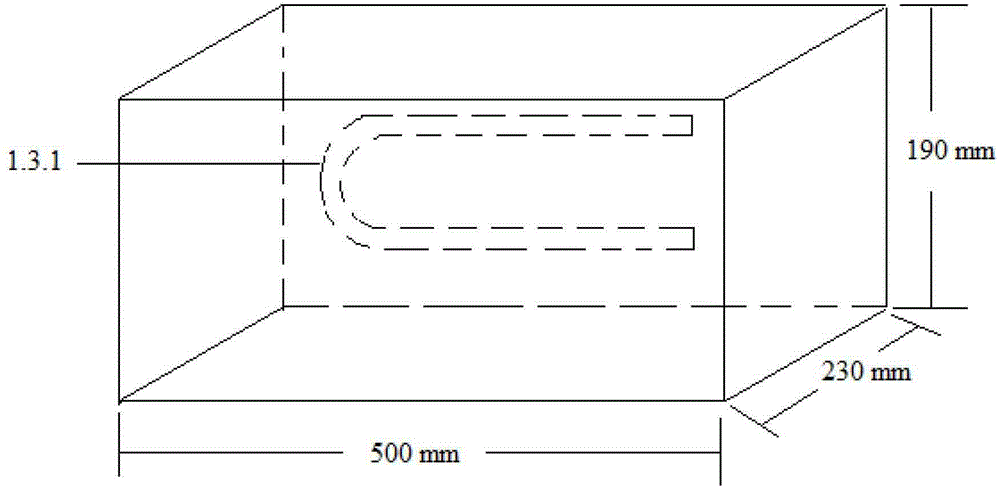

Microwave processing device for dump leaching uranium ores

The invention discloses a microwave processing device for the dump leaching uranium ores. The device uses microwave to carry out irradiation to dump leaching uranium ores, due to the fact that differences exist among the microwave temperature rising effects of different minerals inside the uranium ore particles, heat stress differences are generated among the different minerals inside the uranium ore particles, the grain boundaries of the different minerals inside uranium ore particles break and the cracks inside the particles extend, therefore the poriness of the uranium ore particles is increased, the permeability of the inner portions of the uranium ore particles is improved, the dissociation degree of the uranium ores is improved, the leaching efficiency of the dump leaching of the uranium ores is improved, and a leaching period is shortened. The whole equipment comprises 16 microwave units, a material conveying system, a support, a temperature detecting and controlling system and a microwave suppressor. When the microwave processing device for the dump leaching uranium ores is used to process the dump leaching uranium ores, the microwave processing device has the advantages of being good in the matching of microwave power and the uranium ores, low in processing energy consumption, large in processing quantity, stable in material conveying, and small in microwave leakage, the poriness of the uranium ores and the dissociation degree of the uranium ores are further improved, the leaching efficiency is further improved, and the leaching period is further shortened and the like. The microwave processing device for the dump leaching uranium ores is also suitable for the processing of dump leaching gold ores, dump leaching copper ores and other dump leaching ores, and has obvious effect in increasing poriness of ore particles, improving the permeability of the inner portion of the ore particles, improving the dissociation degree of useful ores, improving leaching efficiency, and shortening leaching efficiency.

