Beneficiation process of polymetallic ore containing betafite

A technology of polymetallic ore and niobium-titanium-uranium ore, applied in flotation, magnetic separation, solid separation, etc., can solve unfavorable mineral flotation separation, poor collector selectivity, difficulty in obtaining high-grade uranium-containing concentrates, etc. problems, to achieve the effect of reducing the cost of water smelting, reducing the amount of treatment, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

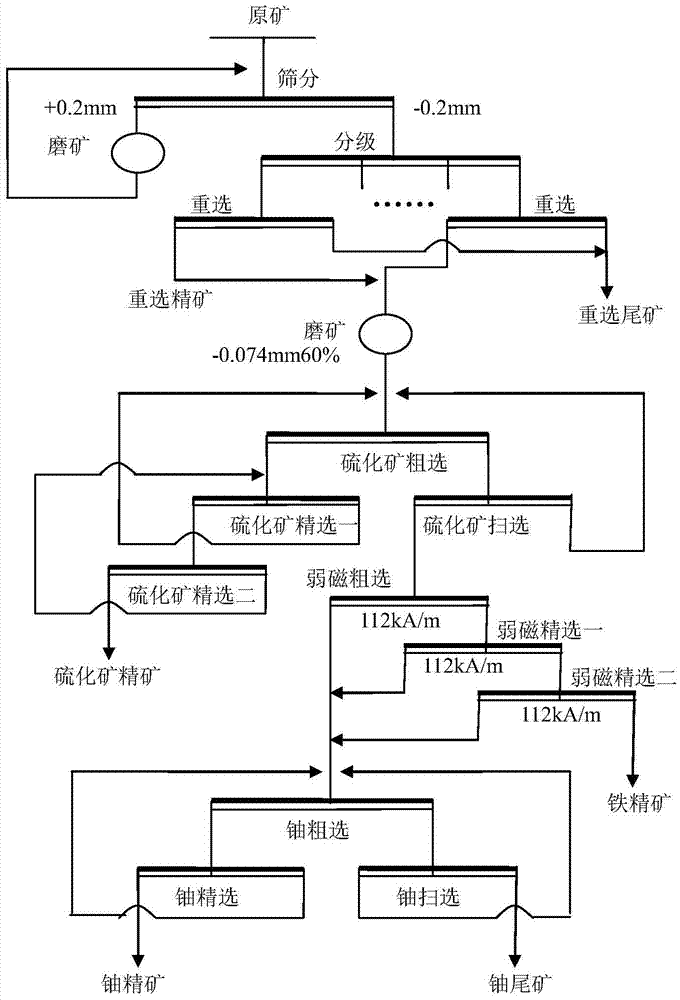

[0058] Example 1, a laboratory beneficiation test was carried out on a certain niobium-titanium-uranium ore in my country by adopting the technical means described in the present invention. The deposit is a complex polymetallic niobium-titanium-uranium deposit, mainly containing barite, calcite, feldspar, quartz, pyrite, sulfide ore, titanite, hornblende, biotite, epidote, and magnetite , niobium titanium uranium ore and other minerals.

[0059] The grade of uranium in the ore is 0.015%, the grade of uranium in gravity concentrate is 0.065%, and the recovery rate of uranium is 73%. Gravity-separated concentrates are then ground to a fineness of -0.074mm, accounting for 60%, and the sulfide ores are first floated - magnetically separated iron. A sulfide ore concentrate with a uranium content of less than 0.01% can be obtained, which can be further processed to obtain a qualified sulfide ore concentrate (not described in detail in this invention). Sulfide ore flotation tailing...

Embodiment 2

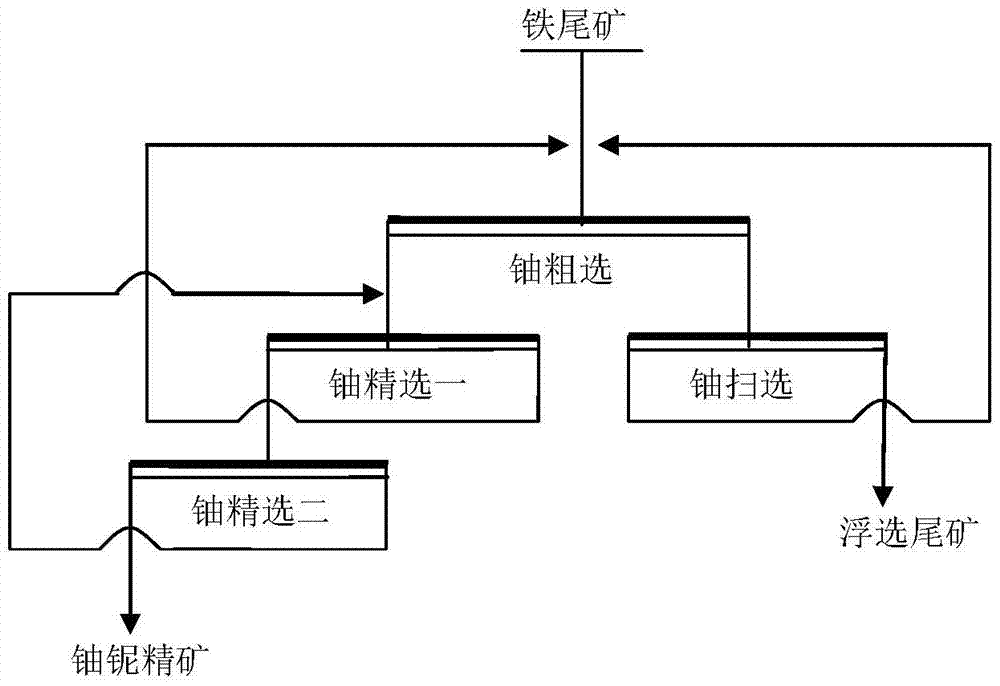

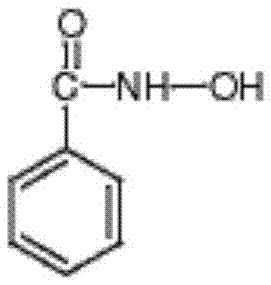

[0061] Example 2, the uranium grade of a certain niobium-titanium-uranium ore is 0.03%, the uranium grade of the concentrate after gravity separation is 0.128%, and the uranium recovery rate is 76.68%. Gravity-selected concentrates are then ground to a fineness of -0.074mm, accounting for 60%. After flotation of sulfide ore and magnetic separation of iron, the uranium grade can be increased to 0.154%, and the uranium recovery rate is 76.13%. Then the uranium is recovered by flotation, and the flotation solid concentration 30%, pulp temperature 20°C, niobium-titanium-uranium ore collector use benzylhydroxamic acid, dosage 1000g / t, kerosene 300g / t as auxiliary collector, 2 # 50g / t of oil is used as a foaming agent, and the first rough, second refined, and first sweep, and medium ore are sequentially returned to the process for closed-circuit flotation, and a flotation concentrate with a uranium grade of 1.12% can be obtained. The flotation recovery rate is 92.69%, and the recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com