Low-toxicity environment-friendly gold mineral separation agent and preparation method thereof

An environment-friendly, beneficiation agent technology, applied in the direction of improving process efficiency, etc., can solve the problems of low leaching rate, high equipment requirements, poor leaching selectivity, etc., and achieve the effect of improving recovery rate, obvious leaching effect, and reducing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned low-toxicity and environment-friendly gold beneficiation agent comprises the following steps:

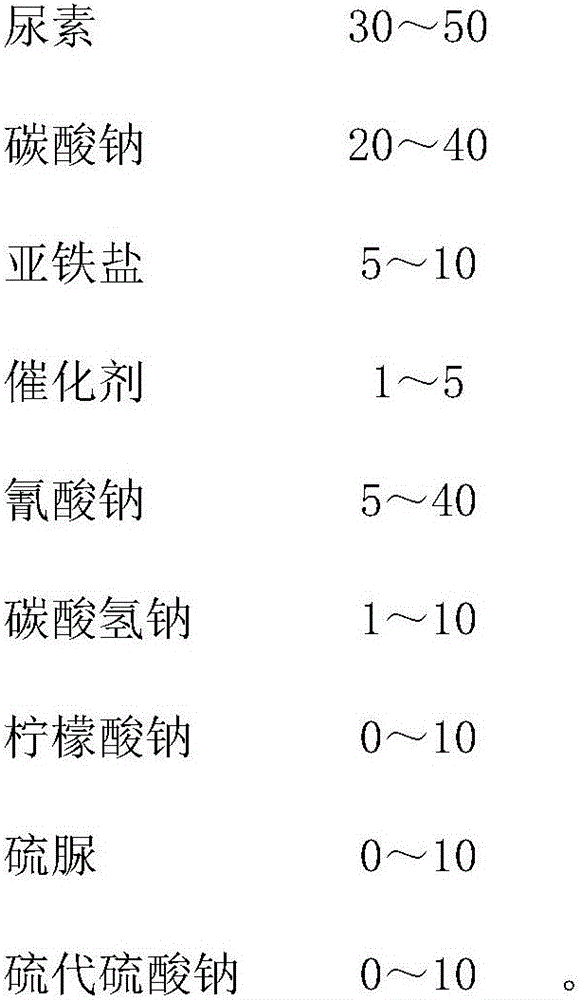

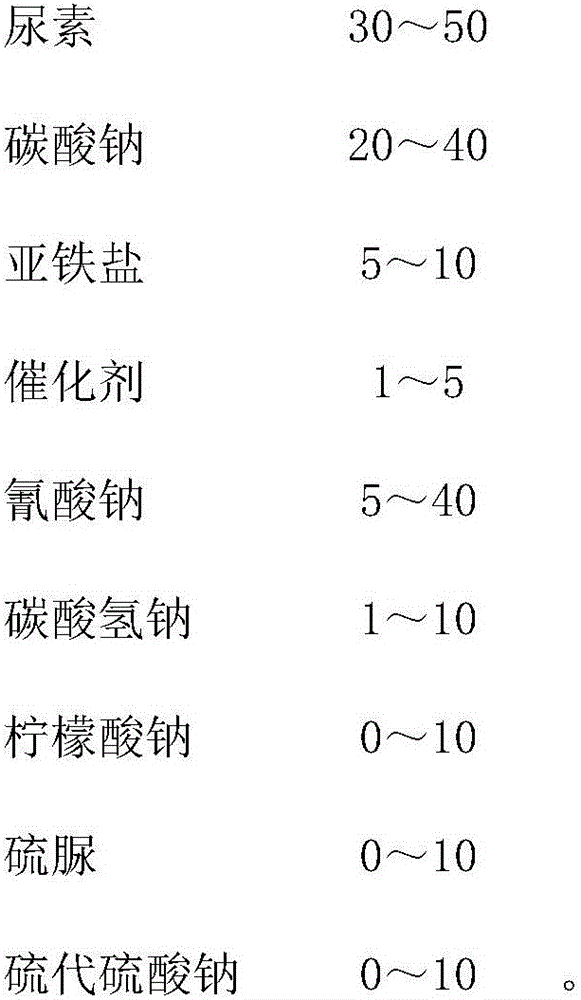

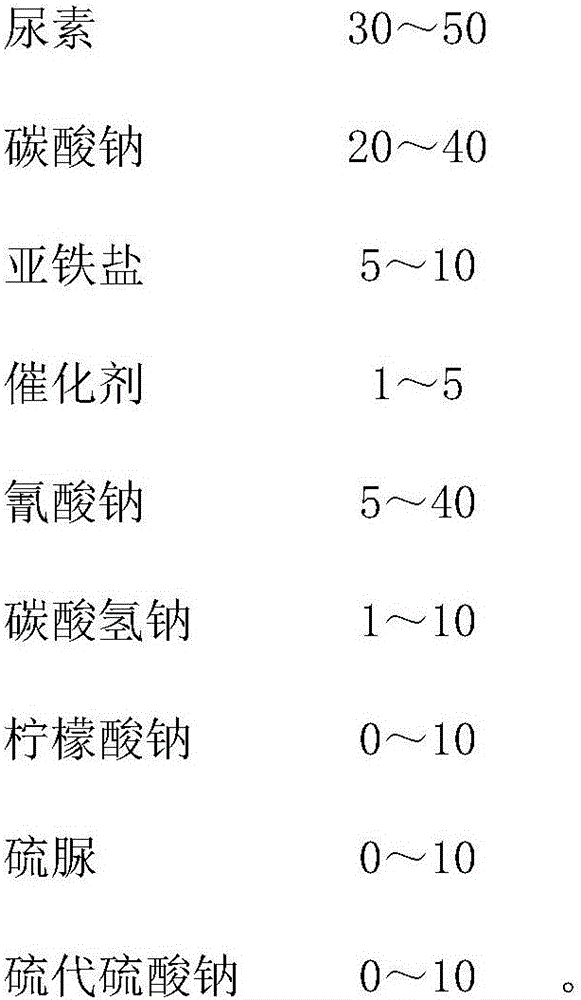

[0029] ⑴ Weigh each component according to the measurement, mix 30-50 parts of urea, 20-40 parts of sodium carbonate, 5-10 parts of ferrous salt, 1-5 parts of catalyst and 0-30 parts of sodium cyanate and add to high-temperature melting reaction container;

[0030] (2) Raise the temperature to 700-850 degrees Celsius to melt all the materials in the high-temperature melting reaction vessel. After reacting for 3 to 5 hours, add 5 to 10 parts of sodium cyanate, and continue to maintain the temperature of 700-850 degrees Celsius to melt all the materials;

[0031] (3) Filter the product of step (2) to remove impurities. Specifically, the clear magma can be obtained by adopting multiple natural sedimentation methods or filtered by a dense high-temperature-resistant and corrosion-resistant filter screen to obtain clear magma, and then ...

Embodiment 1