Owner:NANHUA UNIV

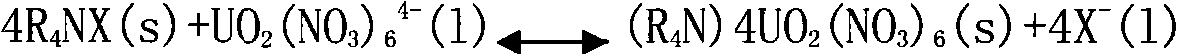

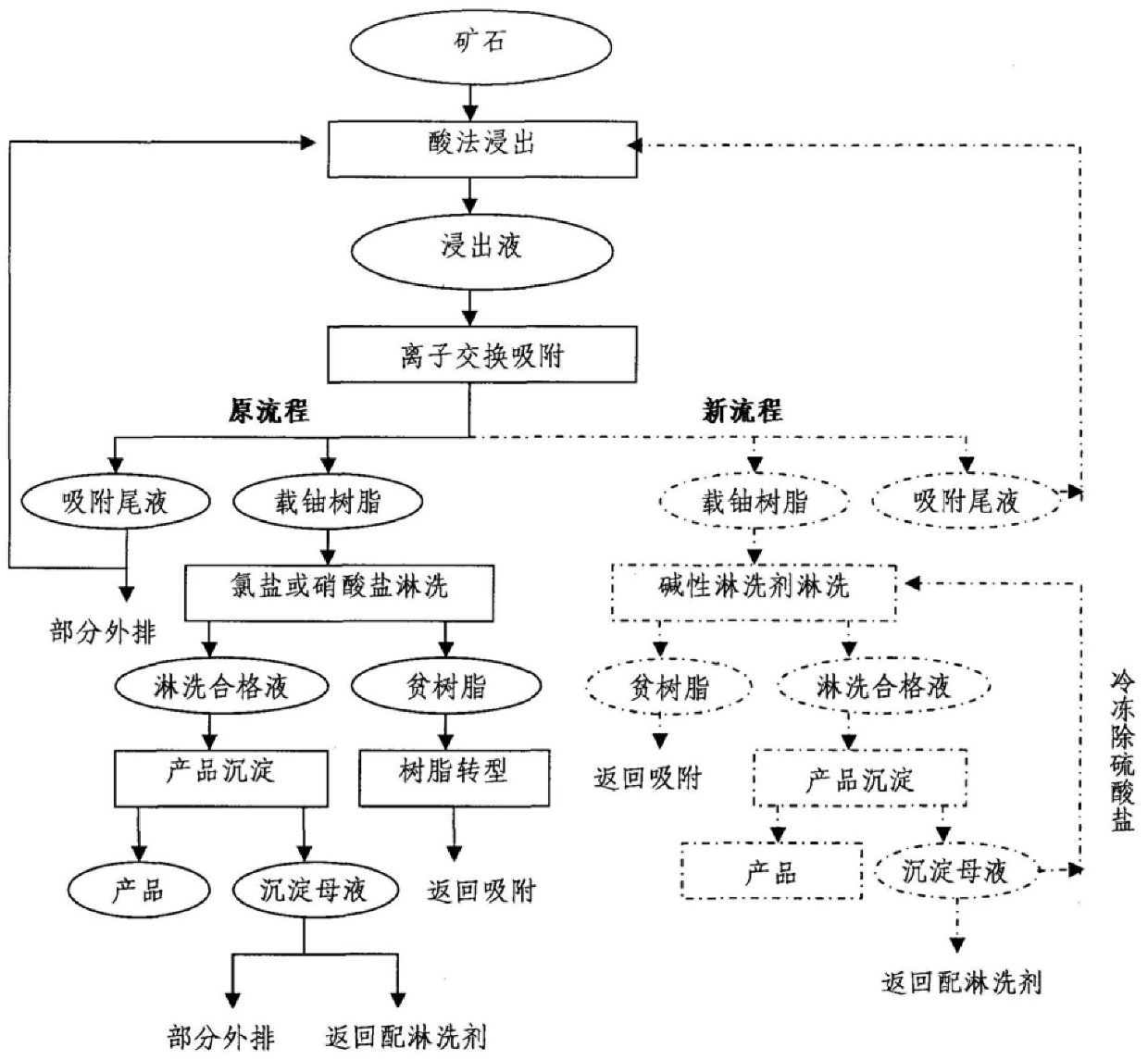

A process for extracting uranium by ion exchange method with water closed loop

The invention provides a process for extracting uranium by the ion exchange method of water closed-circuit circulation, which first uses an acidic leaching agent to leach uranium ore; then uses a weakly basic anion exchange resin to perform ion exchange adsorption on the leaching solution to obtain a uranium-loaded resin and an adsorption tail liquid; leaching the loaded uranium resin, and recovering uranium products from the leaching liquid. It processes the loaded uranium resin according to the following steps: (1) wash the loaded uranium resin with an alkaline solution with a total carbonate or bicarbonate concentration of 0.5-1.5 mol / L; (2) wash the loaded uranium resin The resulting qualified uranium-containing eluting liquid is precipitated with NaOH; all the precipitated mother liquid is cooled by a refrigerator to remove sulfate and then returned to prepare eluent. The invention improves the traditional ion exchange uranium extraction process, that is, does not introduce chloride radicals or nitrate radicals in the leaching process of the uranium-loaded anion exchange resin, avoids adverse effects on the process flow, and realizes closed circuit circulation of process water at the same time, thereby achieving environmental protection requirements.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Big data geological analysis method for sandstone-type uranium ore mineralization prediction

The invention relates to the technical field of sandstone type uranium ore mineralization prediction, and particularly discloses a big data geological analysis method for sandstone type uranium ore mineralization prediction. The method specifically comprises the following steps of 1, collecting data and performing preprocessing to form a database; 2, establishing a sandstone type uranium ore prospecting model; 3, performing technical analysis and effective information extraction on main ore control factors and ore prospecting marks of the to-be-searched sandstone-type uranium ore region; and 4, carrying out sandstone uranium ore prediction. The invention relates to a big data geological analysis method for sandstone type uranium ore mineralization prediction. geological features are synthesized and summarized, a big data platform is applied, ore control conditions and prospecting marks of sandstone-type uranium ore are considered, the method is also combined with digital geology, database technology, modeling and visualization technology, the combination of geology technology and computer big data technology is formed, and the method is a new technology for prospecting prediction at present and can be applied to prospecting initial prediction of the type.

Owner:核工业二0八大队

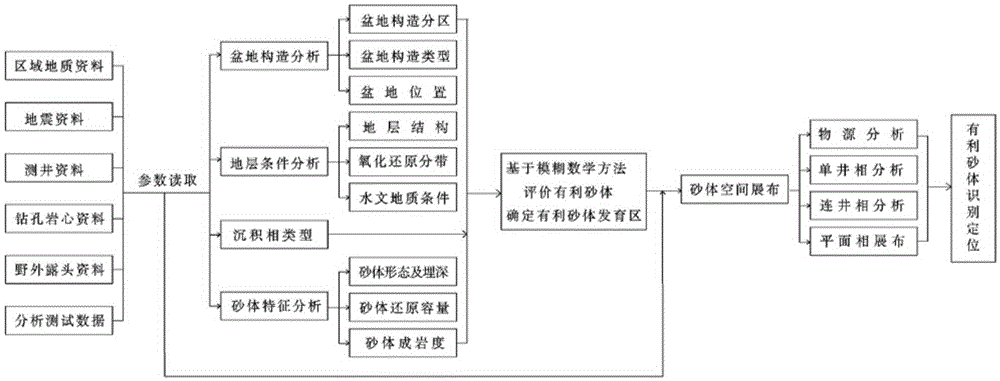

Method for evaluating favorable sand of interlayer oxidation type uranium metallogenesis of superimposed basin

