Objective estimating system for fabric pilling grade

An objective evaluation, fabric technology, applied in textile testing, measuring devices, instruments, etc., can solve the problems of analysis affecting the height of the hair, the clear part is blurred, cannot be fully counted, etc., to achieve the effect of low cost and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

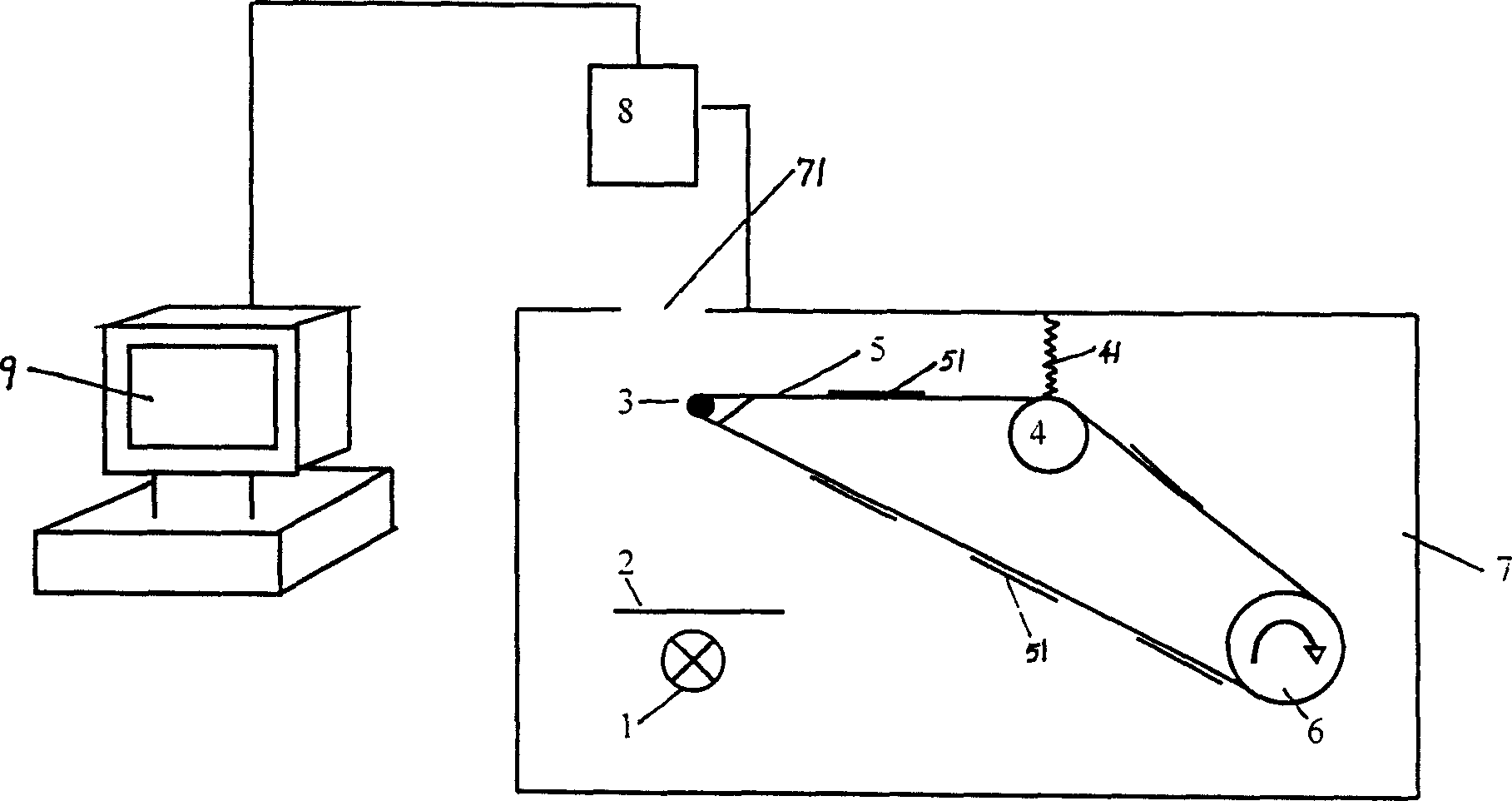

[0047] figure 1 It is a structural schematic diagram of the objective evaluation system of the pilling level of the fabric of the present invention. As can be seen from the figure, the objective assessment system of the pilling level of the fabric of the present invention includes:

[0048] A box body 7, a thin rod 3, a regulating roller 4 and a transmission shaft 6 are arranged in the casing 7, a conveyor belt 5 is wound around the thin rod 3, regulating roller 4 and transmission shaft 6, and when driven by a motor When the transmission shaft 6 moves, the conveyor belt 5 and the fabric 51 fixed on the conveyor belt 5 can be slowly moved around the thin rod 3, the adjustment roller 4 and the transmission shaft 6;

[0049] In the box 7, a light source 1 and a frosted glass 2 are arranged directly below the thin rod 3, and a CCD camera 8 is arranged outside the box 7 directly above the thin rod 3, and a rectangular opening is opened on the box 7. Light hole 71, the light that l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com