[0035] Mix 500Kg of urea, 400Kg of sodium carbonate, 50Kg of sodium ferrocyanide, 10Kg of nickel catalyst, and 200Kg of sodium cyanate evenly, put them into a melting reactor, heat to 800°C, keep them warm for 3 hours after melting, and then add After 80Kg of sodium cyanate is completely melted, pour the molten material liquid into the settling tank for impurity separation. After 10 minutes, the upper layer of clear liquid is diverted to the receiving tray, cooled and crushed, and mixed with 20Kg sodium bicarbonate, 5Kg sodium citrate, 5Kg Sodium thiosulfate is mixed, and the finished product of environment-friendly gold mineral processing agent is obtained after bagging, and the product yield is 87%.

[0036] Full peat slurry process

[0037] Take 1000g of quartz vein-type sulfur-poor gold ore powder provided by Jinbaolun Gold Mine in Hainanshan, the fineness of the ore powder is -200 mesh 78%, put it into a 3L stirring leaching tank, add 1.5L of water, and adjust the pH of t...

Embodiment 2

[0040] Mix 500Kg of urea, 400Kg of sodium carbonate, 30Kg of ferrous ammonium sulfate, 30kg of sodium ferrocyanide, 20Kg of nickel catalyst, and 200Kg of sodium cyanate, put them into a melting reactor, heat to 800°C, and keep warm for 5 hours after melting. Then add 80Kg sodium cyanate in the reactor, after all melting, pour the molten material liquid into the settling tank and carry out impurity separation, after 10min, the clear liquid of the upper floor is divided into the receiving tray, broken after cooling, and 20Kg sodium bicarbonate, 10Kg of thiourea was mixed evenly, and the finished product of the environment-friendly gold mineral processing agent was obtained after bagging, and the product yield was 88%.

[0041] The comparative leaching experiment of the environment-friendly beneficiation agent prepared by this method and sodium cyanide was carried out by the Laizhou refinery of Shandong Gold Group. The gold concentrate grade is 10.18g / t, and the fineness is -200 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com