The invention relates to the field of basic geology research of sandstone style uranium mine, in particular to a method for evaluating favorable sand of interlayer oxidation type uranium metallogenesis of a superimposed basin. The method specifically comprises the following steps of 1, determining control factors of favorable sand of interlayer oxidation type sandstone uranium metallogenesis of a large superimposed basin; 2, identifying the favorable sand based on a fuzzy mathematic method, and determining a development region of the favorable sand of the uranium metallogenesis; and 3, locating the favorable sand more accurately in the identified development region of the favorable sand of the step 2 by applying a sedimentology method. According to the method, the defects of qualitative description and a conventional single-factor exclusion method are made up for; a method process for quantitatively evaluating the favorable sand is established; evaluation indexes of the favorable sand of the metallogenesis are quantified; the purpose of converting qualitative description and single-factor evaluation of the favorable sand into multi-parameter comprehensive quantitative evaluation is achieved; and the development region of the favorable sand of the metallogenesis can be quickly selected out from a regional range.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

High intensity leaching method in initial heap leaching

InactiveCN104928505AReduce in quantityReduce generationProcess efficiency improvementPregnant leach solutionUranium ore

The present invention provides a high intensity leaching method in initial heap leaching. The method comprises the steps of: first crushing uranium ore, separating fine fraction and transferring to a leaching field for heap construction; (2) leaching an ore heap by spray leaching agents; employing a leaching agent with high acidity in the initial leaching agent stage namely acidification stage, and spraying continuously 24 hours a day by high spray intensity; (3) adsorbing the leaching liquid obtained in step (2) to recover uranium, adding acid in the absorption tail liquid and returning to be reused as the leaching agent, and sending the saturated resin into a posttreatment process; (4) when the uranium concentration in the leaching liquid is less than 50mg / L or liquid metered leaching rate reaches 85%, conducting quasi tailings acid curing for a few days, washing the heap, returning the washing liquid to be used as leaching agent for the next heap, neutralizing the tailings and discharged the into a tailings storage. The heap leaching method provided by the invention can prevent the phenomena of ore wrapping by precipitates and leaching channel clogging in the acidification stage of ore heap, shorten leaching time and reduce tailings grade.

Owner:中核赣州金瑞铀业有限公司

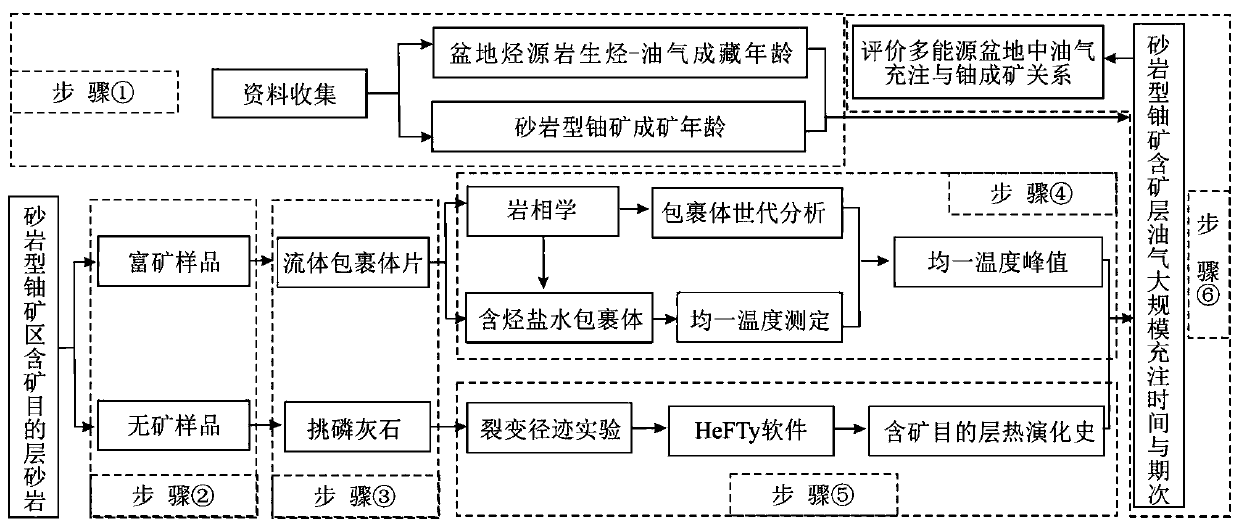

Method for comprehensively recovering uranium and rhenium from leaching solution with ion exchange resin

ActiveCN107686900AEfficient separationEfficient separation and recoveryPregnant leach solutionRhenium

