Desalination little-reagent ground-dipping uranium extraction method

A technology for mining uranium and reagents by in-situ leaching, which is applied to mining fluids, earth square drilling, wellbore/well components, etc. It can solve problems such as prolonging the leaching period, low uranium concentration in the leach solution, and affecting economic benefits, so as to reduce the degree of salinity , Improve the effect of leaching uranium efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] 1. Desalination and low-reagent in-situ leaching uranium mining process

[0056] Test procedure of the present invention comprises the following steps:

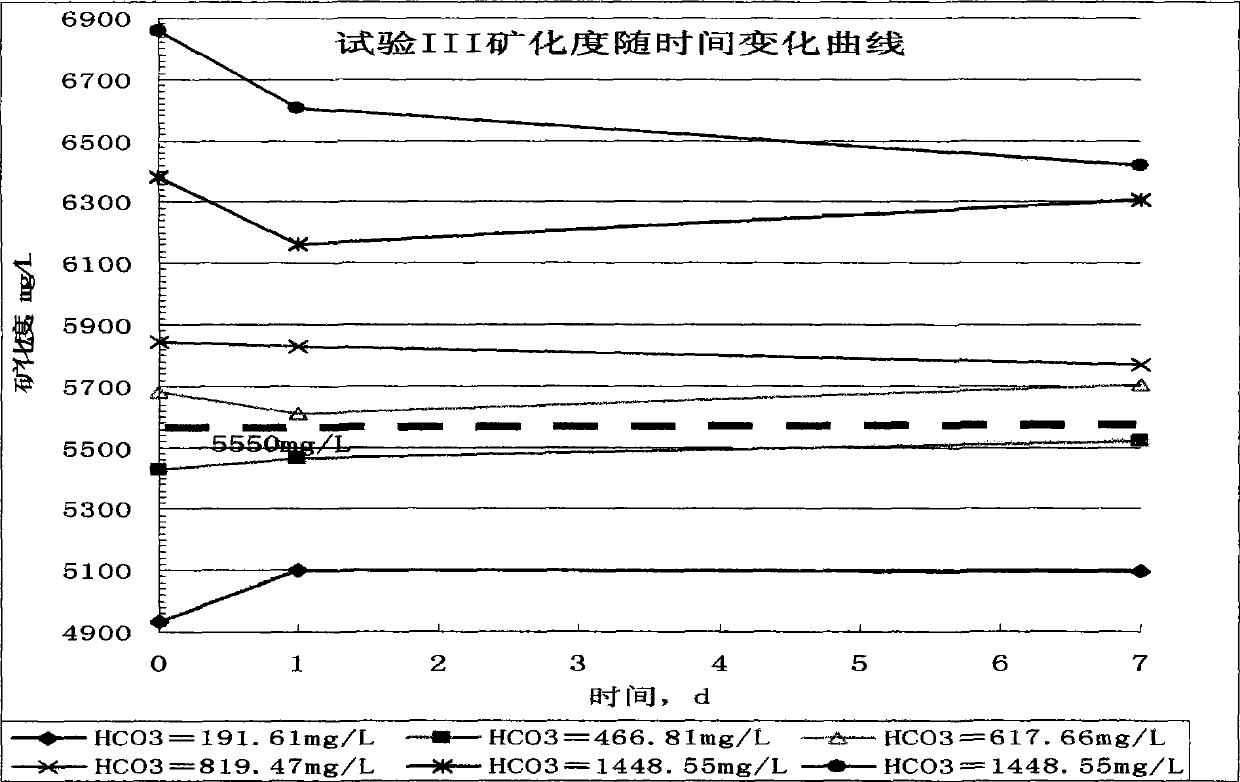

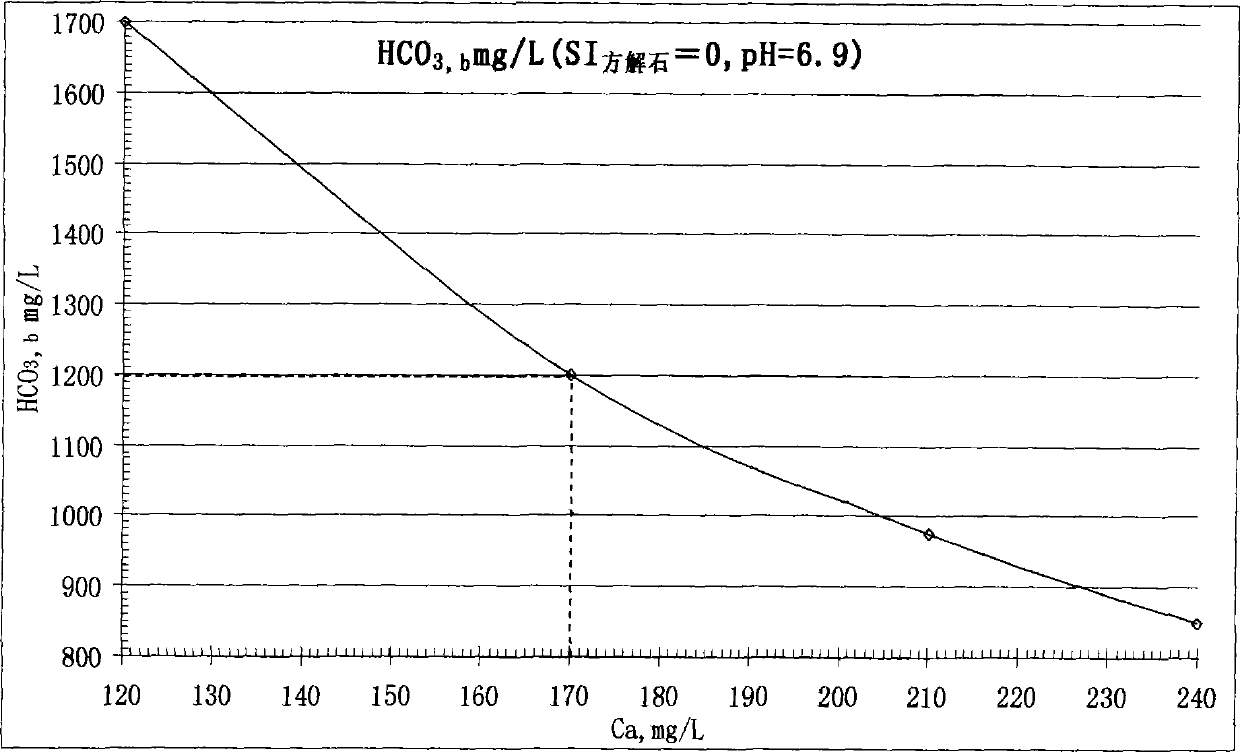