The invention relates to a method for comprehensively recovering uranium and rhenium from a leaching solution with ion exchange resin. Aiming to the problems of large mass concentration ratio of the uranium and the rhenium in a rhenium ore and uranium ore containing leaching solution and difficulty in separation recovery, strongly basic anion-exchange resin with stronger adsorption ability is preferred to adsorb the uranium and the rhenium in the leaching solution firstly at the same time; and then aiming to uranium and rhenium loading resin, by utilizing the characteristic that the resin is stronger in the binding capacity to the rhenium than to the uranium and adopting desorption agents with different desorption capacities to sequentially realize respective desorption and separation of the uranium and the rhenium, comprehensive recovery of the uranium and the rhenium in the leaching solution is finally realized. By adopting the method, 98 percent or above of the uranium and 95 percent or above of the rhenium in the rhenium ore and uranium ore containing leaching solution can be recovered; in an obtained uranium qualified liquid, rho (U) reaches 10g / L or above, and rho (Re) is smaller than 1.0mg / L, and in an obtained rhenium qualified liquid, rho (Re) reaches 0.5g / L, and rho (U) is smaller than 5mg / L. The method is good in separation effect of the uranium and the rhenium, highin recovery rate of the uranium and the rhenium and simple in technological process and is an effective way of comprehensively recovering the uranium and the rhenium from the leaching solution.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

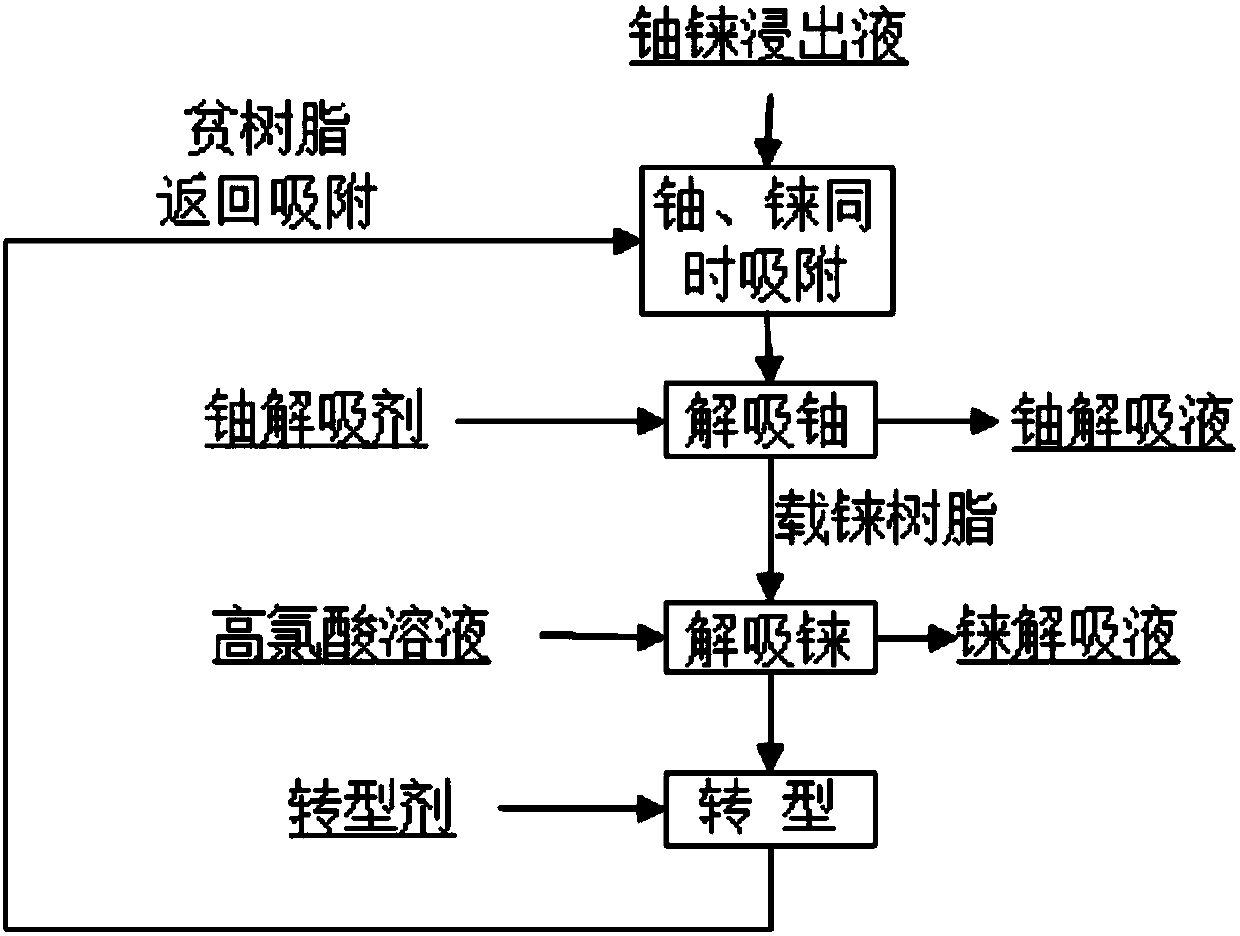

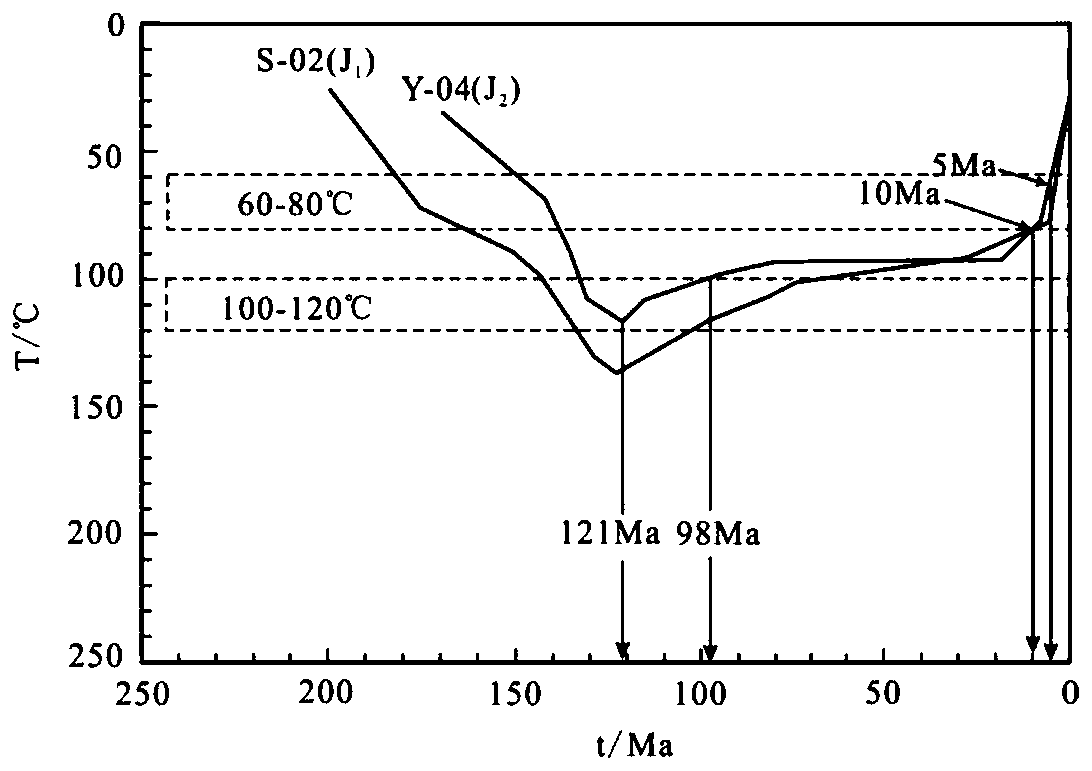

Method for counting large-scale charging time of ore-bearing strata oil gas of sandstone-type uranium ore

InactiveCN110596783AOvercome the problem of being unsuitable for basin-margin sandstone-type uranium depositsGeological measurementsApatiteUranium ore

The invention belongs to the technical field of uranium ores, and particularly relates to a geological method for counting large-scale charging time of ore-bearing strata oil gas of sandstone-type uranium ore. The geological method comprises the steps of S1, preparing related geological document; S2, acquiring an ore-bearing strata sandstone sample of the sandstone-type uranium ore, including an ore-rich sample and an ore-free sample; S3, fabricating fluid inclusion from the ore-rich sample, selecting apatite from the ore-free sample, and observing the fluid inclusion; S4, completing temperature measurement operation of the fluid inclusion on the basis of fluid inclusion observation, and performing comprehensive analysis on uniform temperature data to obtain a uniform temperature peak; S5,inverting thermal evolution history of ore-bearing strata of the sandstone-type uranium ore by apatite fission track method; and S6, projecting the uniform temperature peak obtained in the step S3 onto the thermal evolution history of the ore-bearing strata obtained in the step S4, and indirectly counting large-scale charging time and issue of the ore-bearing strata oil gas of the sandstone-typeuranium ore.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