[0057] The desalination and low-reagent in-situ leaching uranium mining process, through the use of desalination, calcium removal, appropriate amount of leaching uranium co-solvent (ammonium bicarbonate), adding HCl and CO 2 Five key technologies, such as acidification to control the pH of the leaching solution and adding oxygen, have better solved the problem of chemical clogging when traditional leaching uranium is used in areas with high salinity. The leaching rate of uranium creates conditions.

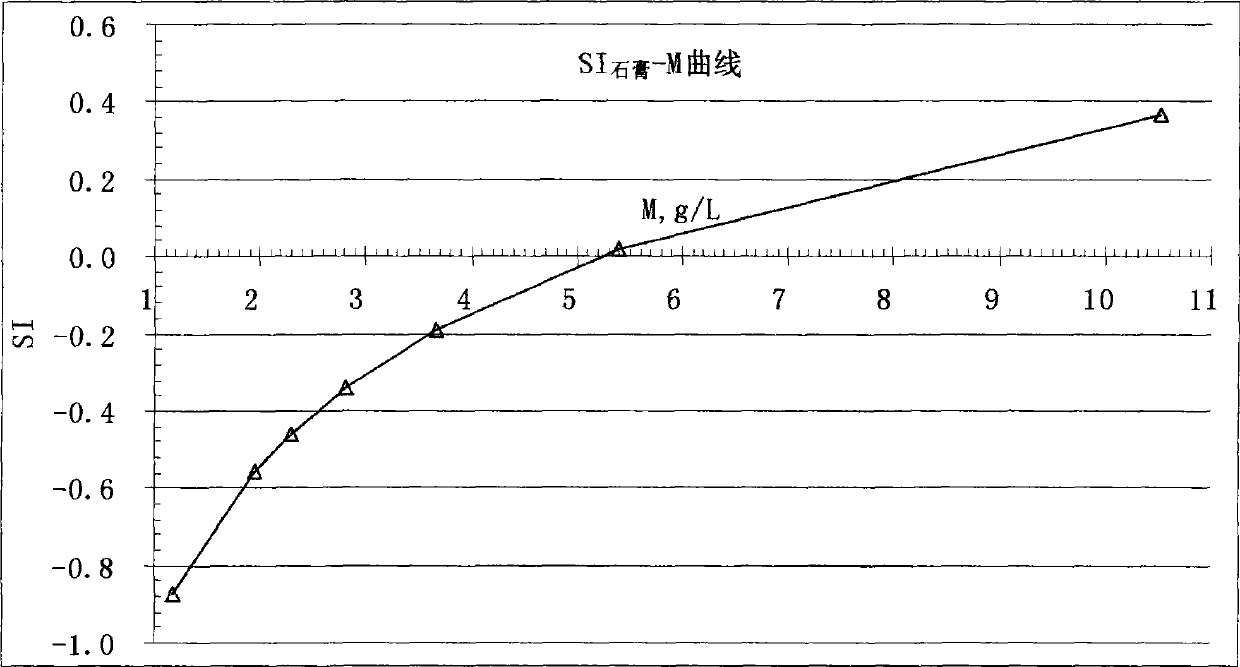

[0058] a. Using desalination technology (desalination process), avoiding calcium sulfate precipitation and clogging (see figure 1 ), and at the same time create conditions for the implementation of less reagent technology. In areas where fresh water exists, the desalination process is an economical and effective technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com