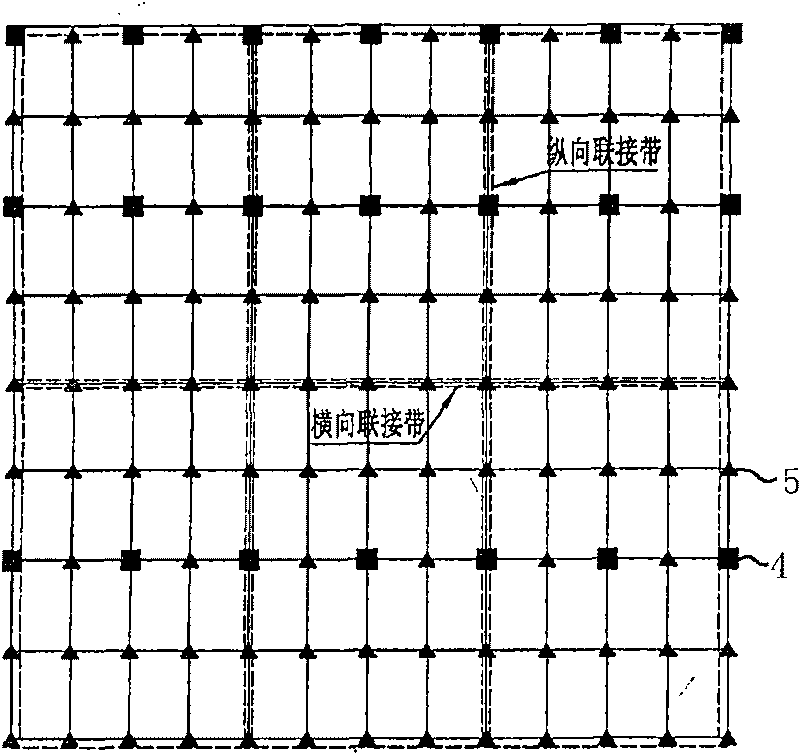

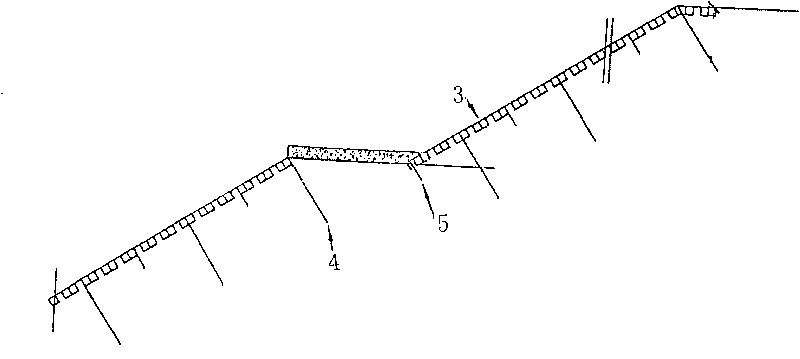

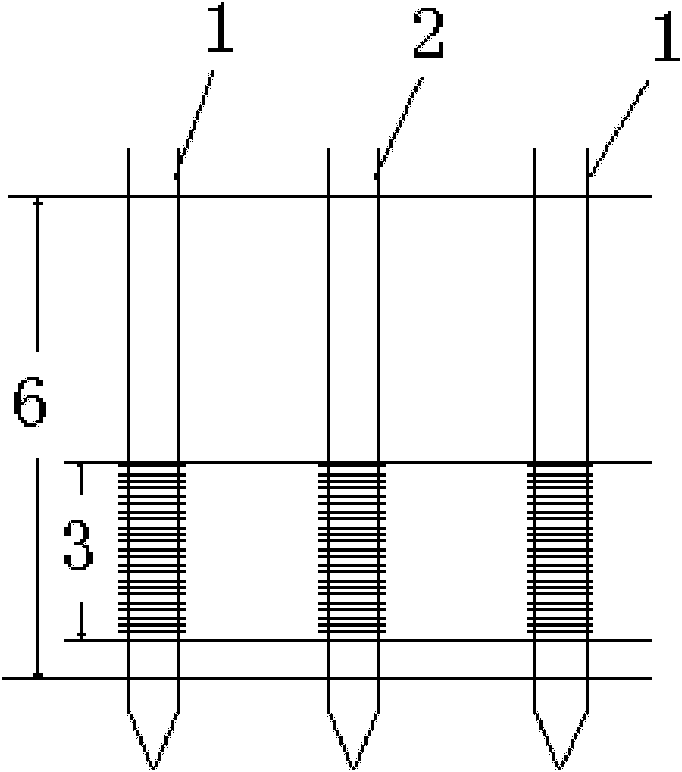

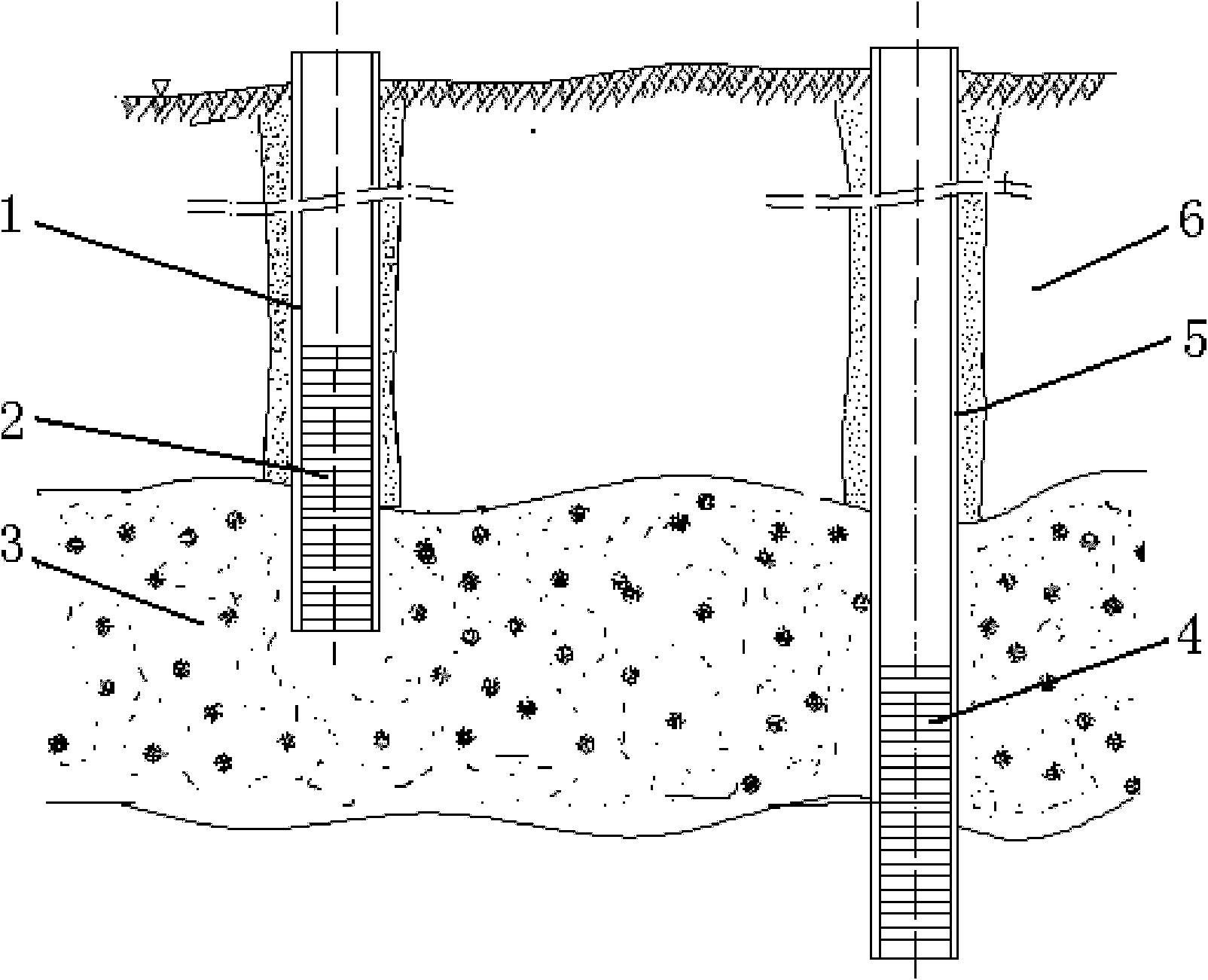

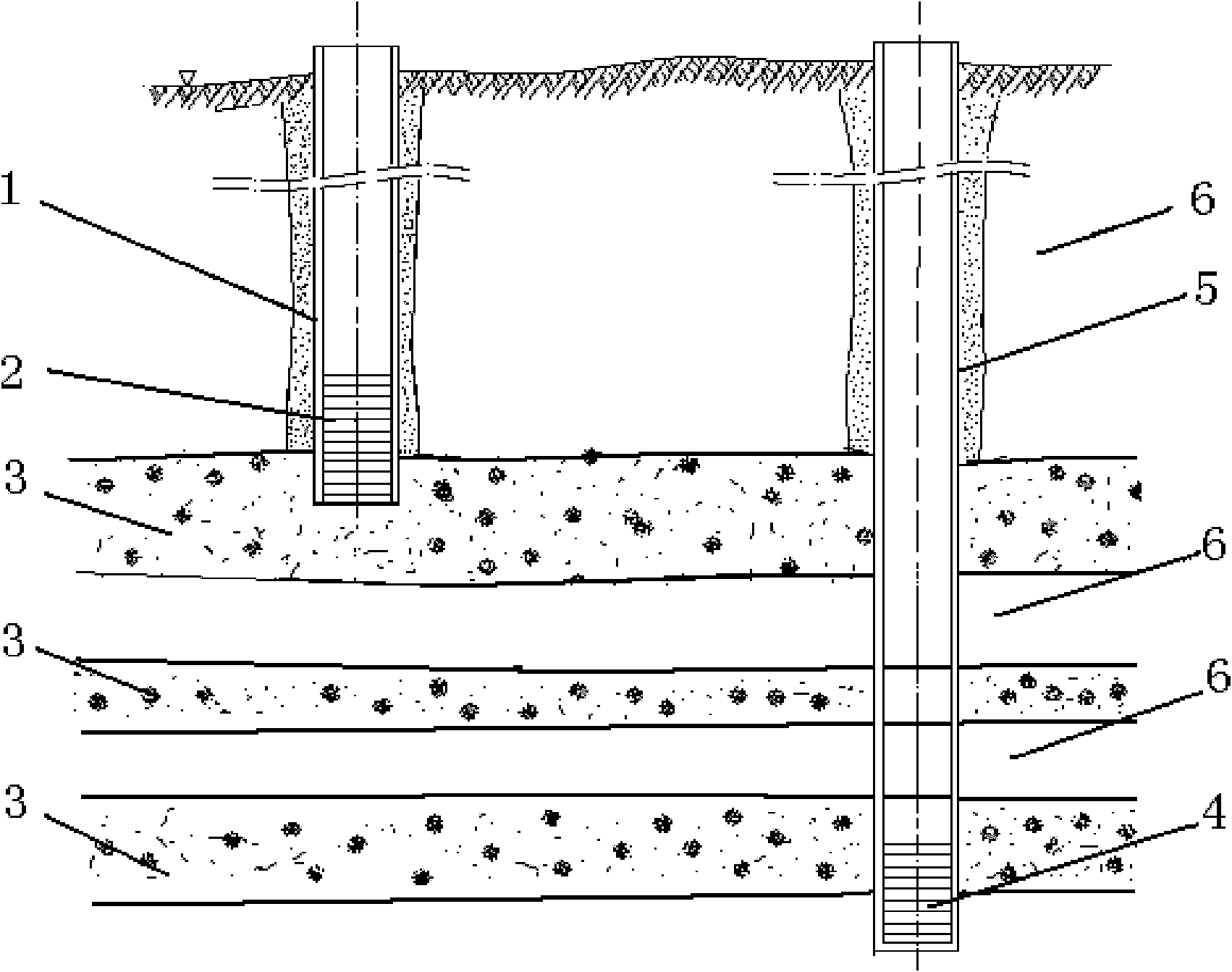

Method for arranging in-situ leaching hole drilling filter

The invention relates to a method for arranging an in-situ leaching hole drilling filter. If a uranium ore has a single vein, the length of a liquid injection hole drilling filter is three fourths to four fifths the thickness of the uranium ore layer, the bottom of the liquid injection hole drilling filter is positioned between the top part and the middle part of the uranium ore layer, the top of the liquid injection hole drilling filter is extended to a non ore layer, the length of an extraction hole drilling filter is three fourths to four fifths the thickness of the uranium ore layer, the top of the extraction hole drilling filter is positioned between the middle part and the bottom of the uranium ore layer and the bottom of the extraction hole drilling filter is extended to the non ore layer; and if the uranium ore has multiple veins, the length of the liquid injection hole drilling filter is three fourths to four fifths the thickness of the topmost uranium ore layer, the bottom of the liquid injection hole drilling filter is positioned between the top part and the middle part of the topmost uranium ore layer, the top of the liquid injection hole drilling filter is extended to the non ore layer, the length of the extraction hole drilling filter is three fourths to four fifths the thickness of the lowest uranium ore layer, and the top of the extraction hole drilling filter is positioned between the middle part and the bottom of the lowest uranium ore layer and the bottom of the extraction hole drilling filter is extended downward to the non ore layer. By the method, leaching liquid can flow directionally, the full and effective contact between the leaching liquid and ore is guaranteed, and the uranium concentration of the leaching liquid is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

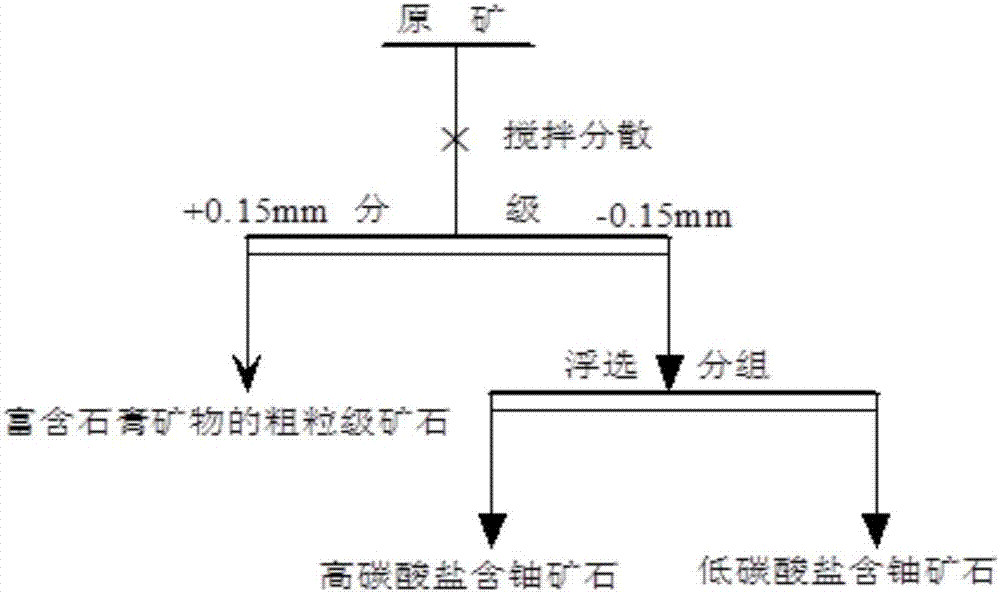

Pretreatment method for mud uranium ores

ActiveCN106944243AHigh recovery rateCost savingFlotationWet separationPretreatment methodUranium ore

The invention belongs to the technical field of uranium mining and metallurgy, and relates to a pretreatment method for mud uranium ores, in particular to a pretreatment method of mud uranium ores rich in gypsum and carbonate minerals. According to the pretreatment method for the mud uranium ores, firstly coarse-grained ores rich in the gypsum are separated, and the coarse-grained ores can recycle uranium through a dump leaching method, the ores grinding cost can be saved and the reagent consumption when fine-grained ores are leached through a alkaline process can be reduced. The fine-grained ores rich in the carbonate minerals are divided into two parts of high-carbonated uranium ores and low-carbonated uranium ores through a flotation method; the uranium can be recycled through subtractive leaching and acid leaching in the follow-up leaching, the reagent consumption can be saved, and the leaching rate is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com